#ball Valve manufacturers in Middle East

Explore tagged Tumblr posts

Text

Valves Market is Estimated to Witness High Growth

Valves Market is Estimated to Witness High Growth Owing to Rising Constructional and Infrastructure Development Activities The valves market comprises products such as gate valves, globe valves, check valves, butterfly valves, ball valves and pressure regulating valves which are used to control the flow, pressure and direction of fluids. Valves are extensively used in power plants, refineries, oil & gas, water & wastewater and construction activities. These products play a key role in fluid transportation and management which makes them an integral component across various industrial sectors. Rising infrastructure development projects across both developed and developing nations are augmenting the demand for valves. Moreover, growing pipeline networks for oil & gas transportation is also favoring market growth. The Global valves market is estimated to be valued at US$ 83 Mn in 2024 and is expected to exhibit a CAGR of 3.5% over the forecast period 2024 To 2031. Key Takeaways Key players operating in the valves market are Tyson Foods, Inc., JBS S.A., Pilgrim's Pride Corporation, Wens Foodstuff Group Co. Ltd., BRF S.A., Perdue Farms, Sanderson Farms, Baiada Poultry, Bates Turkey Farm, and Amrit Group. The major players are focusing on capacity expansion plans and mergers & acquisitions to gain market share. Rising population and changing diets are expected to fuel the growth of the poultry sector which presents significant opportunities for valve manufacturers. With the growing poultry industry, demand for processing equipment including valves is also projected to rise substantially over the forecast period. The global valves market is estimated to witness growth across key regions such as North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. This can be attributed to surging investments in oil & gas, water & wastewater infrastructure, and industrial development projects worldwide. Emerging economies with high urbanization rates like China and India also offer lucrative prospects for market expansion. Market Drivers The key driver behind the Valves Market Demand is the increasing constructional and infrastructure development activities worldwide. There is huge government focus as well as private investments toward projects such as roadways, railways, metro stations, power generation, water supply, etc. which involves extensive use of valves in various process applications. Further, the rising need for energy and growing focus on rural electrification has boosted investments in power transmission and distribution sector augmenting valves demand.

PEST Analysis

Political: The valves market is regulated by laws pertaining to safety, environmental protection and quality standards. New regulations regarding emissions could impact demand patterns. Economic: Changes in the global and regional economic conditions directly impact spending on industries like oil & gas, energy & power, and water & wastewater management which influences Valves demand. Social: Growing population and urbanization is increasing requirements for water, energy and other infrastructure development which boost the usage of valves. Technological: Advancements in materials and designs of valves are improving efficiency, lowering costs and enabling usage in newer applications. Digitalization is also aiding remote monitoring of industrial valves. The regions concentrating maximum valves market share in terms of Valves Market Size and Trends include North America, Europe and Asia Pacific. North America accounts for a major portion owing to strong presence of end-use industries like oil & gas and significant infrastructure spending. Europe and Asia Pacific are also sizable markets led by Germany, China, India respectively. The fastest growing regional market for valves is expected to be Asia Pacific led by increasing investments in water & wastewater management, power projects and industrial activities in China and India. Rising standards of living and initiatives to improve urban infrastructure will further drive the demand across developing nations in the region.

Get more insights Valves Market

Discover the Report for More Insights, Tailored to Your Language.

French German Italian Russian Japanese Chinese Korean Portuguese

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Coherent Market Insights#Valves Market#Control Valves#Globe Valves#Plug Valves#Gate Valves#Ball Valves#Butterfly Valves

2 notes

·

View notes

Text

Cryogenic Valves Market Dynamics: Global Growth and Trends (2023-2032)

The global demand for cryogenic valves was valued at USD 4215.6 million in 2022 and is expected to reach USD 6228.36 million in 2030, growing at a CAGR of 5.00% between 2023 and 2030.

Cryogenic valves are specialized valves designed to control the flow of fluids at extremely low temperatures, typically below -150°C (-238°F). These valves are essential in applications involving cryogenic liquids, such as liquid nitrogen, liquid helium, and liquefied natural gas (LNG). Constructed from materials that can withstand the challenges of low-temperature environments, cryogenic valves are engineered to prevent leakage and ensure reliable operation under pressure and thermal stress. They come in various types, including gate, globe, ball, and check valves, each serving specific functions within cryogenic systems. The design of cryogenic valves incorporates features like extended bonnets, insulation, and sealing technologies to maintain temperature stability and performance. As industries increasingly adopt cryogenic technology for applications in aerospace, medical, and energy sectors, the demand for high-performance cryogenic valves continues to grow, driving innovation and advancements in materials and engineering practices.

The study on the Cryogenic Valves market highlights several key findings that underscore the growth potential and evolving dynamics of this specialized sector. Here are the notable findings:

Growing Demand in LNG Sector: The demand for cryogenic valves is significantly driven by the expanding liquefied natural gas (LNG) market. As countries invest in LNG infrastructure for energy security and cleaner fuel alternatives, the need for reliable cryogenic valves in LNG terminals, storage tanks, and transportation systems is increasing.

Expanding Applications in Various Industries: Cryogenic valves are not limited to the LNG sector; they are increasingly used in diverse industries such as aerospace, medical (for cryopreservation), and industrial gas production. This broadening application base is contributing to market growth as new technologies and processes emerge.

Technological Advancements: Innovations in materials and valve designs are enhancing the performance and reliability of cryogenic valves. Developments such as improved sealing technologies, lightweight materials, and enhanced insulation features are making these valves more efficient and durable in extreme conditions.

Rising Investment in Cryogenic Technologies: Increased investment in cryogenic technology and research is driving the development of advanced valves. Governments and private sectors are focusing on developing cryogenic processes, which necessitates high-quality valves capable of operating under low temperatures and pressures.

Focus on Safety and Compliance: With stringent safety regulations governing cryogenic applications, there is an increasing emphasis on developing valves that meet international safety standards. Manufacturers are investing in testing and certification processes to ensure their products comply with industry regulations, enhancing market credibility.

Emerging Markets as Growth Drivers: Emerging economies, particularly in Asia-Pacific and the Middle East, are witnessing rapid industrialization and infrastructure development, driving demand for cryogenic valves. Investments in energy projects, particularly LNG facilities and petrochemical plants, are creating significant growth opportunities in these regions.

Customization and Specialized Solutions: There is a growing demand for customized cryogenic valves tailored to specific applications and customer requirements. Manufacturers offering specialized solutions, including unique designs and materials, are better positioned to capture niche segments of the market.

Aftermarket Services and Maintenance: The market for cryogenic valves is complemented by a growing focus on aftermarket services, including maintenance, repair, and replacement. Companies providing comprehensive service packages can enhance customer satisfaction and foster long-term relationships.

Increased Competition and Consolidation: The cryogenic valves market is becoming increasingly competitive, with several established players and new entrants. Mergers and acquisitions are expected as companies seek to enhance their technological capabilities, expand their product portfolios, and increase market share.

Sustainability Initiatives: As industries aim to reduce their environmental footprint, the demand for energy-efficient and environmentally friendly solutions is on the rise. Cryogenic valves that facilitate sustainable practices, such as minimizing gas leaks and optimizing energy consumption, are becoming more sought after.

Access Complete Report - https://www.credenceresearch.com/report/cryogenic-valves-market

Key Players

Schlumberger (U.S.)

Flowserve Corp. (U.S.)

Baker Hughes (U.S.)

Emerson Electric Co. (U.S.)

Neles Corp. (Finland)

KITZ Corporation (Japan)

Cryostar GmbH (France)

Bray International (U.S.)

HEROSE GmbH (Germany)

Cryocomp (U.S.)

Velan Inc (Canada)

Phpk Technologies (U.S.)

ACME Cryogenics (U.S.)

The Cryogenic Valves market is experiencing several innovative trends that enhance functionality, safety, and efficiency in cryogenic applications. Here are some of the most notable trends shaping this market:

Advanced Materials Development: Innovations in materials science are leading to the development of advanced alloys and composite materials that can withstand extreme temperatures and pressures. These materials improve the durability and reliability of cryogenic valves, reducing the risk of leakage and failures.

Smart Valve Technologies: The integration of smart technologies into cryogenic valves is gaining traction. Smart valves equipped with sensors and IoT connectivity provide real-time monitoring and data analytics, allowing operators to optimize performance, predict maintenance needs, and improve overall system efficiency.

Enhanced Sealing Technologies: New sealing technologies, such as improved elastomers and metal seals, are being developed to enhance the performance of cryogenic valves. These seals are designed to function effectively at low temperatures and under varying pressure conditions, reducing the risk of leaks and improving safety.

Modular and Customizable Designs: Manufacturers are increasingly offering modular and customizable cryogenic valve solutions that can be tailored to specific applications. This flexibility allows users to adapt valves for various systems and processes, enhancing their usability across different industries.

Focus on Energy Efficiency: As industries become more energy-conscious, there is a growing emphasis on developing energy-efficient cryogenic valves. These valves minimize energy loss during operation and optimize flow control, contributing to reduced operational costs and lower environmental impact.

Sustainable Manufacturing Practices: Companies are adopting sustainable manufacturing practices to reduce their environmental footprint. This includes using eco-friendly materials, optimizing production processes, and implementing waste reduction strategies, aligning with global sustainability initiatives.

Improved Design and Simulation Tools: Advanced computer-aided design (CAD) and simulation tools are enabling manufacturers to optimize the design of cryogenic valves before production. These tools help predict performance under extreme conditions, allowing for better reliability and efficiency.

Increased Focus on Safety Features: The cryogenic industry is placing greater emphasis on safety innovations, such as fail-safe mechanisms and enhanced pressure relief systems in valves. These features ensure that valves operate safely under cryogenic conditions, protecting both equipment and personnel.

Automation and Remote Control Capabilities: The trend toward automation in industrial processes is influencing the cryogenic valves market. Valves that can be remotely controlled and automated contribute to safer operations and reduce the need for manual intervention in potentially hazardous environments.

Collaboration and Partnership Models: Companies are increasingly engaging in partnerships and collaborations to drive innovation in cryogenic valve technology. Collaborations with research institutions, technology providers, and industry stakeholders foster the development of cutting-edge solutions and enhance competitive positioning.

Segmentation

By Valve Type

Globe Valves

Gate Valves

Ball Valves

Check Valves

Butterfly Valves

Others

By Material

Stainless Steel

Brass

Bronze

Plastic

Others

By Application

Industrial Gases

Liquefied Natural Gas (LNG)

Healthcare

Aerospace

Energy

Other Applications

By End-Use Industry

Healthcare

Energy

Industrial Gases

Aerospace and Defense

Oil and Gas

Other Industries

By Valve Size

Small Valves (Up to 2 Inches)

Medium Valves (2 to 8 Inches)

Large Valves (Above 8 Inches)

Browse the full report – https://www.credenceresearch.com/report/cryogenic-valves-market

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

API 6A Valves Market Insights and Growth Projections 2024 - 2032

The API 6A valves market is a critical segment within the oil and gas industry, particularly concerning drilling and production operations. These valves, which conform to the American Petroleum Institute (API) 6A specifications, are designed to handle high pressures and severe conditions encountered in wellhead equipment. This article provides an in-depth look at the API 6A valves market, including market dynamics, trends, challenges, and future outlook.

Introduction to API 6A Valves

The API 6A valves market is positioned for steady growth, driven by increasing energy demands, advancements in technology, and expanding exploration activities. While challenges such as fluctuating oil prices and competition from alternative energy sources exist

What are API 6A Valves?

API 6A valves are specialized valves used in the oil and gas sector, specifically in drilling and production applications. They are designed to withstand high pressures and temperatures while ensuring safety and reliability. These valves are typically used in wellhead control systems and are essential for maintaining the integrity of drilling operations.

Importance of API 6A Valves

The reliability of API 6A valves is crucial for safe and efficient oil and gas extraction. They play a vital role in controlling the flow of fluids, ensuring pressure management, and providing emergency shut-off capabilities. Given the high-risk nature of the oil and gas industry, the performance of these valves directly impacts operational safety and efficiency.

Market Overview

Current Market Trends

The API 6A valves market is experiencing steady growth due to several key trends:

Rising Oil and Gas Production: Increased global demand for energy has led to heightened exploration and production activities, driving the need for reliable valve solutions.

Technological Advancements: Innovations in valve design and materials are improving the performance and durability of API 6A valves, making them more attractive to end-users.

Regulatory Compliance: Stricter safety and environmental regulations are pushing companies to invest in high-quality valves that meet API 6A standards.

Market Segmentation

The API 6A valves market can be segmented based on product type, application, and region.

By Product Type

Gate Valves

Ball Valves

Check Valves

Plug Valves

Others

By Application

Onshore

Offshore

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

Key Drivers of Market Growth

1. Increasing Demand for Energy

The global increase in energy demand, driven by population growth and industrialization, is a significant driver for the API 6A valves market. Oil and gas companies are ramping up production to meet this demand, necessitating reliable and efficient valves.

2. Expansion of Oil and Gas Exploration Activities

New drilling projects and enhanced oil recovery techniques are prompting the need for advanced wellhead equipment, including API 6A valves. This expansion is particularly evident in emerging markets, where untapped reserves are being explored.

3. Investment in Infrastructure Development

Investment in infrastructure, particularly in developing regions, is a crucial factor for market growth. As countries expand their oil and gas capabilities, the demand for high-quality valves is expected to increase.

Challenges Facing the Market

1. Fluctuating Oil Prices

Volatility in oil prices can significantly impact the API 6A valves market. Periods of low prices may lead to reduced exploration and production activities, subsequently affecting valve demand.

2. Competition from Alternative Technologies

The rise of alternative energy sources, such as renewables, poses a challenge to the oil and gas sector. As companies diversify their energy portfolios, the demand for traditional equipment, including API 6A valves, may be impacted.

3. Technical Complexity

The technical complexity involved in designing and manufacturing API 6A valves can be a barrier for new entrants. Established manufacturers with expertise and experience in high-pressure applications dominate the market.

Future Trends in the Market

1. Digitalization and Smart Technologies

The integration of smart technologies and digital solutions into valve management systems is expected to enhance operational efficiency. Smart valves that offer real-time monitoring and predictive maintenance capabilities are likely to gain traction in the market.

2. Sustainable Practices

As the industry shifts towards sustainability, manufacturers are focusing on developing environmentally friendly valves and materials. The adoption of eco-friendly practices will become increasingly important as regulatory pressures mount.

3. Growth in Emerging Markets

Emerging markets, particularly in Asia-Pacific and Latin America, present significant growth opportunities for the API 6A valves market. As these regions enhance their oil and gas production capabilities, the demand for high-quality valves is set to rise.

Conclusion

The API 6A valves market is positioned for steady growth, driven by increasing energy demands, advancements in technology, and expanding exploration activities. While challenges such as fluctuating oil prices and competition from alternative energy sources exist, the future of the market looks promising with trends toward digitalization and sustainability. Stakeholders in the API 6A valves market must navigate these dynamics to seize emerging opportunities and ensure continued success.

0 notes

Text

Global composite Metal Finishing Market — Forecast(2024–2030)

Global Composite Metal Finishing market size is forecast to reach $4.5 billion by 2030, after growing at a CAGR of 7.2% during 2024–2030.

Request Sample

There is an increasing demand for composite metal finishing as it improves chemical, wear, electrical, tarnish and corrosion resistance of the surface. Composite metal finishing even enhances solderability, visual appearance, conductivity, infrared reflectivity, hardness, and torque tolerance. Without metal finishing, products made from metals would last only a fraction of their present lifespan because of corrosion and wear. The rising demand for composite metal finishing to enhance electrical properties, form and shape components, and to augment the bonding of adhesives or organic coatings is driving the global composite metal finishing market during the forecast period. Its wide usage in automotive, electronics, aerospace and oil & gas industries is also driving the market growth.

The aerospace industry is poised for future growth, driven by a surge in passengers, a significant backlog of new aircraft orders, substantial investments, and ongoing advancements in research and development. Meanwhile, factors like increasing disposable income levels and shifting lifestyles are fueling the expansion of the electronics sector. Within the aerospace realm, this material finds application in various critical components including main engine shafts, propellers, gyro parts, engine mounts, oil nozzle components, servo valves, shear bolts, landing gear components, flanges, and engine oil feed tubes. Similarly, in the oil and gas industry, it is utilized for drilling components such as ball valves, cable glands, gate plugs, and tubular components, among others.

An increasing number of passengers, a large backlog of new aircraft orders, huge investments, and research and development advancements will propel the aerospace industry in the future. Similarly, the electronics sector is experiencing expansion fueled by increasing disposable income levels and shifts in lifestyle. Continuous technological progress, substantial investments, and the trend towards digitization will further boost demand for electronic products in the foreseeable future. Consequently, the electronics industry’s optimistic prospects will serve as a catalyst for future market expansion.

Inquiry Before Buying

COVID-19 Impact

The COVID-19 pandemic has had a significant impact on the global composite metal finishing market. With disruptions in supply chains, temporary shutdowns of manufacturing facilities, and fluctuations in demand across various industries, the market experienced challenges during the initial phases of the pandemic. Reduced industrial activities and construction projects further dampened market growth.

However, as economies gradually recovered and adapted to the new normal, the market started showing signs of recovery. The increasing emphasis on hygiene and cleanliness drove demand for antimicrobial coatings, which are commonly used in composite metal finishing.

Report Coverage

The report: “Global Composite Metal Finishing Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the global composite metal finishing Industry.

By Process: Electroplating Process, and Electroless Composite Plating Process

By Filler Used: Diamond, Boron Nitride, Silicon Carbide, Polytetrafluoroethylene (PTFE), and Others

By End Use Industry: Aerospace, Automotive, Electronics, Oil & Gas, Heavy Machinery, and Others

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and Rest of the World (Middle East, and Africa).

Buy Now

Key Takeaways

Asia-Pacific dominates the global composite metal finishing market, owing to the rising demand for tough and corrosion resistant materials from the automotive, electronics and aviation sectors for applications such as pistons, shock absorbers, fuel injection rails, and fuel pumps in the region.

Electroless composite coating technology has various advantages such as energy and cost savings, automatic monitoring of chemical replenishment, and also, it aids in plating blind holes with stable thickness which acts as a driver for global composite metal finishing market.

Development of trivalent chromium hard chrome plating process is anticipated to drive the global composite metal finishing market growth during the forecast period as the hazardous nature of hard chrome plating and the potential risks to the environment and personnel can be drastically reduced.

Composite metal finishing market is driven by its wide usage in oil & gas sector for drilling components, ball valves, cable glands, gate plugs, tubular components and in electronic sector, for Printed Circuit Boards (PCBs), connectors, interlocks, junction fittings, computer drive mechanisms, chassis memory drums and discs, terminals of lead wires.

Global Composite Metal Finishing Market Analysis — By Process

The electroless composite plating process held the largest share in the global composite metal finishing market in 2023, owing to its extensive set of properties, such as improved corrosion resistance due to a more consistent thickness, the ability to plate complicated and irregular shapes, lower operating costs due to improved coating quality, improved mold and die release properties for stamping and drawing, uniform nickel coating composition for less waste and reduced downtime due to plating-related issues. The rising demand from automotive, oil & gas, and heavy machinery industries are expected to boost the market share of electroless composite plating process further during the forecast period.

Global Composite Metal Finishing Market Analysis — By End Use Industry

Automotive sector held the largest share in the global composite metal finishing market in 2023 and is growing at a CAGR of 7.9%, owing to its various applications in vehicle parts such as engines, other under-the-hood components, power steering systems, brake parts and systems, air conditioning components and systems, chassis hardware, climate control components, and fuel systems. Composite metal finishing is one of the prominent methods used to provide a protective layer on the metal components of vehicles. Various minor and major automotive parts need their contact surfaces to be smooth, stress relieved and without burrs or defects, which can be achieved by metal finishing. It is needed as it helps the automotive engines to achieve a surface with lower friction and heat, resulting in more horsepower generation and better overall performance. The constant demand for composite metal finishing from the automotive sector is anticipated to drive the global composite metal finishing market during the forecast period.

Global Composite Metal Finishing Market Analysis — By Geography

Asia Pacific region held the largest share in the global composite metal finishing market in 2023 up to 34%, owing to increased demand of aircrafts in the region. Aircrafts require composite metal finishing for corrosion protection of components such as landing gear and fasteners. For example, during May 2022, China Eastern released additional shares to fund fleet acquisitions. Over the span of 2022 to 2024, China Eastern Group, which encompasses Shanghai Airlines and OTT Airlines, plans to integrate 35 Airbus A320neo aircraft, nine Boeing 787–9s, nine A350–900s, 28 COMAC ARJ21s, and five C919s into its fleet. In February 2023, Air India agreed to buy 250 planes from Airbus and 220 from Boeing, worth a combined $70 billion. Air India plans to fund the order with internal cash and equity. The increasing demand from the aviation industry is anticipated to drive the global composite metal finishing market.

Global Composite Metal Finishing Market Drivers

Increasing Production of Automotives

Providing new coatings for automotive is by far the biggest industry for metal finishing. Automotive coatings revenue, including paint and base coat, is expected to increase the demand of composite metal finishing during the forecast period. In 2023, China’s automobile production and sales volume were 30.16 million and 30.09 million units, respectively. This represents an 11.6% increase in production and a 12% increase in sales. According to Royal Automobile Club of Victoria, 2023 was the best ever year for vehicle sales in Australia, with a total of 1,216,780 vehicles delivered, beating the previous sales record of 1,189,116 set in 2017. Due to the increasing expectations of consumers, the international automotive industry is required to extend vehicle warranties. Thus, improvements in corrosion protection are becoming increasingly important. The increasing automation production will require more composite metal finishing which will act as a driver for global composite metal finishing market.

Need for Durable and Wear Resistant Metal Products

Globally, large investments are being made in development of metals products for transportation infrastructure and vehicles, energy production and machinery, building materials and even consumer products. These investments are fueled by the need to develop metals that are durable, stronger and wear resistant throughout their use. The composite finishing of metals increases the strength, resistance to severe heat temperature, resistance to corrosion in alkaline and chlorine-bearing environments. Also, on proper composite finishing of metals, the metals do not scratch, bend, rot, warp, crack, split, catch fire or break over time. Moreover, finished metals provide strong structural integrity, weather resistance, and long-term strength. These extensive properties of metal finishing are anticipated to drive the global composite metal finishing market during the forecast period.

Global Composite Metal Finishing Market Challenges

Increasing Replacement of Metals by Plastics

Manufacturers have depended on metals due to the extensive properties of metal such as strength, stiffness, ideal traits related to electricity and chemical resistance. Replacing metal with plastic is beneficial as it saves cost and provides improved product quality. The weight of the products such as automobiles dramatically decreases on using parts manufactured by plastics due to which various automobile industries are shifting towards plastics instead of metals to manufacture light weight vehicles. Plastics also help with improving transportation for the end-use industries; by reduce shipping costs for the imports and exports of automotives. Scrap plastic parts or parts that need to be recycled can be ground into the original form, pellets, and reused for another injection process immediately. Also, plastics are preferred as they can be melted again to be reused while metal needs to be re-smelted, which is a longer process. All these enhanced properties of plastic acts as a restrain for the composite metal finishing market during the forecast period.

About IndustryARC™: IndustryARC primarily focuses on Cutting Edge Technologies and Newer Applications of the Market. Our Custom Research Services are designed to provide insights on the constant flux in the global demand-supply gap of markets. Our strong analyst team enables us to meet the client research needs at a very quick speed with a variety of options for your business. We look forward to support the client to be able to better address customer needs; stay ahead in the market; become the top competitor and get real-time recommendations on business strategies and deals. Contact Us: https://tinyurl.com/yk8khvpa Website URL: https://www.industryarc.com/

0 notes

Text

Why Parth Valve is the Go-To Supplier for Quality Dampers and Valves

In today’s increasingly competitive industrial world, choosing the correct supplier for crucial components such as dampers and valves can significantly improve operational efficiency and safety. Parth Valve has over 12 years of experience in manufacturing and exporting industrial dampers and valves, and it has established itself as a trusted partner for businesses in Dubai, Indonesia, Malaysia, Middle East countries, African countries, and beyond. This article investigates why Parth Valve is considered the go-to provider for high-quality dampers and valves, focusing on the fundamental elements that distinguish the company from its competitors.

Permanent Quality Standards

One of the main reasons Parth Valve distinguishes out in the market is its continuous dedication to quality. The company uses cutting-edge manufacturing processes and technology to produce valves and dampers that meet or surpass industry standards. Each product is rigorously tested to guarantee that it can endure the harsh circumstances of industrial applications, whether controlling fluid flow, managing air pressure, or protecting systems from potential threats.

Parth Valve incorporates quality control into every level of the production process, from raw material sourcing to final product inspection. This careful approach to quality assurance not only maintains product reliability but also increases product lifespan, eliminating the need for frequent replacements and maintenance. For clients, this means cost savings and ongoing operations, making Parth Valve a dependable option.

A diverse product range

Parth Valve provides a wide range of products tailored to the specific needs of many industries, such as oil and gas, chemical processing, power generation, HVAC, and more. The company’s product line includes butterfly dampers, louver dampers, and guillotine dampers, as well as a comprehensive range of valves such as ball valves, gate valves, check valves, and globe valves.

This extensive product selection enables clients to discover exactly what they require, whether it’s a custom-engineered solution for a one-of-a-kind application or basic components for regular use. Parth Valve’s ability to deliver a diverse range of high-quality products makes it a one-stop shop for all industrial valve and damper requirements.

Global Reach and Export Expertise

Parth Valve has effectively grown its global footprint by establishing a strong presence in Asian markets such as Dubai and Indonesia. The organization understands the intricacies of exporting industrial components, including navigating international trade restrictions and assuring timely delivery and compliance with local standards.

Parth Valve’s export experience is supported by a robust logistical network, allowing the company to easily serve clients in a variety of geographical regions. Parth Valve’s global reach not only allows it to enter new markets but also assures that clients all over the world receive the same level of service and product quality.

Customization and Engineering Excellence

Industrial applications frequently necessitate unique solutions that are tailored to satisfy specific operational needs. Parth Valve excels at providing bespoke solutions, thanks to its team of talented engineers and technicians who collaborate with clients to understand their requirements and build products that fit seamlessly into their systems.

Whether it’s adapting a current design or developing a whole new product from scratch, Parth Valve uses its engineering skills to create inventive and practical solutions. Parth Valve’s capacity to provide customization offers it a competitive advantage, allowing it to serve a diverse range of sectors with distinct needs.

Customer-centric Approach

Parth Valve’s success stems from its focus on developing long-term relationships with its clients. The organization takes a customer-centric strategy, emphasizing understanding and meeting the unique demands of each client. Parth Valve is committed to offering an amazing customer experience from the beginning to the end.

Clients value the company’s timeliness, dependability, and readiness to go the extra mile to assure satisfaction. Parth Valve’s emphasis on customer care has won them a devoted clientele and a solid name in the business.

Sustainability and Innovation

Parth Valve is dedicated to reducing its environmental impact in an age where sustainability is becoming increasingly vital. To maintain the sustainability of its operations, the company implements environmentally friendly manufacturing practices such as energy-efficient production methods and waste reduction programs.

Innovation is also a crucial factor in Parth Valve’s success. To stay ahead of technological improvements in the valve and damper business, the company invests heavily in R&D. Parth Valve can provide goods that not only function better but also contribute to more sustainable industrial practices by utilizing cutting-edge technology and materials.

Competitive Pricing

While quality is vital, Parth Valve recognizes the need to provide low pricing. The company attempts to deliver good value for money by pricing its products fairly while maintaining high quality. Parth Valve’s cost-quality balance makes it an appealing option for businesses trying to save money without sacrificing performance.

Conclusion

Parth Valve has established itself as a top supplier of dampers and valves by continually supplying high-quality goods, a varied and configurable product line, and great customer service. With a strong global presence, a commitment to innovation and sustainability, and a focus on reasonable pricing, Parth Valve is well-positioned to be the go-to supplier for businesses across several industries. Whether you need dependable industrial components or a partner who knows the difficulties of worldwide trade, Parth Valve is the brand you can trust.

0 notes

Text

Carbon Credits Market Size, Share, Volume, Trends, Demand, Growth and Forecast Report 2024-2032

Carbon Credits Market provides in-depth analysis of the market state of Carbon Credits manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Carbon Credits in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Carbon Credits Market Report:

The report offers a comprehensive and broad perspective on the global Carbon Credits Market.

The market statistics represented in different Carbon Credits segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Carbon Credits are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Carbon Credits.

Major stakeholders, key companies Carbon Credits, investment feasibility and new market entrants study is offered.

Development scope of Carbon Credits in each market segment is covered in this report. The macro and micro-economic factors affecting the Carbon Credits Market

Advancement is elaborated in this report. The upstream and downstream components of Carbon Credits and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/carbon-credits-market-100582

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Plastic Bucket MarketMarket Analysis

Segmented Ball Valves MarketMarket Size

Global Massive Multiplayer Online (MMO) Games MarketMarket Share

Global Residential Interior Door MarketMarket Growth

Boron Doped Diamond Electrode (BDD) MarketMarket

Optical Character Recognition MarketMarket Share

Retail Banking MarketMarket Growth Rate

Rare Disease Treatment MarketMarket Forecast

Global MEMS Microphone MarketMarket Size

Electronic Logging Device MarketMarket Growth

Real Time Payments MarketMarket Analysis

Ion Exchange Resins MarketMarket Size

Global E-Learning Services MarketMarket Share

Global Enterprise Social Networking (ESN) MarketMarket Growth

Iron and Steel MarketMarket

Direct Drive (Gearless) Wind Turbine MarketMarket Share

LVT Flooring MarketMarket Growth Rate

AI in Education MarketMarket Forecast

Global Note Taking App MarketMarket Size

Aluminum Powder in Additive Manufacturing MarketMarket Growth

Free Space Optics Communication Technology MarketMarket Analysis

Curved Televisions MarketMarket Size

Global Laser Communication Terminal MarketMarket Share

Global Unified Communication as a Service (UCaaS) MarketMarket Growth

Produce Wash MarketMarket

Biaxially Oriented Polyamide (Nylon) Film (BOPA) MarketMarket Share

Transaction Monitoring MarketMarket Growth Rate

Wedding Dress MarketMarket Forecast

Global Dry Construction Material MarketMarket Size

Voltage Controlled Crystal Oscillator (VCXO) MarketMarket Growth

Electro Hydraulic Servo Valve MarketMarket Analysis

B2B Publishing MarketMarket Size

Global Rubber Shoe Sole MarketMarket Share

Global Intelligent Virtual Assistant MarketMarket Growth

D-Luciferin Substrate Market Market

Pendant Stations MarketMarket Share

Curved Guide Rail MarketMarket Growth Rate

Insulin Injection Related Product MarketMarket Forecast

Global Selective Wave Solder Pallet MarketMarket Size

Medical Grade Silicone Rubber MarketMarket Growth

0 notes

Text

China Vervo Valve Co., Ltd is One of the biggest Chinese industrial valves manufacturer specializing in floating ball valves, trunnion ball valves, cast steel gate valves, forged steel gate valves, pressure seal gate valves, cast steel globe valves, forged steel globe valves, cryogenic globe valves, forged steel check valves, swing check valves, dual plate check valves, API 609 butterfly valves, steel plug valves, Y strainer valves, etc.

Our main market includes North America, South America, Western Europe, Eastern Europe, Eastern Asia, Southeast Asia, Middle East, Africa, Oceania, from Worldwide Markets. Our Business covers manufacturing, importing and selling all kinds of industrial ball valves, industrial gate valves, industrial globe valves, industrial butterfly valves, industrial check valves, industrial plug valves, industrial special valves.

We are looking forward to cooperating with you with most sincerity!

#Ball Valves#Gate Valves#Globe Valves#Check Valves#Plug Valves#Butterfly Valves#Pipe Strainers#Floating Ball Valves#Trunnion Ball Valves#Cast Steel Valves#Cast Steel Gate Valves#Cast Steel Globe Valves#Pressure Seal Gate Valves#Swing Check Valves#Forged Steel Valves#Forged Steel Gate Valves#Forged Steel Check Valves#Forged Steel Globe Valves#Industrial Ball Valves#Industrial Gate Valves#Industrial Globe Valves#Industrial Check Valves#Industrial Plug Valves#Industrial Strainers#Sleeved Plug Valves#Steel Plug Valves#Steel Ball Valves#Steel Gate Valves#Steel Globe Valves#Steel Check Valves

1 note

·

View note

Text

Fire Safety Valves Market Analysis Report, Growth, Share by 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Fire Safety Valves Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Fire Safety Valves Market Research share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Fire Safety Valves Market?

The global fire safety valves market size reached US$ 5.4 billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 7.8 billion in 2032, exhibiting a growth rate (CAGR) of 4.2% during 2024-2032.

What are Fire Safety Valves?

Fire safety valves are valves specifically created to manage the flow of water or other fire-extinguishing agents in fire protection systems. These valves are crucial in fire sprinkler systems, standpipe systems, and fire hydrants, ensuring that water is distributed to extinguish fires in a controlled and efficient manner. Typically crafted from robust materials like brass or stainless steel, fire safety valves are designed to endure high temperatures and harsh conditions. They play a vital role in containing fires and safeguarding lives and property during fire emergencies.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1948

What are the growth prospects and trends in the Fire Safety Valves industry?

The fire safety valves market growth is driven by various factors. The fire safety valves market is witnessing significant growth, propelled by stringent fire safety regulations and increasing emphasis on protecting life and property from fire hazards. These valves are crucial components in fire protection systems such as sprinklers, standpipes, and hydrants, ensuring the controlled flow of water or other extinguishing agents. Key drivers include the rising adoption of automated fire protection systems, technological advancements in valve design, and growing demand for fire safety equipment in both commercial and residential buildings. Moreover, the introduction of innovative fire safety valves offering enhanced performance and reliability is anticipated to drive further market growth. Hence, all these factors contribute to fire safety valves market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Valve Type:

Ball Valves

Gate Valves

Butterfly Valves

Check Valves

Others

By Application:

Commercial Buildings

Industrial Facilities

Residential Buildings

Oil and Gas

Power Generation

Others

By End-Use Industry:

Oil and Gas

Chemical and Petrochemical

Power Generation

Construction

Automotive

Others

Market Segmentation By Region:

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Who are the key players operating in the industry?

The report covers the major market players including:

Honeywell International Inc.

Tyco International Ltd.

Emerson Electric Co.

Johnson Controls International plc

Siemens AG

Victaulic Company

Cla-Val

AGF Manufacturing Inc.

Potter Electric Signal Company LLC

Pentair plc

Viking Group Inc.

Mueller Co.

Apollo Valves

Zurn Industries, LLC

Watts Water Technologies, Inc.

View Full Report: https://www.reportsandinsights.com/report/Fire Safety Valves-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

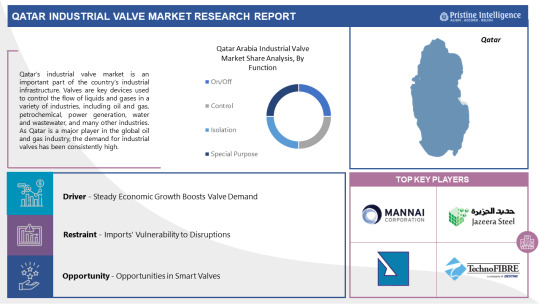

Qatar Industrial Valve Market: Forthcoming Trends and Share Analysis by 2030

The Industrial Valve is Expected to Grow at a Significant Growth Rate, and the Forecast Period is 2023-2030, Considering the Base Year as 2022.

An essential component of the nation's industrial infrastructure is the industrial valve market in Qatar. In many different industries, such as oil and gas, petrochemicals, power production, water and wastewater, and many more, valves are essential components that regulate the flow of liquids and gases. Due to Qatar's significant role in the global oil and gas sector, there has always been a high need for industrial valves.

The industrial valves market in Qatar is influenced by variables such as national economic development, government infrastructure spending, and programs aimed at expanding the industry. The need for valves has grown recently due to the expansion of the energy and construction industries.

Offering a broad range of valve types and sizes for varied industrial needs, major multinational valve makers and local businesses compete in this market. Furthermore, there is a growing need for sophisticated valves that may help save energy and safeguard the environment as a result of the increased emphasis on sustainable and efficient industrial operations.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Qatar Industrial Valve Market include:

Mannai Industrial (Qatar), Al-Jazeera Tube Mills Company (Qatar), Faisal Jassim Trading Company LLC (Qatar), Techno Fibre Middle East W.L.L. (Qatar), Flowline Mechanical Engineering (Qatar), RENKO Group (Qatar), International Gulf Trading Company (IGTC) (Qatar), United International Trading Company (UITC) (Qatar), Elite Middle East (Qatar), Al Jaber Trading & Contracting Company (Qatar), Aswan International Engineering Company (Qatar), Al Shoumoukh Group (Qatar), Hamad and Mohd Al Futtaim Co. LLC (HMAF) (Qatar), KBS Enterprises W.L.L. (Qatar), Al-Asmakh Facilities Management Company W.L.L. (Qatar), Qatar Air Distribution Network Manufacturing Factory W.L.L. (QADNET) (Qatar), Techno Q (Qatar), Power International Holding (Qatar), Qatar Integrated Plastic Bags Factory (Qatar), Qatar Plastic Products Company (QPPC) (Qatar) and other major players.

If You Have Any Query Qatar Industrial Valve Market Report, Visit:

Segmentation of Qatar Industrial Valve Market:

By Type

Ball

Globe

Gate

Butterfly

Plug

Check

By Material

Steel

Brass

Bronze

Cast Iron

Plastic

By Size

< 1”

1”–6”

6”–25”

25”–50”

50”

By Application

Oil & Gas

Power

Energy

Chemical

Water & Waste Treatment

By Function

On/Off

Control

Isolation

Special Purpose

Highlights from the report:

Market Study: It includes key market segments, key manufacturers covered, product range offered in the years considered, Global Qatar Industrial Valve Market, and research objectives. It also covers segmentation study provided in the report based on product type and application.

Market Executive Summary: This section highlights key studies, market growth rates, competitive landscape, market drivers, trends, and issues in addition to macro indicators.

Market Production by Region: The report provides data related to imports and exports, revenue, production and key players of all the studied regional markets are covered in this section.

Qatar Industrial Valve Market Profiles of Top Key Competitors: Analysis of each profiled Roll Hardness Tester market player is detailed in this section. This segment also provides SWOT analysis of individual players, products, production, value, capacity, and other important factors.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96367

Email: [email protected]

#Qatar Industrial Valve#Qatar Industrial Valve Market#Qatar Industrial Valve Market Size#Qatar Industrial Valve Market Share#Qatar Industrial Valve Market Growth#Qatar Industrial Valve Market Trend#Qatar Industrial Valve Market segment#Qatar Industrial Valve Market Opportunity#Qatar Industrial Valve Market Analysis 2023

0 notes

Text

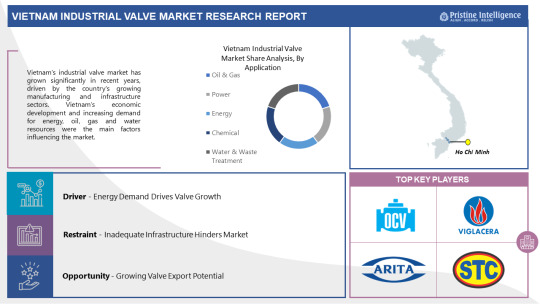

Vietnam Industrial Valve Market: Forthcoming Trends and Share Analysis by 2030

The Industrial Valve is Expected to Grow at a Significant Growth Rate, and the Forecast Period is 2023-2030, Considering the Base Year as 2022.

Vietnam's expanding manufacturing and infrastructure sectors have propelled the country's industrial valve market's recent notable growth. The primary factors driving the market were Vietnam's economic development and the rising need for energy, gas, oil, and water resources.

The market was typified by the existence of both foreign and indigenous valve producers. While multinational players from China, South Korea, Japan, and the United States supplied high-quality valves to diverse industries, local businesses met domestic demand. The construction, petrochemical, power generating, water and wastewater treatment, and oil and gas sectors were the biggest end users of industrial valves.

The need for industrial valves has expanded even more as a result of the Vietnamese government's emphasis on infrastructural development, industrial development, and foreign investment. The market did, however, face certain difficulties, including competition from low-cost import valves and the requirement for ongoing technological advancement to satisfy worldwide standards. Vietnam's industrial valve market appeared to have a bright future because of the nation's ongoing industrialization and economic expansion.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Vietnam Industrial Valve Market include:

Viglacera Corporation (Vietnam) PetroVietnam Valves (PVV) (Vietnam), Viet Valve Joint Stock Company (VVC) (Vietnam), Arita Valve Co. Ltd. (Japan), Hoang Anh Gia Lai Machinery JSC (HGL) (Vietnam), Neway Valve (Suzhou) Co. Ltd. (China), OCV Co. Ltd. (Vietnam), Valves Joint Stock Company (VVS) (Vietnam), Hemaya Co. Ltd. (Vietnam), VNECO Mechanical Engineering Import-export JSC (Vietnam), Industrial Instruments And Equipment Company Limited (VINTEC) (Vietnam), API Valve JSC (AVC) (Vietnam), BP Valve Company Limited (Vietnam), FTech Co. Ltd. (Vietnam), STC Co. Ltd. (Vietnam), HAIYAN SUNFAST TRADING CO. LTD Vietnam Branch (China), Minhtuan Production Trading And Services Co. Ltd. (MT Vietnam) (Vietnam), TBV Vina Co. Ltd. (Vietnam), UniOne Co. Ltd. (Vietnam), Vinacoma JSC (Vietnam) and other major players.

If You Have Any Query Vietnam Industrial Valve Market Report, Visit:

https://pristineintelligence.com/inquiry/vietnam-industrial-valve-market-203

Segmentation of Vietnam Industrial Valve Market:

By Type

Ball

Globe

Gate

Butterfly

Plug

Check

By Material

Steel

Brass

Bronze

Cast Iron

Plastic

By Size

< 1”

1”–6”

6”–25”

25”–50”

50”

By Application

Oil & Gas

Power

Energy

Chemical

Water & Waste Treatment

By Function

On/Off

Control

Isolation

Special Purpose

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Highlights from the report:

Market Study: It includes key market segments, key manufacturers covered, product range offered in the years considered, Global Vietnam Industrial Valve Market, and research objectives. It also covers segmentation study provided in the report based on product type and application.

Market Executive Summary: This section highlights key studies, market growth rates, competitive landscape, market drivers, trends, and issues in addition to macro indicators.

Market Production by Region: The report provides data related to imports and exports, revenue, production and key players of all the studied regional markets are covered in this section.

Vietnam Industrial Valve Market Profiles of Top Key Competitors: Analysis of each profiled Roll Hardness Tester market player is detailed in this section. This segment also provides SWOT analysis of individual players, products, production, value, capacity, and other important factors.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96367

Email: [email protected]

#Vietnam Industrial Valve#Vietnam Industrial Valve Market#Vietnam Industrial Valve Market Size#Vietnam Industrial Valve Market Share#Vietnam Industrial Valve Market Growth#Vietnam Industrial Valve Market Trend#Vietnam Industrial Valve Market segment#Vietnam Industrial Valve Market Opportunity#Vietnam Industrial Valve Market Analysis 2023

0 notes

Text

Ball Valve Market Growing Popularity and Emerging Trends in the Industry

Advance Market Analytics released a new market study on Global Ball Valve Market Research report which presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates for Global Ball Valve Forecast till 2027*. Ball valve, a device with a spherical closure unit which uses a hollow that perforated and pivoting ball to control flow through it. it's open once the ball's hole is in line with the flow and closed once it's pivoted 90-degrees by the valve handle. Rising demand for high-quality ball valves to mitigate the threat of contamination in essential processes, including water and steam handling in food & beverages and chemicals industries are driving the growth of the ball valve market across the globe.

Key Players included in the Research Coverage of Ball Valve Market are

Emerson Electric Co. (United States)

Flowserve Corporation (United States)

Cameron–Schlumberger Ltd. (United States)

Crane Co. (United States)

IMI Plc. (Finland)

Kitz Corporation (Japan)

Metso (Finland)

Astech Valve Co. Ltd. (Taiwan)

Valvitalia S.p.A (Italy)

Velan Inc. (Canada)

Aalberts Industries N.V. (Netherland)

Christian Bürkert GmbH & Co. KG (Germany)

Neway Valves Co. Ltd (China) What's Trending in Market: Increasing Use of 3d Printers in Manufacturing Line

Adoption of Automation in Valves

Challenges: Minimization of Lead Time

The existence of Manufacturers Providing Low-Priced Valves

Opportunities: Integration of IIoT-Enabled Ball Valves to Avoid Unexpected Downtime

Increase in the Number of Refineries, and Petrochemicals and Chemicals Plants Worldwide

Market Growth Drivers: Need for Ball Valve Replacement

Growth in Energy Consumption in Developing Economies

Increasing Industrialization, Urbanization, and Smart City Initiatives Worldwide

The Global Ball Valve Market segments and Market Data Break Down by Type (Trunnion Mounted Ball Valves, Floating Ball Valve, Rising Stem Ball Valve (RSBV)), Application (Oil & Gas, Energy Power, Chemical Industry, Water Treatment Industry, Paper Making Industry, Others), Material Type (Stainless Steel, Cast Iron, Alloy Based (Nickel Aluminium Bronze), Other (Non-metallic Materials (Plastic))) To comprehend Global Ball Valve market dynamics in the world mainly, the worldwide Ball Valve market is analyzed across major global regions. AMA also provides customized specific regional and country-level reports for the following areas. • North America: United States, Canada, and Mexico. • South & Central America: Argentina, Chile, Colombia and Brazil. • Middle East & Africa: Saudi Arabia, United Arab Emirates, Israel, Turkey, Egypt and South Africa. • Europe: United Kingdom, France, Italy, Germany, Spain, Belgium, Netherlands and Russia. • Asia-Pacific: India, China, Japan, South Korea, Indonesia, Malaysia, Singapore, and Australia. Presented By

AMA Research & Media LLP

0 notes

Text

Drum Pump Market Outlook, Current and Future Landscape Analysis 2022 to 2032

The global drum pump market is expected to be worth US$ 503.6 million in 2022. Drum Pump sales are expected to grow at a CAGR of 6.2 percent between 2022 and 2032, totaling US$ 921.0 million. Between 2016 and 2021, demand for Drum Pumps increased at a 5.7% value CAGR.

Industrialization is accelerating in both developed and developing countries, driving up demand for oil and lubricants. Oil, lubricants, and other liquids are stored in tanks, drums, and barrels, among other containers.

A drum pump is a portable, lightweight solution for emptying liquids from tanks, drums, and barrels. Drum pumps are ideal for moving lubricating and corrosive liquids such as diesel oil, gasoline, engine oil, vegetable oil, milk, hydraulic oil, acid, alcohol and other lubricating and corrosive liquids.

When filled into a drum or barrel, many industrial fluids become very heavy. When the liquid is outside the drum or barrel, the manufacturer should use a drum pump rather than tipping to retrieve it. Drum pumps are in high demand in a variety of industries, and this demand is expected to rise during the forecast period.

Request A Sample Copy of this Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-5312

Because it reduces the possibility of spillage or waste, as well as the possibility of injury or accident to the operator, the drum pump is the best solution for emptying liquid from tanks. The drum pump is the preferred method of removing liquid due to its numerous advantages.

Drum Pump – Market Dynamics

Growth in demand of the drum pump market is expected to raise muscularly for numerous reasons. One of the significant factors contributes towards the growth of the drum pump is growing demand by the various industry including oil, chemical, milk, and lubricant etc. Industries import and export the liquids in the big container rather than the small container for saving the shipping and transportation cost.

For dispensing the liquid from big container industries prefer drum pump, so it drives the drum pump market positively. It allows speedy transfer of liquid without spillage it is another factor which contribute to the growth of the drum pump market. Moreover, drum pump saves considerable time, resources & manpower for dispensing the liquid and allow flow control at outlet through the ball valve, they also participate in the growth of the drum pump market.

The demand of the drum pump market is expected to witness an above average growth due to increase in the demand for drum pump by various industry.

Drum Pump – Market Segmentation

Globally, the drum pump market can be segmented on the basis of product type, by material and by application. On the basis of product type drum pump market is segmented into Electric driven, Hydraulic, Rotary / Manual pump, Pneumatic, and others. On the basis of material type drum pump market is segmented into plastic and metal. The plastic segment is sub-segmented into Chlorinated Polyvinyl Chloride (CPC), Polypropylene (PP), Polyvinylidene Fluoride (PVDF) and others.

The metal segment is sub-segmented into Stainless steel, cast iron, aluminium, and others. On the basis of application type drum pump market is segmented into Petroleum industry, Chemical plants, Food processing plants, Manufacturing plants, Automotive industry, wastewater treatment, laboratories etc.

Drum Pump Market – Regional Outlook

The drum pump market can be segmented into North America, Latin America, Europe, Middle East, Africa and Asia Pacific. North America is anticipated to be the largest market for the drum pump market, primarily driven by manufacturer preference towards drum pump which acts as cost-effective and efficient dispenser tools for variety of liquid. Latin America also has a good presence in the drum pump market.

Furthermore, Eastern Europe followed by the Middle East is anticipated to be the second largest marketfor the drum pump. The recent development in the drum pump market has shifted its production base to the east, especially in Asia, the emerging players from China, India and Middle East have started taking the market share in the drum pump industry.

Drum Pump Market – Key Players

Few of the major players identified across the globe in the drum pump market are Fluidyne Instruments Pvt. Ltd., FLUX, Kecol Pumping Systems Ltd,Iwaki Pumps Australia Pty Ltd, JESSBERGER GnbH, Finish Thompson Inc., Lutz Pumps, Inc, NZ Pump Company Inc, Graco etc.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The report covers exhaustive analysis on

Market Segments

Market Dynamics

Market Size

Current Trends/Issues/Challenges

Competition & Companies involved

Value Chain

Read Full Report @ https://www.futuremarketinsights.com/reports/drum-pump-market

Key Segments Covered in the Drum Pump Industry Analysis

Drum Pump Market by Product Type:

Electric Driven Drum Pumps

Hydraulic Drum Pumps

Rotary / Manual Drum Pumps

Pneumatic Drum Pumps

Other Drum Pump Types

Drum Pump Market by Material Type:

Plastic Drum Pumps

Chlorinated Polyvinyl Chloride (CPC)

Polypropylene (PP)

Polyvinylidene Fluoride (PVDF)

Others

Metal Drum Pumps

Stainless Steel

Cast Iron

Aluminium

Others

Drum Pump Market by Application:

Drum Pumps for the Petroleum Industry

Drum Pumps for Chemical Plants

Drum Pumps for Food Processing Plants

Drum Pumps for Manufacturing Plants

Drum Pumps for Automotive Industry

Drum Pumps for Wastewater Treatment

Drum Pumps for Laboratories

Drum Pump Market by Region:

North America Drum Pump Market

Latin America Drum Pump Market

Europe Drum Pump Market

Asia Pacific Drum Pump Market

The Middle East & Africa Drum Pump Market

0 notes

Text

Global Api Gate Valves Market Insights and Expansion Forecasts 2024 - 2031

The global API (American Petroleum Institute) gate valves market is an essential component of the oil and gas industry, facilitating the safe and efficient flow of fluids in various applications. This article explores the key aspects of the API gate valves market, including drivers, challenges, regional insights, and future trends.

Overview of the API Gate Valves Market

API gate valves are designed to provide a straight-line flow of fluid with minimal restriction and are primarily used for on/off service. These valves are critical in maintaining the integrity of pipelines, tanks, and other equipment in industries such as oil and gas, petrochemicals, and water treatment.

The global API gate valves market is poised for growth, driven by increasing demand in the oil and gas sector, infrastructure development, and technological advancements. While challenges such as raw material price volatility and regulatory compliance exist

Market Definition and Segmentation

The API gate valves market can be segmented based on:

Type: Wedge gate valves, parallel gate valves, and others.

Material: Cast iron, stainless steel, carbon steel, and others.

Application: Oil and gas, chemical processing, water treatment, and power generation.

Region: North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Key Market Drivers

1. Growing Demand for Oil and Gas

The increasing demand for oil and gas globally is a significant driver for the API gate valves market. As exploration and production activities expand, the need for reliable flow control solutions becomes critical.

2. Infrastructure Development

Ongoing infrastructure projects in various sectors, including oil and gas, water treatment, and chemical processing, are driving the demand for API gate valves. These projects require high-quality valves to ensure operational efficiency and safety.

3. Technological Advancements

Advancements in valve technology, such as improved designs and materials, enhance the performance and lifespan of API gate valves. Innovations in automation and smart technologies also contribute to increased adoption.

Challenges Facing the Market

1. Price Volatility of Raw Materials

The prices of raw materials, particularly metals, can fluctuate significantly, impacting the production costs of API gate valves. This volatility can affect profit margins for manufacturers and may lead to price increases for end-users.

2. Competition from Alternative Valve Types

The API gate valves market faces competition from other types of valves, such as ball valves and butterfly valves, which may offer advantages in specific applications. This competition can impact market share and growth.

3. Regulatory Compliance

Manufacturers must comply with stringent industry regulations and standards regarding safety and performance. Ensuring compliance can increase operational costs and complexity for valve producers.

Regional Analysis

North America

North America is a prominent market for API gate valves, driven by a well-established oil and gas industry. The U.S. and Canada are major contributors, with ongoing investments in exploration and production activities supporting market growth.

Europe

In Europe, the API gate valves market is growing, supported by stringent regulations regarding safety and environmental standards. Countries like Germany, the UK, and Norway are key markets, with a focus on upgrading aging infrastructure.

Asia-Pacific

The Asia-Pacific region is witnessing significant growth in the API gate valves market, fueled by rapid industrialization and increasing energy demands. Countries like China and India are emerging as major markets, with substantial investments in oil and gas exploration.

Future Outlook

The global API gate valves market is expected to experience steady growth in the coming years. Key trends influencing the market include:

Increased Focus on Sustainability: The growing emphasis on sustainability and environmental protection is prompting manufacturers to develop eco-friendly valves that minimize leakage and emissions.

Integration of Smart Technologies: The adoption of IoT and smart technologies in valve systems is expected to enhance operational efficiency and monitoring capabilities, making API gate valves more attractive to users.

Rising Investments in Renewable Energy: As the energy landscape shifts towards renewable sources, API gate valves will also find applications in new sectors, broadening their market potential.

Conclusion

The global API gate valves market is poised for growth, driven by increasing demand in the oil and gas sector, infrastructure development, and technological advancements. While challenges such as raw material price volatility and regulatory compliance exist, the market's future outlook remains positive. As industries continue to seek reliable and efficient flow control solutions, API gate valves will play a crucial role in ensuring operational safety and efficiency across various applications.

#Global Api Gate Valves Market Size#Global Api Gate Valves Market Trend#Global Api Gate Valves Market Growth

0 notes

Text

Excellent growth of Electric Linear Actuators Market- Comprehensive study by key players: IAI, Parker, THK, LINAK, SKF, etc

The electric linear actuators market refers to the global market for devices that convert electrical energy into linear motion. These devices are used to move or control various mechanisms and equipment, such as valves, doors, robotics, and medical devices, among others. The electric linear actuators are commonly used as a replacement for hydraulic and pneumatic systems due to their high efficiency, low maintenance, and precise control.

The market for electric linear actuators is expected to grow steadily in the coming years due to the increasing demand for automation in various industries, such as manufacturing, healthcare, and automotive. Moreover, the rise in investments for the development of smart cities, renewable energy, and advanced transportation systems is expected to fuel the demand for electric linear actuators.

Click Here By - https://www.marketinforeports.com/

Based on type, the electric linear actuators market can be segmented into ball screw, lead screw, linear motor, and others. The ball screw segment is expected to dominate the market due to its high efficiency and precision. Based on application, the market can be segmented into industrial, medical, automotive, aerospace & defense, and others. The industrial segment is expected to hold the largest market share due to the increasing adoption of automation in the manufacturing industry.