#and if you want a fine dense fabric it's much less efficient

Explore tagged Tumblr posts

Text

If I was going to go back in time to disrupt history with a single technology the temptation would be incredible to make it knitting.

Like I don't know how much that would really do to alleviate human suffering en masse so it's not the heroic option like idk an understanding of germ theory on the level necessary to improve child mortality in the long term? But it would be so cool to see what happened.

Because knitting in the form we know it is basically a 20th century invention.

I hate that! It doesn't seem right at all, huh?? Knitting is over 1000 years old, that's all we know we don't have the artifacts to say more precisely than that, but it spent most of that time being pretty exclusively a means of making socks, and not a viral sensation of a sock method, either. The purl stitch was figured out and then forgotten again.

That's nothing. That's like 0 time, in the history of string.

And then, almost every knitting technique of any serious elaboration, all the complicated stitches and the cable knits and all that: less than 150 years old. Cannot believe this. Wild. What is humanity.

Anyway I just want to see what would happen if you went back to before the proliferation of the loom and taught knitting to a bunch of different communities across the mesolithic world. Some of them would keep it up, if you seeded it widely.

Knitting is way more nomadism-friendly than weaving, so at the very least the early proliferation of knit fabrics would alter the economic balance of pastoral and agricultural communities. i feel like it would also have interesting impacts on the fishing net.

#hoc est meum#knits are not suitable for all the same purposes as woven cloth#and if you want a fine dense fabric it's much less efficient#but stretchy fitted garments...#quick simple lace#the interesting cultural angles opened up by like#linen mesh#being relatively efficient to make

71 notes

·

View notes

Text

Making Acoustic Treatment

Sound likes to reflect around whatever space it's in. It's main mission is to transfer around the space. In an amphitheatre this is ideal and allows for natural amplification of the source. However, whether you're in a recording studio, edit suite or dubbing stage, it's really important to control the sound otherwise your audio mix will never translate properly to the listener, whether in their lounge, car or especially a cinema!

Yes, egg boxes on the walls have remained in our consciousness, it's often said jokingly, but I have met more than a couple of people who would classify this as a real option - while it can offer some help, this is not going to be an effective solution. This is where it gets a little more complicated... Humans hear a range of frequencies (or pitches) from really low rumble at 20Hz to the almost (and genuinely for over 12's!) Imperceptible 20,000Hz. Dealing with high frequencies is relatively easy, a lightweight cotton material will help with echoes (as will egg boxes dare I say), but the low mids and low frequencies are a lot harder to deal with. There is one thing that is key here - Mass/Density. The more dense an absorptive material is the better it will be able to trap lower frequencies. So, with that little bit of context, let's get on with the build.

You don't need any specialist tools or expensive materials to make these, just some patience!

Tools List - Tools:

Power Drill

Saw

Staple Gun

3mm Wood Drill Bit

Sandpaper

Iron

PPE - Gloves, Mask, Goggles (Fiberglass)

Materials List - Materials:

Wood planks for the frames

Rockwool Insulation (more on this below)

Hessian/Acoustically transparent covering fabric

Wood screws - Different lengths

Hanging brackets

Rookwool/Insulation

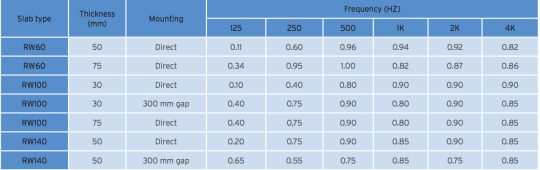

One of the first things you are going to need to decide is how thick the absorbers are going to be - this relates directly to the ability to absorb low frequencies, so the bigger the better generally. I went for 75mm thick RW60 Rockwool, RW60 is dense in Rockwool's range so it should be ideal, I'd of gone heavier if not for the extra cost. Other insulation can be fine, but try and get the most dense you can. It can be useful to look at the absorption co-efficient diagram for the material you are going to use, this will give you an idea of how much of a frequency band is absorbed (the scale is from 0 - 1. 1 is 100% absorption & 0 is 0%). Below you can see the chart:

Absorption co-efficient for Rockwool types

So for our RW60, it absorbs approx 95% of the 250Hz frequency, not bad at all. But notice how the efficiency dramatically improves when it is mounted 300mm off the wall - this where we can really save some money! I mounted all of mine 100mm off the wall, as 300mm was far too intrusive, but if you have a bigger room it may be worth going all the way to 300mm. But as a rule, the larger the room, the less problems there will be with low frequencies anyway. In summary - we are mounting 75mm RW60 Rockwool 100mm off the wall.

Building the Frames

To keep cutting of the Rockwool down to a minimum (to reduce horrible fibreglass particles and save time) I opted to build the frames around the existing sheet size, which is 1200 x 600mm. I wanted a tight fit to avoid having to fix them in the frame, so I made the external size of the frames 1220mm x 610mm. I used softwood for lightness - my timber was 22mm wide and 75mm deep to match the Rockwool. To reduce cutting time I got the timber yard to cut the timbre to 1220mm lengths, so I just needed to cut them in half to make the end pieces. I made 12 of these in total and therefore had 36 lengths - at my local yard it was only 78p a meter!

Start by cutting the lengths ready to construct the frames. I held these in place when assembling with a nail in each corner to hold it ready for screwing together. I drilled a 3mm pilot hole for the screws, which was fine for the 4mm thick screws, I'd have used a 2.5mm drill bit if I had one, but the 3mm worked fine.

Once assembled, I removed any roughness from the outside of the frames with 120grit sandpaper so that the fabric might catch on, I left the inside rough to help keep the Rockwool in place. That's the hard bit over.

Covering with Fabric

When choosing fabric to cover the frames and insulation, use something that sound can pass through otherwise they won't work! I found it quite expensive to buy speaker cloth, as I needed nearly 17 meters! So I found dyed jute/hessian fabric instead, it's also great as it's available in a range of colours - I used orange as it's my company's house colour. It comes in 1 meter wide lengths, which is ideal for covering our 610mm wide panels. When working out how much you need, make sure your account for the depth of the wood as you'll need to staple it to the back of the frames. So for our frames, I worked out that each frame requires at least 1400mm (1220mm frame + 2x75mm end depth + 50mm for safety/stapling). I got mine from eBay.

When it came to the fitment on the frame, there were a couple of important points - keep the fabric parallel with the frame, as the hessian I used had clear lines and would look wonky otherwise. Also keep the fabric tight at all times - I found it useful to a) get help from the Mrs. when she was around or b) keep the edges between my feet and work from one end to the other. I found it best to start at the longest ends first and then do the sides.

The most difficult part here was folding the edges over so they looked neat, when I started it took a few goes, but it became second nature after a while (small caveat from experience - avoid trying this after a pub visit!). I ended up using a lot of staples - probably at least 40 in each panel, but this was necessary to keep it from creasing or sagging at the edges. I got 1000 staples for £5 so no probs there!

Finally, I just pressure fit the Rockwool (use gloves if I were you, the fibreglass is super itchy and irritating).

I also used an iron with lots of steam over the front and sides of the panel, as I found that there were creases from shipping that were still visible even after stretching. It also helped reduce any fuzzy bits from the fabric.

Hanging/Fitment

This is the part that I had to plan/fiddle/replan the most. I originally was going to screw them onto a frame 100mm from the wall, but then realised there was no way that I would be able to get the screwdriver around the back to actually fit them. So I decided to hang them and re-purpose some old brackets I had.

I'd advise to drill the pilot holes for the bracket/fixings when you make the frames, otherwise you'll have to take the Rockwool out and risk tearing the fabric.

Then it's just a case of cutting a slot in the top of the mounting wood on the wall - this will allow the metal mounting bracket to slot into cut and hang away from the wall. I then added some staples to keep the wood from splitting (just in case). All that is left to do is put the Rockwool in the frames and then iron the fabric and then hang them!

Share your pictures of your build and let me know how you get on in the comments!

2 notes

·

View notes

Text

You’ve probably heard of, seen, or used microfiber products. These days they are everywhere.

What makes this tiny fiber so special?

The answer is a lot more interesting than you think. Take a quick read through this guide to level up your microfiber knowledge!

What is Microfiber?

Microfiber is a specific type of very fine synthetic textile fiber. Modern microfibers are finer than 1 denier, a unit of measure for fiber that equals 1 gram per 9000 meters of fiber. To better understand that, a strand of silk is roughly 1 denier. Microfiber is finer than silk!

Microfiber can be made of several different materials, including polyamide (nylon), polyester, and polypropylene (Prolen). Most common microfiber towels sold for automotive detailing are a combination of polyester and polyamide. The polyester provides the structure of the towel. The introduction of polyamide to the towel increases density and absorption.

As you can imagine, manufacturing a product such as this can be quite intricate, explaining the cost increase over that of common cotton terry cloths.

How Microfiber Towels are Made

Ultra-fine fibers have been produced as far back as the 50’s. Microfiber as we know it has only been around for a short while when the ability to extrude it in a single filament of any desired length was perfected. This extrusion process is the first step in the production of microfiber.

Microfibers destined for cleaning applications are then processed mechanically and chemically to be split into finer parts, as fine as 1/100th the diameter of a human hair.

Splitting the fibers not only increases the surface area of the fibers but also creates a positive charge within the fiber.

Finally, the fibers are woven in either a flat or looped weave. Flat weaved microfiber actually repels water and is not ideal for cleaning or polishing applications. Loop weaved microfiber, on the other hand, contain a web of hook-like claws that can reach into nooks and crannies to remove and absorb dirt and liquids.

How Microfiber Works

If you were to look at a cross section of a split microfiber you would find that it resembles a start or asterisk (*), differing from a cotton fiber which resembles a circle.

Microfiber vs Cotton Fiber

This asterisk shape allows microfiber to trap particles, such as dirt and liquid, within the individual fibers. Cotton fibers, in contrast, can only cling to particles around its outer surface and tend to push dirt and liquids around rather than absorb it.

As mentioned above, the fibers are also positively charged. The positive charge of the fibers attract negatively charged dirt and liquid which is then absorbed into the split fibers.

The Benefit of Microfiber

Microfiber is:

Highly Absorbent

Attracts Dirt

Penetrates Small Spaces

Lint Free

Strong and Durable

Cost Efficient

Light Weight

Resists Shrinking and Stretching

Wrinkle Free

A Message From Cabinets To Go

What Makes a Quality Microfiber Towel?

Density / Weight

Microfiber towels are typically rated in GSM which stands for grams per square meter or gm/2. This is a measurement of density of the towel but may also be referred to as the weight by some manufacturers and retailers. Do not confuse this with the denier, which is the measure of individual fibers.

The higher the GSM the thicker, plushier, and generally softer the towel will be. To put this in perspective, towels in the 200-350 GSM range would be suitable for general cleaning of surfaces not prone to scratches such as hard textured plastic, glass, and leather seats. Towels in the 600-700 GSM range would be more suited to cleaning and drying delicate surfaces such as soft automotive paints and clear plastics.

A heavier towel also tends to last longer due to having more fiber contained within. Though heavier towels will certainly cost more, the longer life can make up for it if you plan to use it enough times.

A good physical test of density is to hold a towel up to light and stretch it out. Does light pass through? Quality towels will be dense enough to block out most light.

You can also weigh different towels of similar size to compare them. If you have two 12”x12” towels and one weighs more it is denser and possibly of higher quality.

Blend

Another determination of quality is the blend ratio of polyester to polyamide, usually listed as a fraction such as 70/30 or 80/20. The first number represents the polyester and the second the polyamide. Remember, the polyester provides the structure of the towel. The introduction of polyamide to the towel increases density and absorption.

No longer as big of a differentiator as it used to be, due to modern manufacturing processes, both 70/30 and 80/20 towels are near identical in cleaning and absorbing capabilities. The 70/30 blend towels tend to be common to European manufacturers, while the 80/20 blend are common to Asian manufacturer.

Polyester is cheaper to produce than polyamide so you’ll occasionally find 100% polyester towels. These towels lack the blend necessary for a good cleaning, absorption, and drying.

Modern, quality towels will fall within the 70/30 to 80/20 range.

Origin

There has been a long-held belief that fibers produced in Korea were of a higher quality than those produced in China. From my research, this remains generally true. Whether or not this leads to a higher quality towel is much less clear.

With advances in modern manufacturing and globalization, both China and Korea have a fairly equal capability to produce quality microfiber towels. There are many examples of quality towels originating from both countries.

The problem lies in consistency. Production rates in China tend to be much higher which can result in lower quality control. Even though the fiber in a towel may have started in Korea, once it’s transported to China for assembly into a towel, the future of that towel’s quality is unknown.

There is also something to be said about the consistency in manufacturing and assembly of a towel in the same factory. When a towel is assembled by the same factory that spun the fabric there is a better probability for a quality product. It’s entirely possible that a towel made completely in a single Chinese factory can be better than one manufactured in Korea and assembled in China.

Given this information, I generally look for towels with a consistent manufacturing history and lean toward those with a Korean origin.

Split and Loop

Quality cleaning towels will be made of split fibers as discussed above. The more split segments per fiber, the more absorptive the towel will be. This measurement is not commonly reported by manufacturers. I have seen reports of around 16 splits per fiber being ideal.

Fibers woven in a looped weave rather than flat will be better at absorbing and hanging onto dirt and debris.

You can test whether or not a towel is made of closed loop fibers by rubbing it against your skin and feeling how soft it is. If it grabs at the imperfections of your skin this is a sign it’s made of looped fibers.

Another test of construction is to try and absorb water with the towel. If the towel does not absorb water well or just flat repels water, it’s likely made of poor quality, non-split, or flat weave fibers.

Edges

You want to look for a towel with a soft edge. It should either have a rolled edge, a clean cut edge (sometimes referred to edgeless), or an edge covered in a soft material and thread. Rough edges and hard threads can scratch or mar delicate surfaces.

How to Clean Microfiber Towels

When properly washed, a quality microfiber towel has been reported to last as much as 500 washes. This is a long time and can really extend the towel’s bang for the buck, so follow closely.

youtube

You’ve probably heard of, seen, or used microfiber products. These days they are everywhere. You’ve probably heard of, seen, or used microfiber products. These days they are everywhere. What makes this tiny fiber so special?

0 notes

Text

C. Bechstein Classic 124 Upright Piano (R124) - Demo & Review by Merriam Pianos

youtube

Introduction

The C. Bechstein Classic 124 upright piano is being reviewed by Merriam's own Stu Harrison. This piano is an absolute favorite upright in the Oakville showroom right now. We are going to be covering what makes this piano such an exquisite musical instrument and why so many have an excellent overall impression of the piano.

And for people out there who are thinking, "Why would anybody ever spend this amount of money on a new upright when you could get a very, very good grand piano for the same amount of money, or why not just go for the 124 Imposant?" Well, it all comes down to tonal clarity, it comes down to sympathetic resonance out of this instrument and of course, it comes down to exquisite touch. Because for people who are really focused on the very best musical experience possible, achieving the same quality control, materials, and design sophistication in a grand is going to run you into the $100,000's.

So, while it might seem unusual to be thinking about an upright piano in this price range, for anybody who is space challenged but wants a fine, fine, fine instrument, this actually turns out to be an incredibly good value to invest this level of dollars into an C. Bechstein upright piano of this caliber, of this prestige, of this heritage.

And so, we are going to be talking specifically about where this instrument gets this crazy level of sustain that it has, how it gets this amount of just intense sympathetic resonance out of the instrument. When you play this piano you genuinely feel like the entire body of the instrument is speaking to you, not just the soundboard. And of course, this silky smooth action assembly which piano makers C. Bechstein has been famous for, for well over 100 years. So, thank you so much for spending a little bit of time with us today.

C. Bechstein Classic 124 Upright Piano Review - Video Transcription

Musical Impressions

I'm left with so many distinct first impressions. And for those of you who are privileged enough to have been able to sit down at a fine instrument, whether it's a grand or an upright, and just have one of those immediate first impression aha moments when you're in front of a piano that really touches you musically, you know what I'm talking about. You're struck with these tones in your ear, or this combination of the physical and the aural experience where it genuinely causes you to play differently immediately. And I get that when I'm in front of this instrument - and certainly more so than even the best W. Hoffmann's or Academy uprights that C. Bechstein manufacturers.

Action

For an upright piano, I would say the biggest challenge for a manufacturer is: "how do you get ultimate control at both a high dynamic range and a low dynamic range?" This is something that you really don't usually have the opportunity to choose between or really demand out of an upright, even a really high end upright. Sometimes this is super difficult to get the geometry right in the action, to get the regulation so good in the action that when you play it feels like you can be as expressive as you can on an equally priced grand.

On the Classic 124, the key responds so fluidly that as long as you've got the technique somewhere in your head or in your arms, the note speaks with total intuitiveness. Bechstein spends an insane amount of time regulating these actions in the factory, and that's one big difference between the Gold Action and Silver Actions: the stringent requirements they impose on there tech department. I really like the fact that on Bechstein's website they actually list how many hours are spent creating this instrument. We're talking about well over 40 or 50 prep hours in the factory on the R124's action. That is something that is very difficult to replicate outside of the factory because it's hard to find C. Bechstein concert technicians that are willing to do that level of work on an upright and if you did, you're paying thousands and thousands of dollars in labor just to get that happening. So, the efficiency of having that level of prep done at a factory is far higher than trying to get it done after-sale on an instrument either like this or something a little lower quality.

Bechstein is using genuine felt for all of their bushings. They're using aged hardwoods that are super stable and crafted down to 4/1000 of an inch. Once that action gets regulated, it is not gonna have the same level of change whereas a lower cost wood action where the wood simply hasn't been aged or they're using a slightly less dense wood is going to be a little more reactive to humidity and climate.

Sound & Tone

Let's move on to the tone because this is where the construction, the design of the instrument, play a huge role in producing the highest sound quality possible. And this is where another reason why C. Bechstein instruments have had the reputation with uprights specifically, over 100 years. To sort of paint this with a broad stroke, one could say that Bechstein is one of the only builders that actually puts as much cabinetry care, case design, and as much engineering care into their uprights as they do their grands. That's pretty unusual. So, what you're getting on this upright are vertically laminated bridges, you're getting triple A grade mountain spruce, which is being taken from thousands of feet up in the air in terms of...from a European source. And the concert series (what they call the Residence class) is Val di Fiemme spruce. This is something that the Faziolis use, but more famously the same wood that Stradivarius used. To get this in an upright piano is incredibly unusual.

The other thing, or I should say other things that are also contributing to the tone. That trademark scissor connecting between all of the planks on that soundboard. So, it's not simply one plank and another plank, faced right up against one another. In that joint, there's actually three or four back and forth 90 degree, it almost looks like a scissor cutter or fabric cutter. And that's doubling the surface area between those two planks, so tons of sympathetic resonance throughout the soundboard.

Then we get to the cabinetry of the instrument. And this is where visually it's very, very easy to see some of those differences. And we'll make sure that we are able to show you some B-roll of the back of that piano because what you're gonna notice is you're gonna notice a lot of tension bars and a lot of full perimeter cabinetry on this instrument, which uses the same type of laminating techniques as C. Bechstein is using on the concert grands. This is super unusual. And what does it mean? Well, it means that energy regardless of where it's being put in through bridge on the piano is actually being reflected and transmitted through the entire instrument. And that's where you get this full voice coming from this piano. And so the dynamic output of the instrument is pretty impressive. Well, I wouldn't say pretty impressive, it's just downright surprising.

The sheer volume that this piano is able to create is going to outplay the vast majority of 6 foot pianos. And so in terms of bass tone, what are we getting? Well, really full clear powerful bass. This is coming obviously from the fact that we've got hand wound bass strings on this instrument. We've got a really nice length. We're talking about a 49 inch class piano. So, in terms of a string length, we're gonna be in and about the same range as a 5 9, 5 10 grand.

In terms of the mid tones to me, obviously, super clear sustain is really quite exquisite. I mean, this tone will just keep going on and on forever. But the mid tones have a really nice balance between that first fundamental, as well as the upper three or four fundamentals. So, it's not sounding too sharp, it's not sounding too muddy. It's just got this beautiful clarity to it.

And of course, a treble with a beautiful projection. And unbelievably, like straight as an arrow upper harmonics coming out of this. The feedback that I've got from our tuners is this instrument is incredibly easy to tune on the upper end compared to many other upright pianos because it's so easy to hear the fundamental pitches up in the very top octave or two. That on its own is pretty unusual.

Summary

So, all in all, what we have here is a 49 inch C. Bechstein Classic 124. We've got a piano that for customers who are really looking for absolutely the pinnacle of what acoustic piano tone is capable of timeless design that you get when you go right to the very, very top of the best practices. And you spend this time during the manufacturing process creating an instrument like that at factory. You've got a C. Bechstein piano, that for under $50,000 is going to give a grand piano of $90,000 or $100,000 a serious run for its money in terms of the responsiveness of the action assembly, in terms of the clarity of the tone, and in terms of the sustain of the instrument.

Yes, you're missing out on the grand look. And so, for people who have the space and have the budget, of course, this often doesn't come up. But there's more and more of us who are living in urban areas and townhouses where there's just not enough room for a 6 or 7 foot grand, let's be honest. And so, this up against a wall, or even pulled out against the walls, I would suggest by about 3 or 4 inches is gonna give such an exquisite tone. And hey, you're saving more than half the budget.

The post C. Bechstein Classic 124 Upright Piano (R124) - Demo & Review by Merriam Pianos first appeared on Merriam Pianos

2359 Bristol Cir #200, Oakville, ON L6H 6P8

merriammusic.com

(905) 829-2020

#bechstein 124 demo#bechstein 124 review#c bechstein#c bechstein 124#c bechstein 124 upright piano#c bechstein 124 upright piano demo#c bechstein 124 upright piano review

0 notes

Text

4 Strange New Ways to Compute

At the IEEE Rebooting Computing Conference, deep thinking about computing led to some wild ideas

Image: Eléonore Vissol-Gaudin

This optical micrograph shows a micro-electrode array below a mixture of single-walled-carbon-nanotubes with liquid crystals.

With Moore’s Law slowing, engineers have been taking a cold hard look at what will keep computing going when it’s gone. Certainly artificial intelligence will play a role. So might quantum computing. But there are stranger things in the computing universe, and some of them got an airing at the IEEE International Conference on Rebooting Computing in November.

There were also some cool variations on classics such as reversible computing and neuromorphic chips. But some less-familiar ones got their time in the sun too, such as photonics chips that accelerate AI, nano-mechanical comb-shaped logic, and a “hyperdimensional” speech recognition system. What follows includes a taste of both the strange and the potentially impactful.

Cold Quantum Neurons

Engineers are often envious of the brain’s marvelous energy efficiency. A single neuron only expends about 10 femtojoules (10-15 joules) with each spiking event. Michael L. Schneider and colleagues at the U.S. National Institute of Standards and Technology think they can get close to that figure using artificial neurons made up of two different types of Josephson junctions. These are superconducting devices that depend on the tunneling of pairs of electrons across a barrier, and they’re the basis of the most advanced quantum computers coming out of industrial labs today. A variant of these, the magnetic Josephson junction, has properties that can be tuned on the fly by varying currents and magnetic fields. Both can be operated in such a way that they produce spikes of voltage using only zeptojoules of energy—on the order of a 100,000th of a femtojoule.

The NIST scientists saw a way to link these devices together to form a neural network. In a simulation, they trained the network to recognize three letters (z, v, and n—a basic neural network test). Ideally, the network could recognize each letter using a mere 2 attojoules, or 2 femtojoules if you include the energy cost of refrigerating such a system to the needed 4 degrees Kelvin. There are a few spots where things are quite a bit less than ideal, of course. But assuming those can be engineered away, you could have a neural network with power consumption needs comparable to those of human neurons.

Computing with Wires

With transistors packed so tightly in advanced processors, the interconnects that link them up to form circuits are closer together than ever before. That causes crosstalk, where the signal on one line impinges on a neighbor via a parasitic capacitive connection. Rather than trying to engineer the crosstalk away, Naveen Kumar Macha and colleagues at the University of Missouri Kansas City decided to embrace it. In today’s logic the interfering “signal propagates as a glitch,” Macha told the engineers. “Now we want to use it for logic.”

They found that certain arrangements of interconnects could go a long way toward mimicking the actions of fundamental logic gates and circuits. Imagine three interconnect lines running parallel. Applying a voltage to either or both of the lines on the side, causes a crosstalk voltage to appear at the center line. Thus you have the makings of an OR gate with two inputs. By judiciously adding in a transistor here and there, the Kansas City crew constructed AND, OR, and XOR gates as well as a circuit that performs the carry function. The real advantage comes when you compare the transistor count and area to CMOS logic. For example, crosstalk logic needs just three transistors to carry out XOR while CMOS uses 14 and takes up one-third more space.

Attack of the Nano-Blob!

Scientists and engineers at Durham University in England have taught a dollop of chemicals to solve classification problems, such as spotting a cancerous lesion in a mammogram. Using evolutionary algorithms and a custom circuit board, they sent voltage pulses through an array of electrodes into a dilute mix of carbon nanotubes dispersed in a liquid crystal. Over time, the carbon nanotubes—a mix of conducting and semiconducting varieties—arranged themselves into a complex network that spanned the electrodes.

This network was capable of carrying out the key part of an optimization problem. What’s more, the blob could then learn to solve a second problem, so long as that problem was less complex than the first.

Did it solve these problems well? In one case, the results were comparable to a human’s; in the other, they were a bit worse. Still, it’s amazing that it works at all. “What you have to remember is that we’re training a blob of carbon nanotubes in liquid crystals,” said Elèonore Vissol-Gaudin, who helped develop the system at Durham.

Silicon Circuit Boards

Computer designers have long bemoaned the mismatch between how quickly and efficiently data moves within a processor and how much more slowly and wastefully it moves between them. The problem, according to engineers at the University of California Los Angeles, lies in the nature of chip packages and the printed circuit boards they connect with. Both chip packages and circuit boards are poor conductors of heat so they limit how much power you can expend, they increase the energy needed to move a bit from one chip to another, and they slow computers down by adding latency. To be sure, industry has recognized a lot of these disadvantages and increasingly focuses on putting multiple chips together in the same package.

Puneet Gupta and his UCLA collaborators think computers would be much better if we got rid of both packages and circuit boards. They propose replacing the printed circuit board with a portion of silicon wafer. On such a “silicon integrated fabric,” unpackaged bare silicon chips could snuggle up within 100 micrometers of each other connected by the same type of fine, dense interconnects found on ICs—limiting latency and energy consumption and making for more compact systems.

If industry really did go in this direction, it would likely lead to a change in what kinds of ICs are made, Gupta contends. Silicon integrated fabric would favor breaking up systems-on-a-chip into small “chiplets” that do the functions of the various cores of the SoC. That’s because the SoC’s close integration would no longer give much of an advantage in terms of latency and efficiency, and it’s cheaper to make smaller chips. What’s more, because silicon is better than printed circuit boards at conducting heat, you could run those processor cores at higher clock speeds without having to worry about the heat.

4 Strange New Ways to Compute syndicated from http://ift.tt/2Bq2FuP

0 notes

Text

4 Strange New Ways to Compute

At the IEEE Rebooting Computing Conference, deep thinking about computing led to some wild ideas

Image: Eléonore Vissol-Gaudin

This optical micrograph shows a micro-electrode array below a mixture of single-walled-carbon-nanotubes with liquid crystals.

With Moore’s Law slowing, engineers have been taking a cold hard look at what will keep computing going when it’s gone. Certainly artificial intelligence will play a role. So might quantum computing. But there are stranger things in the computing universe, and some of them got an airing at the IEEE International Conference on Rebooting Computing in November.

There were also some cool variations on classics such as reversible computing and neuromorphic chips. But some less-familiar ones got their time in the sun too, such as photonics chips that accelerate AI, nano-mechanical comb-shaped logic, and a “hyperdimensional” speech recognition system. What follows includes a taste of both the strange and the potentially impactful.

Cold Quantum Neurons

Engineers are often envious of the brain’s marvelous energy efficiency. A single neuron only expends about 10 femtojoules (10-15 joules) with each spiking event. Michael L. Schneider and colleagues at the U.S. National Institute of Standards and Technology think they can get close to that figure using artificial neurons made up of two different types of Josephson junctions. These are superconducting devices that depend on the tunneling of pairs of electrons across a barrier, and they’re the basis of the most advanced quantum computers coming out of industrial labs today. A variant of these, the magnetic Josephson junction, has properties that can be tuned on the fly by varying currents and magnetic fields. Both can be operated in such a way that they produce spikes of voltage using only zeptojoules of energy—on the order of a 100,000th of a femtojoule.

The NIST scientists saw a way to link these devices together to form a neural network. In a simulation, they trained the network to recognize three letters (z, v, and n—a basic neural network test). Ideally, the network could recognize each letter using a mere 2 attojoules, or 2 femtojoules if you include the energy cost of refrigerating such a system to the needed 4 degrees Kelvin. There are a few spots where things are quite a bit less than ideal, of course. But assuming those can be engineered away, you could have a neural network with power consumption needs comparable to those of human neurons.

Computing with Wires

With transistors packed so tightly in advanced processors, the interconnects that link them up to form circuits are closer together than ever before. That causes crosstalk, where the signal on one line impinges on a neighbor via a parasitic capacitive connection. Rather than trying to engineer the crosstalk away, Naveen Kumar Macha and colleagues at the University of Missouri Kansas City decided to embrace it. In today’s logic the interfering “signal propagates as a glitch,” Macha told the engineers. “Now we want to use it for logic.”

They found that certain arrangements of interconnects could go a long way toward mimicking the actions of fundamental logic gates and circuits. Imagine three interconnect lines running parallel. Applying a voltage to either or both of the lines on the side, causes a crosstalk voltage to appear at the center line. Thus you have the makings of an OR gate with two inputs. By judiciously adding in a transistor here and there, the Kansas City crew constructed AND, OR, and XOR gates as well as a circuit that performs the carry function. The real advantage comes when you compare the transistor count and area to CMOS logic. For example, crosstalk logic needs just three transistors to carry out XOR while CMOS uses 14 and takes up one-third more space.

Attack of the Nano-Blob!

Scientists and engineers at Durham University in England have taught a dollop of chemicals to solve classification problems, such as spotting a cancerous lesion in a mammogram. Using evolutionary algorithms and a custom circuit board, they sent voltage pulses through an array of electrodes into a dilute mix of carbon nanotubes dispersed in a liquid crystal. Over time, the carbon nanotubes—a mix of conducting and semiconducting varieties—arranged themselves into a complex network that spanned the electrodes.

This network was capable of carrying out the key part of an optimization problem. What’s more, the blob could then learn to solve a second problem, so long as that problem was less complex than the first.

Did it solve these problems well? In one case, the results were comparable to a human’s; in the other, they were a bit worse. Still, it’s amazing that it works at all. “What you have to remember is that we’re training a blob of carbon nanotubes in liquid crystals,” said Elèonore Vissol-Gaudin, who helped develop the system at Durham.

Silicon Circuit Boards

Computer designers have long bemoaned the mismatch between how quickly and efficiently data moves within a processor and how much more slowly and wastefully it moves between them. The problem, according to engineers at the University of California Los Angeles, lies in the nature of chip packages and the printed circuit boards they connect with. Both chip packages and circuit boards are poor conductors of heat so they limit how much power you can expend, they increase the energy needed to move a bit from one chip to another, and they slow computers down by adding latency. To be sure, industry has recognized a lot of these disadvantages and increasingly focuses on putting multiple chips together in the same package.

Puneet Gupta and his UCLA collaborators think computers would be much better if we got rid of both packages and circuit boards. They propose replacing the printed circuit board with a portion of silicon wafer. On such a “silicon integrated fabric,” unpackaged bare silicon chips could snuggle up within 100 micrometers of each other connected by the same type of fine, dense interconnects found on ICs—limiting latency and energy consumption and making for more compact systems.

If industry really did go in this direction, it would likely lead to a change in what kinds of ICs are made, Gupta contends. Silicon integrated fabric would favor breaking up systems-on-a-chip into small “chiplets” that do the functions of the various cores of the SoC. That’s because the SoC’s close integration would no longer give much of an advantage in terms of latency and efficiency, and it’s cheaper to make smaller chips. What’s more, because silicon is better than printed circuit boards at conducting heat, you could run those processor cores at higher clock speeds without having to worry about the heat.

4 Strange New Ways to Compute syndicated from http://ift.tt/2Bq2FuP

0 notes