#aluminium price trend

Explore tagged Tumblr posts

Text

Aluminium Price Trend | CostMasters

Understand the fluctuations of Aluminium prices in India with CostMasters. Gain valuable insights for your business.

0 notes

Text

Scrap Aluminium Price | Gravita India

Scrap Aluminium Price | Gravita India Driving Sustainable Value Through Innovation and Recycling

Introduction

In a world where sustainability has become a priority, Gravita India emerges as a global leader in the recycling industry, particularly in aluminium recycling. By transforming scrap aluminium into high-quality products, Gravita India not only contributes to environmental conservation but also drives economic value for industries worldwide. Amid fluctuating commodity markets, the price of scrap aluminium plays a pivotal role in influencing manufacturing, recycling operations, and overall sustainability strategies.

The Growing Importance of Scrap Aluminium

Aluminium, often dubbed the “metal of the future,” is one of the most sustainable and versatile materials available. Its lightweight, corrosion-resistant properties make it the backbone of industries such as automotive, aerospace, electronics, and construction. Importantly, aluminium is infinitely recyclable without compromising quality, consuming only 5% of the energy required to produce virgin aluminium.

The increasing demand for aluminium products, coupled with growing awareness of circular economy principles, has led to an unprecedented need for reliable recycling operations. Scrap aluminium prices, therefore, reflect global supply-demand dynamics, energy costs, and sustainability practices, making them a crucial benchmark for industries dependent on recycled aluminium.

Gravita India: Pioneering Scrap Aluminium Recycling

Gravita India has been at the forefront of the aluminium recycling revolution, offering premium aluminium alloy ingots tailored to meet global industry standards. With an extensive presence across India, Africa, and Europe, Gravita combines cutting-edge technology, sustainable processes, and global expertise to transform scrap aluminium into valuable resources.

The company specializes in manufacturing top-tier aluminium alloys like:

ADC12

LM2, LM6, LM24

Custom grades suited to various casting and engineering methods

Gravita’s focus on eco-friendly production methods enables efficient processing of aluminium scrap while minimizing environmental impact. Their state-of-the-art recycling plants are fully compliant with ISO 9001 and ISO 14000 standards, ensuring quality, sustainability, and safety at every stage.

Scrap Aluminium Price: Key Market Drivers

The price of scrap aluminium is influenced by several macroeconomic and industrial factors:

Global Demand and Supply: Industries such as automotive, packaging, and electronics drive high demand for recycled aluminium. A surge in demand often leads to a rise in scrap prices.

Energy Costs: Since aluminium recycling consumes significantly less energy than virgin production, energy price volatility directly affects scrap aluminium pricing.

Raw Material Availability: Collection, sorting, and transportation of scrap aluminium play a major role in its pricing. Gravita India’s robust raw material procurement network ensures consistent supply and mitigates price fluctuations.

Regulations and Sustainability Policies: Government mandates on Extended Producer Responsibility (EPR) and sustainable practices further emphasize the role of scrap aluminium as a preferred raw material.

Economic Conditions: Fluctuations in global economies, trade policies, and geopolitical events have a cascading effect on commodity markets, including aluminium scrap pricing.

Gravita India, with its expertise, effectively navigates these factors to offer cost-efficient and sustainable aluminium solutions to its global clientele.

Why Scrap Aluminium Recycling Matters

Economic Value: Recycling aluminium significantly reduces production costs while maintaining its structural properties, providing cost benefits to industries.

Environmental Benefits: Recycling reduces carbon emissions, conserves natural resources, and minimizes landfill waste.

Energy Efficiency: Aluminium recycling requires 95% less energy compared to mining and refining virgin aluminium.

Circular Economy: By fostering a circular economy, organisations like Gravita India ensure that resources remain in use for extended periods, promoting long-term sustainability.

Gravita India: Setting Benchmarks in Aluminium Sustainability

Gravita India has positioned itself as a trusted partner for businesses seeking quality and reliability in scrap aluminium recycling. Key features that set Gravita apart include:

Global Presence: Operations in 50+ countries, ensuring supply chain efficiency.

Customised Solutions: Tailored alloy compositions to meet client specifications.

Eco-Friendly Practices: Adherence to global environmental standards and minimal waste generation.

Technological Excellence: Advanced recycling facilities equipped with the latest technology for optimal efficiency.

By leveraging decades of experience and innovation, Gravita India drives sustainability while addressing the growing demand for cost-effective and eco-conscious aluminium solutions.

Conclusion

Scrap aluminium prices will continue to remain a vital component in the global recycling landscape as industries shift towards greener alternatives. Gravita India’s pioneering efforts in aluminium recycling set new benchmarks for sustainability, innovation, and economic value. Through efficient scrap procurement, advanced technology, and a commitment to circular economy principles, Gravita India not only delivers high-quality aluminium alloys but also supports a cleaner, more sustainable future.

As industries worldwide look for partners who prioritize sustainability and performance, Gravita India stands tall as the leader in scrap aluminium recycling, offering unparalleled expertise and reliability.

For more information on Gravita India’s recycling solutions and current scrap aluminium trends, visit www.gravitaindia.com.

#Scrap Aluminium Price#Aluminium Recycling#Aluminium Alloy Ingots#Sustainable Aluminium Solutions#Gravita India Aluminium#Aluminium Scrap Rates#Eco-Friendly Aluminium Recycling#Aluminium Price Trends#Aluminium Recycling Company#Scrap Metal Prices India#Aluminium Market Analysis#Aluminium Alloy Manufacturing#Circular Economy Solutions#Aluminium Waste Management#Recycling Industry India#Aluminium Ingot Prices#Sustainable Manufacturing#Gravita India Solutions#Global Aluminium Recycling Leader#Aluminium Recycling Technology.

0 notes

Text

The Growing Demand for Aluminium Tents in India: Key Applications & Trends

The demand for aluminium tents in India has been steadily rising, driven by their durability, versatility, and cost-effectiveness. These tents have become a preferred choice for a variety of applications, ranging from large-scale events and exhibitions to emergency shelters and temporary workspaces. Their ability to withstand harsh weather conditions and their ease of installation make them an attractive option for businesses and event organizers alike.

Why Aluminium Tents Are Gaining Popularity

Aluminium tents offer several advantages over traditional tents and temporary structures. Unlike conventional fabric tents, which may wear out over time, aluminium tents are built with high-quality metal frames that ensure longevity and stability. Additionally, their modular design allows for easy customization, making them suitable for a wide range of uses.

Leading aluminium tent manufacturers in India are continuously innovating to provide structures that meet industry-specific needs. From corporate events to emergency relief operations, aluminium tents are proving to be an indispensable solution for various sectors.

Key Applications of Aluminium Tents in India

1. Events and Exhibitions

The Indian event industry has embraced aluminium tents as a practical and stylish solution for hosting large gatherings. These tents provide an elegant and spacious venue for weddings, trade fairs, product launches, and concerts. Their robust construction ensures safety and comfort for attendees, while their aesthetic appeal enhances the overall ambiance of an event.

2. Temporary Shelters and Relief Camps

In times of natural disasters or humanitarian crises, quick and effective shelter solutions are crucial. Aluminium tents serve as reliable emergency shelters, offering displaced individuals a safe and comfortable space. Government agencies and NGOs utilize these structures to provide immediate relief in affected areas.

3. Outdoor Workspaces and Warehouses

Industries requiring temporary workspaces, such as construction, mining, and logistics, benefit significantly from aluminium hanger tents. These structures protect from the elements while allowing businesses to operate efficiently in remote or open-air environments.

4. Hospitality and Tourism

Luxury resorts and eco-tourism projects are increasingly incorporating aluminium tents into their accommodations. These tents blend seamlessly with nature while offering modern amenities, making them a popular choice for glamping (glamorous camping) experiences.

5. Sports and Recreational Facilities

Aluminium tents are also widely used for sports events, training facilities, and temporary gymnasiums. Their weather-resistant properties make them suitable for both indoor and outdoor sports activities.

Latest Trends in Aluminium Tent Usage

1. Customization and Modular Designs

Modern aluminium tents come with flexible designs that allow businesses to customize them according to specific needs. From adjustable flooring to climate-controlled interiors, these structures can be tailored for various applications.

2. Eco-Friendly Materials and Sustainability

With increasing awareness of sustainability, manufacturers are focusing on using recyclable materials and energy-efficient designs. Aluminium tents align with green building initiatives, making them an environmentally responsible choice.

3. Smart Tents with Advanced Features

Technological advancements have led to the development of smart aluminium tents equipped with solar panels, automated ventilation systems, and integrated lighting solutions. These innovations enhance functionality and reduce operational costs.

4. Cost-Effective Solutions for Businesses

The aluminium tent hanger price in India varies based on size, design, and additional features. However, compared to permanent structures, these tents offer a more affordable and flexible solution for businesses seeking temporary setups.

Choosing the Right Aluminium Tent Manufacturer

When selecting an aluminium tent supplier, consider the following factors:

Material Quality: Ensure that the tents are made from high-grade aluminium for durability.

Customization Options: Look for manufacturers offering tailored solutions to your needs.

Installation and Support: Opt for a professional installation and after-sales service supplier.

Competitive Pricing: Compare the aluminium tent hanger price in India to find a budget-friendly option without compromising on quality.

Customer Reviews: Check testimonials and feedback from previous buyers to gauge the manufacturer’s reliability.

Future Outlook

The future of aluminium tents in India looks promising, with increasing demand across various industries. As innovation continues, these tents will play a crucial role in redefining temporary structures, offering sustainable, cost-effective, and versatile solutions.

Businesses looking for reliable and durable structures should consider investing in aluminium tents. Whether for events, industrial use, or emergency shelters, these tents provide unmatched convenience and adaptability, making them an excellent choice for modern applications.

#aluminium tent hanger price in india#aluminium hanger tent in india#aluminium tent hanger price#aluminium tents in india

0 notes

Text

The Growing Demand for Aluminium Tents in India: Key Applications & Trends

The demand for aluminium tents in India has been steadily rising, driven by their durability, versatility, and cost-effectiveness. These tents have become a preferred choice for a variety of applications, ranging from large-scale events and exhibitions to emergency shelters and temporary workspaces. Their ability to withstand harsh weather conditions and their ease of installation make them an attractive option for businesses and event organizers alike.

Why Aluminium Tents Are Gaining Popularity

Aluminium tents offer several advantages over traditional tents and temporary structures. Unlike conventional fabric tents, which may wear out over time, aluminium tents are built with high-quality metal frames that ensure longevity and stability. Additionally, their modular design allows for easy customization, making them suitable for a wide range of uses.

Leading aluminium tent manufacturers in India are continuously innovating to provide structures that meet industry-specific needs. From corporate events to emergency relief operations, aluminium tents are proving to be an indispensable solution for various sectors.

Key Applications of Aluminium Tents in India

1. Events and Exhibitions

The Indian event industry has embraced aluminium tents as a practical and stylish solution for hosting large gatherings. These tents provide an elegant and spacious venue for weddings, trade fairs, product launches, and concerts. Their robust construction ensures safety and comfort for attendees, while their aesthetic appeal enhances the overall ambiance of an event.

2. Temporary Shelters and Relief Camps

In times of natural disasters or humanitarian crises, quick and effective shelter solutions are crucial. Aluminium tents serve as reliable emergency shelters, offering displaced individuals a safe and comfortable space. Government agencies and NGOs utilize these structures to provide immediate relief in affected areas.

3. Outdoor Workspaces and Warehouses

Industries requiring temporary workspaces, such as construction, mining, and logistics, benefit significantly from aluminium hanger tents. These structures protect from the elements while allowing businesses to operate efficiently in remote or open-air environments.

4. Hospitality and Tourism

Luxury resorts and eco-tourism projects are increasingly incorporating aluminium tents into their accommodations. These tents blend seamlessly with nature while offering modern amenities, making them a popular choice for glamping (glamorous camping) experiences.

5. Sports and Recreational Facilities

Aluminium tents are also widely used for sports events, training facilities, and temporary gymnasiums. Their weather-resistant properties make them suitable for both indoor and outdoor sports activities.

Latest Trends in Aluminium Tent Usage

1. Customization and Modular Designs

Modern aluminium tents come with flexible designs that allow businesses to customize them according to specific needs. From adjustable flooring to climate-controlled interiors, these structures can be tailored for various applications.

2. Eco-Friendly Materials and Sustainability

With increasing awareness of sustainability, manufacturers are focusing on using recyclable materials and energy-efficient designs. Aluminium tents align with green building initiatives, making them an environmentally responsible choice.

3. Smart Tents with Advanced Features

Technological advancements have led to the development of smart aluminium tents equipped with solar panels, automated ventilation systems, and integrated lighting solutions. These innovations enhance functionality and reduce operational costs.

4. Cost-Effective Solutions for Businesses

The aluminium tent hanger price in India varies based on size, design, and additional features. However, compared to permanent structures, these tents offer a more affordable and flexible solution for businesses seeking temporary setups.

Choosing the Right Aluminium Tent Manufacturer

When selecting an aluminium tent supplier, consider the following factors:

Material Quality: Ensure that the tents are made from high-grade aluminium for durability.

Customization Options: Look for manufacturers offering tailored solutions to your needs.

Installation and Support: Opt for a professional installation and after-sales service supplier.

Competitive Pricing: Compare the aluminium tent hanger price in India to find a budget-friendly option without compromising on quality.

Customer Reviews: Check testimonials and feedback from previous buyers to gauge the manufacturer’s reliability.

Future Outlook

The future of aluminium tents in India looks promising, with increasing demand across various industries. As innovation continues, these tents will play a crucial role in redefining temporary structures, offering sustainable, cost-effective, and versatile solutions.

Businesses looking for reliable and durable structures should consider investing in aluminium tents. Whether for events, industrial use, or emergency shelters, these tents provide unmatched convenience and adaptability, making them an excellent choice for modern applications.

#services offered by a construction company#aluminium hangers tents infrastructure#steel building construction company#modern a type canopy tents#aluminium hanger tent in india#aluminium hangers tents manufacturers#pre engineered building manufacturers in india#pre engineered building manufacturers#pre engineering building company in india#aluminium tent hanger price

0 notes

Text

Aluminium Foil Market Trends Future Prospects and Industry Growth Forecast

The packaging sector is the largest consumer of aluminium foil, with increasing applications in food, beverage, and pharmaceutical packaging. The rise of ready-to-eat meals, frozen foods, and flexible packaging solutions has propelled demand for aluminium foil due to its protective properties, lightweight structure, and ability to extend product shelf life.

Sustainability and Recycling Initiatives

As environmental concerns grow, the aluminium foil industry is focusing on sustainability. Companies are investing in recycling programs, reducing carbon footprints, and developing thinner foils that maintain durability while minimizing material use. The increasing adoption of closed-loop recycling systems is expected to improve the circular economy and reduce waste generation.

Technological Advancements in Manufacturing

Innovations in manufacturing processes, such as advanced rolling techniques and improved surface coatings, are enhancing the efficiency and quality of aluminium foil. New embossing technologies and high-barrier films are further improving its performance in food preservation and pharmaceutical applications, making aluminium foil more versatile and cost-effective.

Impact of Rising Raw Material Prices

The aluminium foil market is affected by fluctuations in raw material prices, driven by global mining regulations, energy costs, and supply chain disruptions. Increased demand for aluminium in various industries, coupled with geopolitical factors, has led to pricing volatility. Manufacturers are adopting cost-reduction strategies to mitigate the impact.

Regional Growth and Market Expansion

Asia-Pacific dominates the aluminium foil market, with China and India leading in both production and consumption. Europe and North America focus on sustainable solutions and premium-grade foil products. Emerging markets in Latin America and Africa present new opportunities as urbanization and industrialization drive demand for aluminium-based packaging.

Competitive Strategies and Key Players

Major players such as Hindalco Industries, Novelis, Amcor, and Reynolds Group Holdings are implementing competitive strategies to strengthen their market positions. Mergers and acquisitions, capacity expansions, and research into high-performance foil variants are shaping competition. Companies are also investing in sustainable solutions to meet consumer preferences and regulatory requirements.

Innovations in Flexible and Rigid Packaging

The trend toward flexible packaging solutions has increased the demand for aluminium foil, particularly in food and beverage packaging. Innovations such as easy-peel lids, laminated foils, and biodegradable coatings are gaining traction. In rigid packaging, aluminium foil containers are being designed for improved insulation and convenience in food delivery and storage.

Regulatory Policies and Environmental Impact

Governments worldwide are enforcing stringent regulations on packaging materials, pushing aluminium foil manufacturers to adopt eco-friendly production processes. Initiatives to reduce single-use plastics have positioned aluminium foil as a sustainable alternative. However, compliance with environmental policies and energy efficiency standards remains a key challenge for industry players.

Supply Chain Challenges and Solutions

Supply chain disruptions, including transportation bottlenecks and trade restrictions, have impacted the availability of raw aluminium. The industry is addressing these challenges through localized sourcing, alternative suppliers, and strategic stockpiling. Digitalization and automation in logistics are also being leveraged to streamline distribution and reduce lead times.

Future Prospects and Industry Growth Forecast

The aluminium foil market is set for continued growth, driven by innovations in lightweight, durable, and recyclable materials. Increasing demand for sustainable packaging, advancements in manufacturing, and expansion into emerging markets will fuel industry expansion. Companies that adapt to evolving trends and invest in research and development will gain a competitive edge.

Conclusion

The aluminium foil market is evolving, with demand rising across various sectors. While challenges such as raw material price fluctuations and regulatory pressures persist, innovations in sustainability, packaging design, and manufacturing technologies are shaping the industry's future. Companies that focus on eco-friendly solutions and efficient production processes will be well-positioned for long-term success.

#Aluminium Foil Market#Aluminium Foil Market trends#Aluminium Foil#Aluminium Foil uses#Aluminium#Aluminium Foil service

0 notes

Text

Tube Packaging Market to Develop New Growth and Opportunities Analysis Story

Tube Packaging Market Overview 2023-2033

Tube Packaging Market Growth was valued at USD 9,500 million in 2022 and is projected to grow at a CAGR of 6.6%, reaching an estimated USD 16,890 million by the end of the forecast period.

A tube packaging is a cylindrical, hollow container, typically round or oval, made from materials such as plastic, cardboard, aluminium, or other metals. Also referred to as collapsible or squeeze tubes, these containers are commonly used for viscous products like toothpaste, paints, adhesives, sealants, and ointments.

The market for tubes packaging is expected to grow due to increasing demand from industries such as cosmetics and personal care, healthcare, and food. A key factor driving the expansion of the personal care industry is the growing consumer focus on health and wellness. As self-consciousness rises, the consumption of personal care products is also increasing, fuelling the demand for tube packaging solutions. The U.S. remains a major market in the global beauty and personal care industry, driven by strong consumer purchasing power.

Key Benefits for Stakeholders

Comprehensive Market Insights – This report offers a detailed quantitative analysis of market segments, trends, forecasts, and dynamics within the packaging tube market from 2023 to 2033, helping stakeholders identify key growth opportunities.

Strategic Decision-Making Support – Insights into market drivers, restraints, and opportunities provide stakeholders with a solid foundation for informed decision-making.

Regional and Global Market Assessment – Major countries are mapped based on their revenue contribution, offering a clearer understanding of regional and global market dynamics.

Market Positioning & Benchmarking – Analysis of key market players helps stakeholders gauge their competitive standing and develop strategic initiatives.

Growth & Expansion Strategies – The report examines regional and global market trends, key players, application areas, and proven strategies to support business growth.

Request PDF Sample Report @ https://wemarketresearch.com/reports/request-free-sample-pdf/tube-packaging-market/124

Market Trends and Growth Drivers

Rising Demand for Sustainable Packaging

As environmental awareness grows, both consumers and businesses are prioritizing sustainable packaging solutions. This has fueled demand for recyclable and biodegradable materials like paper-based and bioplastic tubes, helping manufacturers reduce their ecological footprint.

Surging Adoption in Cosmetics and Personal Care

The beauty and personal care industry remains a major driver of tube packaging demand. With increasing consumer interest in skincare and makeup, brands favor tubes for their convenience, portability, and ability to preserve product quality.

Expanding Use in Pharmaceuticals

The pharmaceutical sector is increasingly turning to tube packaging for ointments, gels, and creams. Its hygienic, user-friendly design and precise dispensing capabilities make it an ideal choice for medical applications.

Advancements in Packaging Technology

Innovations such as airless tubes, tamper-evident seals, and smart packaging solutions are elevating tube functionality. These advancements enhance product safety, extend shelf life, and improve the user experience.

Growth of E-Commerce and Direct-to-Consumer Sales

The rise of online shopping has accelerated demand for sturdy, lightweight packaging. Tube packaging offers superior product protection and easy shipping, making it a preferred option for e-commerce and direct-to-consumer brands.

Market Challenges:

One of the primary challenges for tube packaging manufacturers is the fluctuating cost of raw materials. Essential materials like laminate, plastic, and aluminium are highly sensitive to market dynamics. For instance, plastic resin prices are directly influenced by crude oil fluctuations, while aluminium costs can be impacted by supply chain disruptions, trade tariffs, and geopolitical factors. Rising raw material prices drive up production costs, which can either squeeze profit margins or lead to higher consumer prices, potentially reducing demand.

Innovations in Tube Packaging

Sustainable Packaging Advancements

The adoption of bio-based and recyclable materials is set to transform the tube packaging industry. Companies are exploring solutions like sugarcane-derived plastics and mono-material tubes to minimize environmental impact and enhance sustainability.

Smart Packaging Technologies

The integration of advanced technologies, including QR codes, augmented reality, and anti-counterfeiting measures, is enhancing both the functionality and consumer engagement of tube packaging.

Customization and Personalization

Brands are leveraging digital and 3D printing technologies to offer highly customized and visually appealing packaging designs. This focus on personalization enhances brand identity and consumer experience.

Growth in Emerging Markets

Rising disposable income and urbanization in developing regions such as Asia-Pacific and Latin America are fueling demand for tube packaging in personal care and pharmaceutical sectors, creating new growth opportunities for manufacturers.

Market Segments:

By Packaging:

Squeeze

Twist, Stick

Cartridges

Others

By Material:

Laminated

Plastic

Paper

Aluminium

Others

By Application:

Oral Care

Cosmetics

Food & Beverage

Pharmaceuticals

Cleaning Products

Others

Market Regional Analysis:

The key regions shaping the geographical landscape of this market include North America, the Middle East & Africa, Latin America, Europe, and Asia Pacific. Among these, Asia Pacific is expected to experience significant growth from 2022 to 2030, driven by the thriving cosmetics industry, rapid industrialization, and rising consumer purchasing power.

Top Leading Key Companies Profiled in this research report are:

Albea Group

Essel Propack Limited

Hoffman Neopack AG

Huhtamaki Oyj

Berry Global Inc.C

lariant International Ltd.

Holdings SA

CCL Industries Inc.

IntraPac International Corporation

VisiPak Inc.

HCT Packaging Inc.

Printpack Inc.

Unicep Packaging, Inc.

Silgan Holdings Inc.

Fischbach KG.

Commonly Asked Questions?

Q1. What is the global tube packing market report's total market value?

Q2. How long is the global tube packaging market report expected to last?

Q3. How can I obtain a report sample of the worldwide market for tube packaging?

Q4. In the worldwide tube packaging market report, which year is used as the base year?

Q5. Which leading businesses dominate the worldwide market for tube packaging?

Q6. How can I obtain statistical information about the leading companies in the global tube packaging market?

Q7. In the tube packaging market, which market has the largest market share?

Conclusion

The tube packaging market is poised for significant growth in the coming years, driven by sustainability initiatives, increasing consumer demand, and technological advancements. While challenges such as regulatory compliance and raw material fluctuations persist, ongoing innovations and expansion in emerging markets will continue to shape the industry's future. As businesses and consumers increasingly prioritize eco-friendly solutions, tube packaging is set to play a crucial role in the global packaging landscape.

Get a Purchase of This Report @ https://wemarketresearch.com/purchase/tube-packaging-market/124?license=single

#Tube Packaging Market Size#Tube Packaging Market Share#Tube Packaging Market Demand#Tube Packaging Market Scope#Tube Packaging Market Growth#Tube Packaging Market Trends#Tube Packaging Market 2033

0 notes

Text

Aluminium Wire Prices, News, Trend, Graph, Chart, Monitor and Forecast

The aluminium wire market has experienced significant fluctuations in recent years, driven by a complex interplay of factors that influence supply, demand, and pricing dynamics. Aluminium wire, widely used across industries such as electrical transmission, construction, automotive, and telecommunications, remains a crucial commodity in the global economy. The pricing trends of aluminium wire are inherently linked to the performance of the broader aluminium market, which is influenced by global economic conditions, raw material availability, energy costs, and geopolitical factors. As a lightweight, corrosion-resistant, and highly conductive material, aluminium wire continues to see robust demand, particularly with the growing adoption of renewable energy infrastructure and electric vehicles.

The primary driver of aluminium wire prices is the cost of raw aluminium, which is derived from bauxite ore through energy-intensive processes like Bayer refining and Hall-Héroult smelting. The availability and price of bauxite, along with energy costs, significantly impact production expenses. Additionally, market prices are influenced by factors such as import-export policies, trade restrictions, and tariffs. In recent years, disruptions in bauxite supply chains, particularly from major producers like Australia, Guinea, and China, have led to price volatility. Political instability in resource-rich regions and policy changes in key markets have further added to the unpredictability in aluminium wire pricing.

Get Real time Prices for Aluminum Wire: https://www.chemanalyst.com/Pricing-data/stainless-steel-1502

Global economic growth plays a crucial role in determining aluminium wire prices. During periods of strong economic expansion, infrastructure projects and industrial activities increase, driving up the demand for aluminium wire. Conversely, economic slowdowns, like the one witnessed during the COVID-19 pandemic, lead to reduced demand and downward pressure on prices. The pandemic-induced disruptions to global supply chains caused significant fluctuations in aluminium prices, with initial declines followed by sharp recoveries as industries resumed operations and governments implemented stimulus packages to boost infrastructure development.

Energy costs are another critical factor in aluminium wire pricing. The aluminium production process requires substantial electricity, and any fluctuations in energy prices, particularly for fossil fuels and electricity, directly impact production costs. In regions where energy prices are high, aluminium wire producers face higher production costs, which are often passed on to consumers through increased prices. The global push toward cleaner energy sources and the associated costs of transitioning to renewable energy have also affected the aluminium market. As more aluminium producers adopt sustainable practices and invest in energy-efficient technologies, production costs may stabilize, potentially influencing aluminium wire prices.

The automotive industry, particularly the rapid growth of electric vehicles (EVs), has significantly influenced aluminium wire demand and pricing. Aluminium wire is essential for lightweight wiring systems in EVs, contributing to improved energy efficiency and vehicle performance. With major automakers committing to electrification and governments worldwide promoting EV adoption through incentives and regulatory measures, the demand for aluminium wire has surged. This growing demand has contributed to upward pressure on prices, especially as manufacturers compete for high-quality aluminium products.

In the construction sector, aluminium wire is extensively used in electrical wiring, structural components, and infrastructure projects. Urbanization, population growth, and infrastructure development, particularly in emerging economies like India, China, and Southeast Asia, have driven consistent demand for aluminium wire. Large-scale infrastructure projects, such as smart city initiatives, renewable energy installations, and high-speed rail networks, have further boosted market growth. However, fluctuations in construction activity, driven by factors like interest rate changes and economic policies, have led to periodic price variations in the aluminium wire market.

Geopolitical factors, including trade tensions, sanctions, and international agreements, have also played a significant role in aluminium wire pricing. The imposition of tariffs and sanctions on major aluminium producers, such as Russia and China, has led to supply chain disruptions and increased prices in certain regions. Trade policies implemented by the United States, the European Union, and other major economies have influenced the flow of aluminium products across borders, impacting regional price disparities. Additionally, currency fluctuations and changes in global trade dynamics contribute to the complexity of pricing in the aluminium wire market.

Technological advancements and innovations in aluminium wire manufacturing have introduced new market dynamics. The development of high-performance alloys, improved production techniques, and the integration of digital technologies into manufacturing processes have enhanced product quality and efficiency. As manufacturers invest in research and development to create aluminium wires with superior conductivity, strength, and durability, production costs and pricing strategies may evolve accordingly. Furthermore, the increasing focus on recycling and the circular economy has led to the growth of secondary aluminium production. Recycled aluminium requires significantly less energy compared to primary production, potentially mitigating price increases and contributing to more sustainable pricing trends.

Regional variations in aluminium wire prices reflect differences in supply chain structures, production capacities, and demand patterns. Asia-Pacific, led by China and India, remains a dominant player in the aluminium wire market due to its vast manufacturing base and ongoing infrastructure development. North America and Europe, while also significant markets, experience price variations influenced by energy costs, environmental regulations, and import policies. In Latin America and Africa, the availability of raw materials like bauxite and growing industrialization efforts contribute to regional price dynamics.

The outlook for aluminium wire prices remains subject to the interplay of these multifaceted factors. As the world transitions toward cleaner energy sources, the demand for aluminium wire in solar, wind, and electric grid applications is expected to rise. However, potential supply chain disruptions, energy price fluctuations, and geopolitical developments could lead to continued price volatility. Market participants, including manufacturers, traders, and consumers, must stay attuned to these dynamics to make informed decisions and navigate the complexities of the aluminium wire market effectively.

Get Real time Prices for Aluminum Wire: https://www.chemanalyst.com/Pricing-data/stainless-steel-1502

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminium Wire#Aluminium Wire Price#Aluminium Wire Prices#Aluminium Wire Pricing#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Aluminium alloy wheel Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Aluminium alloy wheel Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Aluminium alloy wheel Market scenario, and feasibility study are the important aspects analyzed in this report.

The Aluminium alloy wheel Market is experiencing robust growth driven by the expanding globally. The Aluminium alloy wheel Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Aluminium alloy wheel Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. The global Aluminum Alloy Wheels Market size was USD 14.23 billion in 2020. The market is projected to grow from USD 16.43 billion in 2021 to USD 30.98 billion in 2028 at a CAGR of 9.5% during the 2021-2028 period.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/105603

Key Strategies

Key strategies in the Aluminium alloy wheel Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Aluminium alloy wheel Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Aluminium alloy wheel Market.

Major Aluminium alloy wheel Market Manufacturers covered in the market report include:

LIST OF KEY COMPANIES PROFILED:

Status Wheels Inc. (Florida, U.S.)

Wheel Pros LLC. (Colorado, U.S.)

Fuel Off-Road Wheels (California, U.S.)

Citic Dicastal Co Ltd. (Hebei, China)

Enkei Wheels India Ltd (Pune, India)

Ronal AG (Härkingen, Switzerland)

BBS Kraftfahrzeugtechnik AG (Schiltach, Germany)

Alcoa wheels (Pennsylvania, U.S.)

MHT Luxury Wheels (California, U.S.)

Superior Industries (Minnesota, U.S.)

Alloy wheels have a widespread application due to their high resilience and lightweight. Furthermore, aluminum alloy wheels amplify the aesthetic appearance of the vehicle. Automakers are being forced to manufacture lighter, environment-friendly, and safer cars as the amount of carbon dioxide emitted is proportional to the amount of fuel consumption and the size of the vehicle; hence, reducing weight becomes a critical necessity.

Trends Analysis

The Aluminium alloy wheel Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Aluminium alloy wheel Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Aluminium alloy wheel Market Solutions.

Regions Included in this Aluminium alloy wheel Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Aluminium alloy wheel Market.

- Changing the Aluminium alloy wheel Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Aluminium alloy wheel Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Aluminium alloy wheel Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Aluminium alloy wheel Market?

► Who are the prominent players in the Global Aluminium alloy wheel Market?

► What is the consumer perspective in the Global Aluminium alloy wheel Market?

► What are the key demand-side and supply-side trends in the Global Aluminium alloy wheel Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Aluminium alloy wheel Market?

Table Of Contents:

1 Market Overview

1.1 Aluminium alloy wheel Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

0 notes

Text

Aluminium Foil Pouches Market Trends: How Smart Packaging and Sustainability Are Driving Industry Evolution

Aluminium foil pouches have gained significant traction in the global packaging industry due to their superior properties such as durability, moisture resistance, and extended shelf life. These pouches are extensively used in various sectors, including food & beverages, pharmaceuticals, and cosmetics. With increasing demand for sustainable packaging, manufacturers are innovating new designs and materials that align with environmental standards. This article explores the latest trends shaping the aluminium foil pouches market, the key drivers fueling growth, and the future outlook of the industry.

Growing Demand for Sustainable Packaging One of the most influential trends in the aluminium foil pouches market is the rising preference for sustainable packaging solutions. Consumers and regulatory bodies are emphasizing eco-friendly alternatives, prompting manufacturers to develop recyclable and biodegradable aluminium foil pouches. Companies are now investing in research and development to create packaging solutions that reduce carbon footprints and align with circular economy principles. Technological Advancements in Aluminium Foil Packaging Advancements in technology are playing a pivotal role in the aluminium foil pouch industry. The introduction of advanced barrier coatings, smart packaging solutions, and lightweight designs has enhanced the performance of these pouches. Manufacturers are integrating QR codes, RFID tags, and temperature-sensitive indicators into aluminium foil pouches to improve traceability and ensure product authenticity. These innovations are particularly beneficial for the pharmaceutical and food industries, where safety and freshness are paramount. Expanding Applications Across Industries The versatility of aluminium foil pouches has expanded their applications beyond the food industry. The pharmaceutical sector relies heavily on aluminium foil packaging for medicines, owing to its ability to protect against moisture, light, and contaminants. Similarly, the personal care and cosmetics industry is adopting foil pouches for their ability to preserve product quality and extend shelf life. This diversification of applications is contributing to the steady growth of the market. Rising Demand in the E-commerce Sector The rapid expansion of the e-commerce industry has significantly boosted the demand for flexible and durable packaging. Aluminium foil pouches offer excellent protection during transit, ensuring that products reach consumers in optimal condition. With the rise of online grocery shopping and direct-to-consumer (DTC) brands, packaging solutions that offer convenience, extended shelf life, and aesthetic appeal are becoming increasingly popular. Regional Market Insights North America: The market in North America is driven by stringent food safety regulations and increasing demand for sustainable packaging solutions. Europe: The European market is witnessing growth due to rising environmental awareness and strict regulatory policies regarding single-use plastics. Asia-Pacific: Rapid industrialization, urbanization, and growing disposable incomes are fueling the demand for aluminium foil pouches in countries like China and India. Latin America and Middle East & Africa: Emerging economies are experiencing a surge in packaged food consumption, boosting the demand for innovative packaging solutions. Challenges and Opportunities Despite the growth prospects, the aluminium foil pouch industry faces challenges such as fluctuating raw material prices and stringent environmental regulations. However, these challenges also present opportunities for manufacturers to develop cost-effective and sustainable packaging solutions. Companies that focus on innovation, product differentiation, and sustainability will likely gain a competitive edge in the market. Future Outlook The aluminium foil pouches market is expected to witness steady growth in the coming years, driven by the increasing adoption of flexible packaging solutions across industries. The shift towards sustainable materials, coupled with advancements in smart packaging technology, will shape the future of the industry. As consumer preferences evolve and regulatory standards tighten, companies must adapt by investing in eco-friendly and innovative packaging solutions.

0 notes

Text

Aluminium Price Trend | CostMasters

Stay ahead of the curve with CostMasters' aluminium price trend analysis. Gain valuable insights to optimize your procurement, pricing, and inventory strategies. Explore now!

0 notes

Text

Scrap Aluminium Price | Gravita India

Gravita India, a global leader in sustainable recycling solutions, is at the forefront of aluminium recycling, delivering premium-quality aluminium alloys at competitive scrap aluminium prices. With state-of-the-art facilities and eco-friendly processes, Gravita efficiently transforms aluminium scrap into high-grade alloys like ADC12, LM2, and LM6, catering to industries worldwide. Our focus on innovation, cost-effectiveness, and adherence to global standards ensures superior quality and sustainable solutions. Trusted across 50+ countries, Gravita India remains committed to driving a circular economy, reducing environmental impact, and delivering value-driven recycling solutions for aluminium scrap markets.

#Scrap Aluminium Price#Aluminium Recycling#Aluminium Alloy Ingots#Sustainable Aluminium Solutions#Gravita India Aluminium#Aluminium Scrap Rates#Eco-Friendly Aluminium Recycling#Aluminium Price Trends#Aluminium Recycling Company#Scrap Metal Prices India#Aluminium Market Analysis#Aluminium Alloy Manufacturing#Circular Economy Solutions#Aluminium Waste Management#Recycling Industry India#Aluminium Ingot Prices#Sustainable Manufacturing#Gravita India Solutions#Global Aluminium Recycling Leader#Aluminium Recycling Technology.

1 note

·

View note

Text

How Aluminium Hanger Tents in India Are Revolutionizing Event and Industrial Spaces

The demand for flexible and durable structures has grown significantly in India, especially in the event and industrial sectors. Aluminium hanger tents have emerged as a game-changer, providing a cost-effective and efficient solution for temporary and semi-permanent setups. Whether for corporate events, weddings, exhibitions, or industrial storage, these tents offer unmatched versatility. Their lightweight yet robust construction makes them a preferred choice for businesses and event planners across the country.

The Growing Popularity of Aluminium Hanger Tents in India

Aluminium tents in India are rapidly gaining traction due to their strength, weather resistance, and ease of installation. Unlike traditional tents that rely on fabric and poles, aluminium hanger tents are designed with high-quality aluminium frames that offer superior stability. This makes them ideal for large-scale events and industrial applications where durability is key.

Several aluminium tent manufacturers in India are offering customized solutions to cater to diverse needs. From small-scale gatherings to massive exhibitions, these tents provide the perfect balance of aesthetics and functionality.

Key Benefits of Aluminium Hanger Tents

1. Durability and Strength

One of the biggest advantages of aluminium hanger tents is their durability. Made from high-grade aluminium, these structures are resistant to rust and corrosion, ensuring long-term usability. Unlike conventional fabric tents that can deteriorate over time, aluminium tents provide a more reliable and long-lasting option.

2. Quick and Hassle-Free Installation

Aluminium tents are designed for easy assembly and disassembly, making them a go-to solution for temporary setups. Whether for an outdoor event or industrial storage, these tents can be set up quickly, saving both time and labor costs.

3. Versatile Applications

Aluminium hanger tents serve multiple purposes across various industries. Some of their common applications include:

Corporate Events: Ideal for conferences, trade shows, and product launches.

Weddings and Social Gatherings: Provides an elegant and spacious venue for celebrations.

Industrial Warehousing: Used for temporary storage solutions in factories and manufacturing units.

Emergency Shelters: Deployed during disaster relief operations to provide temporary housing and medical facilities.

4. Weather Resistance

India’s diverse climate necessitates structures that can withstand extreme weather conditions. Aluminium hanger tents are built to endure heavy rains, strong winds, and high temperatures. Their sturdy framework and high-quality roofing materials provide maximum protection, ensuring safety and comfort for occupants.

5. Cost-Effective Solution

Compared to permanent structures, aluminium hanger tents offer a much more economical alternative. The aluminium tent hanger price in India varies based on size, design, and additional features, but they remain a budget-friendly option for businesses and event organizers.

How Aluminium Tents Are Transforming Event Spaces

1. Expanding Venue Options

Gone are the days when events were restricted to traditional banquet halls and auditoriums. With aluminium hanger tents, event organizers can create stunning venues anywhere—from beachfronts to open fields. These tents provide a blank canvas for creative setups, making every event unique.

2. Enhancing Guest Experience

Modern aluminium tents are equipped with advanced features like climate control, lighting systems, and soundproofing. These enhancements ensure a comfortable experience for guests, making them a preferred choice for high-profile events and luxury weddings.

3. Sustainability and Eco-Friendliness

The event industry is moving towards sustainable solutions, and aluminium tents contribute significantly to this trend. Their reusable and recyclable materials reduce the environmental impact, making them a greener alternative to conventional construction.

4. Branding and Customization

Aluminium tents can be customized with company logos, themes, and colors, making them perfect for corporate branding. Whether it’s a trade fair or a promotional event, these tents offer a professional and visually appealing setup.

Industrial Applications of Aluminium Hanger Tents

1. Temporary Warehousing

Industries often require additional storage space for raw materials and finished products. Aluminium hanger tents provide a quick and effective solution for temporary warehousing without the need for permanent construction.

2. Manufacturing Units

In regions where manufacturing facilities are expanding, aluminium tents serve as a cost-effective alternative to traditional factory buildings. Their modular design allows businesses to scale operations efficiently.

3. Military and Defense Use

Defence forces and paramilitary units use aluminium hanger tents for field operations, training camps, and temporary barracks. Their strength and adaptability make them ideal for tough terrains and remote locations.

4. Aviation and Logistics

Airports and logistics companies use aluminium tents for temporary hangars, cargo storage, and maintenance workshops. Their large-span structures provide ample space without the need for additional support columns.

Choosing the Right Aluminium Tent Manufacturer in India

With the rising demand for aluminium tents, multiple manufacturers offer a wide range of options. When selecting an aluminium tent manufacturer in India, consider the following factors:

Quality of Materials: Ensure the tents are made from high-grade aluminium and durable roofing materials.

Customization Options: Choose a manufacturer that offers tailor-made solutions based on your specific requirements.

Installation and After-Sales Support: A reliable manufacturer will provide professional installation services and ongoing support.

Competitive Pricing: Compare the aluminium tent hanger price in India to find a solution that fits your budget.

Customer Reviews and Reputation: Research testimonials and case studies to gauge the manufacturer’s credibility.

Future Trends in Aluminium Hanger Tents

As the demand for aluminium hanger tents continues to rise, several innovations are shaping their future in India:

Smart Tents: Integration of IoT technology for remote monitoring of temperature, lighting, and security.

Hybrid Designs: Combination of aluminium tents with permanent structures to create semi-permanent event and industrial spaces.

Eco-Friendly Materials: Use of biodegradable roofing materials and energy-efficient features for sustainable construction.

Enhanced Mobility: Lightweight yet durable designs for easier transportation and setup in remote areas.

Conclusion

Aluminium hanger tents in India are revolutionizing event and industrial spaces by offering a flexible, durable, and cost-effective alternative to traditional structures. Their ability to withstand diverse weather conditions, coupled with easy installation and customization options, makes them an ideal choice for event organizers, businesses, and industries alike.

With ongoing advancements in design and technology, aluminium tents are set to become even more innovative, catering to a wide range of applications across different sectors. Whether you’re looking for an elegant event venue, a robust industrial warehouse, or a temporary shelter solution, aluminium hanger tents provide the perfect blend of strength, versatility, and affordability.

#aluminium tent hanger price in india#aluminium hanger tent in india#aluminium tents in india#aluminium tent hanger price

0 notes

Text

How Aluminium Hanger Tents in India Are Revolutionizing Event and Industrial Spaces

The demand for flexible and durable structures has grown significantly in India, especially in the event and industrial sectors. Aluminium hanger tents have emerged as a game-changer, providing a cost-effective and efficient solution for temporary and semi-permanent setups. Whether for corporate events, weddings, exhibitions, or industrial storage, these tents offer unmatched versatility. Their lightweight yet robust construction makes them a preferred choice for businesses and event planners across the country.

The Growing Popularity of Aluminium Hanger Tents in India

Aluminium tents in India are rapidly gaining traction due to their strength, weather resistance, and ease of installation. Unlike traditional tents that rely on fabric and poles, aluminium hanger tents are designed with high-quality aluminium frames that offer superior stability. This makes them ideal for large-scale events and industrial applications where durability is key.

Several aluminium tent manufacturers in India are offering customized solutions to cater to diverse needs. From small-scale gatherings to massive exhibitions, these tents provide the perfect balance of aesthetics and functionality.

Key Benefits of Aluminium Hanger Tents

1. Durability and Strength

One of the biggest advantages of aluminium hanger tents is their durability. Made from high-grade aluminium, these structures are resistant to rust and corrosion, ensuring long-term usability. Unlike conventional fabric tents that can deteriorate over time, aluminium tents provide a more reliable and long-lasting option.

2. Quick and Hassle-Free Installation

Aluminium tents are designed for easy assembly and disassembly, making them a go-to solution for temporary setups. Whether for an outdoor event or industrial storage, these tents can be set up quickly, saving both time and labor costs.

3. Versatile Applications

Aluminium hanger tents serve multiple purposes across various industries. Some of their common applications include:

Corporate Events: Ideal for conferences, trade shows, and product launches.

Weddings and Social Gatherings: Provides an elegant and spacious venue for celebrations.

Industrial Warehousing: Used for temporary storage solutions in factories and manufacturing units.

Emergency Shelters: Deployed during disaster relief operations to provide temporary housing and medical facilities.

4. Weather Resistance

India’s diverse climate necessitates structures that can withstand extreme weather conditions. Aluminium hanger tents are built to endure heavy rains, strong winds, and high temperatures. Their sturdy framework and high-quality roofing materials provide maximum protection, ensuring safety and comfort for occupants.

5. Cost-Effective Solution

Compared to permanent structures, aluminium hanger tents offer a much more economical alternative. The aluminium tent hanger price in India varies based on size, design, and additional features, but they remain a budget-friendly option for businesses and event organizers.

How Aluminium Tents Are Transforming Event Spaces

1. Expanding Venue Options

Gone are the days when events were restricted to traditional banquet halls and auditoriums. With aluminium hanger tents, event organizers can create stunning venues anywhere—from beachfronts to open fields. These tents provide a blank canvas for creative setups, making every event unique.

2. Enhancing Guest Experience

Modern aluminium tents are equipped with advanced features like climate control, lighting systems, and soundproofing. These enhancements ensure a comfortable experience for guests, making them a preferred choice for high-profile events and luxury weddings.

3. Sustainability and Eco-Friendliness

The event industry is moving towards sustainable solutions, and aluminium tents contribute significantly to this trend. Their reusable and recyclable materials reduce the environmental impact, making them a greener alternative to conventional construction.

4. Branding and Customization

Aluminium tents can be customized with company logos, themes, and colors, making them perfect for corporate branding. Whether it’s a trade fair or a promotional event, these tents offer a professional and visually appealing setup.

Industrial Applications of Aluminium Hanger Tents

1. Temporary Warehousing

Industries often require additional storage space for raw materials and finished products. Aluminium hanger tents provide a quick and effective solution for temporary warehousing without the need for permanent construction.

2. Manufacturing Units

In regions where manufacturing facilities are expanding, aluminium tents serve as a cost-effective alternative to traditional factory buildings. Their modular design allows businesses to scale operations efficiently.

3. Military and Defense Use

Defence forces and paramilitary units use aluminium hanger tents for field operations, training camps, and temporary barracks. Their strength and adaptability make them ideal for tough terrains and remote locations.

4. Aviation and Logistics

Airports and logistics companies use aluminium tents for temporary hangars, cargo storage, and maintenance workshops. Their large-span structures provide ample space without the need for additional support columns.

Choosing the Right Aluminium Tent Manufacturer in India

With the rising demand for aluminium tents, multiple manufacturers offer a wide range of options. When selecting an aluminium tent manufacturer in India, consider the following factors:

Quality of Materials: Ensure the tents are made from high-grade aluminium and durable roofing materials.

Customization Options: Choose a manufacturer that offers tailor-made solutions based on your specific requirements.

Installation and After-Sales Support: A reliable manufacturer will provide professional installation services and ongoing support.

Competitive Pricing: Compare the aluminium tent hanger price in India to find a solution that fits your budget.

Customer Reviews and Reputation: Research testimonials and case studies to gauge the manufacturer’s credibility.

Future Trends in Aluminium Hanger Tents

As the demand for aluminium hanger tents continues to rise, several innovations are shaping their future in India:

Smart Tents: Integration of IoT technology for remote monitoring of temperature, lighting, and security.

Hybrid Designs: Combination of aluminium tents with permanent structures to create semi-permanent event and industrial spaces.

Eco-Friendly Materials: Use of biodegradable roofing materials and energy-efficient features for sustainable construction.

Enhanced Mobility: Lightweight yet durable designs for easier transportation and setup in remote areas.

Conclusion

Aluminium hanger tents in India are revolutionizing event and industrial spaces by offering a flexible, durable, and cost-effective alternative to traditional structures. Their ability to withstand diverse weather conditions, coupled with easy installation and customization options, makes them an ideal choice for event organizers, businesses, and industries alike.

With ongoing advancements in design and technology, aluminium tents are set to become even more innovative, catering to a wide range of applications across different sectors. Whether you’re looking for an elegant event venue, a robust industrial warehouse, or a temporary shelter solution, aluminium hanger tents provide the perfect blend of strength, versatility, and affordability.

#aluminium hangers tents infrastructure#modern a type canopy tents#services offered by a construction company#pre engineering building company in india#aluminium hanger tent in india#aluminium hangers tents manufacturers#pre engineered building manufacturers in india#pre engineered building manufacturers#steel building construction company#aluminium tent hanger price

0 notes

Text

Enhancing Spaces with Variety Aluminium Traderz: Your Trusted Partner for Interior & Fabrication Solutions

When it comes to transforming interiors with precision and elegance, Variety Aluminium Traderz stands out as a leading name in interior design Kollam and interior works in Trivandrum. Specializing in high-quality aluminium fabrication, they offer a range of solutions tailored to both residential and commercial spaces.

Interior Design Excellence in Kollam

A well-designed interior not only enhances aesthetics but also improves functionality. Variety Aluminium Traderz is known for crafting modern and stylish interiors in Kollam. From sleek partitions to elegant doors and customized aluminium fixtures, their solutions align with the latest trends, ensuring durability and elegance.

Expert Interior Works in Trivandrum

For those seeking professional interior works in Trivandrum, Variety Aluminium Traderz offers innovative solutions that blend style and practicality. Whether it's office spaces, retail showrooms, or residential projects, their expert team ensures seamless execution, enhancing the overall ambiance with premium materials and top-notch craftsmanship.

Superior Aluminium Fabrication in Trivandrum

As a trusted provider of aluminium fabrication in Trivandrum, Variety Aluminium Traderz specializes in crafting aluminium windows, doors, and structural elements with precision. Their fabrication work is designed to offer durability, weather resistance, and aesthetic appeal, making them the go-to choice for builders, architects, and homeowners.

Why Choose Variety Aluminium Traderz?

High-Quality Materials: Using top-grade aluminium for lasting durability.

Customizable Solutions: Tailored designs to meet specific project needs.

Experienced Craftsmanship: Skilled professionals ensuring flawless execution.

Affordable Pricing: Cost-effective solutions without compromising quality.

If you're looking for expert interior design in Kollam, top-notch interior works in Trivandrum, or reliable aluminium fabrication in Trivandrum, Variety Aluminium Traderz is your ideal partner. Contact them today to bring elegance and functionality to your space!

0 notes

Text

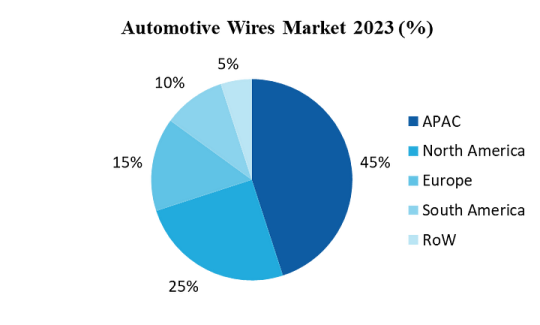

Automotive Wires Market- Opportunity Analysis & Industry Forecast, 2024–2030

Automotive Wires Market Overview:

Request sample :

Automotive wire demand is expected to rise due to the growing trend of lightweight passenger automobiles as a means of reducing carbon emissions. In response to stringent regulations aimed at reducing carbon emissions from automobiles, manufactures will concentrate on producing aluminium automotive wires to reduce the vehicle’s overall weight. This is going to help in achieving the new regulations criteria. The rising focus on enhancing the standards for automotive wire will give opportunities for market expansion. For instance, according to US Auto Outlook 2024, light vehicle sales to grow 3.7% above last year’s level, rising to 16.1 million units. Additionally, the demand for automotive wires is expected to rise in parallel with the volume of vehicles being produced and the increasing demand from customers for better comfort, safety, and convenience.

Market Snapshot

Automotives Wires Market — Report Coverage:

The “Automotive Wires Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Automotives Wires Market.

AttributeSegment

By Material

· Copper

· Aluminium

· Others

By Vehicle Type

· Passenger Vehicles

· Light Commercial Vehicles

· Heavy Commercial Vehicles

By Propulsion

· ICE Vehicles

· Hybrid Vehicles

· Pure Electric Vehicles

By Transmission Type

· Electric wiring

· Data Transmission

By Application

· Engine wires

· Chassis wires

· Body and Lighting wires

· HVAC wires

· Dashboard / Cabin wires

· Battery wires

· Sensor wires

· Others

By End User

· OEM

· Aftermarket

By Geography

· North America (U.S., Canada and Mexico)

· Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe),

· Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific),

· South America (Brazil, Argentina, Chile, Colombia and Rest of South America)

· Rest of the World (Middle East and Africa).

Inquiry Before Buying:

COVID-19 / Ukraine Crisis — Impact Analysis:

The COVID-19 pandemic disrupted global supply chains, leading to delays in production and sales of automobiles which led to decrease in automotive wire manufacturing. Governments worldwide imposed lockdowns and restrictions, which led to shut down of mines, factories, and transportation networks, thus disrupting the supply of raw materials such as copper and aluminum, that are used in making automotive wires.

The Russia-Ukraine war had a huge impact on the global automotive wires market. Ukraine is a major manufacturer of copper, a material used as an automotive wiring component. The war has led to mining disruptions, which in turn has caused the shortages and increase in prices globally.

Key Takeaways:

Copper wires segment is Leading the Market

Copper wires segment holds the largest share in the automotive wires market with respect to market segmentation by material. Electrification will be the biggest driver to copper demand for vehicles. Copper is used throughout electric vehicle powertrains, from foils in each cell of the battery to the windings of an electric motor. In total, each electric vehicle can generate over 30kg of additional copper demand. According to a report by IDTechEx, the demand for copper from the automotive industry was just over 3MT in 2023 but is set to increase to 5MT in 2034. Because of its electrical and chemical characteristics, copper is used in every part of the battery. There are lot of tiny cells in the battery, and each one has a copper foil to carry electricity out of the cell. Large copper bars placed throughout the battery also convey the energy from each cell to the high-voltage connections, which in turn power the motor and electronics. Such parts and components with the copper are driving the market growth of copper wires in automotive wires market.

Passenger Vehicles are Leading the Market

Passenger Vehicles segment is leading the Automotive Wires Market by Application. The passenger vehicle category is currently holding the largest share in the automotive wires market because of a combination of factors including large production volumes, a wide range of wiring requirements, technological developments, and the increasing adoption of electric vehicles. For instance, according to Global and EU Auto industry 2023 report by The European Automobile Manufacturers’ Association (ACEA), European car production grew substantially, reaching nearly 15 million units, marking a significant year-on-year improvement of 12.6%. The growing popularity of electric vehicles (EVs) is also contributing to the growth of the passenger vehicle segment in the automotive wires market. EVs have more complex wiring systems due to the integration of batteries, motors, and charging infrastructure.

Schedule A Call :

Integration of Smart Systems in Automobiles

Global demand for automotive wires is primarily driven by the integration of smart systems in automobiles. Modern automobiles have more wires because electronic control units (ECUs) are becoming more and more popular. Each ECU has been connected to a variety of sensors, actuators, and other ECUs through a complex network of connections. Automotive manufacturers are using sophisticated wiring solutions, such as light-weight harnesses, insulated cables and high-temperature-resistant wires to manage the rising number of connections and ensure reliable performance. For instance, In July 2024, Compal Electronics Inc, a leading contract electronics manufacturer from Taiwan, announced plans to build its first European factory in Poland. The company intends to invest more than $15.4 million to target automotive electronics clients. This strategic move marks Compal’s expansion into the European market. The need for complex and more advanced wiring solutions will continue to grow as automobiles become more technologically advanced, fueling the worldwide automotive wires market’s expansion.

Buy Now :

Fluctuating cost of materials to hamper the market

For more details on this report — Request for Sample

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Automotive Wires Market. The top 10 companies in this industry are listed below:

Aptiv plc

Yazaki Corporation

Furukawa Electric Co., Ltd

Sumitomo wiring systems

Nexans SA

Fujikura Ltd

Samvardhana Motherson International Ltd

Leoni AG

Lear Corporation

THB Electronics

Scope of the Report:

Report MetricDetails

Base Year Considered

2023

Forecast Period

2024–2030

CAGR

5.7%

Market Size in 2030

$ 6.8 Billion

Segments Covered

By Material, By Vehicle Type, By Propulsion, By Transmission Type, By Application, By End User and By Geography.

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

1. Aptiv plc

2. Yazaki Corporation

3. Furukawa Electric Co., Ltd

4. Sumitomo wiring systems

5. Nexans SA

6. Fujikura Ltd

7. Samvardhana Motherson International Ltd

8. Leoni AG

9. Lear Corporation

10. THB Electronics

For more Automotive Market reports, please click here