#Water Treatment Chemicals Market Growth

Explore tagged Tumblr posts

Text

https://akvisintelligence.com/reports/global-water-treatment-chemical-market

#Water Treatment Chemical Market#Water Treatment Chemical Size#Water Treatment Chemical Growth#Water Treatment Chemical Trend#Water Treatment Chemical Segment#Water Treatment Chemical Opportunity#Water Treatment Chemical Analysis 2024#Water Treatment Chemical Forecast

0 notes

Text

Static Mixer Market - Forecast(2024 - 2030)

Static Mixer Market Overview:

The static mixers are market has been growing rapidly mainly due to used extensively for extensively use of static mixer in the process of homogenization various hominization process in various the industrial operations such as food processing, heat transfer, chemical reactions, polymer blending, and cosmetics and pharmaceutics, but also for in water treatment of waste water. The global Static Mixer Market size is estimated to grow at a CAGR of 5.1% during the forecast period i.e. 2018—-2023. The APAC region is estimated calculated to be as the largest segment for market for Static Mixers, with holding a share of 35.28% of the overall market in by 2023, and itsthe value is estimated to grow toreach $965.28mM by 2023. The rising market in China and India, particularly for disposable static mixers will drive the market.

Request Sample

Static Mixer Market Outlook:

The static mixer is also known as a motionless mixer, this device is basically inserted into housing or pipelines with the objective to handle or control the fluid streams. Insertion of a static mixer significantly accelerates inline mixing or reaction. This market includes the technique essentially desirable for inexpensive, fast and continuous operation. According to IndustryARC findings, iIndustrial static mixers will hold the largest market share during the forecast period. In the industrial static mixer, there is a very broad range of applications are incorporated in fluid processing industries such as Chemical Industry, Oil, Gas & Petrochemicals, Plastics Injection Molding & Extrusion, Polymer Production, and other industries. The Industrial segment of the static mixer market was valued at $459.28m in 2017 and by type is estimated to reach $581.29m by 2023, M growing at a CAGR of 4.5% during the forecast period of 2018—-2023 by 2023 from $459.28m M in 2017 and is forecast to grow at a CAGR of 4.5% during the forecast period of 2018-2023.

The average selling price of disposable static mixer was estimated to be $0.75 per unit in 2017 and is anticipated to reach $0.59 per unit. This decline in ASP is more compared to non-disposable static mixer due to the decline in the plastic prices and the increasing number of Chinese players in disposable static mixer market that provides the less priced products.The decline in average selling price of disposable static mixers is higher as compared tothan that of non-disposable static mixers because of the increasing number of Chinese players in the disposable static mixer market offering that offer low-cost products; and also, due to the drop in plastic prices.

Static Mixer Market Growth Drivers:

According to the Organisation for Economic Co-operation and DevelopmentOrganization For Corporation and Development (OECD), in manufacturing sector, countries such as Estonia, Lithuania, the Czech Republic, Brazil, and Slovenia are anticipated to witness a have significant increase of SMEs in the manufacturing sectorin SME’s. The growing number of SMEs coupled with the growing demand for the static mixers in various end- user industries such as water treatment, oil & gas, pulp and paper, and food & beverage for mixing, blending, dispersion, heat transfer, mass transfer, solids suspension, dosing, emulsion formation, dissolution, pH adjustment, and dilution is expected to strengthen the static mixers market growth. The rising market for disposable static mixers in China and India, particularly for disposable static mixers will also act as a growth driver.drive the market.

Inquiry Before Buying

Static Mixer Market Challenges:

Though the helical static mixers market has continued to be in matured over stage the since past 15 recent years, . The customers are still viewing the helical static mixers as a commodity, and are ignoring the difference between the offerings andor performance. This view of customers towards helical static mixers is anticipated to give rise provide prospects to the new entrants in the market offeringthat offer which offers the helical static mixers for at huge price variations. This price variation is anticipated to further result in decreased margins for major players and lessen the number of distribution channels, thereby affecting the overall profitability of the manufacturers of helical static mixers. Thus, the increasing number of new players in the manufacturing of helical static mixers with huge price variation is anticipated to hampering the revenue growth of helical static mixers;, which in turn and consequently, affectings the entire Sstatic Mmixer market growth.

Number of SMEs and Large Enterprises in Brazil, 2012—-2017

Schedule a Call

Static Mixer Market Research Scope:

The base year of the study is 2017, with forecast done up to 2023. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the plastics in electric vehicleStatic Mixer market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the types of static mixer market, and itstheir specific applications in different end user industries in different types of vehicles.

Static Mixer Market Report: Industry Coverage

Types of Static Mixer Market — By Type: Industrial, Laboratory

Structure of Static Mixer Market — By Structure: Helical, Square, Plate

Usage of Static Mixer Market — By Usages: Disposable, Non Disposable

Flow of Static Mixer Market — By Flow: Laminar flow, Turbulent flow, Transitional fFlow

End Users of Static Mixer Market — By End Users: Water Treatment, Oil & Gas, Pulp and Paper, Food and Bbeverages, Pharmaceuticals, Construction, Chemicals, HealthCare and Cosmetics, Mining and Metal, Transportation, and Power Generation.

The Static Mixer market report also analyzes the major geographic regions for the market as well as the major countries for the market in these regions. The regions and countries covered in the study include:

North America: The U.S., Canada, Mexico

South America: Brazil, Chile, Argentina, Ecuador, Peru, Colombia, Costa Rica

Europe: The U.K., Germany, Italy, France, The Netherlands, Belgium, Spain, Denmark

APAC: China, Japan, Australia, South Korea, India, Taiwan, Malaysia, Hong Kong

Middle East and Africa: Israel, South Africa, Saudi Arabia

Static Mixer Market Key Players Perspective:

Nordson Xaloy, SPX Corporation, and Sulzer Ltd. were analyzed to be the dominant players ofin the Static Mixer market in 2017, with a share of 12.7%, 11.4% and 8.8% respectively. EThe extensive product portfolio, along with well- diversified sales and distribution network, provides avail significant exposure and visibility to these players in the market.

Some of the other key players mentioned in this report are DuPont, BASF SE, Solvay SA, Covestro (Bayer), DSM NV, Toray Industries, Celanese Corporation, RTP Company, and Mitsui Chemicals America among others.

Buy Now

Static Mixer Market Trends:

The U.A.E. has planned to establish a comprehensive hub for international pharmaceutical companies, and the country is planning to double its drug manufacturing factories by 2021. As of now, the country has 54 pharmaceutical firms in the region. These i The iIncreasinge in the number of pharmaceutical firms coupled with the deployment of static mixers for various applications such as penicillin production, syrup dilution, and others is anticipated to provide offer prospects for the Static Mixer market.

The manufacturers of static mixers are actively investing in R&D, research and the development of static mixers. These increasing the chances of investments in R&D is primarily responsible for the launching of new products with advanced technology. One such instance is was the launch of PerfectPeak™ 3D Printed Static Mixer by Motto Corp. This product has incorporated incorporates 3D printing technology to reduce the baseline noise significantly. Thus, the increasing investments in R&D is anticipated to provide ample amount of opportunities for Static Mixer market in near future

Water is a critical global resource now and for the future. With the world population expected to reach 9.8 bBillion by 2050 coupled with extensive industrial growth, there is tremendous a pressing need for recycling and reusing of the water. Growing industrialization coupled with erratic rain fall patterns due to climate change in developing countries has resulted in lowering and depletion of water resources. At this juncture, governments around the world have started focusing on setting upthe water treatment plants. This is set to drive the market for the Static Mixers.

DThe dental implants, where the static mixers have direct applications, is one market that is set to witness tremendous growth in the future due to the increased increasing number of dental clinics in developed countries and the growing awareness about dental hygiene in emerging economies. The rising demand for better oral hygiene services coupled with the growing disposable incomes is set to boost the market for dental services.

#static mixer market#static mixer market size#static mixer market shape#static mixer market forecast#static mixer market analysis#static mixer market report#static mixer market growth#motionless mixer#food processing#Water And Wastewater Treatment Technologies#chemical reactions#polymer blending

0 notes

Text

#Global Water Treatment Chemical Market#Global Water Treatment Chemical Market Size#Global Water Treatment Chemical Market Growth#Global Water Treatment Chemical Market Trends#Global Water Treatment Chemical Market Analysis

0 notes

Text

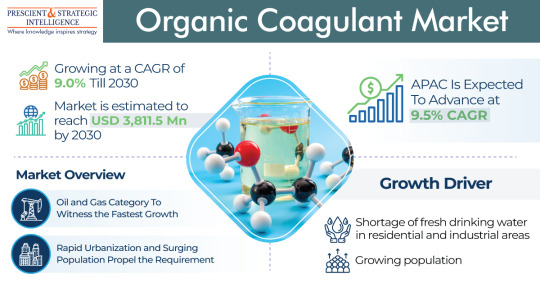

Harnessing Nature: Insights into the Organic Coagulant Market

The organic coagulant market is projected to reach at USD 3,811.5 million in 2030 with a CAGR of 9% in the years to come. The major reasons for this development of the industry are the scarcity of drinking and fresh water in residential and industrial areas along with the rising population, and urbanization.

And the rising demand for facilities like sewage treatment, industrial water treatment, fertilizer production, food & beverage industry, and paper manufacturing helps the demand for the chemical to grow.

And another major reason for the increasing demand is the growing population, which is creating an enormous demand for clean water and for which a need for advanced purification methods and also with the expansion of infrastructure for water treatment by government to meet the demand are all contributing the growth of eco-friendly water purification.

The oil & gas category will grow at a highest CAGR of 10% over the years, which is driven by the increasing use of organic chemicals with water at a required concentration for drilling and petroleum extraction purposes.

While, onshore and offshore operations both require different filtration processes as in onshore normal water is available, whereas offshore require advanced system to filter seawater. In addition, research and development activities are also contributing to the demand for organic coagulants, with eco-friendly solutions being explored for wastewater treatment.

Moreover, the increasing government focus to implement policies for water quality monitoring because of the increasing population all over the world. Strict regulations to prevent the direct release of harmful chemicals from industries and untreated sewage into water bodies.

APAC will grow the fastest in the organic coagulant market at a CAGR of 9.5% in the years to come due to the rapid urbanization and industrialization with rising population along with the rising investments in water treatment plant development and strict regulations on sewage disposal. Countries like India, China, South Korea, and Japan are expanding their contribution for the water treatment.

#organic coagulant#water treatment#wastewater treatment#coagulation solutions#eco-friendly chemicals#sustainable water treatment#natural coagulants#organic flocculants#water purification#organic coagulant applications#environmental sustainability#industrial water treatment#market growth#coagulation technology#organic chemicals

0 notes

Text

The GCC Water & Waste Water Treatment Chemicals Market is projected to grow at a CAGR of around 18.2% during the forecast period, i.e., 2023-2028, says MarkNtel Advisors. The market growth primarily attributes to the increasing issues of water contamination, burgeoning waste from industries, which gets discharged in water bodies, and mounting need for potable water due to rapid industrialization & expansion across the Gulf countries.

#GCC Water & Waste Water Treatment Chemicals Market#GCC Water & Waste Water Treatment Chemicals Market News#GCC Water & Waste Water Treatment Chemicals Market Size#GCC Water & Waste Water Treatment Chemicals Market Growth#GCC Water & Waste Water Treatment Chemicals Market Share

0 notes

Text

#Australia Water Treatment Chemicals Market#Australia Water Treatment Chemicals Market Size#Australia Water Treatment Chemicals Market Share#Australia Water Treatment Chemicals Market Analysis#Australia Water Treatment Chemicals Market Trends#Australia Water Treatment Chemicals Market Growth#Australia Water Treatment Chemicals Market Report#Australia Water Treatment Chemicals Market Research#Australia Water Treatment Chemicals Industry#Australia Water Treatment Chemicals Industry Report

0 notes

Text

Proof from tomatoes that biofertilizers increase yields—minus the environmental costs (Anthropocene Magazine)

Excerpt from this story from Anthropocene Magazine:

Using eco-friendly fertilizers instead of synthetic chemicals produces high quality tomato crops with competitive yields, a team of Italian scientists has shown.

Their new study considered two groups of fertilizer alternatives: a nutrient-rich algae-infused concoction; and fertilizers made with symbiotic root microbes like fungi and bacteria that fix nutrients from the soil to increase crops’ uptake. These alternatives, known broadly as ‘biofertillizers’, can be made without the emissions-intensive process required to make conventional synthetic fertilizers, and can significantly reduce crops’ need for these chemical additives in the first place.

The researchers tested their alternatives on tomato fields in Italy, where they subjected growing tomato plants to different combinations of the two: some tomatoes received one of two fertilizers through drip irrigation, containing a mix of growth-promoting fungi or bacteria; some were treated with the algae infusion; and others received a combination of both microbial and algal fertilizers. In each case, the fertilizer-treated crops were compared with tomatoes that had received no fertilizers at all.

Of all the fertilizers, the second microbial mixture containing a combo of root-colonizing fungi and bacteria produced the tallest and bushiest tomatoes, with the largest root mass. The symbiotic root-colonizing behavior of the microbes in this treatment seem to have supported denser, deeper-reaching roots, which can help plants snare more nutrients—and may also help plants to access deeper water sources in times of drought, the researchers say.

The success of that microbial mixture was exceeded only by tomato plants that received it in combination with the algal fertilizer, which was applied to plants as a growth-promoting spray, rich in amino acids, and vitamins. In those tomatoes plants, not only did this combo exceed all growth parameters, but it also produced striking yields: these double-treated crops generated 67.2 tons of tomatoes per hectare, compared to the 30.3 tons per hectare produced when researchers applied the microbial fertilizer on its own—and almost threefold more than the 26 tons per hectare from tomato plots that received no fertilizers at all.

What’s more, the combination of microbial and algal fertilizers also produced the highest number of marketable fruits, with fewer green and rotten fruits than in those plants that received just one fertilizer treatment or none, the researchers found. Interestingly, they noticed that microbial fertilizers led to larger and sweeter tomatoes, while the algal fertilizers were associated with redder fruits. “We were fascinated by the idea that an environmentally-friendly approach like this could produce such strong results,” the scientists say.

3 notes

·

View notes

Text

A Comprehensive Guide to Naturally Preventing Hair Loss

Introduction : Hair loss can be a distressing experience, affecting both men and women of all ages. While there are numerous treatments and products available on the market, many people prefer to take a more natural approach to tackle this issue. In this comprehensive guide, we will explore a wide range of natural methods and remedies to help you prevent hair loss and promote healthy hair growth. From dietary changes to lifestyle adjustments and herbal remedies, we've got you covered with effective strategies that can make a real difference in maintaining your luscious locks.

Section 1: ( The Role of Nutrition ): A well-balanced diet is fundamental to healthy hair. Essential nutrients, such as vitamins, minerals, and proteins, play a crucial role in hair growth and strength. Incorporating the following elements into your diet can significantly reduce hair fall:

Protein: Hair is primarily composed of a protein called keratin. Ensure you have an adequate intake of lean proteins like eggs, fish, lean meats, and legumes.

Iron: Iron deficiency can lead to hair loss. Include iron-rich foods such as spinach, lentils, and red meat in your meals.

Omega-3 Fatty Acids: These healthy fats found in fatty fish (like salmon and mackerel), walnuts, and flaxseeds can promote scalp health and hair growth.

Vitamins: Vitamins such as A, C, and E are essential for healthy hair. These can be found in foods like sweet potatoes, citrus fruits, and nuts.

Biotin: Biotin, also known as vitamin B7, is crucial for hair health. It's found in eggs, nuts, and leafy greens.

Section 2: ( Proper Hair Care ) The way you care for your hair can have a significant impact on hair fall. Here are some natural tips for maintaining healthy hair:

Gentle Washing: Avoid frequent and aggressive hair washing, which can strip your hair of its natural oils. Wash your hair every 2-3 days with a mild, sulfate-free shampoo.

Scalp Massage: Regular scalp massages can improve blood circulation and stimulate hair follicles. Use natural oils like coconut or almond oil for added benefits.

Natural Hair Products: Opt for natural and chemical-free hair care products. Harsh chemicals in shampoos and conditioners can weaken hair over time.

Avoid Heat Styling: Reduce the use of heat styling tools like straighteners and curling irons. If you must use them, apply a heat protectant spray.

Wide-Toothed Comb: When detangling your hair, use a wide-toothed comb to prevent breakage.

Section 3: ( Lifestyle Changes ) Our lifestyle choices can have a profound impact on hair health. Making the following adjustments can contribute to preventing hair loss naturally:

Stress Management: Chronic stress can lead to hair loss. Practice stress-reduction techniques such as meditation, yoga, or deep breathing exercises.

Adequate Sleep: Aim for 7-9 hours of quality sleep each night. Sleep is essential for hair repair and growth.

Hydration: Stay well-hydrated by drinking plenty of water. Dehydration can make hair brittle and prone to breakage.

Smoking and Alcohol: Both smoking and excessive alcohol consumption can negatively affect hair health. Reducing or quitting these habits can benefit not only your hair but your overall well-being.

Physical Activity: Regular exercise can improve blood circulation, which is beneficial for hair follicles. Find an activity you enjoy and make it a part of your routine.

Section 4: ( Herbal Remedies and Supplements ) : Herbal remedies have been used for centuries to promote hair growth and prevent hair loss. Some popular options include:

Aloe Vera: Aloe vera gel can be applied to the scalp to reduce dandruff and promote hair growth.

Hibiscus: Hibiscus flowers and leaves are known for their hair-strengthening properties. You can make a paste and apply it to your scalp.

Fenugreek: Fenugreek seeds can be soaked overnight and made into a paste for scalp application. They help strengthen hair roots.

Saw Palmetto: This herbal supplement is believed to block the hormone responsible for hair loss (DHT) and is often used to combat hair loss in men.

Conclusion

Preventing hair loss naturally requires patience and consistency in implementing these strategies. Remember that results may vary from person to person due to genetics and other factors. By nourishing your body with the right nutrients, adopting a healthy lifestyle, and using natural hair care methods, you can reduce hair fall and promote a healthier, more vibrant mane. Embrace these natural remedies, and you'll be well on your way to enjoying stronger, more resilient hair.

2 notes

·

View notes

Text

Sodium Silicate Prices Trend | Pricing | News | Database | Chart

Sodium silicate, also known as water glass, plays a crucial role in various industries such as detergents, construction, textiles, and water treatment, making it a vital commodity in the global market. Over recent years, the sodium silicate market has experienced fluctuating price trends influenced by a combination of supply chain dynamics, raw material costs, and shifting demand from end-use industries. The pricing of sodium silicate is closely tied to the availability and cost of raw materials like soda ash and silica sand, both of which are subject to periodic price volatility due to mining regulations, energy costs, and transportation challenges. Additionally, energy-intensive production processes, including the heating and chemical transformation steps, contribute to the cost structure of sodium silicate, which in turn impacts market prices.

A significant factor driving the sodium silicate market is its application in the detergent and cleaning industry. With growing global concerns over hygiene and cleanliness, demand for detergents has surged, especially in developing economies. This increase in demand has translated into higher consumption of sodium silicate, influencing its market value. However, competitive pressures from alternative compounds and advancements in detergent formulations pose challenges to the sustained growth of sodium silicate prices. Another key application sector is the construction industry, where sodium silicate is used as a sealant, binder, and in concrete hardening. The health of the construction sector, often linked to broader economic conditions, plays a pivotal role in determining the pricing trends of sodium silicate. Economic slowdowns or reduced construction activity can result in diminished demand and downward pressure on prices.

Get Real time Prices for Sodium Silicate: https://www.chemanalyst.com/Pricing-data/sodium-silicate-1340

Regional dynamics also significantly impact sodium silicate prices. In Asia-Pacific, which is a major production and consumption hub, countries like China and India dominate the market due to their extensive industrial base and large-scale manufacturing capabilities. Competitive production costs in these regions often lead to relatively lower sodium silicate prices. However, fluctuations in energy costs, environmental regulations, and export policies can create uncertainty in the market. In North America and Europe, stricter environmental regulations and higher production costs typically result in higher sodium silicate prices. These regions are also witnessing a growing inclination toward sustainable and eco-friendly alternatives, potentially reshaping the market landscape in the coming years.

Technological advancements in production methods are another variable affecting sodium silicate pricing. Efforts to improve energy efficiency and reduce environmental impact have led to innovations in manufacturing processes. These advancements can sometimes offset rising raw material costs, helping stabilize prices in the long term. However, initial investments in new technologies and the adoption of cleaner production practices often lead to short-term cost increases, which are reflected in market prices. Furthermore, the interplay between supply and demand remains a critical determinant. Overcapacity or underutilization of manufacturing plants can lead to significant price fluctuations, making it essential for market participants to align production with demand trends.

The global market for sodium silicate has also been shaped by geopolitical factors and trade policies. Tariffs, import-export restrictions, and trade disputes can disrupt supply chains, impacting the availability and cost of raw materials and finished products. For example, trade tensions between major economies or sanctions on key exporters can result in supply shortages and price spikes. On the other hand, favorable trade agreements and regional collaborations can enhance market stability and promote competitive pricing.

Sustainability trends and the growing emphasis on circular economies are expected to play a more prominent role in shaping the sodium silicate market. The push for environmentally friendly production and the adoption of recycling initiatives are likely to influence both demand and pricing strategies. Manufacturers are increasingly exploring ways to repurpose sodium silicate for sustainable applications, which could open up new revenue streams and stabilize market dynamics. However, transitioning to greener practices may require significant investment, potentially leading to price adjustments during the transition period.

In conclusion, the sodium silicate market is characterized by a complex interplay of factors including raw material costs, industrial demand, regional dynamics, and technological advancements. While the market presents significant growth opportunities driven by its diverse applications, it is also subject to challenges such as environmental regulations, competitive alternatives, and economic fluctuations. Understanding these variables is essential for stakeholders to navigate the market effectively and capitalize on emerging opportunities. With sustainability and innovation at the forefront, the sodium silicate market is poised for transformative changes that could redefine pricing trends and market dynamics in the years to come.

Get Real time Prices for Sodium Silicate: https://www.chemanalyst.com/Pricing-data/sodium-silicate-1340

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Sodium Silicate#Sodium Silicate Price#Sodium Silicate Prices#Sodium Silicate Pricing#Sodium Silicate News#Sodium Silicate Database

0 notes

Text

Why Every Industry Needs an Industrial Effluent Treatment Plant

Industries worldwide are critical drivers of economic growth, but they also generate significant amounts of wastewater known as industrial effluent. This wastewater can contain a wide range of harmful substances, including chemicals, heavy metals, organic matter, and pathogens. If left untreated, industrial effluent can cause severe environmental damage, public health risks, and legal consequences. This is why every industry, regardless of its size or type, needs an industrial effluent treatment plant (ETP).

In this article, we will explore why an industrial effluent treatment plant is a necessity for industries, looking at the environmental, regulatory, economic, and social aspects.

1. Environmental Protection

One of the most pressing reasons every industry needs an industrial effluent treatment plant is to protect the environment. Untreated industrial wastewater contains pollutants that can contaminate soil, water bodies, and air. For instance, chemicals, metals, and pharmaceutical residues from industries like textiles, pharmaceuticals, and chemicals can pollute rivers, lakes, and groundwater. This can harm aquatic life, damage ecosystems, and reduce the availability of clean water for other uses.

An industrial effluent treatment plant ensures that pollutants are removed or reduced to safe levels before the wastewater is discharged into the environment. Technologies like membrane filtration, biological treatment, and chemical treatment help industries comply with stringent environmental standards, preventing the harmful effects of industrial effluent.

2. Compliance with Regulatory Standards

Governments and environmental agencies have put in place strict regulations to control the quality of effluent that industries discharge. These regulations often specify limits for contaminants such as biochemical oxygen demand (BOD), chemical oxygen demand (COD), pH levels, and heavy metals. Failure to comply with these regulations can result in hefty fines, penalties, and even the suspension of operations.

An industrial effluent treatment plant is designed to treat wastewater to meet these legal requirements, helping industries avoid non-compliance risks. Adhering to environmental laws not only ensures legal compliance but also enhances a company's reputation as a responsible business.

3. Cost Savings and Resource Recovery

While setting up an industrial effluent treatment plant requires an initial investment, the long-term cost savings and resource recovery it offers are substantial. Treatment plants can help industries reduce their water consumption by enabling water reuse for non-potable purposes, such as cooling, cleaning, or irrigation. This reduces the reliance on external water sources, saving money on water bills.

Furthermore, certain advanced treatment technologies, such as zero liquid discharge (ZLD), can allow industries to recover valuable byproducts from their effluent, such as salts, chemicals, or energy in the form of biogas. This not only minimizes waste but also creates new revenue streams for industries.

4. Corporate Social Responsibility (CSR) and Public Image

In today’s socially-conscious market, industries are increasingly expected to demonstrate responsible environmental practices. Implementing an industrial effluent treatment plant is an important aspect of corporate social responsibility (CSR). It shows a company’s commitment to sustainability, environmental protection, and the well-being of surrounding communities.

A strong environmental track record can enhance a company’s public image, helping it build trust with customers, investors, and regulatory bodies. In contrast, industries that neglect their effluent treatment responsibilities risk damaging their reputation, losing business, and facing public backlash.

5. Public Health and Safety

Industrial effluent can carry hazardous materials that pose significant risks to public health. For example, untreated wastewater may contain pathogens, toxic chemicals, or heavy metals that can contaminate local water supplies and soil. This can lead to diseases, poisoning, and long-term health problems in communities near industrial plants.

By installing an industrial effluent treatment plant, industries play a crucial role in protecting public health. A well-designed ETP eliminates harmful pathogens and reduces the toxic load, ensuring that the treated water released into the environment is safe and does not pose a health risk to humans or animals.

6. Sustainable Business Operations

Sustainability has become a key focus for businesses across the globe. Industries are increasingly recognizing the importance of adopting green practices not only to protect the environment but also to secure long-term viability. Industrial effluent treatment plants are an integral part of sustainable industrial practices. They help reduce water pollution, lower energy consumption, and support the circular economy by recycling and reusing water.

Sustainable businesses attract eco-conscious consumers, investors, and partners, which can lead to new opportunities and competitive advantages in the market. An industrial effluent treatment plant is therefore not just an environmental necessity but a step toward building a more resilient and sustainable business model.

7. Risk Mitigation and Disaster Prevention

Untreated effluent can pose a serious risk to both the environment and a business’s operations. For example, the accidental release of untreated wastewater due to equipment failure, human error, or natural disasters can cause environmental disasters, legal liabilities, and financial losses.

An industrial effluent treatment plant helps mitigate these risks by ensuring that wastewater is treated to the required standards before release. Additionally, advanced monitoring systems in modern treatment plants provide real-time data, allowing industries to quickly detect any issues and prevent potential disasters.

Conclusion

In conclusion, every industry, regardless of its size or sector, needs an industrial effluent treatment plant to ensure the proper treatment of wastewater, protect the environment, comply with regulations, and safeguard public health. Implementing an ETP is not only essential for environmental sustainability but also offers significant financial and reputational benefits. With increasing environmental regulations and growing consumer demand for sustainable practices, the importance of an industrial effluent treatment plant has never been greater.

Industries that prioritize effluent treatment demonstrate a commitment to sustainable practices, reduce operational costs, and enhance their corporate reputation. Investing in an industrial effluent treatment plant is, therefore, a vital step toward building a responsible, sustainable, and future-ready business.

0 notes

Text

𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧𝐬 𝐢𝐧 𝐖𝐚𝐭𝐞𝐫 𝐂𝐥𝐚𝐫𝐢𝐟𝐢𝐜𝐚𝐭𝐢𝐨𝐧: 𝐓𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞 𝐨𝐟 𝐂𝐥𝐞𝐚𝐧 𝐖𝐚𝐭𝐞𝐫-IndustryARC™

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐏𝐃𝐅 𝐁𝐫𝐨𝐜𝐡𝐮𝐫𝐞

Wastewater treatment plants are in existence in one form or another for quite a long time. The main purpose of these plants is to treat tons of solid and liquid waste generated from homes, industries, and other common places. Clarifiers in wastewater treatment plants have been an integral part from the beginning too. Whenever the concentration of suspended solids is high in the wastewater, clarifiers are a necessary component to remove it.

Water clarifiers are chemicals containing positively charged molecules, which are mutually attracted to negatively charged impurities. They are used to separate solid particles from the liquid for clarification. In addition, they aid in eliminating fine particles, sediments, algae, colors, oil, and organic matter from water to make it clean, clear, and potable. This process is done in roundabout settling tanks. The use of water clarifiers improves the visibility of water. With respect to type, the global water clarifier market is fragmented into pH stabilizers, coagulant, and flocculant. The coagulant type is further segregated into organic and inorganic. Water clarifiers find their application across various industries such as pulp & paper, municipal water treatment, metal & mining, petrochemicals, and others.

𝐓𝐨���� 𝐢𝐦𝐩𝐚𝐜𝐭𝐢𝐧𝐠 𝐟𝐚𝐜𝐭𝐨𝐫𝐬: 𝐦𝐚𝐫𝐤𝐞𝐭 𝐬𝐜𝐞𝐧𝐚𝐫𝐢𝐨 𝐚𝐧𝐚𝐥𝐲𝐬𝐢𝐬, 𝐭𝐫𝐞𝐧𝐝𝐬, 𝐚𝐧𝐝 𝐝𝐫𝐢𝐯𝐞𝐫𝐬:-

Implementation of stringent regulations with respect to conservation of water and water quality is the key factor driving the growth of the global water clarifiers market. Moreover, decrease in freshwater resources has enforced the adoption of water clarifiers, which is boosting the of the global market. Furthermore, enforcement of regulations for water reuse and wastage promotes the use of water clarifiers, which significantly contributes toward the growth of the market.

0 notes

Text

#Water Treatment Chemical Market#Water Treatment Chemical Size#Water Treatment Chemical Growth#Water Treatment Chemical Trend#Water Treatment Chemical Segment#Water Treatment Chemical Opportunity#Water Treatment Chemical Analysis 2024#Water Treatment Chemical Forecast

0 notes

Text

Unlocking the Potential of Quartz Granules for Your Business

One of the most useful and necessary minerals for industrial uses are quartz granules, which are a type of silica. They are essential in many industries due to their special qualities, which include great hardness, chemical inertness, and endurance to high temperatures. The need for a premium Supplier of Quartz Granules is still rising worldwide, with applications ranging from electronics and paints to glassmaking and construction.

What Are Granules of Quartz?

Natural crystalline silica particles called quartz granules are produced by crushing and mining quartz rocks. The exceptional homogeneity, hardness, and clarity of these grains are well-known. Depending on their purity and particle size, they are utilized for a variety of industrial applications and come in a range of sizes.

Quartz granules are a popular option for applications needing resistance and endurance because of its high melting point and chemical stability in harsh environments. They are also economically feasible, environmentally benign, and non-toxic, which adds to their appeal in business circles.

Quartz Granules' Industrial Uses in the Construction Sector

Granules of quartz are essential to the building sector. They are an essential part of cement and concrete mixtures, where they improve strength and durability. Quartz is also utilized to make engineered stone and decorative surfaces, which are quite popular for floors and countertops.

Production of Glass

Making glass is one of the main applications for quartz grains. The strength and clarity of glass used for windows, bottles, and specialty optical equipment are guaranteed by high-purity quartz.

The Electronics Sector

The demand for high-purity quartz granules has increased due to the growth of the electronics industry. Because of its dielectric qualities and thermal stability, quartz is utilized in semiconductors and piezoelectric devices.

Coatings and Paints

Paints and coatings employ quartz granules as fillers. They increase the paint's resilience to deterioration, longevity, and aesthetic appeal.

Filtration of Water

Granules of quartz are frequently used as filtration media in water treatment facilities. They are perfect for eliminating contaminants and guaranteeing a clean water supply because of their homogeneity and chemical inertness.

Refractories and Ceramics

Quartz grains are utilized in the ceramics industry to make pottery, sanitary ware, and tiles. They are also appropriate for refractory materials in furnaces and kilns due to their excellent heat resistance.

Qualities of a Trustworthy Quartz Granules Supplier

Industries give quality, consistency, and dependability first priority when choosing a supplier for quartz granules. Some characteristics of a trustworthy supplier are as follows:

High Purity: To achieve strict quality standards, industries need quartz granules free of impurities. Better performance and longer product life are guaranteed by high-purity quartz.

Customizable Sizes: Granules of various sizes are required for various applications. To meet a variety of industrial needs, a good provider provides a range of particle sizes.

Practices for Sustainability: Businesses all throughout the world are starting to prioritize environmental concern. The supply chain gains value when a provider uses sustainable mining and production methods.

On-time Delivery: The timely delivery of raw materials is critical to the effectiveness of industrial operations. Timely and hassle-free logistics are guaranteed by trustworthy vendors.

Demand and Market Dynamics Worldwide

The expansion of the electronics, automotive, and construction industries is driving up demand for quartz granules. Because of their fast urbanization and industrialization, emerging economies—especially those in Asia-Pacific—are significant consumers.

In order to ensure a low ecological impact, environmental restrictions have also encouraged innovation in quartz processing technology. In order to improve product quality and lower their carbon footprints, suppliers are investing in cutting-edge methods.

Selecting the Proper Vendor

When enterprises search for a supplier of quartz granules, they are looking for a partner who can provide constant supply of high-quality materials. In the industry, Pratibha Refractory Minerals is a reputable brand that is well-known for its dedication to excellence and client satisfaction. They guarantee that their quartz granules satisfy the requirements of many industries by maintaining a strong infrastructure and adhering to international standards.

In conclusion

Granules of quartz serve as the foundation for numerous industrial processes, allowing the creation of goods that influence contemporary life. Reliable suppliers are essential to sustaining industrial productivity and innovation as the demand for quartz grows globally. Businesses may guarantee continuous operations and excellent product quality by collaborating with a reliable supplier. Quartz granules continue to be a vital component propelling advancement in a variety of industries, including electronics, water treatment, and construction.

0 notes

Text

Find The Best Commercial RO Plant Manufacturer In Faridabad ?

To meet the high demands of industry, Netsol Water provides a wide choice of industrial & commercial RO plants in Faridabad that incorporate modern world-class RO technology to purify water.

Even though the local government has repeatedly ordered delinquent businesses to separate out harmful chemicals alongside various other impurities from their sewage waste while discarding it in an open environment that complies with standard guidelines, many municipal drains continue to discharge wastewater directly into channels, lakes, as well as nearby water bodies, including overflowing drains.

In Faridabad, both the commercial & residential sectors require clean water.

This renewable but limited resource is under additional stress due to the growing human population & increased consumption, especially for drinking, agricultural, as well as industrialized water supply.

The need for clean water is currently increasing at a very quick pace!

There are plenty of places to eat along with places to stay in the city. Lodging or Homestay spaces are always in high demand because there are so many tourist attractions.

Agriculture continues to be the town's main source of income. In highland hilly regions, farmers grow crops like wheat, maize, as well as various cereals; most of these are sold outside the Haryana state.

Amusement parks are another significant source of revenue in Faridabad. In addition to treating a variety of problems with both mental & physical health, the majority of these riverside amusement facilities are situated right next to lakes, river channels, etc. Due to their reputation for offering superior fitness lessons, even visitors from outside Faridabad enjoy staying near these fitness centers.

Essential Conditions for Water Treatment with the Best Commercial RO Plant Manufacturer in Faridabad

Faridabad has benefited much from its historical accomplishments plus customs, which have not restricted its growth but rather enabled it to generate a large number of jobs & revenue through its manufacturing facilities for its citizens. Residential & commercial sectors in Faridabad are expanding, but utilization & ingestion of toxic water are hampering their growth. Raw Water must be treated & checked with certain plants, such as commercial RO plants, to remove almost all contaminants while maintaining the TDS to keep workers safe while operating.

The most admired Commercial RO Plant Manufacturer In Faridabad has been described:

Netsol Water

With headquartered at Gr. Noida in North India, Netsol Water is establishing itself as the biggest supplier of such RO Plants & proven itself as an well-esteemed commercial RO plant manufacturer in Faridabad. A commercial water treatment facility can treat large amounts of water at once. It is renowned in the field for its outstanding quality & beneficial range. Because of our vast advertising & marketing experience as well as consistent quality, we have a stellar track record in the commercial sectors for providing superior Commercial RO Plants.

What is the uniqueness that an efficient Commercial RO Plant Manufacturer must be having?

It offers various design-based commercial RO plants that significantly purify water on a huge scale.

The integration of digital smart meters & advanced detection systems in Netsol Water's commercial RO plants aids in the rigorous, routine monitoring of water TDS in compliance with established standards & guidelines.

Contaminants, Chemicals along with other dissolved scattered matter can be removed from water in the form of H2O by RO plants installed here.

RO plants may help minimize the risk of a number of illnesses, including waterborne infections.

By routinely as well as constantly purifying wastewater, RO plants can help increase the recycling of water.

Conclusion

Commercial RO plant manufacturing unit at Netsol Water can manufacture, design & produce between 250 & 10,000 LPH, depending on what each industry wants. The professionals at Netsol Water can build along with installation of commercial RO plants in accordance with the adjustments that the clients specify, which undoubtedly satisfies their needs. Engineers may modify the plant's size, design, as well as ability in response to client requests.

Netsol Water & Commercial RO Plant is illustrated among the leading commercial RO plant manufacturer in Faridabad, & clients should give them your highest priority if you have any concerns about any commercial RO-related setup, installation, as well as after-sales services is required. Once you have dealt with them, you won't ever forget about them as well as choose to switch.

0 notes

Text

The MEA Water & Waste Water Treatment Chemicals Market is projected to grow at around 5% CAGR during the forecast period, i.e., 2022-27. The growth of the market is likely to be driven by the rapidly increasing concerns over water contamination, improper treatment & disposal of waste from industries in water bodies, and the burgeoning demand for potable water by the rapidly growing population across the region.

#MEA Water & Waste Water Treatment Chemicals Market#MEA Water & Waste Water Treatment Chemicals Market growth#MEA Water & Waste Water Treatment Chemicals Market size#MEA Water & Waste Water Treatment Chemicals Market industry

0 notes

Text

Soda Ash Market Forecast : Growth Trends And Future Outlook

Soda ash, or sodium carbonate (Na₂CO₃), is a crucial raw material for various industrial applications, including glass manufacturing, detergents, chemicals, and water treatment. With a market value exceeding $20 billion in 2024, soda ash demand is poised for steady growth, fueled by urbanization, industrial expansion, and environmental sustainability initiatives. This forecast explores the future trajectory of the soda ash market, highlighting key trends, drivers, challenges, and regional dynamics shaping its growth through 2030.

Market Size and Growth Projections

The global soda ash market is expected to grow at a compound annual growth rate (CAGR) of approximately 4% from 2024 to 2030, reaching a valuation of nearly $30 billion by the end of the forecast period. Several factors, including the rapid expansion of the construction and automotive industries, increasing renewable energy investments, and rising demand for eco-friendly cleaning agents, are driving this growth.

Key Drivers of Growth

Increasing Demand in Glass Manufacturing Glass production remains the largest consumer of soda ash, accounting for over 50% of global consumption. The growing need for flat glass in the construction and automotive sectors and specialty glass for solar panels is a major growth driver. The global push for renewable energy, particularly solar power, is expected to sustain high demand for soda ash in photovoltaic glass manufacturing.

Urbanization and Infrastructure Development Rapid urbanization in developing economies like China, India, and Southeast Asia has spurred construction activities, increasing the need for soda ash in building materials and glass facades. This trend is likely to persist as these regions invest in smart cities and infrastructure development.

Sustainability and Eco-Friendly Products As consumers and industries prioritize sustainability, soda ash is increasingly used in phosphate-free detergents and water treatment processes. Additionally, natural soda ash, derived from trona ore, is gaining popularity due to its lower carbon footprint compared to synthetic production methods.

Chemical and Industrial Applications Soda ash serves as a vital input in producing sodium bicarbonate, dyes, and other chemical intermediates. Its use in water treatment, pulp and paper manufacturing, and metallurgy is expected to grow in line with industrial expansion.

Challenges and Restraints

Environmental Concerns Synthetic soda ash production, primarily through the Solvay process, is energy-intensive and contributes to carbon emissions. Stricter environmental regulations may impose additional costs on producers, challenging the market’s growth.

Fluctuating Raw Material Prices Volatility in raw material and energy costs can significantly impact profit margins, particularly for synthetic soda ash manufacturers. This underscores the need for cost-efficient production technologies.

Geopolitical Instabilities Soda ash production and trade are sensitive to geopolitical factors, especially in key regions like the U.S., China, and Europe. Trade restrictions, tariffs, and political instability can disrupt supply chains.

Regional Market Outlook

Asia-Pacific Asia-Pacific is the largest and fastest-growing market for soda ash, driven by robust demand in China and India. Key applications include glass production, detergents, and chemicals. The region’s emphasis on infrastructure development and renewable energy adoption will continue to drive demand.

North America The U.S. dominates soda ash production in North America, leveraging vast trona reserves in Wyoming. Natural soda ash from this region is increasingly exported to markets in Asia and Europe due to its cost efficiency and environmental benefits.

Europe Europe’s soda ash market is characterized by stringent environmental regulations and high demand for eco-friendly products. The region’s focus on renewable energy and advanced glass manufacturing technologies makes it a significant contributor to global demand.

Middle East & Africa The growing construction sector and investments in industrial projects are expected to boost soda ash demand in this region, particularly in glass and water treatment applications.

Emerging Trends

Natural Soda Ash Adoption The shift toward environmentally sustainable practices has increased the adoption of natural soda ash, reducing the reliance on synthetic production.

Technological Innovations Innovations in soda ash production processes aim to reduce energy consumption and emissions, aligning with global sustainability goals.

Expanding Applications Emerging uses of soda ash in lithium-ion batteries, pharmaceuticals, and advanced materials could open new avenues for market growth.

Conclusion

The soda ash market is poised for robust growth over the next decade, supported by industrial expansion, sustainability initiatives, and rising demand for glass in renewable energy applications. While challenges such as environmental concerns and cost fluctuations persist, advancements in production technologies and a focus on natural soda ash provide significant opportunities. Stakeholders across the value chain must leverage these trends to capitalize on the evolving market landscape

Get Free Sample and ToC : :https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NDg5&RD=Soda-Ash-Market-Report

0 notes