#UV-Curable Resin Market Industry

Explore tagged Tumblr posts

Text

Photoinitiator Market Industry Leaders Size & Share Outlook & New Revenue Pockets

Growing applications and environmental restrictions on VOCs to drive the acceptance of photoinitiators in the market

The global photoinitiators market size was USD 1.6 billion in 2021 and is expected to reach USD 2.6 billion by 2026, projecting a CAGR of 10.3% between 2021 and 2026. photoinitiators are increasingly used in the adhesive, ink, coating and other end-use industries. The increasing demand of coating industry drives the demand for photoinitiators. However, the outbreak of COVID-19 has created ripples across various application industries leading to reduced demand for photoinitiators. Due to the lockdown scenario in most of the world, the demand for photoinitiators from adhesive, coating, ink and other industries have declined sharply in 2020.

Download PDF Brochure at https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=17512915

As the world is getting ready to open up its economies and reduce restrictions from June 2021, the market will take an upward turn. The photoinitiators market is expected to witness high growth in 2021 owing to increasing applications, technological advancements, and growing demand in APAC. Photoinitiators are largely used in the coating applications by the wood, furniture, and architectural end-use industries apart from adhesive and printing ink industries. This market growth is backed by growing environmental concerns and increasingly stringent regulations.

The increasing number of restrictions on VOCs across the globe is pushing the industry to search for an alternative. Photoinitiators proved to be a safer and economical substitute. It enhances the surface finish as well as the shelf life of the product. Photoinitiators have been developed so that they are safe even for use in the dental industry. Many food safety compatible photoinitiators are also developed. All these photoinitiators are eco-friendly and have virtually no impact on human health.

UV curable resins market has developed high growth prospects in 3D printing, digital printing, packaging, barrier films, and printed circuit applications. Automotive, architecture, medical, and several other industries are using 3D printing solutions to improve their design and manufacturing strategies. The 3D printing technology is expected to advance further in printers and printing methods, materials used in 3D printing, and software for designing and printing. All this directly affects the demand of the photoinitiators market.

Photoinitiators are the key to innovation in coatings, which have influenced the major trends in the coatings industry. The coating industry is largely influenced by stringent regulations set by authorities, including the European Union (EU), for reducing the VOC content from coatings, adhesives and inks. Consequently, the demand has shifted from solvent-borne UV to environmentally friendly products, such as waterborne UV using photoinitiators.

Request For FREE Sample of Report at https://www.marketsandmarkets.com/requestsampleNew.asp?id=17512915

The demand for waterborne photoinitiators has witnessed substantial growth in the past five years owing to rapid technological developments. In addition to eliminating solvent emissions, photoinitiator-based UV curing formulations provide improved mechanical characteristics, and increased production efficiency, particularly, in the spray application. These benefits encourage end users to adopt photoinitiator-based UV technology for new applications.

0 notes

Text

Packaging Coatings Market: Trends, Innovations, and Growth Opportunities

The global packaging coatings market is experiencing a remarkable transformation, fueled by the ever-changing demands of the packaging industry. Coatings are not just a functional aspect of packaging; they are pivotal in enhancing the visual appeal, durability, and sustainability of packaged products. This article explores the significant trends, innovations, and growth factors that are driving the packaging coatings industry, with a focus on the printing process and its impact on various end-user sectors.

An Overview of the Packaging Coatings Market

Packaging coatings, an essential component in the packaging industry, serve to protect, decorate, and add unique functional qualities to materials like paper, plastic, metal, and glass. By safeguarding products from moisture, light, air, and contamination, these coatings ensure that products reach consumers in pristine condition. They also play a vital role in making packaging more appealing, thus increasing the perceived value of the product inside.

The packaging coatings market is projected to grow from USD 4.21 billion in 2024 to USD 5.37 billion by 2029, at a CAGR of 5.0% between 2024 and 2029. North America is one of the largest markets for packaging coatings. The demand for different resin used in packaging coatings is experiencing significant growth across various industries, including food & beverage, industrial goods, medical & pharma, caps & closures, and more.

Key Trends Shaping the Packaging Coatings Market

1. Sustainability and Eco-Friendly Solutions

In recent years, there has been a noticeable shift toward sustainability within the packaging sector. Consumers are becoming more environmentally conscious, and businesses are responding by opting for packaging coatings that are eco-friendly. Traditional solvent-based coatings, which have a higher environmental footprint, are gradually being replaced with water-based and UV-curable coatings that emit fewer volatile organic compounds (VOCs).

These eco-friendly coatings are not only better for the environment but are also helping businesses comply with increasingly stringent regulations regarding waste management and recycling. With innovations in biodegradable and recyclable coatings, packaging manufacturers can offer products that appeal to the growing eco-conscious consumer base without compromising on performance.

2. The Growth of E-Commerce and Digital Printing

The rise of e-commerce has significantly altered the dynamics of the packaging industry. Packaging now needs to be more robust to handle the logistics of online retail, but also stylish enough to create a memorable unboxing experience. This has spurred an increased demand for durable coatings that provide additional protection against physical stress during transit.

Moreover, digital printing has revolutionized the way packaging is designed and produced. It offers benefits such as reduced setup costs, faster production times, and the ability to create custom packaging for specific markets or product batches. Coatings designed for digital printing are essential for ensuring smooth surfaces that enhance color reproduction and maintain the high resolution of digital designs. These coatings allow brands to maintain visual appeal while optimizing the efficiency of the production process, especially in sectors like food and beverage, cosmetics, and personal care.

3. The Demand for Functional Coatings

Beyond aesthetics, the functionality of packaging coatings has become more critical. Functional coatings that offer specific benefits—such as moisture resistance, UV protection, and antimicrobial properties—are increasingly in demand. These coatings help extend the shelf life of products and prevent degradation from environmental factors.

For example, anti-fog coatings, which prevent condensation on packaging, are becoming essential for fresh produce packaging. Similarly, antimicrobial coatings, which inhibit the growth of bacteria on surfaces, are gaining traction in the food packaging sector, helping to ensure food safety and quality. The growing demand for such coatings reflects the need for packaging that is not only visually appealing but also protective and functional.

Key End-User Industries Driving the Packaging Coatings Market

1. Food and Beverage Industry

The food and beverage industry is the largest consumer of packaging coatings, and for good reason. Food packaging must withstand a range of environmental conditions, from refrigeration to high temperatures, all while maintaining the integrity of the product inside. Coatings that provide moisture resistance, grease resistance, and temperature stability are essential in this sector.

In addition, there is a growing trend toward sustainable packaging in the food industry. Coatings that are biodegradable or made from renewable resources are increasingly sought after as brands work to meet consumer demand for more eco-friendly options. Packaging that is visually appealing can also contribute to a brand's image, making it vital to incorporate coatings that help products stand out on crowded store shelves.

2. Pharmaceutical and Healthcare Packaging

In the pharmaceutical and healthcare sectors, packaging coatings are crucial for safeguarding the effectiveness of medicines and medical devices. These coatings are designed to provide a barrier against moisture, oxygen, and light—factors that can compromise the potency of pharmaceuticals.

Packaging coatings in this sector must meet stringent regulatory standards to ensure product safety and reliability. For example, child-resistant and tamper-evident coatings are critical to maintaining the safety of over-the-counter and prescription medicines. As the pharmaceutical industry continues to evolve with more complex formulations, coatings that offer additional protection and functional benefits are becoming increasingly important.

3. Cosmetics and Personal Care

Cosmetics and personal care products rely heavily on packaging to convey their brand image and attract consumers. In this highly competitive market, the right packaging can make all the difference. Coatings used in cosmetics packaging are often designed to create a glossy or matte finish, offering a luxurious appearance that appeals to consumers. Additionally, these coatings protect the products from environmental elements like UV rays, which can degrade product quality over time.

Beyond aesthetics, these coatings often need to offer additional protection, such as resistance to smudging, scratching, or fading, ensuring the packaging remains intact and attractive throughout the product's life cycle.

Challenges and Opportunities in the Packaging Coatings Market

While the packaging coatings market presents significant growth opportunities, it is not without its challenges. Rising raw material costs, evolving regulatory standards, and the need for continuous innovation to meet consumer demands are some of the hurdles that businesses face. However, these challenges also present opportunities for market players to innovate and create more efficient and sustainable solutions.

New technologies, such as smart coatings and coatings that incorporate advanced functionalities like anti-counterfeiting features, are emerging to address these challenges. These innovations not only open new avenues for business growth but also help brands differentiate themselves in an increasingly competitive market.

To know more Download PDF Brochure :

The packaging coatings market is poised for strong growth as businesses continue to seek innovative solutions that meet the ever-evolving needs of the consumer. With a growing emphasis on sustainability, functionality, and aesthetics, packaging coatings are becoming more than just a protective layer—they are a crucial part of the packaging process. As industries such as food and beverage, pharmaceuticals, and cosmetics embrace these changes, the demand for high-performance coatings will continue to rise, providing ample opportunities for manufacturers and end-users alike to innovate and thrive

#Packaging Coatings#Sustainable Packaging#Eco-Friendly Coatings#Digital Printing#Food Packaging#Pharmaceutical Packaging#Packaging Innovation

0 notes

Text

0 notes

Text

Low Temperature Coatings Market — Forecast(2024–2030)

Low temperature coating is widely used to apply coatings to valves, pipes, fittings and welds. They are mostly used in cold temperature conditions as they have the ability to cure down to 0°C. The increase in energy savings due to reduction in cure temperatures is boosting the growth of the market. The Low Temperature Coatings Market is experiencing a significant uptick due to the increasing demand for energy-efficient coatings. As sustainability becomes a focal point across industries, there’s a surge in the adoption of low-temperature cure coatings. These coatings not only reduce energy consumption during the curing process but also contribute to lowering greenhouse gas emissions.

Industries such as construction, automotive, and aerospace are embracing this trend, driven by both environmental concerns and the need for cost-effective, energy-efficient coating solutions. A notable trend in the Low Temperature Coatings Market is the continuous evolution of low-temperature curing techniques. Manufacturers are investing in research and development to innovate coating processes that can cure effectively at lower temperatures, reducing energy requirements and enhancing application flexibility. Advanced formulations, such as UV-curable low-temperature coatings, are gaining traction for their ability to cure rapidly with minimal heat, opening new possibilities in coating sensitive substrates and expanding the range of applications in various industries.

Request Sample

Report Coverage

The report: “Low Temperature Coatings Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the low temperature coatings industry.

By Coating: Powder Based, Liquid Based.

By Chemistry: Polyester, Epoxy, Polyurethane, Acrylic resin, and Others.

By Application: Concrete, Portable water storage tanks, Fittings, Steel, Pipes, Valves, Wood, wheels, Grills, Bumpers, Roof racks, Exterior and Interior trims, Construction and Others.

By End Use: Automotive, Appliances, Furniture, Industrial, Heavy-Duty Equipment’s, and Others

By Geography: North America, South America, Europe, APAC, and RoW.

Inquiry Before Buying

Key Takeaways

Asia-Pacific dominates the low temperature coatings Market owing to increasing demand from growing automotive industry in the region.

The use of environment friendly coating is driving the growth of the low temperature coatings market.

The longer and costlier drying and curing for large parts is hindering the growth of the low temperature coatings market.

By Chemistry — Segment Analysis

Acrylic segment held the largest share in the low temperature coatings market in 2023 as it is widely used in automotive industry. Acrylic formulations provide an ideal solution combining balanced performance, good weather resistance, and advantageous processing. Acrylic based coatings are tremendously versatile. They have low-cost and a broad performance range, from ultra-removable to ultra-high durability depending on the formulation. Due to this benefit, the application of low temperature coatings based on acrylics is increasing greatly in heavy-duty equipment’s. Epoxy segment is the second largest segment in low temperature coating market. Epoxy coatings are widely used due to their exceptional chemical resistance, low porosity, durability, and bond strength. Epoxy coating films are strongly resistant to most chemicals and make excellent anticorrosion coatings. They are one of the principal materials used to control corrosion in the cold environment.

Buy Now

About IndustryARC™: IndustryARC primarily focuses on Cutting Edge Technologies and Newer Applications of the Market. Our Custom Research Services are designed to provide insights on the constant flux in the global demand-supply gap of markets. Our strong analyst team enables us to meet the client research needs at a very quick speed with a variety of options for your business. We look forward to support the client to be able to better address customer needs; stay ahead in the market; become the top competitor and get real-time recommendations on business strategies and deals. Contact Us: https://tinyurl.com/yk8khvpa Website URL: https://www.industryarc.com/

0 notes

Text

"UV Curable Resins Market Analysis: Key Trends and Projections 2024-2033"

UV curable resins and formulated products are revolutionizing the manufacturing landscape with their rapid curing times and minimal environmental impact. These cutting-edge materials harden instantly under ultraviolet light, making them ideal for applications ranging from 3D printing to protective coatings and electronics. With their ability to reduce energy consumption, improve production efficiency, and eliminate harmful solvents, UV curable resins are paving the way for more sustainable and high-performance products across industries. As the demand for eco-friendly and efficient manufacturing processes grows, these resins are setting new standards for innovation and sustainability.

#UVCurableResins #FastCuring #EcoFriendlyMaterials #3DPrinting #AdvancedManufacturing #SustainableTech #RapidPrototyping #ProtectiveCoatings #ElectronicsInnovation #GreenManufacturing #EnergyEfficiency #HighPerformanceMaterials #UVTechnology #IndustrialInnovation #SustainableSolutions

0 notes

Text

"The Curing Adhesives Boom: Driven by Innovation or Just Temporary Market Trends?"

Introduction

Curing adhesives, essential in various industrial and consumer applications, are designed to bond surfaces through chemical reactions that set or cure the adhesive. These adhesives are widely used in automotive, aerospace, electronics, construction, and consumer goods industries due to their superior bonding strength and durability. As industries evolve and seek more efficient and reliable bonding solutions, the curing adhesives market is experiencing significant growth. Advances in technology and increasing demand for high-performance adhesives drive market dynamics, making it a critical area of focus for manufacturers and suppliers.

Market Dynamics

Drivers:

Technological Advancements: Innovations in curing adhesives, such as UV-curable, heat-curable, and moisture-curable formulations, are enhancing performance and expanding application possibilities. These advancements improve curing speed, bond strength, and versatility, driving market growth.

Growth in End-Use Industries: The expansion of automotive, aerospace, and electronics industries boosts demand for high-performance curing adhesives. These sectors require reliable bonding solutions to meet rigorous performance standards and enhance product longevity.

Demand for Energy-Efficient Solutions: The increasing focus on energy efficiency and sustainability drives demand for adhesives that offer improved performance with lower environmental impact. Curing adhesives that meet these criteria are becoming more popular.

Challenges:

Raw Material Costs: Fluctuations in the prices of raw materials, such as resins and additives, can impact the production costs of curing adhesives. These cost variations can affect pricing strategies and profit margins for manufacturers.

Regulatory Compliance: Stricter regulations concerning the environmental and health impacts of adhesives pose challenges for manufacturers. Compliance with these regulations requires investment in R&D and modifications to existing products and processes.

Competition and Market Saturation: The curing adhesives market is highly competitive, with numerous players offering a wide range of products. This competition leads to price pressures and requires companies to differentiate themselves through innovation and quality.

Opportunities:

Emerging Markets: Growing industrialization in regions such as Asia-Pacific and Latin America presents opportunities for market expansion. Increasing demand for high-performance adhesives in these regions offers significant growth potential.

Sustainable Product Development: There is a rising demand for eco-friendly and low-emission curing adhesives. Developing sustainable products that meet environmental regulations and consumer preferences can provide a competitive edge and open new market segments.

Sample Pages of Report: https://www.infiniumglobalresearch.com/reports/sample-request/1025

Regional Analysis

North America: The North American market is driven by advanced manufacturing and technology sectors. The U.S. and Canada have a high demand for curing adhesives in automotive, aerospace, and electronics industries, supported by ongoing technological advancements and industry growth.

Europe: Europe is a significant market for curing adhesives, with a strong focus on high-performance applications in automotive and aerospace sectors. Stringent environmental regulations are pushing the development of eco-friendly and low-emission adhesives.

Asia-Pacific: The Asia-Pacific region is experiencing rapid growth due to expanding industrial activities and increased demand for consumer goods. Countries like China, India, and Japan are major contributors to market growth, driven by rising industrialization and technological advancements.

Latin America & Middle East & Africa: These regions are seeing gradual growth in demand for curing adhesives, supported by industrial development and increasing manufacturing activities. Market expansion in these regions is driven by the growing need for high-performance adhesives in various applications.

Market Segmentation

By Type: The market is segmented into UV-curable, heat-curable, moisture-curable, and others. UV-curable adhesives are gaining popularity due to their fast curing times and high performance.

By Application: Key applications include automotive, aerospace, electronics, construction, and consumer goods. Automotive and electronics are major segments, driven by the need for reliable and high-strength bonding solutions.

By End-User: The market serves various end-users, including industrial manufacturers, electronics producers, construction companies, and consumer product manufacturers.

By Region: Regional segmentation includes North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, each with distinct market dynamics and growth drivers.

Competitive Landscape

Market Share of Large Players: Major players in the curing adhesives market, such as 3M, Henkel, Sika, and H.B. Fuller, hold significant market share due to their extensive product portfolios, established brand presence, and global distribution networks.

Price Control by Big Players: Large companies often influence market pricing through their economies of scale and strategic sourcing. They can set industry standards and pricing trends due to their substantial market presence.

Challenges from Smaller Companies: Small and mid-sized companies challenge larger players by focusing on niche markets, innovative formulations, and cost-effective solutions. They often target specific segments with specialized products that cater to emerging needs.

Key Players:

3M

Henkel AG & Co. KGaA

Sika AG

H.B. Fuller Company

ITW Performance Polymers

Arkema Group

Jowat SE

Report Overview: https://www.infiniumglobalresearch.com/reports/global-curing-adhesives-market

Future Outlook

New Product Development: Innovation is crucial for companies to stay competitive in the curing adhesives market. Developing new products with enhanced performance characteristics, such as faster curing times, higher bond strength, and improved environmental sustainability, helps companies meet evolving market demands and maintain a competitive edge.

Sustainable Products: The demand for eco-friendly and low-emission adhesives is increasing as consumers and industries focus on sustainability. Companies that invest in developing sustainable curing adhesives that meet environmental standards will likely attract a growing segment of environmentally conscious customers and gain a competitive advantage.

Conclusion

The curing adhesives market is characterized by rapid technological advancements and growing demand across various industries. While challenges such as raw material costs and regulatory compliance persist, opportunities in emerging markets and sustainable product development offer pathways for growth. Companies that innovate and adapt to market trends will be well-positioned for success in this dynamic industry.

0 notes

Text

The global demand for paints & coatings was valued at USD 190512.5 Million in 2023 and is anticipated to reach USD 266501.5 Million in 2032, emerging at a CAGR of 3.8% between 2024 and 2032.The global paints and coatings market has experienced significant growth over the past few decades, driven by an increase in urbanization, infrastructure development, and industrialization. This article delves into the current state of the market, key trends, and future prospects, providing a comprehensive overview for industry stakeholders and enthusiasts.

Browse the full report at https://www.credenceresearch.com/report/paints-and-coatings-market

Market Overview

The paints and coatings market can be broadly segmented into decorative and industrial categories. Decorative paints and coatings are primarily used in residential, commercial, and institutional buildings, while industrial coatings are applied to products during manufacturing for protective and aesthetic purposes. Both segments are crucial, but they serve different end-users and applications.

The global market was valued at approximately USD 160 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of around 5% from 2024 to 2030. The Asia-Pacific region dominates the market, accounting for over 40% of global consumption, followed by North America and Europe. This dominance is attributed to rapid urbanization and industrial activities in emerging economies such as China and India.

Key Trends and Drivers

1. Urbanization and Infrastructure Development: As more people move to urban areas, the demand for residential and commercial buildings increases, driving the need for decorative paints and coatings. Governments and private sectors are investing heavily in infrastructure projects, further boosting market growth.

2. Industrial Growth: Industrial coatings are essential in various sectors, including automotive, aerospace, and marine. The growth of these industries, particularly in developing countries, is a significant driver for the industrial coatings segment.

3. Technological Advancements: Innovation in paint formulations, such as waterborne, powder, and UV-curable coatings, has enhanced product performance and environmental compliance. These advancements are attracting consumers and industries looking for sustainable and efficient solutions.

4. Environmental Regulations: Stringent regulations regarding volatile organic compounds (VOCs) emissions have led to the development of eco-friendly paints and coatings. Manufacturers are focusing on producing low-VOC and VOC-free products to comply with environmental standards and meet consumer demand for green products.

5. Aesthetic Appeal: Increasing consumer preference for aesthetically pleasing and personalized spaces drives demand for decorative paints. Innovations in color palettes, textures, and finishes are enabling consumers to achieve unique looks for their spaces.

Challenges

Despite the positive outlook, the paints and coatings market faces several challenges:

1. Raw Material Price Volatility: The cost of raw materials such as titanium dioxide, resins, and pigments can be volatile, impacting profit margins for manufacturers.

2. Environmental Concerns: While advancements have been made, the industry still faces challenges in completely eliminating harmful chemicals and achieving full sustainability.

3. Competition: The market is highly competitive, with numerous players ranging from large multinational corporations to small and medium-sized enterprises. This competition can lead to price wars and reduced profitability.

Future Prospects

The future of the paints and coatings market looks promising, with several factors likely to drive growth:

1. Sustainability: As environmental concerns continue to grow, there will be a greater emphasis on developing sustainable products. Innovations in bio-based and waterborne coatings are expected to play a crucial role in this transformation.

2. Smart Coatings: The development of smart coatings with functionalities such as self-cleaning, anti-microbial, and anti-corrosive properties is gaining traction. These advanced coatings offer added value and are likely to see increased adoption in various industries.

3. Emerging Markets: Growth in emerging markets, particularly in Asia, Latin America, and Africa, presents significant opportunities. Rapid urbanization and industrialization in these regions will drive demand for both decorative and industrial coatings.

4. Digitalization: The integration of digital technologies in the manufacturing process, such as automation and the Internet of Things (IoT), is expected to enhance efficiency and product quality. Digital tools are also improving customer engagement and providing personalized solutions.

Key Players

AkzoNobel (Netherlands)

Kansai Nerolac Paints Ltd (India)

Kwality Paints & Coatings Pvt. Ltd (KPCPL) (India)

Kansai Paint Co. Ltd (Japan)

The Sherwin-Williams Company (U.S.)

NIPSEA GROUP (Singapore)

Nippon Paint Holdings Co. Ltd (Japan)

Jotun (Norway)

Axalta Coating Systems (U.S.)

TIKKURILA OYJ (Finland)

Dunn-Edwards Corporation (U.S.)

Asian Paints (India)

RPM International Inc. (U.S.)

PPG Industries Inc. (U.S.)

Others

Segmentation

By Product Type

Architectural/Decorative Coatings

Interior Paints

Exterior Paints

Wood Coatings

Metal Coatings

Industrial Coatings

Automotive Coatings

Marine Coatings

Industrial Machinery Coatings

Protective Coatings

Specialty Coatings

High-Performance Coatings

Fire-Resistant Coatings

Anti-Corrosion Coatings

Others

By Technology

Waterborne Coatings

Solventborne Coatings

Powder Coatings

UV-Cured Coatings

Others

By Resin Type

Acrylic

Alkyd

Polyurethane

Epoxy

Polyester

Others

By End-User

Construction

Automotive

Aerospace

Oil and Gas

Industrial Manufacturing

Wood and Furniture

Packaging

Consumer Goods

Others

By Distribution Channel

Direct Sales

Distributor Sales

Online Retail

By Application Method

Spray Coating

Brush/Roller Coating

Dip Coating

Electrostatic Coating

Others

By Region

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Epson demonstrates label press concept

Epson showed off a concept label press on a corner of its stand at drupa. The new machine is essentially a much-improved version of its SurePress L4000 series, which all use an aqueous inkset, with both better image quality and higher productivity.

The press uses a new version of Epson’s water-based resin ink technology. As with the existing machines, the Surepress Concept uses a six-color resin inkset. But Epson has separated some components out of the ink. Thus there’s a new optimizer liquid, which is jetted just ahead of the colors, to better control the placement of the dots on the media. This is followed by the colors and then an overprint, which is said to aid with the drying. All of these fluids are water-based.

Most digital label press manufacturers are working to develop machines capable of printing with water-based inks, which is partly because water is seen to be a more environmentally friendly base than UV-curable ink. But it’s mainly because water-based inks have a better chance of being certified as safe for indirect food contact, thereby expanding the applications the press can handle from labels to also include a wider range of packaging, including pouches. In that regard, Epson is ahead of most of the other players, having spent years developing its AQ water-based resin inks.

However, the drawback to Epson’s approach is that it is not a continuous print system, which drastically slows down the production speed. Instead of the roll advancing continuously, it pauses to print one frame at a time with multiple passes. This is becoming an increasing issue for Epson as inkjet label presses are becoming faster, with most now able to reach 70 or 80 mpm, and some up to 100 mpm. In contrast, the current SurePress L4733 is limited to a maximum speed of 8.2 mpm.

So the main advantage of this concept model is a jump in speed to around 13 mpm, which Epson might yet manage to improve on since this press is still a work in progress. This improved speed is partly down to the use of a new printhead. Epson was a little coy about exactly which printhead it’s using other than to hint that it might be a variation on Epson’s new D3000 heads. It’s not unusual for Epson to adapt some of its heads for its own printers.

It prints at 1200 x 1200 dpi resolution, which is an improvement over the existing 720 x 1440. The concept press still prints one frame at a time but in this case, the page-wide array makes just one pass over the length of the frame and then moves on. Marc Tinkler, head of product marketing for the commercial and industrial division at Epson Europe, says that the existing systems use multiple passes, adding, “So the quality is better because its single pass so less chance to get satellites and so on.”

The new head has also allowed Epson to improve its nozzle verification technology or NVT. On the existing models, the nozzles are checked during cleaning or at the start of a job. But for this new model the nozzles are continuously monitored in real-time Tinkler adds, “And it will compensate if a nozzle is not firing. You don’t have to stop the press, it just happens in the background.”

Tinkler told me that the demonstrations at Drupa had been well attended, noting, “A lot of people seem quite excited that we have moved forward with our water-based ink development.”

You can find further details on Epson’s existing label presses at epson.co.uk, but not the new machine since that is not a production model.

0 notes

Text

0 notes

Text

3D Printing Extrusion Materials Market: Exploring UV-Curable Resins for Rapid Prototyping

3D Printing Extrusion Materials is Booming on the Back of Growing Adoption of Additive Manufacturing

The global 3D printing extrusion materials market is experiencing significant growth driven by rapid developments in additive manufacturing technology. 3D printing extrusion materials such as photopolymers, filaments, and pellets offer advantages including high dimensional accuracy, lightweight and durable designs, and cost-effective production of complex geometries. The ability of 3D printing extrusion materials to produce intricate functional parts without tooling or fixtures has boosted their use across various end-use industries including aerospace, automotive, healthcare, consumer goods, and construction. The Global 3D Printing Extrusion Materials Market is estimated to be valued at US$ 12.77 Billion in 2024 and is expected to exhibit a CAGR of 19% over the forecast period from 2023 to 2030.

3D printing extrusion materials enable mass customization and on-demand manufacturing, which has increased their demand for prototyping and production applications. Continuous technological advancements focused on developing enhanced material properties such as strength, durability, and temperature resistance are further driving the market. Key Takeaways Key players operating in the 3D printing extrusion materials are 3D Systems Corporation, Stratasys Ltd., Materialise NV, EOS GmbH, Arkema S.A., SABIC, Evonik Industries AG, DuPont de Nemours Inc., BASF SE, Dow Chemical Company, HP Inc., Royal DSM N.V., EnvisionTEC GmbH, CRP Group., Carbon, Inc. These companies are focusing on new product launches and capacity expansion strategies to strengthen their market position. The growing demand for 3D printed parts and components across various industries is a major factor propelling the 3D printing extrusion materials market. Industries are increasingly adopting 3D printing for rapid prototyping, tooling, and production applications due to advantages such as low costs and reduced turnaround times. The market is also witnessing increased global expansion as players are enhancing their distribution networks across emerging economies. The rising investments in additive manufacturing technologies and growing R&D activities globally present significant growth opportunities for 3D printing extrusion materials over the forecast period. Market Key Trends Particle size reduction and new material formulations are notable trends being observed in the 3D printing extrusion materials market. Market players are focusing on further miniaturization of particle sizes to enable the production of micro-scale features and complex geometries. Continuous innovation in specialty polymer materials including carbon-reinforced, flame-retardant, and biocompatible varieties are expanding the application horizons for 3D printing extrusion materials. The market is also witnessing new opportunities through the development of hybrid and composite materials with blended properties. With the rising popularity of additive manufacturing, the demand for high-performance 3D printing extrusion materials is expected to exhibit strong growth over the next decade.

Porter's Analysis Threat of new entrants: New companies find it difficult to enter the market due to the significant capital investments required for manufacturing 3D printing extrusion materials.

Bargaining power of buyers: Buyers have moderate bargaining power due to the availability of alternatives and substitutes.

Bargaining power of suppliers: Suppliers have moderate bargaining power due to the availability of options for buyers and dominance of few players.

Threat of new substitutes: threat of substitutes is moderate with emerging new alternative 3D printing technologies.

Competitive rivalry: The market is dominated by few major players and there is intense competition. Over the years, North America has been dominating the 3D printing extrusion materials market owing to increasing demand from industries such as aerospace & defense and healthcare. USA holds a significant share in North America. The aerospace & defense industry in USA is increasingly utilizing 3D printing for lightweight components and complex parts for aircraft. The region has witnessed high investments in R&D and new product launches by key players such as 3D Systems Corporation and Stratasys, Ltd. Asia Pacific region is expected to grow at the highest CAGR during the forecast period owing to growing demand from application industries such as consumer goods and foundry in countries such as China and India. Foundry application offers vast opportunities for 3D printing extrusion materials market in Asia Pacific. Expanding manufacturing sector, easy availability of skilled labor force, and government initiatives are promoting adoption of advanced technologies including 3D printing.

#3D Printing Extrusion Materials Market gowth#3D Printing Extrusion Materials Market share#3D Printing Extrusion Materials Market Trend

0 notes

Text

Wood Coatings Market: Trends & Opportunities 2024-2032

According to Triton Market Research, the Global Wood Coatings Market report is sectioned by Resin Type (Polyurethane, Nitrocellulose, Acrylic, Other Resin Types), Technology (Water-Borne, Powder Coatings, UV-cured, Solvent-Borne), Application (Furniture and Fixture, Cabinet, Doors and Window, Flooring, Deck), and Regional Outlook (Middle East and Africa, Europe, Asia-Pacific, North America, Latin America).

The report highlights the Market Summary, Industry Outlook, Porter’s Five Forces Analysis, Market Maturity Analysis, Supply Chain Analysis, Regulatory Framework, Key Buying Impact Analysis, Key Market Strategies, Market Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology and scope, Global Market Size, Forecasts & Analysis (2024-2032).

Based on Triton’s research report, the global market for wood coatings is set to advance in value at a CAGR of 4.02% during the forecast period 2024-2032.

Wood coating serves a dual purpose: safeguarding and enhancing wood or wood-based structures. By shielding wooden surfaces, it bolsters their durability and utility. Simultaneously, it elevates their aesthetic appeal, contributing to effective product promotion.

Factors such as personalized solutions for flooring and furniture, the emergence of smart coating technology, and improved coating performance via nanotechnology, creates lucrative opportunities for the wood coatings market globally. Smart coatings offer an array of functionalities, such as self-healing, anti-fouling, and antimicrobial properties, enhancing the durability and performance of wood surfaces. This extends the lifespan of wood products and reduces maintenance costs. Moreover, smart coatings contribute to sustainability efforts by minimizing the need for frequent reapplications and replacements, thus reducing waste. With increasing environmental concerns and a growing emphasis on eco-friendly solutions, the adoption of smart coatings is set to escalate, driving market growth and innovation.

However, fluctuating raw material costs and competition from composite materials limit the overall development of the wood coatings market worldwide.

The Asia-Pacific region is set for the fastest growth in the coming years. One key driver is the region’s growing construction and furniture industries, particularly in countries like China, India, and Vietnam, where urbanization and rising disposable incomes have fueled demand for high-quality wood products. Additionally, there is a growing awareness and emphasis on environmental sustainability, leading to an increasing preference for eco-friendly coatings with low volatile organic compound (VOC) content. Moreover, technological advancements in coatings formulations, such as the development of water-based and UV-curable coatings, are gaining traction due to their superior performance and reduced environmental impact.

The renowned companies in the wood coatings market are Nippon Paint Holdings Co Ltd, Diamond Paints, PPG Industries Inc, Asian Paints, RPM International Inc, The Sherwin-Williams Company, BASF SE, Akzo Nobel NV, Axalta Coating Systems LLC, and Kansai Helios.

With evolving consumer preferences and stringent environmental regulations, barriers to entry remain significant, deterring potential newcomers. Established players continually innovate to maintain market share, investing in research and development to offer eco-friendly and high-performance coatings. Intense rivalry among existing competitors fuels pricing pressures and product differentiation strategies, compelling companies to enhance quality and expand distribution networks. Amidst these challenges, strategic alliances and mergers are common, reshaping the competitive landscape and fostering consolidation.

0 notes

Text

The Global Solar Encapsulation Market was valued at USD 5.28 Billion in 2023 and is estimated to reach USD 9.86 Billion by 2033, growing at a CAGR of 6.9 % from 2024 to 2033.

A process where solar cell strings are encapsulated between 2 sheets of encapsulated foil is known as Solar Encapsulation. The main purpose of encapsulation is generally to increase the life of PV installation. For encapsulation, the material has features like flame retardance and corrosion resistance. Materials such as Ethylene Vinyl Acetate, UV Curable resin, and Non-Ethylene Vinyl Acetate are mainly used to laminate solar cells which protect them from vibration and shocks. The use of encapsulation is expanding in various industries such as the building and automotive sectors. Solar Encapsulation has gained enormous popularity in recent years due to its ability of efficiency, durability, good performance, and cost-effectiveness of PV modules. Encapsulation ensures the safe operation of solar PV modules resulting in low maintenance.

The worldwide adoption of solar panels and increasing demand for electricity are becoming the primary factors in driving the market growth.

Economic Impact of Covid-19:

The analysis of the COVID-19 recovery trajectory provides an overview of the main strategies that industries are implementing to respond to and recover from the economic crisis. It also focuses on the post-pandemic and pre-pan\demic era of the Global Solar Encapsulation Market through PEST analysis, SWOT, Quantitative and Qualitative analysis, Attractive analysis, and DROs. Innovations by market players and an increasing number of products will propel the growth of this market.

Trends: Increasing demand for sustainability solutions for the environment is boosting the market.

For reducing carbon footprint there is high demand for environmentally sustainable solutions. A drastic shift toward renewable energy sources is seen due to the depletion of conventional energy and growing concerns about the environment, this creates a demand for solar encapsulation in the forecast years. Moreover, rising awareness of the benefits of renewable sources and their properties such as mechanical resistance, and good insulation are expected to drive the growth of the solar encapsulation market in the coming years.

Moreover, rising awareness of reducing carbon footprint, technological advancement, rapid urbanization, and increasing solar applications for power generation are propelling the Solar encapsulation market to growth.

Key Players:

First Solar

Mitsubishi Chemical Corporation

3M

STR Holdings Inc.

Dow

Dupont

RenewSys India Pvt. Ltd

Jinko Solar

Q CELLS

SunPower Corporation

The Solaria Corporation

Elkem ASA

Wacker Chemie AG

Lucent Clean Energy

Novogenio SI

Hangzhou First PV Material Co. Ltd

DNP Solar

Trosifol

Others

Know More- https://nexbindinsight.com/energy-and-power/global-solar-encapsulation-market-by-type-technology-application-and

0 notes

Text

0 notes

Text

Navigating the Future: Wireless Printer Market Trends, Size, and COVID-19 Impact Analysis (2023-2031)

Introduction:

The global wireless printer market is poised for a transformative journey from 2023 to 2031, marked by significant strides in resin technology, diverse applications, cutting-edge printing technologies, and a resilient response to the COVID-19 pandemic. This article unveils the market's key dimensions, shedding light on its size, share, and the profound impact of the ongoing global health crisis.

Get a free pdf sample of this report:- https://www.accuteresearch.com/request-for-free-sample/11035

Market Overview:

The wireless printer market stands at the crossroads of innovation, with resin types at the forefront of this evolution. Resins, once considered a peripheral factor, are now pivotal in shaping the market's trajectory, influencing printing capabilities, and driving sustainability efforts.

Resin Types:

Witness a paradigm shift as eco-friendly alternatives gain prominence, aligning with global sustainability goals. UV-curable and water-based resins emerge as frontrunners, responding to environmental concerns and reducing volatile organic compound (VOC) emissions.

Applications:

The applications of wireless printers are diversifying across a spectrum of industries, including:

Corporate and home offices

Educational institutions

Healthcare facilities

Manufacturing units

Technology Trends:

Cloud printing emerges as a game-changer, facilitating seamless document processing and enabling printing from virtually anywhere. Artificial intelligence (AI) integration enhances printer efficiency, predicts maintenance needs, and fortifies security features.

End-Use Industries:

The wireless printer market finds resonance across a multitude of industries:

Manufacturing witnesses increased efficiency through wireless printing solutions.

Healthcare adopts advanced printing technologies for precise medical imaging.

Education benefits from the flexibility of wireless printing in diverse learning environments.

Retail experiences streamlined operations through innovative printing solutions.

BFSI (Banking, Financial Services, and Insurance) sectors enhance document security and operational efficiency.

Regional Dynamics:

Asia-Pacific emerges as a key growth hub, fuel by technological advancements and an increasing demand for efficient printing solutions. North America and Europe continue to lead the market, emphasizing sustainability and the rapid adoption of advanced printing technologies.

COVID-19 Impact Analysis:

The COVID-19 pandemic has been a catalyst for change, accelerating the adoption of wireless printing solutions. With remote work becoming the norm, businesses and individuals alike sought efficient, reliable, and secure printing options, resulting in a substantial surge in demand for wireless printers.

Get a customised repot:- https://www.accuteresearch.com/request-for-customization/11035

Future Outlook:

As we look ahead to 2031, the wireless printer market is positioned for sustained growth. Advances in resin technology, coupled with innovative applications and a commitment to sustainability, will continue to propel the market forward.

0 notes

Text

Paints and Coatings Market Size, Share, Growth Rate & Outlook: 2028

Paints and Coatings Market is segmented by Resin (Architectural Resins and Other Resins), Technology (Water-borne, Solvent-borne, Powder Coating, and UV-cured Coating), End-user Industry (Architectural, Automotive, Wood, Protective Coating, General Industrial, Transportation, and Packaging), and region (North America, Europe, Asia-Pacific, Middle East and Africa and South America)

The global paints and coatings market size were valued at USD 162,468.23 million in 2020, and the market is projected to register a CAGR of over 4.1% during the forecast period 2021-2028.

Paint is any pigmented liquid, liquefiable, or solid mastic composition that, after application to a substrate in a thin layer, converts to a solid film. It is most commonly used to protect, color, or provide texture to objects. Paint can be made or purchased in many colors—and in many different types, such as watercolor or synthetic.

The wood, automobile & transportation, and construction sectors all make extensive use of paints and coatings. They are widely employed in the building and construction sector to shield structures from any damage from the outside. Additionally, the product is applied in a number of ways to decorate infrastructure and buildings, both residential and non-residential, as well as industrial machinery, automobiles and boats, industrial wood, and other things.

The rise in demand from end-use industries is a major driver propelling the paints & coatings industry. The residential end-use sector in the APAC region is anticipated to grow throughout the anticipated period, which will enhance demand for paints and coatings.

While customers prefer eco-friendly products, research and development for eco-friendly paints has contributed to increase demand. The use of low-VOC and environmentally friendly technologies, such as water-based coatings, powder coatings, and UV curable coatings, is becoming more and more popular in the paints and coatings sector. Rising feedstock prices and erratic availability are further characteristics of solvent-based paints and coatings. Architectural coatings frequently use water-based coatings.

The largest market segment is the residential end-use industry. The increase in urbanization and population is expected to cause the building and construction sector to expand quickly during the next years. Numerous new homes have been built as a consequence of economic expansion and rising earnings in recent years, and the refurbishment of older homes has contributed to increase demand.

Following the epidemic, there has been a spike in demand for automobiles, which has contributed to an increase in demand for paint and coatings.

The paint and coatings industry's supply chain has been hampered by the COVID 19 outbreak. Businesses are focusing on controlling the orders. Inventory levels and shipments in transit in the midst of the epidemic.

Request Research Sample Pages: https://www.delvens.com/get-free-sample/paints-coatings-market-trends-forecast-till-2028

Regional Analysis

Asia-Pacific dominated the market across the world, with the largest consumption from countries such as China, India, and Japan.

Key Players

The Sherwin-Williams Company

PPG Industries Inc.

Akzo Nobel Nv

Nippon Paint Holdings Co. Ltd

Rpm International Inc.

Tikkurila Oyj

Hempel A/S

Berger Paints India Limited

Shalimar Paints

Masco Corporation

BASF Coatings GmbH

Beckers Group

Dunn-Edwards Corporation

Tiger Coatings Gmbh & Co. Kg

Sacal International Group Ltd.

Diamond Vogel Paint Company

To Grow Your Business Revenue, Make an Inquiry Before Buying at: https://www.delvens.com/Inquire-before-buying/paints-coatings-market-trends-forecast-till-2028

Recent Developments

In December 2020, PPG Industries bought 9% shares of Tikkurila, and it is planning to completely acquire the company by March 2021.

In April 2020, Akzo Nobel NV completed the acquisition of Mauvilac, a paints and coatings firm, to expand its presence in Sub-Saharan Africa.

Reasons to Acquire

Increase your understanding of the market for identifying the best and suitable strategies and decisions on the basis of sales or revenue fluctuations in terms of volume and value, distribution chain analysis, market trends and factors

Gain authentic and granular data access for Paints & Coatings Market so as to understand the trends and the factors involved behind changing market situations

Qualitative and quantitative data utilization to discover arrays of future growth from the market trends of leaders to market visionaries and then recognize the significant areas to compete in the future

In-depth analysis of the changing trends of the market by visualizing the historic and forecast year growth patterns

Purchase the Research Report: https://www.delvens.com/checkout/paints-coatings-market-trends-forecast-till-2028

Report Scope

Increased business activity and increased automotive demand are what are driving the North American paint and coating industry.

Paints & Coatings Market is segmented into resin, technology, end user and region.

On the basis of Resin

Architectural resin

Other resin

On the basis of Technology

Water borne

Solvent borne

Powder solvent

UV cured coating

On the basis of End-User

Architectural

Automotive

Wood

Protective Coating

General Industrial

Transportation

On the basis of Region

Asia Pacific

North America

Europe

South America

Middle East & Africa

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-8638-5055

0 notes

Text

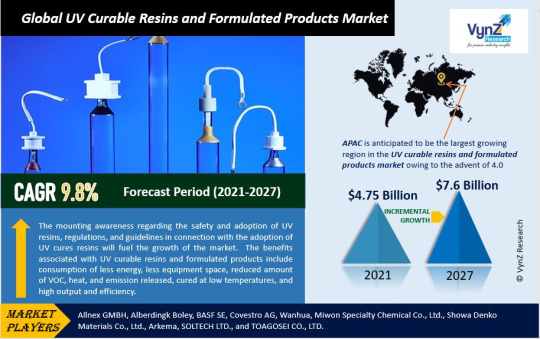

Global UV Curable Resins and Formulated Products Market Size, Share & Trends Analysis Report by 2027

The global UV curable resins and formulated products market is witnessing significant growth, driven by various factors such as increasing demand for eco-friendly and sustainable coatings, rapid industrialization, and technological advancements. According to Vynz Research, a leading market research firm, the market is expected to exhibit strong growth during the forecast period.

Download a Free Sample Copy of the Research Report: https://www.vynzresearch.com/chemicals-materials/uv-curable-resins-and-formulated-products-market/request-sample

Key Market Trends:

Rising Environmental Concerns: With growing environmental awareness and stringent regulations, there is a rising demand for eco-friendly and sustainable coatings. UV curable resins provide a viable solution as they are solvent-free, emit minimal volatile organic compounds (VOCs), and offer faster curing times, reducing energy consumption.

Increasing Industrial Applications: UV curable resins and formulated products find extensive applications across various industries, including automotive, electronics, packaging, and furniture. Their ability to provide superior adhesion, high gloss finish, chemical resistance, and durability makes them suitable for a wide range of applications.

Technological Advancements: Ongoing research and development efforts have led to the development of advanced UV curable resins and formulated products with improved performance characteristics. Innovations such as hybrid resins, water-based UV curable coatings, and bio-based formulations are driving market growth and expanding the application areas.

Market Drivers:

Growing Demand for UV-Cured Inks: The printing industry is witnessing a shift towards UV-cured inks due to their fast curing time, enhanced print quality, and ability to print on various substrates. UV-curable resins are an essential component of these inks, driving the demand for UV-curable resins and formulated products.

Expanding Automotive and Electronics Sectors: The automotive and electronics sectors are experiencing robust growth globally, creating a significant demand for UV-curable coatings, adhesives, and sealants. These products offer excellent resistance to chemicals, weathering, and scratching, thereby extending the lifespan of automotive and electronic components.

Increasing Infrastructure Development: The construction industry is witnessing substantial growth, primarily in developing economies. UV curable coatings are widely used in infrastructure applications, such as flooring, wood coatings, and decorative laminates, due to their quick curing times, durability, and excellent aesthetic appeal.

Market Forecast: The global UV curable resins and formulated products market is poised for significant growth in the coming years. Vynz Research projects a robust CAGR of 9.8% during the forecast period (2021-2027). Factors such as increasing investments in research and development, expanding end-use industries, and the rising popularity of eco-friendly coatings are expected to drive the market.

Moreover, the market is witnessing a surge in strategic collaborations, mergers, and acquisitions, as key players aim to expand their product portfolios and geographical presence. Asia-Pacific is anticipated to dominate the market due to the rapid industrialization in countries like China, India, and Japan.

Conclusion: The global UV curable resins and formulated products market is witnessing strong growth, driven by the increasing demand for eco-friendly coatings, expanding end-use industries, and technological advancements. With their superior performance characteristics and sustainable attributes, UV curable resins are gaining traction across various sectors. As the market continues to evolve, players are focusing on innovation and partnerships to stay competitive.

About Us: VynZ Research is a global market research firm offering research, analytics, and consulting services on business strategies. We have a recognized trajectory record and our research database is used by many renowned companies and institutions worldwide to strategize and revolutionize business opportunities.

Source: VynZ Research

#UV Curable Resins and Formulated Products#UV Curable Resins and Formulated Products Market#UV Curable Resins and Formulated Products Market Size#UV Curable Resins and Formulated Products Market Share#UV Curable Resins and Formulated Products Market Analysis

0 notes