#UV Curable Resins & Formulated Products

Explore tagged Tumblr posts

Text

Latin America UV Curable Resins & Formulated Products Market Outlook and Forecast 2025-2032

The Latin America UV Curable Resins & Formulated Products market was valued at US$ 342 million in 2024 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286476/latin-america-uv-curable-resins-formulated-s-market-2025-2032-468

0 notes

Link

0 notes

Text

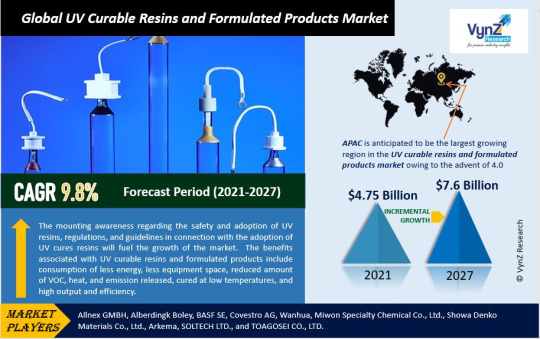

Global UV Curable Resins and Formulated Products Market Size, Share & Trends Analysis Report by 2027

The global UV curable resins and formulated products market is witnessing significant growth, driven by various factors such as increasing demand for eco-friendly and sustainable coatings, rapid industrialization, and technological advancements. According to Vynz Research, a leading market research firm, the market is expected to exhibit strong growth during the forecast period.

Download a Free Sample Copy of the Research Report: https://www.vynzresearch.com/chemicals-materials/uv-curable-resins-and-formulated-products-market/request-sample

Key Market Trends:

Rising Environmental Concerns: With growing environmental awareness and stringent regulations, there is a rising demand for eco-friendly and sustainable coatings. UV curable resins provide a viable solution as they are solvent-free, emit minimal volatile organic compounds (VOCs), and offer faster curing times, reducing energy consumption.

Increasing Industrial Applications: UV curable resins and formulated products find extensive applications across various industries, including automotive, electronics, packaging, and furniture. Their ability to provide superior adhesion, high gloss finish, chemical resistance, and durability makes them suitable for a wide range of applications.

Technological Advancements: Ongoing research and development efforts have led to the development of advanced UV curable resins and formulated products with improved performance characteristics. Innovations such as hybrid resins, water-based UV curable coatings, and bio-based formulations are driving market growth and expanding the application areas.

Market Drivers:

Growing Demand for UV-Cured Inks: The printing industry is witnessing a shift towards UV-cured inks due to their fast curing time, enhanced print quality, and ability to print on various substrates. UV-curable resins are an essential component of these inks, driving the demand for UV-curable resins and formulated products.

Expanding Automotive and Electronics Sectors: The automotive and electronics sectors are experiencing robust growth globally, creating a significant demand for UV-curable coatings, adhesives, and sealants. These products offer excellent resistance to chemicals, weathering, and scratching, thereby extending the lifespan of automotive and electronic components.

Increasing Infrastructure Development: The construction industry is witnessing substantial growth, primarily in developing economies. UV curable coatings are widely used in infrastructure applications, such as flooring, wood coatings, and decorative laminates, due to their quick curing times, durability, and excellent aesthetic appeal.

Market Forecast: The global UV curable resins and formulated products market is poised for significant growth in the coming years. Vynz Research projects a robust CAGR of 9.8% during the forecast period (2021-2027). Factors such as increasing investments in research and development, expanding end-use industries, and the rising popularity of eco-friendly coatings are expected to drive the market.

Moreover, the market is witnessing a surge in strategic collaborations, mergers, and acquisitions, as key players aim to expand their product portfolios and geographical presence. Asia-Pacific is anticipated to dominate the market due to the rapid industrialization in countries like China, India, and Japan.

Conclusion: The global UV curable resins and formulated products market is witnessing strong growth, driven by the increasing demand for eco-friendly coatings, expanding end-use industries, and technological advancements. With their superior performance characteristics and sustainable attributes, UV curable resins are gaining traction across various sectors. As the market continues to evolve, players are focusing on innovation and partnerships to stay competitive.

About Us: VynZ Research is a global market research firm offering research, analytics, and consulting services on business strategies. We have a recognized trajectory record and our research database is used by many renowned companies and institutions worldwide to strategize and revolutionize business opportunities.

Source: VynZ Research

#UV Curable Resins and Formulated Products#UV Curable Resins and Formulated Products Market#UV Curable Resins and Formulated Products Market Size#UV Curable Resins and Formulated Products Market Share#UV Curable Resins and Formulated Products Market Analysis

0 notes

Text

Top 15 Market Players in Global Anti-Cratering Agents Market

Top 15 Market Players in Global Anti-Cratering Agents Market

The global anti-cratering agents market is driven by key players focusing on advanced formulations and innovative technologies to cater to diverse industrial needs. Below are the leading companies dominating this market:

BASF SE A global leader providing high-performance anti-cratering agents for coatings and adhesives with a focus on sustainability.

BYK-Chemie GmbH Specializes in surface additives, including premium anti-cratering agents designed to improve coating quality.

Dow Inc. Offers cutting-edge solutions for surface enhancement in industrial and decorative coatings.

Evonik Industries AG Renowned for its diverse portfolio of additives that include efficient anti-cratering solutions.

Elementis PLC Focuses on high-quality anti-cratering additives, particularly for automotive and industrial applications.

Ashland Global Holdings Inc. A leading producer of innovative anti-cratering agents for paints, inks, and coatings.

Allnex Group Known for its advanced resin and additive technologies, providing reliable anti-cratering agents.

Arkema S.A. Delivers innovative solutions with a focus on high-performance additives for various industries.

Croda International Plc A key player offering eco-friendly anti-cratering agents for environmentally compliant coatings.

Huntsman Corporation Offers customizable additives, including anti-cratering agents, for specialized coating applications.

Wacker Chemie AG Produces silicone-based anti-cratering agents with a strong emphasis on durability and performance.

Shamrock Technologies, Inc. Provides specialty additives, including advanced anti-cratering solutions for niche markets.

Synthron (Protex International) Focuses on innovative and sustainable anti-cratering products for global markets.

Siltech Corporation A key provider of silicone-based anti-cratering agents tailored to industrial coatings.

Kusumoto Chemicals, Ltd. Offers high-quality additives, including anti-cratering agents, for paints and plastics industries.

Request report sample at https://datavagyanik.com/reports/anti-cratering-agents-market/

Top Winning Strategies in Anti-Cratering Agents Market

Companies operating in the global anti-cratering agents market employ various strategies to strengthen their market position and address evolving customer demands:

Sustainability Initiatives Developing eco-friendly and low-VOC anti-cratering agents to meet regulatory and environmental standards is a key focus.

Expansion into Emerging Markets Increasing investments in regions like Asia-Pacific and Latin America, where industrial growth is strong, has helped boost market penetration.

Customized Solutions Tailoring anti-cratering agents to meet specific performance requirements in different applications enhances customer satisfaction.

R&D Excellence Investing in research and development to introduce advanced formulations that improve surface quality and durability.

Strategic Partnerships Collaborating with coating manufacturers to co-develop products and strengthen supply chain integration.

Product Diversification Expanding the portfolio to include anti-cratering agents suitable for multiple coating types, including waterborne, solvent-based, and UV-curable systems.

Cost Optimization Improving production efficiency to offer competitive pricing while maintaining product quality.

Technological Advancements Leveraging innovative technologies, such as nanotechnology and advanced polymer science, to develop next-generation anti-cratering agents.

Regulatory Compliance Ensuring compliance with international standards, such as REACH and EPA regulations, to gain customer trust and ensure market access.

Digital Transformation Utilizing digital platforms for marketing, customer engagement, and distribution to improve global reach.

Acquisitions and Mergers Acquiring regional players to expand geographic presence and strengthen market share.

Focus on High-Growth End-Use Industries Targeting industries such as automotive, construction, and electronics to leverage growing demand for premium coatings.

Enhanced Customer Support Offering technical support and training to clients to optimize the use of anti-cratering agents in their formulations.

Collaborative Innovation Working with raw material suppliers to ensure the development of cost-effective and efficient anti-cratering solutions.

Brand Building Investing in branding and promotional activities to increase product visibility and create a strong market presence.

By employing these strategies, companies are positioned to capitalize on growth opportunities in the anti-cratering agents market while addressing the challenges of evolving customer needs and regulatory environments.

Request a free sample copy at https://datavagyanik.com/reports/anti-cratering-agents-market/

#Anti-Cratering Agents Market#Anti-Cratering Agents Production#market growth#market share#market players#market size#top trends#average price#revenue

0 notes

Text

Photoinitiator Market Industry Leaders Size & Share Outlook & New Revenue Pockets

Growing applications and environmental restrictions on VOCs to drive the acceptance of photoinitiators in the market

The global photoinitiators market size was USD 1.6 billion in 2021 and is expected to reach USD 2.6 billion by 2026, projecting a CAGR of 10.3% between 2021 and 2026. photoinitiators are increasingly used in the adhesive, ink, coating and other end-use industries. The increasing demand of coating industry drives the demand for photoinitiators. However, the outbreak of COVID-19 has created ripples across various application industries leading to reduced demand for photoinitiators. Due to the lockdown scenario in most of the world, the demand for photoinitiators from adhesive, coating, ink and other industries have declined sharply in 2020.

Download PDF Brochure at https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=17512915

As the world is getting ready to open up its economies and reduce restrictions from June 2021, the market will take an upward turn. The photoinitiators market is expected to witness high growth in 2021 owing to increasing applications, technological advancements, and growing demand in APAC. Photoinitiators are largely used in the coating applications by the wood, furniture, and architectural end-use industries apart from adhesive and printing ink industries. This market growth is backed by growing environmental concerns and increasingly stringent regulations.

The increasing number of restrictions on VOCs across the globe is pushing the industry to search for an alternative. Photoinitiators proved to be a safer and economical substitute. It enhances the surface finish as well as the shelf life of the product. Photoinitiators have been developed so that they are safe even for use in the dental industry. Many food safety compatible photoinitiators are also developed. All these photoinitiators are eco-friendly and have virtually no impact on human health.

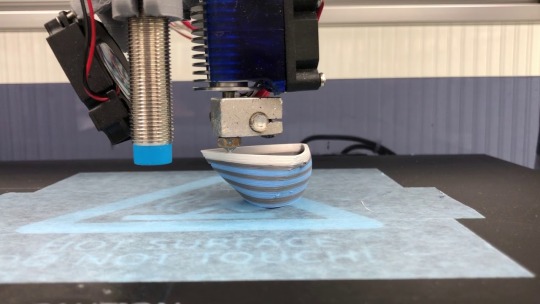

UV curable resins market has developed high growth prospects in 3D printing, digital printing, packaging, barrier films, and printed circuit applications. Automotive, architecture, medical, and several other industries are using 3D printing solutions to improve their design and manufacturing strategies. The 3D printing technology is expected to advance further in printers and printing methods, materials used in 3D printing, and software for designing and printing. All this directly affects the demand of the photoinitiators market.

Photoinitiators are the key to innovation in coatings, which have influenced the major trends in the coatings industry. The coating industry is largely influenced by stringent regulations set by authorities, including the European Union (EU), for reducing the VOC content from coatings, adhesives and inks. Consequently, the demand has shifted from solvent-borne UV to environmentally friendly products, such as waterborne UV using photoinitiators.

Request For FREE Sample of Report at https://www.marketsandmarkets.com/requestsampleNew.asp?id=17512915

The demand for waterborne photoinitiators has witnessed substantial growth in the past five years owing to rapid technological developments. In addition to eliminating solvent emissions, photoinitiator-based UV curing formulations provide improved mechanical characteristics, and increased production efficiency, particularly, in the spray application. These benefits encourage end users to adopt photoinitiator-based UV technology for new applications.

0 notes

Text

Enhancing Color Consistency and Performance with Advanced Solutions

Achieving vibrant and consistent colors in various applications requires high-quality solutions that ensure smooth and even dispersion of pigments. These solutions play a vital role in numerous industries, from paints and coatings to plastics and textiles. By offering uniform distribution, they help create flawless finishes and improved product performance.

What Are Pigment Dispersions?

These are mixtures where pigments are finely distributed within a liquid or resin matrix to ensure optimal color strength and stability. The process of dispersing pigments evenly is essential for avoiding clumping or unevenness in the final product. Whether for industrial coatings, printing inks, or plastics, these dispersions offer superior color consistency, making them essential for achieving desired aesthetic and functional results.

Key Benefits of Using Pigment Dispersions Improved Color Uniformity: High-quality dispersions ensure the pigments are distributed uniformly, leading to consistent color throughout the application.

Enhanced Durability: With advanced formulations, dispersions provide better lightfastness, weather resistance, and chemical stability, making the colors last longer in harsh environments.

Versatility: These dispersions can be used in a variety of applications, from water-based and solvent-based systems to UV-curable formulations, ensuring compatibility with different industries.

Increased Productivity: By using pre-dispersed pigments, manufacturers save time and reduce processing efforts, improving overall production efficiency.

Applications

From automotive paints to decorative coatings and packaging, pigment dispersions are widely utilized to achieve vibrant, long-lasting finishes. Their ability to offer precise color control and enhanced performance makes them invaluable across a range of industries.

By using advanced dispersions, industries can enhance the appearance, quality, and durability of their products, ensuring reliable results every time.

0 notes

Text

0 notes

Text

"The Curing Adhesives Boom: Driven by Innovation or Just Temporary Market Trends?"

Introduction

Curing adhesives, essential in various industrial and consumer applications, are designed to bond surfaces through chemical reactions that set or cure the adhesive. These adhesives are widely used in automotive, aerospace, electronics, construction, and consumer goods industries due to their superior bonding strength and durability. As industries evolve and seek more efficient and reliable bonding solutions, the curing adhesives market is experiencing significant growth. Advances in technology and increasing demand for high-performance adhesives drive market dynamics, making it a critical area of focus for manufacturers and suppliers.

Market Dynamics

Drivers:

Technological Advancements: Innovations in curing adhesives, such as UV-curable, heat-curable, and moisture-curable formulations, are enhancing performance and expanding application possibilities. These advancements improve curing speed, bond strength, and versatility, driving market growth.

Growth in End-Use Industries: The expansion of automotive, aerospace, and electronics industries boosts demand for high-performance curing adhesives. These sectors require reliable bonding solutions to meet rigorous performance standards and enhance product longevity.

Demand for Energy-Efficient Solutions: The increasing focus on energy efficiency and sustainability drives demand for adhesives that offer improved performance with lower environmental impact. Curing adhesives that meet these criteria are becoming more popular.

Challenges:

Raw Material Costs: Fluctuations in the prices of raw materials, such as resins and additives, can impact the production costs of curing adhesives. These cost variations can affect pricing strategies and profit margins for manufacturers.

Regulatory Compliance: Stricter regulations concerning the environmental and health impacts of adhesives pose challenges for manufacturers. Compliance with these regulations requires investment in R&D and modifications to existing products and processes.

Competition and Market Saturation: The curing adhesives market is highly competitive, with numerous players offering a wide range of products. This competition leads to price pressures and requires companies to differentiate themselves through innovation and quality.

Opportunities:

Emerging Markets: Growing industrialization in regions such as Asia-Pacific and Latin America presents opportunities for market expansion. Increasing demand for high-performance adhesives in these regions offers significant growth potential.

Sustainable Product Development: There is a rising demand for eco-friendly and low-emission curing adhesives. Developing sustainable products that meet environmental regulations and consumer preferences can provide a competitive edge and open new market segments.

Sample Pages of Report: https://www.infiniumglobalresearch.com/reports/sample-request/1025

Regional Analysis

North America: The North American market is driven by advanced manufacturing and technology sectors. The U.S. and Canada have a high demand for curing adhesives in automotive, aerospace, and electronics industries, supported by ongoing technological advancements and industry growth.

Europe: Europe is a significant market for curing adhesives, with a strong focus on high-performance applications in automotive and aerospace sectors. Stringent environmental regulations are pushing the development of eco-friendly and low-emission adhesives.

Asia-Pacific: The Asia-Pacific region is experiencing rapid growth due to expanding industrial activities and increased demand for consumer goods. Countries like China, India, and Japan are major contributors to market growth, driven by rising industrialization and technological advancements.

Latin America & Middle East & Africa: These regions are seeing gradual growth in demand for curing adhesives, supported by industrial development and increasing manufacturing activities. Market expansion in these regions is driven by the growing need for high-performance adhesives in various applications.

Market Segmentation

By Type: The market is segmented into UV-curable, heat-curable, moisture-curable, and others. UV-curable adhesives are gaining popularity due to their fast curing times and high performance.

By Application: Key applications include automotive, aerospace, electronics, construction, and consumer goods. Automotive and electronics are major segments, driven by the need for reliable and high-strength bonding solutions.

By End-User: The market serves various end-users, including industrial manufacturers, electronics producers, construction companies, and consumer product manufacturers.

By Region: Regional segmentation includes North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, each with distinct market dynamics and growth drivers.

Competitive Landscape

Market Share of Large Players: Major players in the curing adhesives market, such as 3M, Henkel, Sika, and H.B. Fuller, hold significant market share due to their extensive product portfolios, established brand presence, and global distribution networks.

Price Control by Big Players: Large companies often influence market pricing through their economies of scale and strategic sourcing. They can set industry standards and pricing trends due to their substantial market presence.

Challenges from Smaller Companies: Small and mid-sized companies challenge larger players by focusing on niche markets, innovative formulations, and cost-effective solutions. They often target specific segments with specialized products that cater to emerging needs.

Key Players:

3M

Henkel AG & Co. KGaA

Sika AG

H.B. Fuller Company

ITW Performance Polymers

Arkema Group

Jowat SE

Report Overview: https://www.infiniumglobalresearch.com/reports/global-curing-adhesives-market

Future Outlook

New Product Development: Innovation is crucial for companies to stay competitive in the curing adhesives market. Developing new products with enhanced performance characteristics, such as faster curing times, higher bond strength, and improved environmental sustainability, helps companies meet evolving market demands and maintain a competitive edge.

Sustainable Products: The demand for eco-friendly and low-emission adhesives is increasing as consumers and industries focus on sustainability. Companies that invest in developing sustainable curing adhesives that meet environmental standards will likely attract a growing segment of environmentally conscious customers and gain a competitive advantage.

Conclusion

The curing adhesives market is characterized by rapid technological advancements and growing demand across various industries. While challenges such as raw material costs and regulatory compliance persist, opportunities in emerging markets and sustainable product development offer pathways for growth. Companies that innovate and adapt to market trends will be well-positioned for success in this dynamic industry.

0 notes

Text

The global demand for paints & coatings was valued at USD 190512.5 Million in 2023 and is anticipated to reach USD 266501.5 Million in 2032, emerging at a CAGR of 3.8% between 2024 and 2032.The global paints and coatings market has experienced significant growth over the past few decades, driven by an increase in urbanization, infrastructure development, and industrialization. This article delves into the current state of the market, key trends, and future prospects, providing a comprehensive overview for industry stakeholders and enthusiasts.

Browse the full report at https://www.credenceresearch.com/report/paints-and-coatings-market

Market Overview

The paints and coatings market can be broadly segmented into decorative and industrial categories. Decorative paints and coatings are primarily used in residential, commercial, and institutional buildings, while industrial coatings are applied to products during manufacturing for protective and aesthetic purposes. Both segments are crucial, but they serve different end-users and applications.

The global market was valued at approximately USD 160 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of around 5% from 2024 to 2030. The Asia-Pacific region dominates the market, accounting for over 40% of global consumption, followed by North America and Europe. This dominance is attributed to rapid urbanization and industrial activities in emerging economies such as China and India.

Key Trends and Drivers

1. Urbanization and Infrastructure Development: As more people move to urban areas, the demand for residential and commercial buildings increases, driving the need for decorative paints and coatings. Governments and private sectors are investing heavily in infrastructure projects, further boosting market growth.

2. Industrial Growth: Industrial coatings are essential in various sectors, including automotive, aerospace, and marine. The growth of these industries, particularly in developing countries, is a significant driver for the industrial coatings segment.

3. Technological Advancements: Innovation in paint formulations, such as waterborne, powder, and UV-curable coatings, has enhanced product performance and environmental compliance. These advancements are attracting consumers and industries looking for sustainable and efficient solutions.

4. Environmental Regulations: Stringent regulations regarding volatile organic compounds (VOCs) emissions have led to the development of eco-friendly paints and coatings. Manufacturers are focusing on producing low-VOC and VOC-free products to comply with environmental standards and meet consumer demand for green products.

5. Aesthetic Appeal: Increasing consumer preference for aesthetically pleasing and personalized spaces drives demand for decorative paints. Innovations in color palettes, textures, and finishes are enabling consumers to achieve unique looks for their spaces.

Challenges

Despite the positive outlook, the paints and coatings market faces several challenges:

1. Raw Material Price Volatility: The cost of raw materials such as titanium dioxide, resins, and pigments can be volatile, impacting profit margins for manufacturers.

2. Environmental Concerns: While advancements have been made, the industry still faces challenges in completely eliminating harmful chemicals and achieving full sustainability.

3. Competition: The market is highly competitive, with numerous players ranging from large multinational corporations to small and medium-sized enterprises. This competition can lead to price wars and reduced profitability.

Future Prospects

The future of the paints and coatings market looks promising, with several factors likely to drive growth:

1. Sustainability: As environmental concerns continue to grow, there will be a greater emphasis on developing sustainable products. Innovations in bio-based and waterborne coatings are expected to play a crucial role in this transformation.

2. Smart Coatings: The development of smart coatings with functionalities such as self-cleaning, anti-microbial, and anti-corrosive properties is gaining traction. These advanced coatings offer added value and are likely to see increased adoption in various industries.

3. Emerging Markets: Growth in emerging markets, particularly in Asia, Latin America, and Africa, presents significant opportunities. Rapid urbanization and industrialization in these regions will drive demand for both decorative and industrial coatings.

4. Digitalization: The integration of digital technologies in the manufacturing process, such as automation and the Internet of Things (IoT), is expected to enhance efficiency and product quality. Digital tools are also improving customer engagement and providing personalized solutions.

Key Players

AkzoNobel (Netherlands)

Kansai Nerolac Paints Ltd (India)

Kwality Paints & Coatings Pvt. Ltd (KPCPL) (India)

Kansai Paint Co. Ltd (Japan)

The Sherwin-Williams Company (U.S.)

NIPSEA GROUP (Singapore)

Nippon Paint Holdings Co. Ltd (Japan)

Jotun (Norway)

Axalta Coating Systems (U.S.)

TIKKURILA OYJ (Finland)

Dunn-Edwards Corporation (U.S.)

Asian Paints (India)

RPM International Inc. (U.S.)

PPG Industries Inc. (U.S.)

Others

Segmentation

By Product Type

Architectural/Decorative Coatings

Interior Paints

Exterior Paints

Wood Coatings

Metal Coatings

Industrial Coatings

Automotive Coatings

Marine Coatings

Industrial Machinery Coatings

Protective Coatings

Specialty Coatings

High-Performance Coatings

Fire-Resistant Coatings

Anti-Corrosion Coatings

Others

By Technology

Waterborne Coatings

Solventborne Coatings

Powder Coatings

UV-Cured Coatings

Others

By Resin Type

Acrylic

Alkyd

Polyurethane

Epoxy

Polyester

Others

By End-User

Construction

Automotive

Aerospace

Oil and Gas

Industrial Manufacturing

Wood and Furniture

Packaging

Consumer Goods

Others

By Distribution Channel

Direct Sales

Distributor Sales

Online Retail

By Application Method

Spray Coating

Brush/Roller Coating

Dip Coating

Electrostatic Coating

Others

By Region

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

3D Printing Extrusion Materials Market: Exploring UV-Curable Resins for Rapid Prototyping

3D Printing Extrusion Materials is Booming on the Back of Growing Adoption of Additive Manufacturing

The global 3D printing extrusion materials market is experiencing significant growth driven by rapid developments in additive manufacturing technology. 3D printing extrusion materials such as photopolymers, filaments, and pellets offer advantages including high dimensional accuracy, lightweight and durable designs, and cost-effective production of complex geometries. The ability of 3D printing extrusion materials to produce intricate functional parts without tooling or fixtures has boosted their use across various end-use industries including aerospace, automotive, healthcare, consumer goods, and construction. The Global 3D Printing Extrusion Materials Market is estimated to be valued at US$ 12.77 Billion in 2024 and is expected to exhibit a CAGR of 19% over the forecast period from 2023 to 2030.

3D printing extrusion materials enable mass customization and on-demand manufacturing, which has increased their demand for prototyping and production applications. Continuous technological advancements focused on developing enhanced material properties such as strength, durability, and temperature resistance are further driving the market. Key Takeaways Key players operating in the 3D printing extrusion materials are 3D Systems Corporation, Stratasys Ltd., Materialise NV, EOS GmbH, Arkema S.A., SABIC, Evonik Industries AG, DuPont de Nemours Inc., BASF SE, Dow Chemical Company, HP Inc., Royal DSM N.V., EnvisionTEC GmbH, CRP Group., Carbon, Inc. These companies are focusing on new product launches and capacity expansion strategies to strengthen their market position. The growing demand for 3D printed parts and components across various industries is a major factor propelling the 3D printing extrusion materials market. Industries are increasingly adopting 3D printing for rapid prototyping, tooling, and production applications due to advantages such as low costs and reduced turnaround times. The market is also witnessing increased global expansion as players are enhancing their distribution networks across emerging economies. The rising investments in additive manufacturing technologies and growing R&D activities globally present significant growth opportunities for 3D printing extrusion materials over the forecast period. Market Key Trends Particle size reduction and new material formulations are notable trends being observed in the 3D printing extrusion materials market. Market players are focusing on further miniaturization of particle sizes to enable the production of micro-scale features and complex geometries. Continuous innovation in specialty polymer materials including carbon-reinforced, flame-retardant, and biocompatible varieties are expanding the application horizons for 3D printing extrusion materials. The market is also witnessing new opportunities through the development of hybrid and composite materials with blended properties. With the rising popularity of additive manufacturing, the demand for high-performance 3D printing extrusion materials is expected to exhibit strong growth over the next decade.

Porter's Analysis Threat of new entrants: New companies find it difficult to enter the market due to the significant capital investments required for manufacturing 3D printing extrusion materials.

Bargaining power of buyers: Buyers have moderate bargaining power due to the availability of alternatives and substitutes.

Bargaining power of suppliers: Suppliers have moderate bargaining power due to the availability of options for buyers and dominance of few players.

Threat of new substitutes: threat of substitutes is moderate with emerging new alternative 3D printing technologies.

Competitive rivalry: The market is dominated by few major players and there is intense competition. Over the years, North America has been dominating the 3D printing extrusion materials market owing to increasing demand from industries such as aerospace & defense and healthcare. USA holds a significant share in North America. The aerospace & defense industry in USA is increasingly utilizing 3D printing for lightweight components and complex parts for aircraft. The region has witnessed high investments in R&D and new product launches by key players such as 3D Systems Corporation and Stratasys, Ltd. Asia Pacific region is expected to grow at the highest CAGR during the forecast period owing to growing demand from application industries such as consumer goods and foundry in countries such as China and India. Foundry application offers vast opportunities for 3D printing extrusion materials market in Asia Pacific. Expanding manufacturing sector, easy availability of skilled labor force, and government initiatives are promoting adoption of advanced technologies including 3D printing.

#3D Printing Extrusion Materials Market gowth#3D Printing Extrusion Materials Market share#3D Printing Extrusion Materials Market Trend

0 notes

Text

Wood Coatings Market: Trends & Opportunities 2024-2032

According to Triton Market Research, the Global Wood Coatings Market report is sectioned by Resin Type (Polyurethane, Nitrocellulose, Acrylic, Other Resin Types), Technology (Water-Borne, Powder Coatings, UV-cured, Solvent-Borne), Application (Furniture and Fixture, Cabinet, Doors and Window, Flooring, Deck), and Regional Outlook (Middle East and Africa, Europe, Asia-Pacific, North America, Latin America).

The report highlights the Market Summary, Industry Outlook, Porter’s Five Forces Analysis, Market Maturity Analysis, Supply Chain Analysis, Regulatory Framework, Key Buying Impact Analysis, Key Market Strategies, Market Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology and scope, Global Market Size, Forecasts & Analysis (2024-2032).

Based on Triton’s research report, the global market for wood coatings is set to advance in value at a CAGR of 4.02% during the forecast period 2024-2032.

Wood coating serves a dual purpose: safeguarding and enhancing wood or wood-based structures. By shielding wooden surfaces, it bolsters their durability and utility. Simultaneously, it elevates their aesthetic appeal, contributing to effective product promotion.

Factors such as personalized solutions for flooring and furniture, the emergence of smart coating technology, and improved coating performance via nanotechnology, creates lucrative opportunities for the wood coatings market globally. Smart coatings offer an array of functionalities, such as self-healing, anti-fouling, and antimicrobial properties, enhancing the durability and performance of wood surfaces. This extends the lifespan of wood products and reduces maintenance costs. Moreover, smart coatings contribute to sustainability efforts by minimizing the need for frequent reapplications and replacements, thus reducing waste. With increasing environmental concerns and a growing emphasis on eco-friendly solutions, the adoption of smart coatings is set to escalate, driving market growth and innovation.

However, fluctuating raw material costs and competition from composite materials limit the overall development of the wood coatings market worldwide.

The Asia-Pacific region is set for the fastest growth in the coming years. One key driver is the region’s growing construction and furniture industries, particularly in countries like China, India, and Vietnam, where urbanization and rising disposable incomes have fueled demand for high-quality wood products. Additionally, there is a growing awareness and emphasis on environmental sustainability, leading to an increasing preference for eco-friendly coatings with low volatile organic compound (VOC) content. Moreover, technological advancements in coatings formulations, such as the development of water-based and UV-curable coatings, are gaining traction due to their superior performance and reduced environmental impact.

The renowned companies in the wood coatings market are Nippon Paint Holdings Co Ltd, Diamond Paints, PPG Industries Inc, Asian Paints, RPM International Inc, The Sherwin-Williams Company, BASF SE, Akzo Nobel NV, Axalta Coating Systems LLC, and Kansai Helios.

With evolving consumer preferences and stringent environmental regulations, barriers to entry remain significant, deterring potential newcomers. Established players continually innovate to maintain market share, investing in research and development to offer eco-friendly and high-performance coatings. Intense rivalry among existing competitors fuels pricing pressures and product differentiation strategies, compelling companies to enhance quality and expand distribution networks. Amidst these challenges, strategic alliances and mergers are common, reshaping the competitive landscape and fostering consolidation.

0 notes

Text

Ultraviolet Uv Curable Resins Market Key Players, Economic Impact and Forecast to 2030

The ultraviolet (UV) curable resins market is a segment of the global resin industry that is experiencing significant growth due to its unique properties and wide range of applications. UV curable resins are liquid or semi-solid materials that polymerize and harden when exposed to ultraviolet light. This process is known as UV curing or photo-polymerization.

Here is some full information about the UV curable resins market:

Market Overview: UV curable resins are increasingly being used as an alternative to traditional solvent-based resins due to their low volatile organic compound (VOC) emissions, fast curing time, and high performance characteristics. These resins find applications in various industries such as coatings, adhesives, inks, and electronics.

Types of UV Curable Resins: There are different types of UV curable resins available in the market, including:

Acrylic Resins: Acrylic-based UV curable resins are widely used due to their excellent adhesion, chemical resistance, and durability.

Epoxy Resins: UV curable epoxy resins offer high mechanical strength and are commonly used in coatings and electronic applications.

Polyester Resins: Polyester-based UV curable resins provide good flexibility and weather resistance, making them suitable for outdoor applications.

Others: Other types of UV curable resins include polyurethane, silicone, and hybrid resins.

Market Drivers: Several factors are driving the growth of the UV curable resins market, including:

Environmental Regulations: Increasing regulations on VOC emissions have led to a shift towards eco-friendly and low-emission coatings and adhesives, favoring UV curable resins.

High Performance: UV curable resins offer superior properties such as scratch resistance, chemical resistance, and fast curing, meeting the demand for high-performance materials.

Growing End-use Industries: Industries such as automotive, electronics, packaging, and wood coatings are adopting UV curable resins for various applications, boosting market growth.

Technological Advancements: Ongoing research and development efforts have led to the development of new UV curable resin formulations with improved properties and broader application possibilities.

Applications: UV curable resins find applications in diverse industries, including:

Coatings: UV curable coatings are used in automotive refinishing, industrial coatings, and wood coatings due to their fast curing, high gloss, and excellent durability.

Adhesives: UV curable adhesives offer fast bonding and curing, making them suitable for applications in electronics, medical devices, and optical industries.

Inks: UV curable inks are widely used in digital printing, packaging, and labeling applications due to their high color vibrancy, quick curing, and low VOC emissions.

3D Printing: UV curable resins are extensively used in stereolithography (SLA) and digital light processing (DLP) 3D printing technologies for rapid prototyping and production.

Regional Market: The UV curable resins market is geographically diverse, with significant growth observed in various regions, including North America, Europe, Asia Pacific, and Rest of the World. Asia Pacific is the largest market due to the presence of major end-use industries and increasing investments in infrastructure and construction activities.

Key Players: Some prominent companies operating in the UV curable resins market include:

BASF SE

Allnex Belgium SA/NV

Royal DSM N.V.

Arkema Group

Covestro AG

Toagosei Co., Ltd.

Hitachi Chemical Co., Ltd.

Dymax Corporation

IGM

#Ultraviolet Uv Curable Resins Market#Ultraviolet Uv Curable Resins Market Growth#Ultraviolet Uv Curable Resins Market Trends

0 notes

Text

0 notes

Text

UV Curable Resins and Formulated Products Market 2022-2028

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated Global UV Curable Resins and Formulated Products Market size at USD 4.85 billion in 2021. During the forecast period between 2022 and 2028, BlueWeave expects the size of global UV curable resins and formulated market to grow at a CAGR of 10.5% reaching a value of USD 9.73 billion by 2028. Ultraviolet (UV) curable resins are materials that cure and polymerize using energy from UV devices. When UV light is applied to inks, adhesives, and coatings, the technology allows for instant drying and curing via photopolymerization. Due to the expanding applications and use in numerous fields, including coatings, overprint varnishes, printing inks, adhesives, and others, the demand for UV curable resins and specially formulated products is expected to rise. However, high cost of setup could limit the market growth.

Global UV Curable Resins and Formulated Products Market – Overview

Polymerized substances with the help of energy that is extracted and then radiated from irradiation devices providing ultraviolet (UV) rays, UV curable resins and formulated products are quickly cured. Most industrial materials use UV-curable resins and specially formulated products for coating, bonding, and sealing. They are also utilized by the paint and coatings industry in addition to ink and adhesive industries. For curing and quick drying, UV curable resins and specially formulated products are thought to be the best option. During forecast period of 2022 to 2028, global market for UV curable resins and formulated products is expected to grow due to rising demand for these products.

The increased awareness about safety and use of UV resins, health regulations, and guidelines related to use of UV cured resins have all contributed to market growth. Use of UV cure resins and formulated products have grown in popularity in recent years. Certain benefits and advantages include less energy consumption, less equipment space, less VOC released, good flexibility, minimal heat and emission released, curing at low temperatures, and high output and efficiency. The unique feature of resin is coated on UV and having the ability to be applied on virtually any substrate, such as plastic, metal, and composites is the main factor responsible for the market growth.

Sample Report @ https://www.blueweaveconsulting.com/report/uv-curable-resins-and-formulated-products-market/report-sample

Global UV Curable Resins and Formulated Products Market – Technology Advancements

Global UV curable resins and formulated products market has been divided into Monomer, Oligomers, Photoinitiators, and Additives based on the composition; into Non-Acrylated Oligomers, and Acrylate Oligomers based on the chemistry; and as Coatings, Overprint Varnish, Printing Inks, Adhesives, 3D Printing, and Others based on the technology. Currently, coatings under the technology category dominate the market, accounting for a majority of share.

Technology advancements are also propelling the market growth. Sartomer, an Arkema subsidiary business unit, introduced innovative resin solutions that advance UV/EB curing performance for 3D printing, graphic arts, coatings, electronics, and personal care applications at the RadTech UV+EB 2020 Technology Expo and Conference in February 2020. Sartomer will also release three new N3xt Dimensions engineered resins for UV curable 3D printing. Moreover, working with waterborne products allows one to create Zero VOV lacquers for spraying applications due to their chemical resistance and quick curing efficiency. 3D printing, digital printing, and printed circuit applications are examples of opportunities that are expected to boost the market growth.

Impact of COVID 19 on Global UV Curable Resins and Formulated Products Market

COVID-19 affected global demand for UV curable resins and formulated products due to a drop in end-use applications. COVID-19 disrupted the UV curable resins value chain beginning in 2020. The pandemic had a significant impact on China, which ordered the closure of 21 provinces. Wuhan and Hubei provinces, which are major industrial and commercial hubs, were placed under lockdown. This had an effect on the supply chain for UV curable resins and formulated products. The pandemic later spread to Europe and North America. Because many countries were locked down, the workforce could not be deployed in manufacturing facilities. Demand from various applications decreased as a result of strict lockdown regulations. However, with relaxations on pandemic induced restrictions in place, the market is expected to be back on its growth trend.

Competitive Landscape

Prominent players in global UV curable resins and formulated products market include Allnex Group, Wanhua Chemical Group Co., Ltd., Arkema SA, Showa Denko Materials Co., Ltd., Royal DSM, GM Resins, Covestro AG, Nippon Gohsei, Hitachi Chemical Company Ltd., IGM Resins B.V., Toagosei Co. Ltd., Miwon Specialty Chemical Co. Ltd., BASF SE, Double Bond Chemical Ind. Co. Ltd., Jiangsu Sanmu Group Corporation, and Alberdingk Boley GmbH. These companies use R&D, expansions, acquisitions, and new product releases to improve their market position.

About Us

BlueWeave Consulting provides comprehensive Market Intelligence (MI) Solutions to businesses regarding various products and services online and offline. We offer all-inclusive market research reports by analyzing both qualitative and quantitative data to boost the performance of your business solutions. BWC has built its reputation from the scratch by delivering quality inputs and nourishing long-lasting relationships with its clients. We are one of the promising digital MI solutions companies providing agile assistance to make your business endeavors successful.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

The global UV curable resins and formulated products market size is expected to grow from USD 4.6 billion in 2021 to USD 7.3 billion by 2026, projecting a CAGR of 9.7% during the forecast period between 2021 and 2026.

#UV Curable Resins and Formulated Products Market#UV Curable Resins and Formulated Products#UV Curable Resins and Formulated Products Industry#UV Curable Resins and Formulated Products Manufacture#UV Curable Resins and Formulated Products Market Growth#UV Curable Resins and Formulated Products Market Trends#UV Curable Resins and Formulated Products Market size#UV Curable Resins and Formulated Products Market Report#UV Curable Resins and Formulated Products Market Overview#UV Curable Resins and Formulated Products Market Outlook#UV Curable Resins and Formulated Products Market Share#UV Curable Resins and Formulated Products Market Driver#UV Curable Resins and Formulated Products Market Demand#UV Curable Resins and Formulated Products Market growth#UV Curable Resins and Formulated Products Market insights#UV Curable Resins and Formulated Products Market Forecast#UV Curable Resins and Formulated Products Market Analysis#Global UV Curable Resins and Formulated Products Market#UV Curable Resins and Formulated Products Industry Trends#UV Curable Resins and Formulated Products Market CAGR#UV Curable Resins and Formulated Products Market in Europe#UV Curable Resins and Formulated Products Market in USA#UV Curable Resins and Formulated Products Market in Asia Pacific#reisins#resin

0 notes

Photo

https://www.databridgemarketresearch.com/reports/global-uv-curable-resins-formulated-product-market

0 notes