#Types of Electrical Conduit Fittings

Explore tagged Tumblr posts

Note

Hiiiiiiii, Seffani here. Brain still not working great but I can't keep sitting on this ask lol. I hope it comes out sensical.

Since you are clearly having the time of your life writing about Wizzrobe magic, have you had any thoughts about integrating the elemental-type enemies from Age if Calamity? Like, could a Wizzrobe channel its magic/straight up possess/inhabit another monster and imbue it with elemental magic? I do not know if this would add anything to the narrative other than just continue to complicate it buuuuuut if you wanna explore more relationship stuff between monsters that could be a fun tool. Also Sledge would look baddass as FUCK covered in electric-green markings and floating magic ribbons.

Is this the Steven Universe fan in me talking? Almost certainly. But I also think that possession/bodysharing/fusion is a really cool way to explore the relationships between characters. And oh no I just had the intrusive thought of Wizzrobes fusing like Gems and making new characters oh noooooooooo what have I done to myself I should stop typing and thinking and just send this okay BYE

HELLO SEFFANI!!! Hope you've been doing better :D

Elementally-typed monsters that aren't Wizzrobes are a very interesting elephant in the room that I've been kinda avoiding jhkladsflkhjalkjds

But!!! I do have a little blurb about it

The biggest reason is that when it comes to Zelda games, I try to separate the game mechanics between "what I can consider diagetic to the world of Hyrule" and "what's really only here to make gameplay more varied/engaging that I can kinda just nix from the general story"

Elementally charged monsters I'd see in a bit of a grey area. I like how Wizzrobes are one of the few monster species born with the innate power of their respective element - and how their literal bodies act conventionally different from a biological species.

But!!!! I have shown that magic isn't exclusive to Wizzrobes, both kinetic and elemental. But I also like to show how the struggle is to cast magic for non-Wizzrobes. And how often times they use a conduit for their magic like Riju with her scimitar.

And it's shown that non-Wizzrobes can handle a fair amount of magic themselves if the Sheikah are anything to go by! I wouldn't say a Wizzrobe giving another monster some of their magic would cause that type of fusion you're describing in my AU, BUT I REALLY DO LIKE THE PREMISE

It'd definitely add a lot of a mystical vibe to the Wizzrobe to be more ghost-like in nature with their canon designs if they could use their magic to possess/fuse with others

THIS IS ONE OF THE MOST AGONIZING PARTS ABOUT WRITING BECAUSE I REEEEEEALLY LIKE THIS IDEA BUT I DON'T THINK IT'LL FIT INTO THE ESTABLISHED CANON OF RATC ARGHHHHH

But thank you for the fun lore ideas :3

2 notes

·

View notes

Text

.:Walkabout:.

Chapter 34: Walkabout

Hey guys!

Sorry for the gap! Life stuff got in the way again and I'm currently rearranging my schedule to make sure things get done and all that. All the stuff that goes into adulting. So things still might be a bit sporadic for a bit, but I didn't forget!

Anyways, here's chapter 34! Hope you enjoy!

Without delay, let's jump in!

-------

“I can't believe I’m going through this bullshit."

I growl to myself as I left the hell tent, promptly giving it the middle finger as I left. Once I’m on the move, I look at the folded note I was given, opening it as I go and reading it again.

There were instructions to go to Mercy Hospital and get checked out by a… “Dr. Sims?” Not sure who this guy is, and tell him I’m coming in for a quick physical and an energy reading…. Something about seeing if it could be helpful in speeding up Pangolin’s recovery? I don’t fucking know.

The note also contained a token with the face of a bear stamped in it, an indicator to others the sister I answered to and a reminder that I can “always come to them for aid.” I can’t help but to scoff. Right, aid… Like they haven't “done enough" for me as is.

The physical makes some sense, I guess. Last time I was anywhere near doctors were….

I quickly shake my head to keep the memories from sinking in. Last thing I need is to start having flashbacks of that moment.

The point still stands, however, I haven’t seen a doctor in years. Granted I don’t know how this is gonna work out but I’m guessing this “Sims” character is experienced with Conduit health and anatomy, so he’ll probably do a decent job. Maybe he can explain this energy thing too.

I can feel my blood start to seeth a little at my predicament. Here I am, back to being a fucking errand boy again. I guess the silver lining of it this time around is that it's basically my rent. So any money I earn, I get to keep. Will come in very handy since I don’t know if typical American cash will work since everything has gone to hell.

That and there isn’t some grand scheme over my head, just a simple “I can stay so long as I chip in.” Reasonable expectation, I guess. At least they aren’t tearing my life asunder or forcing grandiose responsibilities onto me.

I spot Mako and flag her down before we meet up in the middle. We catch up with some chit-chat before I ask her where Crow went off to as the last time I saw the brown-haired woman, she was with Mako.

“She had gone back to Mercy Hospital." She answers with a nod of her head towards that direction. "Duty calls and all.”

"Hm.” I grunt. "Seems like I’ll probably be seeing her again soon.” Mako cocks her head before I show her the note and the token I was given. The sight of the bear-faced token makes the Shark chuckle a bit. I raise an eyebrow. "What's so funny?”

"Oh nothing, I’m just not surprised that Bear took you under her wing. She tends to take on hotheads.” Mako replies and I groan as I roll my eyes.

“I take it you answer to a sister too?" I ask and she nods, pulling out a token with the face of a sparrow on it before we start walking.

Huh… Mako was put under the Sparrow bitch’s care? I wonder why, but that's a question for later.

"So, how did everything go?” Mako asks and I freeze before turning my head slowly to her, feeling anger starting to build.

"Woah.” I stop her. "Woah-woah-woah. I’m gonna need you to elaborate on what the fuck that’s supposed to mean.” I see her face go pale a bit as I narrow my eyes at her.

"You know…Your…Trial?"

I growl. “Did you know about all of this?" Electricity starts to pop off of my arms as I glare at her.

"I can explain.” She starts, I growl deeper.

"Then start talking.”

She sighs before looking at me. "Tri-Point tends to attract the misfits of society… The lost, the wandering, the outcasts, you know… The types that would run away and join the circus and all that.” I can help but to roll my eyes at that, how fitting. Though I can't help but to think that all of those words are apt descriptors of myself. Wandering, outcasted and fucking lost.

“With that being said. The Sisters Three needed a system to make sure those who come to Tri-Point are who they say they are and would do w-"

“And that mirror maze from Hell is part of that?!?” I roar out, abruptly interrupting Mako and causing her to flinch. She nods quickly before continuing.

"The Trial of Reflection is unique to whoever participates and it's something that everyone goes through. It’s what shows the truth of a person’s heart!”

“And you didn’t think to, oh I don’t fucking know, give me a heads up about this?! Just like you didn’t think to tell me about the fucking Corrodium?!?” I snarl out, rage spilling out of my mouth out of control. “Something I thought we addressed back before we left Droptown. Did you forget the little detail about how much I fucking hate repeating myself?!” I start getting in her space, electricity popping off of my arms. Mako glares and stands her ground.

“Look Cole!” She starts. “I get it! Not giving you a Wildlands 101 is on Pangolin and I, I’m not denying that! We should have done that before we left and I’m working on trying to rectify that, but when it comes to the rabbit, I couldn’t tell you!” “Why. The hell. Not?!” “Nivens is a key part of the system the Sisters Three set up.” She defends. Great, that horned menace has a name?! “‘The one who sees the Rabbit must make the choice on their own.’ If I told you the true nature of Nivens and what you were about to get into, it would make the system moot!” “Weren’t you the one that encouraged me to chase the damn thing?” I point out with a glare. “You could have still said no!” The shark retorts. “You’re a grown ass man, like you always point out! I can’t make you do anything you didn’t want to do!”

This statement stops my rage in its tracks, causing me to pause and think. Mako’s right, while yeah; she egged me on, I’m still the one who ultimately made the call to fall for the rabbit’s taunting and give into impulse.

Speaking of choices, I remembered that was a big topic that the woodland bitches latched onto, choice or more specifically, my lack of it. My entire life was pretty much planned out before I was even a twinkle in my dad’s eye. Planned out hundreds of years in advance by the failure of a future self that bastard was and even after I broke free from his designs by siding with John, I only found myself in the chains of another grand design when John shirked his responsibilities and forced them onto my shoulders. Responsibilities that weren’t mine to bear.

Ditching the ball-and-chain that was Kuo and John’s army was the first time I ever made a choice that was completely and wholly of my own will and discretion, no bigger scheme, no grand destiny, nothing. Just a man taking back his autonomy. Ever since that day, I’ve had more freedom and choice than I ever had in my entire life. It’s only now that I’m truly and fully seeing this.

Hell, I have so much freedom now that… I’m not even quite sure what to do with it all.

I guess that I’ve become so used to my life being decided for me and my choices being as meaningful as piss in the ocean that without some puppet-master bullshit pulling the strings or some grand plan invalidating my autonomy that I’m used to it. So much so that without some outside force controlling my fate or me rebelling against said controlled fate, I really… Don’t know who exactly I am anymore. I thought I did, but now… I’m not sure.

As much as I hate to admit it…. And I really fucking hate to admit it, Deer was right. I have become disillusioned and lost.

“... Cole?” Mako’s voice penetrates through the whirlwind in my head, causing me to jump a bit in a start. The expression she wears is full of concern and worry, one I remember well back when she was part of John’s army, back when I led it. She was really the only one who'd show concern for me.

“Are you okay?" She asks, her voice tinged with worry. I open my mouth to lie, to tell her that I’m fine, but I pause. Lack of communication, lack of transparency. It's what's getting us into these messes. Seems like a common theme too, one that needs to break. Best start with myself.

"No.” I snap before taking a breath. “No, I’m not okay…” I see Mako about to say something, but I put my hand up. “With the hell I just went through in that madhouse, I need time to think… Process everything.”

Mako pauses, her eyes darting side to side before speaking up. "Well… If you need a listening ear or someone to vent to, you can always come to me or the other Misfits. We’ll be here for you.” She states, I can see she wants to add something, but she seems to dismiss whatever it was. Regardless, I nod.

"Appreciate the offer, Mako.” I mutter slightly. "But this is something I need to sort out on my own." She nods in understanding.

“Anyways, I need to be heading to the hospital. Marching orders and all.” I state simply. She nods before beginning to walk off.

"And Mako?” I stop her before she gets too far. "When you make that ‘Wildlands 101’ class, make sure you cover everything. And I mean everything. No more surprises. I will not repeat myself a third time." I warn, my eyes glowing red. “I mean it."

“Right, I’ll confer with the others to make sure everything gets covered." Mako sheepishly murmurs before rubbing the back of her head. I nod at her and we part ways.

As I walk, I rub my calloused hands over my face tiredly before looking at the sky, noticing the sun was nearing the horizon. I sigh loudly and shake my hands, venting off arrant sparks before continuing on. I don't know what to expect with this hospital visit, but what I do know is I can kiss any hope of getting any sleep at all goodbye.

Because with the hell I just went through? There's no hope of getting any sleep tonight.

#infamous#infamous 2#cole macgrath#demon of empire city#infamous: no man's land#xeno writes#Mako#More and more#The mystery unfolds.#But I wonder how much people truly knows?#Or understands?#Only time will tell.#... Or will it?

4 notes

·

View notes

Text

What You Need to Know About Ductless Mini-Split Systems?

What Is A Ductless Mini-Split System?

A mini-split HVAC system is one that is split into two parts. It has an outdoor compressor and indoor evaporators (there can be four to as many as eight units designed to cool individual zones). No ductwork is used to distribute air, as there is in a central A/C system. This configuration allows the temperature in individual rooms to be set to your liking.

How Does It Work?

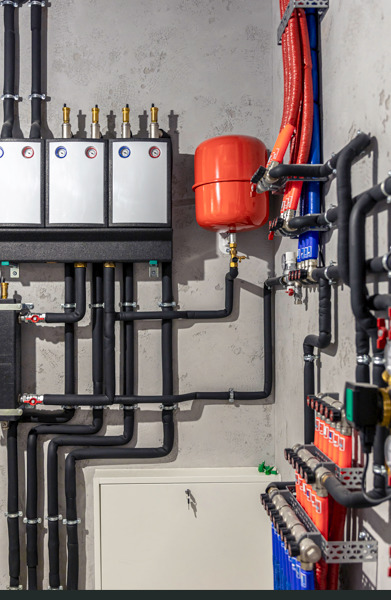

An outdoor compressor pumps pressurized refrigerant through small tubes that are connected to indoor units. These tubes require just a three-inch-wide hole for a small conduit that links the different components. Each indoor evaporator, which serves an individual room, circulates the refrigerant to extract heat from the interior space. The in-room units do the cooling rather than a centralized system from which air is transported through supply and return ducts. Once the refrigerant returns to the outdoor unit, the heat collected from interior air is released into the environment. In addition, some systems integrate a heat pump that extracts heat from outside air and transfers it to the interior to warm your indoor space.

Parts of a Ductless Mini-Split A/C System

There are four main components that make up a ductless system. These include the:

- Condensing unit: In a mini-split system, the condenser is placed outside the home or building and includes condenser coils, which are designed to pump cooled/heated refrigerant through specialized tubes. A fan pulls air through the coil to safely dissipate heat energy into the surrounding environment.

- Refrigerant lines: These line sets are usually passed through a small three-inch hole in the wall (this avoids extensive drilling). In rare setups, they are run through a window. Refrigerant lines link the outdoor unit to one or more indoor units in the system.

- Indoor unit: Releases cold air into the room or space it serves. Although there are many types of indoor units available on the market, the commonality is all are designed to cool or heat a single zone.

Types of Mini Splits

The different types of indoor units can accommodate specific requirements. They all serve the same function but, depending on their configuration, can fit limited space or a particular interior design theme.

Wall-Mounted: The most popular and least expensive indoor unit, a wall-mounted system is available in many types. They can range from 6,000 to 36,000 British Thermal Units (BTUs) and in sizes from 30 to 44 inches wide, 12 to 14 inches tall, and 6 to 10 inches deep. They are best suited for rooms with at least 7- or 8-foot-high walls (and best placed at a height of about 6 feet). The unit must be placed against a level exterior wall, where a 3-inch hole can be drilled to draw the refrigerant lines, drain tube, and electrical wiring.

Ceiling Cassette: An unobtrusive unit installed behind a decorative cassette grill that sits flush with the ceiling, creating a seamless look. No mechanical components are visible. Ceiling recessed cassettes can range up to 48,000 BTU and have four vents, so are best placed in the center of the room. Often installed in commercial settings, they can be installed in a drop ceiling or traditional joust ceiling if there’s enough space (10 to 14 inches of clearance is required). A built-in thermostat adjusts output based on indoor temperature readings.

Concealed Duct: A hybrid unit that uses ductwork to deliver conditioned air through a dropped ceiling, attic, closet, or crawlspace. The ducts can be branched to supply two rooms, where the temperature is controlled by a single thermostat. It’s important to consider the power specifications of the blower when determining the length of the duct run; a stronger blower will be needed for longer runs.

Floor-Mounted: Is typically installed where the wall and floorboards meet to produce a more noticeable effect of cooled or warmed air. A floor-mounted unit is usually more visible, but low ceilings or high windows do not impede installation. It is suited for an attic bedroom where ceiling slant prohibits the use of a wall or ceiling unit. The indoor unit must not be more than 6 inches above the floor on an exterior wall.

#mini split heat pump#ductless heat pump#ductless mini split heat pump#split heat pump#ductless air conditioner#ductless ac

2 notes

·

View notes

Text

Why Piping Design Drawings and 3D BIM Modeling Services Are Vital for Modern Construction Projects

The Role of Piping Design Drawings in Project Planning

At the heart of any mechanical or plumbing system lies a complex web of pipes, valves, and fittings. Whether it's HVAC, water supply, or industrial process piping, these systems must be carefully planned and precisely executed. This is where piping design drawings come into play.

These technical illustrations represent the layout, size, material, and alignment of piping systems in a detailed and structured way. They provide essential information such as:

Pipe routing and elevation

Connection types and specifications

Flow direction and pressure ratings

Equipment locations and clearances

Piping design drawings serve as the blueprint for fabricators, contractors, and engineers. Mistakes or inconsistencies in these drawings can lead to costly delays, safety hazards, or operational inefficiencies. That’s why high-quality, well-coordinated piping drawings are non-negotiable for complex projects.

The Power of 3D BIM Modeling Services

While 2D drawings have their place, the construction industry is increasingly turning to 3D BIM modeling services (Building Information Modeling) to visualize and manage every component of a project. BIM allows stakeholders to create and interact with digital twins of physical spaces—models that include not only geometry but also valuable metadata.

BIM offers a wide range of benefits, including:

Clash detection: Identifying spatial conflicts between systems (e.g., HVAC duct vs. electrical conduit) before construction begins

Improved coordination: Sharing one unified model among architects, engineers, and contractors improves communication and accountability

Accurate quantity take-offs: Generating material lists and cost estimates directly from the model

Lifecycle management: Facility managers can use BIM data long after construction for maintenance and upgrades

For mechanical and piping systems in particular, 3D BIM modeling services allow for more accurate layouts, fewer surprises on-site, and better collaboration among trades.

How 3D Modeling Services Bridge the Gap Between Design and Construction

While BIM is a process and platform, 3D modeling services refer more broadly to the creation of three-dimensional digital models—whether for architectural visualization, mechanical design, or product development. In the context of piping and construction, 3D models act as a bridge between conceptual design and physical implementation.

The benefits of 3D modeling services include:

Visualization: Helping clients and stakeholders understand spatial relationships, aesthetics, and system functionality

Fabrication support: Generating shop drawings and CNC-ready files from accurate models

Simulation and testing: Running performance analyses before anything is built, saving time and money

Precision: Minimizing guesswork in construction through clear, photorealistic representation

With the right modeling approach, even the most complex piping networks can be virtually constructed, inspected, and modified—before a single pipe is installed.

Why Choose Funding Walk?

At Funding Walk, we combine technical expertise with cutting-edge technology to deliver superior piping design drawings, 3D BIM modeling services, and 3D modeling services tailored to your specific needs. We don’t just provide drawings—we deliver confidence. Our team understands how to balance design intent, regulatory compliance, and practical constructability to support your project from concept to completion.

Whether you’re an MEP engineer, a construction firm, or a project manager looking to streamline your operations, Funding Walk can help you:

Avoid costly design errors

Enhance team collaboration

Accelerate project timelines

Deliver better outcomes for clients and stakeholders

0 notes

Text

Electric Door Bell: Essential Guide for Modern Homes

An electric door bell is often the first point of interaction with visitors—making it essential for both functionality and aesthetics. Indian manufacturers like Electrofocus and Dsent offer a rich variety, from classic Ding Dong chimes to electrical ceiling rose with LED flashes and long-range capabilities .

Why it matters:

Clear sound and reliability — Strong audio output ensures you never miss a visitor.

Style options — Plastic or ABS casings, in colors from sleek white to pastel tones, fit any decor .

Low installation cost — Battery-powered or mains models require minimal wiring, offering flexible placement choices.

For those looking for elegant and long-lasting designs, the Orient Electric “Door Bell BS” ranges in matte white, offering both visual appeal and dependable performance .

Lighting Done Right: Electrical Ceiling Rose

The electrical ceiling rose might seem minor, but it plays a key role in secure lighting installations. Ceiling roses connect pendants or chandeliers to the wiring system, ensuring they hang safely and look tidy.

Top reasons to pick quality:

Neat wiring connections — They neatly manage electrical feed-ins and outflows.

Durable materials — Plastic or power-coated finishes resist heat and moisture, ideal for long-term use .

Safety-first installation — They often meet national standards for load-bearing and insulation, protecting both fixtures and inhabitants.

Electrofocus offers jumbo and standard ceiling roses tailored for India’s wiring standards—providing affordability and peace of mind .

Why Buy Electrical Wholesale Online India?

Purchasing from electrical wholesale online India platforms like IndustryBuying, IBO, and local dealers delivers multiple advantages:

Bulk discounts and competitive pricing — Grabbing essentials like doorbells, roses, conduit accessories in volume helps you save substantially .

Vast selection under one roof — Brands such as Anchor/Panasonic, Schneider, Philips, and Hosper offer diversified product lines—fitting needs from basic fittings to advanced smart switches .

Reliable service and delivery — These platforms often guarantee quick shipping, installation support, and easy returns for MRO (maintenance, repair, operations) products .

Tips for Choosing the Best Components

A. For Door Bells:

Decide wired vs wireless: Battery-powered models like Dsent’s kits allow placement flexibility; wired types are better for permanent setups.

Choose audio style: Ding-Dong, musical, or parrot vocal rings cater to different preferences and volumes .

B. For Ceiling Roses:

Ensure load capacity matches fixtures.

Opt for fire-retardant plastic or coated designs to maximize safety .

C. For Online Wholesale Buys:

Compare price-per-unit across brands. Check for authentic certifications

Prioritize vendors offering bulk deals, fast dispatch, and post-sale support.

Final Thoughts

Investing in quality electric door bell units and secure electrical ceiling rose fittings boosts functionality, aesthetic appeal, and safety. Leveraging the cost benefits and convenience from electrical wholesale online India platforms ensures you receive premium products at great values. From crisp “ding-dong” chimes to sturdy ceiling fixtures, your selections today will power a safer, smarter tomorrow.

0 notes

Text

From Power to Performance: Ireland’s Ultimate Source for Electrical Supplies, Lighting & Renewables

In today’s fast-paced construction and energy landscape, sourcing the right products isn’t just about quality—it’s about trust, innovation, and convenience. Across Ireland, electricians, contractors, and homeowners are turning to a single trusted supplier for everything from smart lighting and switches to EV chargers and solar panels: Click Litehouse Ireland, available at Trade Electric.

Let’s explore how this industry leader is helping Ireland power up efficiently and sustainably.

1. Electrical Supplies for Every Sector

From domestic rewires to large commercial installations, the need for reliable electrical supplies in Ireland is constant. Trade Electric understands this demand and caters to professionals and the public alike. Whether you’re based in the capital and searching for electrical wholesalers in Dublin or need a supplier out west through electrical wholesalers in Limerick, their expansive reach ensures nationwide support.

Their catalog covers everything from cable and control gear to lighting, sockets, panels, and more.

2. Managing Cables with Precision

When it comes to planning installations, the devil is in the details—especially when it comes to cable safety and organization. That’s where Cables & Cable Management Ireland products step in. From conduit systems and cable trays to accessories that ensure secure, neat, and compliant installations, Trade Electric offers a solution for every cable challenge.

3. Illuminating Ireland – Indoors & Out

Lighting isn’t just functional—it’s inspirational. The range of indoor & outdoor lighting at Trade Electric combines energy-efficiency, design elegance, and durability. Whether you're upgrading a home, fitting out a restaurant, or illuminating a garden, you'll find modern options with LED technology that offer style and savings.

For locals, exploring the Lighting Shop in Limerick or the Lighting Shop in Dublin means direct access to trending fixtures, helpful staff, and inspiration. Better yet, take a walk through their Lighting Showroom in Limerick, Ireland to see cutting-edge designs in action.

4. Tools, Fixings & Fasteners – The Unsung Heroes

Great work relies on the right foundations. That’s why contractors rely on Trade Electric for Fixings & Fasteners in Ireland. Whether you’re installing lighting brackets or securing panels, you’ll find anchors, screws, plugs, bolts, and more in stock.

Add to that a wide range of Tools & Accessories in Ireland—from drills and testers to hand tools—and you've got everything needed to work smarter and safer on any job.

5. Power in Your Hands: Switches, Sockets & Wiring

Smart homes and professional builds all require reliable accessories that perform—and look good doing it. Trade Electric stocks a vast range of Switches, Sockets & Wiring Accessories suitable for all settings.

From contemporary finishes like brushed chrome and matte black to integrated USB and smart switches, this range balances design with functionality. Whether you’re wiring a new home or upgrading a workspace, these small details make a big difference.

6. Clean Distribution, Smart Control

Safe and efficient electrical systems begin with smart infrastructure. With Trade Electric’s Control & Distribution Solutions, installers gain access to the latest innovations in switchgear, boards, enclosures, and circuit protection.

Every product in this category is selected for reliability, regulatory compliance, and easy integration—helping reduce downtime and improve energy control in homes, offices, and industrial units alike.

7. Ready for the EV Boom

Ireland’s transition to electric vehicles is accelerating. As more people shift away from petrol and diesel, the demand for home and workplace charging grows. Trade Electric answers the call with a wide array of EV Chargers in Ireland suitable for different installation types.

Whether you’re a homeowner looking to install your first charger or a developer needing a fleet-ready solution, this range includes fast, safe, and user-friendly options with smart charging technology.

8. Greener Energy with Solar Solutions

As sustainability becomes central to planning and development, Solar Panels and Renewables in Ireland are in high demand. Solar isn’t just good for the planet—it’s good for your wallet. Lower bills, lower emissions, and increased property value are just a few of the benefits.

With options for both residential rooftops and commercial scale projects, Trade Electric makes solar accessible, with expert advice and dependable stock. You can find more on Solar Panels & Renewables in Ireland via their online hub.

9. Clean Air & Comfort with HVAC Essentials

Comfort and energy efficiency often go hand in hand. Whether you're installing extractor fans in kitchens, ducting systems for commercial buildings, or heaters for winter efficiency, Trade Electric has you covered with Heating, Ventilation & Ducting solutions.

Smart control options, powerful extraction, and silent heating units offer everything needed for a healthier, better-ventilated space.

10. Why Trade Electric Is the Supplier of Choice

When it comes to electrical solutions in Ireland, Trade Electric leads the charge for several reasons:

Product Range: From cables to renewables, they’ve got every category covered.

National Reach: With stores and delivery throughout Ireland, they’re never far away.

Expertise: Their team offers real-world advice and support to professionals and homeowners alike.

Convenience: Online ordering, in-store browsing, and showroom experiences make sourcing seamless.

Powering Ireland’s Future—One Connection at a Time

Ireland’s electrical industry is evolving rapidly. As energy standards rise, technology becomes smarter, and customers demand more sustainable solutions, the need for reliable suppliers is more important than ever.

Whether you’re in search of smart lighting, eco-friendly EV charging, or industrial-grade switchgear, you’ll find what you need at Trade Electric. And with brands like Click Litehouse Ireland leading the way, innovation and quality are always within reach.

So, whether you’re building, renovating, installing, or designing—Trade Electric is Ireland’s partner for power, precision, and progress.

0 notes

Text

Cable Gland Types – A Detailed Guide for Electrical Safety and Performance

Cable glands are essential components used in electrical systems to secure the ends of cables and protect them from environmental and mechanical stress. Whether you're handling industrial machinery, control panels, or home automation, selecting the right Cable Gland Type ensures durability and safety. In this blog, we’ll explore the most commonly used cable gland types, their applications, and how to choose the right one for your project.

What is a Cable Gland?

A cable gland is a fitting that attaches to the end of a cable and connects it securely to electrical equipment. It provides strain relief, ensures insulation, prevents dust or moisture entry, and sometimes offers grounding or earthing functions.

Main Types of Cable Glands

1. Brass Cable Glands

Application: Ideal for industrial and outdoor use.

Features: Corrosion resistance, strong build, suitable for armored and unarmored cables.

2. Nylon/Plastic Cable Glands

Application: Used in domestic and commercial indoor setups.

Features: Lightweight, cost-effective, corrosion-proof, easy to install.

3. Stainless Steel Cable Glands

Application: Found in food processing units, chemical industries, and marine settings.

Features: High resistance to chemicals, temperature, and mechanical stress.

4. Aluminum Cable Glands

Application: Aerospace and transportation.

Features: Lightweight yet durable with good resistance to corrosion.

5. EMC Cable Glands

Application: For systems sensitive to electromagnetic interference (EMI).

Features: Provides grounding and electromagnetic shielding.

6. Explosion-Proof Cable Glands

Application: Hazardous environments (e.g., oil & gas, mining).

Features: Certified for flameproof and explosion-resistant performance.

Cable Gland Types by Cable Configuration

Armored Cable Glands (e.g., BW, CW types) – Used for SWA (Steel Wire Armored) cables.

Unarmored Cable Glands – For flexible cables without metal sheathing.

Flexible Conduit Glands – For conduit wiring in complex installations.

Factors to Consider Before Choosing a Cable Gland Type

Cable diameter and type

Indoor vs. outdoor application

Degree of protection needed (IP rating)

Material compatibility

Compliance with electrical standards (e.g., IS/IEC, ATEX)

Conclusion

The right cable gland type ensures the longevity and reliability of your electrical installation. Each type has a specific use-case, and understanding these differences can help you prevent failures and ensure system safety. Whether it’s for a home, factory, or mission-critical site, always consult an expert or supplier when selecting cable glands for your project.

0 notes

Text

PVC Pipe Nail Clamp Manufacturer | Supplier in Ahmedabad, Gujarat, India

When it comes to safe, secure, and long-lasting pipe installations, choosing the right pipe clamps is essential. As a leading PVC Pipe Clamp Manufacturer based in Ahmedabad, Gujarat, India, we specialize in delivering top-notch quality products that meet the highest industry standards. Whether you're looking for PVC, CPVC, or UPVC pipe nail clamps, we offer a wide range of options that are both reliable and cost-effective.

Our products are widely used in plumbing, electrical wiring, and various construction applications. As one of the most trusted Pipe Clamps Manufacturers in India, we understand the importance of durability, strength, and efficiency in every installation. Our pipe clamps are engineered to ensure secure fittings, minimizing the risk of leaks and damage over time.

Why Choose Our PVC Pipe Nail Clamps?

As a reputed PVC Pipe Clamp Manufacturer, our focus is on quality, innovation, and customer satisfaction. Here’s what sets our pipe clamps apart:

Superior Material Quality: Our clamps are manufactured using premium-grade PVC, CPVC, and UPVC materials. These polymers provide excellent resistance to corrosion, chemicals, and high temperatures.

Precision Engineering: Each clamp is designed with precision to ensure a snug fit around the pipe, offering stable and vibration-free installations.

Variety of Sizes and Types: Whether you need standard-sized pipe clamps or custom solutions, we offer a comprehensive range of options for different pipe diameters and applications.

Easy Installation: The nail clamp design allows for quick and hassle-free installation. Simply position the clamp, drive in the nail, and your pipe is securely fixed.

Applications of Pipe Nail Clamps

Our clamps are ideal for a wide range of applications including:

Residential and commercial plumbing

Electrical conduit management

HVAC pipe installations

Cable and wire routing

This versatility makes us one of the preferred Cable Clips Manufacturers in India as well. Our pipe clamps double as reliable cable management tools in electrical setups.

We Are Also Leading Cable Clips and Cable Ties Manufacturers

In addition to being a prominent Pipe Clamps Manufacturer, we are also a trusted name among Cable Clips Manufacturers and Cable Ties Manufacturers in Ahmedabad. We provide:

Cable Clips for organized and neat wire management in electrical installations.

Cable Ties that are durable, high-tensile, and available in various sizes, ideal for bundling cables in industrial and commercial applications.

Our cable management solutions are widely used in IT, telecom, construction, and manufacturing sectors, reflecting our broad industry reach and product adaptability.

Commitment to Quality and Customer Satisfaction

As a leading Pipe Clamps Manufacturer in Ahmedabad, we adhere to strict quality control standards. Each product undergoes rigorous testing for strength, durability, and performance before reaching our customers. Our clamps are compliant with industry safety norms, ensuring peace of mind for installers and end users alike.

We have built a loyal client base across India and are rapidly expanding our footprint in international markets. Our focus on timely delivery, competitive pricing, and superior customer support sets us apart from other manufacturers in the industry.

Custom Manufacturing Solutions

We understand that different projects require different solutions. As an experienced PVC Pipe Clamp Manufacturer, we offer custom manufacturing services tailored to your specific needs. From private labeling to specialized product dimensions, we are equipped to handle unique client requirements with efficiency and precision.

Our state-of-the-art manufacturing facility in Ahmedabad is equipped with the latest technology and a skilled workforce, allowing us to meet bulk orders without compromising on quality.

Serving Gujarat and Beyond

Based in Ahmedabad, we are strategically located to serve clients not only in Gujarat but across India. With efficient logistics support, we ensure timely dispatches and deliveries. Our reputation as a reliable Cable Clips Manufacturer, Cable Ties Manufacturer, and Pipe Clamps Manufacturer is built on trust, consistency, and commitment.

Partner with Us

If you're looking for a dependable PVC Pipe Clamp Manufacturer in Ahmedabad, Gujarat, India, look no further. Partner with us for high-quality, cost-effective, and innovative solutions that meet your plumbing and electrical installation needs.

Whether you are a wholesaler, retailer, or contractor, we have the right products and solutions to support your business. Get in touch with us today to learn more about our full range of pipe clamps, cable clips, and cable ties.

For More Information:

9099745404

Plot No. 121, Road No. 19, Ambica Nagar, GIDC, Near Chhotalal Chali, Odhav, Ahmedabad-382415, Gujarat, India

#Pipe Clamps Manufacturers#Cable Clips Manufacturers#Cable Ties Manufacturers#gang box manufacturers

0 notes

Text

Excavator Rental Made Simple for Your Next Project

When it comes to getting work done on time and within budget, having the right equipment makes all the difference. We understand the challenges that come with construction, landscaping, and site preparation projects. Whether you're building a new foundation, digging trenches, or handling a demolition job, reliable equipment is the backbone of your success.

That’s why we provide dependable excavator rental options for residents, contractors, and businesses across Douro-Dummer and the surrounding areas. Our goal is simple to help you complete your project safely, efficiently, and with the right tools for the job.

In this article, we’ll walk you through why renting equipment can be a practical solution, the types of projects that benefit from this option, what to consider before renting, and why locals trust Birchview Excavating for all their excavation needs.

The Practical Benefits of Excavator Rental

Excavators are one of the most versatile pieces of equipment available for construction and earth-moving tasks. But owning one isn’t always the most practical option especially for short-term projects or one-time jobs. Here’s where renting offers real value:

1. Cost-Effective for Short-Term Projects

Purchasing heavy equipment like excavators requires a significant investment not to mention the ongoing costs of maintenance, storage, and insurance. For many homeowners and small contractors, renting provides the necessary equipment at a fraction of the cost. You only pay for the time you need, making it a budget-friendly option.

2. Access to the Right Equipment

Different jobs require different machines. Renting gives you access to the right type and size of equipment without being locked into one specific model.

Whether you need a compact mini excavator for tight spaces or a larger machine for heavy digging, we can help you choose the equipment that fits your needs.

3. No Long-Term Maintenance Worries

Owning equipment means dealing with regular servicing, repairs, and storage. When you rent from us, we take care of the maintenance, so you can focus entirely on the job at hand. Our excavators are routinely inspected and maintained to ensure they perform at their best.

4. Reliable Equipment When You Need It

Unexpected breakdowns can delay projects and drive up costs. That’s why we maintain our fleet to high standards, ensuring the excavators you rent are dependable, well-maintained, and ready to work when you are.

Common Projects That Require Heavy Equipment

Excavators are incredibly useful across a wide range of projects, from residential to commercial. Here in Douro-Dummer, where we see everything from rural property development to lakeside construction, an excavator is often a key piece of equipment.

1. Foundation Preparation

Whether you’re building a new home, garage, or workshop, proper foundation preparation is essential. Excavators can efficiently remove soil, dig trenches, and level the site, giving your project a solid start.

2. Landscaping and Property Improvements

Many property owners want to improve the appearance or functionality of their land. From digging ponds to reshaping terrain or removing stumps, a rented excavator makes these tasks manageable and efficient.

3. Driveway or Road Construction

Preparing a gravel driveway or access road often involves clearing, grading, and leveling all jobs that are simplified with the right excavator.

4. Utility Installation

If your project involves running water lines, electrical conduits, or drainage systems, renting an excavator helps speed up trenching work with precision and safety.

5. Demolition and Site Clearing

What to Consider Before Renting an Excavator

Renting an excavator is straightforward, but there are a few important factors to keep in mind to ensure the process goes smoothly and safely.

1. Choosing the Right Size

Excavators come in various sizes, each designed for different tasks and site conditions. Mini excavators are ideal for smaller spaces or lighter jobs, while full-size machines handle more demanding tasks. Our team is here to help you determine the best option based on your project requirements.

2. Understanding Site Conditions

The type of soil, access to the site, and potential obstacles like trees, buildings, or slopes can all influence your equipment choice.When you rent from us, we’ll ask the right questions to make sure the equipment suits your site.

3. Operator Experience

An excavator is a powerful machine that requires skill to operate safely and effectively. If you’re not experienced with this type of equipment, we can assist with operated rentals, providing a trained professional to complete the work for you.

4. Timeframe and Scheduling

Having a clear idea of your project schedule helps avoid unnecessary delays and ensures the excavator is available when you need it. We work closely with our clients to coordinate equipment delivery and pickup based on your timeline.

Why Douro-Dummer Residents and Contractors Trust Local Experts

We’ve been proudly serving Douro-Dummer and surrounding communities for years. We live here, we work here, and we care about providing reliable, trustworthy services to our neighbours.

Here’s why people across the region turn to us for their excavation needs:

1. Local Knowledge

Our team understands the unique conditions of the Douro-Dummer area, from rural terrain to waterfront properties. We’re familiar with the local regulations, soil types, and access challenges, which allows us to provide tailored advice and reliable service.

2. Well-Maintained, Reliable Equipment

We take pride in keeping our equipment in top working condition. When you rent from us, you can count on machines that are clean, inspected, and ready for work helping you avoid downtime and keep your project moving.

3. Experienced, Friendly Team

Our crew brings years of hands-on experience to every project. We’re not just equipment providers we’re partners who want to see your project succeed. Whether you need help choosing the right machine or advice on how to tackle a complex site, we’re here to support you.

4. Flexible Rental Options

Every project is different. That’s why we offer flexible rental terms, from daily to long-term rentals, so you only pay for the time you need. We’re also happy to help coordinate delivery and pickup to keep your project running smoothly.

5. Full Excavation Services Available

In addition to equipment rental, we also offer complete excavation services. If you’d prefer to leave the work to the experts, our experienced operators can take care of everything from site preparation to trenching, grading, Hydrovac excavation, and demolition.

Excavator Rental vs. Buying: Which Makes More Sense?

For many property owners and contractors, deciding whether to rent or buy equipment depends on how often it will be used and the specific demands of the project.

Renting an excavator is ideal for:

Short-term projects

Occasional use

Budget-conscious work

Access to a range of machine sizes

Avoiding maintenance and storage costs

Buying an excavator may make sense if:

You have ongoing, long-term projects

You’re experienced with maintenance and repairs

You have space to store equipment

You regularly require a specific machine size

For most homeowners, small business owners, and independent contractors, renting remains the more practical, cost-efficient solution—especially when you work with a trusted local provider.

Tips for a Smooth Excavator Rental Experience

We’re committed to helping our clients get the most out of their equipment and ensure every project runs smoothly. Here are a few simple tips to ensure everything goes according to plan:

Book Early: Equipment availability can vary, especially during peak construction seasons. Booking ahead helps secure the equipment you need when you need it.

Provide Site Details: Let us know about any site conditions, obstacles, or special requirements so we can recommend the best equipment and prepare accordingly.

Review Safety Guidelines: If you or your team will be operating the equipment, take time to review safety instructions and procedures. We’re always available to answer questions.

Ask for Support: If you’re unsure about equipment size, operation, or project requirements, don’t hesitate to reach out. Our team is happy to provide guidance and recommendations.

Ready to Tackle Your Next Project?

At Birchview Excavating, we take pride in being part of the community. For those searching for excavator rentals near me in Douro-Dummer and the surrounding areas, our reliable equipment, experienced team, and commitment to quality workmanship make us a trusted partner for property owners, contractors, and businesses throughout the region.

Whether you need equipment for a few hours or several weeks, we’re here to help make your project a success with dependable machinery, friendly service, and the local expertise you can rely on.

Contact us today to discuss your next project. We look forward to working with you.

Birchview Excavating 1511 5th Line, Douro, Douro-Dummer, K0L 2H0, Canada https://www.birchviewexcavating.ca/

0 notes

Text

Concrete Coring Near Me

Concrete Coring Near Me: What You Need to Know Before You Drill

When construction projects require precise openings in concrete, one question often arises: where can I find reliable concrete coring near me? Whether you're working on a residential renovation, a commercial upgrade, or an industrial installation, concrete coring is an essential service that allows contractors to create clean, circular holes in concrete, asphalt, stone, and other tough materials. It’s used for everything from HVAC installation to plumbing access, anchor bolt placements, or electrical wiring.

But what exactly is concrete coring? What are the benefits? And how do you know what to look for when searching for “concrete coring near me”? This comprehensive guide breaks down everything you need to know to make an informed decision before hiring or starting a concrete coring project.

Understanding the Process of Concrete Coring

Concrete coring is a technique that uses a diamond-tipped core drill to cut clean, round holes through solid surfaces. The result is a precise opening with smooth edges and minimal impact on the surrounding structure. The tool used, a core drill, can be handheld for small jobs or mounted on rigs for larger projects. It can cut through walls, floors, ceilings, and even reinforced concrete.

What sets this method apart is its accuracy and efficiency. The hollow center of the drill allows it to remove a perfect cylindrical “core” of material. This core can be saved for inspection or disposed of, depending on the project's needs.

Why Precision Matters in Concrete Coring

When you’re searching for “concrete coring near me,” you're not just looking for someone who can cut concrete—you need a provider who can do it with care, accuracy, and safety. Precision coring is vital for projects that require exact hole placement, especially in structures that contain rebar, wiring, or sensitive equipment nearby.

In many cases, these openings aren’t just rough cuts—they’re meant to house pipes, conduits, or ducts, which require accurate sizing to avoid leaks, vibrations, or future structural problems. Proper concrete coring ensures your work passes inspection and performs reliably for the long haul.

Common Applications of Concrete Coring

Concrete coring has a wide range of applications in both commercial and residential settings. Here are a few common scenarios where this service is essential:

HVAC Installation Ductwork and ventilation systems often need access through concrete slabs or walls. Coring ensures those pathways are perfectly sized and positioned.

Plumbing and Electrical Systems Concrete coring creates access holes for running water lines, drainage systems, and conduit for wiring without damaging the structural integrity of the building.

Anchor Bolt Installation For securing heavy machinery or structural steel, coring is used to drill accurate anchor bolt holes.

Drainage and Sewer Lines Larger diameter holes are often needed for utility access or wastewater routing, and coring offers a controlled way to create them.

Retrofitting and Renovation In older buildings, coring is often required to bring them up to modern codes or fit new systems into existing spaces.

Roads, Runways, and Sidewalks Municipal and airport projects use coring to install signage, lighting, and drainage features with minimal surface disruption.

Key Benefits of Hiring Local Concrete Coring Services

When you’re typing “concrete coring near me” into a search engine, what you’re really after is convenience, fast response times, and expert service. Here are some key benefits of choosing a local service provider:

1. Faster Job Turnaround Local teams can get to your site quicker, start the project sooner, and wrap up without unnecessary delays.

2. Site Knowledge and Compliance Companies familiar with your region will better understand local building codes, permit requirements, and conditions like weather or soil composition.

3. Emergency and Same-Day Service If your project is time-sensitive, finding a nearby concrete coring team gives you access to same-day or emergency services that can’t be matched by providers outside your area.

4. Cost Savings Shorter travel distances often mean fewer travel charges, which can help you stay within budget.

5. On-Site Consultations Local teams can easily assess the site in person, which is essential for planning around rebar, wiring, or post-tensioned slabs.

Tools and Techniques Used in Concrete Coring

When evaluating service providers, it’s helpful to understand what tools and methods are used in the concrete coring process:

Diamond Core Bits These bits are embedded with industrial-grade diamonds, which grind through concrete and rebar with exceptional precision.

Core Drilling Rigs For large-diameter or deep cuts, a rig-mounted drill ensures stability and control.

Water Cooling Systems Water is used to reduce dust, cool the drill, and extend the lifespan of the bit. It also keeps the worksite cleaner and safer.

Vacuum or Anchored Stands These stands keep the drill perfectly aligned, especially when drilling into vertical or overhead surfaces.

Wet vs. Dry Coring Wet coring is typically used in most jobs to reduce heat and dust. Dry coring may be used when water isn’t feasible due to the surrounding environment.

Things to Consider Before Hiring for Concrete Coring Near Me

Choosing a provider isn’t just about location—it’s about capability, reliability, and safety. Here are several factors to keep in mind before selecting a coring contractor:

1. Equipment Quality Look for providers who use up-to-date tools and rigs that are well-maintained.

2. Safety Record Drilling through concrete can be dangerous if not done correctly. Ask about their safety procedures and training standards.

3. Experience with Similar Projects Has the team worked on buildings like yours? Do they understand the challenges specific to your project type?

4. Clear Pricing and Estimates Reputable coring providers will offer detailed pricing upfront, with no surprise charges for equipment, cleanup, or labor.

5. Reviews and Testimonials Check online reviews or ask for references. A company with a strong track record will likely have satisfied customers who can vouch for their work.

6. Clean-Up and Disposal Make sure the team handles clean-up, slurry management, and disposal of concrete cores so you’re not left with a mess.

Safety Measures in Concrete Coring

Safety is a top priority when drilling into dense materials. Professional concrete coring teams should adhere to strict safety protocols, including:

Using personal protective equipment (PPE)

Scanning the area for embedded rebar or cables

Marking utilities and potential hazards

Containing slurry and dust from wet drilling

Ensuring the drill is securely mounted and aligned

Choosing a local service that emphasizes safety not only protects the crew but also minimizes liability on your end.

Environmental Benefits of Professional Coring

Professional concrete coring also offers some environmental advantages. The precision of diamond drilling minimizes waste, and the use of water for wet cutting reduces harmful airborne silica dust, which poses a serious health risk. In many cases, the removed concrete cores can be recycled or repurposed, contributing to sustainable construction practices.

Conclusion: The Value of Finding Reliable Concrete Coring Near Me

Concrete coring is an essential part of modern construction, and having a reliable service provider nearby can make all the difference in the efficiency and success of your project. From clean, accurate openings to minimal mess and disruption, this process is designed to help you complete your build or retrofit safely and on schedule.

When you search for concrete coring near me, what you’re really looking for is a team that’s local, dependable, and experienced in delivering precision results. With the right partner, you’ll not only save time and money—you’ll get the peace of mind that comes from knowing your concrete work is in expert hands.

1 note

·

View note

Text

Common Pipe Coupling Types and Their Applications in Industrial Systems

In industrial environments, piping systems form the circulatory network for transporting fluids, gases, and electrical conduits. Ensuring seamless connections in these systems is critical to their performance, safety, and longevity. That’s where pipe couplings come into play — providing a secure, leak-proof method to join pipe segments under varying pressures and temperatures.

What Are Pipe Couplings?

Pipe couplings are short lengths of pipe or fittings used to connect two pipes. They may be rigid or flexible, permanent or detachable, and are manufactured in various materials including stainless steel, galvanized iron, copper, and PVC. The choice of coupling depends on the pipe material, application, operating pressure, and environmental exposure.

Common Types of Pipe Couplings and Their Uses

Rigid Couplings Used in applications where no movement is required, such as water supply or compressed air systems. These couplings offer a tight and permanent seal.

Flexible Couplings Ideal for applications involving vibration or thermal expansion. They absorb shock and misalignment between pipes, commonly used in pump or motor piping systems.

Threaded Couplings Widely used in smaller diameter pipe systems, especially in plumbing, HVAC, and gas supply lines.

Compression Couplings These are tool-free options for quick repairs or temporary connections. They are ideal in fieldwork or emergency maintenance.

Grooved Couplings Designed for easy assembly and disassembly, these are used in large piping systems for fire protection, mining, or oil & gas pipelines.

Flanged Couplings Often used where disassembly is required, such as at equipment interfaces. They’re ideal for high-pressure and corrosive environments.

Industrial Applications

Oil & Gas Plants: For connecting steel pipes carrying crude, water, or steam.

Power Generation: Used in systems that require thermal expansion tolerance.

Chemical Plants: Where chemical resistance and leak-proof seals are critical.

HVAC & Plumbing: For both residential and industrial infrastructure.

Firefighting Systems: Grooved couplings enable quick assembly and replacement in fire suppression pipelines.

Gulf Trans Power’s Coupling Solutions

At Gulf Trans Power, we understand that each industrial project has specific requirements. That’s why we supply a diverse range of coupling types and sizes, tailored for every application and environmental challenge. Our products meet international quality standards and are engineered for maximum reliability and lifespan.

In addition to coupling systems, Gulf Trans Power is also one of the most trusted earthing material suppliers in Saudi Arabia, offering ground rods, clamps, cables, and bonding kits that ensure electrical safety and grounding efficiency across facilities.

Why Choose Gulf Trans Power?

Wide Stock Availability We maintain inventory of standard and special-order couplings for immediate dispatch.

Custom Solutions Need a coupling for an unusual pipe material or size? We’ll source or fabricate it.

Compliant and Certified All products conform to relevant international and regional standards.

Expert Technical Support Our team helps you select the right coupling type for your project, ensuring optimal fit and function.

Final Thoughts

Couplings may seem like small components, but they’re essential for the structural integrity and efficiency of your industrial piping systems. Whether you’re setting up a new plant, performing maintenance, or expanding an existing facility, choosing high-quality couplings for pipes is crucial. With Gulf Trans Power, you gain a supplier that offers not only top-tier pipe connection solutions but also complete system support from one of the leading earthing material suppliers in the region.

👉 Explore our full range of pipe fittings, electrical bulk materials, and grounding solutions here: https://www.gulftranspower.com/products/electric-bulk-materials/

0 notes

Text

Pipe Factories in Egypt

Here’s an enhanced, well-structured overview of pipe factories in Egypt, with no company names or external links, and supported by diverse citations:

At the heart of Egypt’s infrastructure development lies a robust pipe‐manufacturing sector specializing in plastic and ductile-iron products. Leveraging modern extrusion technology, factories produce PVC/UPVC, HDPE, PPR, GRP, and iron pipes to serve water, sewage, irrigation, gas, and industrial networks. Domestic production capacity has risen steadily, reducing import dependence—imports fell to 59.4 million USD in 2022 (down 17.8% since 2019) —while exports, particularly of HDPE, grew to capture key markets across Africa and beyond . Factories adhere to international standards (ISO, ASTM, DIN), employ pressure and mechanical testing for quality assurance, and increasingly embrace recycling of production scrap and energy-efficient processes. Located mainly in major industrial zones such as Giza’s Engineering Square , this sector is poised for continued growth—Cognitive Market Research projects Egypt’s HDPE pipe market at USD 44.62 million in 2024 with a 5.9% CAGR to 2031 .

Materials & Product Range

Egyptian pipe factories manufacture several key types:

PVC/UPVC for drinking water and sewerage, valued for corrosion resistance and light weight .

HDPE for high-pressure water and gas lines, prized for flexibility, impact strength, and recyclability .

PPR for hot/cold potable water, offering thermal and pressure tolerance .

GRP (glass-reinforced polyester) for large-diameter, heavy-load applications like drainage and industrial effluent.

Ductile Iron increasingly produced for heavy-duty infrastructure, combining strength with durability.

Manufacturing Process

Raw Material Preparation Granules are dried, filtered, and blended with stabilizers and colorants to meet strict performance specs .

Extrusion The mix is melted in twin-screw extruders and forced through precision dies to form continuous pipe lengths .

Cooling & Calibration Pipes pass through water baths and vacuum calibration tanks, ensuring tight dimensional tolerances.

Cutting & Labeling Lengths are cut automatically; each piece is stamped with diameter, wall thickness, and production date for traceability .

Quality Assurance & Standards

Pressure Testing: Verifies pipes remain leak-free under operating pressures .

Mechanical Testing: Assesses tensile strength, burst pressure, and impact resistance.

Chemical & Thermal Tests: Ensure compatibility with potable water and industrial fluids.

Standards Compliance: Factories conform to ISO, ASTM, and DIN norms to ensure global interoperability.

Economic & Environmental Impact

Import Trends: In 2022, Egypt’s imports of plastic pipes and fittings declined to 59.4 million USD, down 17.8% from 2019, reflecting stronger local output .

Export Performance: Egypt exports HDPE pipes to over 20 countries, with leading markets in the USA, Argentina, and Uganda, collectively accounting for 70% of volumes .

Sustainability Practices: Scrap from cutting and calibration is recycled; energy-efficient heating systems reduce carbon footprint.

Employment & Growth: The sector supports thousands of direct jobs and drives ancillary services in logistics and maintenance.

Key Applications

Municipal Water & Sewage: Reliable networks built with PVC, UPVC, and HDPE.

Agricultural Irrigation: Flexible HDPE systems for drip and sprinkler setups.

Gas Distribution: High-pressure HDPE and ductile-iron pipes ensure safe delivery.

Industrial & Chemical Lines: GRP and PPR pipes handle aggressive fluids and high temperatures.

Telecommunications: Pipes serve as underground conduits for fiber-optic and electrical cables.

Future Outlook

With national infrastructure initiatives and rising regional demand, Egypt’s pipe manufacturing is set for expansion. Continued investment in:

Advanced Extrusion Lines

Automated Quality Inspection

Sustainable Operations

0 notes

Text

5 Ways Knockout Punches Can Streamline Operations in Your New Small Business

Starting a new business comes with countless decisions — especially when it comes to selecting the right tools for production, fabrication, or electrical work. One underrated yet highly effective tool that can make a major difference in operational efficiency is the knockout punches. Whether you’re setting up a metal shop, manufacturing unit, or electrical contracting business, knockout punches offer precision, speed, and reliability.

Here are five ways these tools can help streamline your operations from day one.

1. Precision and Consistency in Punching Holes

Knockout punches allow you to create clean, uniform holes in sheet metal, plastic, or other materials. This is critical for maintaining professional-quality finishes in control panels, electrical boxes, or structural components. A consistent cut not only looks better but also supports better assembly and fit, reducing rework time.

2. Faster Fabrication and Installation

Time is money in any business. Knockout punches dramatically reduce the time it takes to drill and finish holes manually. With manual, hydraulic, or battery-powered models, you can speed up repetitive tasks, helping your team meet tight project timelines without compromising on quality.

3. Minimal Material Waste

Manual drilling or cutting methods often produce ragged edges or imprecise holes, leading to scrap or the need for additional finishing. Knockout punches reduce waste by providing smooth, burr-free holes, which minimizes the need for grinding or sanding and helps conserve raw materials.

4. Ease of Use for New Hires

If you're building a small team, you need tools that are user-friendly. Knockout punches require minimal training, especially manual or hydraulic types with guide markings. This makes them ideal for new employees or apprentices, allowing them to contribute productively from the start.

5. Compact and Portable Design

Space is often limited in new business setups. Knockout punch kits are compact, lightweight, and easy to store or carry to job sites. Their portability makes them a go-to tool for on-the-spot modifications, especially in field service or contract work.

Common Questions About Knockout Punches

Q1: What materials can knockout punches cut through?

A: Most knockout punches are designed for sheet metal (steel, aluminum), stainless steel, and certain plastics. Always check the tool specs for material compatibility.

Q2: Do I need power tools to use knockout punches?

A: Not necessarily. Manual knockout punches work well for smaller holes and thinner materials. For larger or more frequent punching, hydraulic or battery-powered versions are more efficient.

Q3: Are knockout punches only for electricians?

A: While knockout punches are popular among electricians for making conduit holes in panels, they’re also widely used in HVAC, metal fabrication, manufacturing, and custom enclosure design.

Final Thoughts

Investing in the right tools early can give your new small business a major operational edge. Knockout punches not only simplify and speed up routine tasks but also contribute to a safer, cleaner, and more professional workspace. Whether you’re punching holes in sheet metal or customizing enclosures, these tools prove their value from day one.

📞 Need Help Finding the Right Knockout Punches?

Get expert guidance tailored to your business needs. Whether you're looking for a starter kit or heavy-duty punches for frequent use, we're here to help. 👉 Contact us today for a custom quote or product recommendation!

0 notes

Text

How Does A Suspended Gyprock Ceiling Improve Functionality And Design?

A suspended gyprock ceiling is a secondary ceiling system made from Gyprock plasterboard sheets, which are suspended below the original structural ceiling. This method is widely used in both residential and commercial interiors where design flexibility, utility concealment, and sound insulation are priorities.

By incorporating a suspended gyprock ceiling, spaces can benefit from clean, smooth finishes while also housing electrical cabling, air conditioning ducts, and other infrastructure. It offers a modern and efficient solution to ceiling construction, particularly in spaces that require practical and aesthetic enhancements.

What Makes a Suspended Gyprock Ceiling Unique?

Lightweight CompositionGyprock is a brand of plasterboard known for its light weight and ease of handling. This makes it ideal for suspended applications where added weight on the ceiling structure needs to be minimised.

Smooth Finish CapabilityOnce installed, the ceiling provides a uniform and seamless surface that can be easily painted or decorated. The material accepts a range of finishes to suit any interior style.

Design VersatilityFrom simple flat planes to recessed or stepped ceiling features, Gyprock allows for multiple design interpretations. It can be shaped and layered to meet various architectural needs.

Fire and Acoustic PropertiesGyprock plasterboard is available in fire-rated and acoustic variants. These contribute to overall building safety and comfort, especially in multi-level dwellings or commercial premises.

What Is the Installation Process?

Framing System ConstructionA grid of metal channels is suspended from the main ceiling using hangers or rods. This creates a stable base to support the Gyprock sheets.

Plasterboard Sheet FixingSheets of Gyprock are attached to the frame with screws. Care is taken to align them precisely and leave expansion gaps where necessary.

Jointing and FinishingTaping and compound are used to seal the joints between sheets. Once dried, the surface is sanded to create a flawless finish ready for painting.

Integration of ServicesElectrical boxes, air vents, or light fittings are incorporated during installation. Openings are cut in the Gyprock sheets before they are secured in place.

In What Settings Is This Ceiling Type Beneficial?

Office EnvironmentsIn corporate settings, these ceilings provide space for concealed lighting, climate control systems, and soundproofing materials without compromising design aesthetics.

Home InteriorsPopular in living rooms, bedrooms, and kitchens, Gyprock ceilings can help define zones or hide service conduits while maintaining a clean ceiling appearance.

Healthcare and EducationIn clinics or classrooms, suspended ceilings made from Gyprock offer hygienic surfaces that also support acoustic treatments for better communication and concentration.

Hospitality SpacesRestaurants and hotels use them to conceal infrastructure while enabling lighting and acoustic design flexibility.

What Customisation Options Are Available?

Coffered and Stepped DesignsSuspended ceilings can include recessed or layered sections for visual depth. These are especially common in formal dining rooms or conference halls.

Lighting IntegrationGyprock supports recessed lighting fixtures and cove lighting. This enables even light distribution and design harmony within the space.

Acoustic PanelsGyprock ceilings can incorporate sound-absorbing materials above or within the ceiling void. This helps reduce echo and improves audio clarity in rooms.

Access HatchesWhere regular maintenance is required, access hatches can be installed without disrupting the overall ceiling design.

How Does It Compare to Other Ceiling Types?

Versus Tiled Drop CeilingsA suspended Gyprock ceiling provides a much cleaner and more permanent finish than typical grid-tile ceilings found in older offices or industrial settings.

Versus Traditional PlasterTraditional lath and plaster ceilings are heavier and more labour-intensive. Gyprock offers a modern alternative that is faster and more cost-effective to install.

Versus Direct MountA suspended system allows service space between the structural ceiling and plasterboard — something direct-mount ceilings do not provide.

Versus Timber CeilingsTimber may be more decorative, but it’s less versatile in terms of integration with modern services like lighting and ventilation.

What Maintenance and Considerations Are Important?

Surface UpkeepThe ceiling should be dusted periodically and repainted as needed. Smooth surfaces make this easy to maintain over time.

Moisture AwarenessStandard Gyprock is not moisture resistant. In damp areas, water-resistant plasterboard variants should be used to avoid mould or sagging.

Access PlanningIf future access to concealed services is anticipated, plan for access hatches during the design phase to avoid damaging the plasterboard later.

Load Bearing LimitationsHeavy fixtures such as ceiling fans must be independently supported by the structural ceiling, not by the suspended plasterboard.

A well-designed suspended gyprock ceiling provides a reliable and attractive solution for both modern and traditional interiors. It combines design flexibility with practical features such as service integration and sound insulation. Whether in residential homes or commercial spaces, its balanced functionality and finish make it a preferred option among builders and designers alike.

0 notes

Text

From Pipes to Panels: Stainless Steel Clamps for Every Industry

Ladhani Metal Corporation, a leading Stainless Steel Clamp Manufacturer in India, is proud to deliver high-performance clamping solutions trusted across multiple sectors from plumbing to pharmaceuticals, automotive to architecture. In today’s fast-paced industries, even the smallest components must meet the highest standards. Stainless Steel Clamps are a prime example: compact, robust, and essential for ensuring secure connections.

As industries evolve and demand more from their systems, these clamps are becoming the go-to choice for durability, hygiene, and long-term reliability.

Why Stainless Steel Clamps Lead the Way

Behind their simple design, Stainless Steel Clamps are engineered to provide unmatched performance under extreme conditions. These clamps resist corrosion, support heavy loads, and hold their shape even when exposed to fluctuating temperatures.

Key benefits include:

Corrosion Resistance – Perfect for marine, chemical, and outdoor environments.

High Strength – Capable of securing large pipes and panels under pressure.

Temperature Tolerance – Reliable in both high-heat and freezing conditions.

Non-reactive Material – Ideal for food-grade and pharmaceutical applications.

Low Maintenance – Durable with a long service life.

As a top Stainless Steel Clamp Supplier in India, we offer clamps that meet international quality standards and serve every major sector.

Stainless Steel Clamps in Every Industry

From large-scale pipelines to delicate instrumentation panels, stainless steel clamps are everywhere. Here's how various industries benefit:

1. Plumbing & Water Management

Used to support water supply lines, drainage systems, and underground pipes, Stainless Steel Clamps offer leak-proof, vibration-free operation. Their corrosion resistance makes them a preferred choice for long-term water infrastructure projects.

2. Automotive & Transportation

From securing turbocharger systems to fuel lines and coolant hoses, Stainless Steel Clamp Manufacturers provide solutions built for high-heat and high-vibration environments. These clamps ensure performance and safety in vehicles, boats, and aircraft.

3. Construction & Infrastructure

Whether securing HVAC ducts, cable trays, or solar panel mounting systems, stainless steel clamps are vital in structural applications. Their weather resistance and load-bearing capacity make them a smart choice for modern construction.

4. Food & Beverage Industry

In environments where hygiene is paramount, stainless steel clamps prevent contamination and withstand rigorous cleaning processes. Commonly used in dairies, breweries, and food processing units.

5. Pharmaceutical & Medical Fields

Cleanrooms and sterile production lines rely on stainless steel clamps to maintain pressure and prevent leaks in fluid transfer systems. Grade 316 clamps are especially common due to their higher chemical resistance.

6. Oil & Gas Sector

Designed to endure harsh conditions, these clamps secure pipelines and containment systems in both offshore and onshore installations.

7. Renewable Energy & Electrical Systems

Used for cable management, conduit mounting, and solar panel installations, stainless steel clamps are essential in modern energy systems.

Choosing the Right Stainless Steel Clamp

When selecting clamps, consider:

Material Grade: 304 for general use, 316 for corrosive environments.

Clamp Type: Worm drive, T-bolt, V-band, or spring clamps — each suited to different needs.

Load and Fit: Match the clamp to the system dimensions and operating conditions.

As a trusted Stainless Steel Clamp Supplier, we help clients to choose the perfect clamp for their application.

Conclusion