#Spray Drying Equipment Market Research

Explore tagged Tumblr posts

Text

0 notes

Text

Fluid Bed Dryer Granulator Processor: A True All-in-One Solution?

The Multitasking Marvel of Pharmaceutical Production

Efficiency and quality are paramount in pharmaceutical manufacturing. Drug production demands precision, consistency, and streamlined processes. This is where the fluid bed dryer granulator processor shines. This versatile system has revolutionized how pharmaceuticals and other products are made, offering a compelling solution for companies seeking to optimize production and enhance product quality. But does it truly live up to its all-in-one claim? Let's explore this multifaceted technology.

What is a Fluid Bed Dryer?

A stream of hot air is used by a fluid bed drier to dry solids. The material is suspended and agitated by the upward airflow, creating a "fluidized bed" where each particle is enveloped in drying gas. This ensures efficient heat and mass transfer, resulting in rapid and uniform drying. While widely used in pharmaceuticals, fluid bed dryer are also employed in food processing, chemical production, and agriculture for drying powders, granules, and crystals.

What is a Fluid Bed Granulator?

Granulation combines small particles into larger granules, improving flow properties, reducing dust, and enhancing compressibility for tablet formation. A fluid bed granulator achieves this by spraying a binding solution onto the fluidized bed, causing particles to agglomerate into granules. This method offers precise control over granule size and density, ensuring consistent product quality.

What is a Fluid Bed Processor?

A fluid bed processor expands on the dryer and granulator, enabling coating, agglomeration, and spheronization. This versatility makes it invaluable for developing and manufacturing a wide range of products with specific characteristics. Fluid bed processing allows for modifying particle size, shape, and surface properties, improving drug dissolution, bioavailability, and stability.

Fluid Bed Dryer Granulator Processor: The All-in-One Wonder

The beauty of this system lies in its ability to perform multiple operations in a single unit. This eliminates transferring materials between different pieces of equipment, reducing contamination risk, minimizing material losses, and streamlining production. By combining drying, granulation, and other processing steps, it significantly reduces production time and labor costs while minimizing equipment footprint.

Advantages of Using a Fluid Bed Dryer Granulator Processor

Consistent processing conditions are guaranteed by fluid bed technology, which produces consistently high-quality products. The all-in-one nature minimizes downtime associated with equipment changeovers and cleaning.Additionally, it lessens the need for manual intervention, which lowers labor expenses. Fluid bed dryer granulator processors can be customized to meet specific product requirements and production volumes, allowing manufacturers to adapt to changing market demands.

Industries that Benefit

Pharmaceutical Industry: Ensures drug quality and efficacy in producing tablets, capsules, powders, and granules.

Food Industry: Preserves flavor, aroma, and nutritional value while extending the shelf life of products like fruits, vegetables, and spices.

Chemical Industry: Enables precise processing for consistent results in drying, granulation, coating, and agglomeration.

Choosing the Right System

Selecting the appropriate system requires considering factors like production capacity, desired features, and customization options. Researching reputable manufacturers specializing in fluid bed technology is crucial.

Maintenance and Troubleshooting

It is essential to do routine maintenance, which includes cleaning, inspecting, and replacing worn parts. Reducing downtime can be achieved by being aware of typical issues and how to resolve them. Consulting the manufacturer's troubleshooting guide or seeking expert assistance can be beneficial.

The Future of Fluid Bed Dryer Granulator Processors

Ongoing research and development focus on improving efficiency, sustainability, and automation. Advancements in process analytical technology (PAT) and control systems enable real-time monitoring and optimization of fluid bed processes. Fluid bed technology is inherently energy-efficient, and further advancements aim to reduce energy consumption, minimize waste, and utilize eco-friendly materials.

Conclusion: Investing in Efficiency and Quality

Fluid bed dryer granulator processors offer a compelling solution for industries seeking to optimize production and enhance product quality. Their versatility, efficiency, and ability to streamline operations make them a valuable investment. By carefully considering their needs and selecting the right equipment, companies can reap the numerous benefits of this all-in-one technology, ensuring consistent product quality, improved process efficiency, and a competitive edge.

0 notes

Text

Conveyor Belt Washer, The Top 15 Largest Companies in World Ranked by Revenue in 2023 (2023)

Conveyor Belt Washer Market Summary

A conveyor belt washer is a type of industrial washing machine that is used to clean equipment and products that move along a conveyor belt. This type of machine can be used in a variety of sectors, such as food and beverage, pharmaceuticals, and electronics manufacturing. The conveyor system is typically made up of several sections, including a loading area, washing section, rinsing section, and a drying section. The machine uses either a spray system or immersion technology to remove contaminants and other impurities from the surface of the products or equipment. The washing process is automated and can be customized to fit the specific needs of each user. Conveyor belt washers are designed to be efficient, reliable, and easy to operate, and they can handle large volumes of products and equipment in a short amount of time.

According to the new market research report "Global Conveyor Belt Washer Market Report 2024-2030", published by QYResearch, the global Conveyor Belt Washer market size is projected to reach 104 million by 2030, at a CAGR of 4.7% during the forecast period.

Figure. Global Conveyor Belt Washer Market Size (US$ Million), 2019-2030

Figure. Global Conveyor Belt Washer Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of Conveyor Belt Washer include Cleaning Technologies Group, RG Hanson, PROCECO, Jenfab Cleaning Solutions, Almco Inc, Alliance Manufacturing, ANMASI A/S, Better Engineering, Niagara Systems, International Thermal Systems, etc. In 2023, the global top five players had a share approximately 50.0% in terms of revenue.

Figure. Conveyor Belt Washer, Global Market Size, Split by Product Segment

In terms of product type, currently Medium Belt Washer (24"-48") is the largest segment, hold a share of 25.0%.

Figure. Conveyor Belt Washer, Global Market Size, Split by Application Segment

In terms of product application, currently Automotive is the largest segment, hold a share of 30.6%.

Figure. Conveyor Belt Washer, Global Market Size, Split by Region

About The Authors

Jiashi Dong

Lead Author

Email: [email protected]

QYResearch Nanning Branch Analyst, as a member of the QYResearch Semiconductor Equipment and Materials Department, his main research areas include automotive electronics, semiconductor equipment, materials and thermally conductive powders. Some subdivided research topics include automotive diodes, automotive inductors, automotive lidar, radio frequency power supplies, plastic sealing machines, high-purity non-ferrous metals, battery materials, precursors, electroplating equipment, thermal conductive ball aluminum, semiconductor chemical plating solutions, semiconductor coating devices, etc. At the same time, he is also engaged in the development of market segment reports and participates in the writing of customized projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

0 notes

Text

0 notes

Text

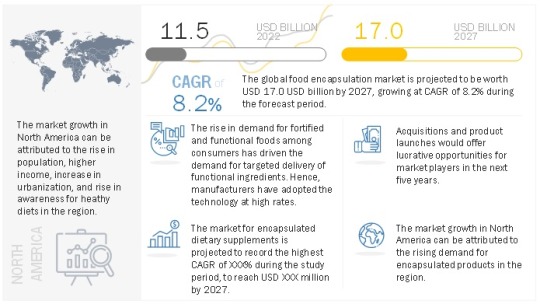

Food Encapsulation Market Company Share, Growth Drivers, and Forecast - 2027

The global food encapsulation market was valued at USD 11.5 billion in 2022 and is projected to reach USD 17.0 billion by 2027, growing at a CAGR of 8.2% during the study period. The market for encapsulation is growing globally at a significant pace due to its numerous applications and multiple advantages over other technologies. Some of the major advantages of encapsulation are that it helps provide enhanced stability and bioavailability to the bioactive ingredients, increases the shelf life of food products, and maintains the taste and flavor for a longer period of time. Encapsulation is increasingly used in various industrial areas, such as nutraceuticals and food & beverages.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=68

Restraints: More inclination toward traditional preservation methods over encapsulation techniques

Manufacturers of small and medium-sized companies in the food & beverage industry use the traditional method of preservation techniques over the encapsulation technique because food encapsulation can be expensive. New markets are being established within the functional foods sector, and researchers are in the process of meeting this demand to reduce high production costs. Encapsulation results in extra cost, which needs to be minimized to be economically acceptable by all manufacturers. This applies not only to the materials used to build capsules but also to the equipment or processing conditions. The number of core materials suitable for encapsulation is also limited. Currently, only a few bioactive ingredients and specialty ingredients, such as artificial sweeteners and encapsulated flours, which have been encapsulated, are showing desired results in terms of their sensorial properties in food applications. Further research is needed to successfully encapsulate ingredients that provide an edge over other techniques.

Energy-efficiency of spray chilling technique to drive its use in bakery products.

Spray chilling is also known as spray cooling, prilling, or spray congealing. Spray chilling is the process of solidifying an atomized liquid spray into particles. In this method, a mixture of core and wall is atomized into the cooled or chilled air, which causes the wall to solidify around the core. Unlike spray-drying, spray-chilling does not involve mass transfer (water evaporation). Therefore, it is more energy efficient. In the spray cooling method, the coating material is typically some kind of vegetable oil or its derivatives, including fat and stearin, with melting points of 45°C - 72°C.

Make an Inquiry: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=68

North America dominated the food encapsulation market; it is projected to grow at a CAGR of 7.8% during the forecast period.

The food encapsulation market in North America is influenced by factors like health awareness, the promotion of nutraceuticals and functional foods, and growing expenditure on prevention of chronic noncommunicable diseases. Food encapsulation adds value to foods and effectively delivers potent bioactives in isolation as supplements or as value addition in functional foods. The US dominated the market in 2021 and is projected to be the fastest-growing market for food encapsulation in North America. The market in this region is driven by technological advancements in food encapsulation techniques such as liposome compression, inclusion complexes, and centrifugal extrusion and the growing demand for functional and fortified foods that use encapsulated nutrients and the growing consumption of convenience foods that use encapsulated flavors and colors. Most of the key market players have a presence in the region.

The key players in this market include Cargill, Incorporated (US), Balchem (US), International Flavors & Fragrances Inc. (US), and Encapsys LLC (US).

#Food Encapsulation Market#Food Encapsulation#Food Encapsulation Market Size#Food Encapsulation Market Share#Food Encapsulation Market Growth#Food Encapsulation Market Trends#Food Encapsulation Market Forecast#Food Encapsulation Market Analysis#Food Encapsulation Market Report#Food Encapsulation Market Scope#Food Encapsulation Market Overview#Food Encapsulation Market Outlook#Food Encapsulation Market Drivers#Food Encapsulation Industry

0 notes

Text

Spray Drying Equipment Market Size Worth $7.19 Billion By 2025

The global spray drying equipment market size is estimated to reach USD 7.19 billion by 2025 registering a CAGR of 6.8%, according to a new study by Grand View Research, Inc. Spray drying envisages transforming a liquid, slurry, or semi-solid feed into a dried powder form using hot gas. It is a widely preferred method to dry food materials, pharmaceutical products, and other temperature-sensitive…

View On WordPress

0 notes

Text

Consumer Demand for Organic to Drive Biopesticides Market

The global biopesticides market is anticipated to advance at a CAGR of 15.13% during the forecast period 2023-2030.

Triton Market Research presents the Global Biopesticides Market report segmented by Formulation (Liquid Formulation, Dry Formulation), Product (Bioherbicide, Bioinsecticide, Biofungicide, Other Products), Mode of Application (Foliar Spray, Seed Treatment, Soil Treatment, Post-Harvest), Application (Crop [Grains and Cereals, Oil Seeds, Fruits and Vegetables], Non-Crop [Turf and Ornamental Grass, Other Non-Crops]), Ingredient (Microbial [Bacteria, Virus, Fungal, Nematode, Other Microbials], Biorational [Botanical {Insect Growth Regulators, Feeding Detergents, Repellants, Confusants, Plant Allelopathy, Plant Growth Regulator, Fungicidal Control, Induced Resistance, Pyrethrum, Neem, Essential Oils}, Semiochemical {Repellants, Pheromones, Kairomones, Allomones}), and Regional Outlook (North America, Asia-Pacific, Latin America, Middle East and Africa, Europe).

The report further includes the Market Summary, Industry Outlook, Impact of COVID-19, Key Insights, Porter’s Five Forces Analysis, Market Maturity Analysis, Regulatory Framework, Key Market Strategies, Drivers, Challenges, Opportunities, Competitive Landscape, Research Methodology & Scope, Global Market Size, Forecasts & Analysis (2023-2030).

According to Triton’s research report, the global biopesticides market is anticipated to advance at a CAGR of 15.13% during the forecast period 2023-2030.

A biopesticide is derived from natural materials or organisms to control pests, including insects, weeds, and pathogens, in agriculture and other fields. Unlike chemical pesticides, which are often synthetic and can have harmful environmental and health effects, biopesticides are generally considered more environmentally friendly and sustainable.

Growing consumer preference for organic products is anticipated to expand the biopesticides market during the projected period. Organic food and related agriculture account for around 5-10% of the total food sector. Therefore, the increasing popularity of organic farming leads to increased demand for biopesticides. Moreover, the rising use of nano biopesticides in pest control coupled with advanced genetic engineering will create lucrative opportunities for the reviewed market.

However, the development of the biopesticides market is hindered by constraints such as precision targeting and limited product availability.

The Asia-Pacific is anticipated to experience the fastest growth over the forecasted period. China is the dominant player in the biopesticides market, closely followed by India. For instance, the Chinese government has introduced subsidies to encourage developing and using environmentally friendly pesticides, especially for major cereal crops. This push is driven by the urgent need to meet the escalating food demands of the growing population. In the country, where pesticide use has historically been minimal, biopesticides are widely opted as a sustainable solution, significantly driving the Asia-Pacific biopesticides market.

The established companies in the biopesticides market include Pro Farm Group, Rovensa Group, Isagro SpA, Koppert Biological Systems, Andermatt Group AG, BioWorks Inc, BASF SE, IPL Biologicals Limited, Certis Europe BV, Bayer CropScience AG, Novozymes A/S, The Stockton Group, and Valent BioSciences Corporation.

The initial investment required to start a biopesticide manufacturing company is relatively low. This is facilitated by the ready availability of essential raw materials such as crops, growth materials, and production equipment in local markets, which can be acquired with little capital investment. In addition, the growing demand for biopesticides provides a favorable environment for new players to enter the market. This regulatory advantage encourages companies to expand their biopesticide portfolio. Hence, the threat of new entrants is expected to be high over the forecast years.

0 notes

Text

Aerosol Marking Paint, Global Market Size Forecast, Top 12 Players Rank and Market Share

Aerosol Marking Paint Market Summary

Aerosol marking paint is a type of paint that is sprayed in aerosol form and is commonly used for marking and painting on various surfaces. It is made up of pigments, solvents, and propellants. Aerosol marking paint is known for its ease of use, quick drying time, and bright colors, making it suitable for applications such as road marking, construction, and sports field marking.

According to the new market research report “Global Aerosol Marking Paint Market Report 2023-2029”, published by QYResearch, the global Aerosol Marking Paint market size is projected to reach USD 4.56 billion by 2029, at a CAGR of 6.3% during the forecast period.

Figure. Global Aerosol Marking Paint Market Size (US$ Million), 2022-2029

Above data is based on report from QYResearch: Global Aerosol Marking Paint Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

Figure. Global Aerosol Marking Paint Top 12 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Aerosol Marking Paint Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Aerosol Marking Paint include Sherwin-Williams (Krylon), Nippon Paint, PPG, Rust-Oleum, 3M, Technima, SANVO Fine Chemicals Group, Seymour, Dy-Mark, LA-CO Industries, etc. In 2022, the global top five players had a share approximately 59.36% in terms of revenue.

Market Drivers:

Infrastructure Development: The growth of infrastructure development projects, such as road construction and expansion, contributes to the demand for aerosol marking paints. As more roads, highways, and parking lots are built, the need for efficient and effective marking solutions increases.

Urbanization: The trend towards urbanization and the development of smart cities also drives the demand for aerosol marking paints. With increasing population densities and limited space, well-marked roads, parking lots, and public spaces become more important for safety and efficient use of space.

Athletic Facilities: The growing popularity of sports and recreational activities, such as soccer, football, and track and field, creates demand for marking paints specifically designed for use on athletic fields. These paints are designed to be durable and withstand harsh weather conditions.

About The Authors

Yunmei Sun---Lead Author

Email: [email protected]

Sun Yunmei has 2 years of industry research experience, focusing on research in the chemical industry chain related fields, including medical grade reagents, high-purity reagents for semiconductors, and chemical laboratory equipment.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Revolutionizing Vehicle Protection: Waterborne Automobile Coatings Market Overview

The waterborne automobile coatings market has witnessed significant growth in recent years due to the increasing demand for environmentally friendly and sustainable coatings in the automotive industry. Waterborne coatings offer various advantages over traditional solvent-based coatings, such as lower VOC emissions, reduced environmental impact, and improved worker safety. This article provides a comprehensive overview of the waterborne automobile coatings market, including its current status, key drivers and challenges, market segmentation, and future prospects.

Market Overview:

The waterborne automobile coatings market refers to the market for coatings that are used to protect and enhance the appearance of automotive vehicles, such as cars, trucks, and motorcycles. These coatings are water-based and consist of resins, pigments, additives, and water as the primary solvent. Waterborne coatings have gained popularity in the automotive industry due to their superior performance, ease of application, and compliance with stringent environmental regulations.

Market Drivers:

Several factors are driving the growth of the waterborne automobile coatings market:

a. Environmental Regulations: Increasingly stringent regulations regarding volatile organic compound (VOC) emissions have compelled automotive manufacturers to shift towards eco-friendly coating solutions, boosting the demand for waterborne coatings.

b. Sustainability Initiatives: Rising awareness about environmental sustainability among consumers has led to a growing preference for waterborne coatings, as they offer reduced emissions and a lower carbon footprint compared to solvent-based coatings.

c. Performance and Quality: Waterborne coatings have evolved significantly in terms of performance and quality, providing excellent durability, corrosion resistance, and aesthetic appeal to automotive finishes.

d. Technological Advancements: Ongoing research and development efforts have resulted in the development of advanced waterborne coating formulations, leading to improved properties and increased adoption in the automotive industry.

Market Segmentation:

The waterborne automobile coatings market can be segmented based on the type of coating, layer, vehicle type, and region:

a. By Type of Coating:

Basecoat: Provides color and aesthetic appeal. Primer: Ensures adhesion and corrosion protection. Clearcoat: Offers gloss and protection against UV radiation. Electrocoat: Used for electrodeposition of coatings.

b. By Layer:

Single-layer Waterborne Coatings: Consist of a single coating layer. Multi-layer Waterborne Coatings: Comprise multiple coating layers, including basecoat, primer, and clearcoat.

c. By Vehicle Type:

Passenger Cars: Includes sedans, hatchbacks, SUVs, and other personal vehicles. Commercial Vehicles: Encompasses trucks, buses, and other commercial transportation vehicles. Two-Wheelers: Includes motorcycles, scooters, and bicycles.

d. By Region:

North America Europe Asia Pacific Latin America Middle East and Africa Market Challenges:

Despite the positive growth trajectory, the waterborne automobile coatings market faces some challenges:

a. High Cost: Waterborne coatings often have higher initial costs compared to solvent-based coatings due to the use of advanced technologies and raw materials.

b. Limited Application Techniques: Waterborne coatings require specific application techniques, such as electrostatic spraying or airless spraying, which may necessitate investment in equipment and training.

c. Drying Time: Waterborne coatings typically have longer drying times compared to solvent-based coatings, which can impact production efficiency.

Future Prospects:

The future of the waterborne automobile coatings market looks promising:

a. Increasing Adoption: As environmental regulations become more stringent worldwide, the adoption of waterborne coatings in the automotive industry is expected to rise significantly.

b. Research and Development: Continued research and development efforts are likely to result in the development of innovative waterborne coating technologies, enhancing their performance, durability, and application properties.

c. Emerging Markets: Rapid urbanization, increasing disposable incomes, and the growth of the automotive sector in emerging markets such as China, India, and Brazil present significant growth opportunities for waterborne automobile coatings.

d. Collaboration and Partnerships: Collaboration between coating manufacturers, automotive OEMs, and research institutes can drive technological advancements and facilitate market expansion.

Conclusion:

The waterborne automobile coatings market is experiencing robust growth, driven by stringent environmental regulations, sustainability initiatives, and technological advancements. With increasing consumer awareness and the automotive industry's focus on eco-friendly solutions, the demand for waterborne coatings is expected to witness sustained growth. However, challenges such as higher costs and longer drying times need to be addressed to ensure wider adoption. Continued research and development, along with collaborations, can pave the way for innovative solutions and expanded market opportunities in the future.

0 notes

Text

Is Taste Masking Possible in Syrups? Find Out Here

Table of content

An Overview

Taste masking

Role of contract manufacturers

Akums Drugs and Pharmaceuticals Ltd.

An Overview

Medications remain an integral part of human survival. Their importance and vitality can never be missed. The therapeutic segment comprises many types of dosages inclusive of tablets, capsules, and syrups. Syrups are considered the most convenient option for those who find difficulty in gulping down those bitter and heavy capsules or tablets. The taste remains quite considerable while preparing the dosage forms. Taste is an action of the taste buds in the mouth, a vital parameter in the oral administration of drugs, and a critical factor. These tastes can be classified into four components like sourness, saltiness, sweetness, and bitterness. The last component is considered the most crucial when considering drug formulations. Masking the flavor of drugs is a probable instrument for the improvement of patient compliance which in turn chooses the marketable accomplishment of the product. The unfriendly and unpleasant flavor was the strongest barrier to completing treatments in pediatrics.

Taste masking

Two methods are usually applied to overcome the bad taste of the drug. There are certain very common techniques of taste masking which include inclusion complexation, using exchange resin, mass extrusion, solid dispersions, coating granulation, spray drying, microencapsulation, liposomes, emulsions, and gel formation effervescence. The tasks stated here require a professional and expert approach so that prompt and quality processing can be attained within the set time limits.

Role of contract manufacturers

The fleetness and worth of contract manufacturing in the field of the pharmaceutical industry have grown up meaningfully over the last few decades. There are many substantial reasons why Pharmaceutical Contract Manufacturing Services are fast-tracking. The uncompromised quality and best standards of manufacturing make them so demanding. Akums drugs and pharmaceutical Ltd is a tech-driven top third-party pharma manufacturer in India whose all the mechanical owns WHO-GMP competent units. There are many effective reasons for which it has been well thought-out for contract manufacturing, some are listed below:

• They provide the best match manufacturing capacity and outsourcing the same lowers the overall operational cost significantly. With the lessened drug cost, they offer rapid and more sensible work.

• They remain in hundred present compliance and decrease the difficulties faced during the governing procedures

• With state-of-the-art facilities and well-equipped infrastructural or machinery support their production efficiencies get enhanced.

•Reduces investments in capital-intensive services and upsurges income source

·Inspires resources to emphasize different capabilities like marketing

• Install dependability and proficiency transversely to the supply chain and extensive nets of vendible and manufacturing management. The growing working cost of R&D combined with destitute baselines and low output has made many pharmaceutical companies outsource both research and development, and manufacturing actions to low-priced manufacturing thus reducing fixed costs and time in the process.

Akums Drugs and Pharmaceuticals Ltd.

Promptness and perfections are the basic skills that are inherited by the top pharmaceutical contract manufacturers Akums drugs and Pharmaceuticals Ltd. They own and possess the best capabilities to offer the best quality products as per the need and demand. Many such hassles are being promptly and efficiently resolved by these firms. Simplifying the taste of bitter medications, making them more accessible to people, catering to different age groups and sections of society, etc. are some of the tasks which are taken up by Akums successfully in the last few decades.

Key Takeaways

·Medications remain an integral part of human survival. Their importance and vitality can never be missed.

·The fleetness and worth of contract manufacturing in the field of the pharmaceutical industry have grown up meaningfully over the last few decades.

·Simplifying the taste of bitter medications, making them more accessible to people, catering to different age groups and sections of society, etc. are some of the tasks which are taken up by Akums Drugs and Pharmaceuticals Ltd. successfully in the last few decades.

0 notes

Text

Top Tips for Choosing the Right Car Wash Equipment

Car wash equipment is a major investment for any car wash business. To make sure you select the right equipment to meet your car wash needs, it is important to do thorough research and understand the different options available on the market. This selection process becomes even more complex when you consider the various design features, added benefits, and industry advancements that have taken place in recent years. By taking into account Top Tips for Choosing the Right Car Wash Equipment, you can ensure that you make an investment that will provide the best return and the best user experience possible. Consider components such as the size, type, and design of the equipment, as well as its performance abilities, warranties, and service support to make sure you get the most out of your car wash equipment. Investing in the right equipment will improve the productivity of your car wash while ensuring that you are meeting the highest industry standards. Generally, the car wash advisory recommends hand washing the vehicle with a mild detergent and a soft cloth.

Identify Your Needs

Before you purchase any type of car wash equipment, it is important to identify your needs. Car wash businesses can vary; some businesses are specifically dedicated to washing cars, others use car washes as part of their overall service, and there are also self-serve car washes available in many markets. Once you have decided upon the type of car wash service you would like to provide, you can begin to assess the types of car wash equipment that will best fit your needs. Consider factors such as the types of vehicle and how often the car wash will be used, the size of your facility, and any special needs you may have such as handicapped access. Depending on the type of car wash equipment you choose, you may also need to consider the addition of other items such as flags, signage, and hoses.

Research Types of Car Wash Equipment Available

Once you have identified your needs, you can begin to research the types of car wash equipment available. The most common type of car wash equipment is an automated car wash system, which is powered by an electric pump. These systems operate by spraying a mixture of soaps and chemicals onto the car's exterior, and then rinsing and drying the car using air or water jets. You can also purchase roll-over equipment, which is a simpler option that requires the user to drive the car over a conveyor belt. This type of car wash usually consists of several stations with specific processes such as pre-soaking, shampooing, and waxing. Other types of car wash equipment include touchless car washes and pressure washers.

Consider Maintenance and Repair Costs

It is important to consider the ongoing costs of maintenance for car wash equipment. Although the initial purchasing cost of the equipment is important, you should also factor in the cost of regular maintenance, repairs, and replacements that you may be required to make. Depending on the type of car wash equipment you opt for, maintenance costs can vary. Automated systems tend to require more maintenance than roll-over systems, and touchless car washes will need more servicing and repairs than pressure washers. Make sure that you obtain information about the expected lifespan of the equipment, as well as any additional costs that you may encounter, such as spare parts and labor.

Assess Quality, Durability, and Reliability

When looking at car wash equipment, it is essential to assess the quality, durability, and reliability of the product. Check that the components of the equipment are of a high quality, and that the materials used in construction are able to hold up to the rigors of regular use. Reliable car wash equipment will also have a long lifespan, and ideally, you should be able to source replacement parts if needed. It is also important to assess the safety of the equipment and make sure that it meets the necessary regulations and guidelines. This will help ensure the safety of both you and your customers.

Research Pricing and Installation Costs

The cost of car wash equipment will vary depending on the type and size of the equipment. Be sure to research the different brands and models on the market to find the most affordable option for your needs. Make sure that you factor in additional costs such as installation fees and shipping fees, as these can add up quickly. There may also be additional costs for any extras such as signage, flags, and hoses.

Choose a Reputable Supplier and Manufacturer

Once you have assessed the different types and prices of the car wash equipment, you should be sure to choose a reputable supplier and manufacturer. Take some time to read reviews from other customers and get feedback about the quality of the supplier and manufacturer. This will give you an idea of the delivery time, customer service, and overall satisfaction with the product or service. Make sure that you also understand the terms and conditions of the purchase, and that you have a clear understanding of any warranties or guarantees that are offered.

Invest in Ongoing Support and Training

Finally, it is important to invest in ongoing support and training for your car wash equipment. Having reliable customer service is essential for any car wash business, and investing in staff training will ensure that you have knowledgeable technicians on hand to provide support. Training for car wash equipment can be provided by the manufacturer, or by external organizations. Make sure to budget for this cost, as this will ensure that your car wash equipment remains in good working order.

Conclusion

Choosing the right car wash equipment is an important decision, and there are many factors to consider to ensure a successful car washing business. Taking the time to research the best equipment for your needs, consult an experienced car wash professional, and considering of factors such as cost, quality, safety, environmental impact and local regulations are all important tips when considering which car wash equipment to purchase. With these tips in mind, car wash owners can make informed decisions on the right car wash equipment for their business.

0 notes

Text

0 notes

Text

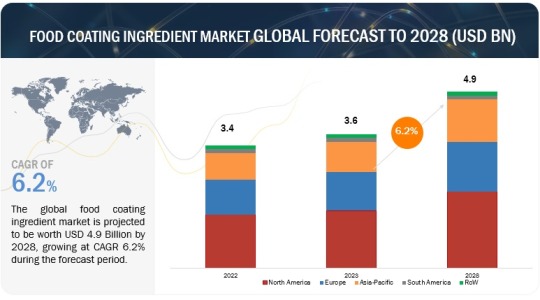

Food Coating Market Projected to Garner Significant Revenues by 2028

According to a research report "Food Coating Market by Ingredient Type (Batter, Flours), Application (Bakery, Snacks), Equipment Type (Coaters and Applicators, Enrobers), Form (Dry, Liquid), Mode of Operation (Automatic, Semiautomatic) and Region - Global Forecast to 2028" published by MarketsandMarkets, the food coating ingredients market is estimated at USD 3.6 billion in 2023 and is projected to reach USD 4.9 billion by 2028, at a CAGR of 6.2% from 2023 to 2028.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=168532529

The food coating equipment market is estimated at USD 5.7 billion in 2023 and is projected to reach USD 7.7 billion by 2028, at a CAGR of 6.3% from 2023 to 2028.

Food coating refers to the process of adding a layer of coating or breading to food products, which can provide improved texture, taste, appearance, and preservation. The market for food coating is driven by several factors, including the growing demand for convenience and processed food products, increasing consumer preferences for crispy and crunchy food textures, and the need for extended shelf life of packaged food. The demand for convenience food products, such as frozen and ready-to-eat meals, has been on the rise. Food coatings are used to enhance the taste and texture of these products, thereby driving the market growth. The food coating equipment market is steadily increasing in North America and Europe and growing consistently due to established equipment manufacturers and the organized food industry.

The Cocoa & Chocolates in by ingredient type segment accounted for the largest share of the food coating market in 2023 in terms of value.

Chocolate and cocoa are crucial ingredients that are used to make a variety of products, including cereal, protein bars, dried fruits, and nuts. These components are frequently used to add a delightful chocolate flavor to bakery and confectionery items. Enrobing, panning, and dipping are the three main techniques for coating foods like caramel or almonds in chocolate. The centers that will be covered in chocolate are transported via a machine during the enrobing process. Chocolate is sprayed onto revolving centers that are put on pans during panning, and then the chocolate is solidified by air that has been cooled. The centers are dipped, then cooled after being submerged in molten chocolate.

The North America region accounted for the largest share, in terms of value, of the global food coating ingredients market in 2023.

The food coating ingredient market in North America is witnessing substantial growth, primarily fueled by the thriving food processing industry. Furthermore, the region's rising health concerns, including obesity and heart ailments, have led to a heightened emphasis on consuming healthy products such as low-sugar breakfast cereals. In response to this demand, food coating ingredient manufacturers have introduced products with reduced sugar content and allergen-free formulations. These factors have provided a significant boost to the North American food coating ingredient industry.

The North American food coating market is experiencing robust expansion, driven by various factors. One of the key drivers is the increasing demand for convenience foods, which arises from evolving lifestyles and busy schedules. Consumers are actively seeking quick and easy food options that align with their time constraints. Food coatings play a crucial role in enhancing the appeal of convenience foods by adding layers of flavor and texture. Additionally, these coatings aid in preserving the freshness and quality of products during transportation and storage, contributing to their popularity in the market.

Request Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=168532529

The Asia Pacific region accounted for the largest share, in terms of value, of the global food coating equipment market in 2023.

The Asia Pacific area is poised to become the largest market for food coating equipment. This expansion is being fueled largely by causes such as the region's growing industrialization, rising demand from numerous applications, and government measures to assist food producers and processors in modernizing their technology and processes. Many multinational corporations are creating manufacturing facilities, distribution centers, and research & development centers to capitalize on the promise of these expanding markets. Due to favorable government backing and cheap labor costs, India is likely to enjoy tremendous development, drawing investments from global firms. Small and medium-sized equipment manufacturers in the Asia Pacific area mostly supply semi-automatic coating equipment, responding to the rising demand from diverse end-use applications in countries such as China, India, Indonesia, and other Asian nations, driving the expansion of the coating equipment market in the region.

Major key players operating in the food coating market Cargill Incorporated (US), Kerry Group plc. (Ireland), ADM (US), Ingredion (US), Newly weds Food (US), Associated British Foods PLC (UK), Tate & Lyle (UK), Solina (France), Idan Foods (US), POPLA International, Inc. (US).

0 notes

Text

Shotcrete is a novel approach that is redefining modern construction.

New construction technology has been critical to the growth of today's market. Shotcrete is a new construction technology that was used to build the Los Angeles Holocaust Museum, which won the American Institute of Architects Award for Interior Architecture in 2014. Shotcrete is mortar or small-aggregate concrete that is pneumatically projected at high velocity onto a surface.

Shotcrete is ideal for shallow repairs that are thin or curved, as well as concrete structures. Shotcrete, on the other hand, is strong enough to be used for almost any job. Shotcrete is stronger than traditional concrete because it is sprayed, allowing more air to be removed from the product and thus increasing its strength.

One of the most significant advantages of using the procedure is that it allows for faster construction, especially for complex shapes, curved walls, arches, and designs. It can be sprayed in place without the need for forming on vertical and overhead surfaces. There are two types of shotcrete applications: wet and dry. Because the material must be of a flowable consistency to be pumped, the wet process has a slightly higher water content, so accelerators are commonly used. The material is conveyed through the hose in a dry or damp state in dry process shotcreting, and water is added at the nozzle.

Because the material is shot into its final location, forming is either eliminated or reduced by half when one-sided forms are required. Shotcrete is an excellent material for the construction of a variety of new structures, ranging from foundations to arenas and everything in between. After years of research and testing, an increasing number of new construction jobs chose shotcrete because of lower costs due to reduced forming and the ability to build a variety of shaped surfaces while providing a strong concrete structure.

You want to hire a company that will meet or exceed your project expectations while charging a reasonable price. The contractor must have the necessary qualifications and be able to supply the necessary materials, equipment, and personnel. Shotcrete is also useful for tunnelling and mining ground support. It provides immediate ground support following excavation or blasting. Shotcrete projects were completed 33 to 50 percent faster than other projects.

Shotcrete Systems is essential in the development of shotcrete construction projects such as the Fox Parking Structure. Visit their website if you want to learn more about shotcrete construction.

0 notes