#Small wood cutter machine

Explore tagged Tumblr posts

Text

i mean the truth is that we do not need and should not have all this stupid plastic clutter in or houses. no one should be producing or selling this shit. everyone make your own merchandise and charge a living hourly wage to sell it 🤷 sorry to be so simplistic about this but it's one of the results of the lack of class unity specifically in the means of production-owning creative class, who is not mentioned or dealt with by the core Marxist texts as far as I know (i asked about this earlier on here, did marx ever address in his analysis people like, for example, a professional photographer who owns a camera ans prints his own dagguereotypes? or a portrait painter or idk, independent milliner or seamstress? these people all own the means of production and do not employ anyone, and the answer from better educated people than I was that no, Marx didn't mention them), I'm not well read on this at all, there is just a big void where leftist analysis of what modern economists call "the creative class"

I'm getting off topic. my point is make your own keychains in your kitchen. it's actually not hard. you can even mass produce (on a small scale) little plastic crap if you want, with resin and a UV lamp, or a 3d printer, or a laser cutter and acrylic sheets (or just use balsa wood damn, at least its biodegradable and less tacky).

all this stuff is available to little creators AND there are hundreds of people who already own these machines who will take work for you and produce your designs. you just have to actually find them and know them and email them. that's what I mean about the class unity issue with creatives. we have no large scale union, we have no large scale class consciousness, and we're all sending our orders for little plastic crap to sweatshops instead of emailing a guy with a laser cutter in his garage and saying "hey Keith can I get uhhhhhhhhhhh 50 laser cut keychains of this twerking Diggler design I made, like how much would that cost" and he's like sure here's the work and materials cost and tbh it's always always less than i think it's going to be. you just have to do some basic arithmetic and then order shipping, and I hate order fulfillment with my life but you can actually pay or barter with someone to do that for you too. learn to delegate and then factor that into your unit cost. this is basic shit every commercial creator needs to know. they should teach you this in art school but they dont

don't give me crap about "I can't afford a laser cutter" either because I just told you to email Keith. and all these machines get sold secondhand when a manufacturer or hobbyist needs to upgrade. i got a color laser printer perfect for making zines and wheatpastes and shipping labels from a retired lesbian on capital hill for $75 and it was still full of ink. my friend gave me her 20 year old canon dslr because she just didn't need it and didn't want to bother selling it. it works fine because I spent the time finding the right drivers and shit for my computer. and card readers exist. Craigslist. Facebook marketplace. nextdoor sales section. eBay. everyone always forgets eBay. eBay lets you save searches and will email you when it finds a guy selling his vinyl plotter in your city with local pickup. I'm serious

#long post#pro doom strats#leather embossing is another one#risograph prints#woodblock prints#rubber prints#etchings even#silicon molds for sculpey or resin or clay#local pottery studios#local photography studios#professional art printers with giclee printers!#ive used all these techniques to make merch#none of them are difficult or out of reach its just EASIER and adverised more to order shit from china#oh my god i forgot button presses#ALSO WE NEED A UNION AND STANDARDIZED HOURLY WAGES BTW#TIRED OF THIS BICKERING ABOUT PRICE UNDERCUTTING

401 notes

·

View notes

Text

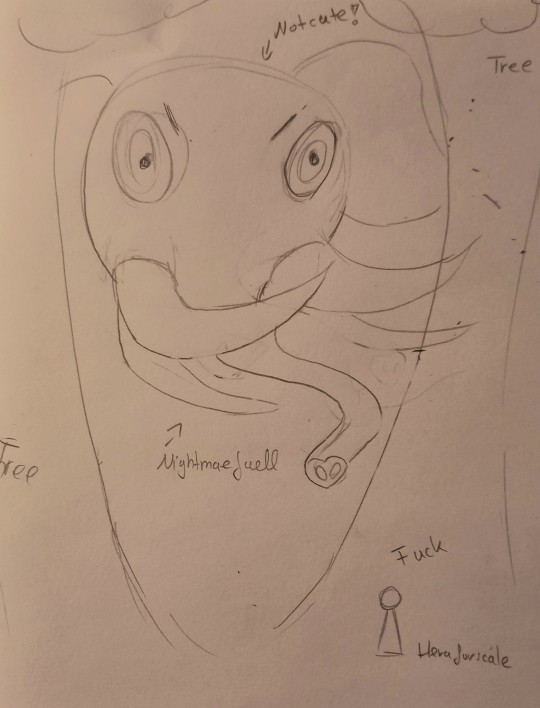

I watched the war of the rohirrim!

And I have thoughts spoilers under the cut + some crappy doodles ❤️

Man that Oliphant was nightmare fuel.

I never thought I would be scared of elephants but here I am.

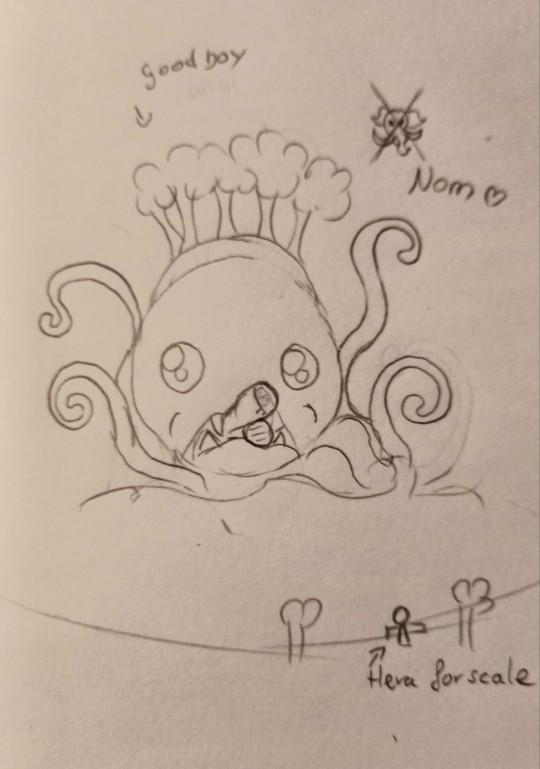

The watcher was kinda adorable!

Here some doodles xD

Wulf is now forever a raccoonTM in my head.

What a pathetic man.

Whoever said Hera is a Mary sue needs to check their brain OR the definition of Mary Sue.

For God sake her first real kill was with the help of her horse and a pitchfork while laying down being terrified.

I do like that she used the "death" Sentence in her amazing show off against the racoonTM because that what Rohans warrior use to say while riding into battle!

I disapprove about her daily clothing choice. White boots and shirt? Really? That poor laundry lady!

Now to the more important part that I need to say:

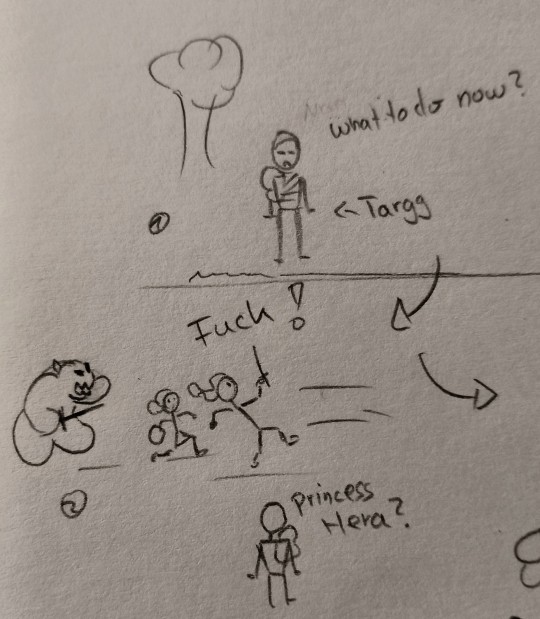

I loved Targg and the shield maiden Owlyn so much. I want a healing fix it and I ship them.

Did they had any interactions with each other. No. But that's not gonna stop hopefully anyone!

He was a really good general with great moral compass! He would have spared Hama and the small folk. Now let me get this quick~ out of the system:

I loved his clothing and I mean he got just stabbed once(1)time he could survive that! (Helm got shot with arrows like 6 times and was fist fighting people while being very depressed in a snowstorm like a week after that)

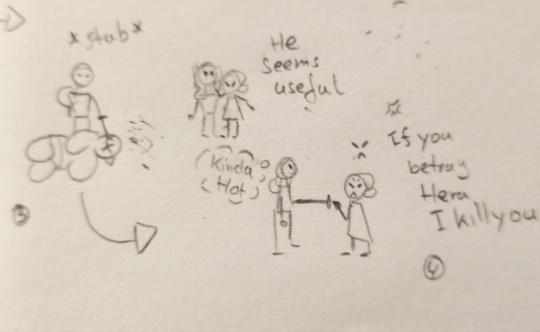

Let there be some loyal wild men safe Targg from the battle field and then he heals but doesn't know what to do with his life and then he meets hera and olwyn and he tags along because he respects her and he has nothing better to do. They could go on a adventure together.

Or idk let him see that the raccoon man is crazy earlier and safe hama for negotiations or whatever and he helps Rohan idk I read fics with much worse unrealistic premise and it still worked great!

Here have a little comic

So let's talk about Helm hammerhand!

What a legend. No really I'm gonna draw him standing heroics with his tits out and his hammer holding into the sky.

He would approve.

I laughed out loud that he kinda froze to death and suddenly had his hammer in his hand!

He punched a ogre/orc to death! Sauron and the Balrog should be thankful that he does not have access to thermo leggings and the blood of the Numenorian because he would have punched them all straight into the void!!

He would have throw the ring into the fire because he has no use of such nonsense!

And Haleth !! The silm Haleth would have approved of him!!!

So cool,so hot and even his death was kinda cool, very quick but so heroic.

The twink bard hama got used up to show that the raccoonTM is a terrible war lord and a super pathetic man. Kinda sad and underwhelming. Good part to start a fix it fic!

And wulf Ach wulf man idk what to say I will say that the German dub gave him a better and deeper voice then the English voice so that was nice! I had some feeling for him when his father died and he got choked out by helm but he really went all out to become very pathetic.

I hope there are some good fics that work on his very odd characteristics

I'm gonna draw him once being even much more pathetic but I need to confess he is rather bland next to Targg or Frealaf!!

Frealaf ❤️ God he is SO handsome and so cool in the rescue and he got that calm vibe about him.

He makes a great King.

I loved his clothing so much in general the clothing was great!! (Except the white pants/boot from hera!!)

Very beautiful and I can't wait to see more close up pics!! It was of course alot of fantasy style belts and fur but I do not mind that!

Then the very funny siege machine.

In all earnestly if the wild men are so good at building stuff and hauling around ridiculous amount of woods then they missed their opportunity to become middle earth's greatest engineers!!

Builders!

Wood cutters!

Why fighting around and eating scraps if you could become middle earth's best architect??

And what the hell did the poor drum player did wrong that he got a free yeeting into the atmosphere???

At least he was dedicated to play his drum until his end I guess?

But I loved the skull masks! Hehe very easy way to draw some hot wild men ~

That's my thoughts I did not went into much details about what could have been better or what is not really like in the books. I'm just glad that there is another great addition to the Tolkien fandom!!

#tolkien#the war of the rohirrim#war of the rohirrim#helm hammerhand#Haleth#hama#hera#frealaf#wulf#i didnt even mind the german dub!#it was really good but i need to hear the original voices to get a better feeling#i think this movie will do great if its accessible online!#so anyway#who is writing me a good fix it#or self insert/oc#i also need a Targg/olwyn fic#i cant be the only one that ships them#let them be surrogates parents for hera xD#and sombody save hama !

49 notes

·

View notes

Note

HELLO!!! It is I! I’ve been thinking… if you’d be able to do an Irish!fem!reader who has all these Irish dancing trophies and the little dresses and shoes from when she was small, cuz I still do 😭, and reader gets so embarrassed because she can’t do it anymore and the boys insist on doing the walls of limerick with her!!!! Thank you!!!!

Platonic!141 x Reader - Sweet Music

Fem!Reader

A/N: OK, I am actually so fucking sorry this took forever. I was caught up with mock exams but they are over! And I shall be writing more! I had alot of fun writing this even tho I didn't do ur ask justice. I really hope that you enjoy it tho Teddy! Thank you for being the actual best and being so patient and kind! Masterlist

Cw: Brief mentions of alcohol, Reader has a dog Word Count: 1624

Kyle ‘Gaz’ Garrick

‘You got the last box?’

‘Yea.. yes! Don’t worry’ You struggled to grip the dusty cardboard against your body, your foot catching your ankle on the last step of the attic later. Earlier that day, you had asked Kyle to help with the daunting task of breaking open your sealed off attic and clearing it for storage of your military gear. Getting rid of whatever your mother had decided what was best to collect and hoard before she left. You both were able to clear out the majority of the space that afternoon, choking on the kicked up dust and cobwebs. You had piled the boxes in your living room, circling your couch and chairs. You dog, Jax, strutted around the constructed towers, cautiously bending his head to sniff the stale cardboard. As you huffed the final box atop a stack that was starting to bleed into your kitchen, both you and Gaz admired your efforts with your hands resting on your hips. ‘You wanna crack em’ open?’ ‘Let me get the wine first’ You could hear Kyle snicker behind you as you made your way to the kitchen. Returning with two glasses and one of your more expensive bottles of chilled red in hand, you settled yourself on the carpeted floor. Your head resting against the seated cushion of the couch. You handed Gaz the bottles and glasses and in trade he handed you a box cutter. The echo of the wine filling the glasses was drowned by the blade of your knife ripping through the packaging tape lining the top of the box settled in front of you. Gaz did the same with a pair of kitchen scissors. You took a generous swig of your glass before diving your hands into the brown packing paper. Jax had settled his head on Kyle’s thighs, watching him unwrap a picture frame, starting a pile of garbage packing paper to be burned in your wood stove. ‘Oh-hoo.. What’s this?’ You lifted your head from the unwrapped shot-glasses to see that Gaz held a small rusted golden plaque in his hands. Your name scrawled in chipped cursive across the bottom of the frame. ‘Holy, haven’t seen that in forever. This must be my old dancing stuff’ ‘Wha- you did dance?’ ‘Surprised are you? Mom signed me up for it to get me outta the house.. I only continued with it cause’ Nan wanted me to get closer to my “gaelic roots” as she put it’

You scooted over to sit next to him, your hand instinctively finding Jax’s ears to scratch behind. You reached into the box and pulled out a bound pile of plaid. Undoing the twine, you unfolded a deep green plaid skirt, the seam stitched golden by your grandmother's hand. You ran your fingers down the trailing glint, it was as if you could feel your grandmother's touch holding down the fabric as she delicately thred it through her sewing machine. You could hear her sighs and coo’s of approval as you stumbled out of your bedroom, wearing the skirt for the first time. ‘So! Keep or give away?’ Kyle said before taking a swig of his own wine. He pulled another box closer to him, a small cloud of dust kicking up from his scissors gilding across the cardboard.

‘Keep for now, might get rid of the trophies but I can gives the dresses to Emi’ ‘She’d really like that’ Kyle said smiling back at you, his rich chocolate eyes highlighted in the early evening sun. You held the small dress close to your chest for a moment before setting it beside you, in the now ‘keep’ pile.

Simon ‘Ghost’ Riley

You could feel the cold of the metal seat through the lining of your tactical pants. The weight of your combat vest held you down against the bench. It was cold, the air thick with the smell of gasoline and salt. The warm brush of your lieutenant's arm against the side of yours was the only thing reminding you that there would be a bed and a warm meal to hopefully return too after this mission. It was just you and Simon on the installed benches in the transport plane, the rest of the squad just offloading moments before. ‘Leave is com’in up.. plans?’ Simon's thick, graveled baritone cut through your coms, bringing you back into the familiar state of heightened awareness.

‘Oh.. umm.. Just gunna head back home.. Emi has a dance recital ‘week before Christmas and Mari wants me to drive her north for a weekend with her girlfriend, I told her no but she’s been begging me over the phone so-’ ‘Friends?’ Simon asked, looking over at you. You glanced up at his eyes, darkened and blood-shot. The deep onset of the pale skull mask making them appear blended into the dirtied black fabric of the hood. ‘No.. my sisters, I thought I told you- hold on’ You smiled as you reached around and dug out from a small back pocket in your vest a chipped golden photo case. Excitement brewed within you at the chance to discuss your little family. Clicking it open and holding it up for Simon, he held it between his large gloved fingers. You focused back on his eyes, watching as they looked over the photos set into the sides of the case. The first being a blurred still of Mari holding your infant sister a few days after she was born. You were able to catch her mid laugh, her smile drawn tight, deepening her dimpled cheeks. Emi was swaddled in her lap, her soft chubby cheeks poking out from the quilted blanket she was wrapped in. The second photo was an old-black and white still of your grandmother when she was younger, her hair swooped elegantly over her forehead. It was the same photo that was kept in your grandfather's wallet, given to you after he passed. Behind it was a small swath of deep green plaid fabric. Simon ran his thumb over the black crossing lines, looking back to you with confusion. ‘Oh.. that umm.. Was a piece of one of my dancing dresses.. Nan made them for me and.. I don’t know, keeping it with me is a sort of reminder I guess’ You say taking the golden frame back from him, shutting it with a click. You rubbed your thumb over the scratches and dents in the metal, a testament to the many trips the case took with you throughout your multiple deployments and missions. ‘Dancing?’ ‘Ha… yea.. Mom umm.. She had me do it throughout primary’ ‘I.. wasn’t expecting that..’ Simon mumbles, shifting on the metal bench. ‘What? Do I not look like a child dance prodigy?’ You say, nudging his arm with your elbow. ‘No just… god.. cannot picture you.. I mean-’ You tried to hold back the ripple of amusement from your lips, watching the metaphorical gears turn in Simon's head. He quickly glanced back at you, confirming your clear enjoyment in his confusion. You leaned your head back against the metal wall, thumbing the photo case before tucking it back into the pocket of your vest. It was within these small moments of reprieve from tactical expectations that you wished you could put Simon, and the rest of your team's photo within the case alongside your sisters.

John ‘Soap’ MacTavish

‘Johnny! Food’s here!’ You call up from your living room, placing the hot paper bags on the low coffee table. You expected to hear his harsh footsteps down the creaking wooden stairs. Yet, only the sound of the dimmed slow piano crackling from your record player and the high-pitched thrum of late evening summer crickets filled the air. ‘Johnny!’ You shouted, unpacking the food. ‘Where..? God..’ You groaned, looking towards the hallway stairwell. You trudged up the stairs, two at a time. Your feet bouncing down the carpeted hallway, the dark glow of the evening sunset casting a dim glow from the hallway window. ‘John..?’ You said, poking your head into one of the spare bedrooms. ‘In here!’ Relief broke in your chest like the shell of an egg as you heard your sergeant's rough voice from your bedroom. You hadn’t been able to yet undo the familiar anxiety that comes with the lack of response from your teammates, an anxiety bred from being their stand-by medic.

You pushed open your bedroom door, the hinges squeaking. You had stopped using this room as yours a long time ago. It was now more a storage shed for your sister's old clothes and your military gear. You found John standing by an old dresser, dusty plaques and trophies covering the top of the mahogany wood. You watched as John held one of the frames in his large scarred hand. ‘What did ya find?’ You ask, standing by his shoulder while stuffing your hands in your pockets. ‘You should've told me you did dance’ He said, placing the frame back down. The picture he was looking at was an old, sunbleached still of you as a child, standing in a plaid dress next to your grandmother who was holding your then infant sister. Your smile held a few dark spots as you had just started losing your baby teeth.

‘Why’s that?’ You say, picking up another photo, you used the sleeve of your sweater to rub the dust from the shiny metal frame. ‘Well because my gran’ forced me into it too’ ‘Shut up’ You say, placing the cleaned frame back down with a thump. ‘Im serious, once we fly up with Roach, me’ sister’ll show you the photos’ ‘That is.. I never would have guessed’ ‘Can say the same thing for you Bonnie’

#141#141 x reader#cod 141#task force 141#tf 141#mw2 141#cod#gaz x reader#kyle gaz garrick#call of duty#cod modern warfare#cod mwf2#john price#kyle garrick#gaz#gaz x y/n#gaz x you#simon ghost x reader#simon ghost riley#simon x reader#simon riley#simon riley x reader#simon riley x you#john soap mactavish#john soap mctavish x reader#soap x reader#soap cod#soap mw2#mw2#john mactavish

33 notes

·

View notes

Note

Sorry to bother you, my wife and I are working on making a Leonardo Da Vinci Caster cosplay for her and it's our first cosplay (I'm hoping to do a Warframe one eventually, but actual cloth costumes first)- do you have any advice on how to do details, etc? We seem to have the general shape of things down and already have the cloak & skirts done.

Ooh, Da Vinci! I'd say I'm still winging it with the fabric stuff; my experience is mostly with armor and props. If by details you mean stuff like the applique or something...

I did this for my sister a couple years back. Zhongli cosplay. Made pattern, cut fabric, applied clear nail polish to edges, pinned to base garment, used one of the buttonhole stitch settings on my sewing machine for the edges. I was improvising then. Something similar would probably be done on the stocking details, but I have no experience with stretchy fabric yet.

For the curvy edges... just. Lots of pins so they hold the shape while sewing.

The star patterns on the blue fabric... If it were me I'd just use a stencil and fabric paint if there's nowhere to buy it from. Several layers of it so the yellow looks good. However, the pattern might be generic enough that you can get fabric already printed with it somewhere.

The small accessories hanging from the collar (and hat depending on Ascension level)... small chains with gems... I'm not sure about your access to supplies so you might or might not have to make the gems and stuff yourself. Usually for these I use those rigid PVC sheets. Cut and whittle with cutters as needed. Maybe something like foam clay or resin stuff if you wanna be fancy. Put some thin wire hoops to attach them to the chains. Or you could use EVA foam here as well. 2mm. Also works with the fleur-de-lis looking brooch.

If Props:

Speaking of EVA foam... 5mm and 2mm thickness should cover all kinds of needs in this case. PVC piping for the staff. at this scale (and in most situations), contact cement for gluing together. Measure to proportion, make patterns, trace onto foam, cut with cutters. Make sure the blades are sharp for the smoothest cuts.

You can do a lot of stuff with EVA foam. So much stuff. If you plan on using it more in the future, I suggest getting a heat gun. Smooths out the foam. Priming before painting... I live in Japan so I use something like Zeque... rubber paint similar to Plastidip but much cheaper. For something much easier to get... Wood glue diluted with water, 3-4 coats of it or until satisfactory. Thin layers. Let previous layer dry before next one. This one's not flexible though - if the foam bends, wrinkles can't be avoided.

If Gauntlet:

5mm foam would probably be enough for the base gauntlet... or anything, really. Maybe 2mm foam for the smaller details. The gold filigree and trim detailing on the gauntlet... I'd paint them on. Paint those parts of the gauntlet gold first, have a pattern ready cut from some sticker paper of the details, put those on, paint the rest of the gauntlet. Once the dark blue paint dries, you can remove the sticker paper mask. The green bits... EVA foam as well, the final coat of paint would have to be something very glossy for the shine.

I'm not sure how you want to do the gauntlet. Will you keep the proportions, a.k.a. very big, or shrink it to fit the wearer's hand? Building it to proportion is more complicated - need to build a rig first that's fixed to the wearer's hand with something flexible for the core of the gauntlet digits, and string to pull the gauntlet digits. And since you'd hold the staff with the same hand, your hand has to be outside for the grip. Should be okay if the gauntlet digits are big enough to cover them.

If Staff:

The more organic-looking bits of the staff... I'd use foam clay, but if you think you can do it with just EVA foam, do that instead. Not sure how expensive foam clay is for you. Change your cutting angle to make sloped edges, trim with scissors - whatever works.

For ease of transport you may need to plan on splitting the staff in parts. Maybe the star, then the handle, then the bottom tip? Attachment might be complicated, so you may not want them detachable as well.

Clear plastic acetate for the star. This one's complicated. Hot glue could work. Lots of triangles. I'll just look this up if it were me. Don't be pressured to make this glow.

Not sure what else I can say about this unless you ask for something very specific, but I wish y'all well in this project!

2 notes

·

View notes

Text

i NEED to organise my craft room into something usable and I'm overwhelmed and the internet keeps offering me storage ideas that will become impossible to maintain the moment I take a single item out, or that involve mounting like seven hundred mason jars to my walls or hanging shit from the ceiling. help me out and tell me your best storage tips?

stuff I need to find a spot for includes

-bookbinding supplies (paper up to 12"x18", multiple rolls of bookcloth, endpaper, and mull, awls and threads and glues and bookboards, small book press, etc)

-general craft supplies (different types of glues, tapes, long straight edges, cut mats, right angle guides, paints, easel, brushes, inks, pencils, printer, paper cutter)

-sewing stuff (fabric, poly fill, scraps, threads, needles, pins, scissors, sewing machine, iron/ironing board, tape measures, patterns, dressmaker form, etc)

-fiber craft stuff (fiber, yarn, spinning wheels, drop spindles, knitting needles, crochet hooks, stitch markers, embroidery hoops and threads, bobbin lace bobbins and pillows and pins and threads, half finished cardigans...)

-random shop-type items like wood clamps, a mallet, wood stain, paintbrushes, etc.

and idk even what else. help.

#this room needs to let me store stuff in a way I can put back and take out easily#or i will never put anything away#help?#I need ideas I'm so. overwhelmed

2 notes

·

View notes

Text

April and May Events

We have a couple upcoming member events that are also open for potential prospective members. See our membership page for qualifications and how to apply, and see our visiting page for the address and other details, including our code of conduct and masking policy.

Laser-cutting event, April 21st, 1-3 pm. Bring an SVG image or draw an image, and try our glowforge laser cutter on some of the wood and acrylic sheets we have available. This will be a great chance for people interested in Double Union membership to ask any questions.

Intro to sewing machines workshop. May 5th, noon-4pm. This will be a hands on workshop for those interested in how to use our sewing machines. We'll go over how to thread our machines, tips for choosing needles and feet, and time permitting attempt a small project like a pouch.

We still have ongoing Wednesday coworking sessions. If you're a prospective member feel free to reach out to confirm the time and if the session is happening on a particular week.

We're still working on getting more events on our calendar, so keep an eye out for future events if you're interested in membership but can't make any of these events.

For members, we have our upcoming member meeting. We'll be doing a hybrid in-person and virtual meeting; details will be sent via the members mailing list.

2 notes

·

View notes

Text

Small Shenanigans

Riddle was sitting on your bedside table. You were currently out shopping so he thought he'd keep an eye on everyone.

There was Ace, currently running from an angry Deuce. Cater was laying on your bed, playing with the silky pillows. And Trey was right beside Riddle, reapplying the bandages on his arm. The old ones were getting stained by excess ink.

"Sorry-" Trey began before Riddle promptly cut him off.

"Don't. It's not your fault." And before the clover could even get a word in, you arrived back home.

"I'm back!" You called through. Cater immediately perked up before rushing to greet you, he's such an affectionate little guy. You chuckled and let him climb up your shoulder. Ace gave you the stink eye while Deuce timidly waved at you.

"I restocked so I can make you guys a new attire." You explained. The diamond on your shoulder let out a little squeal, clearly delighted at the prospect of new clothing.

You chuckled at his antics, he’s such a little guy!

“Oh and Riddle, I can fix your dress now.” You turned to the red head. He gave a polite, yet appreciative, nod of the head. Gosh he’s so cute!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

You flicked the light switch on as you entered your workshop. You really like your workshop, it has a nice homey feeling to it.

“Here, you lot wait here while I make your clothes. I’ll call you up for measurements but until then wait patiently.” You told the five boys as you set them down on your desk before turning to the cabinets that held fabric, threads and needles and anything else you may need.

Ace crossed his arms before glancing around, it was much nicer here now he could actually see. A glint caught his eye. Turning he saw what looked like a big machine, he had no idea what it was but he felt compelled to press the big red button on it.

“Hey we’re are you going?” Deuce whisper-shouted at him, he didn’t know he was moving towards the odd machine until Deuce hissed at him. Glancing at the older three, Ace saw that they were having a nice time chatting and watching you. Perfect.

He looked at Deuce with a sweet smile on his face, said spade immediately felt the urge to ignore him.

“Heyy Deucey~ How about we go play with that thing over here.” He said pointing at the weird machine, the blueberry looked over to where he was pointing before fixing Ace with a disappointed look.

“No Ace, we were told to wait here.” Ace sighed, what a goofy-two-shoes!

“But they didn’t say we can’t touch anything or look!” He tried to reason, it was working as Deuce started looking conflicted, battling his inner curiosity.

“Fine but we’ll just look okay!” His curiosity won today.

The two sneaked over to the machine, Deuce checking it out but didn’t get too close. Ace on the other hand just, pressed the big red button.

SHREEEEEOOOMMMM

“WHAT’S THAT?!” Cater yelled over the noise, covering his ears. Trey covered his as well before yelling “I DON’T KNOW BUT IT DOESN’T SOUND GOOD!” Ace and Deuce stared in horror as the machine started moving towards them.

Riddle was in a state of panic, he has to get those two idiots to safety but he can’t even stand on his own. Before he could move, the noise died down.

“Huh?”

There you stood, your wood cutter in hand, unplugged and Ace and Deuce in the other.

“You’ve got to be more careful.” You said with a sigh before setting the two troublemakers back down. “Seriously there is dangerous stuff in here.”

“What is that?” Surprisingly it was Trey who asked, the little lad who you have not heard a peep from. You couldn’t understand him though, it was like he was squeaking. You wonder why that is. Still by context clues you could deduce what he was trying to get at.

“This is a wood cutter, I use it to well cut wood. It is very sharp and dangerous though so I don’t want any of you near it.” You explained to them. It is important they know that they cannot just touch the stuff in your workshop.

#twisted wonderland#toy maker au#riddle rosehearts#ace trappola#cater diamond#trey clover#deuce spade#heartslabyul#reader insert#gonna do silly little scenarios now because writing plot tires me#brrr’s writing

12 notes

·

View notes

Text

Josef Frank Inspired Menorah

Project by David Stark:

Chanukah is most often a blue and white affair, sometimes with a little silver thrown in, sometimes a little gold. But in ruminating on the holiday, we couldn’t help but ask ourselves: “Why does it need to be?”

Now, we know that the bold, floral prints of Josef Frank are, perhaps, not the most likely of Chanukah inspirations, but that’s exactly the point. We turned to a pattern we love entitled, “Vegetable Tree” as inspiration for this vibrant menorah – the perfect pop of color as we move into the darker winter months! We chose colored papers and floral shapes influenced by the motifs and palettes found in the print and are thrilled to share this how-to with you!

We opted to make our menorah base. But, it would be equally as charming to use a classic menorah you already own and wrap the wire stems around it. Or, pick up an affordable one and paint it! (Thank you to Just Scandinavian for loaning us this great Josef Frank fabric!) ––David Stark

SUPPLIES

1” x 4” wood board (cut to 20”)

Coping saw (or other hand saw) and clamps

Two 1” dowel rods (either 36” or 48” long)

Drill with 1”, 3/8”, and 1/16” drill bits

Ruler and pencil

Acrylic paint and paint brushes

Red and white gel pens

Scissors and craft knife

Permanent glue stick or hot glue gun

Wire cutters

Bone folder

20-gauge straight wire (any color)

Various colors floral tape (we used: red, green, blue)

Various colors cover-weight paper (we used: red, hot pink, yellow, orange, blue)

Chanukah candles or LED candles

Craft cutter machine (optional)

PDF template (Link to download in Step 1 below)

INSTRUCTIONS

Step 1

Download the PDF template.

Using your ruler, find the center of the wood board and measure nine 2” intervals along that center line. Using your drill with the 1” drill bit, drill approximately ¼” deep holes at each mark. Use clamps to secure the board in place if needed.

Step 2

Using your ruler, measure eight 7” and one 9.5” lengths of dowel. Use your saw to cut each piece, being sure to cut as straight as possible. Use clamps to secure the dowels in place if needed.

Step 3

Assemble the menorah base by placing four 7” dowels at each end and the 9.5” dowel in the center. You may need to twist the dowels to secure them in place. Next, using your drill with the 3/8” drill bit, drill approximately ¼” deep holes on the end of each dowel. (3/8” is the width of our Chanukah candles, check yours before you begin and drill the appropriate size holes.)

Step 4

Paint your menorah! We painted a base color of dark green and added pale blue, turquoise, and grey dots. Allow the paint to dry fully.

Step 5

Use the template provided to cut out multiples of each shape. Or, use the SVG file to cut using a craft cutter.

Step 6

Using the red and white gel pens, add decorative details to the shapes and fold down the center or along each petal using a bone folder to press the crease.

Step 7

Apply a heavy layer of glue stick (or a line of hot glue) to the tab portion of each shape and press the wire into the glue. Once dry, cover the connection and the remaining length of wire with floral tape, occasionally attaching the wire stems together. For the yellow flowers, bend the wire and attach to the back of the flowers with hot glue.

Step 8

Using your drill with the 1/16” drill bit, drill holes into the menorah base and insert the wire stems into the holes. If you are using a menorah you already own, simply wrap the wires around it. We opted to keep our flowers low and pulled away from the candles. Be mindful of this when you are assembling. Dripped wax will not alight paper, but be cautious of the flames. We recommend if you are using this menorah with small children in the house, to use LED candles.

4 notes

·

View notes

Text

How Laser Cutting Technology is Shaping the Future of Industry

Laser cutters have revolutionized modern manufacturing, providing unmatched precision, speed, and efficiency. From small businesses to large-scale industries, laser cutting machines have become an essential tool in various applications. Whether you're in metal fabrication, automotive, or signage production, choosing the right laser cutter can significantly impact productivity and cost savings.

In this guide, we will explore the features, benefits, and applications of laser cutting machines, along with insights into why SLTL Group is a trusted name in the laser technology industry.

What is a Laser Cutter?

A laser cutter is a high-precision machine that uses a focused laser beam to cut, engrave, or mark various materials, including metals, plastics, wood, and glass. The laser technology ensures clean cuts, minimal material wastage, and high-speed processing, making it a preferred choice for manufacturers worldwide.

Key Features of Laser Cutting Machines

High Precision and Accuracy

Laser cutting technology provides micrometer-level precision, ensuring clean edges and intricate designs without the need for secondary processing.

Versatile Material Compatibility

Laser cutters can process a wide range of materials, including stainless steel, aluminum, brass, acrylic, MDF, and even fabrics.

Automation and Smart Controls

Advanced laser cutting machines come with CNC (Computer Numerical Control) technology, allowing automated operations, minimal human intervention, and high repeatability.

Energy Efficiency and Low Maintenance

Compared to traditional cutting methods, laser cutters consume less power, require minimal maintenance, and have a longer lifespan.

Customizable Power Levels

Laser cutting machines are available in different power configurations, such as fiber lasers, CO2 lasers, and diode lasers, catering to specific industrial needs.

Types of Laser Cutting Machines

Fiber Laser Cutting Machines

Best for cutting metals like stainless steel, aluminum, and copper.

High-speed processing with lower operational costs.

Used in industries like aerospace, automotive, and metal fabrication.

CO2 Laser Cutting Machines

Ideal for non-metallic materials such as wood, acrylic, and leather.

Offers excellent engraving capabilities for creative and artistic applications.

Preferred in signage, advertising, and decoration industries.

Hybrid Laser Cutting Machines

Combines fiber and CO2 laser technology for enhanced versatility.

Provides users with the flexibility to cut both metallic and non-metallic materials.

Used in diverse applications ranging from industrial manufacturing to customized product design.

Industries That Benefit from Laser Cutters

Metal Fabrication

Laser cutters provide clean and precise cuts, reducing material waste and improving efficiency in metalworking.

Used for cutting sheet metal, pipes, and intricate components.

Automotive Industry

Used for cutting vehicle components with high accuracy and repeatability.

Helps in creating complex parts for engines, chassis, and interiors.

Aerospace and Defense

Critical for manufacturing lightweight and high-strength aircraft parts.

Ensures high-quality production of specialized components for satellites and military applications.

Signage and Advertising

Enables intricate designs, detailed engravings, and custom signage solutions.

Creates illuminated signs, nameplates, and decorative pieces with high precision.

Jewelry and Fashion

Provides fine detailing for intricate jewelry designs and textile cutting.

Used for personalized engraving on rings, bracelets, and pendants.

Electronics and PCB Manufacturing

Used for precise cutting and marking of circuit boards and electronic components.

Ensures non-contact processing, preventing damage to delicate components.

Architecture and Interior Design

Laser cutters help create decorative panels, wall art, and custom furniture components.

Widely used for intricate wooden, acrylic, and metal designs in luxury interiors.

Advantages of Laser Cutting Machines

Superior Cut Quality

Produces smooth edges without burrs, eliminating the need for additional finishing processes.

Ensures precise cuts even in highly detailed designs.

Minimal Material Wastage

Laser cutting is a non-contact process, reducing material deformation and maximizing efficiency.

Optimizes material usage, leading to cost savings in production.

High-Speed Operations

Capable of cutting complex designs at high speeds, improving production rates.

Reduces lead times in manufacturing processes.

Cost-Effective Manufacturing

Reduces labor costs, material wastage, and maintenance expenses.

Long-term savings by increasing productivity and reducing errors.

Eco-Friendly Process

Produces less waste and consumes lower energy compared to conventional cutting methods.

Reduces reliance on hazardous chemicals used in alternative cutting techniques.

Enhanced Safety

Modern laser cutting machines come with enclosed workspaces and safety interlocks.

Minimizes risks associated with manual cutting processes.

Choosing the Right Laser Cutter

When selecting a laser cutting machine, consider the following factors:

Material Type: Determine the materials you need to process (metals, plastics, wood, etc.).

Cutting Thickness: Ensure the machine supports the required cutting thickness for your applications.

Power and Speed: Higher power levels offer faster cutting speeds but may increase energy consumption.

Software Compatibility: Look for CNC and CAD software integration for seamless operation.

Budget and ROI: Balance the initial investment with long-term benefits and cost savings.

Support and Maintenance: Choose a manufacturer that provides reliable after-sales service and spare parts availability.

Why Choose SLTL Group for Laser Cutting Machines?

SLTL Group is a leading manufacturer of laser cutting machines, offering advanced solutions tailored to various industrial needs. Here’s why SLTL Group stands out:

Innovative Technology: Pioneering research and development in laser technology.

High-Quality Products: Machines designed for precision, durability, and efficiency.

Custom Solutions: Tailored laser cutting solutions for specific industry requirements.

Global Presence: Trusted by businesses worldwide for superior laser technology.

Exceptional Customer Support: Comprehensive after-sales service and technical support.

Wide Product Range: SLTL Group offers a variety of laser cutting solutions, including fiber lasers, CO2 lasers, and hybrid laser systems.

Conclusion

Investing in a laser cutting machine can transform your manufacturing processes, enhancing productivity, accuracy, and cost efficiency. Whether you are a small business or a large enterprise, choosing the right laser cutter is crucial for optimizing operations.

SLTL Group offers state-of-the-art laser cutting machines designed to meet industry demands. With cutting-edge technology, superior precision, and excellent customer support, SLTL Group continues to be a trusted partner for businesses looking to enhance their production capabilities.

For more information, visit SLTL Group and take your manufacturing capabilities to the next level!

0 notes

Text

The Essential Guide to Laser Cutting File Formats

YOU CAN ALSO TRY THIS PRODUCT:300.000 Laser Cut Files

Introduction

Brief overview of laser cutting technology

Importance of vector files in precision cutting and engraving

Understanding Vector Files

Difference between raster and vector graphics

Why vector files are essential for laser cutting

Popular Vector Formats for Laser Cutting

Overview of commonly used file formats: SVG, DXF, AI, CDR, and EPS

SVG (Scalable Vector Graphics)

Key features and advantages

Common use cases in laser cutting

DXF (Drawing Exchange Format)

Origin and compatibility

Why DXF is favored for CAD and industrial applications

AI (Adobe Illustrator File)

Role of AI files in professional design workflows

Advantages of using AI for intricate laser cutting designs

CDR (CorelDRAW File)

Popularity among designers and engravers

How CDR files integrate with laser cutting machines

EPS (Encapsulated PostScript)

Versatility in design and printing

Strengths and limitations for laser cutting

Choosing the Right File Format for Your Project

Factors to consider: material type, machine compatibility, and design complexity

Preparing Files for Laser Cutting

Key steps to optimize vector files

Common mistakes and how to avoid them

Conclusion

Summary of key takeaways

Encouragement to experiment with different file formats

Now, here’s the complete article:

The Essential Guide to Laser Cutting File Formats

Introduction

Laser cutting has revolutionized the way creators, hobbyists, and industrial professionals bring designs to life. Whether crafting intricate patterns on wood, engraving logos on acrylic, or slicing precise metal components, the success of a project hinges on the quality of the digital file used. Vector files, such as SVG, DXF, AI, CDR, and EPS, are the backbone of laser cutting, enabling precise, scalable, and adaptable designs. Understanding their differences and applications ensures seamless results in any laser-cutting endeavor.

Understanding Vector Files

Digital graphics are broadly classified into two types: raster and vector graphics. Raster images, such as JPEGs and PNGs, are composed of pixels, which lose quality when resized. In contrast, vector files use mathematical equations to define shapes, lines, and curves, making them infinitely scalable without distortion. This characteristic is vital for laser cutting, as precision and clarity are paramount.

YOU CAN ALSO TRY THIS PRODUCT:300.000 Laser Cut Files

Popular Vector Formats for Laser Cutting

Laser cutters are compatible with a range of vector formats, each offering unique benefits. Among the most widely used are:

SVG (Scalable Vector Graphics) – A web-friendly, open-standard format

DXF (Drawing Exchange Format) – Designed for CAD and technical applications

AI (Adobe Illustrator File) – Industry standard for detailed graphic design

CDR (CorelDRAW File) – Favored by designers using CorelDRAW software

EPS (Encapsulated PostScript) – A versatile format with broad software compatibility

Each format serves a specific purpose, and selecting the right one depends on the project’s requirements.

SVG (Scalable Vector Graphics)

SVG files are lightweight, adaptable, and widely supported. They use XML-based code to define vector shapes, making them easy to modify using design software like Adobe Illustrator, Inkscape, and CorelDRAW.

Why SVG for laser cutting?

Maintains crisp quality at any size

Supports transparent backgrounds

Easily editable for quick modifications

Many online marketplaces provide free and premium SVG files for laser cutting, making it a go-to format for small businesses and DIY enthusiasts.

DXF (Drawing Exchange Format)

Originally developed by Autodesk for AutoCAD, DXF files have become a standard in industrial and engineering applications. Unlike other formats, DXF files are purely vector-based, ensuring they are highly precise and compatible with CAD software.

Key advantages of DXF:

Ideal for CNC machining and technical drawings

Preserves exact dimensions, essential for manufacturing

Compatible with almost all laser-cutting software

For architectural models, mechanical components, and custom signage, DXF is often the preferred choice.

AI (Adobe Illustrator File)

The AI file format is a proprietary format of Adobe Illustrator, widely regarded as the gold standard in graphic design. It allows designers to create complex, multi-layered artwork with extreme precision.

Why AI files stand out:

Supports advanced design tools and effects

Retains original layers and paths for detailed editing

Works seamlessly with Adobe Creative Suite

However, not all laser-cutting software directly supports AI files, so they may need to be exported as SVG, DXF, or EPS before use.

CDR (CorelDRAW File)

CorelDRAW is a popular choice among engravers and sign-makers, and its native CDR format is optimized for vector-based design workflows. Many commercial laser engraving businesses rely on CorelDRAW due to its robust node-editing capabilities and precision control.

Advantages of CDR files:

Ideal for text-heavy and logo-based designs

Advanced shape manipulation tools

Directly compatible with certain laser cutter software

However, CDR files may require conversion for non-CorelDRAW users.

EPS (Encapsulated PostScript)

EPS is a versatile format commonly used in printing and design. It supports both vector and raster data, making it useful for high-resolution engraving projects.

Strengths of EPS files:

Can store detailed vector graphics with embedded fonts

Supported by most professional design applications

Suitable for large-format laser engraving

One drawback is that EPS files can be bulky compared to SVG or DXF. They also sometimes require specialized software for full editing capabilities.

Choosing the Right File Format for Your Project

Selecting the best file format depends on multiple factors, including:

Material type: Some files work better for intricate cuts on delicate materials, while others suit robust applications.

Software compatibility: Ensure your laser cutter supports the chosen file format.

Design complexity: Detailed engravings may require AI or EPS, while simple cuts may work best with SVG or DXF.

Preparing Files for Laser Cutting

Before sending a file to a laser cutter, it must be optimized for accuracy and efficiency. Here are some best practices:

Convert text to outlines – Prevents font issues during processing

Ensure proper line thickness – Thin lines may not be detected by the laser

Use RGB color mode – Some laser cutters use colors to differentiate cutting and engraving operations

Check for overlapping paths – Avoids duplicate cuts that can damage materials

Proper preparation ensures cleaner cuts, minimal material waste, and faster production times.

YOU CAN ALSO TRY THIS PRODUCT:300.000 Laser Cut Files

Conclusion

Mastering laser-cutting file formats empowers creators to bring their ideas to life with precision and efficiency. Whether you’re an artisan crafting intricate wooden ornaments, an engineer designing machine components, or a hobbyist experimenting with acrylic etching, understanding SVG, DXF, AI, CDR, and EPS will help streamline the design process. By selecting the right format and optimizing files correctly, anyone can achieve professional-grade laser-cut results.

YOU CAN ALSO TRY THIS PRODUCT:300.000 Laser Cut Files

0 notes

Text

Top Industrial Hardware Tools You Should Invest In for Your Business

Introduction

Running a successful construction or industrial business requires the right set of tools to ensure efficiency, safety, and high-quality work. Industrial hardware tools play a crucial role in streamlining operations, enhancing productivity, and reducing downtime on job sites. Whether you are managing a small-scale workshop or a large construction project, investing in high-quality industrial tools is essential for achieving precision and durability.

In this guide, we will explore the must-have industrial hardware tools for businesses and why you should prioritize purchasing them from trusted online suppliers like AHM Building Materials.

1. Power Tools: The Backbone of Industrial Work

Power tools are indispensable in industrial settings as they provide efficiency and precision for various tasks such as cutting, drilling, grinding, and fastening. Investing in durable, high-performance power tools ensures long-term reliability and reduced manual labor.

Essential Power Tools for Industrial Use:

Electric Drills: Used for drilling holes and driving screws into wood, metal, and concrete.

Angle Grinders: Ideal for cutting, grinding, and polishing surfaces.

Impact Wrenches: Provide high torque for loosening or tightening bolts efficiently.

Rotary Hammers: Essential for heavy-duty drilling into concrete or masonry.

Circular Saws: Perfect for making precise cuts in wood, plastic, and metal.

When buying power tools, opt for brands known for durability and efficiency to ensure that your investment lasts for years.

2. Hand Tools: The Essentials for Precision Work

Even with advancements in power tools, hand tools remain a necessity for fine-tuning, assembling, and finishing tasks. These tools provide control and accuracy in situations where power tools might not be suitable.

Must-Have Hand Tools for Every Industrial Business:

Wrenches and Pliers: Used for gripping, bending, and turning nuts and bolts.

Hammers and Mallets: Essential for driving nails and breaking materials.

Screwdrivers: Available in different types for handling various fasteners.

Measuring Tape & Levels: Ensure accuracy and precision in construction tasks.

Utility Knives: Used for cutting materials like plastic, cardboard, and insulation.

For builders and technicians, multi-purpose screwdrivers and wrenches are crucial tools that enhance efficiency and ease of work.

3. Fasteners and Fixing Tools: Ensuring Strong and Secure Joints

Fasteners are used to assemble, secure, and connect different components in industrial and construction work. Without high-quality fasteners, the stability of a structure or equipment can be compromised.

Common Types of Industrial Fasteners:

Bolts, Nuts, and Screws: Used in metal and wood constructions.

Anchors and Rivets: Provide additional support in concrete and brick structures.

Washers and Studs: Improve grip and durability in fastened joints.

To maintain efficiency and quality, always buy industrial hardware tools online from reputable suppliers who offer a wide range of fastening solutions.

4. Cutting and Welding Equipment: Precision in Metalwork

If your business involves metalworking, fabrication, or construction, then having cutting and welding tools is essential. These tools help shape and join metals for various industrial applications.

Must-Have Cutting and Welding Equipment:

Welding Machines: Used for joining metal components.

Cutting Torches: Ideal for slicing through thick metal sheets.

Plasma Cutters: Provide precision cutting for complex designs.

Welding Rods: Available in different types for various welding applications.

When buying welding rods and cutting tools, always consider durability and ease of use to ensure seamless operations.

5. Heavy-Duty Lifting Equipment: Handling Large Loads Safely

Industrial and construction projects often require lifting and transporting heavy materials, making heavy-duty lifting equipment a necessity. This equipment helps prevent workplace injuries while improving workflow.

Reliable Lifting Equipment for Businesses:

Electric Hoists: Used for lifting heavy materials effortlessly.

Lifting Slings and Chains: Ensure safe and secure transportation of loads.

Cranes and Winches: Essential for large-scale lifting tasks.

Hydraulic Jacks: Provide lifting power for automotive and industrial applications.

Investing in the right lifting tools not only enhances productivity but also ensures worker safety. If you’re looking to buy electric hoists online, choose models with high load capacity and durable construction.

6. Construction Toolkits: A One-Stop Solution for Professionals

Instead of purchasing tools individually, many professionals opt for comprehensive construction toolkits for professionals that include a variety of essential tools in one package.

Benefits of Using Construction Toolkits:

✔ Cost-Effective: Buying a complete set is often more affordable than purchasing tools separately. ✔ Convenience: Having all necessary tools in one kit saves time and effort. ✔ Portability: Toolkits come with cases that make transportation easy. ✔ Versatility: Includes tools for multiple industrial applications.

For large-scale projects, investing in high-quality toolkits ensures that your workers have everything they need to perform tasks efficiently.

7. Where to Buy the Best Industrial Hardware Tools Online?

Finding premium-quality industrial hardware tools can be challenging, but online shopping has made it easier than ever to access a wide range of products.

✔ Why Buy Industrial Hardware Tools Online?

Wider Selection: Online stores offer more brands and tool varieties.

Convenience: Shop from anywhere and get tools delivered to your location.

Competitive Pricing: Many online suppliers offer discounts and bulk deals.

Detailed Product Information: Access reviews and specifications before purchasing.

For the best selection of industrial hardware tools, construction toolkits, and heavy-duty equipment, visit AHM Building Materials and explore high-quality products at competitive prices.

Conclusion

Investing in industrial hardware tools is a necessity for businesses that prioritize efficiency, safety, and durability. Whether you need power tools, hand tools, fasteners, or lifting equipment, selecting high-quality materials will improve work performance and ensure long-term reliability.

By purchasing from reputable online suppliers like AHM Building Materials, businesses can access premium tools at the best prices, making every investment worthwhile.

Are you ready to upgrade your industrial hardware collection? Explore the best tools online today!

0 notes

Text

CNC Laser Cutting Machine Price: Key Factors That Influence Cost

In today’s fast-evolving manufacturing landscape, CNC laser cutting machines have become an essential tool for precision cutting and enhanced productivity. Whether you’re a small business or a large-scale manufacturer, investing in a CNC laser cutter can revolutionize your production process. However, understanding CNC laser cutting machine prices is crucial before making a purchase. Various factors determine the cost of a CNC fiber laser cutting machine, and this guide explores these key elements to help you make an informed decision.

1. Type of CNC Laser Cutting Machine

The type of CNC laser cutting machine significantly impacts its price. There are different categories based on technology and application:

CNC Fiber Laser Cutting Machine: These machines use fiber optics to deliver a highly efficient laser beam, making them ideal for metal cutting. Fiber lasers are known for their speed, precision, and energy efficiency, making them more expensive than CO2 lasers.

CO2 Laser Cutting Machine: Suitable for cutting non-metallic materials like wood, plastic, and glass. They tend to be more affordable but are not as effective for metal cutting.

CNC Metal Laser Cutting Machine: Specifically designed for cutting metals like stainless steel, aluminum, and copper. These machines are generally equipped with high-powered fiber lasers, which can increase the overall cost.

Each type has its advantages and disadvantages. For example, fiber lasers have lower operational costs due to minimal maintenance requirements, while CO2 lasers offer better flexibility for cutting organic materials. When choosing between them, it’s crucial to consider your production needs and long-term expenses.

2. Laser Power and Cutting Capacity

The power output of a CNC laser cutter plays a crucial role in determining its price. Higher wattage allows for cutting thicker and denser materials with ease. Common power options include:

1kW to 3kW: Suitable for thin metal sheets and small-scale production.

3kW to 6kW: Ideal for medium-sized operations requiring high-speed cutting.

6kW and above: Designed for heavy-duty industrial applications that demand ultra-precise cuts.

Higher power machines tend to be more expensive, but they also provide better efficiency and faster cutting speeds, which can justify the investment over time. For businesses that require versatility in material thickness, opting for a higher-wattage machine can lead to increased productivity and reduced production time.

3. Cutting Bed Size

CNC laser cutting machines come in various bed sizes to accommodate different material dimensions. A larger cutting bed allows for processing bigger sheets of metal, reducing material wastage and enhancing productivity. However, machines with larger work areas come at a higher price due to increased material and construction costs.

Common Cutting Bed Sizes:

Small Format (600mm x 900mm): Ideal for small businesses and hobbyists.

Medium Format (1300mm x 2500mm): Suitable for moderate-scale production.

Large Format (2000mm x 4000mm and above): Best for industrial applications and bulk processing.

When selecting a bed size, businesses should assess their material handling needs and the volume of production. Larger bed sizes allow for seamless large-batch production, reducing downtime caused by frequent material reloading.

4. Automation and Additional Features

The inclusion of automation features significantly affects the CNC laser cutting machine price. Some key enhancements include:

Auto-focus and Beam Adjustment: Helps in maintaining optimal cutting quality across different materials.

CNC Control Software: Advanced software allows for precise programming and easy operation.

Rotary Attachments: Enables cutting of cylindrical objects, which increases versatility.

Fume Extraction Systems: Essential for ensuring a clean working environment, especially when cutting metals that generate harmful fumes.

Material Handling Systems: Automated loading and unloading systems boost productivity but add to the overall cost.

Investing in automation not only enhances efficiency but also reduces labor costs. Businesses looking for long-term cost savings should consider these features despite the initial higher investment.

5. Brand and Manufacturer

The reputation of the manufacturer plays a significant role in pricing. Established brands like SLTL Group provide high-quality CNC laser cutting machines backed by advanced technology, durable components, and excellent after-sales support. While these machines may come at a premium price, they offer long-term reliability and performance benefits.

Brands with a strong track record often provide extensive warranties, training, and customer support, making them a safer investment. On the other hand, lesser-known brands may offer lower prices but could compromise on quality and reliability.

6. Geographic Location and Import Duties

Prices of CNC laser cutting machines can vary depending on the country of purchase. Import duties, taxes, and shipping costs all contribute to the final price. Buyers should consider local suppliers or distributors to reduce additional expenses and ensure timely support.

If importing from another country, understanding international trade regulations, tariffs, and potential customs clearance delays is essential. Partnering with an established distributor can help mitigate these costs.

7. Maintenance and Operating Costs

The initial purchase price is just one aspect; operating costs also need to be considered. Factors such as power consumption, cooling systems, and consumable parts like lenses and nozzles can add up over time. Regular maintenance is essential to ensure optimal performance and longevity of the machine.

A well-maintained CNC laser cutter reduces downtime and extends the life of the machine, maximizing return on investment. Investing in a model with lower operating costs can lead to significant savings over time.

8. Customization and Upgrades

Businesses often require specific modifications to meet their unique production needs. Custom-built CNC metal laser cutting machines with tailored specifications, additional power options, and specialized software can significantly increase costs. It’s advisable to assess whether standard models meet your requirements or if customization is necessary.

Many manufacturers offer upgrade options, allowing businesses to enhance machine capabilities as their production demands grow. This flexibility ensures that businesses remain competitive without the need for a full system replacement.

How Much Does a CNC Laser Cutting Machine Cost?

While prices vary depending on the factors mentioned above, here is a general pricing range for different CNC laser-cutting machines:

Entry-Level Machines: $10,000 - $50,000 (Best for small businesses and startups)

Mid-Range Machines: $50,000 - $150,000 (Ideal for medium-scale production)

High-End Industrial Machines: $150,000 - $500,000+ (For large-scale manufacturing and high-precision applications)

Understanding the expected price range helps businesses allocate their budget accordingly. It is advisable to request quotes from multiple suppliers and compare features before finalizing a purchase.

Conclusion

Investing in a CNC laser cutting machine requires careful consideration of various factors, including type, power, size, features, brand, and ongoing operational costs. Understanding these key aspects helps in making a cost-effective decision tailored to your business needs.

For high-quality CNC fiber laser cutting machines, explore options from SLTL Group, a leader in laser technology solutions. Whether you’re looking for an entry-level machine or an advanced industrial model, SLTL Group offers a wide range of reliable and innovative laser-cutting solutions.

0 notes

Text

CNC Wood Router Machine in Uttar Pradesh

Success Technologies is a Manufacturer, and Supplier of CNC Wood Router Machine in Uttar Pradesh, India. Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. We offer a wide range of Mini Tabletop CNC Router, CNC Engraving & Router Machine 2D/3D, CNC Rotary Wood Router Machine, CNC Engraving & Router Machine, 4 Axis CNC Router, CNC Router with Wood Turning Lathe, CNC Router for Door Lock Hole and Hinge. CNC Router with Saw Blades, CNC Router Double Head with Drilling Head, For Sewing Machine Wooden Table Top Making Industries, ATC CNC Router With Automatic Tool Changer, CNC Machine for Horizontal Wood Processing, CNC Router Machine with CCD Camera Customized, CNC Router Machine, CNC Router for Pattern Industries. Our advanced machines deliver exceptional precision and efficiency in woodworking, helping businesses and craftsmen bring creative ideas to life. A CNC Wood Router Machine uses computer programming for precise cutting, carving, and engraving of wood and other materials. It enables high-speed, precise, and repeatable machining of intricate designs, ideal for industrial and small-scale woodworking applications. The machine works with various tools, offering versatility for producing simple cuts to complex 3D carvings in woodworking. Features: High Precision and Accuracy: CNC Wood Routers provide consistent, high-precision cuts, ensuring parts meet exact specifications. Automated Control: Computer-controlled programming ensures repeatability and error-free production. Speed and Efficiency: CNC routers offer faster production cycles, reducing labor costs. Versatility: They work with various materials like wood, MDF, acrylic, and soft metals, offering flexibility. Advanced Software Integration: Equipped with software that simplifies design and programming for both beginners and experts. Customizable Tooling: Easily switch between tools (e.g., drills, cutters) for different tasks like engraving and shaping. User-Friendly Interface: Touchscreen controls and software integration allow for easy operation and monitoring. Applications: Furniture Making Cabinetry Signage Wood Carving Architectural Model Engraving Success Technologies is a Manufacturer, and Supplier of CNC Wood Router Machine in Uttar Pradesh India Including Agra, Aligarh, Amroha, Ayodhya, Azamgarh, Bahraich, Ballia, Banda, Bara Banki, Bareilly, Basti, Bijnor, Bithur, Budaun, Bulandshahr, Deoria, Etah, Etawah, Faizabad, Farrukhabad-cum-Fatehgarh, Fatehpur, Fatehpur Sikri, Ghaziabad, Ghazipur, Gonda, Gorakhpur, Hamirpur, Hardoi, Hathras, Jalaun, Jaunpur, Jhansi, Kannauj, Kanpur, Lakhimpur, Lalitpur, Lucknow, Mainpuri, Mathura, Meerut, Mirzapur-Vindhyachal, Moradabad, Muzaffarnagar, Partapgarh, Pilibhit, Prayagraj, Rae Bareli, Rampur, Saharanpur, Sambhal, Shahjahanpur, Sitapur, Sultanpur, Tehri, Varanasi. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#4AxisCNCRouter#Agra#Ahmedabad#Aligarh#Amroha#ATCCNCRouterWithAutomaticToolChanger#Ayodhya#Azamgarh#Bahraich#Ballia#Banda#BaraBanki#Bareilly#Basti#Bijnor#Bithur#Budaun#Bulandshahr#CNCEngraving&RouterMachine#CNCEngraving&RouterMachine2D/3D#CNCMachineforHorizontalWoodProcessing#CNCRotaryWoodRouterMachine#CNCRouterDoubleHeadwithDrillingHead#CNCRouterforDoorLockHoleandHinge.CNCRouterwithSawBlades#CNCRouterforPatternIndustries#CNCRouterMachine#CNCRouterMachinewithCCDCameraCustomized#CNCRouterwithWoodTurningLathe#CNCWoodRouterMachine#CNCWoodRouterMachineinAhmedabad

0 notes

Text

Maximizing Efficiency With Laser-Cutting Machines: Melbourne’s Best Solutions

Laser-cutting technology has revolutionized manufacturing and fabrication across various industries. From precision cutting in metal fabrication to intricate designs in signage and jewelry, laser cutting machines in Melbourne are transforming production processes. Whether you're a small business, startup, or large enterprise, choosing the right laser cutter is essential for efficiency and profitability.

This guide explores the features, benefits, and costs of laser-cutting machines while highlighting why SLTL Group is the go-to provider for advanced laser solutions in Melbourne.

Key Features of Laser Cutting Machines

1. High-Precision Cutting

Modern fiber laser cutting machines offer unmatched precision, making them ideal for industries requiring accuracy in metal and non-metal applications. These machines utilize advanced beam technology, ensuring sharp edges and minimal burrs on cut materials.

2. Speed and Efficiency

With advanced CNC technology, laser cutters provide high-speed cutting, reducing production time and increasing output. This efficiency is particularly beneficial in mass-production industries such as automotive and aerospace manufacturing.

3. Versatility Across Materials

Laser machines can cut a wide range of materials, including:

Stainless steel

Aluminum

Carbon steel

Copper and brass

Acrylic

Wood

Plastics

Composites

4. Automation and Smart Integration

SLTL Group offers automated laser cutting solutions integrated with AI-driven systems, improving workflow and reducing manual labor costs. Features like real-time monitoring, remote control, and predictive maintenance make these machines highly efficient.

5. Energy-Efficient Technology

Modern fiber laser systems consume less power while delivering high-performance cutting, reducing operational expenses. Compared to traditional CO2 laser machines, fiber lasers are more energy-efficient, contributing to sustainable manufacturing practices.

Benefits of Using Laser Cutting Machines

1. Improved Productivity and Output

With high-speed laser cutters, businesses can meet tight deadlines without compromising on quality. Automated feeding systems and multi-axis cutting capabilities further enhance production efficiency.

2. Cost-Effective Operations

Laser cutting reduces material wastage, minimizes labor requirements, and enhances overall cost-efficiency. Traditional cutting methods, such as mechanical or plasma cutting, often result in higher maintenance and operational costs.

3. Enhanced Design Flexibility

Laser technology allows for intricate and complex cuts that traditional methods cannot achieve. This is particularly useful in custom fabrication, where precision and customization are essential.

4. Minimal Maintenance Requirements

Compared to traditional cutting machines, fiber laser cutters require minimal upkeep, leading to lower maintenance costs. The absence of mechanical contact with the material also reduces wear and tear.

5. Safe and Eco-Friendly Processing

SLTL Group’s laser cutting solutions adhere to global safety standards while ensuring eco-friendly operations with minimal emissions. With features such as fume extraction systems and protective enclosures, workplace safety is enhanced.

Understanding Laser Cutting Machine Costs

The cost of laser-cutting machines in Melbourne depends on several factors, including:

1. Type of Laser Cutter

CO2 Laser Cutters: Ideal for non-metal materials like wood and acrylic, generally lower in cost.

Fiber Laser Cutters: Best for metal applications, offering high efficiency but at a higher initial investment.

Hybrid Laser Cutters: Combining fiber and CO2 technology for multi-material applications, often priced at a premium.

2. Power and Cutting Capabilities

Higher-wattage machines provide faster cutting speeds and deeper penetration but come at a premium price. Entry-level laser machines start at around AUD 20,000, while industrial-grade models can exceed AUD 500,000.

3. Automation and Software Integration

Advanced CNC systems with automation features increase machine costs but improve long-term efficiency. Integrated ERP and CAD software compatibility adds to the overall investment.

4. Brand and Warranty

Trusted brands like SLTL Group offer high-quality, reliable laser machines backed by comprehensive warranties and excellent customer support. Investing in a reputable brand ensures long-term reliability and reduced downtime.

Case Study: How SLTL Group Helped a Melbourne Manufacturer Scale Production

A leading sheet metal fabrication company in Melbourne struggled with inefficiencies in its cutting processes, leading to high material wastage and production delays. After integrating an SLTL Group fiber laser cutting machine, the company achieved:

40% faster production times

30% reduction in material wastage

Enhanced precision, eliminating the need for secondary processing

By choosing SLTL Group, the company not only improved operational efficiency but also increased its competitive edge in the market.

Why Choose SLTL Group for Laser Cutting Machines in Melbourne?

SLTL Group is a global leader in fiber laser cutting technology, providing innovative and customized laser solutions to businesses in Melbourne and beyond.

1. Cutting-Edge Laser Solutions

SLTL Group offers state-of-the-art laser cutting machines designed for high-speed, precision cutting across industries. Their machines incorporate AI-driven automation and cloud-based monitoring for optimal performance.

2. Customization Options

Tailored solutions to meet specific industry needs, from small-scale startups to large industrial enterprises. SLTL Group provides customizable laser power options, automation levels, and additional attachments like tube-cutting modules.

3. Comprehensive After-Sales Support

Customers benefit from training programs, maintenance services, and 24/7 support for uninterrupted operations. SLTL Group ensures that businesses maximize the value of their investment.

4. Industry-Leading Experience

With decades of expertise in laser technology, SLTL Group remains at the forefront of innovation. Their ongoing research and development efforts ensure that customers receive cutting-edge solutions tailored to their needs.

Industries Benefiting from SLTL Group’s Laser Cutting Machines

1. Metal Fabrication

High-precision metal cutting for industrial and commercial applications. SLTL Group’s fiber laser cutters are widely used in steel processing plants, HVAC manufacturing, and heavy machinery production.

2. Automotive and Aerospace

Production of lightweight, high-strength components for advanced manufacturing. Aerospace manufacturers rely on laser cutting for producing intricate airframe components with minimal material distortion.

3. Signage and Advertising

Custom signage and branding materials with intricate laser-cut designs. The ability to create precise lettering, logos, and detailed engravings makes laser cutting a preferred choice for the advertising industry.

4. Jewelry and Creative Arts

Fine detailing and engraving for bespoke jewelry and artistic creations. Laser cutting enables jewelry makers to work with precious metals, creating intricate patterns with extreme precision.

Future Trends in Laser Cutting Technology

AI-Powered Automation: Enhancing efficiency with intelligent laser systems that optimize cutting parameters in real time.

Eco-Friendly Processing: Reducing emissions with sustainable laser technology, including energy-efficient fiber lasers.

Smart Manufacturing Integration: Seamless ERP and CAD software integration for optimized production, reducing material waste, and improving workflow automation.

Conclusion

Investing in a high-quality laser cutting machine in Melbourne can transform your business operations, enhancing productivity, precision, and cost-effectiveness. SLTL Group stands as a trusted provider of innovative fiber laser cutting solutions, offering superior performance and unmatched customer support.

Looking for the best laser-cutting machine in Melbourne? Explore SLTL Group’s Laser Solutions today and elevate your production capabilities!

#artificial intelligence#machine learning#business#lasercutting#precision machining#writers on tumblr#blog

0 notes

Text

Twin Shaft Shredder: A Deep Dive in to Understanding its working mechanism

Shredders, which shred, tear down, and reduce waste into smaller pieces, are considered extremely important machines for the waste management and recycling industries. Twin-shaft shredder makes better use of their ability and shreds tough materials with two rotating shafts with cutting blades versus single-shaft shredders. This article examines the detailed working of a Twin Shaft Shredder with explanations of its design, functioning, and benefits.

Working Mechanism of Twin Shaft Shredders

Working with a large-solid dual shaft mechanism, the Twin Shaft Shredder allows for a shredder process that works in perfect balance and synchrony. The main parts involved in its operation include:

Rotating shafts with cutting knives: The shredder incorporates two parallel shafts with cutting blades. These counter-rotating shafts pull materials into the shredder and break them down using shear, tear, and compressive forces.

Inter-meshing cutters: Each shaft has specially shaped blades that mesh, giving instantaneous grab and shreds of materials. This design can shred heavy bulky materials like rubber, plastics, metals, and electronic waste.