#Rubber Rollers for Printing Machines

Explore tagged Tumblr posts

Text

www.conpaptex.com

#conpaptex#printing roller#rubber roll#machinery#manufacture#machine#rubber roller#industry#packaging

1 note

·

View note

Text

Arvind Rubber – Premier Rubber Roller Suppliers

The name that dominates the industry of rubber roller suppliers is the Arvind Rubber. It started its operations in 1984 and now our expertise lies in customizing, manufacturing, and supplying rubber rollers along with many other products like Bow Banana Roller, Silicon Rollers, and Carbon Fiber Rubber Roller, designed to achieve optimal performance across several sectors, including paper, textile, and packaging.

Visit: https://www.arvindrubber.com/

#rotogravure printing#rubber roller#air expanding shaft#rubber roller grinding machine#industrial rubber roller manufacturer

0 notes

Note

Does your 1219 have a nickname?

Also, I was wondering if you have any fun stories surrounding it! Strange quirks it has or anything like that.

I'd love to see more photos if you're allowed to post them!

Thanks for the question! These are my favorite part about my blog by far.

Not exactly, the UNIVAC 1219 doesn’t have a nickname. I did realize recently that I should specify the pronunciation (Twelve-Nineteen), but it doesn’t have any nicknames. Apart from ‘the 1219’, it’s also regularly referred to as the CPU or just ‘the computer’.

Fun stories or weird quirks? Boy, I could fill a book with this machine’s weird quirks (or as we say, intermittent issues), but I’ll try to blitz through the most common ones:

Sometimes the computer will stop running and enter a WAIT mode. No reason, it just needs a break. We can’t fix it, it just has to decide to go back into operating mode.

The computer will often start attempting to communicate on IO channel 13. We’re not telling it to talk to anything, it just decides to try to.

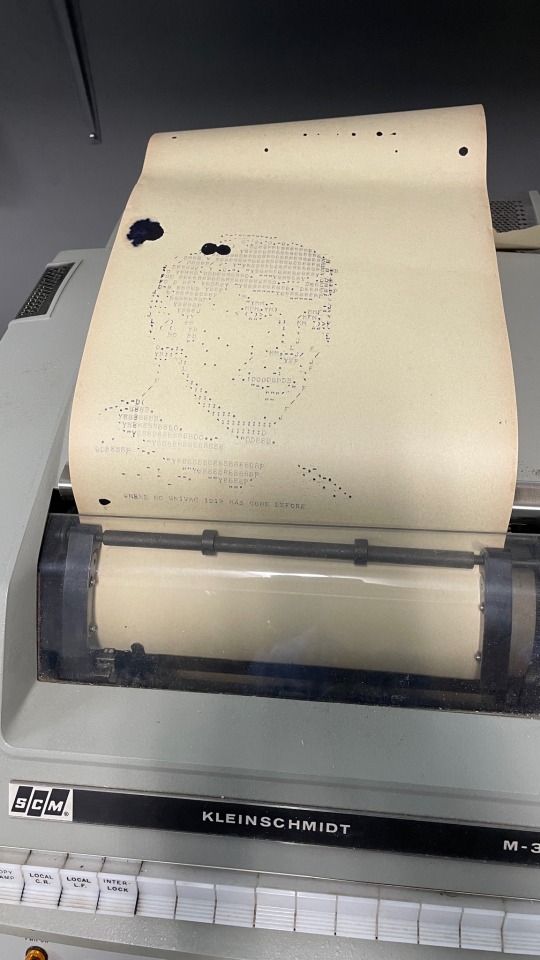

One of our teletypes (the Kleinshmidt) stamps ink splotches into the paper rather than characters most of the time. However, this weekend it worked for the first time in 10 months! We didn’t change anything, it just had an extra cup of coffee or something.

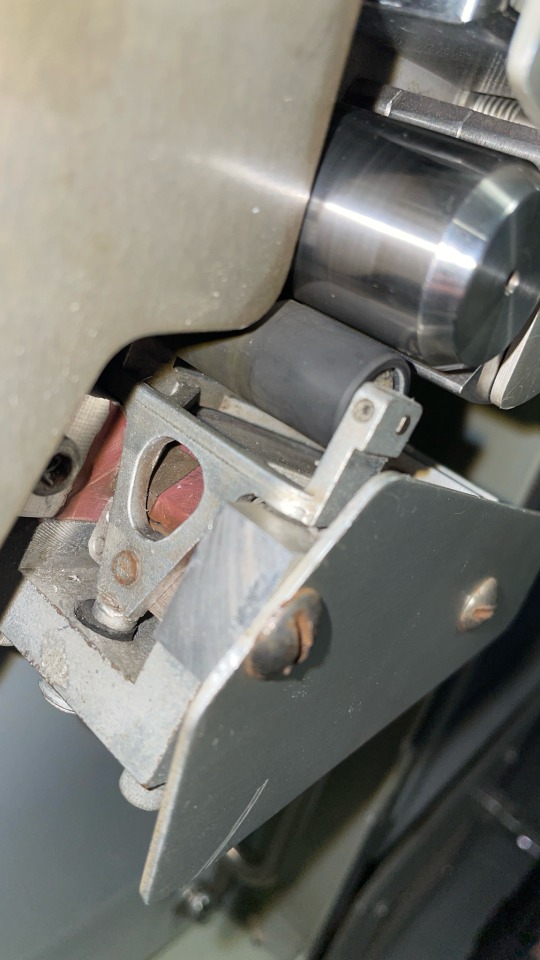

The Digital Data Recorder, or the tape drive, has the most gremlins out of any of our units. The top handler works fairly well, but the bottom handler won’t properly read data, write data, move the tape forward, initialize the tape, or any number of other issues.

There’s more but hopefully this satisfies your curiosity.

Fun stories? Well, I can’t name any specific ones, but I can say it’s a very endearing machine. It’s the very last of its kind and being one of three individuals in the world responsible for it makes every issue that more frustrating. There is no real forum for it, the subject matter experts sit next to me and are often just as exasperated as I am.

But the unique nature of this situation make every successful diagnostic test that much sweeter. Every new addition (5.25” floppy drive via serial) that much cooler. I have an IBM PC-XT clone at home, but I thank my lucky stars every day that this big iron is what I get to specialize in.

As for more photos, I have none that are as grandiose as you would probably expect. I do have my working photos though. I took all my photos when I first started working on it and now I am more dedicated to fixes than photo-ops.

This is a photo of our finicky Kleinshmidt teletype. Still has blotches but it actually printed!

This is the back of the bottom handler. Pictured is the vacuum pump in the bottom left (so sudden stops just yank magnetic tape slack rather than ripping tape). The big cylinder in the center is a motor for running the magnetic tape handler itself. The big black ‘hose’ of wires coming out of the steel plate contains all the cables that come right off the handler’s head for reading and writing data!

This is the forward pinch roller of the bottom handler. It was replaced after this photo was taken as you can see the rubber has deteriorated in the 55 years this machine has been operating.

As for being allowed to post photos, that’s not an issue. The last 1219 was decommissioned in 2014 and now you can find all of its documentation online at http://www.bitsavers.org/pdf/univac/military/1219/

#vintagecomputing#mainframe#antiquetech#digitalarchaeology#navy#new jersey#oldtechnology#retrotech#tech#univac#new blog#computerarchaeology#computerhistory#old technology#old computers#vintagehardware#classiccomputing#technology#retro tech#big iron#computer

60 notes

·

View notes

Text

The Application of Ink Doctor Blade in Gravure Printing

The selection, installation, and adjustment of the ink doctor blade in gravure printing have a significant impact on the quality of printed products. Below are some insights on the application of the doctor blade in gravure printing and related issues.

1. Selection and Installation of the Doctor Blade

For high-speed gravure printing machines, imported, highly elastic steel doctor blades with a thickness of 0.15–0.2mm are commonly used. When installing the doctor blade, it is important that the blade is longer than the printing plate by 10–20mm to prevent ink from splashing onto the rubber roller. The steps and key points for installation are as follows: 1. The distance between the backing and the blade should be approximately 10mm. The distance between the backing and the blade should be 5–7mm. However, depending on specific circumstances, the distance can be appropriately increased (i.e., using a soft blade) or decreased (using a hard blade). 2. Place the new blade behind the backing and insert it into the blade slot. Tighten the backing screws, starting from the middle of the blade and gradually working outward. Alternate tightening from both ends. Here is a tip to avoid blade warping: when tightening the screws, it should be done in two or three rounds, not all at once. While tightening the screws, use a piece of cloth to clamp the blade and backing and pull it toward one side with force. This ensures that the blade is installed more evenly. A flat blade ensures a uniform ink layer on the printing plate. 3. Select appropriate tools and methods for blade sharpening. When sharpening a blade with a sharpening stone, if the stone is too coarse, it is not suitable for new blades. Based on practical experience, using 1-grit diamond sandpaper is suitable for sharpening both new and old blades with significant damage. If 1-grit sandpaper feels too coarse for sharpening a new blade, you can finish sharpening with finer 0-grit sandpaper. There are two main sharpening methods: one is folding the sandpaper into a "V" shape, ensuring several layers to prevent the blade from cutting through the paper and hurting the user. This method is efficient and easier to control the blade's edge angle, but it is not very safe. The other method is to use both hands to pull the sandpaper at both ends while sharpening, which is safer but less precise for controlling the angle of the blade. Both too blunt and too sharp blades can negatively affect printing quality.

2. Proper Adjustment of the Doctor Blade

The pressure, sharpness, and the contact position of the blade with the printing plate all influence printing quality. By properly adjusting these factors according to the actual needs, many printing problems can be resolved. 1. Pressure Factors that affect the pressure of the doctor blade include the cylinder pressure, the choice of soft or hard blades, and the angle at which the doctor blade crosses the printing plate. The greater the angle, the higher the pressure. Excessive pressure can reduce ink transfer efficiency and cause greater wear on both the printing plate and blade. Insufficient pressure can lead to dirty plates or visible blade lines. 2. Blade Sharpness The sharpness of the blade depends on whether it is new, the sharpening angle, and the type of abrasives (such as sharpening stones) used. The optimal sharpness should effectively clean the ink without creating blade marks. Overly sharp blades tend to produce blade marks, and they also wear out the printing plate more quickly. 3. Contact Distance between the Blade and the Printing Plate Reducing the contact distance between the doctor blade and the printing plate can improve ink transfer efficiency, but it can also cause dirty plates. Conversely, increasing the distance can reduce the occurrence of dirty plates and avoid fine line defects, but it may lower ink transfer efficiency.

Explore our book printing services on the Printing in China page. 4. Blade Flatness The flatness of the blade and whether it warps primarily depends on the installation method, though it may also be influenced by foreign matter on the blade or backing. If the blade is not flat, it can cause issues such as water drop-like marks on the print edges or intermittent lines. Some may think that rough ink or poor ink flow is the cause of such issues, but in reality, an uneven blade can also lead to these problems. 5. Movement of the Doctor Blade The lateral movement of the doctor blade is important for reducing blade lines, increasing blade utilization, and minimizing wear on the printing plate. If the blade movement is irregular, it should be adjusted to improve performance.

0 notes

Text

The Science Behind Effective Rubber Roller Design at Anar Rub Tech Pvt Ltd

Rubber rollers are a crucial component in various industrial applications, including printing, textile, food processing, and pharmaceutical industries. Effective rubber roller design is essential to ensure optimal performance, productivity, and product quality. Anar Rub Tech Pvt Ltd, a leading manufacturer of high-quality rubber rollers, has rubber roller manufacturer heavily in research and development to understand the science behind effective rubber roller design. In this article, we will delve into the science behind Anar's rubber roller design, exploring the key factors that contribute to their exceptional performance.

Material Selection: The Foundation of Effective Rubber Roller Design

The selection of the right material is the foundation of effective rubber roller design. Anar's team of experts carefully chooses the most suitable rubber compound, taking into account factors such as the application, operating conditions, and desired performance characteristics. The company uses a range of rubber compounds, including natural rubber, synthetic rubber, and specialized compounds, to cater to diverse industrial requirements. By selecting the right material, Anar ensures that its rubber rollers exhibit the necessary properties, such as abrasion resistance, chemical resistance, and flexibility, to perform optimally in various applications.

Surface Texture and Finish: A Critical Aspect of Rubber Roller Design

The surface texture and finish of a rubber roller play a critical role in determining its performance. Anar's rubber rollers feature a range of surface textures and finishes, designed to meet specific application requirements. For instance, a smooth surface finish is ideal for applications where a high level of precision is required, such as in printing and pharmaceutical industries. On the other hand, a textured surface finish is better suited for applications where a high level of grip is necessary, such as in textile and food processing industries. By carefully designing the surface texture and finish, Anar ensures that its rubber rollers provide optimal performance and minimize the risk of product defects.

Dimensional Tolerance and Geometric Accuracy: Ensuring Precision and Consistency

Dimensional tolerance and geometric accuracy are essential aspects of rubber roller design. Anar's team of experts uses advanced manufacturing techniques, such as CNC machining and grinding, to ensure that its rubber rollers meet precise dimensional tolerances and geometric accuracy. This attention to detail ensures that Anar's rubber rollers provide consistent performance, minimize the risk of product defects, and reduce downtime. By maintaining precise dimensional tolerances and geometric accuracy, Anar's rubber rollers also ensure optimal compatibility with other machine components, reducing the risk of premature wear and tear.

Curing and Vulcanization: The Secret to Long-Lasting Rubber Rollers

Curing and vulcanization are critical processes in rubber roller manufacturing. Anar's team of experts carefully controls the curing and vulcanization processes to ensure that its rubber rollers exhibit optimal properties, such as strength, flexibility, and resistance to chemicals and abrasion. By optimizing the curing and vulcanization processes, Anar ensures that its rubber rollers provide long-lasting performance, minimizing the need for frequent replacements and reducing maintenance costs.

Testing and Validation: Ensuring Performance and Reliability

Anar's commitment to quality and performance is reflected in its rigorous testing and validation procedures. The company's team of experts conducts a range of tests, including tensile strength, abrasion resistance, and chemical resistance tests, to ensure that its rubber rollers meet the highest standards of performance and reliability. By testing and validating its rubber rollers, Anar ensures that they provide optimal performance, minimize downtime, and reduce maintenance costs.

Conclusion

Effective rubber roller design is a complex process that requires a deep understanding of the underlying science. Anar Rub Tech Pvt Ltd has invested heavily in research and development to understand the science behind effective rubber roller design. By carefully selecting the right materials, designing the surface texture and finish, ensuring dimensional tolerance and geometric accuracy, optimizing curing and vulcanization processes, and conducting rigorous testing and validation, Anar ensures that its rubber rollers provide exceptional performance, productivity, and product quality. As industries continue to evolve, Anar remains committed to innovation and customer satisfaction, providing tailored solutions to meet the unique needs of each industry.

0 notes

Text

EXPLORING THE INNOVATIONS IN RUBBER ROLL MANUFACTURING AT KRISHNA ENGINEERING WORKS

INTRODUCTION TO RUBBER ROLL MANUFACTURING

we will explore the innovations in rubber roll manufacturing at Krishna Engineering Works. The focus will be on the advanced techniques and technologies that enhance product quality and efficiency. Join us as we uncover the key developments driving this industry forward.

Rubber Roller

HISTORY OF RUBBER ROLL MANUFACTURING

Understanding the history of rubber roll manufacturing provides insight into its evolution. From traditional methods to modern automated processes, this journey highlights the challenges and triumphs faced by manufacturers, setting the stage for current innovations.

INNOVATIVE MATERIALS USED

Krishna Engineering Works utilizes cutting-edge materials that enhance the durability and performance of rubber rolls. Innovations such as synthetic rubbers and composite materials are pivotal in meeting the demands of various industries, ensuring longevity and efficiency.

ADVANCED MANUFACTURING TECHNIQUES

The adoption of advanced manufacturing techniques, such as 3D printing and CNC machining, has revolutionized the production of rubber rolls. These methods not only improve precision but also reduce waste and enhance overall product quality.

Krishna Engineering Works

CONCLUSION AND FUTURE OUTLOOK

In conclusion, the innovations in rubber roll manufacturing at Krishna Engineering Works highlight the importance of technology and quality in the industry. As we move forward, continued investment in research and development will be crucial for sustaining growth and meeting future challenges.

#manufacturer#machinery#industrial#supplier#exporter#textiles#rubber#roller#rubber roller#machinemanufacture#industry

0 notes

Text

When to Replace Printing Press Rollers: Signs of Wear and Tear

Printing press rollers are essential components in the printing industry, responsible for transferring ink to paper and maintaining consistent print quality. Over time, however, these rollers experience wear and tear that can negatively affect print output. Knowing when to replace printing press rollers is crucial to avoid production delays and ensure high-quality prints. This article will explore the key signs that indicate it's time for replacement, helping you maintain optimal performance.

1. Inconsistent Print Quality

One of the most noticeable signs that printing press rollers need replacing is a decline in print quality. When rollers become worn or damaged, they may not distribute ink evenly across the substrate. This can result in streaks, smudges, or uneven colour coverage. If you notice frequent variations in print output despite regular maintenance and cleaning, the rollers may be at fault. Inconsistent print quality can lead to wasted materials and increased production costs, making it essential to address roller issues promptly.

2. Visible Damage to the Rollers

Inspecting the rollers regularly is an effective way to spot signs of damage. Common visible issues include cracks, flat spots, or worn-out areas on the roller surface. These imperfections can disrupt the smooth transfer of ink and negatively impact print consistency. Rollers made from rubber or polyurethane are especially prone to surface damage over time, particularly when exposed to harsh chemicals or abrasive cleaning methods. If you notice any significant wear or physical damage during inspection, it is time to consider replacing the rollers.

3. Hardening or Softening of the Roller Material

Roller material changes can be another indicator of wear and tear. Over time, rollers can harden due to exposure to heat, ink solvents, or prolonged use. When rollers harden, they lose their ability to conform to the surface they are printing on, resulting in uneven ink distribution. Conversely, rollers can also soften and become overly pliable, which can cause excessive ink absorption and poor transfer. Regularly checking the hardness of the roller material and comparing it to the manufacturer’s specifications can help you determine when it’s time for a replacement.

4. Excessive Ink Consumption

If your printing press seems to be using more ink than usual, worn-out rollers might be the culprit. As rollers degrade, they may require more ink to achieve the desired print quality, leading to higher ink consumption. This not only increases operational costs but can also create issues with drying and smudging. Monitoring ink usage can help identify when the rollers are no longer functioning efficiently.

5. Increased Roller Slippage

Roller slippage is another common problem associated with worn printing press rollers. When rollers lose their grip, they may slip or skid during the printing process, causing poor image registration and misalignment. Slippage often occurs when the surface of the roller has become too smooth or the material has degraded. If adjustments to roller settings do not resolve the issue, replacement may be necessary to restore proper functioning.

6. Frequent Roller Adjustments

If you find yourself frequently adjusting the roller settings to maintain print quality, it could be a sign that the rollers are nearing the end of their useful life. Regularly having to recalibrate the rollers to compensate for wear can be time-consuming and may eventually lead to machine downtime. Replacing the rollers can eliminate the need for constant adjustments and ensure consistent performance.

Conclusion

Knowing when to replace printing press rollers is essential for maintaining high-quality prints and efficient operation. By paying attention to signs such as inconsistent print quality, visible damage, changes in roller material, excessive ink consumption, roller slippage, and frequent adjustments, you can identify when your rollers are due for replacement. Regular maintenance and timely replacements will help extend the life of your printing press and keep production running smoothly.

0 notes

Text

Is Your Industrial Application Suitable for Idler Rollers?

Idler rollers are widely used in industrial applications for various purposes such as conveying, guiding, supporting, and tensioning. They are typically used in conveyor systems, printing presses, packaging machines, and other types of machinery where material needs to be transported from one point to another.

If you are considering using idler rollers in your industrial application, it is important to determine whether they are suitable for your specific needs. There are several factors to consider when assessing the suitability of idler rollers for your application:

One of the most important factors to consider is the load capacity of the idler rollers. You need to make sure that the idler rollers can support the weight of the materials being transported without causing any issues such as deflection or failure.

Idler rollers are designed to operate at specific speeds and under certain operating conditions. You need to ensure that the idler rollers you choose are suitable for the speed and operating conditions in your application.

It is important to choose idler rollers that are the right size and dimensions for your application. The rollers should fit properly within your machinery and conveyor system to ensure smooth operation.

Different idler rollers are made from different materials such as steel, aluminum, plastic, or rubber. The choice of material will depend on the specific requirements of your application such as the type of materials being transported and the environmental conditions.

0 notes

Text

Advantages and Uses of Rubber Rollers in Manufacturing

What is a Rubber Roller?

A rubber roller is a machine part composed of an inner round shaft or tube covered by an outer layer of elastomer compounds. The inner shaft is made of steel, aluminum alloys, or other strong and rigid material composites. On the other hand, the outer layer is typically fabricated from a polymer such as polyurethane, silicone, EPDM, neoprene, and natural rubber. Rubber rollers are used in different manufacturing processes for performing operations such as:

Pressing

Laminating

Driving

Deflecting

Feeding

Printing

Pushing and Pulling

Film Processing

Material Conveying

Squeezing and Wringing

Straightening

Cooling and Uncooling

Rubber rollers benefit from elastomers' advantageous qualities, which include high coefficient of friction, resilient to abrasion and chemicals, impact strength, shock absorption, compression and deflection, and adjustable hardness. Comparing them to metal rollers, these characteristics allow them to handle produced products without harming the product or the item itself. Furthermore, in most situations, it takes less time and money to reassemble or repair the rubber covering than it does to repair the metal core, extending its useful life. When good surface durability and moderate to medium hardness are required, they are the recommended machine parts. Rubber rollers that have been properly designed and engineered can endure the deteriorating forces caused by mechanical and thermal causes.

Rubber Rollers' Benefits

The elastic qualities of rubber, which no metal can match, are the reason rubber rollers are utilised. Scratches, dents, corrosion, and cracks are all common and easy ways for metals to get damaged. Furthermore, metals' roughness and texture cause abrasions and deterioration on any surface they come in contact with. Though more costly and scarce, alternative materials such as fiber-reinforced composites can offer superior quality. Their availability is limited, and their cost is usually higher. The most cost-effective approach is to use rubber rollers, which have special mechanical qualities that are both physical and mental, including:

high coefficient of friction surface: In dry, clean environments, the coefficient of friction between steel surfaces is between 0.5 and 0.8. This produces a similar value of roughly 0.45 for aluminium to steel as well. The coefficient of friction of rubber, on the other hand, varies from 0.6 to 1.2 depending on the material. For transporting equipment like rollers, rubber is a good lining material because of this. When transporting items on an uneven plane, a high coefficient of friction keeps the objects from sliding.

Retains its shape in the face of impact: Rubbers are known for their good impact strength due to their flexibility. With ease, they can take in energy and spread it over a greater surface area before reverting to their previous form. This keeps the roller from breaking down too soon by preventing surface cracks and indentations.

Superior resistance to chemicals: Certain varieties of rubber have varying levels of chemical resistance. Rust can permanently harm a roller, thus it can be avoided by covering the roller core. Though significantly more expensive than rubber linings, stainless steel is the most often used metal roller choice that can withstand chemical attacks.

The replaceable lining preserves the robust roller core without causing any structural damage, as the rubber lining sustains the most damage during operation. By taking out and replacing the worn rubber liner, the roller core is easily serviceable. The roller core's and the equipment's overall lifespan are increased in this way. Furthermore, it averts costly maintenance such as cylinder or roller replacement. For optimal performance and longevity, it is advisable to work with a reputable rubber roller manufacturer to ensure the highest quality materials and workmanship.

#rubberroller#rubberrollermanufacturers#industrialproducts#manufacturers#anarrubtechpvtltd#anarrubtech

0 notes

Text

Are you looking for best Industrial Roller Manufacturer in India?

Industrial rollers is a cylindrical or cylindrical-like component used in various industrial applications. Industrial rollers are used in a variety of situations, including conveyor systems, printing presses, feeding machines, bending machines, and stamping presses. These rollers come in different shapes, sizes, materials, and designs, used for its specific industrial application, processes and requirements.

We are Leading manufacturer of rollers, Industrial Rollers. We are Supplier and Exporter of Conveyor Rollers, Conveyor Accessories, Conveyor Idler Roller, Taper Roller, Rubber Rollers, Teflon Roller, PP Coated Roller, Food Grade Coated Roller, Polyurethane Rollers, Nylon Roller, Textile Roller, Sugar Mill Roller, Paper Mill Roller, Silicone Rubber Coated Roller, Sponge Roller (Paint Roller), Plastic Roller (PVC Roller), Idler Rollers, Natural Rubber Roller, Ebonite Rubber Rollers, Hard Chrome Plated Roller. Industrial Rollers Supplier and Exporter in Noida, Bengaluru, Coimbatore, Maharashtra, Punjab, Rajasthan, Gujarat, Goa, Chhattisgarh, Madhya Pradesh, South Africa, Oman, US, UK.

For More Details Click here: https://www.jekminindustries.com/

0 notes

Text

Reasons for Common Faults in Offset Printing Plates and Corresponding Solutions

Misty Patterns

"Misty patterns" refer to the gradual reduction of halftone dots on the printing plate during the printing process, resulting in whitish areas in solid fields, influenced by factors such as fountain solution, ink, paper, and machine friction.

01

Strongly acidic fountain solution or excessive moisture content

This is a significant cause of misty patterns, requiring continuous attention in offset printing.

Solution: Regularly check the pH value of the fountain solution during printing. Modern advanced printing machines have automatic pH control devices for the fountain solution, reducing faults caused by inappropriate pH values. However, the crucial aspect is to control the amount of water used for the plates. Additionally, different ink types require compatible acidic fountain solutions, necessitating adjustments when using different inks.

02

Excessive pressure between the dampening roller and the plate

While the acidic fountain solution cleans the plate surface during printing, excessive pressure on the plate from the dampening roller can cause gradual dot reduction and result in misty patterns.

Solution: Re-adjust the pressure between the dampening roller and the printing plate.

03

Poor ink transfer

Insufficient pressure between the inking roller and the plate can result in inadequate ink supply to the graphic parts, damaging the plate and leading to misty patterns.

Solution: Re-adjust the pressure between the inking roller and the plate for the former; for the latter, consider adding a moderate amount of reducer to the ink and increasing the ink supply.

04

Excessive pressure between rollers

Adjusting printing pressure might inadvertently increase pressure between the plate and the rubber roller. This can cause both blurred and misty patterns in different areas of the plate.

Solution: Check roller pressure and the appropriate thickness of rubber and plate cushions, ensuring uniformity and smoothness.

Blurring

Blurring is a severe fault in printing conditions, caused by:

01

Excessively thin ink

Ideal offset ink possesses appropriate viscosity and flow. While additives might be used to reduce powdering and hairing, excessive amounts can decrease viscosity, leading to blurred images.

Solution: For ink causing blurring after additives, especially in dark ink, consider replacing it with new ink or adding concentrated ink oil. To clean blurred areas, dab medicine solution and adhesive and rub gently.

02

Excessive drying oil in ink

Ink sometimes contains excessive drying oil to expedite drying. If there's an excess, it accumulates on the plate and under pressure spreads to cause blurring.

Solution: Clean the old ink from the rollers and consider minimizing downtime for ink with excessive drying oil.

03

Excessive pressure between rollers

When excessive pressure exists between the plate roller and rubber roller, the plate's surface sand grains can flatten, causing blurring and subsequent misty patterns.

Solution: Maintain ideal pressure between plate and rubber rollers, considering correct cushioning data for the plate.

04

Insufficient tension in the rubber blanket

Insufficient tension in the rubber blanket leads to slippage during printing, resulting in double images and blurring.

Solution: Immediately tighten the rubber blanket when noticing looseness or natural relaxation, securing it with appropriate tension.

05

Plate dehydration causing blurring

Dehydration due to extended machine stoppage without cleaning or insufficient cleaning leads to plate dehydration and eventual blurring.

Solution: Promptly use a clean cloth soaked in a solution to clean. For small areas, use a minimal solution, while for full-blown blurring, apply solutions consecutively.

Floating Ink Staining

Floating ink staining manifests as dot or thread-like forms, sometimes varying between consecutive sheets.

01

Serious ink-water emulsion

Some inks possess hydrophilic properties, which might react with acidic fountain solutions during printing, resulting in waterlogging or emulsification.

Solution: Reduce plate water content and add appropriate quantities of drying oil to counter emulsification. Lowering the acidity of the fountain solution may also help.

02

Severe ink emulsification

Excessive plate water leads to ink emulsification under rapid roller pressure. This loosens ink adhesion and scatters ink particles onto the plate's surface, causing staining.

Solution: Analyze the cause and act accordingly, adjusting gum solution amounts, fountain solution acidity, and plate water content. Adding concentrated ink oil to ink might also help. If the fault is severe, consider replacing the ink.

Click to learn more about book printing, sticker printing, medicine box, hardcover book printing, PE bag, Bible printing, paper bag printing, catalog printing, and printing in China.

03

Excessive ink on rollers

Excessive ink on rollers might result in ink splatter, causing floating ink stains. This may be due to excessive plate water, resulting in an imbalance between water and ink, leading to ink splatter.

Solution: Correct the plate water-ink balance or remedy offset plate tone values if they're insufficient.

This piece covers issues related to offset printing plates and their potential remedies, providing insights into troubleshooting these common problems.

1 note

·

View note

Text

Understanding Offset Printing Machines and Its Ways of Working

The Blog Offset printing is a widely preferred printing method, known for its high efficiency and exceptional quality. This indirect technique involves transferring ink from a plate to a rubber blanket and then onto the printing surface, ensuring vibrant and consistent results, especially in large print runs. Essential components of offset printing machines include printing plates, rubber blankets, an inking system, paper feed, and delivery systems.

The process begins with plate preparation, where digital designs are transferred to light-sensitive plates. Ink and water are then applied to the plate, ensuring precise image rendering by dampening non-image areas. The inked image is transferred to a rubber blanket, enabling flexibility and even ink distribution before the final imprint on paper. A drying process, either heat or air-based, follows to prevent smudging.

Post-printing steps, such as cutting, folding, and binding, ensure polished outcomes. Rigorous quality control checks maintain alignment and color accuracy. Offset printing stands out for its cost-effectiveness in large runs, sharp image quality, and adaptability to various materials like paper, cardboard, and plastic.

For optimal performance, using high-quality materials like durable printing rubber rollers is crucial. Businesses can achieve superior printed materials, leaving a lasting impression in a competitive marketplace.

0 notes

Text

Uneven Printing Ink Color? Check These 4 Points...

The uniformity of ink color is crucial for the quality of newspapers. In black and white, it affects readability, while in color, it impacts the presentation of images. This is especially critical for full-page advertisements where uniformity across colors is essential to achieve the desired effect. There are various factors contributing to uneven ink color in newspapers. Here, I will analyze each factor systematically, focusing on equipment-related issues.

Aging of Electrical Components

Modern printing machines are highly automated, with modular management of electrical components. If these modules age, it may result in a mismatch between the control panel keys and their actual functions, leading to uneven ink color. During adjustment, it is necessary to correspond the control panel keys with the ink keys on the equipment and observe their sensitivity.

Improper Pressure of Rubber Rollers

It is crucial to strictly and properly adjust the pressure on all rubber rollers. Insufficient pressure can lead to poor ink and water transfer, while excessive pressure increases friction between rollers, causing them to heat up and accelerating wear and tear. Therefore, maintaining the right pressure between rubber rollers is vital for ink transfer. Regularly inspecting the pressure between each roller is an indispensable step in equipment maintenance.

Damage to Rubber Roller Bearings and Inappropriate Surface Roughness

Regularly remove all rubber rollers and inspect whether the roller bearings need replacement. Prolonged use without replacing bearings can lead to issues such as oil depletion, aging, and damage, resulting in misalignment or bouncing of rollers during high-speed operation. Due to the dense arrangement of rollers in printing machines, such issues may not be easily noticeable at low speeds. Therefore, disassembling and inspecting each roller individually is necessary to identify damaged bearings.

The surface roughness of rubber rollers also plays a crucial role in ink transfer, often overlooked by operators. Prolonged exposure to ink can create a smooth and hard film on the roller surface, while cleaning agents may cause unevenness. Hence, regular checks on the surface roughness of rubber rollers are essential.

Inspection of rubber rollers can be conducted in two ways: 1) removing rollers and checking surface wear while using a hardness tester to ensure ink roller hardness remains between 30-35HS and water roller hardness between 25-28HS; 2) measuring roller diameter with calipers and maintaining it within the factory-set range. Timely replacement and re-inking are necessary.

Inadequate Ink Layer Thickness on the Ink Fountain Roller

The thickness of the ink layer on the ink fountain roller directly affects the amount of ink transferred to the anilox roller. Over prolonged usage of the ink fountain roller, the gap between the ink fountain roller and the ink knife may reduce, resulting in an overall decrease in ink transfer and insufficient saturation of colors in images.

Regular cleaning of the ink fountain roller is necessary to maintain a consistent gap between the ink fountain roller and the ink knife. Adjustments to the ink lever screws should be made to ensure an even layer of ink, approximately 3-5mm thick, adheres uniformly to the surface of the ink fountain roller. This ensures a consistent ink application on the ink rollers and stable ink transfer.

Click to learn more about book printing, sticker printing, medicine box, hardcover book printing, PE bag, Bible printing, paper bag printing, catalog printing, and printing in China.

Apart from equipment-related factors, there are many other elements that can impact print color. Factors such as the pH level of the fountain solution, concentration ratios of the fountain solution, regulation of temperature and humidity in the printing workshop, paper quality, ink properties, and the skill level of the operator can all influence print quality. Only through continuous experience and the accumulation of knowledge during prolonged production can one understand and master these patterns, leading to high-quality printing results.

0 notes

Text

Printing & Packaging Solutions

Gravure printing is a widely used processing method often used to print large volumes of magazines and catalogues. Opposed to flexo printing, the ink in gravure printing is transferred from carved micro cavities and not from a relief. These cavities, embedded in the printing cylinder, form the printing pattern. With many years of experience and in-depth knowledge in this domain, we are enthusiastically engrossed in providing highly reliable and cost-effective our gravure printing services to our valued customers situated all over the nation. These services are required for printing on to different films that include PP, polythene, nylon and so forth - gravure printing cylinder.

This offers the defect free printings and comes with the standard certificates. This is idyllic for any kind of printing substrate, including crystal, glass, rubber, leather, BOPP, PE, plywood, stone and so forth.. For two decades we now have been a leading producer and supplier of excessive end, high efficiency, dependable merchandise and solutions for printing and packaging industry. We ensure that our merchandise conform to the customer’s requirements. We manufacture and distribute all forms of consumables used in the flexo process in the flexible packaging, labels, corrugated cardboard and paper sectors.

We have many years of experience in manufacturing precision machined rollers for a variety of makes use of, together with steel cores and sleeves. We supply all kinds of inks and consumables for graphic printing, industrial and textile marking. The primary setup is the gravure cylinder urgent towards the substrate which itself is against a deformable roll so that adequate pressure could be utilized. Gravure printing of mesoporous architectures bares a strong potential for automated skinny movie manufacturing with extremely outlined composition. In addition, standardization and automation of the movie preparation course of as well as complex film structure fabrication ought to be relatively easy - rotogravure printing cylinder.

All our shoppers profit from our expertise and expertise, as we offer comprehensive help throughout the whole manufacturing journey. We produce tailored embossing rollers with the most recent laser, etching and knurling applied sciences and methods, effortlessly reproducing intricate particulars and patterns. We utilize the very newest digital structure and 3D expertise to support our clients in making the best choice for his or her embossing needs. For more information, please visit our site https://packadvance.com/

1 note

·

View note

Video

tumblr

China what is flexographic printing machine manufacturers - GZLABEL what is flexographic printing ? this is flexographic printing kind of like a high -output vrsion of rubber stamping but using a flexible plate that transfers your design to materail ,now i was supposed to keep this quick solet me dig in there's five for components of machinery make this process possible down here ,you 've got you ink sitting in an inkwell and then the fountain roller picks up the ink and transfers it to the analects roller now the intellect is covered in tiny little cells that pick up the ink more cells per inch mean more ink converage and it transfers the ink to your plate cylinder ,this is wehre you do the full design loops and then your materail with a courgette box is going right through here and the impression cylinder is squeezing it against the plate so you got a beautiful print .so that's flexographic printing

0 notes

Text

Roller for Bi-Oriented Stretch Film Production Line

Jwell Machinery Co., Ltd. not only focuses on the design and manufacture of the roller of plastic plate sheet, meets the requirement of the clients, but also supplies the high quality roller for the plastic film business area. We import the foreign advanced roller manufacture technology, supply the high quality roller for the machine of casting film and stretch film. Such as chill roller, stretch roller, preheat roller, pull roller, corona roller, rubber roller, TEFLON roller etc. The roller rotate in higher speed when produce the plastic film, so that high precision of the roller dynamic balance is important particularly. Our specified large dynamic balance testing equipment and various balance process can ensure these request effectively. According to the strict molding request of final film product to the temperature error on the roller surface, The roller which has the spiral inner flow channel is a high-tech product, it has a very good heat exchange ability and this roller can reach the minimum temperature fluctuation which is allowed in production. Features 1. Our manufacturing capacity of roller: ● Max. machining length: 14000mm ● Max. machining diameter: Φ1600 mm 2. Manufacturing precision of roller ● Concentricity: ≤ 0.01mm ● Cylindricity: ≤ 0.01mm ● Surface roughness: Ra0.005 ~ 0.01μm 3. Roller surface treatment ● Electroplate hard chrome coating ● Rubber overlay coating ● Stainless steel overlay coating ● Special coating like TEFLON etc Due to the higher request for the tension / coated angle/ high line speed/ temperature precision control of the stretching film roller , we can provide the following certificates for each roller: ● Shafts material ● Outer jacket material ● Dimension and geometrical report ● Roughness (measures on the sides and in the center of the table) ● Chrome coating hardness ● Coating thickness (measures on the sides and in the center of the table) ● Final balancing reach to G2.5 (machine Printed) ● Weight, inertia , déflection under own weight, critical speed ● Static pressure test to prevent the leakage ● Temperature difference on the table surface ● Cooling water flow ● Inlet/Outlet water pressure difference Product image display Read the full article

0 notes