#Rotogravure-inks

Explore tagged Tumblr posts

Text

AFFORDABLE ROTOGRAVURE (GRAVURE) SURFACE PRINTING INK,ROTOGRAVURE (GRAVURE) REVERSE PRINTING INK

ROTOGRAVURE (GRAVURE) SURFACE PRINTING INK Rotogravure, also known as gravure, is a type of intaglio printing process in which the image is engraved onto a cylinder. The engraved cylinder is then coated with ink, and the excess ink is wiped away, leaving ink only in the engraved areas. The cylinder is then pressed onto the surface of the substrate, transferring the ink onto the material.

Rotogravure surface printing inks are available in a wide range of colors and formulations to suit different printing needs. They are commonly used to print on flexible packaging materials, such as plastic films, paper, and foil, as well as on labels, wallpaper, and decorative laminates. The ink’s properties can be adjusted to meet specific requirements, such as fast drying time, high gloss, or resistance to water or heat.

Overall, rotogravure surface printing ink is an important component in the production of high-quality printed materials, offering excellent color accuracy, sharpness, and durability.

ROTOGRAVURE (GRAVURE) REVERSE PRINTING INK Rotogravure reverse printing ink is a type of ink specifically designed for the reverse printing process in rotogravure printing. In reverse printing, the image is printed on the backside of a transparent substrate, such as a plastic film or a laminate, so that the printed image is viewed through the substrate. This process is commonly used for flexible packaging, such as snack bags, where the printed surface needs to be protected from damage during handling and transportation.

Reverse printing inks are formulated differently from surface printing inks, as they need to be able to adhere to the substrate while still providing good clarity and brightness of color when viewed through the transparent material. The ink is printed onto the non-printed side of the substrate so that when the material is flipped over, the image is viewed through the substrate. This means that the ink needs to have good opacity, as well as good adhesion to the substrate to prevent it from delaminating.

Rotogravure reverse printing inks typically consist of pigments, binders, solvents, and additives, similar to surface printing inks. However, they are formulated to have higher pigment loading, to ensure good opacity, and lower viscosity, to facilitate penetration into the substrate. They also contain additives that improve adhesion to the substrate and provide good scratch resistance.

Overall, rotogravure reverse printing ink is an important component in the production of high-quality reverse printed materials, offering good clarity, color vibrancy, and durability.

0 notes

Text

Rotogravure Inks

Rotogravure inks, vital for the printing industry, are produced by several esteemed manufacturers across India. These inks are specifically designed for rotogravure printing, a high-speed, high-quality printing process commonly used for packaging materials, decorative laminates, magazines, and more.In India, manufacturers of rotogravure inks adhere to stringent quality standards and employ advanced technologies to formulate inks that meet the demanding requirements of the rotogravure printing process. These inks are engineered to provide vibrant colors, excellent adhesion, and exceptional print clarity, even on challenging substrates.

0 notes

Text

Ink Manufacturing

Some prominent ink manufacturers in the U.S. include: Hewlett Packard (HP) – Known for inkjet and laser toner cartridges. InkJet, Inc. – Specializes in inkjet inks for various printing equipment. Sun Chemical – A leading producer of rotogravure inks and specialty materials. Flint Group – Manufactures inks for packaging and commercial printing. Siegwerk – Focuses on rotogravure inks for…

0 notes

Text

Flexible Plastic Packaging Market worth $264.9 billion by 2030

The report "Flexible Plastic Packaging Market by Packaging Type (Pouches, bags, roll stock, films & wraps), Printing Technology (Flexography, Rotogravure, Digital Printing), End-user Industry, Material (Plastics, aluminum Foils,) and Region - Global Forecast to 2030", is approximated to be USD 182.4 billion in 2022, and it is projected to reach USD 264.9 billion by 2030, at a CAGR of 4.8%.

Download pdf- https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=1271

The Flexible plastic packaging market is experiencing significant growth driven by several factors, including the increasing demand for packaged and processed food and beverages, changing lifestyles, rising disposable income, and a growing awareness of sustainable packaging. Additionally, rising urbanization and a focus on hygiene are also contributing to the market's expansion. However, the high cost of raw materials and poor recycling infrastructure may limit market growth. Despite these challenges, opportunities exist in the market for sustainable packaging alternatives and as a substitute for traditional packaging materials. The Flexible plastic packaging industry also faces the challenge of adapting to rapid technological changes.

By Packaging type, Bags accounted for the 2nd largest share in 2021

Paper and plastic bags are prevalent packagings used for various purposes. Plastic bags (of the thin film) are usually made of LDPE, HDPE, and polypropylene. Common uses of plastic bags include bags for shopping, household garbage, food packaging, dry cleaning, newspapers, frozen foods, fresh produce, agricultural products, medical & biohazard waste, and antistatic bags. Plastic bags are inexpensive to mass-produce, relatively easy to transport due to their lightweight, and can be folded into small sizes. They are water-resistant and do not add weight to the goods they carry. Due to the pandemic, single-use plastic bags are one of the most preferred packaging options among consumers. Despite growing environmental concerns, the production and consumption of single-use plastic bags are increasing worldwide. In the current scenario, countries are not focusing on sustainability. In the US, New York is among the states that have postponed implementing a ban on plastic bags.

By Material, Aluminium Foils accounted for the 2nd largest share in 2021.

Aluminum foil is a thin aluminum sheet (produced from bauxite ore) and is a lightweight metal with a silvery-white appearance. It is also the world’s most abundant metal in free and combined states. The aluminum used in Flexible plastic packaging is in the form of rolled products. Aluminum foil packaging with multilayered plastics is widely used for packaging fresh and processed meat, poultry, and fish, as they provide better hygiene and increase product shelf-life. They are extensively used in the food & beverage and healthcare sectors for packaging products, such as cheese cubes and blister packs. Aluminum has high ductility, and barrier protection, making it an ideal packaging material. It increases the shelf-life of products by keeping food, drinks, and other products safe and fresh. Another factor that enhances the use of aluminum for packaging purposes is its unparalleled recyclability.

By Printing Technology, Rotogravure accounted for the 2nd largest share in 2021.

Rotogravure is widely used for high-quality prints, producing fine images. The rotogravure printing process consists of a cylinder, a rubber-covered impression roll, an ink fountain, a doctor blade, and fluid ink. This process uses a printing cylinder embedded with minute cells capable of retaining ink directly transferred onto the substrate with a combination of pressure and capillary action. The inks used in rotogravure are low viscosity, which enables them to be drawn into the engraved cells in the cylinder and then transferred onto the substrate. Rotogravure printing technology is expected to experience rapid growth in the flexible plastic industry. It provides high-quality, high-speed printing with precise and consistent ink transfer, making it an ideal choice for printing high-resolution images and text on flexible plastic packaging materials. Additionally, rotogravure printing can be used on a wide range of materials, including films, foils, and laminates, making it a versatile option for various applications.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=1271

By Applications, the Flexible plastic packaging Market and Pharmaceutical & Healthcare Industry segment accounted for the largest share in 2021

The pharmaceuticals & healthcare segment is one of the most important industries that drive the demand for flexible plastic packaging. The demand for these types of packaging is driven by several factors, including the need for reliable and safe packaging solutions to protect sensitive products from contamination, ensure proper dosages, and extend the shelf life of medicines and medical devices. Healthcare products, including pharmaceuticals and medical products, must be protected from external conditions, such as light and moisture, as well as contamination and physical damage, which could alter the quality of the product.

North America accounted for the largest share of the Flexible plastic packaging Market in 2021

The flexible plastic packaging market in North America is growing owing to the rising demand for single portion packs or small packs, high disposable income levels, growing demand for convenience food, improving economic situation, and increasing consumption of packed food. An increase in the export of food products is expected to fuel the growth of the market in North America during the forecast period. Technological advancements drive the growth of the flexible plastic packaging market in North America in the food, beverage, and healthcare industries.

The Flexible plastic packaging Market comprises major players such as Huhtamaki Oyj (Finland), Berry Global Group Inc. (US), Amcor Limited. (Australia), Mondi Group. (UK), Sonoco Products Company (US), Westrock Company (US), Constantia Flexibles (Austria), Sealed Air Corporation (US), Transcontinental Inc (Canada), DS Smith (UK), and others are covered in the Flexible plastic packaging market. Expansions, acquisitions, joint ventures, and new product developments are some of the major strategies adopted by these key players to enhance their positions in the Flexible plastic packaging Market.

#FlexiblePackaging#PackagingSolutions#SustainablePackaging#EcoFriendlyPackaging#FlexiblePackagingDesign#FoodPackaging#PackagingInnovation#PlasticPackaging#PackagingTrends#PackagingIndustry#FlexiblePouches#PackagingMaterials#SmartPackaging#GreenPackaging#RecyclablePackaging

0 notes

Text

Packaging Printing Market - Forecast(2024 - 2030)

Packaging Printing Market Overview

Packaging Printing market is analyzed to grow at a CAGR of 5.09% during the forecast period 2024 - 2030 to reach $94.25 billion. Packaging printing can be defined as the process of labelling packages in the form of written, electronic or graphical representations, meant to create brand awareness. The packaging printing industry makes use of different technologies, be it digital printing, flexography, rotogravure and so on along with inks in order to meet various end use customer demands. With aesthetic appeal and digital printing, personalized or custom packaging, seasonal festive prints, 3D graphical pictures or holograms, texts with varied fonts among others have been also contributing towards the growth of packaging printing market. However, advent of smart packaging options including AI, augmented reality, scannable QR codes, RFID chips and so on along with growing adoption towards digital printing are some of the major factors driving the market of printed packaging solutions. Prior to rising counterfeiting, printed packaging acts as a crucial factor in order to increase product authenticity, alongside offering customer retention, improving purchasing power of the consumers, sustaining its market position and so on.

👉 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞

The packaging printing industry witnessed a notable shift towards digital printing technologies. This trend emerged as businesses sought more flexible, cost-effective, and customizable solutions for packaging production. Digital printing offered shorter turnaround times, reduced setup costs, and the ability to cater to smaller batch sizes, thus enabling brands to personalize packaging designs and adapt quickly to market demands.

Concerns over environmental sustainability drove a considerable push towards eco-friendly packaging solutions. Companies increasingly adopted sustainable materials, such as recycled paper and biodegradable substrates, and implemented eco-conscious printing processes. This trend was fueled by consumer preferences for environmentally responsible products and regulatory pressures to minimize packaging waste and carbon footprints. As a result, the packaging printing market witnessed a surge in demand for sustainable packaging options and innovations aimed at reducing environmental impact.

COVID-19 Impact

The COVID-19 pandemic had a significant impact on the packaging printing market. Initially, there was a surge in demand for essential goods, leading to increased production and demand for packaging materials. However, as lockdowns and restrictions were enforced worldwide, many industries experienced disruptions in their supply chains, causing a slowdown in packaging printing activities. Moreover, consumer behavior shifted during the pandemic, with a preference for online shopping and contactless delivery. This change led to an increased demand for e-commerce packaging solutions, such as corrugated boxes and pouches, while traditional packaging sectors like print advertising and promotional materials faced challenges due to decreased demand.

Additionally, health and safety concerns prompted companies to adopt stringent hygiene measures in their packaging facilities, impacting production efficiency and output. Overall, while certain segments of the packaging printing market experienced growth, others faced challenges during the COVID-19 pandemic, highlighting the importance of adaptability and resilience in the industry.

Report Coverage

The report: “Packaging Printing Industry Outlook – Forecast (2024 - 2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Packaging Printing industry.

By Technology: Digital, Flexography, Offset/Lithography, Three-Dimensional, Rotogravure, Screen Printing.

By Material: Glass, Metal, Wood, Paper, Paperboard, Cloth, Plastic (Flexible & Rigid), Others.

By Application: Healthcare, Food & Beverages, Cosmetics and Toiletries, Consumer, Industrial Goods, Others.

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and Rest of the World (Middle East, and Africa)

Key Takeaways

• Growing advent of smart packaging and increasing adoption of digital printing technique is analyzed to significantly drive the packaging printing market during the forecast period 2024 - 2030.

• Food & Beverage sector had accounted for the largest market share in 2023, attributed to the factors including customized or personalized printed packaging options, highlighting health benefits, nutritional information and so on.

• Presence of key market players such as Sonoco, Coveris, Graphic Packaging International and many others opting for partnerships, acquisition or expansion to improve printed packaging activities have helped in boosting its growth across North American markets.

0 notes

Text

Direct Printed Mylar Bags: How Digital Printing Is Revolutionizing Custom Mylar Bags

In the changing realm of packaging staying ahead of the competition requires a focus, on innovation. A notable advancement in this field is the adoption of printing, which has transformed the creation of custom Mylar bags.

This cutting edge technology offers advantages in terms of quality, flexibility and efficiency making it a game changer for businesses seeking to enhance their packaging solutions. Lets explore how digital printing is reshaping the world of customized Mylar bags and why its becoming the choice for brands.

The Fundamentals of Digital Printing

What is Digital Printing?

Digital printing is a method that directly transfers images onto packaging materials. Unlike techniques, like flexographic or rotogravure printing that rely on plates or cylinders digital printing utilizes files to generate high resolution prints.

How Does It Operate?

The process commences with a rendition of the design, which is transmitted to a printer. The printer then deposits ink directly onto the Mylar film resulting in an vivid image. This approach enables color replication and intricate detailing making it well suited for designs and top notch graphics.

Advantages of Digital Printing, for Customized Mylar Bags

Unrivaled Quality and Attention to Detail

A benefit of printing is its capability to create high quality images with exceptional detail. This is especially valuable for brands seeking packaging that mirrors the excellence of their products. Digital printing captures every aspect of the design resulting in vibrant and professional customized Mylar bags.

Versatility and Personalization

Digital mylar bag printing provides versatility in terms of customization. Brands can easily refresh their designs include themes or introduce limited edition packaging without the need for time consuming adjustments. This adaptability fosters. Enables responses to market trends.

Cost Effective for Small Orders

Printing methods often involve setup expenses making them less cost efficient for small production batches. Digital printing eliminates these setup costs making it a budget friendly option for runs and customized orders. This is especially advantageous for startups, niche products or brands experimenting with designs, without committing to quantities.

Quicker Turnaround Times

In todays moving market landscape speed plays a role. Digital mylar bag printing provides a turnaround compared to methods since there is no need, for extensive setup or plate creation. This enables brands to bring their products to market keeping them ahead of the competition and meeting consumer demands promptly.

Eco Friendly Option

Moreover digital printing is an environmentally conscious choice. It generates waste. Consumes fewer resources than conventional custom mylar bag printing techniques. By eliminating the requirement for plates and reducing ink usage digital printing contributes to reducing the impact of packaging production.

Utilization of Direct Printed Mylar Bags

Food and Beverage Industry

The food and beverage sector can significantly benefit from the high quality prints offered by printing. Whether its eye catching coffee bags, colorful snack packaging or elegant tea pouches digital printing ensures that packaging stands out on store shelves and attracts consumers attention.

Personal Care

In the realm of cosmetics and personal care products packaging plays a role in conveying brand identity and product excellence. Digital custom mylar bag printing allows for designs that reflect the nature of these products aiding brands in setting themselves apart in a competitive market.

Nutritional Supplements

In industries such, as pharmaceuticals and nutritional supplements precise labeling is crucial.Digital printing offers the precision and level of detail to ensure that all essential information is clear and complies, with regulations while also allowing for appealing and professional packaging.

In the consumer goods sector digital printing brings benefits in terms of flexibility and personalized options. From special edition packaging to materials digital printing empowers brands to craft captivating custom mylar packaging that connects with customers.

BrandMyDispo; Pioneering Digital Printing for Custom Made Mylar Bags

Why Opt for BrandMyDispo?

BrandMyDispo leads the charge in the printing realm by providing top notch custom Mylar bags utilizing cutting edge printing technology. Here's why you should choose BrandMyDispo for your packaging requirements;

State of the Art Technology

BrandMyDispo utilizes printers that produce exceptional quality and intricate detailing. Whether you require designs or vibrant colors BrandMyDispos technology ensures your custom made Mylar bags stand out beautifully.

Expertise in Customization

Backed by a knowledge of printing capabilities BrandMyDispo offers unmatched customization possibilities. Whether its small scale runs or large orders they can manage any project, with accuracy and innovation.

Swift and Dependable Service

Recognizing the value of time BrandMyDispo prioritizes turnaround times to meet your needs. Their efficient methods of production ensure that your personalized Mylar bags are delivered punctually every time.

Environmentally Friendly Solutions

Committed, to sustainability BrandMyDispos digital printing processes are crafted to minimize wastage and lessen the impact on the environment. By opting for BrandMyDispo you not receive top notch mylar packaging. Also contribute to a more eco conscious world.

In Summary

Digital mylar bag printing is transforming the realm of custom Mylar bags granting brands a tool to craft appealing, high quality packaging, with unparalleled adaptability and speed. Whether you're a burgeoning startup aiming to make an impact or an established brand striving to stay competitive digital printing offers the solution.

BrandMyDispo leads the charge in this printing evolution by providing customization methods and premium service to showcase your brand. Delve into the potential of printing with BrandMyDispo. Elevate your packaging game.

0 notes

Text

Pelican Rotoflex's 'Make in India' innovations at drupa 2024

Rajkot-based Pelican Rotoflex highlighted the ‘Make in India’ theme at drupa 2024, showcasing its Solomark 6450 ELS rotogravure press technology and the Acrostar turret slitter at the printing expo held in Düsseldorf from 28 May to 7 June.

“We did not run the full press but displayed a demo unit that showcased all the features of the Solomark 6450. We highlighted various features of the machine, including the semi-floatation dryer and the highly efficient ventilation module. The efficiency of this press is fantastic. There is a servo control damper for recycling air, which reduces energy consumption,” said Yash Shrimanker of Pelican Rotoflex.

The Solomark 6450 rotogravure printing press has been designed for a wide range of print substrates, including new eco-friendly substrates. It features easy operation, quick changeover with multiple trolley options, and aims to reduce wastage. “As margins are shrinking and the industry is becoming competitive, customers are ready to invest in quality machinery that can help them reduce costs. At Pelican, we provide the best solutions to help reduce wastage, ink consumption, and save power. And the best part is, our presses are made in India,” Shrimanker added.

Talking about drupa, Shrimanker said the show was great and they received some genuine inquiries during the expo. “We had many overseas visitors who were impressed not only by our Solomark 6450 but also the our converting equipment. Our displays and presentation evoked extremely positive response and appreciation from our visitors,” he stated.

Shrimanker also commented on the potential of the Indian packaging market, stating, “To be honest, the Indian market is where the big growth is. We expect the Indian packaging market to be robust for many years to come. A lot of global companies and investors are looking to invest in India. The biggest thing is, the name of 'Made in India' products is now getting due recognition globally.”

Pelican’s new state-of-the-art manufacturing plant, set up on a sprawling estate of 24 acres in 2020, is located about 25 kilometers from the city of Rajkot in Gujarat.

0 notes

Text

What Machine is Used to Make Custom Mylar Bags?

Custom Mylar bags are the superheroes of the packaging universe, boasting durability, flexibility, and top-notch protection. If you're gearing up to create these custom bags, understanding the machinery involved is your first step.

The big three in the Mylar printing world are digital printers, flexographic printers, and rotogravure printers. Each has its own superpowers, tailored to different needs and scales of production. Let's dive into the specifics and see which machine suits your custom Mylar bag dreams.

Digital Printers: The Masters of Flexibility and Precision

Overview

Digital printers are the modern marvels of the printing world, using digital files to print directly onto Mylar film. Known for their flexibility and ability to produce high-quality prints, digital printers are perfect for small to medium runs and custom designs.

How Digital Printing Works

Digital mylar bag printing involves sending a digital file (like a PDF or TIFF) to the printer. The printer processes this file and prints the image directly onto the Mylar film using inks like solvent-based, UV-curable, or water-based inks.

Benefits

Flexibility: Digital printers are like chameleons, allowing for quick design changes and personalization. Ideal for businesses needing to keep designs fresh or offer bespoke packaging.

High Quality: Expect vibrant colors and sharp details that make your designs pop. Digital printing ensures your Mylar bags look professional and eye-catching.

No Plate Costs: Digital printing skips the plate-making process, cutting down on setup costs and time.

Fast Turnaround: These printers can swiftly process and print designs, making them ideal for meeting tight deadlines.

Ideal For

Small to medium-sized orders

Custom and limited edition packaging

Businesses needing rapid design changes

Considerations

Cost: Digital printing is cost-effective for short runs but can get pricey for high-volume production.

Durability: The durability of digital prints can vary, so ensure the inks are suitable for Mylar’s non-porous surface.

Digital Printing Process

Design Preparation: Create a high-resolution digital design file.

Printer Setup: Send the digital file to the printer.

Printing: The printer applies the design directly onto the Mylar film.

Curing: Depending on the ink, the printed film may need to be cured to set the ink.

Inspection: Check for any printing defects and ensure quality.

Flexographic Printers: The Speed Demons

Overview

Flexographic printing, or flexo, is the go-to for high-speed, high-volume printing. Using flexible relief plates to transfer ink onto Mylar film, flexo is ideal for large production runs due to its speed and cost-efficiency.

How Flexographic Printing Works

Flexographic printing involves creating a flexible plate with a raised image of the design. This plate is wrapped around a cylinder on the printing press. As the Mylar film passes through the press, the plate is inked, transferring the image onto the film.

Benefits

Cost-Effective for Large Runs: Flexo becomes more economical as production volumes increase, making it ideal for bulk orders.

High Speed: Flexo presses can churn out prints at high speeds, ensuring quick turnaround times and high output.

Versatility: Flexo can handle various substrates, including Mylar, making it a versatile option for different packaging needs.

Ideal For

Large-scale production

Food, pharmaceutical, and cosmetic packaging

Businesses aiming to minimize per-unit costs

Considerations

Initial Setup Costs: Creating the flexible plates can be a significant upfront expense, less ideal for short runs.

Print Quality: Flexo offers good quality, but it doesn’t match the fine detail and sharpness of digital or rotogravure printing.

Flexographic Printing Process

Design Creation: Develop a high-quality design and transfer it to flexible plates.

Plate Creation: Create the flexible plates with the design image.

Mounting: Mount the plates on the printing press cylinders.

Inking: Apply ink to the plates and transfer the image onto the Mylar film.

Drying: Dry the printed film to ensure the ink sets properly.

Inspection: Conduct quality checks to ensure the print meets standards.

Rotogravure Printers: The Titans of Precision

Overview

Rotogravure printing, or gravure, is the elite athlete of the printing world, using engraved cylinders to transfer ink onto Mylar film. Known for its exceptional print quality and precision, gravure is the top choice for premium packaging.

How Rotogravure Printing Works

Rotogravure printing involves engraving the design onto a cylinder. The cylinder is then inked, and the excess ink is wiped off, leaving ink only in the engraved areas. As the Mylar film passes through the press, the ink is transferred from the engraved cylinder to the film.

Benefits

High Quality: Rotogravure delivers unmatched detail and color consistency, ensuring your designs are vibrant and precise.

Durability: The ink adheres strongly to the Mylar film, providing long-lasting prints that can withstand handling and environmental factors.

Efficiency: Ideal for large production runs, gravure is cost-effective when producing high volumes.

Ideal For

Premium product packaging

Large-scale, high-volume production

Businesses requiring detailed and high-quality prints

Considerations

Initial Costs: Engraving the cylinders is costly, making rotogravure less suitable for small or short-run projects.

Lead Time: Preparing the cylinders can take time, extending the overall production schedule.

Rotogravure Printing Process

Design Creation: Develop a detailed, high-resolution design.

Cylinder Engraving: Transfer the design onto the cylinders.

Inking: Apply ink to the engraved cylinders and wipe off excess ink.

Printing: Transfer the ink from the cylinders to the Mylar film as it passes through the press.

Drying: Dry the printed film to ensure the ink adheres properly.

Inspection: Perform quality checks to ensure the print meets the desired standards.

Choosing the Right Machine for Your Needs

Selecting the right machine for your custom Mylar bag production depends on several factors, including production volume, budget, design complexity, and turnaround time. Here’s a quick guide to help you decide:

Digital Printers

Choose Digital If:

You need flexibility and quick design changes.

You’re producing small to medium-sized orders.

High-quality, detailed prints are a priority.

You want to avoid the costs associated with plates.

Flexographic Printers

Choose Flexographic If:

You’re handling large-scale production.

Speed and cost-effectiveness are crucial.

You need a versatile printing solution for various substrates.

Your design doesn’t require extremely fine details.

Rotogravure Printers

Choose Rotogravure If:

You need premium-quality, detailed prints.

You’re producing large volumes.

Durability and long-lasting prints are important.

You’re ready to invest in higher initial setup costs for superior quality.

Conclusion

Creating custom Mylar bags involves choosing the right printing method to match your needs and goals. Digital printers offer flexibility and high quality for smaller runs, flexographic printers provide speed and cost-effectiveness for large volumes, and rotogravure printers deliver exceptional precision and durability for premium packaging.

By understanding the capabilities and nuances of each type of printer, you can make an informed decision that ensures your Mylar bags stand out and meet your business needs. Whether you're looking to produce small batches with intricate designs or large-scale runs with consistent quality, there's a printing solution tailored for you.

Dive into the world of custom Mylar bag production and discover the best machine to bring your packaging vision to life.

Learn more at Brandmydispo.com.

1 note

·

View note

Text

Ceramic Anilox Sleeves

Anilox Rollers can be constructed in Steel, Aluminium, or Stainless steel with a lightweight tube building for simple dealing with. Our specially formulated and tested sealing technique is utilized for the Ceramic coating. Following years of testing different strategies and merchandise, we developed this distinctive course. This will ensure opposition to any probability of long-term corrosion issues and in addition, assist the engraving course by permitting an easy efficient burn/engraving process to make sure we obtain high consistency in the course of the laser engraving process. We offer excessive dot definition without sacrificing color intensity - cylinder rotogravure.

Good prepress requires an anilox capable of transmitting all screen dots accurately, without spitting, and with minimum dot achievement. In addition to the above, TAD engraving maintains an actual ink supply thanks to the geometry of the cell, making certain that the density doesn't fall beneath the outlined standard. Our innovative merchandise, technical experience, and skilled technical assistance lead the market. A statement justified by the enviable industry accolades and long-standing, loyal buyer base - gravure printing cylinder.

The target for all Flexo printers is to make certain that the anilox gives the correct print density from print number 1 and stays consistent and clear throughout the whole print run. This relies on receiving good recommendations about which anilox specification is right for his or her utility and then receiving an anilox that conforms to the target and has a cell profile with a glorious ink switch. The firm uses interferometry to measure its anilox volumes and to examine that the rollers are made uniformly. Every anilox engraved is set up within the laser using 3D high quality control measurement verification prior to engraving and checked across the anilox surface after engraving.

The safety sleeve also supplies a label, which indicates the color, volume, and display ruling of the anilox, providing a simplified identification process. Anilox rollers are produced from either steel or aluminum and have a ceramic covering and their surface is made up of cells. A tougher surface turns into extra brittle which can lead to injury and a softer coating can cause premature wear. If the ultrasonic system isn't specifically designed and confirmed for this application then injury could happen. For more information, please visit our site https://packadvance.com/

0 notes

Text

Polymer/Plastic Doctor Blade

🔍✨ Introducing Our Polymer/Plastic Doctor Blade! ✨🔍

Are you working in flexographic, rotogravure printing, or solventless machine operations? Our innovative product the Polymer/Plastic Doctor Blade designed to elevate your printing experience to new heights! 🌟

🖨️ Precision Performance: Our doctor blade is meticulously engineered for optimal ink metering and precise ink transfer, ensuring crisp, consistent prints every time.

🌈 Versatile Compatibility: Whether you're running flexographic, rotogravure, or solventless machines, our doctor blade is tailored to meet the unique demands of your printing process.

💪 Durable Design: Crafted from high-quality polymer/plastic materials, our doctor blade offers superior durability and wear resistance, reducing the need for frequent replacements and maintenance.

🚀 Enhanced Efficiency: Experience smoother printing operations with reduced downtime, thanks to the reliable performance and longevity of our doctor blade.

🌎 Environmentally Friendly: Engineered with sustainability in mind, our doctor blade is eco-friendly and contributes to waste reduction in the printing industry.

🤝 Trusted Partner: countless printing professionals who rely on our polymer/plastic doctor blade for exceptional results and unparalleled support.

Ready to take your printing quality to the next level? Get in touch with us today to learn more about our Polymer/Plastic Doctor Blade and upgrade your printing process! 🎨✨

Contact Us For More Details Call Us:- (+91) - 9911909910, (+91) -83476 46816 Mail Us:- [email protected]

#Flexographic#Rotogravure#SolventlessPrinting#Innovation#QualityPrinting#FlexographicPrinting#RotogravurePrinting#DoctorBlade#PolymerDoctorBlade#PlasticDoctorBlade#PrintingIndustry#PolymerBlade#PlasticBlade#SustainablePrinting

0 notes

Text

Impact of COVID-19 on the Rigid Packaging Market: Resilience and Adaptation

Rigid Packaging: Enhancing Product Protection and Consumer Appeal Raw Materials and Production Techniques Rigid packaging utilizes a variety of durable materials to securely contain products. Common materials include plastic, glass, metal, and wood. Plastics like polyethylene terephthalate (PET) and high-density polyethylene (HDPE) are popular due to their light weight and shatter resistance. Glass provides visibility and barrier protection but is heavier. Metal cans made of aluminum or tinplate resist denting while maintaining recyclability. Composite materials like fiberboard combine fibers like paper, paperboard, and plastic to achieve rigidity at lower costs than solid materials. Raw materials undergo fabrication processes to form rigid containers. Plastics are blow molded, injection molded, or thermoformed. Glass undergoes forming with heat before filling and sealing. Cans are produced through three-piece drawn and wall ironed or two-piece drawn, wall ironed, and sealed methods. Composite materials require lamination of layers with adhesive plus die cutting and scoring. Automated lines coordinate shaping, decorating, filling, sealing, and packaging at high speeds. Protection from Damage and Contamination Rigid packaging superbly protects products from damage caused by external forces. Plastic, glass, metal, and composite materials withstand crushing pressures and prevent breakage that could compromise contents. Rigid containers also provide tamper evidence through unbroken seals or labels. Once sealed, consumers can trust contents were not accessed until opening. Their impermeability to gases and liquids renders rigid packages ideal for preventing contamination and preserving freshness. Plastic, glass, and metal containers create absolute barriers blocking entry of air, moisture, light, and microbes that could degrade products. Composite boards further laminate layers for multi-directional strength blocking infiltration. Certain rigid containers like canned goods even allow hot filling and retort sterilization for long shelf-stable preservation without refrigeration. Graphic customization Rigid packaging facilitates protection yet also attracts attention on shelves. Vibrant graphics, photorealistic images and infographics adorn surfaces to highlight key selling points and information about contained products. Advanced printing techniques like rotogravure, flexography and digital bring designs to life in high resolution and colors. Metallic inks, foils, and dimensional effects add richness. Containers even undergo decorative processes like label wrapping and end printing. Sustainability considerations As a long-lasting package format, rigid containers prompt consideration of sustainable practices across their lifecycles. Lightweighting initiatives reduce materials while maintaining strength. Post-consumer recycled content increases in resins and boards. Mono-material structures like all-plastic or all-aluminum facilitate recycling. Reusable versions enable multiple refill cycles before disposal. Collection infrastructure improves recycling rates for rigid plastic, metal, and glass. New recycling technologies also extract value from "mixed rigid" streams. Compostable and biodegradable materials debut for select applications. Brands participate in sustainable packaging coalitions and adopt circular economy principles including design for reuse/refill. Rigid packaging manufacturers collaborate across supply chains on initiatives like carbon footprint reduction. Consumer appeal and trust Rigid containers achieve consumer appeal through protective functionality that builds quality perceptions. Contents remain cleanly enclosed and unbroken seals signal safety. Visual customization attracts eyes on shelves while communication graphics aid decisions. Stackability and sturdiness withstand distribution without destruction. Reclosability preserves freshness of partially used products.

0 notes

Text

Packaging Printing Market - Forecast(2024 - 2030)

View More @ https://bit.ly/42QrUDI

Packaging printing can be defined as the process of labelling packages in the form of written, electronic or graphical representations, meant to create brand awareness. The packaging printing industry makes use of different technologies, be it digital printing, flexography, rotogravure and so on along with inks in order to meet various end use customer demands.

0 notes

Text

Solvent Base Inks

Solvent-based inks are manufactured by several reputable companies in India, offering a wide range of products tailored to various printing needs. These inks are specifically formulated to dissolve in solvents and are commonly used in printing applications where fast drying and durability are essential.In India, manufacturers of solvent-based inks adhere to stringent quality standards to ensure optimal performance and reliability. These companies employ advanced technology and expertise to produce inks that deliver vibrant colors, excellent adhesion, and resistance to fading and abrasion.

0 notes

Text

SWASTIK PLASTIC

product polythene printing

The majority of polythene products are available with full color printing, adding the finishing touch to packages and making your brand instantly recognizable.

We offer a broad variety of printing techniques and designs, such as:

Branding: We are able to fully brand polythene items.

Mark and Identifying Information

For internal sorting and packing of a wide range of products, we can print clear labels on polythene products, which enables personnel to rapidly write product details on packages.

Usage Guidelines for the Product

Polythene packaging can be an excellent way to emphasize that your products need assembly, fitting, or additional instructions.

Safety Alert

Additionally, polythene packaging is ideal for highlighting any possible dangers or risks associated with the product, providing your clientsProduct Types

Applications for printed polythene materials are numerous and include:

Personalized Carrier Bags

Printed polythene carrier bags are perfect for the retail industry since they make it simple to promote your brand both in-store and at trade exhibitions and events.

Layflat tubing that is printed

Printed polythene layflat tubing is perfect for packaging long goods, creating custom-sized bags or packages, and enhancing the security of your products during shipment.

Polythene bags with printing

Polythene bags with printing work well for shipment and regular packaging at your warehouse. Perfect for applications in retail and industry, where you can brand things before they are sold or quickly and simply identify them.

Printed PP Sacks with Weave

When it comes to loose items, printed woven PP sacks are the ideal option because they guarantee that clients can easily recognize the products. Nuts, soils, and other loose or perishable commodities are especially well-suited applications for printed woven polypropylene (PP) sacks.

Product polythene printing is important

When it comes to branding and marketing, high-quality printing is crucial. Businesses can draw in clients, build brand awareness, and project a dependable and strong image by creating polished and eye-catching products. The advantages of superior printing for a company's branding and marketing initiatives will be discussed in this section.

The impact of high-quality printing on brand image: A company's brand image is positively impacted by high-quality printing, which is one of the biggest advantages. Customers' perceptions of a firm and its goods or services make up its brand image.

Technology used

We have used rotogravure printing in an industry.

Rotogravure printing:Rotogravure printing is frequently used to print on packaging materials as bread wrappers, polythene packs,milk pouches, soap wraps, and other pliable packaging materials. Because more and more of these packaging products are being used, rotogravure printing is becoming more and more important.

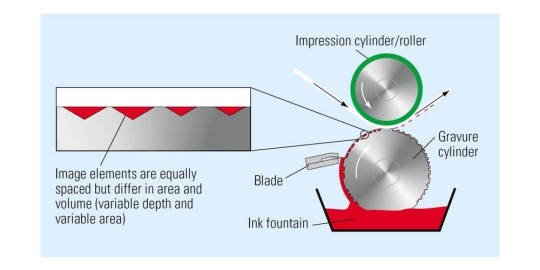

Components of a rotogravure

The engraved cylinder:This is one of the key components of the gravure planting machine, sometimes referred to as the gravure cylinder. The image you wish to print is typically engraved on the cylinder. The cylinder surface will be bent into cells through etching. The various diameters of the cells need to be carefully specified. The ink will be transported to the cell in order to be transferred to the substrate. In this instance, the substrate is paper. Large, deep cells are a fantastic choice for colors that are darker and more intense, and vice versa. Steel or plated copper are the usual materials used to make these cylinders. Moreover, ceramic gravure cylinders are in demand.

Rotogravure Ink:The ink fountain is the component where the ink is stored. It is then transferred to the cylinder carefully and precisely.

Doctor blade assembly:The doctor blade's job is to take away extra ink from the areas that aren't etched. An assembly of doctor blades is also present on the engraved cylinder because it has multiple cells on it. Before the ink is applied to a printing plate, the blades can also produce a homogeneous layer of ink. Keep in mind that standard doctor blades used in flexographic and other printing processes are usually not very expensive.

An impression roller:It is the imprint roller's responsibility to exert pressure such that the entire substrate makes contact with the cylinder. The substrate is sandwiched between the impression roller and the gravure cylinder. Therefore, the impression roller aids in ensuring maximal and uniform coverage.

1 note

·

View note

Text

Graphic Film Market Size, Growth, Analysis, Trends and Opportunity 2024-2032

IMARC Group's report titled "Graphic Film Market Report by Polymer (Polyvinylchloride (PVC), Polypropylene (PP), Polyethylene (PE), and Others), Film Type (Reflective, Opaque, Transparent, Translucent), Printing Technology (Rotogravure, Flexography, Offset, Digital), End Use (Promotional and Advertisement, Automotive, and Others), and Region 2024-2032",The global graphic film market size reached US$ 29.0 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 41.1 Billion by 2032, exhibiting a growth rate (CAGR) of 3.8% during 2024-2032.

For an in-depth analysis, you can refer sample copy of the report:https://www.imarcgroup.com/graphic-film-market/requestsample

Factors Affecting the Growth of the Graphic Film Industry:

Growing Digital Advertising:

The increasing improvement in digital advertising is impelling the growth of the market. With the rise in internet usage and the shift of marketing efforts towards online platforms, businesses are increasingly relying on captivating visuals to engage their target audiences. Graphic films are instrumental in this endeavor as they enable the creation of visually appealing content that can be displayed across websites, social media, and digital signage. Graphic films offer flexibility in design and can be tailored to suit various digital advertising needs.

Rising Popularity of Vehicle Wraps:

The rising popularity of vehicle wraps as an innovative advertising medium is propelling the market growth. Businesses are increasingly recognizing the effectiveness of transforming their vehicles into mobile billboards. Graphic films play a pivotal role in this trend, as they are specifically designed to adhere to various surfaces, including vehicles. These films not only serve as a protective layer for the paint of the vehicle but also allow for vibrant and intricate graphics that can withstand exposure to the elements. The appeal of vehicle wraps lies in their ability to reach a diverse audience while vehicles are on the move, making them highly visible in both urban and suburban settings.

Advancements in Printing Technology:

Advancements in printing technology are supporting the market growth. Innovations, such as wide-format digital printing and eco-solvent inks, are revolutionizing the way graphic films are produced and utilized. Wide-format digital printing allows for the creation of large-scale graphics with exceptional precision and detail. This technology enables businesses to produce visually stunning displays, murals, and signage that can captivate audiences in various settings, from retail environments to trade shows. Eco-solvent inks are also having a transformative impact by providing a more environment friendly and durable printing solution. These inks are designed to adhere well to graphic films while minimizing harmful volatile organic compounds (VOCs).

Leading Companies Operating in the Global Graphic Film Industry:

3M Company,

Achilles Corporation

Arlon Graphics LLC (FLEXcon Company Inc.)

Avery Dennison Corporation, CCL Industries Inc.

Constantia Flexibles Group

Drytac Corporation

DUNMORE Corporation (API Group)

DuPont de Nemours Inc.

FDC Graphic Films Inc.

Hexis S.A.

Kay Premium Marking Films Ltd.

Graphic Film Market Report Segmentation:

By Polymer:

Polyvinylchloride (PVC)

Polypropylene (PP)

Polyethylene (PE)

Others

Polyvinylchloride (PVC) represents the largest segment due to its versatility.

By Film Type:

Reflective

Opaque

Transparent

Translucent

Opaque exhibits a clear dominance in the market as it can be customized with logos, branding, or decorative patterns.

By Printing Technology:

Rotogravure

Flexography

Offset

Digital

Flexography accounts for the majority of the market share. They are suitable for various applications, such as labels, packaging, newspapers, and more.

By End Use:

Promotional and Advertisement

Automotive

Others

Promotional and advertisement holds the biggest market share driven by the rising adoption of effective advertising strategies.

Regional Insights:

North America (United States, Canada)

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Asia Pacific's dominance in the graphic film market is attributed to investment in research and development (R&D), leading to advanced technological developments in this field.

Global Graphic Film Market Trends:

The increasing demand for signage and wayfinding solutions is strengthening the market growth. In various sectors, such as healthcare, hospitality, transportation, and retail, there is a growing need for clear and visually appealing signage to guide visitors, customers, and patients. Graphic films are an ideal choice for creating vibrant and durable signage, contributing to their rising popularity. People and businesses alike are seeking more personalized experiences. Graphic films enable customization and personalization on a wide range of surfaces, from smartphone covers to interior decor. This trend is leading to higher demand for graphic films that can be easily tailored to meet individual preferences and branding requirements.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARCs information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the companys expertise.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

Uflex Engineering introduces Automatic Inks Change Trolley system at PlastIndia 2023

Mr.Ajay Tandon, President, Engineering business and new product development, UFlex Limited said, “Plastindia is one of the largest platforms to display raw material, converting machines, processing machines, and other products and solutions catering to the packaging and printing industries. Here we are promoting our rotogravure machine with quick auto change over trolley and displaying a solventless laminator with improved tension control systems at the stand. The displayed laminator has a speed of 400 to 450 mtr/min. We also have a different range of slitters, like the new Ecoslit- 600, which can accurately perform at 600 mtrs/mins, giving value for money and better ROI to customers.”

Recently, we have introduced the automatic ink trolley change system. It is the first-of- its-kind innovation in the world, where the trolley change-over happens with the press of a button. Usually, in a gravure press, it takes almost 45 minutes to do a change-over of the job, and it is the most tedious process to change the cylinders, ink, doctor blade, etc.one by one and at every station.

Read more

0 notes