#Roll Stretch Wrapping Machine Manufacturer

Explore tagged Tumblr posts

Text

Why Stretch Wrap is Essential for Safe and Secure Shipping in the UK

Shipping products in the UK has always come with its fair share of challenges—from safeguarding goods during transport, to reducing the risk of damage, to maintaining cost efficiency. However, one standout solution that has revolutionized packaging across industries is stretch wrap. Widely recognized for its versatility and effectiveness, stretch wrap plays a vital role in ensuring safe and secure shipping.

Whether you're in logistics, manufacturing, or retail, stretch wrap provides an indispensable way to protect your items and optimize your shipping process. In this blog, we’ll explore what makes stretch wrap essential, its benefits, and why more businesses in the UK are choosing premium solutions like Tilak Polypack stretch films.

What is Stretch Wrap?

Stretch wrap, also referred to as stretch film or stretch wrap roll, is a highly stretchable plastic film made from polyethylene. Its elastic properties allow the material to tightly and securely wrap items or pallet loads without the need for adhesives or heat. It ensures tight containment, reduces risk of shifting during transport, and protects goods from external elements.

Stretch films are available as hand rolls for manual application and machine rolls for automated operations, making them highly versatile for various packaging needs. Advanced versions now also come with additional features like UV resistance or pre-stretching for added convenience and cost savings.

Popular Use Cases for Stretch Wrap:

Logistics and Warehousing: Streamlining palletized shipping and reducing the risk of goods tipping over.

E-commerce and Retail: Efficiently bundling packages together and securing items for delivery.

Food and Beverage Industries: Safeguarding products against dust, moisture, and contamination.

Manufacturing: Containing irregularly shaped items or bundling loose components.

Why Stretch Wrap is Essential for Shipping in the UK

1. Protection from Damage and Moisture

Shipping involves handling, vibrations, and exposure to external factors like rain or humidity. Stretch wraps act as a durable shield, preventing scratches, dents, dust, and moisture from damaging your goods. For sensitive or fragile products, such as electronics or fabrics, this level of protection is critical.

2. Secure Load Stability

Stretch wrap increases the stability of pallet loads, reducing the risk of shifting or toppling during transport. This makes it a reliable choice for the UK’s busy distribution networks, where goods are constantly loaded and unloaded at warehouses, ports, and delivery hubs.

3. Cost-Effective Packaging Solution

Stretch film is not only affordable but also reduces the need for additional packing materials such as strapping or adhesives. Its high conformability ensures that every inch of material is effectively used, minimizing waste while delivering superior results.

4. Ease of Usage for Businesses of All Sizes

From small retailers to large-scale logistics operations, stretch wrap offers scalability. Hand rolls cater to small packaging needs, while machine stretch wraps are perfect for bulk operations. Combined with its lightweight and recyclable nature, stretch wrap becomes a practical addition to any packaging workflow.

5. Sustainability and Eco Friendliness

Many businesses are now adopting more sustainable practices, and using recyclable stretch wraps is a great way to reduce environmental impact. Choosing eco-friendly options from a provider like Tilak Polypack not only ensures high quality but also supports your business’s green initiatives.

Benefits of Stretch Wrap Rolls

Here are some solid reasons why stretch wrap rolls are the go-to packaging choice for UK businesses:

Secure Packaging: Keeps items tightly bound, preventing them from slipping or shifting.

Damage Prevention: Minimizes the risk of scratches, breaks, or exposure to external elements.

Load Stability: Provides excellent grip for stacked pallets, preventing toppling during transport.

Versatility: Ideal for pallets, irregularly shaped loads, or bundling small items.

Transparency: Easy product identification during inventory checks.

Efficiency: Streamlines packaging and unpacking processes, saving time.

Eco-Friendly: Recyclable materials are available, contributing to sustainability goals.

Customizable Options: Different thicknesses, lengths, and features are available to meet unique needs.

Why Choose Tilak Polypack for Your Stretch Film Needs?

When it comes to premium stretch wraps, Tilak Polypack stands out as a trusted manufacturer and supplier. What makes them the ideal choice for UK businesses? Here’s why:

Top-Quality Products

Tilak Polypack offers durable, high-performance stretch film that meet stringent manufacturing and quality standards. You can trust their products to keep your shipments protected at all times.

Eco-Friendly Solutions

Committed to sustainability, Tilak Polypack provides recyclable and eco-conscious wraps that minimize environmental impact—a win for your business and the planet.

Customizable Packaging Options

With a variety of film thicknesses, lengths, and widths available, Tilak Polypack ensures you receive the perfect solution tailored to your needs.

Global Reach and Trusted Expertise

With over 20+ years of experience and a strong presence in global markets like the US, UK, Australia, and Singapore, Tilak Polypack is a reliable partner for businesses worldwide.

Excellent Customer Support

From choosing the right type of stretch film to resolving queries, their attentive team ensures a seamless experience for all their customers.

2 notes

·

View notes

Text

Traditional or Coreless Stretch Film? Making the Best Choice for Your Business

In the fast-paced world of logistics, manufacturing, and retail, choosing the right packaging materials can make a significant difference in efficiency and cost-effectiveness. One such critical decision involves selecting between traditional stretch film and coreless stretch film. Both options have their pros and cons, and understanding these can help you make an informed choice that benefits your business.

Introduction to Stretch Film

Stretch film is a versatile plastic film used to secure, bundle, and stabilize products. It is commonly used in various industries, including logistics, warehousing, retail, agriculture, automotive, and construction. The film’s ability to stretch and cling to itself makes it an ideal solution for securing pallet loads and protecting goods during transport and storage.

The Basics of Traditional Stretch Film

Traditional stretch film has been the go-to choice for many industries for years. It typically comes with a cardboard or plastic core around which the film is wrapped. This core provides structure and stability, making it easy to handle and apply using manual or automatic stretch wrap machines.

Benefits of Traditional Stretch Film

Traditional stretch film is known for its durability and strength, which ensures that pallet loads are securely wrapped and protected. The core adds stability, making it easier to use with various wrapping equipment. Additionally, traditional stretch film is widely available and comes in numerous thicknesses and strengths to suit different applications.

Disadvantages of Traditional Stretch Film

One of the main drawbacks of traditional stretch film is the environmental impact. The cardboard or plastic cores generate waste, which adds to disposal costs and environmental concerns. Furthermore, the cores can be cumbersome to handle and dispose of, particularly in high-volume operations.

What is Coreless Stretch Film?

Coreless stretch film, as the name suggests, eliminates the need for a core. This innovative solution wraps the stretch film around itself, creating a more eco-friendly and cost-effective option. Coreless stretch film is designed to be used with specialized dispensers or hand rolls, ensuring ease of application and reducing waste.

Advantages of Coreless Stretch Film

Coreless stretch film offers several benefits, including reduced environmental impact, as there are no cores to dispose of. This not only saves on disposal costs but also promotes sustainability within your business. Additionally, coreless stretch film is lighter, making it easier to handle and reducing shipping costs. The absence of a core also means more film per roll, increasing efficiency and reducing the frequency of roll changes.

Potential Drawbacks of Coreless Stretch Film

While coreless stretch film has many advantages, it may not be suitable for all applications. Some users may find it challenging to adapt to the new dispensing methods required for coreless film. Additionally, the initial cost of specialized dispensers or equipment may be higher than traditional stretch film solutions. However, these costs can be offset by the long-term savings and environmental benefits.

Comparing Strength and Durability

When comparing traditional and coreless stretch film, it’s essential to consider strength and durability. Both options offer robust and reliable performance, but coreless stretch film is designed to provide comparable strength while being more environmentally friendly. Ensuring that your chosen film meets the demands of your specific application is crucial for maintaining product integrity and safety.

Application and Use Cases

Both traditional and coreless stretch film can be used in various industries, but certain applications may benefit more from one option over the other. For example, coreless stretch film is an excellent choice for businesses looking to reduce waste and promote sustainability, while traditional stretch film may be better suited for applications requiring heavy-duty wrapping and stability.

Logistics and Warehousing

In logistics and warehousing, the choice between traditional and coreless stretch film can significantly impact efficiency and cost savings. Coreless stretch film reduces waste and disposal costs, making it an attractive option for high-volume operations. However, traditional stretch film may be preferred for heavy loads or applications requiring additional stability.

Retail and Distribution

For retailers and distributors, both traditional and coreless stretch film can provide effective packaging solutions. Coreless stretch film offers a more eco-friendly option, aligning with growing consumer demand for sustainable practices. Traditional stretch film, on the other hand, may be favored for its ease of use and compatibility with existing wrapping equipment.

Agriculture Sector

In the agriculture sector, stretch film is commonly used to bundle and protect crops during transport and storage. Coreless stretch film’s reduced environmental impact makes it an appealing choice for farmers and agricultural businesses. However, traditional stretch film’s durability and strength may be necessary for securing heavy or bulky loads.

Automotive Industry

The automotive industry often requires high-strength packaging materials to secure parts and components during transport. Traditional stretch film’s robust performance makes it a reliable choice for these applications. However, coreless stretch film can still provide adequate protection while offering environmental benefits.

Construction Industry

Construction businesses can benefit from both traditional and coreless stretch film for securing materials and equipment. Coreless stretch film’s lighter weight and reduced waste make it an attractive option for construction sites. Traditional stretch film, with its proven durability, remains a dependable choice for heavy-duty applications.

Environmental Impact

One of the most significant considerations when choosing between traditional and coreless stretch film is the environmental impact. Coreless stretch film’s elimination of cores reduces waste and promotes sustainability, making it a more eco-friendly option. Businesses looking to enhance their green credentials and reduce their environmental footprint may find coreless stretch film to be the better choice.

Cost Considerations

Cost is always a critical factor in business decisions. While traditional stretch film may have a lower upfront cost, the long-term savings offered by coreless stretch film can make it a more cost-effective option over time. Reduced disposal costs, increased efficiency, and fewer roll changes contribute to the overall cost savings associated with coreless stretch film.

Ease of Use and Handling

Both traditional and coreless stretch film are designed for ease of use, but there are differences in handling and application. Traditional stretch film’s core provides stability and makes it compatible with various wrapping equipment. Coreless stretch film, while lighter and easier to handle, may require specialized dispensers or equipment for optimal performance.

2 notes

·

View notes

Text

Discover the Versatility of Stretch Film Rolls for Pallets, Boxes, and Bundles

When it comes to simplifying packaging and securing goods during transit or storage, stretch film rolls have become an indispensable tool in industries like logistics, warehousing, and manufacturing. Whether you are a warehouse operator, a packaging specialist, or a logistics manager, understanding the benefits and diverse applications of stretch films can significantly enhance your operations.

This article will deep-dive into the versatility of stretch film rolls, explore their benefits, and highlight how a trusted plastic film manufacturer like Tilak Polypack can provide custom solutions tailored to your business needs.

What are Stretch Film Rolls?

Stretch film rolls, often referred to as stretch wrap or stretch wrap rolls, are highly elastic plastic films made from polyethylene. Designed to be stretched tightly around products, these films hold items together securely without additional adhesives or heat applications.

Available in hand rolls for manual use or machine rolls for automated packaging processes, stretch films are versatile solutions compatible with various industries. Specialized options, such as pre-stretched films or UV-resistant films, add an extra layer of functionality and cost efficiency.

Their purpose? To ensure products stay protected and intact throughout transportation and storage, offering peace of mind to businesses.

Benefits of Stretch Film Rolls

Whether you’re bundling boxes or stabilizing large pallet loads, stretch films offer a multitude of benefits for packaging operations, making them a smart choice for businesses aiming for both efficiency and cost-effectiveness.

1. Secure Packaging and Load Stability

Stretch films keep your products firmly in place, preventing movement or toppling during transport. This ensures goods arrive at their destination in pristine condition.

2. Protection Against External Elements

These films act as a barrier against dust, dirt, moisture, and scratches, preserving the quality and cleanliness of your packaged items.

3. Cost-Effective Solution

By reducing the need for additional materials like straps or cords, stretch films streamline packaging needs and lower costs.

4. Versatility in Applications

From pallets and boxes to irregularly shaped items, stretch films can handle packaging requirements of all shapes and sizes.

5. Tamper Resistance

The tight wrap of stretch films offers tamper resistance, deterring pilferage and ensuring goods remain secure throughout the supply chain.

6. Transparent for Easy Inspection

Transparent stretch films allow quick visual identification of packaged items, making inventory and shipment inspections more efficient.

7. Eco-Friendly Options

Recyclable stretch films stand out as a sustainable option, reducing packaging waste and supporting eco-conscious business practices.

8. Enhanced Handling Convenience

Stretch films improve compactness, simplify handling, and optimize storage, making warehouse operations more efficient.

Applications of Stretch Film Rolls

Stretch film rolls find extensive applications across industries. Here are a few scenarios where they shine brightest:

Unitizing Pallets: High elasticity ensures pallets stay bundled tightly, even during rough transport conditions.

Bundling Packages: Use stretch films for binding smaller boxes, files, or items that need to stay together during transit.

Protecting Odd-Shaped Items: Wrap bulky or irregularly shaped goods without compromising their stability or safety.

With their ability to cater to diverse packaging needs, stretch films have become essential in logistics, manufacturing, and retail industries.

Why Choose Tilak Polypack as Your Plastic Film Manufacturer?

Tilak Polypack is one of the leading plastic film manufacturer globally, recognized for its high-quality stretch films, innovative solutions, and customer-centric approach. With over 20 years of industry expertise, Tilak Polypack specializes in providing eco-friendly and customizable packaging solutions to meet your unique business needs.

Highlights of Tilak Polypack Stretch Films

Top Quality Products: Every film meets the highest manufacturing and quality standards.

Eco-Friendly Options: Commitment to sustainability with recyclable and greener stretch films.

Customizable Solutions: Film thickness, width, and length tailored to your specific requirements.

Global Reach: Presence in multiple countries, from the US and Canada to Germany and Singapore.

Reliable Partner: Trusted by businesses across industries for consistent quality and exceptional customer support.

Special Features of Stretch Films from Tilak Polypack

UV Resistance: Ideal for items stored or transported under sunlight exposure.

Pre-Stretched Films: Reduce effort during application while maintaining strong elasticity.

Durable Materials: Designed to withstand wear and tear for long-term reliability.

Choosing Tilak Polypack as your stretch film manufacturer ensures that your packaging needs are met with top-notch quality, sustainability, and efficiency.

How to Optimize Your Use of Stretch Film Rolls

Integrating stretch films into your operations is simple but incredibly rewarding. Here are some pro tips to get the most value out of your stretch films:

Use the Right Thickness: Thicker films are better for heavy-duty applications, while thinner films work well for smaller loads.

Pair with the Right Tools: Automatic or semi-automatic wrapping machines can amp up packaging efficiency and reduce labor costs.

Monitor Wrapping Patterns: Consistent application ensures better load stability and reduces film waste.

How Tilak Polypack Supports Your Packaging Goals

Tilak Polypack understands the challenges businesses face in optimizing logistics and packaging operations. With a comprehensive lineup of stretch films and tailored solutions, they help streamline your processes, reduce costs, and improve sustainability.

Fun fact: Did you know that Tilak Polypack stretch films are trusted by Fortune 500 companies in industries like retail and logistics? That’s because their robust solutions tick all the boxes—reliability, quality, and eco-friendliness.

Take Your Packaging Efficiency to the Next Level

Stretch film rolls are an integral part of modern-day packaging, delivering unmatched versatility, protection, and cost efficiency. From safeguarding products during transit to boosting warehouse productivity, their applications are vast and varied.

Partnering with a trusted plastic film manufacturer like Tilak Polypack ensures you get the best quality materials with the added benefits of customization, sustainability, and global expertise.

Looking to elevate your packaging game? Discover the perfect stretch film roll for your business with Tilak Polypack—your trusted packaging partner.

1 note

·

View note

Text

Flexibond: Your Trusted Stretch Film Manufacturer in Gujarat, India

Flexibond Industries manufactures stretch films in Gujarat, India. Quality and excellence define us as a brand of choice. We engineer films for article protection during transit and storage, and our products measure up to high standards in the industry.

Our Stretch Films: Unmatched Quality and Durability

Our stretch films are designed to be both effective in securing and preserving products. They come into use in several industries: packaging and manufacturing. Our films hold products stable and protected from risks of damage by falling during transportation and storage.

Flexibond is a prominent name in the stretch film manufacturing industry, headquartered in Gujarat, India. The company is known for its high-quality, durable, and customizable stretch film solutions tailored to the unique needs of various industries. With a commitment to excellence, Flexibond has become a reliable partner for businesses looking to secure their products during storage and transportation.

Comprehensive Product Range

Flexibond offers a wide array of stretch films, including hand stretch films, machine stretch films, and colored stretch films. These films provide superior load stability, ensuring products remain securely wrapped throughout the shipping process. Available in various sizes, thicknesses, and colors, the films can be customized to meet industry-specific requirements, making them a versatile choice for logistics, manufacturing, and warehousing sectors.

Focus on Quality and Innovation

Quality is at the heart of Flexibond’s manufacturing process. Each stretch film undergoes stringent quality checks to ensure durability, tear resistance, and exceptional cling. The company employs advanced production techniques and high-grade materials to produce films that maintain their integrity, even under challenging conditions. This level of reliability helps businesses minimize product damage, reduce waste, and optimize operational efficiency.

Cost-Effective and Eco-Friendly Solutions

Flexibond understands the importance of balancing cost and sustainability. Their stretch films are designed to be cost-effective, reducing material usage without compromising performance. Additionally, the company prioritizes sustainability by offering eco-friendly stretch film options that align with global efforts to reduce plastic waste. Businesses that choose Flexibond's products can enhance their corporate social responsibility (CSR) while also benefiting from reduced operational costs.

Why Choose Flexibond Industries?

Flexibond is a leading Stretch Film Manufacturer in India. The company is known for its durable, customizable, and cost-effective packaging solutions designed to meet the diverse needs of businesses across industries. Flexibond offers a wide range of stretch films, including hand stretch films, machine stretch films, and colored stretch films, catering to industries like manufacturing, logistics, and warehousing.

Quality Assurance: We implement very strict quality control at each processing stage. Any rolled stretch film is strictly tested to meet international quality standards. The quality-oriented approach makes our films strong, durable, and reliable.

Customization Options: Knowing that different businesses have different packaging requirements, we also offer customized stretch films. Customers would be allowed to specify the thickness, size, and other properties of the film in relation to the needs. This greatly enables us to cover a wide base of applications.

Sustainability Commitment: At Flexibond Industries, considerations towards the environment are taken into the design of stretch films for minimal wastage, using materials that will bring reduced environmental impact. This commitment to sustainability aids customers in reducing their carbon footprint while maintaining product protection.

Competitive Pricing: We offer top-grade stretch films at very competitive prices. This approach ensures that businesses of all sizes could avail reliable packaging solutions without compromising on quality. On price, we emerge to be very cost-effective in the market.

Our Product Range

Hand Stretch Film: These films are suitable for manual application. Easy to use, these films offer flexibility. They find applications in smaller-scale operations where wrapping is done by hand.

Machine Stretch Film: These films are designed for use with automated stretch wrapping machines and suited for high-volume applications. They offer constant performance and are critical to any business looking to package efficiently and reliably.

Colored Stretch Film: Our colored stretch films bring functional and aesthetic benefits in one product for our customers. They aid in product identification, inventory management, and branding—thereby bringing value addition into the process of packaging.

Serving Gujarat, India, and Beyond

Needless to say, Flexibond Industries, sited strategically in Gujarat, enables us to easily and effectively serve all of our clients both within and outside India. We have gained admiration by virtue of timely delivery that ensures the customers get exactly what they ordered. This is very crucial in ensuring unhindered operation of business operations of our clientele.

Contact Us

In search of better stretch films, Flexibond Industries has a wide array of products that would meet diversified requirements. Contact us today to find out more about stretch film solutions from our stable, to request a quote, or simply to discuss customization options with our team of experts who are ready to offer solution assistance and ensure that you get the best products for your packaging.

Flexibond Industries: Quality, durability, and sustainability—this is what the stretch film fraternity has to ensure in their products if they are going to be successful. This, coupled with competitive prices, makes one understand why demand is always so high. We have varieties of products to offer and ensure our customers are highly satisfied.

1 note

·

View note

Text

Comprehensive Guide to Packaging Supplies in Melbourne: Essential Products for Every Industry

Packaging supplies in Melbourne are vital for the majority of enterprises, whether they be manufacturing facilities, warehouses, godowns, food facilities, or any other kind of commercial or industrial institution. The top suppliers of packaging items are aware of the particular requirements of the sector and provide a wide range of goods, from vacuum sealers to various kinds of sticky tapes.

Examining the Varieties of Packaging Products and Their Characteristics

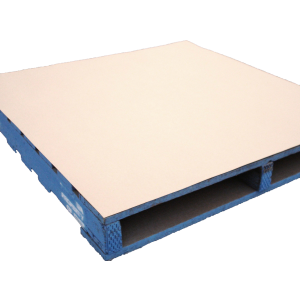

There are many different types of packaging items, each created to satisfy certain industry standards. Pallet pads are quite an important product when sending important items on pallets as some splinters, dust, etc may damage the products. Sheets of corrugated cardboard are used to create protective layers between goods. Secure packing options for goods of all forms are provided by cartons and boxes, which come in a variety of sizes and strengths. For products’ organisation and storage, corrugated trays and folders are perfect, especially in retail and warehouse settings.

Leading packaging product providers serve not just the industrial sector but also the service industry, including the food and hotel sectors. Biodegradable wrap, plates and bowls, mugs of various kinds, and cutlery such as knives, spoons, forks, etc. are some of the items used to package and deliver food to customers in an appropriate manner. Dispensing cartons, retail rolls, bags, sheets, tubes, wraps, and takeout bowls are examples of eco-friendly sustainable packaging that has become increasingly popular in recent years as people's awareness of environmental issues has grown.

The top providers of packaging materials also address janitorial demands, providing a wide variety of items to preserve safety and cleanliness in commercial and industrial settings. Workplace hygiene requires supplies including roll-up hand towels, toilet tissue dispensers, and face tissues. The room or restroom is kept fresh and clean using products like odour control dispensers and antibacterial hand cleaners.

In recent decades, the e-commerce business has expanded rapidly, and as a result, packing machines and dispensers have become crucial for suppliers of goods sold online. Stretch wrap machines, vacuum sealers, and automatic tape dispensers are all made to handle large quantities of goods, increasing output and lowering labour expenses.

Look through the products area of the websites of top packaging product providers and purchase what you need or what businesses need.

Source: https://paramount-packaging.blogspot.com/2024/11/comprehensive-guide-to-packaging.html

0 notes

Text

Cast and Blown Pallet Stretch Wrap

There are two different types of stretch wrap: blown stretch wrap and cast stretch wrap. These two types have their similarities, but there are also many differences between them. This includes the way that they are manufactured, their application use, and more. It is important to choose the right kind of stretch wrap for your secondary packaging needs. If you use the wrong type of film for your load, it could lead to product loss or damage during freight shipment, along with other issues, such as difficulties reading or scanning. two.

Which One Is Better? Neither type of stretch wrap is inherently better than the other. They are simply better suited for different purposes. You can compare these two types of stretch wrap in seven categories: load retention, film memory, film yield, puncture resistance, cling, visual clarity, and noise of unwind. Understanding the differences between cast and blown stretch wrap when it comes to these seven factors is the easiest way to determine which type of stretch wrap is the best option for a specific load.

Load Retention: If you want less stretch, blown film is the better choice. Even after being applied to the pallet, cast film will stretch easily.

Film Memory: Blown film has much better film memory, which means it can shrink back after stretching. Cast film will have a much harder time returning to its original state.

Film Yield: Cast film will stretch much further than blown film, which will allow you to cover more pallets with less film.

Picture Resistance: Blown film is much more resistant to breaking, although cast film will normally only tear when put under great amounts of stress.

Cling: Blown film is only clingy on one side. Cast film is naturally clingy on both sides, which can cause pallets to stick together.

Visual Clarity: Since blown film is not completely translucent, it can make reading and scanning more difficult. It does, however, have a lower gloss that can reduce reflections. If you want something that is clear, go with cast film—just keep in mind that it has higher gloss.

Noise of Unwind: If you want some peace and quiet, opt for cast film, which is silent when it is being unwound from the stretch roll. Blown film, on the other hand, tends to be loud.

All our stretch films are available in both cast and blown film (machine film, hand wrap, pre-stretched hand and machine films and narrow width banding films). Call us at 813 242 6995 or reach out to [email protected]

#pricing news#quickpakinc#stretch film pricing#free pallet wrapper#resin pricing#free machine#quick pak inc#stretch film#youtube#coreless film#cast film#blown hand film#blown and cast film which is better

0 notes

Text

Maximize Packaging Productivity with Expert-Recommended Professional Wrapping Machines

In today’s fast-paced industrial environment, efficiency is everything. Businesses are always seeking ways to streamline operations, reduce waste, and improve productivity. One critical area where these goals converge is packaging. Whether you are packaging food, electronics, or other goods, the right equipment can make all the difference. Professional wrapping machines are vital tools in this endeavor, helping companies to maximize packaging productivity while ensuring the safety and integrity of their products.

The Role of Professional Wrapping Machines

Professional wrapping machines are designed to automate and enhance the packaging process. These machines are capable of handling a wide variety of packaging materials and product types, making them essential in industries ranging from food production to logistics. By automating the wrapping process, these machines significantly reduce the time and labor required to package products, leading to increased efficiency and lower operational costs.

Maximizing packaging productivity with professional wrapping machines involves selecting the right type of machine for your specific needs. There are various types of wrapping machines available, each designed for different applications. Some of the most common types include:

Stretch Wrapping Machines: Ideal for securing pallet loads for transport, these machines stretch plastic film around products to keep them stable and protected during shipping.

Shrink Wrapping Machines: These machines apply heat to shrink a plastic film around a product, providing a tight, tamper-evident seal.

Vacuum Packaging Machines: Particularly useful in the food industry, these machines remove air from the packaging to extend the shelf life of products.

Flow Wrapping Machines: Commonly used in the confectionery and pharmaceutical industries, these machines wrap products in a continuous roll of film.

Benefits of Using Professional Wrapping Machines

The benefits of using professional wrapping machines extend beyond just speed and efficiency. These machines also contribute to product protection, reducing the risk of damage during transit. Additionally, they ensure consistent packaging quality, which is crucial for maintaining brand reputation and meeting customer expectations.

Increased Efficiency: Wrapping machines can package products faster than manual methods, allowing companies to keep up with high demand without sacrificing quality.

Cost Savings: By reducing the need for manual labor, businesses can save on wages and benefits. Additionally, wrapping machines minimize material waste, leading to further cost reductions.

Enhanced Product Protection: Proper packaging is essential for protecting products from damage during transport. Wrapping machines ensure that products are securely wrapped, reducing the likelihood of damage and returns.

Improved Consistency: Machines deliver consistent results, ensuring that every package is wrapped to the same standard. This consistency is critical for maintaining brand image and meeting regulatory requirements.

Selecting the Right Wrapping Machine

When choosing a wrapping machine, it’s important to consider the specific needs of your business. Factors to consider include the type of products you are packaging, the volume of production, and the level of automation required. Consulting with experts or working with reputable suppliers can help you make the best choice.

For example, vacuum packaging machine manufacturers offer specialized machines designed to remove air from packages, which is ideal for preserving perishable goods. These machines are particularly valuable in the food industry, where extending shelf life is a top priority. When selecting a vacuum packaging machine, it’s important to choose a model that can handle the specific type of packaging you use and the volume of products you need to package daily.

Additionally, partnering with vacuum packing machine suppliers who offer comprehensive support and maintenance services can ensure that your machine operates efficiently over its lifespan. Regular maintenance and access to genuine spare parts are crucial for preventing downtime and maximizing the return on your investment.

Innovations in Wrapping Machine Technology

The packaging industry is constantly evolving, with new technologies emerging to meet the demands of modern businesses. One of the most significant trends in wrapping machine technology is the integration of smart features. These include:

Automated Adjustments: Advanced wrapping machines can automatically adjust the tension and speed of the wrapping film based on the size and shape of the product, ensuring optimal packaging every time.

Real-Time Monitoring: Some machines come equipped with sensors and software that monitor the packaging process in real-time, providing data on performance and identifying potential issues before they cause downtime.

Sustainability Features: As environmental concerns grow, many manufacturers are developing machines that use less plastic and other packaging materials, helping businesses reduce their environmental impact.

Case Study: Boosting Productivity with Wrapping Machines

Consider the case of a mid-sized food processing company that struggled with packaging inefficiencies. The company was using manual methods to package its products, which led to inconsistencies and slow production times. After consulting with experts, the company decided to invest in a vacuum packaging machine.

The machine, supplied by a reputable vacuum packing machine supplier, was tailored to the company’s specific needs. It allowed the company to package its products faster and more consistently, leading to a 30% increase in productivity. Moreover, the vacuum packaging extended the shelf life of the company’s products, reducing waste and improving customer satisfaction.

The Importance of After-Sales Support

Investing in a professional wrapping machine is a significant decision, and the right after-sales support can make all the difference in ensuring that your machine continues to perform at its best. Reputable vacuum packaging machine manufacturers and suppliers often provide comprehensive after-sales support, including installation, training, maintenance, and access to spare parts. This support is crucial for maximizing the lifespan and efficiency of your machine.

For businesses that operate in high-demand industries, even a short period of downtime can have significant financial consequences. Having access to prompt and reliable support can help you avoid costly interruptions and keep your packaging operations running smoothly.

Conclusion

Maximizing packaging productivity is essential for businesses looking to stay competitive in today’s market. Professional wrapping machines offer a range of benefits, from increased efficiency and cost savings to improved product protection and consistency. By selecting the right machine for your needs and partnering with reputable vacuum packing machine suppliers, you can significantly enhance your packaging operations.

As packaging technology continues to evolve, businesses that invest in modern, efficient wrapping machines will be better positioned to meet the demands of their customers and reduce their environmental impact. Whether you’re in the food industry, manufacturing, or logistics, the right wrapping machine can help you achieve your productivity goals and ensure the success of your business.

For expert guidance on selecting the best professional wrapping machines, contact us today at +91-9891151877.

0 notes

Text

The Top Features of Tilak Polypack's Machine Stretch Film: Quality and Performance

In the fast-paced world of manufacturing and packaging, ensuring that goods are securely wrapped and protected during transit is essential. That's where Tilak Polypack's machine stretch film comes in. This high-performance stretch wrap is designed to meet the rigorous demands of the industry, offering exceptional quality and reliability. In this blog post, we'll explore the top features of Tilak Polypack's machine stretch film, highlighting why it's the go-to choice for packaging professionals.

What is Machine Stretch Film?

Machine stretch film, also known as machine stretch wrap, is a highly stretchable plastic film used to wrap around goods and pallets to keep them secure during transportation. Unlike manual stretch film, this type is specifically designed for use with wrapping machines, ensuring uniform and consistent application.

High Transparency

One of the standout features of Tilak Polypack's machine stretch film is its high transparency. This clarity allows for easy identification of wrapped products without the need to remove the film. High transparency is especially important for inventory management and quality control, as it enables quick and efficient visual inspections.

No Discoloration

Tilak Polypack's machine stretch film maintains its clarity and does not discolor over time. This ensures that the wrapped goods remain visible and presentable, which is crucial for maintaining product aesthetics and brand image. Discoloration can be a sign of inferior quality, but with Tilak Polypack, you can be confident in the consistent appearance of your wrapped products.

Superior Tensile Properties

The tensile properties of a stretch film determine its strength and elasticity. Tilak Polypack's machine stretch film boasts superior tensile properties, allowing it to stretch significantly without breaking. This elasticity ensures that the film tightly secures the load, providing excellent containment and protection against shifting and damage during transit.

High Packaging Flexibility

Packaging flexibility is crucial for accommodating different sizes and shapes of loads. Tilak Polypack's machine stretch film offers high packaging flexibility, allowing it to conform to various load configurations. Whether you're wrapping small boxes or large pallets, this stretch film can handle the job with ease.

Cost-Saving Packaging Solution

Cost-effectiveness is a key consideration for any business. Tilak Polypack's machine stretch film provides a cost-saving packaging solution by reducing material usage and minimizing waste. Its high stretchability means you can use less film while still achieving optimal load containment, ultimately lowering your packaging costs.

Strength and Durability

When it comes to protecting goods during transit, strength and durability are paramount. Tilak Polypack's machine stretch film offers exceptional strength, withstanding wear and tear during loading, unloading, and transportation. This durability ensures that your products arrive at their destination in perfect condition.

Differential Cling Capability

Tilak Polypack offers machine stretch films with one-sided and two-sided cling capabilities. This feature allows for secure wrapping without the film sticking to itself excessively, making the wrapping process smoother and more efficient. Differential cling capability also helps prevent film layers from separating, ensuring a tight and secure wrap.

Quality Assurance

At Tilak Polypack, quality assurance is a top priority. The company adheres to stringent quality control measures throughout the manufacturing process, ensuring that every roll of machine stretch film meets the highest industry standards. This commitment to quality means you can trust Tilak Polypack to deliver reliable and consistent products every time.

1 note

·

View note

Text

Mastering the Art of Stretch Wrapping Film: Best Practices, Benefits, and Applications Unveiled

In the world of packaging, where efficiency and protection are paramount, stretch wrapping film has emerged as a cornerstone technology. Singhal Industries Pvt Ltd, India's foremost packaging company, is at the forefront of mastering this art. Let's delve into the best practices, benefits, and applications of Stretch film roll, shedding light on why Singhal Industries stands as the pinnacle of excellence in this domain.

Understanding Stretch Wrapping Film:

Stretch wrapping film, also known as stretch film or stretch wrap, is a highly versatile packaging material used to secure and protect goods during storage and transportation. Composed of polyethylene plastic, this thin, elastic film is stretched around products or pallets, providing a tight and secure wrap that prevents shifting, tampering, and damage.

Best Practices for Stretch Wrapping:

Proper Film Selection: Selecting the right type and gauge of stretch film is crucial for effective wrapping. Factors such as load weight, dimensions, and storage conditions should be considered to ensure optimal performance.

Equipment Calibration: Calibrating stretch wrapping machines to the appropriate settings, including film tension, pre-stretch level, and wrap speed, is essential for consistent and reliable wrapping results.

Uniform Application: Ensuring uniform tension and coverage during wrapping helps distribute the load evenly and minimizes the risk of product damage or instability during transit.

Corner Reinforcement: Paying special attention to the corners and edges of palletized loads by applying additional layers of film or using corner boards can enhance load stability and protection.

Quality Control: Regular inspection of wrapped pallets for tears, punctures, or loose film ends is necessary to identify and rectify any issues before shipment.

Benefits of Stretch Wrapping Film:

Cost-Effectiveness: Stretch film offers a cost-effective solution for securing and protecting goods compared to alternative packaging materials such as strapping or shrink wrap.so always have an idea on Stretch film price per kg, before buying.

Versatility: Stretch film is suitable for a wide range of applications across various industries, including manufacturing, logistics, retail, and agriculture.

Load Stability: The elastic properties of stretch film provide superior load stability by conforming to the shape of the product or pallet and holding it securely in place during transit.

Product Protection: Stretch film acts as a protective barrier against moisture, dust, and other environmental factors, safeguarding goods from damage and contamination.

Efficiency: Automated stretch wrapping systems streamline the packaging process, increasing efficiency and throughput while reducing labor costs and manual handling risks.

Applications of Stretch Wrapping Film:

Palletizing: Stretch film is commonly used to secure and stabilize palletized loads of goods for storage and transportation, minimizing the risk of product damage and loss.

Bulk Packaging: Large rolls or bundles of products, such as paper, textiles, or building materials, can be efficiently bundled and protected using stretch wrapping film.

Unitizing: Individual items or packages can be unitized and grouped together using stretch film, reducing the risk of loss or damage and facilitating handling and storage.

Food Packaging: Stretch film with specialized properties, such as high clarity or food-grade certification, is used for packaging perishable goods in the food and beverage industry. The question is do you know the price of Stretch film roll price per kg to maintain better profit margins and packaging quality in your business.

In conclusion, stretch wrapping film stands as a cornerstone technology in the realm of packaging, offering unparalleled efficiency, protection, and versatility. Singhal Industries Pvt Ltd, with its commitment to excellence, competitive pricing, and customer-centric approach, remains at the forefront of mastering this art. As industries continue to rely on efficient and reliable packaging solutions, the adoption of stretch wrapping film emerges as a strategic imperative for safeguarding goods and optimizing supply chain operations.

Frequently Asked Questions:

1.What is the price per kg of stretch film offered by Singhal Industries?

Singhal Industries offers competitive pricing for stretch film, with rates varying based on factors such as quantity, gauge, and customization requirements.

2.Do you offer different types of stretch film rolls?

Yes, Singhal Industries provides a variety of stretch film rolls, including standard, pre-stretched, and specialty films tailored to specific application needs.

3.What is the price per kg of stretch film roll?

Singhal Industries offers transparent pricing for stretch film rolls, with rates calculated based on the weight of the roll and the desired specifications.

4.Is stretch film suitable for wrapping irregularly shaped or oversized items?

Yes, stretch film can be stretched and manipulated to conform to the shape and size of virtually any item, providing secure and reliable packaging.

0 notes

Text

Seal & Secure: The Ultimate Guide to Stretch Wrapping Films

Introduction

Stretch wrapping films have become indispensable in various industries for packaging and securing goods during transportation and storage. Among the myriad of packaging solutions available, stretch wrapping films offer unparalleled versatility, strength, and cost-effectiveness. This guide aims to delve into the intricacies of stretch wrapping films, shedding light on their types, benefits, applications, and key considerations for choosing the right one for your needs.

Understanding Stretch Wrapping Films

Stretch wrapping films, also known as stretch wrap or stretch film, are highly elastic plastic films used to tightly bind and secure items together. These films are typically made from linear low-density polyethylene (LLDPE) and are engineered to stretch around products, providing stability and protection against dust, moisture, and tampering.

Types of Stretch Wrapping Films

Machine Stretch Film: Designed for use with stretch wrapping machines, this type of film offers high efficiency and consistency in wrapping palletized loads. Machine stretch films are available in various thicknesses and widths to accommodate different packaging requirements.

Hand Stretch Film: As the name suggests, hand stretch films are manually applied without the need for specialized equipment. These films are suitable for smaller-scale operations or for wrapping irregularly shaped items. They come in handy rolls that are easy to maneuver and apply.

Pre-Stretched Film: Pre-stretched films undergo a manufacturing process that stretches the film close to its breaking point before winding it onto rolls. This results in a lighter, thinner film that still offers excellent load stability and cost savings.

Benefits of Stretch Wrapping Films

Enhanced Protection: Stretch wrapping films create a protective barrier around goods, safeguarding them from dust, moisture, and other environmental factors during transit and storage.

Improved Stability: By securely bundling items together, stretch films prevent shifting and movement during handling, reducing the risk of damage or loss.

Cost-Effectiveness: Compared to other packaging materials, stretch wrapping films offer a cost-effective solution for packaging large volumes of goods. Additionally, their lightweight nature helps minimize shipping costs.

Versatility: Stretch films are suitable for a wide range of applications across various industries, including manufacturing, logistics, agriculture, and retail.

Applications of Stretch Wrapping Films

Stretch wrapping films find applications in diverse industries and scenarios, including:

Manufacturing: In manufacturing facilities, stretch films are used to secure and protect finished products, raw materials, and components during handling and transportation within the facility or to distribution centers.

Logistics and Distribution: Stretch wrapping films play a crucial role in the logistics and distribution sector by stabilizing palletized loads for safe transit. They ensure that goods reach their destination intact, minimizing the risk of damage or pilferage.

Retail: In retail environments, stretch films are employed for packaging and displaying merchandise, ensuring product integrity and presentation on store shelves.

Key Considerations for Choosing Stretch Wrapping Films

When selecting stretch wrapping films for your packaging needs, consider the following factors:

Load Characteristics: Assess the size, weight, and shape of the items being packaged to determine the appropriate film thickness and stretchability required to secure the load effectively.

Application Method: Decide whether you'll be using a stretch wrapping machine or applying the film manually. Choose the type of film (machine or hand) accordingly.

Environmental Conditions: Consider the environmental factors your packaged goods will be exposed to, such as temperature variations and humidity levels, to select a stretch film with suitable properties for protection.

Cost and Efficiency: Evaluate the overall cost-effectiveness of the stretch film, taking into account factors such as film price, material usage, labor costs, and potential savings in transportation and storage.

Manufacturers in Gujarat

Gujarat, a thriving industrial hub in India, is home to several reputable stretch wrap film manufacturers. These manufacturers produce a wide range of high-quality stretch films tailored to meet the diverse packaging needs of industries across the globe. By leveraging advanced manufacturing technologies and stringent quality control measures, Stretch wrap film manufacturers in Gujarat ensure consistency, reliability, and performance in their products.

Prices of Stretch Wrap Film

The Stretch Wrap Film Price can vary depending on various factors such as film thickness, width, length, quantity purchased, and supplier pricing policies. Generally, machine stretch films may be priced differently from hand stretch films due to differences in manufacturing processes and material usage. It's essential to obtain quotes from multiple suppliers and compare prices to find the most cost-effective solution that meets your requirements without compromising quality.

Stretch Wrapping Film Manufacturer in India leverage India's robust manufacturing infrastructure and skilled workforce to produce high-quality stretch films that cater to both domestic and international markets. With a focus on innovation, sustainability, and customer satisfaction, stretch wrapping film manufacturers in India continue to play a pivotal role in meeting the evolving packaging needs of diverse industries.

Conclusion

Stretch wrapping films serve as indispensable packaging solutions across a myriad of industries, offering unparalleled protection, stability, and cost-effectiveness. Whether you're securing palletized loads in a warehouse or packaging goods for retail display, choosing the right stretch film is crucial for ensuring product integrity and minimizing risks during transit and storage. By understanding the different types of stretch films available, their benefits, applications, and key considerations for selection, you can make informed decisions that optimize packaging efficiency and enhance supply chain performance. With reputable manufacturers in Gujarat and throughout India, sourcing high-quality stretch wrapping films has never been easier, empowering businesses to seal and secure their products with confidence.

FAQs

What are the different types of stretch wrapping films available?

There are several types of stretch wrapping films, including machine stretch film, hand stretch film, and pre-stretched film. Machine stretch film is designed for use with stretch wrapping machines and offers high efficiency and consistency in wrapping palletized loads. Hand stretch film is applied manually and is suitable for smaller-scale operations or irregularly shaped items. Pre-stretched film undergoes a manufacturing process that stretches the film close to its breaking point before winding it onto rolls, resulting in a lighter, thinner film that still offers excellent load stability.

What are the key benefits of using stretch wrapping films?

Stretch wrapping films offer numerous benefits, including enhanced protection for goods, improved stability during transit, cost-effectiveness compared to other packaging materials, and versatility in various industries and applications. These films provide a protective barrier against dust, moisture, and other environmental factors, reducing the risk of damage or loss during handling and transportation.

How do I choose the right stretch wrapping film for my packaging needs?

When selecting a stretch wrapping film, consider factors such as the size, weight, and shape of the items being packaged, the application method (machine or hand), environmental conditions, and overall cost-effectiveness. Assessing these factors will help determine the appropriate film thickness, stretchability, and properties required to securely package and protect your goods.

#stretch wrap film manufacturers in gujarat#stretch wrap film price#stretch wrapping film manufacturer in india

0 notes

Text

Building Scaffold Safety Net

Material:PP, PE

Color:Various

Mesh type:Diamond

Weight:7-350gsm

Width:6.3mm-558mm

Length:Can be customized

Package :Film wrapped and 1 roll/bag

There is two kind of protective tube you can choose for different use. FT SERIES is a soft extruded net used for protecting cartridges outside. It also can be used in other fields for protecting machined parts and delicate objects. It is designed to stretch around components, hugging their contours. Rigid Tubular net,is a hard tube, it can be used both as inner support and outer protection for filtration cartridges in chemical, pharmaceutical and food industry.

0 notes

Text

Affordable and High-Quality Plastic Wrap Rolls: Where to Buy in India

Efficient packaging is the backbone of any business that handles storage, logistics, or transportation of goods. And when it comes to packaging, few materials offer the versatility and reliability of plastic wrap rolls, also commonly known as stretch film rolls.

Whether you're a growing e-commerce business, a logistics expert, or a large-scale manufacturer, securing your shipments with durable plastic wrap rolls ensures protection, efficiency, and cost savings. If you're in India and searching for high-quality yet affordable plastic wrap rolls, this guide will walk you through the benefits of using stretch wrap rolls and where to find the best ones.

What Are Plastic Wrap Rolls (Stretch Films)?

Plastic wrap rolls, or stretch films, are flexible yet durable plastic materials primarily made from polyethylene. Their elasticity allows them to stretch tightly around products, holding items in place during transit or storage. Unlike other packaging materials, stretch films don't require additional adhesives or heat sealing—making them practical and efficient for various industries.

Stretch wrap rolls are available in different forms:

Hand Rolls for manual application

Machine Rolls for automated or large-scale packaging processes

Plus, they can be customized based on thickness, width, and length to meet unique business needs.

The Benefits of Using Plastic Wrap Rolls

Why are plastic wrap rolls the go-to packaging solution for so many industries? Below are the standout benefits of stretch films:

1. Secure Packaging

Stretch films hold products tightly, preventing shifting, scratches, and damage during transportation. They're particularly effective for safeguarding fragile or irregularly shaped items.

2. Load Stability

By securing items on pallets, stretch wrap rolls prevent them from toppling over, ensuring load stability during transit.

3. Moisture and Dust Protection

These rolls act as a protective layer, shielding products from moisture, dirt, and dust, which is vital for long storage periods or sensitive goods like electronic equipment.

4. Transparent Layers for Easy Identification

The transparency of most stretch films enables quick identification of packaged items without the need for opening and inspecting every parcel.

5. Cost Efficiency

Stretch wrap rolls reduce the need for other costly packaging materials. Their stretchability ensures minimal waste, lowering overall packaging costs.

6. Eco-Friendly Options

With the rise of sustainability concerns, many manufacturers now offer recyclable plastic wrap rolls that reduce environmental impact.

7. Improved Packaging Processes

Stretch films streamline both packaging and unpacking, thanks to their high conformability and ease of application.

Whether you're bundling items, securing boxes, or wrapping irregularly shaped products, plastic wrap rolls consistently deliver reliable results.

Why Tilak Polypack Is India's #1 Choice for Plastic Wrap Rolls

When it comes to dependable plastic wrap roll manufacturers in India, Tilak Polypack is a name that stands out. With more than two decades of industry expertise, Tilak Polypack has become synonymous with quality, innovation, and environmental responsibility.

Key Features of Tilak Polypack Solutions

Here’s why businesses across industries trust Tilak Polypack for their packaging needs:

Top-Notch Quality: Every stretch film produced meets high manufacturing and performance standards, ensuring long-lasting durability.

Customizable Options: From thickness to width, every roll can be tailored to meet your specific requirements.

Eco-Friendly Solutions: Sustainability is at the heart of Tilak Polypack's operations. Their recyclable films are ideal for businesses committed to environmentally conscious practices.

Reliable Partnerships: Trusted by businesses worldwide, including those across the US, UK, Singapore, and more, Tilak Polypack delivers consistent packaging solutions on time.

Customer-Focused Service: Exceptional customer support ensures that every packaging challenge is met with a prompt and effective solution.

Applications of Tilak Polypack Plastic Wrap Rolls

Tilak Polypack's stretch films are versatile and cater to multiple industries:

Logistics and Warehousing: Unitizing pallet loads and securing boxes for transport or storage.

E-commerce and Retail: Preventing product damage and ensuring secure shipments.

FMCG and Manufacturing: Safeguarding goods like appliances or food items.

Pharmaceuticals: Protecting sensitive products from contamination during handling.

No matter the sector you operate in, Tilak Polypack offers solutions tailored to your needs.

How to Choose the Right Plastic Wrap Roll for Your Business

Now that you know where to find the best plastic wrap rolls, how do you pick the right one? Consider these factors before making your purchase:

Film Thickness: Heavier items or those requiring extra protection may need thicker films.

Width and Length: Larger packages or pallets will require wider film rolls.

Special Features: For outdoor use, opt for UV-resistant films; for efficiency, consider pre-stretched options.

Sustainability: Choose recyclable or eco-friendly films to align with modern sustainability goals.

Tilak Polypack offers plenty of customization options for each of these variables, making it a no-brainer for businesses.

Take Your Packaging to the Next Level

Stretch films are more than just a practical packaging material—they’re a strategic investment in product protection, operational efficiency, and brand reputation. Especially when sourced from a trusted provider like Tilak Polypack, you gain access to affordable, high-quality plastic wrap rolls that fit seamlessly into your business needs.

Ready to Enhance Your Packaging?

Explore Tilak Polypack’s complete range of plastic wrap rolls today and discover why businesses across 10+ countries trust their innovative solutions. Reach out to their team to request a quote or discuss your packaging requirements.

Protect your goods. Streamline your operations. Choose quality. Choose Tilak Polypack.

1 note

·

View note

Text

The Benefits of Using Specialty Stretch Films for Unique Packaging Needs

In today's competitive market, finding the right packaging solution can make a significant difference in product protection, efficiency, and cost savings. Specialty stretch films are gaining traction across various industries for their versatility and ability to meet unique packaging needs. This comprehensive guide will explore the benefits of using specialty stretch films and how they can revolutionize your packaging process.

Mini Stretch Wrap Rolls for Precision Packaging

Perfect for Small Items

One of the standout features of mini stretch wrap rolls is their suitability for wrapping small items. These rolls allow for precision packaging, ensuring that even the tiniest products are securely bundled. This makes them an ideal choice for manufacturers and industrial companies dealing with small parts or products.

Ease of Use

Mini stretch wrap films are incredibly user-friendly, making them perfect for manual wrapping tasks. The compact size of the film allows for easy handling and application, reducing the time and effort required to bundle items. This ease of use is particularly beneficial for retailers and wholesalers who often deal with various small products.

Customizable Options

We offer mini stretch wrap rolls in thicknesses ranging from 11 microns onwards and widths starting at 50mm. Additionally, these films are available in a variety of colors, including natural, white, black, and blue, allowing you to choose the best option for your specific needs. This customization ensures that you have the right film for every unique packaging requirement.

Machine Stretch Film for Pallet Wrapping

Maximizing Efficiency

Machine stretch film is a game-changer when it comes to pallet wrapping. Designed for use with pallet wrapping machines, these films maximize efficiency by significantly reducing the time required to wrap large quantities of products. This feature is particularly advantageous for logistics and distribution companies that handle high volumes of goods.

Superior Puncture Resistance

Our machine stretch films are manufactured using the blown film process, which provides better puncture resistance compared to cast-based films. This superior durability ensures that your pallets remain securely wrapped during transit, reducing the risk of damage and loss. It's a crucial benefit for industries like electronics and consumer goods, where product integrity is paramount.

High Pre-Stretch Capability

We use the best possible grades of materials to ensure maximum pre-stretch while wrapping. This high pre-stretch capability means you can cover more pallets with less film, resulting in cost savings and reduced waste. For pharmaceuticals and food and beverage industries, this can translate into significant operational efficiencies.

Silage Stretch Film for Agricultural Use

Optimal Tackiness and UV Protection

Silage stretch film is specifically designed for agricultural and horticultural applications. Our silage films incorporate additives imported from Europe, providing optimal tackiness and UV protection. This ensures that your silage remains securely wrapped and protected from the elements, which is essential for maintaining feed quality.

Long-Lasting Durability

Our 29-micron silage stretch film is engineered to withstand up to 10-12 months of exposure to sunlight under European conditions. This longevity means fewer replacements and reduced overall costs for farmers and agricultural businesses. The film's durability ensures that your silage is well-preserved, contributing to better yield and productivity.

Versatile Color Options

Available in white, black, and yellow, our silage stretch films offer versatility to suit different preferences and needs. The color options also help in identifying and managing stored silage, making it easier for farmers to keep track of their inventory.

Cling Film for Food Packaging

Safe and Non-Toxic

Cling film is indispensable in the food packaging industry. Our cling films are made from LLDPE, ensuring they are 100% non-toxic and free from harmful plasticizers. This makes them safe for direct contact with food, a critical requirement for food and beverage companies. The non-toxic nature of our cling film ensures that your food products remain safe and uncontaminated.

Cost-Effective

Due to its lower density compared to PVC cling films, our LLDPE cling film offers a cost-effective packaging solution. The material's efficiency translates into savings without compromising on quality. This cost-effectiveness is particularly beneficial for catering services and food packaging businesses that require large quantities of cling film.

Special Additives for Enhanced Performance

Our cling films can be supplied with special additives like anti-fog, which is essential for packaging higher temperature materials. This feature ensures that the film remains clear and visually appealing, even when used on hot foods. The anti-fog property is particularly useful for ready-to-eat meals and other freshly prepared food items.

The Benefits of Using Specialty Stretch Films

Enhanced Product Protection

The primary benefit of using specialty stretch films is the enhanced protection they offer for your products. Whether you're wrapping small items with mini stretch wrap rolls or securing large pallets with machine stretch film, these films provide superior stability and protection against damage. This is crucial for maintaining product quality and reducing returns.

Improved Efficiency

Specialty stretch films significantly improve packaging efficiency. From the ease of manually wrapping small items with mini stretch wrap rolls to the automated efficiency of machine stretch film, these solutions save time and labor. This increased efficiency translates into cost savings and higher productivity for your business.

Customization and Flexibility

The ability to customize stretch films to meet specific needs is another major advantage. With options for different thicknesses, widths, and colors, you can select the perfect film for every application. This flexibility ensures that you have the right packaging solution for every unique requirement, enhancing overall operational efficiency.

1 note

·

View note

Text

Custom Stretch Wrap Roll Solutions for UAE's Diverse Industrial Needs

Stretch films, also known as stretch wrap rolls, are revolutionizing the packaging and logistics industries in the UAE. With the rapid growth of sectors ranging from manufacturing to e-commerce, secure and efficient packaging has become more important than ever. The versatility and durability of these films make them an indispensable solution for businesses aiming to streamline their operations while maintaining impeccable product protection.

But what exactly are stretch films, and why are they the preferred packaging solution for so many industries in the UAE? This post dives deep into the benefits of stretch wrap rolls, their diverse applications, and why Tilak Polypack, a leading global manufacturer, is the ideal partner for custom stretch wrap solutions in the UAE.

Stretch Films Demystified

Stretch films are elastic plastic materials, typically made from polyethylene, designed to tightly secure items during transportation and storage. These films can stretch without the need for adhesives or heat sealing, offering a cost-effective and efficient solution for packaging.

Why Are Stretch Films Essential?

Elasticity for a Tight Grip: Their stretchable nature ensures items are securely held in place.

Versatility: Available in hand rolls and machine rolls to cater to various operational needs.

Special Features: Some variants include UV resistance or pre-stretched designs for enhanced efficiency and cost savings.

Stretch films are not one-size-fits-all. With customization options available for thickness, width, and length, businesses can find solutions tailored to their specific needs.

Wide Applications in UAE Industries

The UAE’s industrial landscape is diverse, encompassing sectors like logistics, warehousing, shipping, and manufacturing. Stretch films are pivotal in addressing their specific packaging requirements. Here's how they’re being used:

1. Logistics and Shipping

Unitizing pallet loads to ensure items stay intact during transit.

Securing packages to prevent damage and pilferage.

Protecting goods against external factors like dust, moisture, and dirt.

2. Warehousing

Simplifying inventory management with transparent films that allow easy product identification.

Protecting stored items from environmental damage.

3. Manufacturing

Bundling products or raw materials together for easy handling and storage.

Providing tamper resistance for sensitive materials.

4. E-commerce

Enhancing load stability for irregularly shaped or mixed-package shipments.

Compact and dust-free packaging for customer-ready items.

Whether you’re transporting fragile goods across the UAE’s busy trade channels or securing toppling-prone pallet loads in your warehouse, stretch films prove to be a game-changer.

Why Stretch Wrap Rolls Are the Smart Packaging Solution

Using stretch wrap rolls offers a wide range of benefits that make them indispensable for businesses:

Secure Packaging: Protect products from shifting, scratches, and environmental damage during transportation.

Cost-Effectiveness: Reduce packaging waste and eliminate the need for additional materials.

Environmental Impact: Choose from recyclable options to align with sustainability goals.

Efficiency: Speed up packaging and unpacking processes with user-friendly films.

Visibility: Transparent films allow for easy inspection without unpacking.

For forward-thinking organizations in the UAE, stretch wrap rolls are not just a packaging material—they are a strategic investment.

Meet Tilak Polypack - World-Class Stretch Film Manufacturer

When it comes to sourcing premium stretch films, Tilak Polypack stands out as a trusted provider. With over 20 years of experience and a global presence spanning countries such as the US, the UK, Australia, and Germany, Tilak Polypack brings unmatched expertise to the UAE.

What Sets Tilak Polypack Apart?

Top-Notch Quality: Each roll meets stringent manufacturing and quality standards.

Customization Options: Select the thickness, width, and length of your film to meet your unique requirements.

Sustainability Focus: Eco-friendly solutions for businesses aiming to reduce their carbon footprint.

Global Expertise with Local Support: A reliable packaging partner that understands the challenges of diverse industries.

Customer-Centric Approach: Get outstanding customer support with every order.

Choosing Tilak Polypack means more than just high-quality products—it means partnering with a company that values your business success.

Sustainable Packaging with Tilak Polypack

Sustainability has become a critical concern in the UAE, where environmental initiatives are gaining momentum. Tilak Polypack takes this issue seriously by offering recyclable stretch films that contribute to reducing packaging waste. By investing in eco-friendly packaging, businesses not only meet environmental regulations but also align with consumer demands for greener practices.

Custom Stretch Wrap Solutions for UAE Businesses

No two businesses are alike, and their packaging needs shouldn���t be either. Tilak Polypack offers bespoke solutions to fit specific industry requirements. Whether you're looking for machine rolls with UV protection for outdoor logistics or pre-stretched films for cost-effective warehousing, we've got you covered.

Popular Types of Tilak Polypack Stretch Films:

Standard Stretch Film: Ideal for everyday use in various industries.

Pre-Stretched Film: A lightweight option for reducing material use without compromising strength.

UV-Resistant Film: Perfect for outdoor applications under the UAE's intense sun.

Tilak Polypack helps you find the perfect solution that balances performance, quality, and sustainability.

Why the UAE Needs Custom Stretch Wrap Rolls Now More Than Ever

The UAE is undergoing tremendous growth in trade, manufacturing, and e-commerce. Businesses must adapt to increasing demand, faster shipping times, and stricter environmental regulations. High-quality, customized stretch films can help meet these challenges effectively.

By choosing Tilak Polypack’s stretch wrap rolls, businesses can stay ahead of the curve with secure, efficient, and eco-conscious packaging solutions.

Better Packaging, Better Business

Stretch films are no longer just a packaging necessity—they’re a competitive advantage. They not only protect your products but also improve efficiency, reduce costs, and demonstrate your commitment to sustainability.

Tilak Polypack leads the industry in providing custom stretch wrap rolls tailored to your needs. Whether you’re in logistics, manufacturing, or e-commerce, our solutions will ensure your operation runs seamlessly.

Take the Next Step

Partner with Tilak Polypack and experience the benefits of expertly crafted stretch films. Contact us today to discuss your custom packaging requirements and discover the perfect solution for your business.

1 note

·

View note

Text

Durant is a leading Manufacturer and Distributor with more than 75 years of Count and Control Products, Wire Machinery, Coil Handling, Material Feeding Equipment, and Rotary Turntables for factory automation, exhibit/display, stretch wrapping, and all stainless steel models. Counters, Decoilers, Uncoilers, Pallet Decoilers, Stock Reels, unwinding machines, rewinders, recoilers, coil straighteners, material lubricators, material oilers, roll feeders, electronic servo feeders, air feeders, scrap cutters.

0 notes

Text

Boost Efficiency with Melbourne Packaging Supplies: A Comprehensive Overview