#Rigging equipment

Explore tagged Tumblr posts

Text

Elevate Your Project with Top-Quality Rigging Equipment from Roma Enterprises LLC

Roma Enterprises LLC is a trusted provider of top-quality rigging equipment in Dubai, UAE. With a solid reputation in the market, they offer a comprehensive range of products designed for safety and durability, including lifting slings, shackles, wire ropes, and hoists. Their equipment is sourced from leading manufacturers, ensuring compliance with international standards. Whether you're in construction, oil and gas, or marine industries, Roma Enterprises LLC delivers reliable solutions tailored to meet your specific project needs. For the best rigging equipment in Dubai, Roma Enterprises LLC is your go-to partner.

0 notes

Text

How Strong Are Wire Rope Clamps?

Understanding Wire Rope Clamps

Wire rope clamps consist of three main components:

U-Bolt: A U-shaped bolt that fits around the wire rope.

Saddle: The part that rests on the wire rope, held in place by the U-bolt.

Nuts: These are used to tighten the U-bolt, securing the wire rope between the U-bolt and the saddle.

There are primarily two types of wire rope clamps:

Drop Forged: These are made from a single piece of metal and are incredibly strong. They are used in critical applications where maximum strength is required.

Malleable Cast Iron: These are less expensive and are suitable for non-critical applications. They are not as strong as drop forged clamps but are sufficient for many tasks.

Factors Affecting the Strength of Wire Rope Clamps

Material and Construction: The strength of a wire rope clamp heavily depends on its material. Drop forged clamps are made from high-quality steel, providing superior strength and durability. In contrast, malleable cast iron clamps are weaker and prone to deformation under heavy loads.

Proper Installation: The effectiveness of wire rope clamps also hinges on proper installation. Here are a few key installation tips:

Number of Clamps: Using an inadequate number of clamps can compromise the strength of the connection. Typically, at least three clamps are recommended for most applications.

Spacing: Clamps should be spaced correctly to distribute the load evenly. The general rule is to space them six rope diameters apart.

Torque: The nuts should be tightened to the manufacturer’s recommended torque specifications. Over-tightening or under-tightening can both reduce the clamp’s holding power.

Wire Rope Condition: The condition of the wire rope itself is crucial. A damaged or corroded rope can significantly weaken the connection, regardless of the clamp’s quality.

Load Conditions: The type of load applied to the wire rope clamp affects its strength. Dynamic loads (those that change or fluctuate) are more challenging for the clamp to handle compared to static loads (constant and unchanging).

Environmental Factors: Exposure to harsh environmental conditions such as saltwater, chemicals, and extreme temperatures can degrade both the wire rope and the clamps. Using clamps made from corrosion-resistant materials can help mitigate these effects.

SVIBO Industries: A Leader in Quality and Innovation

When discussing wire rope clamps, it’s essential to highlight some of the industry leaders who set the standards for quality and reliability. One such notable company is SVIBO Industries.

About SVIBO Industries

SVIBO Industries is a renowned manufacturer and supplier of high-quality rigging hardware and lifting equipment. With decades of experience, SVIBO has established itself as a trusted name in the industry, known for its commitment to innovation, quality, and safety. The company offers a comprehensive range of products, including wire rope clamps, shackles, hooks, and other rigging accessories, designed to meet the diverse needs of various industries.

SVIBO Wire Rope Clamps

SVIBO’s wire rope clamps are particularly noteworthy for their exceptional strength and durability. Here’s what sets them apart:

High-Grade Materials: SVIBO uses only the finest materials, such as drop forged steel and stainless steel, ensuring maximum strength and resistance to wear and corrosion.

Precision Manufacturing: SVIBO’s state-of-the-art manufacturing processes guarantee precise dimensions and consistent quality across all products.

Rigorous Testing: Each wire rope clamp undergoes stringent testing to meet and exceed industry standards, providing peace of mind for critical applications.

Innovative Design: SVIBO continuously invests in research and development to innovate and improve the design of their wire rope clamps, enhancing their performance and ease of use.

Customer Support: SVIBO is known for its excellent customer service, offering technical support and guidance to ensure customers choose the right products for their specific needs.

Applications of SVIBO Wire Rope Clamps

Construction and Rigging: SVIBO’s clamps are used extensively in construction projects for lifting, securing, and rigging applications. Their drop forged clamps provide the necessary strength and reliability for heavy-duty tasks.

Marine Industry: In the marine sector, SVIBO’s stainless steel clamps are favored for their corrosion resistance, making them ideal for securing lines and cables in harsh saltwater environments.

Industrial and Manufacturing: SVIBO wire rope clamps are used in various industrial applications, from manufacturing to logistics, where reliable and robust connections are paramount.

Recreational and DIY Projects: For lighter applications, such as setting up outdoor structures or DIY projects, SVIBO offers malleable iron clamps that are both cost-effective and reliable.

Conclusion

Wire rope clamps are robust and reliable tools when used correctly. The strength of these clamps depends on several factors, including their material, installation, and the conditions they are subjected to. Companies like SVIBO Industries, the best wire rope clamp manufacturers and suppliers in India play a crucial role in providing high-quality wire rope clamps that meet the demands of various applications. For critical applications, opting for high-quality clamps and following all installation guidelines is essential to ensure maximum strength and safety. By understanding these factors and applying best practices, you can confidently use wire rope clamps for a variety of applications, knowing they will provide the necessary support and security.

0 notes

Text

What Rigging Equipment is used in Material Handing?

Great information by Bishop Lifting the leader in the rigging supplies and rigging equipment industry on what equipment you need to consider when it comes to material handling.

1 note

·

View note

Text

What is rigging equipment?

Learn more about rigging equipment and rigging supplies from the industry leader Lifting.com

1 note

·

View note

Text

Getting Around the World of Rigging Supplies and Equipment: A Complete Guide

Rigging supplies and equipment are the unsung heroes of the heavy lifting and complex maneuvers world, making it possible for manufacturing, transportation, entertainment, and construction as well as other industries to proceed safely and effectively. Rigging gear is essential to the practical management of large loads, from towering cranes on building sites to carefully planned stage setups. This thorough book explores the many facets of the world of rigging supplies and equipment, including their various types, important uses, safety precautions, and important factors to take into account when choosing the appropriate equipment for any operation.

Comprehending Rigging Supplies and Equipment

The term "rigging equipment" refers to a wide range of instruments and materials that are painstakingly created to guarantee the secure and effective transportation of large loads. Below is a summary of a few typical types:

Hoists: Used to lift or lower heavy items vertically, hoists are mechanical workhorses. Different weight capacities and operational requirements are met by variations such chain hoists, lever hoists, and electric hoists, which provide versatility in a range of applications.

Slings: Slings offer flexible support for lifting and securing loads. They are made of materials such as nylon, polyester, wire rope, or chain. With configurations like endless slings, double-leg, and single-leg options, they can adjust to a variety of lifting situations.

Shackles: U-shaped connections with bolts or pins holding the opening secure, shackles are strong connectors. Shackles with bolt-type, round-pin, and screw-pin designs provide unique benefits and safe attachment locations for rigging elements.

Hooks: Hooks serve as a link between the loads that rigging equipment lifts and itself. They are essential links in the rigging chain, with alternatives like eye hooks, clevis hooks, and grab hooks, each suited to particular load capabilities and attachment requirements.

Hardware for Rigging: Turnbuckles, wire rope clips, thimbles, and swivels are the parts of hardware needed to put together and modify rigging arrangements. These elements are essential for preserving load stability and enabling efficient lifting operations.

Uses for Rigging Supplies and Equipment

A wide range of businesses and endeavors employ rigging equipment, including:

Construction: To lift and move heavy machines, steel beams, and concrete panels, construction sites mostly depend on rigging equipment. The skyline is dominated by cranes with rigging gear, guaranteeing the secure lifting of cargo to the desired heights.

Shipping and marine: Rigging equipment is essential to marine operations because it makes it easier to load and unload cargo, secure containers for transportation, and perform repairs on board ships. Everywhere in the world, ports and shipyards depend on rigging gear to remain operational.

Entertainment Industry: The elaborate setups of stage lighting, sound equipment, and scenery for plays, concerts, and live events are made possible by Rigging Equipment and Rigging Supplies, which takes center stage in this sector. Prioritizing safety, motorized hoists, truss systems, and rigging accessories turn imaginative ideas into real experiences.

Manufacturing: To move large machines, parts, and completed goods along assembly lines, manufacturing facilities need rigging equipment. Rigging gear-equipped overhead cranes optimize industrial operations, increasing productivity and workspace utilization.

Safety Factors to Take Into Account When Rigging

Safety is the cornerstone of rigging operations, and there are strict procedures in place to guard against mishaps and safeguard people and property. Important safety factors consist of:

Training: Employees who operate rigging equipment safely receive in-depth instruction on a variety of subjects, including hazard identification, load calculations, and rigging procedures.

Inspection: Rigging equipment is routinely inspected to look for indications of fatigue, damage, or wear. To preserve operational integrity, any compromised equipment is quickly removed from service and replaced.

Load Capacity: To guarantee safe lifting operations, rigging equipment is never subjected to loads more than its rated capacity. Load weights are precisely calculated.

Secure Connections: To reduce the possibility of load shifting or detaching during lifting, rigging components are firmly fastened to loads using the proper hooks, shackles, and slings.

Selecting Appropriate Rigging Equipment

When choosing the right rigging equipment, it's important to take a number of things into account, such as:

Load Requirements: Choosing rigging equipment with the right capacity and configurations is influenced by the load's weight, size, and center of gravity.

Environmental Conditions: The choice of materials and coatings for increased durability is influenced by environmental factors such as temperature, humidity, and exposure to corrosive substances.

Application-Specific Needs: Optimizing performance and safety through the customisation of rigging equipment to meet specific needs such as clearance height, reach, and maneuverability is important.

Compliance with Standards: In order to guarantee adherence to strict safety standards, rigging equipment conforms with industry standards and laws, such as those outlined by agencies like OSHA (Occupational Safety and Health Administration).

In summary

For companies that depend on the secure and effective handling of large weights, rigging supplies and equipment are essential. Organizations may increase productivity, reduce risks, and promote a safety culture in rigging operations by being aware of the many kinds of rigging gear, following safety procedures, and choosing the right equipment for given applications. Investing in top-notch rigging equipment guarantees seamless operations and protects the safety of people and property alike, whether it's on a busy construction site, a busy shipping dock, or an enthralling concert stage.

0 notes

Text

What is Rigging Equipment?

Need rigging equipment and rigging supplies? Check out Bishop Lifting for the best prices where you can buy online easy and shipped directly to you.

1 note

·

View note

Text

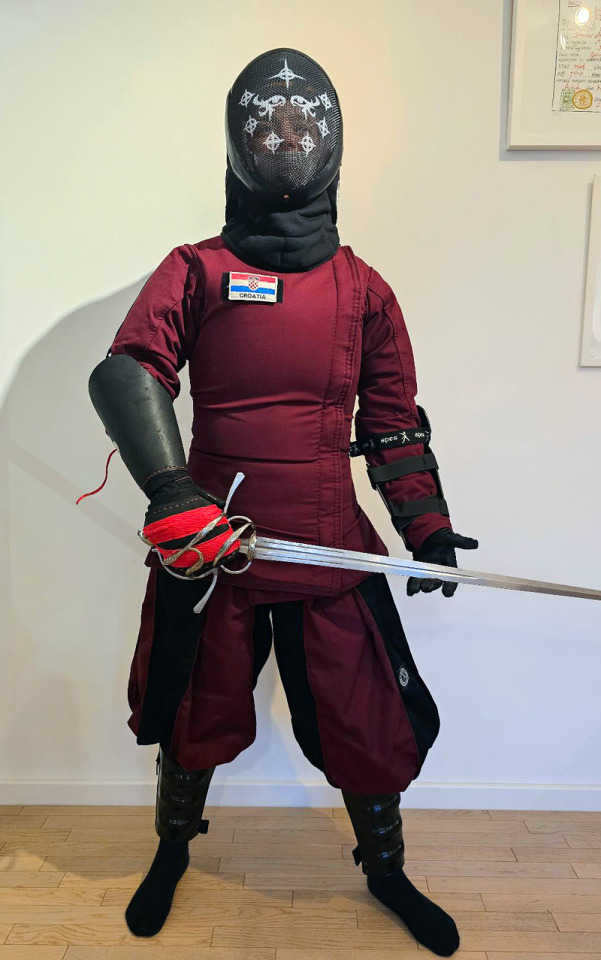

Break is over, sword season is on, let's goooooo.

#i wish i was approximately dame aylin sized#and there was hema equipment that actually fit me#without extensive customisation and jury-rigging#and everyone in sparring didn't have extreme reach advantage#ah......... the dream#instead i'm just very small and angry i guess#hema#swords#swash#c'est moi#why must beekeepers fight???

46 notes

·

View notes

Text

You know what? Now that I know I'm not the only one, I kind of want to see how this poll pans out....

#if you've beat it.... please teach me your ways because from where I stand this stage is freaking rigged lol#and if you havent beat it... join the dang club lol#feel free to tag/comment how long you've been stuck or what your strategy has been#love and deepspace#love and deepspace polls#seriously tho? how tf did i just beat a level 65 Ice trial boss with no memories over level 50...#but i can't beat a level 58 boss with 2 memories over 67 and the rest 50-55 range with enough protocores equipped to blow up a planet.#its been 4 fkin weeks send help 😭😭🤬😡

21 notes

·

View notes

Text

maybe i should start streaming viddy games

#i have like. all the equipment#my rig is powerful enough#I've got a good mic#and a whole ass stream deck#i just need to set everything up

3 notes

·

View notes

Text

me at my old job asking people why they were working in the dark vs me not turning lights on in my apartment unless absolutely necessary (or if maintenance comes by and turns on a light while they work)

#telomirage.txt#to be fair usually I would be talking to coworkers who had windows but didn't turn lights on during storms or after the sun set#and it was dark outside and inside unless someone was moving out in the hallway#also it was dim pretty much everywhere for product photosensitivity reasons so if you were in an area that COULD be brighter…why not 😂#sometimes D and I would go stand in M's office because she had a window#and then we'd get to see the sun#the one time D and I tried working in the dark was not by choice#he had to rig up an old inspection table lamp and I had to give up because it was way too dark#and there wasn't a brightness setting on my computer that was dim enough to not hurt 😅#they'd cut the lights in our hallway in the middle of the building to work on some equipment on the lines#because those were connected. somehow#and we were like well. very little work to do today I guess#I was thinking about this while waiting for maintenance to maybe come by (they did not)

3 notes

·

View notes

Text

EEAAYAAAH COUGHING AND WHEEZING AND SHAKIGN

Why is it so HARD to get technology set UP this is REDICULOUD I JUST WANNA ANIMAATE,💥💥💥

#ruckis borks#I was lucky enough to recieve a professional tablet that was SUPPOSED to work w my device#it does not work with my device#😔#truth be told im overdue for a new laptop but they so spensive...#so I have to wait longer and hope that whatever I get runs flipaclop#but I will be looking into programs that have puppet rigging. i cant do frame by frame anymore I have the patience of a wasp in a jar#going feral#light vent??? idk Im just a *little* frustrated abt the whole situation#I have so many things I want to animate and none of the right equipment

2 notes

·

View notes

Text

Types of Rigging Equipment

Rigging equipment includes essential tools for lifting and moving heavy loads. Wire rope slings offer flexibility and durability, while shackles provide versatile connectors for secure attachments. Spreader bars contribute to load stability by distributing weight evenly, enhancing overall safety in rigging operations.

0 notes

Text

Elevate Your Lifting Operations: Unveiling the Power of Chain Pulley Blocks with SVIBO Industries

Introduction: In industries and construction sites where heavy lifting is a routine necessity, having a dependable lifting solution is paramount. Chain pulley blocks, also known as chain hoists or chain blocks, are versatile and robust tools designed to tackle a variety of lifting tasks efficiently and safely. At SVIBO Industries, we pride ourselves on offering top-quality lifting solutions tailored to meet the diverse needs of our customers. Join us as we explore the key features and benefits of chain pulley blocks and discover how they can elevate your lifting operations to new heights.

Heavy-Duty Construction: At SVIBO Industries, we understand the importance of durability and reliability in lifting equipment. That's why our chain pulley blocks are constructed with a sturdy steel housing, housing a reliable lifting mechanism. This robust construction enables them to handle heavy loads effortlessly, making them ideal for demanding industrial applications. Whether it's in manufacturing facilities, warehouses, or construction sites, our chain pulley blocks are built to withstand the rigors of heavy lifting.

Versatility in Lifting Capacity: One of the standout features of SVIBO chain pulley blocks is their ability to cater to a wide range of lifting requirements. Available in various lifting capacities, our pulley blocks can hoist loads ranging from a few hundred kilograms to several tons. This versatility makes them suitable for a myriad of lifting tasks, from light-duty operations to heavy industrial lifting applications.

Smooth and Controlled Operation: At SVIBO Industries, we prioritize precision and control in lifting operations. Our chain pulley blocks employ a sophisticated system of gears and pulleys to ensure smooth and controlled lifting and lowering of loads. The chain mechanism enables precise load positioning, allowing operators to handle heavy objects with ease and precision. Whether lifting machinery, equipment, or construction materials, our chain pulley blocks offer unparalleled control and maneuverability.

Ease of Use and Portability: We understand that ease of use and portability are essential factors in selecting lifting equipment. That's why our chain pulley blocks are designed with user convenience in mind. Featuring ergonomic handles for comfortable operation and a compact size for easy transport and maneuverability, our pulley blocks are ready to deliver reliable lifting performance whenever and wherever needed.

Conclusion: At SVIBO Industries, we're dedicated to providing top-quality lifting solutions that meet the needs of our customers. With our heavy-duty construction, versatile lifting capacities, smooth operation, and user-friendly design, our chain pulley blocks are indispensable assets for industries and construction sites alike. Elevate your lifting operations with SVIBO Industries and experience the power of our chain pulley blocks today.

Contact SVIBO Industries at 8208803755 or visit https://sviboindustries.in/ to learn more about our chain pulley blocks and other lifting solutions.

0 notes

Photo

Mining Raise Bore Drilling with Laxyo Energy

Laxyo Energy Limited is a mining raise bore drilling company based in India. They specialize in providing RBM drilling services to the mining and metals industry. They expert in providing drilling services to the region.

For more Info please visit our website: http://www.laxyo.com/raise-boring-contractors.php

Contact us at: +91-9425103444, +91-731-4043798

Email: [email protected]

#Mining Raise Bore Drilling#Raise Boring machines & equipment#Raise and shaft drilling#Raise Boring Rigs shafts#Raise bore mining method#Raise boring technique#raise boring reaming#Raise bore mining#raise bore drilling jobs#raise bore equipment#underground boring contractors#raise bore job#Raise boring equipment

2 notes

·

View notes

Text

#𝐄𝐎𝐒𝐇 - 𝗨𝗞 𝗟𝗶𝗳𝘁𝗶𝗻𝗴 & 𝗥𝗶𝗴𝗴𝗶𝗻𝗴 𝐂𝐨𝐮𝐫𝐬𝐞𝐬#Award in Equipment Safety Inspection#Award in Flagman Safety Training#Award in Lifting & Rigging Supervisor#Award in Lifting Supervisor#Award in Train The Trainer - Lifting & Rigging#Level 2 - Award in Lifting & Rigging Safety#Level 2- Award in Basic Rigger and Signalman#Level 3 - Award in Lifting & Rigging Safety#Level 3- Award in Principles of Rigger and Signalman#Level 4- Award in Advanced Rigger and Signalman#Contact Us:#Mob:#+919787872866#Email:#[email protected]#Web:#www.cosmostrg.com#WhatsApp Channel :#https://whatsapp.com/channel/0029VaHMYayGufJ45OH4Xo1n#WhatsApp Group :#https://chat.whatsapp.com/IunhDueyuLsEPc9SkB7dlK#eoshcourses#eoshcourse#eosh#eoshuk#lifting#rigging#flagmen#flagmansafety

0 notes

Text

Check out this great blog on optimizing your chest rig setup for any adventure. Learn how to choose the right gear, organize it efficiently, and enhance your performance in the field. Don't miss these essential tips!💯

0 notes