#RTD Thermocouple

Explore tagged Tumblr posts

Text

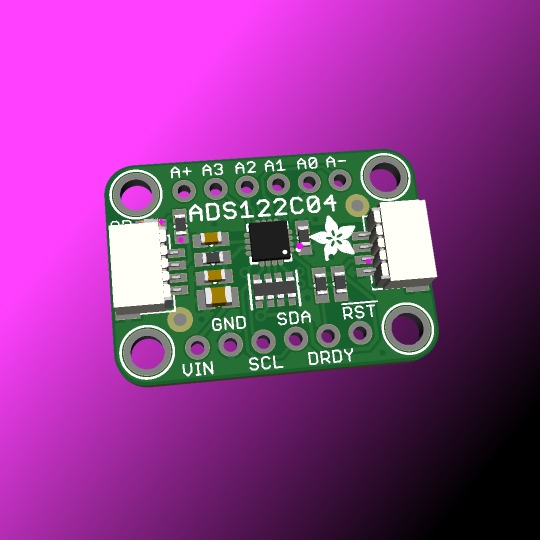

We stock and use a couple of different I2C ADCs, such as the NAU7802

and the HX711

Both of these are kinda designed specifically for load cells. This is a more general-purpose 24-bit ADC using the ADS122C04

with adjustable 1x to 128x gain, up to 2ksps and an internal reference. It can be single or differential input. Good for sensitive things like RTDs, thermocouples, or resistive bridges like load cells! Coming soon.

#adafruit#ADS112C04#24bit#4channel#i2c#adc#NAU7802#loadcells#ti#texasinstruments#rtd#thermocouples#24bitadc#analogtodigital#electronicsdesign#sensormeasurement#embeddedhardware#differentialinput#internalreference#gaincontrol#highresolution#texasinstrumentsadc#sensorinterface#loadcellapplications#precisionelectronics#thermocouplesupport#rtddesign#adcdesign#i2cinterface#resistivebridges

12 notes

·

View notes

Text

Thermocouples vs. RTDs: Which Is the Ideal One for Your Industrial Application?

In the context of temperature measurements, choosing an ideal sensor could considerably impact the accuracy & reliability of your industrial data. The 2 most commonly used sensors in this regard happen to be thermocouples & RTDs or resistance-temperature-detectors. What more?

Read our article to know more.

Looking to purchase different types of Heating Sensors ?

Call Heatcon Sensors on 098442 33244 to start a discussion and place your order. Heatcon Sensors have been manufacturing reliable, accurate and long lasting thermocouples, RTD & Cartridge Heaters with customizations to suit a particular business' needs for more than 35 years.

#heatconsensorspvtltd#calibration#thermocouples#RTD#Accuracy#pharmaceutical#foodindustry#precise#heatingsensors

1 note

·

View note

Text

RK Temp Sensor are one of the leading thermowell manufacturers in Chennai. We offer a wide range of thermowell products and services.

1 note

·

View note

Text

Measuring Temperature through Electrical Properties

There are three common temperature sensors that rely on the electronic properties of materials to determine temperature.

The first are thermocouples. Thermocouples measure temperature based on the Seebeck effect. When a temperature difference exists between two connected and dissimilar (electrically conductive) metals, charge will flow from the warm end to the cool end, creating a voltage that is used to calculate the temperature. There are multiple types of thermocouples, including thermocouple probes and wires, and multiple materials that are used for these sensors. Commercial thermocouples are fairly inexpensive but may not be accurate to more than a degree or so.

The term thermistors, the second type of sensor, comes from thermal resistor. These are semiconducting resistors, whereas the resistance of the material is strongly dependent on temperature. There are two general types of thermistors, negative-temperature-coefficient (NTC) thermistors and positive-temperature-coefficient (PTC) thermistors, which have either less or more resistance at higher temperatures, respectively. These sensors are typically highly accurate, but have a limited range.

Finally, resistance temperature detectors (RTDs) also use electrical resistance to measure temperature, but whereas thermistors use semiconductors, RTDs use pure metals. Platinum, copper, and nickel wires are common choices and RTDs are typically produced in 2-, 3-, or 4-wire configurations, where the 4-wire varieties have the highest accuracy.

Sources/Further Reading: (Image source - MadgeTech) Thermocouples: (Omega, Wikipedia); Thermistors: (Omega, Wikipedia); RTDs: (Electrical4U, Wikipedia)

12 notes

·

View notes

Text

From Sensors To Systems: The Evolution Of Industrial Measurement

Industrial measurement plays a crucial role in manufacturing, engineering, and various industrial processes. Over time, measurement technologies have evolved from basic mechanical tools to sophisticated digital systems, improving accuracy, efficiency, and automation. This blog explores the evolution of industrial measurement, highlighting key advancements and their impact on different industries.

Early Mechanical Measurement Tools

Before modern technology, industrial measurement relied on mechanical tools such as calipers, micrometers, and dial indicators. These instruments provided accurate readings for dimensions, tolerances, and alignments in manufacturing and engineering applications. However, they required skilled operators and were subject to human error, limiting their precision and repeatability.

The Rise of Electronic Sensors

The introduction of electronic sensors marked a significant leap in industrial measurement. Sensors enabled real-time data collection and improved precision across various applications. Some key developments include:

Temperature Sensors – Devices like thermocouples and resistance temperature detectors (RTDs) allowed for accurate temperature monitoring in industrial environments.

Pressure Sensors – Strain gauges and piezoelectric sensors provided reliable pressure measurements for applications such as hydraulic systems and process control.

Flow Meters – Technologies like ultrasonic and electromagnetic flow meters enhanced liquid and gas flow monitoring in industries such as chemical processing and water treatment.

These sensors improved efficiency by automating data collection, reducing manual errors, and enabling better process control.

Integration of Digital Measurement Systems

As industries adopted automation, digital measurement systems became essential for real-time monitoring and data analysis. Digital measurement instruments combined sensors with microprocessors, enabling enhanced data processing, storage, and communication. Some major advancements include:

Laser Measurement Systems – Non-contact laser sensors provided highly precise measurements for quality control, material thickness, and alignment in manufacturing.

Coordinate Measuring Machines (CMMs) – Used in precision engineering, CMMs allowed for detailed three-dimensional measurements of complex parts.

Automated Vision Systems – High-speed cameras and image-processing software enabled real-time inspection of products, improving quality assurance and defect detection.

Digital measurement systems offered higher accuracy, reduced waste, and improved overall productivity in industrial applications.

Smart Measurement and Industry 4.0

With the rise of Industry 4.0, industrial measurement has evolved into interconnected, intelligent systems. Smart measurement technologies integrate IoT (Internet of Things), AI (Artificial Intelligence), and cloud computing to provide predictive insights and automated decision-making. Some key features include:

Wireless Sensors – Eliminating the need for wired connections, these sensors enhance flexibility and remote monitoring capabilities.

Big Data Analytics – Advanced software analyzes vast amounts of measurement data, identifying trends and optimizing processes.

Predictive Maintenance – Smart measurement systems detect anomalies and predict equipment failures, reducing downtime and maintenance costs.

These advancements continue to revolutionize industrial measurement, making processes more efficient, accurate, and automated.

The evolution of industrial measurement from mechanical tools to smart systems has significantly improved accuracy, efficiency, and automation. As technology continues to advance, future measurement solutions will further enhance industrial processes, ensuring higher productivity and precision across various industries.

0 notes

Text

Temperature Sensor Market Key Trends, New Opportunities, Analysis And Sales Revenue 2025-2032

The temperature sensor market is witnessing robust growth, fueled by increasing demand across various industries such as automotive, healthcare, industrial automation, and consumer electronics. Temperature sensors are essential for monitoring and controlling temperature in critical applications, driving the adoption of advanced technologies and ensuring efficient operations.

According to SkyQuest’s latest market research, Temperature Sensor Market size is poised to grow at a CAGR of 5.6% by 2032, driven by technological advancements, the rise of automation, and the increasing adoption of smart devices.

Request a sample of the report here: https://www.skyquestt.com/sample-request/temperature-sensor-market

Market Overview: The Expanding Role of Temperature Sensors

Temperature sensors are devices that detect and measure temperature changes, playing a pivotal role in a wide range of industries. With applications spanning from manufacturing to healthcare, these sensors help optimize performance, improve safety, and enhance efficiency.

The demand for temperature sensors is increasing as industries continue to prioritize automation, precision, and monitoring of environmental conditions. From industrial machines to consumer electronics, temperature sensors ensure that systems operate within their optimal thermal conditions.

Key Market Drivers

Rising Demand from Automotive & Industrial Automation The automotive industry relies heavily on temperature sensors for engine management, climate control, and battery monitoring in electric vehicles (EVs). Similarly, temperature sensors are critical in industrial automation processes to maintain optimal operating conditions in factories and manufacturing plants.

Healthcare Applications With the rise of wearable medical devices and the need for accurate monitoring of patient temperature, the healthcare sector is increasingly incorporating advanced temperature sensors to improve diagnostics, patient care, and medical equipment performance.

Advancements in IoT and Smart Devices The growing adoption of the Internet of Things (IoT) and smart home devices is driving demand for temperature sensors in applications like smart thermostats, temperature control systems, and HVAC solutions.

Technological Innovations in Sensor Design Advancements in temperature sensor technology, such as miniaturization, wireless communication, and improved accuracy, are boosting the market’s growth by making sensors more versatile, reliable, and cost-effective.

Speak with an analyst for more insights on industry trends: https://www.skyquestt.com/speak-with-analyst/temperature-sensor-market

Market Segmentation

By Sensor Type

Thermocouples – Dominating due to their wide temperature range and versatility across various applications.

RTDs (Resistance Temperature Detectors) – Known for their accuracy and stability, ideal for precision applications.

Thermistors – Common in consumer electronics due to their sensitivity and cost-effectiveness.

Semiconductor-Based Sensors – Gaining popularity in small-scale electronics and integrated circuits.

By Application

Automotive – Used in engine monitoring, battery temperature regulation in EVs, and climate control systems.

Healthcare – Crucial for temperature monitoring in medical devices, wearables, and diagnostic equipment.

Industrial Automation – Integral to manufacturing processes, equipment monitoring, and machine efficiency.

Consumer Electronics – Employed in devices like smartphones, computers, and household appliances.

Food & Beverage – Essential for temperature control in production and storage to ensure product quality and safety.

HVAC Systems – Ensures optimal heating, ventilation, and air conditioning for comfort and energy efficiency.

Regional Insights

North America: Leading the Temperature Sensor Market The United States and Canada are at the forefront, driven by robust industries in automotive, healthcare, and industrial automation. Increased demand for electric vehicles and smart technologies are major factors contributing to the market’s growth in the region.

Europe: Technological Advancements & Sustainability Focus Europe’s growing emphasis on sustainability and energy-efficient technologies has driven the demand for temperature sensors in renewable energy, HVAC, and automotive applications. Countries like Germany, the UK, and France are key players in this market.

Asia-Pacific: Rapid Growth in Automotive & Industrial Sectors China, Japan, and India are rapidly adopting advanced sensor technologies, especially in automotive, industrial, and consumer electronics sectors. The rise of electric vehicles and automation is accelerating the market in this region.

Latin America & Middle East: Emerging Market Potential Countries in Latin America and the Middle East are witnessing growing demand for temperature sensors in energy, construction, and manufacturing sectors, presenting new market opportunities.

For a detailed market analysis and strategic insights, explore the full SkyQuest report:

Top Companies in the Temperature Sensor Market

Leading companies in the temperature sensor industry are focused on research and development, expanding their product offerings, and advancing manufacturing processes to maintain a competitive edge:

Honeywell International Inc.

Siemens AG

TE Connectivity Ltd.

Texas Instruments Inc.

Emerson Electric Co.

Analog Devices, Inc.

ABB Ltd.

Bosch Sensortec

STMicroelectronics

NXP Semiconductors

Emerging Trends in the Temperature Sensor Market

Wireless and IoT-enabled Sensors The integration of wireless connectivity in temperature sensors is transforming the market, enabling remote monitoring, real-time data collection, and predictive maintenance in industrial and consumer applications.

Miniaturization and Integration with Smart Devices The demand for smaller, more integrated sensors in wearables, portable medical devices, and consumer electronics is growing. Miniaturization allows for easier integration into smaller systems without compromising performance.

Self-Calibration and Enhanced Accuracy Advances in self-calibration technologies are allowing temperature sensors to maintain higher accuracy and reduce manual recalibration, ensuring reliability in critical applications like healthcare and automotive.

AI and Data Analytics in Temperature Monitoring Artificial intelligence and data analytics are being applied to temperature sensor systems to optimize energy consumption, improve predictive maintenance, and enhance system performance.

The temperature sensor market is poised for rapid growth as technological advancements continue to shape the demand for more efficient, accurate, and cost-effective sensors. With industries increasingly prioritizing automation, sustainability, and IoT connectivity, the market for temperature sensors is expanding across various sectors, from automotive to healthcare.

Companies focusing on innovation, miniaturization, wireless integration, and sustainability will find themselves at the forefront of this rapidly evolving market.

#Asia Temperature Sensor Market#Europe Temperature Sensor Market#Middle East Temperature Sensor Market Size#North America Temperature Sensor Market

0 notes

Text

Unlock Precision with Multipoint RTDs: Thermal Instrument's Reliable Temperature Measurement Solutions

When it comes to accurate temperature measurement in complex industrial processes, especially in reactors with multiple temperature zones, Thermal Instrument’s Multipoint RTDs stand as the global leader in reliable and cost-effective solutions.

What Makes Multipoint RTDs Indispensable?

In environments where space is limited, and cost is a critical factor, multipoint RTDs become essential. These advanced instruments allow for precise temperature control and monitoring across various elevations within a reactor, ensuring efficiency and consistency in processes.

A multipoint RTD features measuring junctions at multiple immersion depths, tailored to specific industrial needs. With nearly limitless variations in design, these instruments are manufactured with precision to meet the unique requirements of diverse applications.

Features That Set Multipoint RTDs Apart:

Customized Solutions: Fully tailored to your specific application needs.

Space Efficiency: Ideal for applications with space limitations.

Cost-Effectiveness: Reduces expenses while enhancing functionality.

Versatile Design: Can be constructed to practically any length.

Proven Reliability: Backed by a strong track record across industries.

Ease of Maintenance: Construction allows for thermocouple removal for maintenance.

Material Options: Compatible with various thermocouples and materials of construction (MOC).

Routine Tests for Quality Assurance:

To guarantee reliability and precision, each Multipoint RTD undergoes rigorous testing, which includes : Accuracy/Calibration Test

Nitrogen Leakage Test (Weld Closure Conformity)

Insulation Resistance Test

Thermal Response Time Test

Continuity Test

Dimension Checks

Helium Leakage Test

Pneumatic Leakage Test

Hydro Test

Dye Penetration (LPT) Test

Radiography Test

Your Trusted Partner in Temperature Measurement

With decades of experience and a commitment to innovation, Thermal Instrument has become synonymous with excellence in process control instrumentation. Our multipoint RTDs have been trusted by industries worldwide, ensuring reliable performance in even the most demanding environments.

Take the Next Step Toward Precision

Are you ready to elevate your temperature measurement systems? Trust Thermal Instrument, the leader in multipoint RTD manufacturing, for solutions tailored to your needs.

Contact us today to explore how our multipoint RTDs can revolutionize your process control!

Visit us at https://thermalinstrument.net/ to learn more.

1 note

·

View note

Text

Tempcon Instrumentation

Tempcon Instrumentation

Tempcon Instrumentation Ltd was established in 1980; we specialise in Instrumentation and sensors (probes) for Measuring, Controlling and Logging: temperature, humidity, pressure, water level, water temperature, Air Quality/CO2, voltage, current, energy (kWh), wind speed/direction, and most other parameters required for process control, environmental research, or quality control.

Why should you do business with us?

Put simply, we will make your life easier! Our company has thrived because we are very good at working with our customers in developing solutions that deliver what they need.

We don’t just offer a catalogue of technical products; our specialists know how to integrate the technologies and systems that we provide in order to deliver what you need.

We are a trusted supplier to thousands of organisations throughout the UK and beyond – including 120 UK universities, British Antarctica Study teams, Formula One teams and Premier League football clubs – and we’d love to help you too!

What do we do?

We offer a huge range of Data Loggers, Energy Loggers, Weather Stations, Digital Thermometers, Process Controllers, Panel Indicators, Signal Conditioners, Chart Recorders,Temperature Probes/Sensors for use in environmental monitoring, manufacturing, food processing, logistics, university research projects, and more.

We manufacture: Thermocouple, Thermistor, and Platinum Resistance RTD, PT100, PT1000, temperature sensors and probes in any quantity.

Tempcon are appointed UK and Ireland distributors for world-leading brands including Onset and Davis. Interested in becoming a Reseller?

We also provide temperature and humidity calibration services using equipment calibrated and traceable to UKAS.

How do we do it? By working with you to determine what you need. Although many people are happy to buy direct from our website, you should be aware that it only represents a fraction of the technology available to you. This is especially true of our temperature sensors, if you can’t see the type of sensor you want then call us; we may have what you need but haven’t listed it on our website and if we don’t we are always happy to quote for a custom build.

Whether you are purchasing or specifying components as part of a system, or just want reassurance that the products you believe you need are the right ones, then contact us and one of our specialists will be happy to advise you.

You can be assured of quality from us and our Quality System is accredited to BS EN 9001:2015 by National Quality Audits.

contact us

Tempcon Instrumentation https://www.tempcon.co.uk/ Address: Ford Lane Business Park Ford, West Sussex BN18 0UZ, UK Phone: 01243 558270

Twitter

Facebook

LinkedIn

1 note

·

View note

Text

Cảm biến nhiệt độ là gì? Nguyên lý hoạt động và các loại phổ biến

Cảm biến nhiệt độ là một thiết bị điện tử dùng để đo sự biến đổi nhiệt độ của các đại lượng. Khi nhiệt độ thay đổi, cảm biến phát ra tín hiệu và truyền về bộ đọc, giúp chúng ta biết chính xác nhiệt độ. Thiết bị này ngày càng phổ biến, đặc biệt trong công nghiệp thực phẩm, hóa chất, y tế, hàng hải hay ô tô, nhờ khả năng đo chính xác và nhanh hơn so với nhiệt kế truyền thống.

Ứng dụng của cảm biến nhiệt độ trong đời sống

Trong y tế: Cảm biến nhiệt độ được tích hợp trong nhiệt kế điện tử giúp đo thân nhiệt nhanh chóng và chính xác, hỗ trợ bác sĩ chẩn đoán bệnh hiệu quả.

Trong công nghiệp: Thiết bị này giúp kiểm soát nhiệt độ trong sản xuất thực phẩm, dược phẩm, luyện kim, đảm bảo chất lượng sản phẩm và an toàn cho công nhân.

Trong vận chuyển: Cảm biến giúp giám sát nhiệt độ trong container hay xe tải, bảo quản chất lượng hàng hóa.

Trong nhà ở: Được dùng trong điều hòa, lò sưởi để đo và điều chỉnh nhiệt độ phòng, mang lại sự thoải mái và tiết kiệm năng lượng.

Trong nước và hóa chất: Cảm biến đo nhiệt độ nước trong bồn, nồi nấu phở hoặc các dung dịch đặc biệt khác.

Cấu tạo và nguyên lý hoạt động của cảm biến nhiệt độ

Cảm biến nhiệt độ gồm các bộ phận chính:

Bộ phận cảm biến: Quyết định độ chính xác của phép đo.

Dây kết nối: Loại 4 dây cho độ chính xác cao nhất, trong khi loại 2 dây có độ chính xác thấp hơn.

Vỏ bảo vệ và phụ chất làm đầy: Bảo vệ bộ cảm biến khỏi va đập, rung động.

Chất cách điện: Phòng ngừa đoản mạch và tăng an toàn.

Nguyên lý hoạt động của cảm biến dựa trên sự thay đổi điện trở của kim loại theo nhiệt độ. Khi nhiệt độ thay đổi, điện trở cũng thay đổi và được chuyển thành tín hiệu điện để hiển thị nhiệt độ cụ thể.

Các loại cảm biến nhiệt độ phổ biến

Cảm biến nhiệt điện (thermocouple): Giá rẻ, tuổi thọ cao, đo nhiệt từ -100°C đến 1800°C.

Cảm biến điện trở (RTD): Chính xác, thường dùng trong công nghiệp, phổ biến nhất là loại Pt100.

Cảm biến nhiệt kế: Đo nhiệt độ chất rắn, lỏng hoặc kh�� bằng sự giãn nở của thủy ngân hoặc rượu trong ống thủy tinh.

Cảm biến nhiệt độ là thiết bị không thể thiếu trong nhiều lĩnh vực. Với ưu điểm vượt trội về độ chính xác và khả năng ứng dụng rộng rãi, nó đang dần trở thành một phần quan trọng trong đời sống và công nghiệp. Nếu bạn cần thêm thông tin, hãy liên hệ với VoHoang.vn để được tư vấn chi tiết.

Tìm hiểu thêm: https://vohoang.vn/cam-bien-nhiet-do-la-gi

1 note

·

View note

Text

0 notes

Text

0 notes

Text

Your Trusted Partner for K-Type Thermocouples

The K-type thermocouple is one of the most widely used temperature sensors, known for its reliability and versatility. Constructed from a combination of nickel-chromium (positive leg) and nickel-aluminum (negative leg) alloys, it operates effectively across a broad temperature range, from -200°C to 1,260°C (-328°F to 2,300°F). Its linear output and consistent accuracy make it a preferred choice in industries like aerospace, automotive, and manufacturing. Due to its durability, the K-type thermocouple is ideal for high-temperature environments and applications involving oxidizing or inert atmospheres. Additionally, it boasts a long lifespan, making it a cost-effective solution for monitoring extreme conditions.

Pelican Wire: Your Trusted Partner for K-Type Thermocouples At Pelican Wire, we specialize in providing top-quality resistance and K type thermocouple wires, including K-type thermocouples. Our products are crafted to meet the highest standards, ensuring precise and dependable performance. Whether you're monitoring industrial furnaces or conducting laboratory experiments, Pelican Wire’s K-type thermocouples deliver accurate readings and unmatched reliability. With years of expertise, we understand the critical role temperature measurement plays in various applications and are committed to offering solutions tailored to your needs. Trust Pelican Wire for all your K-type thermocouple and resistance heating wire requirements, and experience excellence in every product. Visit Now: https://pelicanwire.com/product-category/thermocouple-rtd/insulated-thermocouple

0 notes

Text

Industrial Sensors: The Core of Modern Automation Systems

In today’s highly automated industrial landscape, the role of sensors cannot be overstated. Industrial sensors are the key components that collect critical data to monitor, control, and optimize industrial processes. From manufacturing to energy production, sensors are integral in ensuring the efficiency, safety, and precision of operations. As industries advance, the demand for high-quality sensors has grown exponentially. In India, sensor manufacturers are playing a vital role in meeting this demand, providing solutions that cater to diverse industrial needs.

What Are Industrial Sensors?

Industrial sensors are devices designed to detect variations in the physical environment and translate them into signals for processing by controllers or monitoring systems. These sensors are engineered to measure various parameters, including temperature, pressure, humidity, flow, proximity, and vibration. By converting physical changes into measurable data, they provide real-time insights into machine performance, environmental conditions, and overall system functionality.

Types of Industrial Sensors

The diversity of industrial applications requires a wide range of sensors, each designed to measure specific variables:

Temperature Sensors: Temperature sensors, including thermocouples and RTDs (Resistance Temperature Detectors), are widely used in industrial environments to measure the temperature of machinery, fluids, and gases. These sensors ensure that equipment operates within safe temperature ranges, preventing overheating and failure.

Pressure Sensors: Pressure sensors are crucial in industries where fluid dynamics are involved, such as oil and gas, water treatment, and manufacturing. These sensors detect the pressure of gases or liquids, ensuring systems remain under optimal pressure levels for efficiency and safety.

Flow Sensors: Flow sensors measure the speed at which fluid or gas moves through pipelines.Industries like chemical manufacturing and pharmaceuticals rely on these sensors to maintain consistent flow rates, which is critical for maintaining quality and consistency in production.

Proximity Sensors: Proximity sensors identify the presence or absence of objects without making physical contact.These sensors are often used in automation systems to detect the position of parts on assembly lines or the proximity of tools to workpieces in robotic systems.

Vibration Sensors: Vibration sensors are essential in predictive maintenance applications. They monitor the vibrations of machinery and equipment, alerting operators to potential issues before they result in costly breakdowns.

Applications of Industrial Sensors

Industrial sensors are employed in a wide range of industries, such as manufacturing, energy, automotive, and pharmaceuticals.Their applications are broad and encompass several critical tasks, such as:

Process Monitoring and Control: Sensors ensure that industrial processes are running within designated parameters. For example, in a chemical plant, temperature and pressure sensors monitor reactors, providing real-time data for efficient control of reactions.

Predictive Maintenance: Vibration and temperature sensors help predict equipment failure by monitoring mechanical wear and tear, allowing for preventive maintenance to be performed before failure occurs.

Safety and Compliance: Industrial sensors play a crucial role in ensuring workplace safety and regulatory compliance. Gas sensors, for instance, detect dangerous leaks in industries like oil and gas, preventing hazardous situations from escalating.

Energy Management: Sensors are also used for energy management, helping industries monitor energy usage and optimize consumption to reduce costs and environmental impact.

Why Choose Sensor Manufacturers in India?

India's expanding industrial sector has led to a substantial increase in the demand for high-quality industrial sensors. As a hub for manufacturing, the country is home to several leading sensor manufacturers in India that produce sensors catering to both domestic and global markets. These manufacturers offer a variety of sensors designed to meet the unique needs of different industries, ranging from food processing to automotive and energy.

Indian sensor manufacturers are known for their competitive pricing, advanced technology, and high-quality products. With an increasing focus on industrial automation and smart factories, the demand for advanced sensors is expected to rise. Manufacturers in India are also investing in research and development to create sensors that meet the latest industry standards and technological advancements.

One of the key advantages of working with sensor manufacturers in India is their ability to provide customized solutions. Whether a company requires sensors for specific environmental conditions or bespoke designs for unique industrial applications, Indian manufacturers are adept at creating tailored solutions that meet the specific needs of their clients.

Moreover, the Indian government’s push toward 'Make in India' has helped bolster the local manufacturing industry, encouraging innovation in sensor technology. This initiative has also led to better collaboration between sensor manufacturers and industries, ensuring that sensors are specifically designed to handle the challenges faced by the industry.

The Future of Industrial Sensors

As industries move towards greater automation and digitalization, the role of sensors in industrial applications will only grow. Emerging technologies such as the Internet of Things (IoT), Industry 4.0, and artificial intelligence (AI) are driving the demand for more sophisticated sensors that can deliver high precision, reliability, and real-time data analysis.

The future of industrial sensors is closely linked to advances in wireless communication, miniaturization, and energy-efficient designs. With increasing reliance on data-driven decision-making, industrial sensors will continue to be the cornerstone of smart, connected factories that optimize processes, improve productivity, and ensure safety.

Conclusion

Industrial sensors play a vital role in maintaining the smooth functioning of industries. From monitoring temperatures and pressures to detecting vibrations and fluid flow, sensors provide the necessary data to optimize industrial processes. As a rapidly growing hub for manufacturing, sensor manufacturers in India are stepping up to meet the evolving demands of industries by providing innovative, reliable, and cost-effective sensor solutions. With advancements in technology and a growing focus on industrial automation, the role of industrial sensors in shaping the future of manufacturing and production is poised to become even more significant.

0 notes

Text

Bộ chuyển đổi nhiệt độ TK4L 14SN Autonics thuộc dòng TK Series, điện áp cung cấp 100 240VAC, đầu vào cảm biến Thermocouple K CA , J IC , E CR , T CC , B PR , R PR , S PR , N NN , C TT , G TT , L IC , U CC , Platinel II RTD DPt100Ω, DPt50Ω, JPt100Ω, Cu100Ω, Cu50Ω, Nikel 120Ω Analog 0 100mV, 0 5V, 1 5V, 0 10V, 0 20mA, 4 20mA, đầu ra điều khiển 1 SSR 11VDC , kiểu kết nối Bắt vít, kích thước 96x96mm, cân nặng 198g https://hoplongtech.com/products/tk4l-14sn

0 notes

Text

Calibration and verification of sensors such as RTDs (Resistance Temperature Detectors), PRTs (Platinum Resistance Thermometers), thermocouples, tri-clamp sanitary clamps, dial gauges, thermistors, and other temperature monitoring/control devices are crucial for ensuring accurate temperature readings, which are vital for many industrial processes, especially in regulated industries like pharmaceuticals.

Calibration and Verification Definition:

Calibration refers to the process of adjusting and validating the measurement accuracy of a sensor or instrument against a known standard, ensuring that the readings it provides are accurate within specified limits. Verification involves confirming that the sensor or device is functioning as intended and producing consistent and accurate readings, without necessarily adjusting its output.

Frequency of Calibration:

The frequency at which sensors are calibrated depends on several factors, including the criticality of the sensor in the process, the regulatory environment, and the performance stability of the sensor.

Standard Calibration Cycle: Many industrial applications, including those in pharmaceutical manufacturing, calibrate sensors every 3 to 6 months.

Critical Applications (e.g., Pharmaceuticals): In highly regulated industries where product quality and safety are paramount, sensors, such as RTDs used for temperature control, may be calibrated more frequently—sometimes as often as weekly or even per production batch to ensure precision and reliability.

For example, a large pharmaceutical company might calibrate their RTDs every week because even a slight deviation in temperature could impact the quality or safety of the product being manufactured.

In summary, calibration and verification are essential processes for ensuring the accuracy and reliability of temperature sensors, particularly when precise temperature control is crucial, such as in the pharmaceutical industry, where even minor temperature fluctuations can affect product quality.https://sapphire-tech.com/industries/pharmaceutical/

0 notes