#Quality Management Software Market Quality Management Software Market Quality Management Software Market Forecast

Explore tagged Tumblr posts

Text

#Quality Management Software Market#Quality Management Software Market Size#Quality Management Software Market Share#Quality Management Software Market Growth#Quality Management Software Market Trends#Quality Management Software Market Forecast#Quality Management Software Market Analysis

1 note

·

View note

Text

Boosting Efficiency: The Role of ERP Software in Modern Manufacturing Operations

In today's fast-paced manufacturing landscape, efficiency is not just a desirable trait; it's a necessity. To stay competitive and meet the demands of the market, manufacturers must streamline their processes, optimize resource utilization, and enhance decision-making capabilities. This is where Enterprise Resource Planning (ERP) software steps in as a game-changer. In this article, we'll delve into the pivotal role of ERP systems in revolutionizing manufacturing operations, particularly in India's thriving industrial sector.

Understanding ERP for Manufacturing Industry

ERP systems for manufacturing are comprehensive software solutions designed to integrate and automate core business processes such as production planning, inventory management, supply chain logistics, financial management, and human resources. By consolidating data and operations into a unified platform, ERP empowers manufacturers with real-time insights, facilitates collaboration across departments, and enables informed decision-making.

Streamlining Operations with ERP Solutions

In the dynamic environment of manufacturing, where every minute counts, efficiency gains translate directly into cost savings and competitive advantages. ERP software for manufacturing offers a multitude of features that streamline operations and drive efficiency:

1. Enhanced Production Planning: ERP systems enable manufacturers to create accurate production schedules based on demand forecasts, resource availability, and production capacity. By optimizing production timelines and minimizing idle time, manufacturers can fulfill orders promptly and reduce lead times.

2. Inventory Management: Efficient inventory management is crucial for balancing supply and demand while minimizing holding costs. ERP software provides real-time visibility into inventory levels, automates reorder points, and facilitates inventory optimization to prevent stockouts and overstock situations.

3. Supply Chain Optimization: ERP solutions for manufacturing integrate supply chain processes from procurement to distribution, enabling seamless coordination with suppliers and distributors. By optimizing procurement cycles, minimizing transportation costs, and reducing lead times, manufacturers can enhance supply chain resilience and responsiveness.

4. Quality Control: Maintaining product quality is paramount in manufacturing to uphold brand reputation and customer satisfaction. ERP systems offer quality management modules that streamline inspection processes, track product defects, and facilitate corrective actions to ensure adherence to quality standards.

5. Financial Management: Effective financial management is essential for sustaining manufacturing operations and driving profitability. ERP software provides robust accounting modules that automate financial transactions, streamline budgeting and forecasting, and generate comprehensive financial reports for informed decision-making.

6. Human Resource Management: People are the cornerstone of manufacturing operations, and managing workforce efficiently is critical for productivity and employee satisfaction. ERP systems for manufacturing include HR modules that automate payroll processing, manage employee records, and facilitate workforce planning to align staffing levels with production demands.

The Advantages of ERP for Manufacturing Companies in India

India's manufacturing sector is undergoing rapid transformation, fueled by factors such as government initiatives like "Make in India," technological advancements, and globalization. In this dynamic landscape, ERP software plays a pivotal role in empowering manufacturing companies to thrive and remain competitive:

1. Scalability: ERP solutions for manufacturing are scalable, making them suitable for companies of all sizes – from small and medium enterprises (SMEs) to large conglomerates. Whether a company is expanding its operations or diversifying its product portfolio, ERP systems can adapt to evolving business needs and support growth.

2. Compliance: Regulatory compliance is a significant concern for manufacturing companies in India, given the complex regulatory environment. ERP software incorporates compliance features that ensure adherence to industry regulations, tax laws, and reporting requirements, minimizing the risk of non-compliance penalties.

3. Localization: ERP vendors catering to the Indian manufacturing sector offer localized solutions tailored to the unique requirements of the Indian market. From multi-currency support to GST compliance features, these ERP systems are equipped with functionalities that address the specific challenges faced by Indian manufacturers.

4. Cost Efficiency: Implementing ERP software for manufacturing entails upfront investment, but the long-term benefits far outweigh the costs. By streamlining processes, optimizing resource utilization, and reducing operational inefficiencies, ERP systems drive cost savings and improve overall profitability.

5. Competitive Edge: In a fiercely competitive market, manufacturing companies in India must differentiate themselves through operational excellence and agility. ERP software equips companies with the tools and insights needed to outperform competitors, adapt to market dynamics, and capitalize on emerging opportunities.

Choosing the Right ERP Software for Manufacturing

Selecting the right ERP solution is crucial for maximizing the benefits and ensuring a smooth implementation process. When evaluating ERP software for manufacturing, companies should consider the following factors:

1. Industry-specific functionality: Choose an ERP system that offers industry-specific features and functionalities tailored to the unique requirements of manufacturing operations.

2. Scalability and flexibility: Ensure that the ERP software can scale with your business and accommodate future growth and expansion.

3. Ease of integration: Look for ERP systems that seamlessly integrate with existing software applications, such as CRM systems, MES solutions, and IoT devices, to create a cohesive technology ecosystem.

4. User-friendliness: A user-friendly interface and intuitive navigation are essential for ensuring widespread adoption and maximizing user productivity.

5. Vendor support and expertise: Select a reputable ERP vendor with a proven track record of success in the manufacturing industry and robust customer support services.

Conclusion

In conclusion, ERP software has emerged as a cornerstone of modern manufacturing operations, empowering companies to enhance efficiency, drive growth, and maintain a competitive edge in the global market. For manufacturing companies in India, where agility, scalability, and compliance are paramount, implementing the right ERP solution can be a transformative investment that paves the way for sustainable success. By harnessing the power of ERP, manufacturers can optimize processes, streamline operations, and unlock new opportunities for innovation and growth in the dynamic landscape of the manufacturing industry.

#ERP software providers in India#Manufacturing enterprise resource planning#ERP systems for manufacturing companies#ERP system for manufacturing industry#ERP for manufacturing companies#ERP software for engineering company#ERP software for engineering companies in India#ERP software for engineering companies in Mumbai#ERP solution providers in India#ERP for manufacturing industry#ERP systems for manufacturing#ERP solutions for manufacturing#ERP software manufacturing industry#ERP for manufacturing company in India#India

8 notes

·

View notes

Text

Accounting and Bookkeeping Services in Delhi by SC Bhagat & Co.

Efficient financial management is the cornerstone of any successful business. Whether you're a startup, small business, or an established enterprise, maintaining accurate financial records is essential for growth and compliance. In the bustling hub of Delhi, SC Bhagat & Co. stands out as a trusted provider of professional accounting and bookkeeping services, tailored to meet diverse business needs.

Why Choose Accounting and Bookkeeping Services in Delhi? Accounting and bookkeeping are more than just financial chores. They form the backbone of strategic decision-making, regulatory compliance, and overall business stability. Here’s why professional accounting and bookkeeping services are crucial:

Accurate Financial Records: Ensure precise tracking of all transactions and cash flows. Regulatory Compliance: Stay updated with tax laws and regulatory changes. Time Savings: Focus on your core business while experts handle the numbers. Better Financial Insights: Gain actionable insights for informed decision-making. Avoid Errors: Eliminate mistakes that can lead to penalties or financial loss. About SC Bhagat & Co. With decades of expertise, SC Bhagat & Co. has become a trusted name in Delhi for accounting and bookkeeping services. The firm is known for its reliability, professionalism, and a client-centric approach that ensures tailored solutions for businesses across industries.

Key Services Offered:

Accounting Services:

Preparation and maintenance of financial statements. Monthly and annual reporting. Budgeting and forecasting. Bookkeeping Services:

Recording daily financial transactions. Reconciliation of accounts. Payroll processing and management. Tax Compliance and Planning:

GST filing and compliance. Income tax returns and advisory. Support during audits and assessments. Financial Advisory:

Cash flow management. Profitability analysis. Strategic financial planning. Why SC Bhagat & Co. Stands Out for Accounting and Bookkeeping Services in Delhi

Experienced Professionals: A team of qualified accountants ensures top-notch service quality. Customized Solutions: Services are tailored to the specific needs of your business. Cutting-Edge Technology: Use of advanced accounting tools and software for accuracy and efficiency. Transparent Pricing: Competitive and clear pricing with no hidden charges. Client-Centric Approach: Emphasis on understanding client goals and delivering results that align with their vision. Industries We Serve SC Bhagat & Co. serves a wide range of industries, including:

Manufacturing Retail and e-commerce Real estate Healthcare IT and software Non-profit organizations Benefits of Partnering with SC Bhagat & Co. When you choose SC Bhagat & Co., you gain a partner who is invested in your success. Key benefits include:

Enhanced financial accuracy and efficiency. Assurance of compliance with all regulatory requirements. Access to real-time financial data for better decision-making. Reduction in operational costs through outsourcing. Why Delhi Businesses Trust for Accounting and Bookkeeping Services in Delhi by SC Bhagat & Co. Operating in Delhi’s dynamic business environment requires financial precision and agility. SC Bhagat & Co. has a deep understanding of the local market, tax regulations, and industry-specific challenges, making it the go-to firm for accounting and bookkeeping services in the capital. Get Started Today Simplify your financial management and focus on scaling your business by outsourcing your accounting and bookkeeping needs to SC Bhagat & Co.. Contact us today for a consultation and take the first step toward streamlined financial operations.

3 notes

·

View notes

Text

Harnessing CRM Analytics for Business Growth

Advanced analytics powered by Artificial Intelligence provides invaluable insights to any business. Integration with AI elevates the reporting capabilities of a Customer Relationship Management system. Fetching data from various points of contact results in forming comprehensive client profiles, which when analyzed provide accurate insights.

Built-in AI features allow the system to generate predictive insights about customer payments, unit bookings, site visits and more. Delivering cutting-edge solutions and insights to its clients is the realm of customer relationship management (CRM) software.

It generally consists of a comprehensive suite of services designed to help businesses leverage the full potential of their data, making data-driven decisions, identifying actionable insights, and driving more personalized customer experiences. CRM Analytics offers a range of services, providing unparalleled value through:

Data Collection

Data Analysis

Reporting

Dashboard Development

Data Visualization

Predictive Analytics

Custom reporting

Data integration

Data is the lifeblood of any business, and the goal of CRM software should be to empower clients with the tools and expertise they need to harness the power of their data for business growth and success. These insights empower companies to make informed decisions, tailor their marketing strategies, enhance customer experiences, and ultimately drive business growth.

Data-Driven Decision Making: CRM analytics transforms raw customer data into actionable insights. Businesses can use these insights to make informed decisions about product offerings, marketing campaigns, sales strategies, and customer service improvements.

Customer Understanding: By analyzing customer interactions, purchase histories, and engagement patterns, businesses can gain a deep understanding of their customers. This understanding helps in segmenting customers, identifying their needs, and tailoring products and services to better serve them.

Personalized Marketing: It enables businesses to create personalized marketing campaigns. By knowing individual preferences, purchase histories, and browsing behaviors, companies can deliver targeted and relevant messages to customers, increasing the chances of conversion.

Sales Performance Improvement: CRM analytics provides sales teams with data on lead conversions, sales cycles, and customer buying patterns. This information can help identify areas for improvement, optimize sales processes, and allocate resources more effectively.

Customer Retention and Loyalty: Understanding customer behaviors and preferences allows businesses to proactively address issues, offer personalized solutions, and foster customer loyalty. Satisfied customers are more likely to remain loyal and recommend the company to others.

Forecasting and Planning: CRM analytics can provide insights into future trends and demands by analyzing historical data. This helps businesses forecast sales, plan inventory levels, and allocate resources appropriately.

Identifying Cross-Selling and Upselling Opportunities: By analyzing customer purchasing patterns, businesses can identify opportunities for cross-selling or upselling additional products or services, increasing revenue per customer.

Monitoring Marketing Campaign Effectiveness: CRM analytics helps evaluate the success of marketing campaigns by tracking metrics such as click-through rates, conversion rates, and customer engagement. This allows for real-time adjustments and optimizations.

Improving Customer Service: By analyzing customer service interactions and feedback, businesses can identify common issues and areas for improvement. This leads to better service quality and enhanced customer satisfaction.

Competitive Advantage: Companies that effectively use CRM analytics gain a competitive edge by making data-driven decisions that are aligned with customer needs and market trends.

CRM analytics becomes an essential part of the software. It enables businesses to gain valuable insights into customer behaviors, preferences, and interactions.

2 notes

·

View notes

Text

Strengths & Weaknesses

Strengths & Weaknesses Entering the world of entrepreneurship is an exhilarating yet intimidating experience. When I think back on my own business abilities, I see both my Strengths & Weaknesses . Gaining an understanding of these can direct my professional development and success.

Strengths

Adaptability: This is one of my strongest suit. I work well in dynamic settings and modify my plans in response to fresh knowledge or evolving conditions. For instance, we ran across unforeseen software problems in college when managing a project team. I came up with a backup plan really fast to make sure we didn't sacrifice quality in order to meet our deadline.

Creative Problem-Solving: I am great at coming up with novel solutions by thinking outside the box. I created a distinctive social media campaign during my internship at a marketing company, which raised customer engagement by 30%. This experience proved that I can come up with original concepts that work.

Resilience: Being an entrepreneur comes with a lot of hurdles, and one of the main reasons I have succeeded is my resilience. I turned adversity into opportunity when my first attempt to create an e-commerce store encountered logistical difficulties. I learnt from the setbacks, improved my business plan, and successfully relaunched.

Weaknesses

Delegation: I occasionally find it difficult to assign work to others since I frequently believe that completing everything myself will produce the finest results. Nevertheless, this strategy may result in inefficiency and burnout. In order to get better, I'm concentrating on developing my team's trust and employing clear communication techniques to make sure jobs are finished efficiently.

Financial Acumen: I know the fundamentals of financial management, but I also know I can improve in areas like financial forecasting and budgeting. In order to improve my knowledge in this crucial area, I intend to enroll in online financial management classes and look for mentorship from seasoned business owners.

Networking: I find big networking gatherings scary, even if I feel at ease in small group situations. To get around this, I am establishing modest, do able objectives for every occasion, like striking up a discussion with three new individuals and then getting in touch with them later to create lasting relationships.

2 notes

·

View notes

Text

How business analytics can be used in supply chain management

Introduction:

In today's rapidly evolving business landscape, organizations across various industries face the challenge of managing complex supply chains efficiently. To overcome this hurdle, many companies are turning to business analytics to gain valuable insights and make data-driven decisions. In this blog post, we will explore how business analytics can be used to enhance supply chain management, specifically focusing on supply chain solutions, management software, and consulting services in Australia.

Enhancing Visibility and Transparency:

Supply chain management involves a multitude of interconnected activities, making it crucial to have a clear understanding of the entire process. By implementing advanced analytics techniques, companies can gain real-time visibility into their supply chains. This enables them to identify bottlenecks, monitor inventory levels, and track shipments, thereby improving overall operational efficiency. Supply chain solutions in Australia, such as predictive analytics models, can help identify potential disruptions and take proactive measures to mitigate risks.

Demand Forecasting and Inventory Optimization:

Accurate demand forecasting is essential for efficient supply chain management. Business analytics leverages historical data, market trends, and customer insights to predict future demand patterns more accurately. By applying advanced forecasting algorithms, businesses can optimize inventory levels, minimize stockouts, and reduce excess inventory costs. With supply chain management software in Australia, companies can automate the process of demand forecasting and leverage predictive analytics to make informed decisions regarding production, procurement, and distribution.

Streamlining Supplier Management:

Supplier management plays a critical role in supply chain performance. By analyzing supplier data, including quality, delivery times, and cost, organizations can identify high-performing suppliers and build stronger partnerships. Business analytics tools provide a comprehensive view of supplier performance, allowing companies to optimize sourcing strategies, negotiate better contracts, and identify alternative suppliers in case of disruptions. Through supply chain management consulting in Australia, businesses can leverage the expertise of industry professionals to design effective supplier management frameworks.

Optimizing Logistics and Transportation:

Efficient logistics and transportation are vital for smooth supply chain operations. By leveraging analytics, organizations can optimize routing, mode selection, and load planning to minimize transportation costs and improve delivery timelines. Predictive analytics models can anticipate potential transportation delays and help companies proactively manage risks. Additionally, supply chain management software in Australia provides real-time tracking and monitoring capabilities, enabling businesses to track shipments and make informed decisions to ensure timely deliveries.

Continuous Improvement through Data-Driven Insights:

One of the key advantages of using business analytics in supply chain management is the ability to gain actionable insights for continuous improvement. By analyzing historical and real-time data, companies can identify inefficiencies, optimize processes, and implement cost-saving measures. Furthermore, analytics tools enable businesses to conduct scenario analysis and simulate different supply chain strategies to identify the most effective approaches. This data-driven decision-making approach empowers organizations to stay agile and responsive in the face of changing market dynamics.

Conclusion:

In the era of data-driven decision-making, leveraging business analytics has become essential for effective supply chain management. Supply chain solutions, management software, and consulting services in Australia provide companies with the tools and expertise needed to optimize their supply chains. By enhancing visibility, improving demand forecasting, streamlining supplier management, optimizing logistics, and leveraging data-driven insights, organizations can achieve higher operational efficiency, reduced costs, and improved customer satisfaction. Embracing business analytics in supply chain management is a strategic move that helps organizations stay ahead of the competition in today's dynamic business landscape.

#supply chain solutions in Australia#supply chain management software in Australia#supply chain management consulting Australia#vncglobal

3 notes

·

View notes

Text

Luxury Car Rental Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Luxury Car Rental Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Luxury Car Rental Market scenario, and feasibility study are the important aspects analyzed in this report.

The Luxury Car Rental Market is experiencing robust growth driven by the expanding globally. The Luxury Car Rental Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Luxury Car Rental Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing.

The global in-vehicle payment system market size was USD 2.98 billion. The market is projected to grow from USD 3.32 billion in 2021 to USD 12.50 billion in 2028 at a CAGR of 20.9% in the 2021-2028 period.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/103652

Key Strategies

Key strategies in the Luxury Car Rental Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Luxury Car Rental Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Luxury Car Rental Market.

Major Luxury Car Rental Market Manufacturers covered in the market report include:

Avis Budget Group (U.S.),Sixt (Germany), Enterprise Holdings (U.S.), Movida (Brazil), Hertz (U.S.), Localiza (Brazil), Europcar Mobility Group (France) , Car Inc. (China)

The application of car rental management software represents a significant growth opportunity for the market players.

Trends Analysis

The Luxury Car Rental Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Luxury Car Rental Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Luxury Car Rental Market Solutions.

Regions Included in this Luxury Car Rental Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Luxury Car Rental Market.

- Changing the Luxury Car Rental Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Luxury Car Rental Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Luxury Car Rental Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Luxury Car Rental Market?

► Who are the prominent players in the Global Luxury Car Rental Market?

► What is the consumer perspective in the Global Luxury Car Rental Market?

► What are the key demand-side and supply-side trends in the Global Luxury Car Rental Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Luxury Car Rental Market?

Table Of Contents:

1 Market Overview

1.1 Luxury Car Rental Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

0 notes

Text

Clinical Documentation Improvement Market Global Supply Chain Trends and Market Expansion

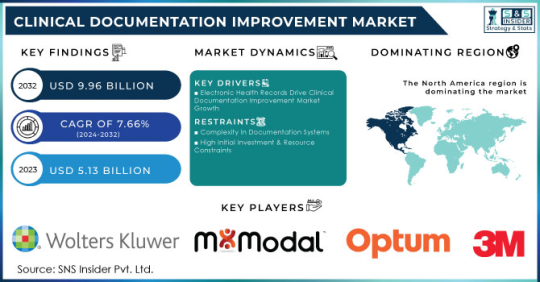

The global Clinical Documentation Improvement (CDI) market is experiencing robust expansion, with its valuation projected to escalate from USD 5.13 billion in 2023 to approximately USD 9.96 billion by 2032, reflecting a Compound Annual Growth Rate (CAGR) of 7.66% during the forecast period.

Market Overview

Clinical Documentation Improvement encompasses strategies and solutions aimed at enhancing the accuracy and quality of clinical documentation within healthcare systems. The primary objective is to ensure that patient records accurately reflect the diagnoses, treatments, and services provided, thereby facilitating improved patient care, compliance with regulatory standards, and optimized revenue cycle management.

Get Free Sample Report @ https://www.snsinsider.com/sample-request/2090

Regional Analysis

North America: Currently leading the CDI market, North America's dominance is attributed to the widespread adoption of Electronic Health Records (EHRs), stringent regulatory requirements, and a strong focus on value-based care models.

Asia-Pacific: This region is anticipated to witness the fastest growth, propelled by increasing healthcare expenditures, rapid digitization of healthcare infrastructure, and heightened awareness regarding the benefits of precise clinical documentation.

Market Segmentation

The CDI market is segmented based on:

Product and Service:

Solutions: Including software tools designed for clinical documentation, coding, charge capture, and improvement analytics.

Consulting Services: Professional services offering expertise in implementing and optimizing CDI programs.

End Users:

Healthcare Providers: Such as hospitals, clinics, and long-term care facilities.

Healthcare Payers: Including insurance companies and other entities responsible for financing or reimbursing the cost of health services.

Key Clinical Documentation Improvement Companies:

Clinical Documentation Improvement Solutions

3M Health Information Systems

Wolters Kluwer Health

MModal

Optum360

Aviacode

Cotiviti, Inc.

R1 RCM, Inc.

Craneware

Consulting Services for Clinical Documentation

The HCI Group, Inc.

Ingenious Med, Inc.

SSI Group, LLC

Documentation and Data Capture Solutions

ClinCapture

PerfectServe, Inc.

Health Language, Inc.

ChartMaxx

Key Market Drivers

Transition to Value-Based Care: Shifting from fee-for-service to value-based care models necessitates accurate documentation to ensure appropriate reimbursement and quality care.

Regulatory Compliance: Adherence to standards like ICD-10 and HIPAA drives the need for improved clinical documentation practices.

Technological Advancements: Integration of Artificial Intelligence (AI), Natural Language Processing (NLP), and predictive analytics enhances the efficiency and effectiveness of CDI solutions.

Revenue Cycle Optimization: Accurate documentation directly impacts the financial health of healthcare organizations by reducing claim denials and ensuring proper reimbursement.

Future Outlook

The CDI market is poised for sustained growth, driven by continuous technological innovations and the increasing complexity of healthcare delivery. The integration of AI and NLP is expected to revolutionize CDI processes, offering real-time insights and automating routine tasks. Moreover, as healthcare systems worldwide emphasize patient-centric and coordinated care, the demand for comprehensive and accurate clinical documentation will intensify. Emerging markets, particularly in the Asia-Pacific region, present significant opportunities due to ongoing healthcare reforms and investments in digital health infrastructure.

Conclusion

Accurate and efficient clinical documentation stands as a cornerstone of modern healthcare systems. As the global healthcare landscape evolves, the importance of robust CDI programs becomes increasingly evident. Stakeholders across the spectrum—including solution providers, healthcare institutions, and policymakers—must collaborate to harness the full potential of CDI, ensuring enhanced patient outcomes and operational excellence.

Contact Us: Jagney Dave - Vice President of Client Engagement Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

Other Related Reports:

Urgent Care Apps Market

Healthcare Chatbots Market

Artificial Intelligence in Healthcare Market

#Clinical Documentation Improvement Market#Clinical Documentation Improvement Market Share#Clinical Documentation Improvement Market Size#Clinical Documentation Improvement Market Trends

0 notes

Text

ERP in Manufacturing: What You Need to Know for Business Growth

In today's dynamic business landscape, manufacturing companies face numerous challenges, from volatile market demands to complex supply chain management. To thrive in this competitive environment, organizations are increasingly turning to Enterprise Resource Planning (ERP) systems. In this blog post, we will explore the significance of ERP systems for manufacturing companies, their role in software development companies, and the key factors that contribute to business growth.

Understanding ERP Systems for Manufacturing Companies

The Core of ERP: Integration and Automation

ERP systems are comprehensive software solutions designed to integrate and streamline various business processes within an organization. For manufacturing companies, ERP serves as a centralized platform that connects different departments such as production, inventory, procurement, finance, and human resources. The integration of these processes results in improved communication, data accuracy, and operational efficiency.

Key Features of ERP in Manufacturing

1. Production Planning and Scheduling:

ERP systems enable manufacturing companies to optimize production processes by providing real-time insights into resource availability, production capacity, and demand forecasting. This ensures that production schedules are aligned with market demands, reducing the risk of overproduction or stockouts.

2. Inventory Management:

Efficient inventory management is crucial for manufacturing companies. ERP software helps organizations maintain optimal inventory levels, minimize carrying costs, and prevent stockouts. It also facilitates better demand planning and order fulfillment.

3. Quality Control:

ERP systems play a vital role in maintaining product quality by tracking and managing every stage of the manufacturing process. This includes monitoring raw materials, production processes, and finished goods to ensure they meet industry standards and customer expectations.

4. Supply Chain Visibility:

With ERP, manufacturing companies gain better visibility into their supply chain. This visibility helps in identifying potential bottlenecks, reducing lead times, and enhancing collaboration with suppliers. A transparent supply chain is essential for meeting customer demands and maintaining a competitive edge.

5. Financial Management:

ERP systems provide robust financial modules that help manufacturing companies manage budgets, track costs, and generate accurate financial reports. This financial transparency enables informed decision-making and ensures compliance with regulatory requirements.

ERP for Software Development Companies: A Unique Perspective

While traditionally associated with manufacturing, ERP systems have found their way into software development companies as well. The principles of integration, automation, and streamlined processes are just as applicable in the software industry.

Project Management and Collaboration

In software development, ERP systems assist in project management by centralizing tasks, timelines, and resource allocation. This ensures that development teams work cohesively, deadlines are met, and resources are utilized efficiently. Collaboration is enhanced through shared data and communication channels, leading to improved project outcomes.

Resource Allocation and Time Tracking

ERP software allows software development companies to optimize resource allocation and track time spent on different projects. This data-driven approach enhances project planning, improves resource efficiency, and provides insights for future capacity planning.

Scalability and Flexibility

Software companies often face rapidly changing project scopes and client requirements. ERP systems provide the scalability and flexibility needed to adapt to these changes seamlessly. Whether it's adding new features, accommodating changes in project timelines, or expanding the scope, ERP systems empower software development companies to stay agile.

Key Considerations for Implementing ERP in Manufacturing

1. Customization and Flexibility:

Manufacturing companies should look for ERP solutions that offer customization options to align with specific industry needs. Flexibility is crucial, considering the diverse manufacturing processes and business models.

2. User Training and Change Management:

Successful ERP implementation requires thorough training of users and effective change management strategies. Employees need to understand the benefits of ERP and be comfortable with the new system to ensure smooth adoption.

3. Data Security and Compliance:

Given the sensitive nature of manufacturing data, security is a top priority. ERP systems must comply with industry regulations and provide robust security features to safeguard intellectual property, customer information, and business-critical data.

4. Integration with Existing Systems:

Seamless integration with existing software and systems is essential for a smooth transition to ERP. Compatibility with other tools and technologies ensures that there is no disruption in day-to-day operations during the implementation phase.

5. Scalability for Future Growth:

An ERP system should be scalable to accommodate the growing needs of a manufacturing company. It should support expansion into new markets, additional product lines, and increased production volumes without compromising performance.

Conclusion: Driving Business Growth with ERP

In conclusion, ERP systems have become indispensable tools for manufacturing companies seeking sustainable growth in a competitive market. By integrating and automating core business processes, ERP not only enhances operational efficiency but also provides valuable insights for strategic decision-making.

For software development companies, the adaptability of ERP systems offers a unique advantage in managing the dynamic and ever-evolving nature of the industry. The principles that make ERP effective in manufacturing—integration, automation, and streamlined processes—are equally applicable and beneficial in the software development landscape.

As businesses continue to evolve, embracing ERP is not just a technological choice; it's a strategic one. Those who invest in robust ERP solutions position themselves for improved competitiveness, increased profitability, and sustainable growth in the long run.

#ERP systems for manufacturing companies#ERP for manufacturing companies#ERP for software development company#ERP software for manufacturing companies#India#Gujarat#Vadodara#ERP India#Business Solutions#manufacurer#ERP software

7 notes

·

View notes

Text

How Corrugated Packaging Software ERP Transforms the Manufacturing Industry

Introduction

In the ever-evolving world of manufacturing, businesses must leverage cutting-edge ERP solutions to streamline operations, optimize resources, and enhance profitability. Corrugated packaging software ERP has emerged as a game-changer for packaging manufacturers, offering advanced capabilities to improve efficiency, reduce waste, and increase production speed. This article delves deep into the ways ERP software transforms the corrugated packaging industry and why companies should invest in it.

What Is Corrugated Packaging Software ERP?

Corrugated packaging software ERP is an integrated enterprise resource planning system specifically designed for corrugated box software. It offers end-to-end solutions, from order management and production planning to supply chain optimization and financial tracking. By automating workflows and centralizing data, ERP systems help manufacturers stay competitive in a rapidly evolving market.

Key Benefits of Corrugated Packaging ERP Software1. Enhanced Production Planning and Scheduling

A robust ERP system enables manufacturers to efficiently manage production schedules, ensuring that raw materials and resources are utilized optimally. It eliminates bottlenecks by offering real-time insights into production processes, reducing lead times and improving on-time deliveries.2. Streamlined Inventory and Supply Chain Management

Efficient inventory management is crucial for corrugated packaging manufacturers. ERP software provides real-time inventory tracking, helping businesses maintain optimal stock levels, reduce wastage, and minimize holding costs. With better supply chain visibility, manufacturers can coordinate seamlessly with suppliers and distributors, ensuring a smooth workflow.3. Improved Quality Control

Maintaining high-quality standards is non-negotiable in the corrugated packaging industry. ERP software comes equipped with quality control modules that allow businesses to monitor defects, enforce compliance standards, and track quality across various production stages.4. Cost Reduction and Profit Maximization

By automating manual processes, ERP systems help reduce labor costs and material waste. Advanced analytics within ERP software offer insights into cost structures, enabling businesses to optimize pricing strategies, improve margins, and maximize profitability.5. Real-Time Data and Analytics

Modern ERP systems offer real-time dashboards, helping decision-makers analyze trends, forecast demand, and make data-driven decisions. This level of transparency ensures better control over operations and enhances strategic planning.6. Seamless Order Processing and Customer Management

An ERP system centralizes customer data, automating order processing, pricing calculations, and invoicing. This results in faster order fulfillment, improved customer satisfaction, and enhanced CRM (Customer Relationship Management) capabilities.7. Regulatory Compliance and Sustainability

With growing environmental concerns, ERP software helps packaging companies stay compliant with industry regulations. By tracking carbon footprints, optimizing material usage, and promoting eco-friendly production methods, businesses can achieve sustainability goals effectively.

Key Features of an Ideal Corrugated Packaging ERP Software1. Customizable Workflow Automation

A well-designed ERP solution should allow businesses to tailor workflows to meet specific production needs, ensuring efficient operations without unnecessary complexities.2. Advanced Machine Integration

Modern ERP systems integrate with manufacturing machines, enabling automatic data collection, predictive maintenance, and real-time monitoring of production equipment.3. Cloud-Based Accessibility

Cloud-based ERP software enables remote access, making it easier for manufacturers to manage operations across multiple locations without investing in extensive IT infrastructure.4. Business Intelligence (BI) and Reporting

Comprehensive BI tools within ERP software provide detailed reports on financial performance, production efficiency, and market trends, allowing businesses to make informed decisions.5. Multi-Location Support

For large-scale corrugated packaging manufacturers, an ERP system should support multi-location management, ensuring seamless collaboration across different plants.

How to Choose the Best Corrugated Packaging ERP System

When selecting an ERP solution, businesses should consider the following factors:

Industry-Specific Functionality – Choose software specifically designed for corrugated packaging to ensure it meets your unique requirements.

Scalability – Ensure the ERP system can grow with your business and adapt to future demands.

Integration Capabilities – Opt for software that integrates with existing machinery and third-party applications like accounting and supply chain platforms.

User-Friendly Interface – A well-designed, intuitive dashboard is essential for ensuring seamless adoption and usage.

Security and Compliance – Prioritize ERP solutions with robust security features and compliance tracking to safeguard business data.

Case Studies: Success Stories of ERP Implementation in Corrugated Packaging

Case Study 1: Boosting Efficiency in a Large-Scale Packaging Firm

A leading corrugated manufacturing software implemented a cloud-based ERP system, resulting in a 30% reduction in material waste, a 25% increase in production efficiency, and enhanced real-time reporting capabilities.Case Study 2: Small Business Scaling Operations with ERP

A mid-sized packaging company struggling with manual processes adopted an AI-driven ERP solution. The result? A 50% decrease in lead times, improved customer order accuracy, and a 20% boost in profit margins within a year.

Future Trends in Corrugated Packaging ERP Software1. AI and Machine Learning Integration

Modern ERP systems are integrating AI-powered analytics to improve demand forecasting, production planning, and predictive maintenance.2. IoT-Enabled Smart Manufacturing

IoT (Internet of Things) sensors in manufacturing plants help track machine performance, detect faults, and optimize production efficiency.3. Blockchain for Supply Chain Transparency

Blockchain technology enhances traceability, ensuring that raw materials and finished products comply with regulatory standards.4. Eco-Friendly and Sustainable Solutions

ERP software is increasingly focusing on sustainability, helping businesses track carbon footprints and adopt green manufacturing practices.

Conclusion

The erp for corrugated packaging industry is evolving rapidly, and implementing a robust ERP system is no longer optional—it’s a necessity. From streamlining production and inventory management to enhancing cost efficiency and compliance, ERP software is transforming how packaging businesses operate. Investing in the right corrugated packaging ERP can significantly improve productivity, profitability, and sustainability, ensuring a competitive edge in the market.

1 note

·

View note

Text

Supply Chain Innovations: Reshaping the American Landscape

One of the most significant trends is the embrace of digital transformation. This includes the adoption of technologies like:

Artificial Intelligence (AI) and Machine Learning (ML): AI-powered predictive analytics is being used to forecast demand, optimize inventory levels, and identify potential disruptions before they occur. ML algorithms are automating tasks like route optimization and warehouse management, leading to significant efficiency gains.

Internet of Things (IoT): IoT devices, such as sensors and tracking systems, provide real-time visibility into the location and condition of goods throughout the supply chain. This data allows for better decision-making, improved quality control, and reduced waste.

Blockchain Technology: Blockchain is proving valuable for improving transparency, security, and traceability in the supply chain. Sustainable Supply Chain USA It allows for the secure and immutable tracking of products, from raw materials to final delivery, building trust and reducing fraud.

These technological advancements are not only impacting large corporations but are also becoming increasingly accessible to small and medium-sized businesses (SMBs). Cloud-based solutions and readily available software are leveling the playing field, allowing smaller companies to optimize their operations and compete more effectively.

Another critical area of innovation is nearshoring and reshoring. Companies are reevaluating their global supply chains, seeking to reduce reliance on distant suppliers and mitigate the risks associated with long lead times and geopolitical instability. This trend is leading to increased investment in domestic manufacturing and distribution centers, creating jobs and boosting the American economy.

Furthermore, Tourism marketing courses USA are becoming increasingly important. Companies are working together to build more resilient and responsive supply chains. This includes sharing data, coordinating logistics, and developing joint strategies to address challenges like capacity constraints and labor shortages. Effective collaboration between suppliers, manufacturers, distributors, and retailers is essential for success in today's dynamic environment.

Sustainable Supply Chain USA is another top priority. Driven by consumer demand and environmental regulations, companies are implementing strategies to minimize their environmental impact. This involves initiatives like:

Reducing Carbon Footprint: Companies are focusing on reducing emissions through the use of electric vehicles (EVs) for transportation, optimizing routes to minimize fuel consumption, Supply chain innovations America and sourcing renewable energy for their facilities.

Sustainable Sourcing: Businesses are prioritizing suppliers that adhere to environmentally responsible practices, such as using recycled materials, reducing waste, and conserving water.

Circular Economy Principles: Companies are adopting circular economy models, which focus on reducing waste and maximizing resource utilization through processes like reuse, recycling, and remanufacturing.

These sustainable practices not only benefit the environment but also enhance brand reputation, attract environmentally conscious consumers, and improve long-term cost efficiency.

To support the growth of sustainable supply chain and increase the understanding of the consumers related to the sustainable supply chain, we will create some of Tourism marketing courses USA and Tourism marketing training America for the stakeholders.

0 notes

Text

Anesthesia Apparatuses Market Companies: Growth, Share, Value, Analysis, and Trends

Anesthesia Apparatuses Market Size And Forecast by 2032

The revenue analysis and revenue forecast for the Anesthesia Apparatuses Market reveal a promising upward trajectory, driven by innovative product offerings, strategic collaborations, and expanding applications. With leaders in the industry focusing on enhanced customer experiences and operational efficiency, the market continues to present lucrative opportunities for growth. The report provides a detailed overview of these trends and their implications for the market’s future.

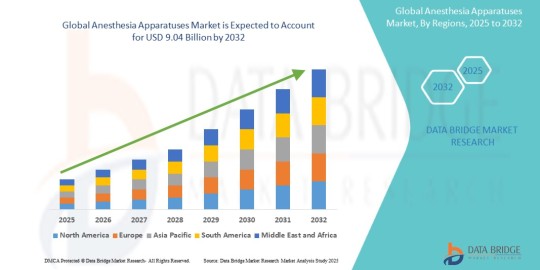

The global anesthesia apparatuses market size was valued at USD 4.39 billion in 2024 and is projected to reach USD 9.04 billion by 2032, with a CAGR of 9.46% during the forecast period of 2025 to 2032.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-anesthesia-apparatuses-market

Which are the top companies operating in the Anesthesia Apparatuses Market?

The Top 10 Companies in Anesthesia Apparatuses Market include well-established names that lead the industry with their innovative products and strong market presence. These companies are recognized for their quality, reliability, and ability to meet the evolving needs of consumers. each known for their significant contributions and competitive strategies that drive growth and maintain their leadership in the industry.

**Segments**

- Based on type, the anesthesia apparatuses market can be segmented into anesthesia machines, anesthesia disposables, anesthesia monitors, and anesthesia information management systems. Anesthesia machines are essential equipment used to deliver precise amounts of medical gases and anesthetic agents during surgery. Anesthesia disposables include items such as face masks, breathing circuits, and laryngeal mask airways. Anesthesia monitors are devices that track a patient's vital signs during surgery, including heart rate, blood pressure, and oxygen saturation levels. Anesthesia information management systems (AIMS) are software solutions that help anesthesiologists track patient data, medication dosages, and other vital information during surgical procedures.

**Market Players**

- Some of the key players in the global anesthesia apparatuses market include GE Healthcare, Drägerwerk AG & Co. KGaA, Mindray DS USA, Inc., Fisher & Paykel Healthcare Limited, Medtronic, Smiths Group plc, ResMed, Inc., Koninklijke Philips N.V., Teleflex Incorporated, and others. These companies are focused on developing advanced anesthesia equipment that improves patient safety, enhances surgical outcomes, and increases efficiency in operating rooms. Strategic partnerships, mergers, and acquisitions are common strategies employed by market players to expand their product portfolios and geographic presence in the competitive anesthesia apparatuses market.

The global anesthesia apparatuses market is witnessing steady growth due to the increasing number of surgical procedures, advancements in technology, and rising demand for anesthesia equipment in hospitals and ambulatory surgical centers worldwide. The adoption of anesthesia apparatuses is driven by factors such as the growing prevalence of chronic diseases, the expansion of healthcare infrastructure in developing countries, and the emphasis on patient comfort and safety during surgical interventions. Additionally, the shift towards minimally invasive procedures and the rising geriatric population are contributing to the market's expansion.

North America dominates the anesthesia apparatuses market, attributed to well-established healthcare infrastructure, high healthcare spending, and the presence of key market players in the region. Europe is also a significant market for anesthesia apparatuses, driven by the increasing number of surgeries, favorable reimbursement policies, and technological advancements in anesthesia equipment. The Asia Pacific region is expected to witness rapid growth in the forecast period, owing to the rising healthcare investments, improving healthcare facilities, and the growing prevalence of chronic diseases that require surgical interventions.

The global anesthesia apparatuses market is competitive and fragmented, with a focus on product innovation, quality, and regulatory compliance. Market players are investing in research and development to introduce cutting-edge anesthesia solutions that cater to the evolving needs of healthcare providers and patients. Overall, the market shows promising growth prospects, driven by the continual advancements in anesthesia technology and the increasing demand for surgical procedures worldwide.

https://www.databridgemarketresearch.com/reports/global-anesthesia-apparatuses-market The global anesthesia apparatuses market is experiencing a paradigm shift towards digitalization and automation, with the integration of artificial intelligence (AI) and machine learning algorithms in anesthesia equipment playing a significant role in enhancing patient outcomes. The use of AI-powered anesthesia systems enables real-time monitoring of vital signs, predictive analytics for anesthesiologists, and personalized anesthesia delivery based on individual patient characteristics. This advanced technology not only improves the efficiency and accuracy of anesthesia administration but also enhances patient safety by minimizing human errors and optimizing dosages.

One emerging trend in the anesthesia apparatuses market is the increasing focus on sustainability and eco-friendliness in product design and manufacturing. Market players are gradually shifting towards the development of environmentally friendly anesthesia equipment that reduces carbon footprint, minimizes medical waste, and promotes energy efficiency. Sustainable anesthesia solutions not only align with global environmental initiatives but also resonate with healthcare facilities striving to adopt greener practices and reduce overall operational costs.

Another key aspect shaping the anesthesia apparatuses market is the rise of telemedicine and remote monitoring solutions in anesthesia management. With the growing demand for telehealth services and the need for decentralized patient care, anesthesia information management systems are being integrated with telemedicine platforms to enable remote monitoring of patient vitals, real-time consultation with anesthesiologists, and seamless data exchange between healthcare providers. This trend is particularly beneficial for rural areas, underserved communities, and home healthcare settings where access to on-site anesthesia expertise may be limited.

Furthermore, the increasing emphasis on value-based care and healthcare reimbursement models is driving the market towards outcome-based solutions that prioritize patient satisfaction, cost-effectiveness, and long-term clinical benefits. Anesthesia apparatuses are evolving to incorporate features that promote faster recovery, reduce post-operative complications, and enhance overall patient experience, aligning with the shift towards value-driven healthcare delivery. Market players are investing in evidence-based practices, clinical data analytics, and quality improvement initiatives to demonstrate the efficacy and value of their anesthesia products in real-world clinical settings.

Overall, the global anesthesia apparatuses market is poised for continued growth and innovation, fueled by technological advancements, changing healthcare dynamics, and the evolving needs of healthcare providers and patients. As the industry evolves, market players will need to adapt to emerging trends, regulatory requirements, and consumer preferences to stay competitive and address the complex challenges of modern healthcare delivery. The convergence of digital health technologies, sustainability initiatives, telemedicine integration, and value-based care principles will shape the future landscape of the anesthesia apparatuses market, driving towards improved patient outcomes, operational efficiency, and sustainable healthcare practices.**Segments**

Global Anesthesia Apparatuses Market Segmentation:

-**Product**: - Anesthesia Workstation - Anesthesia Delivery Machines - Anesthesia Disposables and Accessories - Anesthesia Ventilators - Anesthesia Monitors - AIMS (Anesthesia Information Management Systems)

-**Type**: - General Anesthesia - Local Anesthesia

-**Application**: - Cardiology - Neurology - Dental - Ophthalmology - Urology - Orthopedics - Others

-**End-User**: - Hospitals - Clinics - Ambulatory Service Centers - OPDs - Assisted Living Facilities - SNFs

The segmentation of the global anesthesia apparatuses market by product, type, application, and end-user provides a comprehensive understanding of the diverse needs and preferences of healthcare providers and patients. This segmentation allows market players to tailor their product offerings and strategies to meet specific requirements across different segments, driving growth and innovation in the dynamic healthcare industry landscape.

**Market Players**

- General Electric Company (U.S.) - OSI Systems, Inc. (U.S.) - Septodont Holding (France) - Drägerwerk AG & Co. KGaA (Germany) - Beijing Aeonmed Medical Systems Co., Ltd. (China) - Heyer Medical AG (Germany) - ORICARE Inc. (India) - Biovo Technologies Ltd (U.K.) - Koninklijke Philips N.V. (Netherlands) - BD (U.S.) - Getinge AB (Sweden) - Smiths Group plc. (U.S.) - Infinium Medical (U.S.) - CardiacDirect (U.S.) - Penlon Limited (U.K.) - B. Braun SE (Germany) - Medtronic (U.S.) - Fisher & Paykel Healthcare Limited (New Zealand) - Shenzhen Mindray Bio-Medical Electronics Co., Ltd (China) - Ambu A/S (Denmark) - Teleflex Incorporated (U.S.) - SunMED Medical (U.S.) - KARL STORZ SE & Co. KG (Germany)

The key players in the global anesthesia apparatuses market represent a diverse range of companies with a strong focus on innovation, quality, and customer-centric solutions. These market players leverage their technological expertise, global presence, and strategic partnerships to drive growth and capture market share in the competitive healthcare industry. Collaborations, acquisitions, and product developments are key strategies employed by these players to stay ahead of the curve and meet the evolving needs of healthcare providers and patients worldwide.

Overall, the global anesthesia apparatuses market is poised for substantial growth and transformation, driven by technological advancements, changing healthcare dynamics, and the emphasis on patient-centered care. Market players will continue to navigate through challenges and opportunities, leveraging emerging trends such as digitalization, sustainability, telemedicine integration, and value-based care to shape the future of anesthesia equipment and enhance healthcare delivery on a global scale. The relentless pursuit of innovation, coupled with a focus on patient outcomes and operational efficiency, will be critical in driving the growth and success of the anesthesia apparatuses market in the coming years.

Explore Further Details about This Research Anesthesia Apparatuses Market Report https://www.databridgemarketresearch.com/reports/global-anesthesia-apparatuses-market

Key Insights from the Global Anesthesia Apparatuses Market :

Comprehensive Market Overview: The Anesthesia Apparatuses Market is expanding rapidly, driven by innovation and growing global demand across key regions.

Industry Trends and Projections: Automation, sustainability, and digital transformation are key trends, with strong growth projected over the next few years.

Emerging Opportunities: New growth opportunities are emerging in eco-friendly technologies and untapped regional markets.

Focus on R&D: Companies are heavily investing in R&D to develop next-gen technologies like AI, IoT, and sustainable solutions.

Leading Player Profiles: Market leaders, such as Company A and Company B, dominate due to strong portfolios and global distribution.

Market Composition: The market is fragmented, with both large corporations and emerging startups driving innovation.

Revenue Growth: The market is experiencing steady revenue growth, driven by both consumer demand and industrial applications.

Commercial Opportunities: Key commercial opportunities lie in expanding into emerging markets and forming strategic partnerships.

Find Country based languages on reports:

https://www.databridgemarketresearch.com/jp/reports/global-anesthesia-apparatuses-markethttps://www.databridgemarketresearch.com/zh/reports/global-anesthesia-apparatuses-markethttps://www.databridgemarketresearch.com/ar/reports/global-anesthesia-apparatuses-markethttps://www.databridgemarketresearch.com/pt/reports/global-anesthesia-apparatuses-markethttps://www.databridgemarketresearch.com/de/reports/global-anesthesia-apparatuses-markethttps://www.databridgemarketresearch.com/fr/reports/global-anesthesia-apparatuses-markethttps://www.databridgemarketresearch.com/es/reports/global-anesthesia-apparatuses-markethttps://www.databridgemarketresearch.com/ko/reports/global-anesthesia-apparatuses-markethttps://www.databridgemarketresearch.com/ru/reports/global-anesthesia-apparatuses-market

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

0 notes

Text

Warehouse Management Logistics Market Opportunities: Growth, Share, Value, Size, and Insights

"Warehouse Management Logistics Market Size And Forecast by 2032

The Warehouse Management Logistics Market is an evolving industry that holds significant potential across various sectors, driven by advancements in technology, shifting consumer preferences, and growing demand for innovative solutions. With a robust ecosystem of players and a dynamic competitive landscape, the market offers ample opportunities for growth and value creation. This report delves into the size, share, and scope of the Warehouse Management Logistics Market, providing a detailed analysis of its current state and future outlook.

The global warehouse management logistics market size was valued at USD 5.21 billion in 2024 and is projected to reach USD 17.30 billion by 2032, with a CAGR of 16.20% during the forecast period of 2025 to 2032.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-warehouse-management-logistics-market

Which are the top companies operating in the Warehouse Management Logistics Market?

The Top 10 Companies in Warehouse Management Logistics Market include leading industry players that have established a strong presence through innovation, quality products, and strategic partnerships. These companies dominate the market by leveraging advanced technologies, extensive distribution networks, and a deep understanding of consumer needs. Their market leadership is often driven by significant investments in research and development, as well as their ability to adapt to changing market trends and consumer demands.

**Segments**

- By Component: On the basis of components, the global warehouse management logistics market can be segmented into software and services. The software segment is expected to dominate the market due to the increasing adoption of cloud-based software solutions that offer scalability, flexibility, and cost-effectiveness. The services segment is also witnessing growth as companies are increasingly outsourcing their warehouse management operations to experts for better efficiency and focus on core business activities.

- By Type: The market can be categorized into on-premise and cloud-based warehouse management logistics solutions. The cloud-based segment is anticipated to witness significant growth during the forecast period owing to benefits such as remote accessibility, real-time tracking, and reduced upfront infrastructure costs. On the other hand, the on-premise segment is expected to hold a stable market share due to the data security and customization advantages it offers to enterprises.

- By Vertical: Based on verticals, the warehouse management logistics market can be segmented into manufacturing, retail, healthcare, automotive, and others. The retail sector is expected to command a substantial share of the market due to the increasing demand for efficient inventory management and order processing in e-commerce and brick-and-mortar retail operations. The healthcare sector is also poised for growth as regulatory compliance and traceability requirements drive the adoption of advanced warehouse management solutions.

**Market Players**

- SAP SE - Oracle - Manhattan Associates - HighJump - JDA Software - IBM Corporation - Infor - PSI Software - PTC - Epicor Software Corporation

The global warehouse management logistics market is highly competitive with several key players focusing on strategic alliances, product innovations, and expanding their geographical presence to gain a competitive edge. These market players are investing in R&D activities to introduce advanced technologies such as AI, IoT, and blockchain in warehouse management solutions to cater to the evolving needs of various industries. The market is witnessing significant mergers and acquisitions as companies aim to strengthen their market position and enhance their product portfolios to meet the growing demand for efficient warehouse management logistics solutions.

https://www.databridgemarketresearch.com/reports/global-warehouse-management-logistics-marketThe global warehouse management logistics market is undergoing a dynamic transformation driven by technological advancements and the increasing focus on enhancing operational efficiency across various industries. One of the emerging trends in the market is the integration of advanced technologies such as Artificial Intelligence (AI), Internet of Things (IoT), and blockchain to optimize warehouse operations. AI-powered algorithms are being utilized to forecast demand, optimize storage space, and streamline inventory management processes. IoT-enabled devices are facilitating real-time tracking of inventory, enhancing visibility across the supply chain, and ensuring timely order fulfillment. Additionally, blockchain technology is being leveraged to enhance data security, improve transparency in transactions, and enable seamless collaboration among supply chain partners.

Moreover, the rising trend of omnichannel retailing is driving the adoption of advanced warehouse management logistics solutions. Companies are increasingly focusing on providing a seamless shopping experience across online and offline channels, leading to the need for integrated warehouse management systems that can efficiently manage inventory, orders, and deliveries across multiple sales channels. The integration of automation technologies such as robotics and autonomous vehicles is also gaining traction in the warehouse management logistics market. These technologies are enhancing operational productivity, reducing manual errors, and enabling faster order processing and fulfillment.

Furthermore, the increasing emphasis on sustainability and environmental responsibility is influencing the warehouse management logistics market. Companies are adopting eco-friendly practices such as energy-efficient warehouse designs, optimized transportation routes, and recyclable packaging materials to reduce carbon footprint and minimize environmental impact. The implementation of sustainable practices is not only aligning businesses with regulatory standards but also enhancing brand reputation and attracting environmentally conscious consumers.

In terms of market dynamics, the global warehouse management logistics market is expected to witness steady growth in the coming years driven by the increasing demand for efficient inventory management, order processing, and fulfillment services across various industry verticals. The market is characterized by intense competition among key players such as SAP SE, Oracle, Manhattan Associates, and JDA Software, who are focusing on strategic initiatives such as mergers, acquisitions, and product innovations to gain a competitive edge in the market. Overall, the warehouse management logistics market is poised for significant expansion as companies continue to invest in advanced technologies and solutions to address the evolving needs of modern supply chains and logistics operations.**Segments**

Global Warehouse Management Logistics Market, By Component: The warehouse management logistics market can be segmented into software and services. The software segment is expected to dominate the market due to the increasing adoption of cloud-based software solutions that offer scalability, flexibility, and cost-effectiveness. On the other hand, the services segment is witnessing growth as companies are increasingly outsourcing their warehouse management operations to experts for better efficiency and focus on core business activities.

Deployment Mode: The market can be categorized into on-premise and cloud-based warehouse management logistics solutions. The cloud-based segment is anticipated to witness significant growth during the forecast period owing to benefits such as remote accessibility, real-time tracking, and reduced upfront infrastructure costs. The on-premise segment is expected to hold a stable market share due to the data security and customization advantages it offers to enterprises.

Tier Type: The warehouse management logistics market can be further segmented by tier types into advanced, intermediate, and basic solutions to cater to the varying needs of businesses based on their size, complexity, and operational requirements.

Function: Within the warehouse management logistics market, various functions are essential for seamless operations. These include Labor Management System, Analytics and Optimization, Billing and Yard Management Systems, Integration and Maintenance, and Consulting Services to ensure efficient warehouse operations and supply chain management.

Country: The market analysis extends to various countries such as the U.S., Canada, Mexico, Brazil, Argentina, Germany, Italy, U.K., France, Spain, China, India, Japan, Australia, Saudi Arabia, U.A.E, South Africa among others, providing insights on regional trends and market dynamics.

Industry Trends and Forecast to 2032:

- Increasing adoption of cloud-based warehouse management solutions for scalability and cost-effectiveness. - Growing demand for efficient inventory management in the retail sector. - Integration of advanced technologies such as AI, IoT, and blockchain for optimized warehouse operations. - Focus on sustainability and environmental responsibility in warehouse management practices. - Rising trend of omnichannel retailing driving the need for integrated warehouse management systems. - Emphasis on automation technologies such as robotics and autonomous vehicles for enhanced productivity.

**Market Players**

The major players covered in the warehouse management logistics market include Epicor Software Corporation, Oracle, IBM Corporation, SAP SE, Infor, PSI Logistics, HighJump, Tecsys Inc., Manhattan Associates, HAL SYSTEMS, Codeworks, LLC, Blue Yonder Group, Inc., PRIMA SOLUTIONS LTD., Magaya Corporation, Softeon, Synergy Ltd, datapel, DassaultSystèmes, Bastian Solutions, Inc., and PTC among other domestic and global players. These companies are actively engaged in strategic alliances, product innovations, and expanding their geographical presence to gain a competitive edge in the market. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA), and South America separately, with competitive analysis provided for each competitor individually.

Explore Further Details about This Research Warehouse Management Logistics Market Report https://www.databridgemarketresearch.com/reports/global-warehouse-management-logistics-market

Key Insights from the Global Warehouse Management Logistics Market :

Comprehensive Market Overview: The Warehouse Management Logistics Market is witnessing strong growth driven by increasing demand and technological advancements.

Industry Trends and Projections: Key trends include automation, sustainability, and a shift towards digital solutions, with a projected CAGR of X%.

Emerging Opportunities: Opportunities are emerging in green technologies, personalized services, and untapped geographical regions.

Focus on R&D: Companies are heavily investing in R&D to drive innovation, especially in AI, IoT, and sustainable solutions.

Leading Player Profiles: Dominant players like Company A and Company B lead the market with robust portfolios and global reach.

Market Composition: The market is fragmented, with a mix of established companies and innovative startups.

Revenue Growth: Revenue in the Warehouse Management Logistics Market is steadily increasing, fueled by rising consumer demand and expanding commercial applications.

Commercial Opportunities: Commercial opportunities lie in entering emerging markets, digital expansion, and forming strategic partnerships.

Find Country based languages on reports: