#Pressure Vessel Composite Market

Explore tagged Tumblr posts

Link

Pressure Vessel Composite Materials Market refers to the market for composite materials used in the manufacturing of pressure vessels. A pressure vessel is a container designed to hold gases or liquids at a pressure that is different from the surrounding environment. Pressure vessels are used in various industries, including oil and gas, chemical, and power generation, where the storage and transportation of high-pressure gases and liquids are required.

Composite materials, such as carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP), are increasingly being used in the manufacturing of pressure vessels due to their high strength-to-weight ratio, corrosion resistance, and durability. Composite pressure vessels offer several advantages over traditional metallic pressure vessels, including lower weight, longer lifespan, and reduced maintenance costs.

0 notes

Text

Buy SS 304 Blind Flange | Lowest Price in India

SS 304 Blind Flanges are a vital component for industrial piping systems, known for their durability, corrosion resistance, and strength. These flanges, made from stainless steel grade 304, are designed to seal the ends of pipes or valves, making them ideal for industries such as oil and gas, chemical processing, water treatment, and more. For businesses in India, finding SS 304 Blind Flanges at the lowest price is essential for minimizing operational costs while ensuring high-quality performance. With a wide range of suppliers offering competitive pricing, it's easier than ever to source these flanges at the best rates.

What is SS 304 Blind Flange?

SS 304 Blind Flanges are flat, circular components used to close off the ends of pipelines, valves, or pressure vessels. Unlike other flanges, the blind flange does not have a central bore, meaning it completely blocks the flow of liquid or gas through the pipe. This makes it useful for isolating sections of a piping system for maintenance, testing, or system shutdowns.

The material used in these flanges—stainless steel grade 304—is an austenitic alloy with high chromium (18%) and nickel (8%) content. This composition gives SS 304 its excellent corrosion resistance, making it a perfect choice for harsh industrial environments where chemicals, moisture, and high temperatures are present.

Benefits of SS 304 Blind Flange

1. Outstanding Corrosion Resistance: The SS 304 Blind Flange’s high chromium content allows it to form a passive layer of chromium oxide on its surface, which prevents rust and corrosion. This makes it ideal for use in chemical processing, oil refineries, water treatment plants, and other industries that deal with corrosive environments.

2. High Strength and Durability: SS 304 Blind Flanges are designed to withstand extreme pressures and temperatures. This makes them suitable for high-pressure applications, including oil and gas pipelines, steam systems, and heavy-duty processing plants. Their durability ensures long-term performance without frequent replacements, reducing maintenance costs.

3. Low Maintenance: Due to its superior resistance to corrosion and wear, SS 304 Blind Flanges require minimal maintenance compared to other materials. This makes them a cost-effective choice for industries where reliable performance and low upkeep are critical.

4. Versatile Applications: SS 304 Blind Flanges are used across a wide range of industries. They are suitable for temporarily sealing off pipelines during repairs or permanently closing off systems. Their versatility makes them valuable in oil and gas, petrochemical, marine, pharmaceutical, food processing, and water treatment industries.

Why Buy SS 304 Blind Flanges in India?

India is home to a vast array of suppliers and manufacturers offering SS 304 Blind Flanges at competitive prices. Buying locally ensures that you have access to high-quality products that meet Indian and international standards, such as ASTM or ASME certifications. Here are a few reasons why purchasing SS 304 Blind Flanges in India makes sense:

1. Cost-Effective Pricing: Indian suppliers offer some of the most competitive prices in the global market for SS 304 Blind Flanges. Whether you're looking to buy in small quantities or bulk, Indian manufacturers provide quality products at reasonable rates, often with the option to negotiate prices for large orders.

2. Fast Delivery and Local Availability: When you buy from Indian suppliers, you benefit from faster delivery times and lower shipping costs, especially for domestic orders. Many suppliers have stock readily available, ensuring that you can meet your project deadlines without delays.

3. Industry-Standard Certifications: SS 304 Blind Flanges manufactured in India often adhere to industry standards such as ASTM, ASME, or DIN. These certifications guarantee that the flanges meet the required quality and performance specifications, ensuring safety and reliability in industrial applications.

4. Bulk Discounts: Many suppliers in India offer discounts on bulk orders, making it more affordable for businesses that need large quantities of SS 304 Blind Flanges. Bulk purchasing not only reduces the unit price but can also lead to savings on transportation and logistics.

Applications of SS 304 Blind Flange

SS 304 Blind Flanges are used in various industrial settings due to their robust and corrosion-resistant properties. Common applications include:

Oil and Gas Industry: SS 304 Blind Flanges are used to close off pipeline sections during repairs or testing, especially in environments where corrosion is a concern.

Chemical Processing: In chemical plants, these flanges are used to block pipes that carry corrosive fluids, ensuring the system remains secure and sealed.

Water Treatment Plants: SS 304 Blind Flanges help in sealing off sections of water pipelines, providing a rust-resistant solution for water treatment facilities.

Marine Applications: Due to their resistance to seawater corrosion, SS 304 Blind Flanges are used in marine environments, including shipbuilding and offshore drilling operations.

Pharmaceutical and Food Industry: The non-reactive and hygienic properties of SS 304 make it an excellent choice for industries that require clean and sterile processing, such as pharmaceuticals and food manufacturing.

Tips for Finding SS 304 Blind Flanges at the Lowest Price in India

1. Compare Multiple Suppliers: When purchasing SS 304 Blind Flanges in India, it’s important to compare prices from several suppliers. This will allow you to find the most competitive pricing while ensuring the quality of the product.

2. Look for Bulk Discounts: If your project requires a large quantity of flanges, ask suppliers about bulk pricing. Many manufacturers offer substantial discounts for large orders, helping you reduce the cost per unit.

3. Check for Certifications: Make sure the supplier offers SS 304 Blind Flanges that meet industry standards like ASTM, ASME, or DIN. Certified products provide assurance that the flange will perform under the required conditions.

4. Negotiate for Better Pricing: Negotiation is common in the industrial supply market. If you’re placing a large order or planning a long-term partnership, don’t hesitate to ask for better terms or discounts.

5. Look for Seasonal or Promotional Offers: Some suppliers may offer seasonal discounts or promotional deals on SS 304 Blind Flanges. Stay on the lookout for such opportunities to get the best value for your money.

#SS304BlindFlange#BuySS304Flange#StainlessSteelFlange#IndustrialFlange#CorrosionResistantFlange#LowestPriceInIndia#PipelineSolutions#OilAndGasFlange#MarineFlange#WaterTreatmentFlange#BuyNow#IndiaFlangeDeals

5 notes

·

View notes

Text

SS 304 Blind Flange at Lowest Price From Manufacturer

In the realm of piping systems, flanges play a crucial role in connecting pipes and maintaining the integrity of the system. Among the various types of flanges available, the SS 304 blind flange stands out for its strength, durability, and corrosion resistance. If you're searching for SS 304 blind flanges at the lowest price, look no further than Udhhyog. As a leading supplier of industrial steel products in India, Udhhyog is committed to providing high-quality solutions tailored to the needs of micro, small, and medium enterprises (MSMEs).

What is an SS 304 Blind Flange?

An SS 304 blind flange is a solid piece of stainless steel used to close off the end of a piping system. Unlike regular flanges that connect two pipes, blind flanges do not have a hole in the center, which makes them ideal for sealing a pipe, valve, or vessel. The 304 grade stainless steel offers excellent corrosion resistance, making these flanges suitable for various applications, especially in environments exposed to moisture and chemicals.

Key Features of SS 304 Blind Flanges:

Corrosion Resistance: The stainless steel composition ensures that the flanges resist rust and corrosion, making them ideal for harsh environments.

Durability: SS 304 blind flanges are known for their strength and durability, allowing them to withstand high pressure and temperature.

Easy Installation: These flanges are designed for easy installation, saving time and labor costs during assembly.

Versatility: SS 304 blind flanges are used in a variety of industries, including oil and gas, chemical processing, food and beverage, and water treatment.

Why Choose Udhhyog for SS 304 Blind Flanges?

At Udhhyog, we take pride in being a reliable supplier of SS 304 blind flanges in India. Here are several reasons why you should consider us for your procurement needs:

1. High-Quality Products

Udhhyog prioritizes quality and ensures that our SS 304 blind flanges meet stringent industrial standards. Manufactured from top-grade stainless steel, our flanges are designed to provide long-lasting performance, ensuring the integrity of your piping systems.

2. Lowest Prices in the Market

We understand the importance of cost-effectiveness for businesses. Udhhyog offers SS 304 blind flanges at the lowest prices, making it easier for MSMEs and other businesses to access high-quality materials without breaking the bank. Our competitive pricing strategy ensures you receive maximum value for your investment.

3. Streamlined Procurement Process

Udhhyog’s technology-driven platform simplifies the procurement process. Our user-friendly website allows you to browse, select, and order SS 304 blind flanges with ease. Real-time inventory updates and transparent pricing help you make informed purchasing decisions quickly.

4. Comprehensive Product Range

In addition to SS 304 blind flanges, Udhhyog offers a wide array of industrial steel products, including valves, fittings, and other types of flanges. This extensive range allows you to source all your piping needs from one reliable supplier, streamlining your procurement process.

5. Tailored Solutions for MSMEs

Udhhyog is dedicated to supporting MSMEs by offering tailored procurement solutions. We provide flexible payment options, including credit facilities, ensuring that smaller businesses can access the materials they need without financial strain.

6. Nationwide Delivery

Our extensive distribution network enables Udhhyog to deliver SS 304 blind flanges promptly across India. Whether you’re in a major city or a more remote area, you can rely on us for fast and reliable service.

Applications of SS 304 Blind Flanges

SS 304 blind flanges are used in various industries and applications, including:

Oil and Gas: These flanges are commonly used to seal off the ends of pipelines and prevent leakage in oil and gas installations.

Chemical Processing: Their corrosion resistance makes them ideal for applications in chemical processing plants, where exposure to harsh chemicals is common.

Water Treatment: SS 304 blind flanges are used in water treatment facilities to ensure safe and efficient operation.

Food and Beverage Industry: In food processing, these flanges maintain hygiene standards while providing a secure seal in piping systems.

HVAC Systems: Blind flanges are utilized in heating, ventilation, and air conditioning systems to close off unused or temporary openings.

Why Udhhyog is the Right Choice

At Udhhyog, we strive to ensure that our customers receive the best possible service and products. Our knowledgeable team is ready to assist you in finding the right SS 304 blind flanges for your specific requirements, providing expert advice and support throughout the procurement process.

By focusing on quality, affordability, and exceptional customer service, Udhhyog has established itself as a trusted supplier in the Indian industrial steel market. Explore our offerings today on our website and discover the seamless procurement experience that Udhhyog provides!

#SS304BlindFlange#BlindFlangeSupplier#StainlessSteelFlanges#IndustrialFlanges#SteelSuppliers#SteelIndustry#PipingSolutions#Udhhyog#B2BSteel#AffordableSteel#CorrosionResistantFlanges#ManufacturingFlanges#MSMEs#FlangeApplications

2 notes

·

View notes

Text

Key Drivers Fueling Growth in the Aramid Fiber Market

The global aramid fiber market was estimated at USD 4.09 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.1% from 2024 to 2030. This growth is largely attributed to rising demand from various industries, including oil and gas, healthcare, and manufacturing. The increasing focus on workplace safety, driven by stringent government regulations, is anticipated to further fuel market expansion throughout the forecast period.

However, the market experienced sluggish growth during the COVID-19 pandemic, primarily due to a decline in demand from the industrial sector. Government-imposed restrictions led to temporary shutdowns across a wide range of industries, significantly limiting market activity during that period.

Gather more insights about the market drivers, restrains and growth of the Aramid Fiber Market

Market Dynamics

Aramid fibers are renowned for their strength, synthetic nature, and heat resistance. These advantageous properties make them highly desirable in military and aerospace applications, particularly for ballistic-grade body armor fabric. One of the key features of aramid fibers is that they neither ignite nor melt under typical levels of oxygen, which provides excellent flame and heat resistance. Additionally, aramid fibers serve as substitutes for metal wires and organic fibers in structural composite applications, particularly in ropes used on oil rigs, marine and aerospace industries, automobiles, and bulletproof vests. Their superior mechanical properties—5% to 10% higher than those of other synthetic fibers—enhance their applicability in these demanding environments.

The aramid fiber industry is continuously evolving, with ongoing efforts to develop and manufacture synthetic fibers that meet the demands of new technologies. This includes replacing asbestos, which is known to be carcinogenic and toxic. Aramid fibers contribute strength and wear resistance to friction materials that do not contain asbestos. They allow for the selection of inert fillers based on thermal and wear characteristics, minimizing concerns related to the physical properties of those fillers. While asbestos is strong and can withstand chemical and high-temperature exposure, making it relatively inexpensive compared to other materials, its hazardous nature makes it a less desirable option in many applications.

Aramid fibers are used in two main types of applications: reinforcement in composites and fabrics in clothing. In the composite sector, they are utilized in military vehicles, sports goods, and aircraft. In the fabric sector, aramid fibers are crucial in creating protective clothing, such as bulletproof vests and fire-resistant garments. They are extensively employed across various applications, including protective gloves, sailcloth, flame- and cut-resistant clothing, snowboards, helmets, filament-wound pressure vessels, body armor, optical fiber cable systems, ropes and cables, tire reinforcement, rubber goods, tennis strings, hockey sticks, jet engine enclosures, asbestos replacement, and circuit board reinforcement.

In the U.S. market, growth is expected to be driven by the increased adoption of advanced material handling equipment, such as wagon tipplers, belt conveyor systems, and bucket elevators. These innovations facilitate the efficient movement and handling of materials, particularly within the cement industry. Additionally, the trend towards zero-labor warehousing has led to the adoption of advanced robotic systems, which is expected to further benefit market growth. Protective gear designed to safeguard workers from risks associated with hazardous jobs and challenging environmental conditions is another critical aspect of the aramid fiber market.

A significant portion of this protective gear is specifically engineered to shield employees from infections and pollution. Various end-use industries, including manufacturing, oil and gas, mining, healthcare, construction, and military, extensively utilize protective apparel. The ongoing increase in both onshore and offshore drilling activities, along with the expansion of the shale oil and gas industry, is expected to drive demand for aramid fibers in the U.S. market.

Among the different types of aramid fibers, the para-aramid fiber segment is projected to witness significant growth. This increase is attributed to the rising demand for para-aramid fibers across various applications, driven by their rigid molecular structure, which enhances their performance in demanding environments. As industries continue to recognize the value of aramid fibers in enhancing safety and performance, the market is well-positioned for robust growth in the coming years.

Order a free sample PDF of the Aramid Fiber Market Intelligence Study, published by Grand View Research.

#Aramid Fiber Market#Aramid Fiber Market Analysis#Aramid Fiber Market Report#Aramid Fiber Industry#Aramid Fiber Market Dynamics

0 notes

Text

Breather Vent Market Size, Share, Analysis and Opportunities by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Breather Vent Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Breather Vent Market, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Breather Vent Market?

The breather vent market is expected to grow at a CAGR of 7.8% during the forecast period of 2024 to 2032.

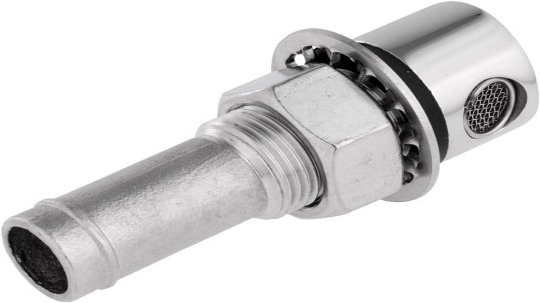

What are Breather Vent?

A breather vent is a specialized device designed to allow air to flow in and out of a sealed container or system, such as tanks, vessels, or pipelines, while keeping out contaminants, dust, and moisture. Its primary function is to equalize pressure changes that occur due to temperature variations, liquid transfers, or operational activities, thereby safeguarding the integrity of the container and its contents. Breather vents may include filters or check valves to enhance their effectiveness, ensuring that only clean air enters while allowing gases to escape safely. By maintaining proper pressure and preventing vacuum conditions, breather vents play a crucial role in the safe and efficient functioning of various industrial applications, including chemical storage, fuel tanks, and wastewater treatment systems.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1927

What are the growth prospects and trends in the Breather Vent industry?

The breather vent market growth is driven by various factors and trends. The breather vent market is witnessing consistent growth, propelled by the rising demand for effective pressure management solutions across various sectors, including oil and gas, chemical processing, and wastewater treatment. As regulations concerning safety and environmental protection tighten, companies are increasingly utilizing breather vents to maintain the integrity of their storage systems and prevent contamination. The market features a diverse range of products, including vents equipped with advanced functionalities such as filters, check valves, and automated monitoring systems that enhance both performance and reliability. Additionally, the growing emphasis on sustainable practices and the need for efficient resource management are contributing to market expansion. With ongoing technological innovations and heightened awareness of air quality and safety, the breather vent market is well-positioned for further growth, serving a variety of applications across multiple industries. Hence, all these factors contribute to breather vent market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Inline Breather Vent

Threaded Breather Vent

Bayonet Breather Vent

Customized Breather Vent

By Material:

Metal Breather Vent

Plastic Breather Vent

Composite Breather Vent

By End-Use Industry:

Automotive

Aerospace and Defense

Manufacturing

Oil and Gas

Chemicals and Pharmaceuticals

Electronics

Food and Beverage

Others

By Sales Channel:

Direct Sales

Distributor Sales

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Parker Hannifin Corporation

Donaldson Company, Inc.

MANN+HUMMEL GmbH

L. Gore & Associates, Inc.

Pall Corporation

Porvair Filtration Group

Eaton Corporation plc

SMC Corporation

Bosch Rexroth AG

Festo AG & Co. KG

Swagelok Company

Emerson Electric Co.

IMI plc

Camfil AB

WAMGROUP S.p.A.

View Full Report: https://www.reportsandinsights.com/report/Breather Vent-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Growing Importance of Duplex Plate Suppliers in Modern Industry

Duplex plates have gained success in many industries due to their unique properties of acquiring the best of austenitic and ferritic stainless steel characteristics. Strength, corrosion resistance, and cost-effectiveness make the duplex sheet highly used in oil and gas applications, chemical processing and in many marine applications. This paper delves deeper into the position duplex stainless steel plate occupy in the market, key applications, and major drivers for such growth.

Understanding Duplex Plates

Duplex plates are made of stainless steel alloy containing a mixture of almost 22% chromium, 5% nickel, and 3% molybdenum. The microstructure resulting from this unique composition is about 50% austenitic and 50% ferritic. These two phases combined provide duplex plates with exceptional mechanical properties, qualifying it for such vast applications.

One of the major strength-to-weight ratios duplex plates offer. This attribute allows for the employment of relatively thinner plates for construction and fabrication processes, which is likely to provide material savings along with weight reduction in the structure itself. The second attribute of duplex plates is excellent resistance to localized corrosion, including pitting and crevice corrosion, thus making it ideal for harsh environments.

Key Application Areas for Duplex Plates

Oil and gas industry: The application of duplex plates is highly important in offshore structures, pipelines, pressure vessels, etc. as it has high tensile strength along with the greater resistance to corrosion, thus suitable for aggressive conditions.

Chemical Processing: The chemical industry relies heavily on duplex plates for the manufacture of equipment that handles corrosive products. The advantage of duplex plates in this regard is their excellent resistance to harsh chemicals without diminishing the structural integrity of the equipment. This is why a lot of storage tanks, reactors, and heat exchangers are made from duplex plates.

Marine Applications: The excellent corrosion resistance of duplex plates in saltwater makes them suitable for use in marine environments. They are used in shipbuilding and in the construction of other applications, such as offshore platforms, that demand high strength and reliability.

Construction and Infrastructure: Duplex plates are widely applied in various structural applications in construction. They include beams, columns, and bracing systems. Such high strength allows for the creation of lighter and more efficient constructions, further contributing to overall project sustainability.

The pulp and paper industry is now widely using duplex plates for processing equipment manufacturing for wood pulp and other products. Due to the high strength associated with corrosion resistance, they are well applied in digesters, bleach towers, and other processing equipment.

Role of Duplex Plates

Duplex sheet are important so that the industries can get duplex plates of high quality to cater to their particular requirements. They procure duplex plates from the approved manufacturers and deliver them to the companies that require tough and reliable products.

A reliable duplex steel plate supplier provides several important advantages:

Quality Assurance: Suppliers that have a tight system of quality control ensure that duplex plates comply with the highest standards of requirement to be in line with designed applications. This is an assurance quality suited for safety and reliability during application.

Inventory Vasta: Reliable suppliers normally possess a gigantic inventory of duplex plates in various grades, sizes, and thickness. This is important so that firms might find the right product tailored to the right application.

Practical Guidelines from Experienced Suppliers Proficient suppliers provide actionable guidance and recommendations on the ideal DSS to be chosen for different purposes. This knowledge is actually beneficial to businesses to take the correct decision and, consequently, performs better.

Timely Shipment Duplex plates are essential to maintaining timeliness in projects. Logistically responsible suppliers ensure business schedules function seamlessly without any production delay.

Conclusion

Duplex steel sheet is one of those newly developed materials that in recent times have proved indispensable for innumerable industries around the world, because of their unique characteristics and suitability for various applications. Duplex plate suppliers play a very important role in offering high-quality material that needs to fulfill the strict demands of various applications. In diversifying the inventory, ensuring good quality, and guiding professionals, these suppliers play a significant role in the efficacy and prosperity of industrial operations. As the concept of industries continues to evolve and there are changes in the demand for duplex plates, reliance on good suppliers will definitely form a very important part of manufacturing and construction in the future.

0 notes

Text

Copper Nickel Alloy Flat Bar Cut Lengths

Copper Nickel (Cu-Ni) 90/10 scrap is a valuable and widely recycled material in various industries, including marine, chemical, and energy sectors. Composed of 90% copper and 10% nickel, this alloy offers excellent corrosion resistance, particularly in seawater and brine environments. Its scrap form is increasingly sought after due to the high value of both its primary constituents and its utility in environmentally friendly recycling processes.

Composition and Properties

The 90/10 Copper-Nickel alloy consists mainly of copper, with nickel making up the rest, along with trace elements like iron and manganese to enhance its corrosion resistance and strength. The alloy’s key properties include:

Corrosion resistance: Especially in marine environments, making it ideal for use in shipbuilding, offshore platforms, and desalination plants.

High strength and durability: Suitable for use in demanding applications, such as heat exchangers, hydraulic lines, and pressure vessels.

Thermal and electrical conductivity: Its relatively high conductivity makes it useful in heat exchanger tubes and power generation equipment.

Biofouling resistance: Reduces the accumulation of organisms on marine structures, further improving longevity in saltwater applications.

Sources of Copper Nickel 90/10 Scrap

Marine Equipment: Since Cu-Ni 90/10 is used extensively in shipbuilding for components like piping, heat exchangers, and condensers, decommissioned ships and maritime equipment provide a significant source of scrap.

Heat Exchangers: Widely used in industries such as power generation, chemical processing, and oil refineries. Damaged or outdated heat exchangers contribute to the scrap supply.

Manufacturing Offcuts: Waste from the manufacturing process of new copper-nickel products is a valuable source of scrap, as it can be re-melted and reformed.

Obsolete Equipment: Industrial equipment containing 90/10 copper-nickel alloys, particularly in desalination plants and petrochemical refineries, provides another source.

Recycling Process

The recycling process for Copper Nickel 90/10 scrap is straightforward and energy-efficient compared to mining and refining new raw materials. Here's an outline of the general steps involved:

Collection and Sorting: Scrap is collected from various sources and sorted based on composition. Scrap dealers and industrial recyclers assess its purity and content.

Melting: The sorted scrap is melted down in a furnace, where impurities are removed. Advanced technologies, such as induction or electric arc furnaces, are used to ensure purity.

Refining and Alloying: If necessary, the molten scrap is refined further to adjust the proportions of copper, nickel, and other trace elements.

Casting and Forming: The purified material is cast into ingots or other shapes for re-use in manufacturing.

Economic Value

The market value of Cu-Ni 90/10 scrap is closely tied to the global prices of copper and nickel. Both metals are crucial in various industrial applications, making their demand relatively stable. Given the cost of producing new copper-nickel alloys, recycling scrap offers significant savings in terms of energy, raw material costs, and environmental impact. Additionally, as industries become more focused on sustainability, the demand for high-quality recycled materials continues to grow.

Environmental Impact

Recycling Copper Nickel 90/10 scrap helps to significantly reduce the environmental footprint of copper and nickel production. Mining and refining copper and nickel ores are energy-intensive and produce a substantial amount of greenhouse gases. By reprocessing scrap, the need for raw material extraction is minimized, leading to lower energy consumption, reduced emissions, and conservation of natural resources.

Applications of Recycled Copper Nickel 90/10

Recycled Copper Nickel 90/10 scrap is re-used in several industries, often in the same applications as the original material:

Marine Engineering: Pipes, heat exchangers, and valves used in seawater environments.

Desalination Plants: Condensers and heat exchangers for handling high-salinity fluids.

Chemical Processing: Equipment in chemical plants that need to withstand corrosive environments.

Energy Production: Heat exchangers and power generation equipment.

Challenges in Recycling

While the recycling process for Cu-Ni 90/10 scrap is efficient, there are some challenges:

Contamination: Scrap may sometimes be contaminated with other metals, which can affect the purity of the recycled material. Sorting and refining processes must be precise to ensure a high-quality end product.

Supply Fluctuations: The availability of scrap depends on the lifecycle of industrial equipment and structures, leading to potential fluctuations in supply.

Conclusion

Copper Nickel 90/10 scrap is a highly valuable and versatile material that plays a critical role in the circular economy. Its excellent corrosion resistance and thermal properties make it ideal for demanding applications, particularly in marine and industrial environments. The recycling of this alloy not only conserves natural resources but also reduces the environmental impact of metal production. As industries move toward more sustainable practices, the demand for Copper Nickel 90/10 scrap is expected to grow, further enhancing its importance in global markets.

0 notes

Text

A Comprehensive Guide to "Which Poppers Are the Best?" and "Strongest Poppers in the UK"

When it comes to choosing the best poppers and identifying the strongest poppers available in the UK, it's essential to have accurate and reliable information. Poppers, widely recognized for their recreational use, especially within certain communities, are a type of inhalant that provides a quick, intense, and often euphoric experience. However, with the variety of brands and formulations available in the market, finding the best poppers can be a daunting task. This article aims to guide you through the process, helping you make informed decisions on which poppers are the best for your needs.

Understanding Poppers: A Quick Overview

Before diving into the specifics, it's essential to understand what poppers are and how they work. Poppers are a class of chemicals called alkyl nitrites, with amyl nitrite, isopropyl nitrite, and butyl nitrite being the most common. When inhaled, poppers cause a rapid dilation of blood vessels, leading to increased blood flow and a short-lived but intense sensation of warmth, light-headedness, and euphoria. This effect is primarily due to the sudden drop in blood pressure and the rush of blood to the brain.

Factors to Consider When Choosing Poppers

Selecting the best poppers involves considering several factors that contribute to their effectiveness and safety. Here are the key considerations:

Chemical Composition: Different poppers are made from various nitrite compounds, each offering a slightly different experience. Amyl nitrite, for example, is known for its potent effects and longer-lasting high, while isopropyl nitrite provides a quick but brief rush.

Brand Reputation: The reputation of the brand is crucial. Established brands are more likely to produce high-quality, safe products. Reading reviews and seeking recommendations can help you identify trusted brands.

Potency and Strength: The strength of the poppers is a significant factor, especially for those seeking the strongest poppers in the UK. Some products are specifically formulated to provide a more intense experience.

Legality and Safety: Ensure that the poppers you choose are legal in your country or region. In the UK, for instance, certain types of nitrites are regulated, and it's important to purchase poppers from a reputable source that complies with local laws.

User Experience: Consider what kind of experience you are seeking. Some users prefer a mild, relaxing sensation, while others may be looking for a more intense and prolonged effect. The best poppers for you will depend on your preferences.

Which Poppers Are the Best?

Now that we have outlined the factors to consider, let's explore some of the best poppers available in the UK market, taking into account their strength, reputation, and user feedback.

1. Amyl Night

Amyl Night is often considered one of the best poppers due to its strong and long-lasting effects. It is made from amyl nitrite, which is known for providing a powerful and extended high. Users frequently report that Amyl Night offers a deep, euphoric experience with a slower onset, making it ideal for those who prefer a more prolonged sensation.

2. Rush Poppers

Rush Poppers are one of the most iconic and widely recognized brands globally. Known for their consistent quality, Rush Poppers offer a potent but smooth experience. They are particularly popular among those who are new to using poppers because of their balanced effects. Rush is made from isopropyl nitrite, which gives a fast-acting, intense rush that fades quickly, making it suitable for short bursts of euphoria.

3. Amsterdam Poppers

Amsterdam Poppers are another top contender, especially for those looking for a strong and reliable product. Named after the famous city, these poppers are known for their potent effects and long-lasting high. Amsterdam Poppers are particularly favored by users who enjoy a stronger experience without the harshness that some other brands might cause.

4. Jungle Juice

Jungle Juice is a brand that has gained a reputation for producing some of the most potent poppers on the market. They offer a variety of formulations, including Jungle Juice Platinum and Jungle Juice Black Label, both of which are known for their strength and intensity. These poppers are made from a blend of nitrites, offering a balanced yet powerful effect, making them a popular choice among experienced users.

5. Liquid Gold

Liquid Gold is a classic brand that has been a staple in the poppers market for years. Known for its smooth and consistent effects, Liquid Gold is made from isopropyl nitrite and offers a quick, intense rush. It is particularly popular for its reliability and is often recommended for both new and experienced users.

The Strongest Poppers in the UK

For those specifically seeking the strongest poppers available in the UK, the following brands and products are highly recommended:

1. Titanium

Titanium poppers are known for their exceptional strength and are considered one of the most potent options available in the UK. Made from a blend of powerful nitrites, Titanium poppers provide a fast and intense rush that is ideal for those who want a more extreme experience. They are particularly popular among seasoned users who are looking for the strongest effects.

2. Everest Premium

Everest Premium poppers are another top choice for those seeking strength and intensity. These poppers are formulated to provide a powerful and long-lasting high, making them a favorite among experienced users. Everest Premium is known for its purity and potent effects, offering one of the most intense experiences available.

3. The Real Amsterdam

The Real Amsterdam is often cited as one of the strongest poppers available in the UK. It is made from a high-purity formula that delivers a powerful and immediate rush. This product is particularly popular in the gay community, where it is often used for its intense and prolonged effects.

4. Iron Horse

Iron Horse poppers are known for their strength and endurance. Made from a high-quality isopropyl nitrite formula, Iron Horse offers a potent and lasting experience. These poppers are ideal for users who want a strong and consistent effect that doesn’t fade too quickly.

Safety Tips When Using Poppers

While poppers are widely used and generally considered safe when used responsibly, it's essential to follow some basic safety guidelines:

Do Not Ingest: Poppers are for inhalation only and should never be ingested, as this can be extremely dangerous.

Avoid Prolonged Use: Frequent or prolonged use of poppers can lead to adverse health effects, including headaches, dizziness, and respiratory issues.

Store Properly: Keep poppers in a cool, dry place, away from direct sunlight and heat, to maintain their potency and prevent accidents.

Use in a Safe Environment: Always use poppers in a safe, controlled environment where you feel comfortable. Avoid using them while driving or operating machinery.

When searching for the best poppers in the UK, several options stand out based on popularity, potency, and user preference. Here are some top recommendations from UK-Poppers.com:

Jungle Juice Black - Known for its potent blend and consistent, powerful sensation, it's a favorite among experienced users (UK Poppers).

Liquid Gold - A classic choice in the UK, appreciated for its reliable quality and pleasant aroma, making it suitable for both beginners and seasoned users (UK Poppers) (UK Poppers).

Rush Black Label - Renowned for its intense sensation and distinctive packaging, it's a top pick for those seeking a robust experience (UK Poppers).

Original Amsterdam Gold - A staple with a rich heritage, offering a classic formulation and unforgettable aroma (UK Poppers).

Double Scorpio - A newer entry that's quickly become popular due to its unique formulation and premium quality (UK Poppers) (UK Poppers).

For those new to poppers, starting with milder options like Liquid Gold can provide a balanced experience without overwhelming the senses. It's important to pay attention to your body's response and seek advice from knowledgeable sources when selecting the right product for your needs (UK Poppers).

Conclusion

Choosing the best poppers and identifying the strongest poppers in the UK depends on your individual preferences and experience level. Brands like Amyl Night, Rush, and Titanium offer some of the best options available, known for their quality, potency, and user satisfaction. Always prioritize safety and legality when selecting poppers, and consider starting with well-known, reputable brands. Whether you're new to poppers or an experienced user, this guide should help you make an informed choice that suits your needs.

1 note

·

View note

Text

A remarkable steel component - Duplex and Super Duplex stainless steel

Best mechanical gear in the City, Duplex and Super duplex stainless steel are one of those market disrupters products which are high in demand due to it’s strength, anti-corrode, and affordability. Cut to chase these material are a form of unique microstructure, which induges both austenitic and ferrritic steel properties. As Duplex stainless steel is a permutation combination of 50% austenite and 50% ferrite, let’s take a thorough understanding about Super Duplex steels, further to add these steel component has a high chromium content, increasing the efficiency of resistance against corrosion.

The very initial stage that lies in their advance mechanical properties which makes Duplex and Super duplex stainless steel an Superficial metal. Offering a sense of superior strength in comparison to traditional austenic steel, which stands parallel to performance in very high stress environments.

For oil & gas industries Duplex and Super duplex stainless steel are boon for sure, as steel plays a crucial role in pipeles and pressure vessels that effectively sustains even in extreme environments.

However, affordability of Duplex and Super duplex stainless steel cannot be diminished. Despite their highly efficient performance, these materials are the most refined form of steel, compared to astenic steel the prices of Duplex and Super Duplex steel is even affordable due to lower range of nickel content. The cost-effieciency and durable margins, makes a stricking remark for these steel for multiple industrial scenarios.

A crucial factor is their ease of fabrication. Duplex and Super Duplex Steels can be molded and mechanically monitored with relative ease, for more flexible design and manufacturing processes. The versatile ability like mechanical and chemical composition, maes therm suitable for any condition, from construction, infrastructure to chemical processing and power generation.

To conclude, Duplex and Super Duplex steels are significantly the most versatile materials which offers relevant balance of strength, anti-corrosion, & affordability. Such USP makes the steel an invaluable asset in challenging conditions, ensuring that the performance of steel is not compromised and it sustains in critical applications too.

1 note

·

View note

Text

Composites In Oil & Gas Industry Market worth $3.4 billion by 2028

The report "Composites In Oil & Gas Industry Market by Resin Type (Epoxy, Composites, Polyester, Phenolic), Fiber Type (Carbon, Glass,), Application (Pipes, Tanks, Top Side Applications, Pumps & Compressors), and Region - Global Forecasts to 2028", is estimated at USD 2.3 billion in 2022 and is projected to reach USD 3.4 billion by 2028, at a CAGR of 6.1% from 2023 to 2028. Factors such as the superior properties of composites like corrosion resistance, lightweight and high strength, durability, and improved performance are positively driving the growth of the Composites In Oil & Gas Industry Market. Furthermore, The rising applications from emerging economies and the adoption of composites will further propel the growth rate of the oil and gas composites market. The low maintenance cost of composites is projected to strengthen the market's growth.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=75947166

Glass fiber segment is expected to account for largest share in 2022.

Glass fiber composites are widely used in the oil and gas industry due to their excellent mechanical properties and resistance to corrosion. They are used in various applications such as pipelines, tanks, pressure vessels, and offshore structures. The market for glass fiber composites in the oil and gas industry is expected to grow significantly in the coming years, driven by the increasing demand for lightweight and durable materials in various applications. The market is also influenced by the increasing need for efficient and safe operations in the oil and gas industry.

Pipes application segment held the largest market share in the composites in oil & gas industry market

There has been major advances in the fields of composite pipe work and fluid handling. Cost-cutting due to composites replacing steel piping in retrofit applications is a major driver for the market. Cost advantage can also be witnessed during the manufacturing process of risers, tubings, and storage and transport systems in offshore platforms when composites are used in place of expensive corrosion-resistant metals. Another important propellant for the market is amplified longevity of new, reliable, safe, and cost-effective construction, which can withstand severe conditions anticipated in an offshore environment.

Sample Request-https://www.marketsandmarkets.com/requestsampleNew.asp?id=75947166

North America is expected to account for the largest share in 2022

The composites in oil & gas industry market has been studied in North America, Europe, Asia Pacific, Middle East & Africa and Latin America. The Asia-Pacific composites in oil & gas industry market is being driven by growing need of energy which propelling the need for oil & gas resources. North America is likely to remain the key region owing to the rising number of natural gas infrastructure projects and growing awareness about advantages of composite materials in the region. The market in the region is expanding also due to the rise in demand for high-performance lightweight materials and new products developed using them.

Major players operating in the composites in oil & gas industry market Baker Hughes (US), NOV Inc. (US), SLB (Schlumberger N.V.) (US), Halliburton (US), Shawcor (Canada), are some of the market players.

#OilAndGas#Composites#EnergySector#OilAndGasIndustry#CompositeMaterials#EnergyInnovation#AdvancedMaterials#IndustrialComposites#OilAndGasTechnology#SustainableEnergy#MaterialScience#EngineeringInnovation#CompositeEngineering#OilGasMarket#EnergyEfficiency

0 notes

Text

Hydrogen Storage: Advancements, Challenges, and Opportunities in the Quest for Clean Energy

Hydrogen is considered as one of the cleanest and most abundant energy resources available on Earth. Being the lightest element, hydrogen has the highest energy content per unit of weight. However, hydrogen has low energy density per unit volume as a gas which makes its storage challenging. Advancements in storage is crucial for developing a hydrogen economy and enabling its use as a renewable transportation fuel.

Physical vs Chemical Storage Methods

Physical storage methods involve compressing or liquefying hydrogen into a liquid or dense gas while chemical storage incorporates hydrogen molecules into chemical compounds. Both approaches have their advantages and limitations. Compressed Gas Storage

Storing hydrogen gas at high pressures up to 700 bar is currently the most developed storage method in use. Compressed hydrogen gas cylinders allow quick refueling but have relatively low gravimetric and volumetric densities. Additionally, high pressure vessels require heavy reinforcement increasing system weight. Ongoing research focuses on developing low cost high strength lightweight composite tanks to improve storage capacities. Liquid Hydrogen Storage

Cooling hydrogen to below -252.8°C is another physical method to condense it into a liquid with increased density. However, cryogenic Hydrogen Storage requires considerable energy input for liquefaction and insulation to prevent boil off losses. Special cryogenic tanks must also withstand temperature fluctuations. Researchers have managed to reduce boil off rates to acceptable levels but further cost reductions are needed. Metal Hydrides for Storage

Metal hydrides are among the most promising chemical storage methods. They involve hydrogen reacting reversibly with metals or alloys to form metal hydrides. Various hydrides demonstrate reasonable storage capacities, fast reaction kinetics for refueling and ability to operate under moderate temperatures and pressures. However, hydrides often have high material costs and weight penalties limiting practical gravimetric storage densities. Ongoing R&D focuses on exploring new low cost high capacity hydride materials. Complex Hydrides

Complex hydrides containing light elements like boron and nitrogen in addition to metals show enhanced hydrogen capacities exceeding typical metal hydrides. Examples include sodium and magnesium borohydrides (NaBH4, Mg(BH4)2). Although these have high theoretical hydrogen densities, current materials release hydrogen only at elevated temperatures above 200°C limiting practical use. Understanding decomposition pathways and developing destabilized derivatives remains an active area of complex hydride research. Get more insights on Hydrogen Storage

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

0 notes

Text

A516 Grade 70 Steel Plates Dealers

INTRODUCTION:- Vandan Steel & Engg. co. depended on the hypothesis of persistently seeing the necessities of its customers and understanding that quality, on-time movement, cost and customer advantage are imperative to it accomplishment. Vandan Steel & Engg. co. depended on the hypothesis of persistently seeing the necessities of its customers and understanding that quality, on-time movement, cost and customer advantage are imperative to it accomplishment. Vandan Steel & Engg. co. is a fundamental exporter and shipper of SA 516 GR.70 plates in the overall trading market. These plates are extensively used in a wide extent of uses in both the advanced and business division. The plates are made into different shapes, sizes, structures and points of interest recalling the requirements of customers. In any case, SA 516 GR.70 is one of the conspicuous steel assessments used for collecting different applications. In the realm of structural engineering and industrial applications, the choice of material holds paramount importance. Among the plethora of options, A516 Grade 70 steel plate emerges as a beacon of reliability and durability. As pioneers in the steel industry, Vandan Steel & Engg. Co. brings forth an in-depth exploration of the unmatched attributes of A516 Grade 70 steel plate.

DESCRIPTION:- A516 Grade 70 steel plate is a high-quality carbon steel plate primarily designed for use in pressure vessels and boilers. Its superior characteristics stem from its composition, which includes elements like carbon, manganese, phosphorus, sulfur, silicon, and trace amounts of other alloying elements. This concoction results in a robust material with exceptional tensile strength, yield strength, and notch toughness, making it ideal for withstanding extreme operating conditions.

The plates are known for their incredible features and properties which makes them much all the additionally mentioning for a wide extent of uses. We have a guaranteed getting and exchanging industry hold an enormous stock of such plates. Before giving it to the customers, we guarantee that all of our things are deformation and damage free and offer the best results under the specific areas of working.

The steel plates are made available to customers as per their advantage and need. The total name for SA516 standard is the standard detail for carbon steel, weight vessel plates, and lower temperature. What's more, the SA 516 assessment is astoundingly one of the standard steel assessments having five engineered segments that are demonstrated with the three mechanical properties.

The assessment doesn't require to be warmth treated; subsequently it offers the best properties and features. Our point is to outfit our customers with a high bore of the thing which has all of the attributes that an application requires for working. The plates are comprehensively used in different applications in perspective on its easy to use and foundation process.

SPECIFICATION:- High tensile strength Corrosion and oxidation resistance Durability Workability Formability Long service life Excellent weldability

BENEFITS:- High Strength: A516 Grade 70 steel plate exhibits remarkable strength properties, ensuring structural integrity and longevity even under demanding environments. Excellent Weldability: Its weldability characteristics facilitate ease of fabrication, allowing for efficient construction processes. Resistance to Corrosion: With its corrosion-resistant properties, A516 Grade 70 steel plate guarantees longevity and low maintenance requirements, thus offering cost-effective solutions. Versatility: From pressure vessels to boilers, A516 Grade 70 steel plate finds extensive applications across diverse industries, showcasing its versatility and adaptability. Cost Efficiency: The longevity and reliability of A516 Grade 70 steel plate translate into cost savings over its lifecycle, making it a prudent investment for various projects.

CONCLUSION:- In conclusion, A516 Grade 70 steel plate stands as a testament to innovation and excellence in material engineering. Its unparalleled strength, durability, and versatility make it the preferred choice for critical applications in numerous industries. At Vandan Steel & Engg. Co., we take pride in offering top-tier products like A516 Grade 70 steel plate, backed by our commitment to quality and customer satisfaction.

CONTACT US:- Phone : 022-23893665 Phone : +91-8828813630 E-mail : [email protected]

0 notes

Text

Pressure Vessel Market Outlook to 2031

The Insight Partners recently announced the release of the market research titled Pressure Vessel Market Outlook to 2031 | Share, Size, and Growth. The report is a stop solution for companies operating in the Pressure Vessel market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. Pressure Vessel Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, The Insight Partners is helping brands unlock revenue opportunities in the Pressure Vessel market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated Pressure Vessel market research has all that you need.

What are Key Offerings Under this Pressure Vessel Market Research?

Global Pressure Vessel market summary, current and future Pressure Vessel market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global Pressure Vessel Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the Pressure Vessel Market?

Pressure Vessel market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. Pressure Vessel market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their Pressure Vessel market share.

Report Attributes

Details

Segmental Coverage

Material

Steel Alloys

Other Alloys

Composites

Type

Boilers

Nuclear Reactors

Separators

Others

End user Industry

Oil and Gas

Chemicals

Power Generation

Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

BabcockandWilcoxEnterprisesInc.

BharatHeavyElectricalsLimited

DoosanHeavyIndustriesandConstruction

GeneralElectricCompany

HalvorsenCompany

IhiCorporation

LarsenandToubroLimited

MitsubishiHeavyIndustriesLtd.

PressureVessels(India)

WestinghouseElectricCompanyLlc.

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective Pressure Vessel market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The The Insight Partners offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The Pressure Vessel market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

Innovative Materials and Technological Advancements Propel the Pressure Vessel Market to Remarkable Growth, Anticipated CAGR Surge Ahead

Overview and Scope Pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. These are used for storing liquid or gases such as petroleum products, chemicals, or even air or water at high pressure. Sizing and Forecast The pressure vessel market size has grown strongly in recent years. It will grow from $38.33 billion in 2023 to $40.39 billion in 2024 at a compound annual growth rate (CAGR) of 5.4%. The pressure vessel market size is expected to see strong growth in the next few years. It will grow to $49.94 billion in 2028 at a compound annual growth rate (CAGR) of 5.4%. To access more details regarding this report, visit the link: https://www.thebusinessresearchcompany.com/report/pressure-vessel-global-market-report Segmentation & Regional Insights The pressure vessel market covered in this report is segmented – 1) By Type: Boiler, Reactor, Separator, Other Types 2) By Heat Source: Fired, Un-Fired 3) By Material Type: Steel Alloys, Composites, Other Material Types 4) By Application: Storage Vessels, Processing Vessels 5) By End-User Channel: Power, Oil and Gas, Food and Beverages, Pharmaceuticals, Chemicals, Other End-User Channels North America was the largest region in the pressure vessel market share in 2023. Western Europe was the second-largest region in the pressure vessel market analysis. The regions covered in the pressure vessel market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa. Intrigued to explore the contents? Secure your hands-on sample copy of the report: https://www.thebusinessresearchcompany.com/sample.aspx?id=8567&type=smp Major Driver Impacting Market Growth The rising global thermal energy demand leading to the growing adoption of pressure vessels is the major driver for the growth of the market. Thermal energy is the term used to describe the energy present in a system that determines its temperature. Nuclear energy is used to generate thermal power and there are different pressure vessels used in the production process where vessels provide one of several barriers that keep radioactive material out of the environment. Key Industry Players Major companies operating in the pressure vessel market report are Babcock & Wilcox Enterprises, General Electric Company, Larsen & Toubro, Mitsubishi Hitachi Power Systems, Hitachi Zosen, Bharat Heavy Electricals Limited, Samuel Pressure Vessel Group, Halvorsen Company, Doosan Heavy Industries & Construction Co. Ltd The pressure vessel market report table of contents includes: 1. Executive Summary 2. Market Characteristics 3. Market Trends And Strategies 4. Impact Of COVID-19 5. Market Size And Growth 6. Segmentation 7. Regional And Country Analysis . . . 27. Competitive Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected] Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Unveiling the Strength and Versatility of Duplex Stainless Steel

In the world of metallurgy, a material that has been gaining significant attention for its exceptional properties is Duplex Stainless Steel (DSS). This alloy, known for its unique combination of austenitic and ferritic microstructures, offers a myriad of benefits that make it a standout choice in various industries.

1. Corrosion Resistance: One of the most remarkable features of Duplex Stainless Steel is its outstanding corrosion resistance. With a balanced composition of chromium, nickel, and molybdenum, DSS can withstand aggressive environments, making it ideal for applications in chemical processing, marine engineering, and oil and gas industries.

2. High Strength: Duplex Stainless Steel boasts a high tensile strength, providing exceptional durability and structural integrity. This makes it an excellent choice for demanding applications, such as in the construction of bridges, pressure vessels, and offshore structures.

3. Versatility in Applications: From heat exchangers to piping systems, Duplex Stainless Steel finds its utility in a wide range of applications. Its versatility extends to various industries, including architecture, food processing, and pulp and paper, showcasing its adaptability to diverse and challenging environments.

4. Cost-Effective Solution: While Duplex Stainless Steel offers superior performance, it also presents a cost-effective solution compared to some other high-performance alloys. Its longevity and minimal maintenance requirements contribute to its overall economic appeal.

5. Sustainability in Design: As sustainability becomes a focal point in material selection, Duplex Stainless Steel aligns with the principles of eco-friendly engineering. Its longevity, recyclability, and energy efficiency make it a responsible choice for environmentally conscious projects.

In conclusion, Duplex Stainless Steel stands as a testament to the advancements in metallurgical engineering, combining strength, corrosion resistance, and versatility in a single alloy. As industries continue to seek materials that can withstand challenging conditions without compromising on performance, Duplex Stainless Steel emerges as a frontrunner, paving the way for innovation and reliability in engineering and construction.

Browse More reports:

0 notes

Text

Why Nobody Cares About Silicon Bronze Fasteners

Marine fasteners play an important duty on the planet of seafaring, guaranteeing the safety and also integrity of ships, boats, offshore structures, and also marine equipment. These important elements secure numerous components of vessels, offering a robust connection that can withstand the severe problems of the open sea. In this write-up, we delve into the importance of marine bolts, their various types, materials, as well as applications, along with the difficulties faced in guaranteeing their effectiveness in maritime atmospheres.

The Significance of Marine Fasteners

Marine bolts work as the supports of the maritime market. They are in charge of holding with each other vital parts such as hulls, decks, poles, rigging, and numerous mechanical systems on board ships and also boats. Given the extreme conditions encountered at sea, consisting of saltwater direct exposure, high humidity, continuous resonances, as well as significant mechanical stress and anxiety, aquatic bolts have to be extremely long lasting, corrosion-resistant, and also reputable.

Kinds Of Marine Fasteners

Screws and also Nuts: Bolts and also nuts are amongst the most typically utilized fasteners in aquatic applications. They are developed to supply a strong, removable link as well as can be found protecting equipment, structures, and equipment aboard ships.

Screws: Screws are used when a solid long-term link is required. They are commonly made use of to fasten timber, steel, or composite products in different aquatic applications.

Rivets: Rivets are bolts that create an irreversible link between 2 or more components by warping the tail end of the rivet after setup. They are widely made use of in shipbuilding as well as repair.

Washers: Washers are utilized with bolts as well as nuts to disperse the pressure and avoid damages to the linked products.

Pins and also Clips: These fasteners are utilized to secure rigging and also various other elements that require constant disassembly and reassembly.

Materials Used in Marine Fasteners

Marine bolts are made from products that show phenomenal resistance to rust as well as wear and tear in aquatic environments. Some common materials consist of:

Stainless-steel: Marine-grade stainless steel, such as 316 or 316L, is widely utilized due to its outstanding rust resistance, strength, and also sturdiness.

Brass: Brass bolts are prominent for their corrosion resistance as well as visual appeal, making them appropriate for sure marine applications.

Silicon Bronze: Silicon bronze fasteners are known for their exceptional deterioration resistance, making them ideal for marine hardware like cleats, hatches, and also port lights.

Monel: Monel fasteners provide excellent resistance to deep sea deterioration and are typically utilized in aquatic applications where high stamina is required.

Difficulties in Marine Fasteners

The aquatic setting presents one-of-a-kind difficulties for bolts, necessitating mindful design and also selection. Some of the major challenges include:

Corrosion: The most significant difficulty faced by marine bolts is rust due to exposure to deep sea, bring about galvanic deterioration, gap rust, and also pitting. Selecting the best corrosion-resistant material is important.

Load and Vibration: Ships as well as boats experience constant loads as well as resonances throughout operation, which can create fasteners to loosen up with time. Proper tightening methods as well as lock nuts are employed to combat these effects.

Temperature Level Extremes: Marine fasteners must stand up to a variety of temperature levels, from freezing conditions in polar areas to scorching warm Copper Nails in exotic locations.

UV Exposure: Fasteners on the outside components of a vessel are exposed to dangerous UV radiation, which can degrade particular products in time.

Marine bolts are the backbone of maritime safety and security and also dependability. From huge cargo vessels to little enjoyment boats, these unassuming elements ensure that ships as well as boats remain structurally sound, reliable, and safe in the challenging marine setting. The option of appropriate materials and layouts is critical to deal with deterioration as well as mechanical stresses, ensuring that marine fasteners continue to satisfy their essential role in the seafaring market. As modern technology as well as product science advancement, aquatic fasteners will unquestionably come to be much more durable, additional boosting the safety as well as performance of vessels around the world.

0 notes