#Pharmaceuticals Packaging Testing Equipment Market forecast

Text

Global top 13 companies accounted for 66% of Total Frozen Spring Roll market(qyresearch, 2021)

The table below details the Discrete Manufacturing ERP revenue and market share of major players, from 2016 to 2021. The data for 2021 is an estimate, based on the historical figures and the data we interviewed this year.

Major players in the market are identified through secondary research and their market revenues are determined through primary and secondary research. Secondary research includes the research of the annual financial reports of the top companies; while primary research includes extensive interviews of key opinion leaders and industry experts such as experienced front-line staffs, directors, CEOs and marketing executives. The percentage splits, market shares, growth rates and breakdowns of the product markets are determined through secondary sources and verified through the primary sources.

According to the new market research report “Global Discrete Manufacturing ERP Market Report 2023-2029”, published by QYResearch, the global Discrete Manufacturing ERP market size is projected to reach USD 9.78 billion by 2029, at a CAGR of 10.6% during the forecast period.

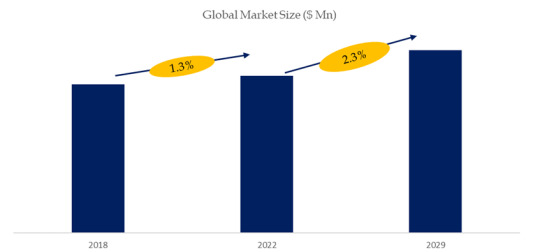

Figure. Global Frozen Spring Roll Market Size (US$ Mn), 2018-2029

Figure. Global Frozen Spring Roll Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Discrete Manufacturing ERP include Visibility, Global Shop Solutions, SYSPRO, ECi Software Solutions, abas Software AG, IFS AB, QAD Inc, Infor, abas Software AG, ECi Software Solutions, etc. In 2021, the global top five players had a share approximately 66.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

2 notes

·

View notes

Text

Ginger Market Developments, Trends & Opportunities till 2032

Ginger Market provides in-depth analysis of the market state of Ginger manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Ginger in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Ginger Market Report:

The report offers a comprehensive and broad perspective on the global Ginger Market.

The market statistics represented in different Ginger segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Ginger are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Ginger.

Major stakeholders, key companies Ginger, investment feasibility and new market entrants study is offered.

Development scope of Ginger in each market segment is covered in this report. The macro and micro-economic factors affecting the Ginger Market

Advancement is elaborated in this report. The upstream and downstream components of Ginger and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/ginger-market-100565

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Artificial Meat MarketMarket Growth

Dermo-Cosmetics MarketMarket Analysis

Hand Dryers MarketMarket Size

Global Glass Fiber Reinforced Gypsum (GFRG) Panels MarketMarket Share

Global Mountain Bicycles MarketMarket Growth

Aseptic Packaging For The Pharmaceutical MarketMarket

Automotive Simulation MarketMarket Share

Semiconductor Chip Handler MarketMarket Growth Rate

Transcranial Magnetic Stimulator MarketMarket Forecast

Global Cloud Natural Language Processing MarketMarket Size

Education Technology (EdTech) MarketMarket Growth

Digital English Language Learning MarketMarket Analysis

Macromolecule Hydrogel MarketMarket Size

Global Luxury Vinyl tile (LVT) MarketMarket Share

Global Virtual Power Plant MarketMarket Growth

Digital Diagnostics MarketMarket

LED Lens MarketMarket Share

UAV Propellers MarketMarket Growth Rate

Computer Keyboards MarketMarket Forecast

Global Peanut Allergy Therapeutics MarketMarket Size

Advanced Ceramics MarketMarket Growth

Drone Defense System MarketMarket Analysis

Urea Formaldehyde Concentrate (UFC) MarketMarket Size

Global Bike Tube & Tire MarketMarket Share

Global Rhodiola Rosea P.E. MarketMarket Growth

Aerospace Inconel Blisk MarketMarket

Commercial Airport Baggage Handling System MarketMarket Share

Mica Tape for Insulation MarketMarket Growth Rate

Radio Frequency (RF) Energy Harvesting MarketMarket Forecast

Global Architectural Acoustic Panels MarketMarket Size

Arsenic Removal MarketMarket Growth

Carbon Dioxide MarketMarket Analysis

Air Quality Apps MarketMarket Size

Global Positive Temperature Coefficient (PTC) Thermistors MarketMarket Share

Global X-ray Non-Destructive Testing Equipment MarketMarket Growth

Atorvastatin Calcium MarketMarket

Fermentation Airlock MarketMarket Share

Mica Paper MarketMarket Growth Rate

Baggage Towing Tractor MarketMarket Forecast

Global Foldable IOL Market MarketMarket Size

0 notes

Text

Reverse Tuck Box Market Insights: Comprehensive Global Forecast (2023-2032)

The global Reverse Tuck Box Market is projected to grow from USD 2415.4 million in 2024 to USD 2989.19 million by 2032, reflecting a compound annual growth rate of 2.70%.

A reverse tuck box is a type of packaging commonly used for retail products, particularly in the cosmetics, pharmaceuticals, and consumer goods industries. This box design features two tuck flaps that open in opposite directions; one flap tucks in from the front, and the other tucks in from the back. This unique structure provides added security and ease of access for consumers while maintaining the integrity of the product inside. The reverse tuck box is often preferred for its versatility, cost-effectiveness, and efficient use of material, making it a popular choice for manufacturers looking to balance functionality with aesthetic appeal. Additionally, these boxes can be easily customized with various printing options to enhance brand visibility and product presentation on store shelves.

The reverse tuck box market faces several challenges that impact its growth and adoption across various industries. These challenges include:

Cost Fluctuations in Raw Materials: The prices of raw materials, such as paperboard and printing inks, can fluctuate due to changes in supply and demand, affecting the overall production cost of reverse tuck boxes. Manufacturers must manage these cost variations to remain competitive.

Environmental Concerns: Increasing awareness about environmental sustainability and the demand for eco-friendly packaging solutions pose a challenge for the reverse tuck box market. Manufacturers need to adopt sustainable practices and materials, which can be more costly and complex.

Intense Competition: The packaging industry is highly competitive, with numerous alternatives available, such as blister packs, clamshells, and flexible packaging. Reverse tuck box manufacturers must continually innovate to differentiate their products and maintain market share.

Customization Costs: While customization is a key advantage of reverse tuck boxes, it can also be a challenge. Custom designs, printing, and finishing options can significantly increase production costs and lead times, making it difficult for smaller manufacturers to compete.

Regulatory Compliance: Packaging for certain products, particularly in the pharmaceutical and food industries, must adhere to stringent regulatory standards. Ensuring compliance can be challenging and may require additional testing and certification, adding to production costs and time.

Supply Chain Disruptions: Disruptions in the supply chain, such as delays in raw material delivery or transportation issues, can impact the timely production and delivery of reverse tuck boxes, affecting customer satisfaction and business operations.

Technological Advancements: Keeping up with technological advancements in printing and packaging machinery is essential for maintaining efficiency and product quality. However, the high cost of upgrading equipment can be a barrier for some manufacturers.

Market Saturation: In mature markets, the demand for reverse tuck boxes may be nearing saturation, limiting growth opportunities. Manufacturers need to explore new markets and applications to sustain growth.

Consumer Preferences: Changing consumer preferences towards minimalist or alternative packaging solutions can affect the demand for reverse tuck boxes. Manufacturers must stay attuned to market trends and adapt their offerings accordingly.

Labor Shortages: Skilled labor is essential for producing high-quality packaging. Labor shortages or increased labor costs can pose challenges in maintaining production efficiency and meeting quality standards.

Key Player Analysis

Georgia Pacific

International Paper

Smurfit Kappa

Mondi Group

Cascades Inc.

Rose City Box

Lindquist and Co.

LDC Packaging

E Molding International.

PakFactory

Elixir Packaging

More About Report- https://www.credenceresearch.com/report/reverse-tuck-box-market

The reverse tuck box market exhibits varied dynamics across different regions, driven by factors such as economic conditions, industrial growth, consumer preferences, and regulatory landscapes. Here are regional insights into the reverse tuck box market:

North America

Market Maturity: The market in North America is relatively mature, with high demand from well-established industries such as pharmaceuticals, cosmetics, and consumer goods.

Sustainability Focus: There is a strong emphasis on sustainable and eco-friendly packaging solutions. Manufacturers are increasingly using recyclable materials and environmentally friendly production processes.

Technological Advancements: Advanced printing and packaging technologies are widely adopted, contributing to high-quality and customizable reverse tuck boxes.

Regulatory Environment: Stringent regulations, especially in the pharmaceutical and food sectors, drive the demand for compliant and safe packaging solutions.

Europe

Sustainability and Eco-Friendliness: Europe leads in sustainable packaging initiatives, with significant investments in recyclable and biodegradable materials due to strict environmental regulations.

Market Demand: The cosmetics and personal care industry is a major driver of demand for reverse tuck boxes, with a focus on aesthetically appealing and high-quality packaging.

Innovation: European manufacturers emphasize innovation in design and printing, offering highly customized and unique packaging solutions to meet diverse consumer preferences.

Regional Differences: Western Europe exhibits higher demand due to economic stability and higher consumer spending, while Eastern Europe is witnessing growth driven by industrial expansion and increasing retail activities.

Asia-Pacific

Rapid Growth: The Asia-Pacific region is experiencing rapid market growth, fueled by expanding pharmaceutical, cosmetics, and consumer electronics industries.

Cost Sensitivity: Price sensitivity among consumers and manufacturers drives the demand for cost-effective packaging solutions without compromising on quality.

Industrial Expansion: Growing industrialization and urbanization contribute to increased demand for packaged goods, thereby boosting the reverse tuck box market.

Adoption of Technology: While there is a gradual adoption of advanced packaging technologies, many manufacturers focus on improving production efficiency and scalability.

Latin America

Emerging Market: The market in Latin America is emerging, with increasing demand for packaged goods driven by rising consumer incomes and urbanization.

Regulatory Compliance: Manufacturers are focusing on meeting regulatory standards, particularly in the food and pharmaceutical sectors, to ensure product safety and quality.

Local Production: There is a trend towards local manufacturing to reduce costs and improve supply chain efficiency, catering to the growing domestic demand.

Middle East and Africa

Developing Market: The market in the Middle East and Africa is developing, with significant potential for growth as industrial and retail sectors expand.

Infrastructure Development: Improving infrastructure and logistics capabilities are facilitating better distribution and availability of packaged goods, including those using reverse tuck boxes.

Consumer Awareness: Increasing consumer awareness about the benefits of proper packaging, particularly in healthcare and food sectors, is driving market demand.

Economic Variability: Market growth can be uneven, with more developed economies in the region showing higher demand compared to less developed areas.

Segments:

Based on Product Type:

Standard reverse tuck boxes

Double reverse tuck boxes

Triple reverse tuck boxes

Quadruple reverse tuck boxes

Collapsible reverse tuck boxes

Other boxes: Pillow style, telescoping, modular

Based on Application:

Retail packaging

E-commerce shipping

Storage and inventory

Gift packing

Based on End Use:

Food and beverages

Pharmaceuticals

Industrials

Medical

Browse the full report – https://www.credenceresearch.com/report/reverse-tuck-box-market

Browse Our Blog: https://www.linkedin.com/pulse/reverse-tuck-box-market-projections-mlsdf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

GLOBAL AUTONOMOUS MOBILE MANIPULATOR ROBOTS (AMMR) MARKET FORECAST 2024-2032

According to Inkwood Research, the Global Autonomous Mobile Manipulator Robots (AMMR) Market is estimated to project a CAGR of 23.42% in terms of revenue during the forecasting years of 2024-2032.

VIEW TABLE OF CONTENTS: https://inkwoodresearch.com/reports/autonomous-mobile-manipulator-robots-market/#table-of-contents

Autonomous Mobile Manipulator Robots (AMMR) represent a significant leap in robotics, combining the mobility of autonomous mobile robots (AMR) with the dexterity of robotic manipulators. These advanced systems are revolutionizing various industrial sectors by enhancing productivity, efficiency, and safety.

In the industrial landscape, AMMRs are primarily employed in manufacturing, warehousing, and logistics. Their ability to navigate complex environments and perform intricate tasks makes them indispensable in modern factories. AMMRs can autonomously move materials, assemble components, and even perform quality control checks, reducing the need for human intervention in hazardous or repetitive tasks.

REQUEST FREE SAMPLE: https://inkwoodresearch.com/reports/autonomous-mobile-manipulator-robots-market/#request-free-sample

Key Growth Driver: Advancements in Robotics and AI

AI algorithms and machine learning techniques empower AMMRs to learn from data, identify patterns, make decisions, and solve complex problems autonomously. In healthcare, these algorithms analyze medical data to aid in disease diagnosis and treatment planning. In manufacturing, they enable AMMRs to perform complex tasks like assembling intricate components, conducting quality control inspections, and operating in hazardous environments with precision and speed.

Computer vision, a branch of AI, applies machine learning to images and videos, allowing AMMRs to recognize and interpret objects, people, and gestures for sophisticated interaction with their surroundings. For example, a London-based emotion AI startup used computer vision to analyze facial expressions through cameras, helping brands like Coca-Cola and AT&T evaluate commercial effectiveness based on viewer emotions.

The rapid advancements in AI technology, including sensor technologies, machine learning, and computer vision, have significantly enhanced AMMRs' capabilities, making them highly effective and versatile across various industries.

Fastest-Growing End-User: Electronics and Semiconductors

In the electronics and semiconductor industry, Autonomous Mobile Manipulator Robots (AMMR) are utilized for assembly, dispensing, material removal, and packaging. Robotics have always been crucial in these sectors for executing complex assemblies with high precision. AMMRs specifically handle tasks such as quality inspection, stress testing, product packaging, palletizing, painting, arranging, and testing. As the electronics industry evolves, there is an increasing demand for advanced AMMRs capable of managing more critical operations in electronics manufacturing.

Prominent Geography: Asia-Pacific

In Asia-Pacific, where manufacturing plays a critical role in the economy, AMMRs are streamlining processes such as material handling, assembly, and quality control. This leads to higher efficiency, lower operational costs, and improved safety standards in factories and warehouses.

Healthcare in Asia-Pacific is also benefiting from the deployment of AMMRs. These robots assist in transporting medical supplies, pharmaceuticals, and equipment within hospitals, allowing healthcare workers to focus more on patient care. With their precise manipulation capabilities, AMMRs are utilized in tasks such as medication delivery and sample collection, ensuring accuracy and minimizing the risk of errors.

Request for Customization: https://inkwoodresearch.com/request-for-custom-report/

About Inkwood Research

Inkwood Research specializes in syndicated & customized research reports and consulting services. Market intelligence studies with relevant fact-based research are customized across industry verticals such as technology, automotive, chemicals, materials, healthcare, and energy, with an objective comprehension that acknowledges the business environments. Our geographical analysis comprises North & South America, CEE, CIS, the Middle East, Europe, Asia, and Africa.

Contact Us

https://www.inkwoodresearch.com

1-(857)293-0150

Related Reports:

GLOBAL AGRICULTURAL ROBOTS MARKET: https://inkwoodresearch.com/reports/agricultural-robots-market/

GLOBAL AUTONOMOUS MOBILE ROBOTS (AMR) MARKET: https://inkwoodresearch.com/reports/autonomous-mobile-robots-market/

GLOBAL AUTONOMOUS VEHICLE MARKET: https://inkwoodresearch.com/reports/autonomous-vehicle-market/

#autonomous mobile manipulator robots#ammr#automation#robotics#inkwood research#market research trends

1 note

·

View note

Text

Plastic Bucket Market: Dissecting the Factors Steering Growth and Potential Risks

Plastic Bucket Market provides in-depth analysis of the market state of Plastic Bucket manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Plastic Bucket in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Plastic Bucket Market Report:

The report offers a comprehensive and broad perspective on the global Plastic Bucket Market.

The market statistics represented in different Plastic Bucket segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Plastic Bucket are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Plastic Bucket.

Major stakeholders, key companies Plastic Bucket, investment feasibility and new market entrants study is offered.

Development scope of Plastic Bucket in each market segment is covered in this report. The macro and micro-economic factors affecting the Plastic Bucket Market

Advancement is elaborated in this report. The upstream and downstream components of Plastic Bucket and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/plastic-bucket-market-101475

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Plastic Bucket Market Analysis

Solar Photovoltaic Glass Market Share

Swimming Pool Treatment Chemicals Market Growth

Kids Smartwatch Market

Global Pigmentation Disorders Treatment Market Size

Global Air Disinfection and Purification Machine Market Growth

Premium Audio Market Forecast

Global Waterproof Breathable Textiles (Wbt) Market Share

Testing, Inspection, and Certification (TIC) Market Growth Rate

Sharing Economy Market Size

Virtual Production Market Share

Drone Defense System Market Analysis

Digital Media Market

Tire Fabrics Market Growth

Global Pharmacy Automation Equipment Market Growth

Global Semiconductor Packaging And Assembly Equipment Market Size

Global Carbon Management Software Market Share

Paints and Varnishes Market Forecast

Web to Print Software Market Size

Through Wall Radar Market Growth Rate

Auction House Market Analysis

Disposable Camera Market Share

Bioreactor Market Growth

Zinc Aluminum Magnesium Coated Steel Market

Global Freeze Drying Market Size

Global Fireproofing Material Market Growth

E-Commerce Of Agricultural Chemicals Products Market Forecast

Global Machinable Ceramic Market Share

Self Injection Device Market Growth Rate

Touch Based Human Machine Interface (Hmi) Market Size

NGOs and Charitable Organizations Market Share

Electro Hydraulic Servo Valve Market Analysis

Collaborative Robots Market

Diaphragm Valves for Pharmaceutical Process Market Growth

Global Robotic Vacuum Cleaner Market Growth

Global Personal Care Wipes Market Size

Global Document Scanning Services Market Share

Baby Wipes Market Forecast

Military Laser Designator Market Size

Automatic License Plate Recognition (ALPR) Market Growth Rate

#Plastic Bucket Market Size#Plastic Bucket Market Share#Plastic Bucket Market Trends#Plastic Bucket Market Industry#Plastic Bucket Market Growth

0 notes

Text

Semiconductor Capital Equipment Market Outlook to 2030

The Insight Partners recently announced the release of the market research titled Semiconductor Capital Equipment Market Outlook to 2030 | Share, Size, and Growth. The report is a stop solution for companies operating in the Semiconductor Capital Equipment market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. Semiconductor Capital Equipment Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, The Insight Partners is helping brands unlock revenue opportunities in the Semiconductor Capital Equipment market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated Semiconductor Capital Equipment market research has all that you need.

What are Key Offerings Under this Semiconductor Capital Equipment Market Research?

Global Semiconductor Capital Equipment market summary, current and future Semiconductor Capital Equipment market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global Semiconductor Capital Equipment Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the Semiconductor Capital Equipment Market?

Semiconductor Capital Equipment market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. Semiconductor Capital Equipment market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their Semiconductor Capital Equipment market share.

Report Attributes

Details

Segmental Coverage

equipment type

Automated Test Equipment

Die-Level Packaging and Assembly Equipment

Wafer-Level Manufacturing Equipment

end-user

Water and Sewage Treatment

Food and Beverage

Pharmaceuticals

Oil and Gas

Power Plants

Pulp and Paper

Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Tencor

Kulicke and Soffa

Lam Research

Nikon

Planar

Tokyo Electron

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective Semiconductor Capital Equipment market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The The Insight Partners offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The Semiconductor Capital Equipment market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

AI In The Oil, Gas, And Energy Sector: How Safe Is AI Dealing With Chemicals?

AI is crucial in enhancing safety in the oil, gas, and energy sectors, particularly in handling chemicals. Through predictive analytics and real-time monitoring, AI systems can identify potential hazards, optimize processes, and mitigate risks. By analyzing vast datasets, AI can predict equipment failures, detect leaks, and ensure compliance with safety protocols. However, the safety of AI in chemical handling relies on robust data quality, accurate modeling, and rigorous testing to minimize errors and prevent accidents. Continuous monitoring, human oversight, and regulatory adherence are essential for maintaining safety standards in AI-driven chemical processes.

What Is The Chemical Industry?

The chemical industry encompasses the production, refinement, and distribution of chemicals and chemical products. It includes the manufacturing of basic chemicals, such as polymers and petrochemicals, as well as specialty chemicals for pharmaceuticals, agriculture, cosmetics, and electronics. The industry plays a crucial role in supplying raw materials for other industries, driving technological advancements, and contributing to global economic growth. Additionally, it involves processes like chemical synthesis, purification, formulation, and packaging, often utilizing advanced technologies and rigorous safety measures due to the potentially hazardous nature of many chemicals.

Role Of AI In the Chemical Industry

AI optimizes chemical processes, predicts equipment failures, accelerates product development, ensures product quality, streamlines supply chains, enhances safety and enables customization. Its role encompasses efficiency, reliability, compliance, and innovation in the chemical industry.

Process Optimization: AI employs advanced algorithms to analyze vast amounts of data generated during chemical processes. By identifying patterns and correlations in this data, AI can optimize parameters such as temperature, pressure, flow rates, and ingredient proportions. This optimization leads to increased efficiency, reduced energy consumption, and minimized waste generation. AI can dynamically adjust process parameters in real time, ensuring that operations run at peak efficiency while maintaining product quality and safety standards.

Predictive Maintenance: AI systems continuously monitor the condition and performance of equipment used in chemical manufacturing. By collecting and analyzing data from sensors, AI can detect early signs of equipment degradation or failure. Predictive maintenance algorithms leverage this data to forecast when maintenance interventions will be required, allowing operators to schedule repairs proactively. This approach minimizes unplanned downtime, reduces maintenance costs, and extends the lifespan of critical assets.

Product Development: AI is crucial in accelerating the chemical product development lifecycle. AI can predict the properties and behavior of new chemical compounds or formulations using machine learning models and computational simulations. This predictive capability enables researchers to explore a vast chemical space more efficiently, identifying promising candidates for further experimentation. Additionally, AI can optimize reaction conditions and synthesis routes, leading to faster development cycles and improved product performance.

Quality Control: AI-driven quality control systems enhance product consistency and reliability in chemical manufacturing. AI can detect defects or impurities in raw materials, intermediate products, and finished goods using machine vision, spectroscopy, and other sensing technologies. AI algorithms analyze sensor data in real-time to detect anomalies and deviations from quality standards. By automating inspection processes, AI reduces the risk of human error and ensures that only high-quality products reach the market.

Supply Chain Management: AI optimizes various aspects of the chemical supply chain, from procurement and inventory management to logistics and distribution. Artificial intelligence can forecast demand more accurately by analyzing historical data, market trends, and external factors. These demand forecasts enable companies to optimize inventory levels, minimize stockouts, and reduce carrying costs. AI also identifies opportunities for cost-saving and efficiency improvements in transportation routes, warehousing operations, and supplier relationships.

Safety and Compliance: AI enhances safety and regulatory compliance in the chemical industry by providing real-time monitoring and risk assessment capabilities. AI systems analyze sensor data from manufacturing processes to detect potential hazards such as leaks, spills, or equipment malfunctions. AI contributes to the prevention and mitigation of accidents by promptly alerting operators to safety risks. Furthermore, AI-powered analytics ensure compliance with environmental regulations, emissions standards, and workplace safety protocols, reducing the risk of fines or legal liabilities.

Customization and Personalization: Artificial intelligence allows chemical companies to tailor their products and services to meet the unique needs of their customers. y analyzing customer preferences, usage data, and market trends, AI can recommend personalized product formulations or delivery options. AI-driven manufacturing processes allow for greater flexibility in product customization, accommodating variations in ingredient preferences, dosage strengths, or packaging formats. This customization enhances customer satisfaction, strengthens brand loyalty, and drives competitive differentiation in the chemical market.

As a result of artificial intelligence, the chemical industry can improve efficiency, reliability, compliance, and innovation, ensuring long-term growth and competitiveness. With its transformative capabilities, AI revolutionizes operations, from process optimization to personalized customer solutions, shaping the future of the chemical sector.

How Safe Is AI Dealing With Chemicals?

Safety in AI handling chemicals demands accurate predictions, robust data, regulatory compliance, and human oversight. Uncertainties require adaptable algorithms. Continuous monitoring and personnel training are vital for a safe deployment.

Accuracy and Reliability: AI models must accurately predict chemical properties, reactions, and hazards to ensure safe handling. Errors or inaccuracies in AI predictions could lead to unintended consequences, such as chemical spills or explosions. Rigorous validation and testing are essential to ensuring the reliability of AI algorithms.

Data Quality and Integrity: The quality and integrity of data used to train AI models are critical. Inaccurate or incomplete data can lead to biased or unreliable predictions, potentially compromising safety. Therefore, robust data collection, verification, and validation processes are necessary to ensure the accuracy and reliability of AI systems.

Uncertainty and Robustness: Chemical processes often involve inherent uncertainties and variability. AI systems must be robust against uncertainties and capable of handling unforeseen circumstances effectively. It requires the development of AI algorithms that can adapt to changing conditions and make reliable predictions even in the presence of uncertainty.

Regulatory Compliance: AI applications in the chemical industry must adhere to strict regulatory standards and safety protocols. Compliance with OSHA standards, EPA regulations, and other relevant guidelines is critical to ensuring chemical safety.

Human Oversight and Intervention: While AI systems can automate many aspects of chemical handling processes, human oversight and intervention are still crucial. Human operators must monitor AI systems, interpret results, and intervene when necessary to prevent accidents or mitigate risks. Human expertise is essential in complex or unforeseen situations where AI may struggle to make accurate predictions.

Continuous Monitoring and Maintenance: AI systems used in chemical handling should be continuously monitored and maintained to ensure proper functioning. Regular inspections, updates, and maintenance activities are necessary to identify and address any issues that may arise, thereby ensuring the ongoing safety of AI systems.

Training and Education: Proper training and education of personnel involved in AI systems are essential for ensuring safety. Operators must have sufficient education in the operation of AI technology, in safety procedures and protocols specific to chemical handling. Education programs raise awareness of the risks associated with AI technology while fostering a safe culture within the organization.

By addressing these considerations, artificial intelligence can ensure safety and efficiency in chemical handling processes, ensure compliance with regulations, and foster a safety culture.

Conclusion

AtliQ Technologies stands at the forefront of AI consulting, offering innovative solutions tailored to enhance safety, efficiency, and compliance in the chemical industry. Through our expertise in AI-driven process optimization, predictive maintenance, and quality control, we empower organizations to unlock new levels of productivity and reliability. We enable our clients to confidently navigate the complexities of chemical handling by leveraging cutting-edge AI technologies while adhering to strict data integrity and regulatory compliance. AtliQ Technologies is committed to shaping a safer, more sustainable future for the chemical industry through the transformative power of AI.

0 notes

Text

Global Top 15 Companies Accounted for 58% of total Smart Access Control market (QYResearch, 2021)

According to the new market research report “Global Smart Access Control Market Report 2023-2029”, published by QYResearch, the global Smart Access Control market size is projected to reach USD 1.83 billion by 2029, at a CAGR of 5.1% during the forecast period.

Figure. Global Smart Access Control Market Size (US$ Million), 2018-2029

Figure. Global Smart Access Control Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Smart Access Control include Ring (Amazon), Zkteco Co.,Ltd, Salto Systems, Hivision, ASSA ABLOY, Johnson Controls, dormakaba, GU Group, Suprema, HEJIANGDAHUATECHNOLOGYCO.,LTD. , etc. In 2021, the global top 10 players had a share approximately 58.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Gas Chromatography Market is Estimated to Witness High Growth Owing to Increasing Demand from Petrochemical Industry

Gas chromatography is an analytical technique used to separate and analyze compounds that can be vaporized without undergoing decomposition. It relies on gas-solid adsorption and is useful for analyzing petrochemicals, gases in the atmosphere, flavors and fragrances.

Market Dynamics:

The growing petrochemical industry is one of the major drivers augmenting the growth of gas chromatography market over the forecast period. Petrochemicals are widely used in various manufacturing industries such as plastic, rubber, synthetic fibers and detergents among others. According to Indian Brand Equity Foundation (IBEF), India’s petrochemical industry is projected to reach $300 billion by 2025 on account of rising demand from end-use industries. Furthermore, technological advancements in chromatography systems is another key factor propelling the market growth. Major players are focused on developing new systems such as compact GC systems for on-site analysis and portable GC systems.

Gas Chromatography Market Drivers: Growing Applications Across Healthcare Industry

The healthcare industry has seen a rapid increase in the adoption of gas chromatography techniques for clinical diagnosis, drug discovery, and disease treatment over the past decade. Gas chromatography is commonly used for analysis of biological samples like blood, serum, urine, and tissues to detect biomarkers for various diseases and medical conditions. The rising prevalence of chronic diseases like cancer has also fueled demand for GC systems in clinical research studies to identify new drug candidates and treatment protocols. Moreover, strict regulations regarding quality control and safety testing of pharmaceutical drugs and medical devices have further propelled the use of GC in quality assurance applications within healthcare. The market is expected to witness continued growth driven by increasing R&D investments in personalized medicine and ongoing advancement of GC technologies with improved efficiency, accuracy, and throughput.

Gas Chromatography Market Drivers: Environmental Monitoring & Testing Norms

Stringent environmental regulations across the globe concerning pollution control, emissions monitoring, and product safety have significantly boosted the adoption of gas chromatography systems by industries and government agencies. GC allows for precise detection and quantification of pollutants, toxins, contaminants, and chemicals in air, water, soil, and waste samples. It is extensively employed for regulatory compliance monitoring of air quality, emissions from factories and vehicles, water purity, and soil contamination levels. Similarly, GC finds widespread application in food and beverage testing to analyze food ingredients, flavors, additives, preservatives, contaminants, and ensure adherence to quality and safety standards. Growing concerns about air, water and soil pollution along with rising focus on sustainable development are compelling both public and private sectors to increase environmental protection spending, thus propelling GC sales.

Gas Chromatography Market Restrain: High Cost of Advance GC Systems

While Gas Chromatography technology offers unmatched separation power and analytical capabilities, the acquisition and maintenance costs of more sophisticated GC systems remain significantly high. State-of-the-art GC equipment integrated with sophisticated detectors, automated sampling systems, and software packages demand substantial capital investments, which is a major roadblock particularly for small and mid-scale end-use industries. The high cost is further escalated due to requirement of skilled workforce to operate advanced GC instruments and recurring expenses related to consumables, repairs, and calibrations. Large capital outlay discourages many potential customers, especially in price-sensitive developing markets, from adopting GC systems or delaying such capital expenditures. To mitigate this restrain, manufacturers continue investing in developments to make GC technology more affordable without compromising on performance.

Gas Chromatography Market Opportunity: Emergence of Portable GC Devices

The gas chromatography market is poised to gain significant opportunities from the emergence and expected commercialization of portable GC devices in the coming years. Though desktop GC still dominate applications requiring high sample throughput and precision analysis, there is a growing demand for field-deployable and on-site GC analytical systems across various industries. Portable GC promises greater flexibility, accessibility and remote monitoring capability compared to traditional benchtop models. Sectors like environmental monitoring, agricultural testing, food safety inspection, and petrochemical processing would particularly benefit from portable GC ability to conduct real-time analysis directly at the source of sampling. Ongoing advancements in miniaturization of GC components, improvement of battery lives, and development of user-friendly interfaces are bringing the vision of portable GC closer to reality. This represents a major greenfield opportunity area for both instrument manufacturers and end-users in the near future.

Gas Chromatography Market Trend: Integration with other Techniques

One of the key trends witnessed in the gas chromatography market is increasing adoption of hyphenated gas chromatography techniques that integrate GC with other analytical methods. Coupling GC with mass spectrometry (GC-MS) and GC with infrared/fluorescence spectroscopy (GC-IR/GC-FLD) allows for enhanced detection and compound identification capabilities. Similarly, two-dimensional gas chromatography (GC×GC) provides improved resolution of co-eluting peaks. Moreover, trends such as GC×GC coupled with mass spectrometry (GC×GC-MS) and comprehensive GC×GC for metabolic fingerprinting are gaining widespread recognition. Integration of GC with selective detectors tailored for specific applications like nitrogen/phosphorus detection further fuel its appeal. Such multidimensional and tandem GC techniques offer complementary information, better separation efficiencies and enhanced qualitative and quantitative outcomes. They are particularly important in

0 notes

Text

Top 5 Pharmaceutical Machinery Manufacturers in the World

Originally Published on: SpendEdge |Top 5 Pharma Machinery Manufacturers Worldwide

The pharmaceutical industry is experiencing rapid global growth due to technological advancements, increased income levels, and a greater willingness to invest in modern healthcare. To meet the rising demand for pharmaceutical products, pharmaceutical companies must acquire top-tier pharmaceutical machinery. The global pharmaceutical plant machinery and equipment market encompasses industrial machinery used in the production, processing, and packaging of pharmaceutical products. There are two primary categories of pharmaceutical machinery: drug formulation and manufacturing equipment, and packaging equipment. According to a procurement market intelligence report from SpendEdge, the global pharmaceutical machinery market is projected to grow at a healthy rate of 7.73% during the forecast period. The report also predicts that the formulation and manufacturing equipment segment is expected to reach approximately US$15.48 billion by 2021.

Top Manufacturers of Pharmaceutical Machinery:

GEA: GEA is a global provider of process equipment and solutions serving industries such as food and beverage, pharmaceutical, healthcare, transport, and dairy. The company offers a wide range of products and services, including pharmaceutical plant equipment and machinery, equipment installation and commissioning, equipment maintenance, support and spare part provision, and pharmaceutical drug discovery, processing, and packaging equipment.

Merck KGaA: Merck KGaA is a British company that caters to the life sciences, chemical, and pharmaceutical industries. It is known for its expertise in genome editing and gene therapy. The firm offers services such as pharmaceutical plant equipment and machinery, consumer healthcare, life sciences services and research, food and beverages research, and government and academic research. In November 2017, the company introduced a new filter bottle system for sterile filtration of cell culture media.

ACG Worldwide: ACG Worldwide is a unique supplier offering integrated manufacturing solutions for the pharmaceutical industry. It provides a comprehensive range of pharmaceutical equipment and has more than 13 subsidiaries worldwide. The company's offerings include capsules, films and foils, engineering solutions, inspection services, and R&D services. ACG Worldwide also provides process, packaging, inspection, and track and trace solutions throughout the drug manufacturing process.

Silverson: Silverson is a world leader in the manufacturing and design of high shear mixers. The company specializes in process mixing equipment for pharmaceutical, chemical, food and beverage, and cosmetic industries. Its product range encompasses pharmaceutical plant equipment and machinery for various applications, including cream and ointments, ophthalmic solutions, syrups, tablet coating, vaccines, and testing.

ROMACO Group: The Romaco Group is a global supplier of formulation and packaging equipment for various powdered and liquid drug forms. The company's portfolio includes blister and strip packaging machines, granulating and coating machines, tablet presses, tube filling machines for effervescent tablets, liquid filling cartoners, end-of-line equipment, and powder dosing machines, as well as counting devices. Romaco Group operates multiple brands, including INNOJET, MACOFAR, NOACK, KILIAN, and SIEBLER, each offering solutions for different drug processing and packaging needs.

These top pharmaceutical machinery manufacturers play a crucial role in ensuring the efficient production and packaging of pharmaceutical products, contributing to the growth and success of the pharmaceutical industry.

For expert insights into pharmaceutical machinery, contact us today!

0 notes

Text

Inspection Machines Market Analysis, Key Players, Industry Segments & Forecast 2022 to 2032

The global inspection machines market is expected to develop at a high CAGR of 5.1% between 2022 and 2032. The global market is expected to rise from US$ 643.1 million in 2022 to US$ 1,053.5 million in 2032. A rising number of inspection checkpoints have been seen to be distributed across the manufacturing line. As a result, sales of inspection equipment are projected to rise. However, integrating inspection equipment into the production and packing lines is difficult owing to the complexity of the machinery and the demanding end-use environment. Investing in R&D operations for biotech and pharmaceutical businesses, on the other hand, is expected to result in increased market prospects.

Several research studies, along with various product development and launches are anticipated to surge the growth of the inspection machines market trends. A new VT-X750-V3 system, which is considered to be the fastest CT-type X-ray inspection device, was released by OMRON Corporation in 2021. Other market players launched X-ray technologies OEM product range for industrial and pre-clinical X-ray imaging systems.

Over the recent years, a new concept of the non-destructive testing device with the help of a novel carbon nanotube (CNT) based miniature X-ray tube has been introduced recently. Such advancement is estimated to increase the adoption of inspection machines since they can be used for small-scale internal inspection of objects.

Request a Sample Copy of this Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-2132

Key Takeaways

Product recalls have been surging due to unearthed issues including such cases when it is defective or at risk of health or both. Furthermore, rising regulatory compliance with good manufacturing practices (GMP) is contributing to the presence of major governmental and non-governmental authorities that inspect the final products deployed in the market by manufacturers. These factors are expected to propel the demand for inspection machines.

Within the pharmaceutical sector, several regulatory agencies such as the Food and Drug Administration (FDA), European Medicines Agency, and the Pharmaceuticals and Medical Devices Agency carefully monitor the compliance of manufacturers with Current Good Manufacturing Practice (CGMP) regulations to ensure the quality of drugs and medical devices. These regulations are important as they ensure product safety, and the claims of ingredients provided are verifiable.

The prominence of CMOs and CROs has surged in manufacturing and packaging due to the possibility of reducing timeframes with simultaneously offering external validation and expertise. Since contract manufacturers have specialized teams that can efficiently grasp client quality standards are now known to be a valuable source for OEMs. These aforementioned factors are likely to accelerate the growth of the inspection machines market share.

Developing markets have witnessed a surge within the unorganized healthcare systems. Due to this, the lack of adequate infrastructure and poverty limit the expansion of the industry. Additionally, there has been an increase in the demand for refurbished machines, although these machines are expensive. These factors are expected to hinder the global market growth.

Competitive Landscape

The inspection machines market share is predicted to increase as manufacturers are searching to expand their production and presence all over the market through several strategic tactics such as various collaborations and product launches. Furthermore, the industry is becoming highly competitive amongst market players in terms of product variation and pricing.

More Insights into the Inspection Machines Market

North America is expected to witness lucrative growth opportunities over the projection period by accounting for a total revenue of around 23.5%. This has been attributed to several types of research that have been conducted over the years based on the importance of the inspection of devices during manufacturing.

Sound manufacturing practices must be inherently built right into the manufacturing process since they are unable to get tested on individual batches of products. Therefore, the inspection machines market growth is anticipated to propel attributing to such research to emphasize the importance of GMP.

Prominent market players are focusing on introducing technologically advanced gadgets with systems such as the In-Sight 3D-L4000 embedded vision system. It allows engineers to be quicker and more accurate and cost-effectively solve a range of inspections on automated production lines through the implementation of 3D laser displacement technology.

Owing to rising technological advancements, recently, a new concept for a non-destruction device has emerged which is based on an X-ray tube. With the help of carbon nanotube-based miniature x-ray tubes, such devices are gaining traction in the global inspection machines market. These technological advancements are expected to bolster market growth over the projection period.

Get Full Information on this Report @

https://www.futuremarketinsights.com/reports/inspection-machines-market

Key Segments Profiled in the Inspection Machines Market Survey

By Packaging Type:

Blisters

Ampoules

Syringes

Vials

By Machines:

Colour Sorters

Checkweighers

Metal Detectors

By End User:

Pharmaceuticals

Medical Devices

By Region:

North America

Latin America

Asia Pacific

MEA

Europe

0 notes

Text

Industrial Chemical Packaging Market Witness a Spike in Growth Pace Recent Improvements in Pricing Models: FMI

The industry is anticipated to grow steadily at a 4.0% CAGR until 2033. The revenue share of the industrial chemical packaging market is anticipated to increase from US$ 133.58 billion in 2023 to US$ 197.52 billion in 2033, according to FMI.

The expansion of international trade is likely to be a major driver of the industrial chemical packaging sector during the forecasted period. The expansion of international trade has been driven by a number of factors, including changing technology, industrial activity, governmental choices, increasing competition, new trade agreements, etc.

The governments of several affected countries have pushed the food industry’s players to increase production in order to avoid supply-side shocks, shortages, and interruptions in supply.

For More Insights on this Market, Get A Sample Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-5234

As a result, FMCG companies are requesting more industrial chemical packaging materials. For instance, Britannia Industries has requested that the Indian government permit the supply chain’s cross-state movement of raw materials and packaging materials.

Industrial packaging producers are adjusting to meet the demands of contemporary markets. All enterprises, big or small, must upgrade their production technology continuously to remain competitive in the market.

Modern leak detection equipment and sophisticated testing methods are created to ensure that the chemical packing solution complies with weight handling capacity and international safety standards.

Key Takeaways from Industrial Chemical Packaging Market

Intermediate bulk containers are the most widely used packaging format for safe and easy transportation of industrial chemicals, as these containers are versatile, pallet mounted cost-effective. IBC’s currently account for more than 64% of industrial chemical packaging solutions sold worldwide.

Backed by the presence of the renowned pharmaceutical companies in the country, the U.K. is the largest consumer of chemical packaging solutions. The U.K. market is anticipated to offer incremental opportunities worth US$ 5.40 billion over the next decade.

Recyclable and re-usable features make plastic preferred material in the industrial chemical packaging market. It is expected to account for over 40% of packaging solutions produced over the forecast period.

After witnessing slight decline in FQ-20, Germany market is expected to register a y-o-y growth of almost 4.8 % in the year 2022.

Specialty chemicals segment will offer incremental opportunity of US$ 197.52 Bn between 2023 and 2033.

Are you looking for customized information related to the latest trends, drivers, and challenges? @ https://www.futuremarketinsights.com/customization-available/rep-gb-5234

Key players

ProAmpac

Tote Systems International, LP

US Display Group

Myers Industries, Inc.

Assmann Corp. of America

DENIOS Ltd.

Hoover CS

Segezha Group GmbH

CLA Containers

Greif, Inc.

RIKUTEC Group

Müller Group

Speak to Our Analyst @ https://www.futuremarketinsights.com/ask-the-analyst/rep-gb-5234

Key segments

By Packaging Format:

Intermediate bulk containers (IBCs)

Flexitanks

Drums

Pails & Jerry Cans

Bags & Sacks

Others (Bins & Liners, etc.)

By Material:

Metal

Plastic

Paper & Paperboard

By Chemical Type:

Specialty Chemicals

Commodity Chemicals

By Region:

North America

Latin America

Europe

South Asia

East Asia

Oceania

0 notes

Text

Analytical Standard Market Industry Analysis By Size, Growth Rate, Trends, Share, Developments, And Forecast 2028

An analytical standard is a compound of high purity and known concentration to be used as a calibration standard for a given assay. As the regulatory requirements are constantly becoming stricter which is increasing the pressure on product documentation and quality control for all the industries. Analytical standards finds application in various verticals including food and beverage, forensics, veterinary, environmental and pharma, and life sciences. The analytical standards employs in measuring the purity and quality of the formulations, drugs, biomarkers to increase the precision of an analytical procedure and to calibrate various analytical equipment. There are stringent regulations in the pharmaceutical sector all across the globe by WHO as well as several government regulations by every country or region across the globe is one of the reasons for the growth of the analytical standard market.

To know the scope of our report get a sample on https://www.axiommrc.com/request-for-sample/10230-analytical-standards-market-report

ANALYTICAL STANDARDS MARKET OUTLOOK

increase in industrialization, along with financial support extended by central agencies for pollution prevention and control, has been increasing environmental consciousness among industrialists will bring in a potential growth and development in the global analytical standard market. Also, the increasing demand of testing to maintain the optimum quality standards in food industry and rising awareness of locals towards the safety measures is also adding up in the major growth of the analytical standards market. For instance, In India, the Food Safety and Standards Authority of India (FSSAI) plans to invest about USD 72.3 million to support the food testing infrastructure across the country as the food industry in India was roughly 32% of the country’s total food market in 2017. However, The COVID-19 pandemic has significantly impacted the analytical standards market. The analytical instrumentation sector is facing challenges in the manufacturing and supply chain, such as delivering products to end users promptly and attending to an uneven demand for the products and services in this sector.

ANALYTICAL STANDARDS MARKET COVID 19 IMPACT

The COVID-19 pandemic has significantly affected the analytical standards market. The market for analytical standards market is anticipated to be marginally affected due to the outbreak of COVID-19.The analytical instrumentation sector is facing challenges in the manufacturing and supply chain, such as delivering products to end-users promptly and attending to an uneven demand for the products and services in this sector. The pandemic has also impacted the operation of manufacturing companies. Moreover, manufacturing plants in a number of countries have been shut down to contain the spread of the virus. According to WHO data, there were 62.3 million confirmed COVID-19 cases and 1.4 million deaths globally, as of November 30, 2020. Due to the COVID-19 outbreak, the number of patient data globally has increased. With the COVID-19 pandemic, most countries, including the whole of Europe, the US, India, and Australia, among others, are following complete nationwide lockdowns. Companies are functioning with a limited workforce. Moreover, the turnaround time for the delivery of products and services is affected due to newer packaging protocols and lockdown measures imposed by countries. All these factors are negatively impacting the manufacturing and supply chain of analytical standards products

ANALYTICAL STANDARDS MARKET SEGMENTAL OVERVIEW

Global analytical standards market is analysed based on product, technique, methodology, category and geography.

ANALYTICAL STANDARDS MARKET BY PRODUCT

The Analytical Standard products includes food & beverages standards, forensic standards, veterinary drug standards, petrochemistry standards, environmental and pharmaceutical and life science standards. Food and beverage analytical standards market includes flavor & fragrance standards, carbohydrate standards, peptide/amino acid standards, food additive standards, fatty acid/lipid/fame standards, GMO (genetically modified organisms) standards and mycotoxin standards. Forensic standards includes drugs of abuse standards and doping standards. Various environmental analytical standards consists of pesticide standards, volatiles/semivolatiles standards, flame retardant standards, aroclor/pcb, and dioxin standards, alkyl phenol standards and solid waste standard. Pharmaceutical and life sciences standards covers cosmetic standards, herbal drug/phytopharmaceutical standards, pharmaceutical secondary standards, pharmaceutical impurity reference standards, pharmacopoeia standards and fluorescent microparticle standards. While the purview of this technique also holds prominence in analysing flavors and fragrances, GMO, Mycotoxins, and food additives, to ensure food safety. In the pharmaceutical industry, this technique is used to meet ideal drug and cosmetic standards.

ANALYTICAL STANDARDS MARKET BY TECHNIQUE

Chromatography, spectroscopy, titrimetry and physical property testing are the techniques of analytical standards covered in this market study. Commercial laboratories are increasingly under pressure to get new drugs to market faster and an increasing trend has been to bring sample and reaction analysis closer to the user. This has posed a challenge for traditional analytical methods which has led to development of novel technique. Chromatography dominated analytical standards, observing gains at 6.31% from 2021 to 2027. Chromatographic techniques like gas chromatography has key advantages such as high sensitivity and relatively cheap operating cost which has made it appealing to many industries needed to detect and measure compounds and molecules within a sample

ANALYTICAL STANDARDS MARKET BY METHODOLOGY

The global analytical standards by methodology is classified into bioanalytical testing, dissolution testing, raw material testing, stability testing and other methodologies etc. The global analytical standards market offers rising public concerns related to optimal food safety and quality, growing applications of analytical techniques in proteomics & metabolomics, and greater regulatory emphasis on effective pollution monitoring & control are some of the key factors driving the growth of the analytical standards market.

ANALYTICAL STANDARDS MARKET BY CATEGORY

Analytical standards are accessible as organic and inorganic analytical standards. The market is dominated by organic analytical standards. Increasing demand for refrigerants and HVAC systems, booming pharmaceutical industry, growing prevalence of infectious diseases, growing construction industry, increasing car sales are the factors responsible for the exponential growth of the segment. On the other hand, inorganic analytical standards market growth is driven by a wide range of applications in chemical, pharmaceutical, petroleum, packaging, cosmetics industries.

ANALYTICAL STANDARDS MARKET BY GEOGRAPHY

In terms of region, the analytical standard market is studied for the key regions including North America, Europe, Asia Pacific, and Rest of the World. North America emerged as a dominant region for the industry and accounted for 40.06% of the market revenue share in 2020. An enforcement of stringent regulatory norms in the region is projected to lead to a large market size in the region. Also, presence of a high volume of key players with higher affordability and favourable government initiatives to develop innovative drugs will drive the growth of the market i this region, Even though North America segment has the highest market share Asia Pacific regional segment of the analytical standard market is expected to grow at the highest CAGR over the forecast period.

ANALYTICAL STANDARDS MARKET KEY PLAYERS

The key competitors of this market include Agilent Technologies (U.S), Accustandard Inc. (U.S.), Thermo Fisher (U.S.), Cambridge Isotope Laboratories, Inc. (CIL) (U.S.), Cayman Chemical Company (U.S.), Chiron AS (Norway), CPI International (U.S.), Cresent Chemicals (U.S.), GFS Chemicals (U.S.), Water Corporation (U.S.) , Merck KGAA (Germany) , Rica Chemicals Company (Japan), Restek Inc. (Germany), Reagecon Diagnostics Ltd (Ireland), PerkinElmer (U.S.), LGC Standards (UK) , SPEX CertiPrep (U.S.), Mallinckrodt Pharmaceuticals (UK), and Inorganic ventures (U.S.) among others.

ANALYTICAL STANDARDS MARKET KEY DEVELOPMENTS

May 2018: Agilent Technologies, Inc. entered into a definitive agreement to acquire all the business assets of Ultra Scientific, a leading provider of chemical standards and certified reference materials. The acquisition leads to significant expansion of Agilent’s certified reference materials and chemical standards business.

August 2019: LGC acquired Toronto Research Chemicals, a manufacturer and supplier of synthetic organic bio-chemicals that are used as reference standards and research tools in the pharmaceutical, applied, and research sectors. The acquisition of TRC has strengthened the product portfolio of LGC’s existing reference standards business.

Buy now Analytical Standards Market Report https://www.axiommrc.com/buy_now/10230-analytical-standards-market-report

About Us:

Axiom Market Research & Consulting™ is a full-service market research and data analytics company providing key market intelligence to global companies to take informed business decisions pertaining to their marketing strategy, investments, new product launches, market competition, consumer or end users, social media trends etc.

Axiom Market Research & Consulting™ offers market research services such as syndicated market research, custom market research, business consulting, and consumer/end user surveys. Under Business to Consumer (B2C) market research offerings, Axiom MRC assists its clients in finding quantitative information/preferences of its brands and services such as, awareness, usages, satisfaction, tracking, ethnicity etc. Axiom MRC offers data collection services through online surveys, social media, data processing and interpretation.

Axiom MRC with its experienced team of research and data analysts, has delivered more than 5000+ Market Research Projects, 3800+ Data Analytics Projects, 1200+ Business Support Projects and has a 800+ Global Client Base. Axiom Market Research & Consulting™ aims to become the preferred market research and data analytics company by providing key market intelligence solutions for client’s business growth.

Contact Us:

Axiom Market Research & Consulting™

3 Germay Dr. Ste 4 - 4666

Wilmington DE 19804

U.S.:- + 1 (845) 875-9786

U.K.:- + 44 (0) 20 3286 9707

Email: [email protected]

Website: https://www.axiommrc.com/

Blog: https://industrywatch24.com/

Follow On

LinkedIn: https://www.linkedin.com/company/axiom-market-research-and-consulting/

Twitter: https://twitter.com/AxiommrcCom

0 notes

Text

An Updated Analysis of India's Pharmaceutical Equipment Market

A Look at the Various Tools Used

To the tune of $55 billion by 2020, India's pharmaceutical market is forecast to expand at a CAGR of 8.4 percent.

Twenty percent of the world market for generic medications comes from India, making it the largest provider of generic drugs in the world. 2 The increasing size of the Indian pharmaceutical industry has led to a rise in the need for specialized medical equipment.

Instruments have a wide range of uses in the pharmaceutical industry, from research and development to quality assurance. They're put to use in the processes of preparing and testing pharmaceuticals. They also play a role in ensuring the quality and efficacy of the final product.

There are numerous varieties of pharmaceutical instruments available; selecting the right one for your company is a matter of careful consideration. However, among the numerous kinds of pharmaceutical equipment in use in India, the fbd fluid bed dryer, double cone blender, ball mill in pharmaceutics, and many more stand out as the most common.

The Indian pharmaceutical market relies heavily on high-quality pharmaceutical tools. Medicines and pharmaceuticals can't be made or tested for quality without them. In India, you can get anything from basic tools to complex manufacturing equipment for the pharmaceutical industry.

Tablet presses, tablet sealing machines, morris water maze, and tablet cutting machines are some of the most widespread types of pharmaceutical equipment in use throughout India. Tablets and capsules, the two most often used dosage forms in the country, are produced using these machines. The granulator, mixer, and mill are also common pharmaceutical tools. These devices are utilized in the manufacturing process, specifically for mixing, grinding, and processing raw materials.

Rapid expansion in India's pharmaceutical sector has resulted in rising demand for corresponding equipment. Indian pharmaceutical firms rely on these instruments to help them manufacture safe and effective medications.

Why Each Tool Is Important

One of the fastest-growing sectors in India is the pharmaceutical industry. The rising need for pharmaceuticals and other healthcare goods is a major factor in this expansion. The industry needs a wide range of tools and machinery to keep up with the demand.

In the pharmaceutical industry, tablet coater, capsule filling machines, ointment filling machines, and blister packing machines are all widely utilized in India. Products ranging from medications to health aids are manufactured using these devices.

If you need uniformly sized tablets made from powder, the fluid bed processor machine is for you. Capsules can be filled with any powder or liquid using the capsule filling machine. Fill containers with ointments, creams, and gels with the help of the ointment-filling machine. Blister packaging machines are utilized for the packaging of various commodities such as pills, capsules, and other similar items.

Medications can't be made or tested for effectiveness without the use of pharmaceutical tools. Instruments like this are crucial to the pharmaceutical sector, and India is among the world's top producers of them.

Indian Pharmaceutical Industry Prospects

Tablet presses, capsule fillers, a pharmaceutic plethysmometer, and granulators are just some of the most frequently used devices in the pharma industry. While capsule fillers are used to fill empty capsules with powders or liquids, tablet presses are used to compress powders into tablets. Granulators are used to reduce the size of particles, whereas ointment mills are used for mixing and grinding ointments.

Many of the world's largest pharmaceutical instrument manufacturers also operate factories in India, attesting to the country's status as a global leader in this industry. For one, India has a sizable population of talented people and a slick infrastructure. Not only that but India's

Finally, the Indian market for pharmacological instruments is expanding significantly. This is because of the high need for safe and effective drugs in a country with a large population. Many producers can keep up with the growing demand, and the government actively promotes the industry. It is anticipated that as the market expands, more businesses will enter it, raising the level of competition.

0 notes

Text

Gravimetric Filling Machines