#Pharmaceutical Processing Seals Market Growth

Explore tagged Tumblr posts

Text

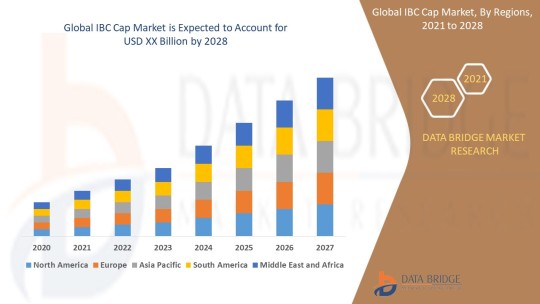

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

Exploring the Pharmaceutical Sterile Fill-Finish Market: Trends, Innovations, and Industry Growth Drivers - UnivDatos

The Pharmaceutical Sterile Fill-Finish Market was valued at USD 3500 million in the year 2022 and is expected to grow at a strong CAGR of around 5% during the forecast period. In recent years, there has been a significant rise in the demand for vaccine and biologics. This article delves into the intricacies of the pharmaceutical sterile fill-finish market, exploring its applications, pivotal role in the pharmaceutical industry, and the driving forces shaping its growth trajectory.

Pharmaceutical Sterile Fill-Finish Demand in the Global Market

The pharmaceutical sterile fill-finish process plays a critical role in the production of sterile pharmaceutical products. It involves the aseptic filling of drug formulations into containers followed by sealing, labeling, and packaging. The global pharmaceutical sterile fill-finish market has witnessed significant growth in recent years, driven by various factors contributing to its expansion and evolution. The expanding pipeline of biopharmaceuticals, including monoclonal antibodies, vaccines, and cell therapies, has bolstered the demand for sterile fill-finish solutions. Biopharmaceutical products often necessitate specialized fill-finish processes to maintain product integrity and safety, thereby driving market growth.

Further, One of the major driver for the growth of the market is associated with the increasing prevalence of chronic diseases and the development of biologic drugs. For instance, as per the data of Certers for Disease Control and Prevention, 60% of the Amaercans are living with atleast one of the chronic disorder like heart disease, diabetes, or cancer.

Request To Download Sample of This Strategic Report - https://univdatos.com/get-a-free-sample-form-php/?product_id=56729&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Applications of Pharmaceutical Sterile Fill-Finish

Pharmaceutical sterile fill-finish finds widespread applications across various therapeutic areas, including but not limited to:

1, Biologics: Biopharmaceuticals, including monoclonal antibodies, vaccines, and recombinant proteins, often require sterile fill-finish processes to maintain product integrity and efficacy.

2. Injectable Drugs: Sterile fill-finish is indispensable for preparing injectable medications such as antibiotics, analgesics, and chemotherapy agents, ensuring sterile administration and patient safety.

3. Parenteral Nutrition: Intravenous solutions and parenteral nutrition products necessitate sterile fill-finish procedures to prevent microbial contamination and ensure patient well-being.

4. Ophthalmic Preparations: Sterile fill-finish plays a vital role in manufacturing ophthalmic solutions, suspensions, and ointments, safeguarding ocular health and minimizing the risk of infections.

5. Sterile Liquids and Suspensions: Various sterile liquids, suspensions, and emulsions formulated for intravenous, intramuscular, or subcutaneous administration rely on sterile fill-finish processes for quality assurance.

Recent Developments/Awareness Programs: - Several key players and governments are rapidly adopting strategic alliances and recent product launches are supplementing the growth of the market.

· IN 2023, Sartorius AG announced the launch of their innovative sterile fill-finish system equipped with advanced robotics and automation technology. This system enables precise and efficient filling and sealing of parenteral drug products, enhancing production efficiency and reducing the risk of contamination.

· In 2022: Catalent, Inc. introduced a new sterile fill-finish solution utilizing blow-fill-seal (BFS) technology for aseptic packaging of injectable medications. This technology offers superior product protection, extended shelf life, and reduced environmental impact compared to traditional packaging methods.

· In 2020, Bausch Health Companies Inc. announced a strategic collaboration with a leading contract manufacturing organization (CMO) specializing in sterile fill-finish services. This collaboration aimed to leverage Bausch's extensive pipeline of sterile injectable pharmaceuticals with the CMO's expertise in aseptic manufacturing to accelerate product development and market access.

· In 2020, Bausch Health Companies Inc. announced the acquisition of an aseptic manufacturing facility in North Carolina, aimed at expanding its sterile fill-finish capabilities to support the production of sterile injectable pharmaceuticals.

Ask for Report Customization - https://univdatos.com/get-a-free-sample-form-php/?product_id=56729&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Conclusion

The pharmaceutical sterile fill-finish market plays a pivotal role in ensuring the safety, efficacy, and accessibility of parenteral medications worldwide. With increasing demand for injectable drugs, advancements in biopharmaceuticals, and a regulatory focus on quality and compliance, the market is poised for continued growth and innovation, driving the adoption of advanced sterile fill-finish technologies and services. Through a combination of applications spanning various therapeutic areas, stringent regulatory standards, and technological innovations, the pharmaceutical sterile fill-finish market remains a cornerstone of the pharmaceutical industry, facilitating the delivery of life-saving medications to patients around the globe.

0 notes

Text

Top Packaging Machinery in UAE : Complete Guide to Packaging Solutions

Selecting the right packaging solutions is essential for companies to uphold product quality and boost customer satisfaction in today's competitive market. Triveni Packaging, recognized as a top packaging machine suppliers in the UAE, delivers a wide range of packaging machinery in UAE, including induction cap sealing machines, tray sealing machines, shrink wrap machine, cling wrapping machine, protective packaging, vacuum packing machines, sleeve wrapping machine, carton sealing machine, and more. This guide delves into different types of packaging machines that can optimize your packaging operations and protect your products effectively.

Top 8 Packaging Solutions

1. Induction Cap Sealing Machine

An induction cap sealing machine plays a crucial role for achieving secure seals on containers, offering tamper-proof protection for your products. These machines create airtight seals that help retain freshness in food, beverage, dairy, pharmaceutical, healthcare, cosmetic, chemical, petroleum, and other packaging industries.

2. Tray Sealing Machines

Tray sealing machines offer a reliable solution for businesses aiming to package perishable items effectively. These machines create airtight seals around food items placed in pre-formed trays, ensuring protection from contamination and spoilage. With a range of customizable film options, tray sealing machines preserve freshness and enhance the overall visual appeal of products in retail shelves.

3. Shrink Wrap Machine

For businesses that need to secure their products for shipping and storage, a shrink wrap machine is invaluable. These machines use heat to shrink film tightly around products, providing a protective wrap that prevents damage during transport. Widely utilized across various sectors, shrink wrap machines are essential for preserving the quality of products throughout the shipping process.

4. Cling Wrapping Machine

Cling wrapping machine offer an efficient solution for tightly wrapping products using a stretchable film that clings securely to items. This wrapping method is highly effective for food products, keeping them fresh and shielded from contaminants.Cling wrapping machines provide a budget-friendly solution for packaging a wide range of products.

5. Vacuum Packing Machines

For companies working with perishable items, vacuum packing machines play an essential role. These machines remove air from the packaging to prevent oxidation and the growth of bacteria, thereby extending product shelf life. Vacuum packing machines are especially useful for sensitive items like meats, cheeses, and other perishables.

6. Sleeve Wrapping Machine

Sleeve wrapping machine is designed for high-speed packaging, allowing businesses to wrap products swiftly and efficiently. These machines use polyethylene film to securely encase multiple items like plastic bottles, jars, and cans, ensuring visibility and protection.

7. Carton Sealing Machine

Carton sealing machine automate the process of sealing boxes for shipping, improving efficiency in packaging operations. These machines can accommodate different box sizes and types, ensuring your products are securely sealed and safeguarded during transport. Using an effective carton sealing machine can save time and reduce labor costs.

8. Protective Packaging

Protective packaging is designed to shield products from damage during shipping and can function as either primary or secondary packaging, depending on the product. Its main goal is to ensure that items arrive in perfect condition. We offer a wide range of protective packaging options, including air pillows, packing paper, foam, and bubble bags.

Why Choose Triveni Packaging?

Triveni Packaging Trading Company LLC is a top choice among packaging machine suppliers, offering innovative solutions in packaging machinery in UAE. We provide a diverse selection of high-quality and affordable packaging machinery designed to meet all your packaging needs. Our commitment to quality ensures that all machines meet the highest industry standards, utilizing durable materials and advanced technology for long-lasting performance.

Our dedicated customer service team supports clients from the initial consultation through after-sales, ensuring that quality solutions are accessible at competitive pricing. With years of experience and a strong reputation, we are trusted as the best packaging machine suppliers for our reliable packaging machinery in UAE.

Conclusion

Choosing the right packaging solutions is essential for improving product safety and operational efficiency. Triveni Packaging is a top choice among packaging machine suppliers in the industry. Our wide selection of packaging machinery in UAE is tailored to accommodate various packaging requirements.With a focus on quality and innovation, we provide the machinery you need to ensure your products are protected. Reach out to Triveni Packaging Trading Company LLC and explore our packaging solutions.

#packaging solutions#packaging machinery in uae#packaging machines#packaging machine suppliers#vacuum packing machines#cling wrapping machines#sleeve wrapping machines#protective packaging#shrink wrapping machines#tray sealing machines

0 notes

Text

Astaxanthin Market Share and Growth Information Analysis Report by 2030

The global astaxanthin market was valued at USD 2.34 billion in 2023, with a projected compound annual growth rate (CAGR) of 17.1% from 2024 to 2030. This growth is driven by rising demand across multiple sectors, including aquaculture, animal feed, nutraceuticals, cosmetics, pharmaceuticals, and food and beverages. Astaxanthin is particularly valued in aquaculture as a feed ingredient for prawns, salmon, trout, and ornamental fish to enhance their coloration, which increases their commercial appeal. Besides improving pigmentation, astaxanthin also contributes to enhanced stress tolerance, improved performance, immune support, reproductive health, increased survival rates, and disease resistance in aquatic animals. To meet this demand, major market players are focusing on product innovation and forming partnerships, especially in the aquaculture sector.

Organizations promoting awareness about astaxanthin’s applications further support market growth. The Natural Algae Astaxanthin Association (NAXA), for example, plays a significant role in advocating for natural astaxanthin, promoting its benefits across various industries, supporting research, and certifying products with the NAXA Verification Seal.

Gather more insights about the market drivers, restrains and growth of the Astaxanthin Market

To expand market reach, companies are leveraging strategies such as product launches and collaborations with leading firms in key industries. For example, in May 2022, Algalif partnered with Divi’s Nutraceuticals to launch AstaBeads, a high-concentration astaxanthin beadlet targeting sports nutrition and healthy aging applications. This collaboration is poised to boost market penetration of natural astaxanthin products. Furthermore, The Lubrizol Corporation introduced ASTAGILE microcapsules in October 2020 to promote cognitive health and agility for both young and elderly consumers.

In May 2022, Algalif and Divi’s Nutraceuticals collaborated on producing high-concentration natural astaxanthin beadlets. Based in Iceland, Algalif uses a renewable-energy-powered process to produce high-quality astaxanthin oleoresin from microalgae. Divi’s Nutraceuticals then applies its expertise in fat-soluble ingredients to transform this oleoresin into AstaBead beadlets, which contain a concentrated 5% astaxanthin. This partnership emphasizes both sustainability and premium product quality, showcasing a commitment to environmental stewardship and product excellence.

Application Segmentation Insights:

In 2023, the aquaculture and animal feed sector held the largest market share at 46.39%, primarily due to astaxanthin’s extensive use as a feed additive to enhance reddish pigmentation in species like salmon, trout, and shrimp, which is a key consumer preference. Astaxanthin oil also promotes better feed uptake, accelerating shrimp growth. The growing adoption of astaxanthin in the aquaculture sector to improve seafood quality supports this segment’s dominance in the market. Leading players are also launching new products with health benefits for animal feed. For instance, AstaReal introduced Novasta in July 2022, an astaxanthin-based ingredient for animal feed, expanding health-focused applications in animal nutrition.

The nutraceuticals segment is anticipated to experience the fastest CAGR during the forecast period, driven by increasing demand for natural astaxanthin in health supplements due to its superior antioxidant properties compared to other supplements. The rising need for nutritional products, alongside aging populations, nutrient deficiencies, and lifestyle-related health concerns, is boosting demand in this sector. Astaxanthin’s antioxidant benefits are linked to support against conditions like liver and oral cancers, cardiovascular diseases, and obesity. Thus, the growing prevalence of chronic and infectious diseases is expected to provide substantial growth opportunities for the nutraceuticals market.

Order a free sample PDF of the Astaxanthin Market Intelligence Study, published by Grand View Research.

#Astaxanthin Market Share#Astaxanthin Market Analysis#Astaxanthin Market Trends#Astaxanthin Market Growth

0 notes

Text

Astaxanthin Market - Recent Industry Developments and Growth Strategies till 2030

The global astaxanthin market was valued at USD 2.34 billion in 2023, with a projected compound annual growth rate (CAGR) of 17.1% from 2024 to 2030. This growth is driven by rising demand across multiple sectors, including aquaculture, animal feed, nutraceuticals, cosmetics, pharmaceuticals, and food and beverages. Astaxanthin is particularly valued in aquaculture as a feed ingredient for prawns, salmon, trout, and ornamental fish to enhance their coloration, which increases their commercial appeal. Besides improving pigmentation, astaxanthin also contributes to enhanced stress tolerance, improved performance, immune support, reproductive health, increased survival rates, and disease resistance in aquatic animals. To meet this demand, major market players are focusing on product innovation and forming partnerships, especially in the aquaculture sector.

Organizations promoting awareness about astaxanthin’s applications further support market growth. The Natural Algae Astaxanthin Association (NAXA), for example, plays a significant role in advocating for natural astaxanthin, promoting its benefits across various industries, supporting research, and certifying products with the NAXA Verification Seal.

Gather more insights about the market drivers, restrains and growth of the Astaxanthin Market

To expand market reach, companies are leveraging strategies such as product launches and collaborations with leading firms in key industries. For example, in May 2022, Algalif partnered with Divi’s Nutraceuticals to launch AstaBeads, a high-concentration astaxanthin beadlet targeting sports nutrition and healthy aging applications. This collaboration is poised to boost market penetration of natural astaxanthin products. Furthermore, The Lubrizol Corporation introduced ASTAGILE microcapsules in October 2020 to promote cognitive health and agility for both young and elderly consumers.

In May 2022, Algalif and Divi’s Nutraceuticals collaborated on producing high-concentration natural astaxanthin beadlets. Based in Iceland, Algalif uses a renewable-energy-powered process to produce high-quality astaxanthin oleoresin from microalgae. Divi’s Nutraceuticals then applies its expertise in fat-soluble ingredients to transform this oleoresin into AstaBead beadlets, which contain a concentrated 5% astaxanthin. This partnership emphasizes both sustainability and premium product quality, showcasing a commitment to environmental stewardship and product excellence.

Application Segmentation Insights:

In 2023, the aquaculture and animal feed sector held the largest market share at 46.39%, primarily due to astaxanthin’s extensive use as a feed additive to enhance reddish pigmentation in species like salmon, trout, and shrimp, which is a key consumer preference. Astaxanthin oil also promotes better feed uptake, accelerating shrimp growth. The growing adoption of astaxanthin in the aquaculture sector to improve seafood quality supports this segment’s dominance in the market. Leading players are also launching new products with health benefits for animal feed. For instance, AstaReal introduced Novasta in July 2022, an astaxanthin-based ingredient for animal feed, expanding health-focused applications in animal nutrition.

The nutraceuticals segment is anticipated to experience the fastest CAGR during the forecast period, driven by increasing demand for natural astaxanthin in health supplements due to its superior antioxidant properties compared to other supplements. The rising need for nutritional products, alongside aging populations, nutrient deficiencies, and lifestyle-related health concerns, is boosting demand in this sector. Astaxanthin’s antioxidant benefits are linked to support against conditions like liver and oral cancers, cardiovascular diseases, and obesity. Thus, the growing prevalence of chronic and infectious diseases is expected to provide substantial growth opportunities for the nutraceuticals market.

Order a free sample PDF of the Astaxanthin Market Intelligence Study, published by Grand View Research.

#Astaxanthin Market Share#Astaxanthin Market Analysis#Astaxanthin Market Trends#Astaxanthin Market Growth

0 notes

Text

Choosing the Right Rapid Mixer Granulator: What to Expect in an Investment

Rapid Mixer Granulators and their Use

A Rapid Mixer Granulator is very important in today’s pharmacy industry. It takes raw powder materials and mixes them uniformly into granules, ready for compression into tablets or filling into capsules. With an RMG, mixing, granulation, and drying are all carried out in a single unit, which makes the process very efficient in terms of streamlining production while maintaining the quality of the final product.

Granulation quality is one of the most critical factors for manufacturing success. Poor granulation can lead to inconsistent tablet hardness, dissolution rates, and bioavailability, all of which are critical to product efficacy and regulatory compliance. Optimal granulation, on the other hand, improves flow properties, reduces dust, and ensures uniform distribution of active ingredients.

Critical Performance Parameters in RMG Selection

Processing Capability and Batch-to-Batch Consistency

In the selection of RMG, processing capability is a key consideration. Some of the key metrics include:

Impeller and chopper speed ranges

Consistency of the blend in different batch sizes

Time to granulate

Temperature control accuracy

Energy consumption efficiency

Manufacturing sites will measure these attributes against their unique manufacturing requirements. For instance, a site producing several products will want equipment capable of broader speed ranges and the ability for high accuracy of temperature control to meet different formulation requirements.

Scalability and Production Flexibility

Markets evolve; thus, scalability is a factor in long-term value of equipment. Consider these scalability aspects:

Minimum and maximum size batches

Bowl geometry and implications for scale-up

Power draw at different operating conditions

Clean-in-place (CIP) system compatibility

Process parameter adjustability

Equipment that can handle different batch sizes with the same quality is a goldmine for facilities with different production schedules or growth plans.

Design and Construction Quality

Material quality and construction design significantly impact both performance and life:

Bowl and blade material grade

Seal design and durability

Loading/discharge valve construction

Control panel protection rating

General GMP compliance features

Look for equipment constructed of pharmaceutical-grade stainless steel and which have designs to protect product purity while allowing thorough cleanability.

Maintenance Needs and Access

Maintenance ensures that the equipment functions predictably and extends its useful life. Essential factors for easy maintenance are:

Accessibility to critical components

Toolless disassembly where practical

Standard stock of spares

Incorporated cleaning systems

Maintenance documentation

Equipment designed to be easier to maintain reduces downtime, and makes possible the completion of cleaning validation.

Control Systems and Documentation

Modern Rapid Mixer Granulator should have solid control systems that do the following:

Monitor critical process parameters

Record data automatically batch by batch

Enable recipe management

Facilitate optimization of the process

Produce all-inclusive batch reports

High-tech control systems ensure product quality consistency while ensuring easier documentation for regulatory compliance.

Safety Features and Operator Protection

The safety features help ensure operators do not harm themselves while also protecting the quality of the product:

Emergency stop systems

Interlock mechanisms

Dust collection systems

Noise abatement systems

Ergonomically designed loading/unloading systems

These safety features are useful not only in the safety of personnel but also ensure GMP compliance and avoidance of product contamination.

Selection of the Right RMG

The selection of a proper RMG involves proper judgment of various factors against certain manufacturing requirements. Pay emphasis to:

Matching the equipment's capabilities with the specifications of the product

Suitability with the existing facility

Vendor support capabilities

Total cost of ownership

Features of regulatory compliance

The proper evaluation process will highlight the equipment that offers maximum performance within the budget constraints. Of course, the initial investment in a quality RMG usually generates value through better product consistency, reduced waste, and improved operational efficiency.

Detailed technical specifications, validation documentation, and ideally, trial runs or site visits to similar installations by the vendors can be of great assistance in ascertaining the suitability of equipment for certain applications.

The right Rapid Mixer Granulator investment considers not only the immediate production needs but also future growth and regulatory demands. Selecting machinery that delivers long-term operational efficiency ensures consistent value throughout its entire lifecycle.

#Rapid Mixer Granulator#pharmaceutical manufacturing#granulation equipment#mixing technology#investment in granulators#pharmaceutical production

0 notes

Text

Global Hook Type Cold Room Panels Market: Trends, Drivers, and Future Prospects:

The global market for hook type cold room panels is witnessing rapid growth, driven by increased demand from the food and beverage, pharmaceutical, and logistics industries. Hook type cold room panels, known for their ease of installation and efficiency in maintaining low temperatures, are an essential component in the cold storage industry. These panels are built with interlocking hooks that create airtight seals, which ensure better insulation and energy efficiency. As cold storage facilities expand worldwide to accommodate a growing need for temperature-controlled environments, hook type cold room panels have become an attractive solution for businesses seeking to optimize storage while minimizing costs.

What Is Hook Type Cold Room Panels?

Hook type cold room panels are insulated panels specifically designed for cold storage. They are manufactured with interlocking hooks on their edges, allowing for quick and easy installation without the need for additional fasteners or adhesives. This interlocking design also ensures a tight seal, minimizing temperature fluctuations and reducing energy consumption. Typically made from materials like polyurethane foam (PUF), polyisocyanurate (PIR), or expanded polystyrene (EPS), these panels offer high thermal resistance, making them ideal for industries that rely on cold storage for their operations.

Unlike traditional cold room panels, hook type panels can be disassembled and reassembled without damage, making them versatile for industries that may need to relocate or resize their cold storage spaces. They are commonly used in food processing, pharmaceuticals, logistics, and retail sectors, where maintaining consistent low temperatures is essential for product quality and safety.

MORE ABOUT REPORT: https://www.xinrenresearch.com/reports/global-hook-type…om-panels-market-market/

Key Market Drivers for Hook Type Cold Room Panels

Growing Demand for Cold Storage in the Food Industry: The food and beverage industry is one of the largest consumers of cold storage facilities, driven by the need to preserve perishable goods. With the rise of global food trade and increasing demand for frozen and refrigerated products, the need for efficient cold storage solutions has surged. Hook type cold room panels, with their ease of installation and energy efficiency, are ideal for building or expanding cold storage facilities in this sector. Additionally, the growth of e-commerce and online grocery shopping has increased the demand for cold storage and transportation solutions, further propelling the market.

Rising Demand in the Pharmaceutical Sector: The pharmaceutical industry requires controlled environments to store temperature-sensitive products, including vaccines, biologics, and other medical supplies. With the rise of biologic drugs and the COVID-19 pandemic emphasizing the importance of vaccine storage, the need for reliable cold storage facilities has grown significantly. Hook type cold room panels offer the thermal insulation and reliability necessary to maintain specific temperature ranges required by the pharmaceutical industry, making them an attractive choice for healthcare companies.

Increasing Urbanization and Changing Consumption Patterns: As urban populations grow and disposable incomes rise, consumers are shifting towards more convenience foods, which are often refrigerated or frozen. This trend has resulted in a higher demand for cold storage in urban centers to store products like dairy, frozen meals, and beverages. Hook type cold room panels, with their ease of setup and space efficiency, allow retailers and food distributors to build compact, modular cold storage solutions in urban areas, where space is often limited.

Expansion of E-Commerce and Cold Chain Logistics: E-commerce, especially in the grocery and meal kit delivery segments, has led to increased demand for cold chain logistics to ensure the safe transport of perishable goods. Hook type cold room panels are particularly suitable for e-commerce and logistics companies that need scalable, flexible cold storage solutions. As more consumers embrace online grocery shopping and fresh food delivery services, the demand for these cold storage panels is expected to rise.

Energy Efficiency and Environmental Regulations: With growing concerns over energy consumption and environmental impact, companies are increasingly focused on improving the energy efficiency of their cold storage facilities. Hook type cold room panels, with their high thermal resistance and tight sealing capabilities, help reduce energy costs by minimizing heat transfer. Moreover, many countries are introducing regulations that promote energy-efficient construction practices, further incentivizing the use of insulated panels in cold storage.

Market Segmentation for Hook Type Cold Room Panels

By Material Type:

Polyurethane Foam (PUF): Known for its excellent insulation properties and lightweight nature, PUF is one of the most commonly used materials in cold room panels. Its high thermal resistance makes it ideal for cold storage applications, although it can be relatively costly compared to other materials.

Polyisocyanurate (PIR): PIR panels offer higher fire resistance than PUF, making them suitable for industries with stringent fire safety regulations. They also provide good thermal insulation, though they are typically more expensive.

Expanded Polystyrene (EPS): EPS is a cost-effective option that provides adequate insulation for cold storage. While it may not offer the same level of thermal efficiency as PUF or PIR, EPS panels are popular in budget-conscious applications.

By Application:

Food and Beverage Storage: The majority of cold storage facilities cater to the food and beverage industry, where hook type cold room panels are used to preserve perishable goods such as meat, dairy, seafood, and frozen foods.

Pharmaceutical and Healthcare: Cold storage is essential for the pharmaceutical industry to store vaccines, medicines, and other temperature-sensitive products. Hook type cold room panels are used to create sterile, temperature-controlled environments.

Retail and E-commerce: With the expansion of online grocery shopping, retail companies are increasingly investing in cold storage facilities for perishable goods. Hook type cold room panels are used to construct walk-in coolers and freezers within retail facilities.

Logistics and Warehousing: The logistics sector requires large-scale cold storage facilities to handle perishable goods during transit. Hook type cold room panels are ideal for warehouses and distribution centers due to their scalability and durability.

By End-Use Industry:

Food and Beverage

Pharmaceuticals

Logistics and Warehousing

Retail and E-commerce

Challenges Facing the Hook Type Cold Room Panels Market

High Initial Costs: While hook type cold room panels offer long-term energy savings, the initial cost of installation can be a barrier for small and medium-sized enterprises (SMEs). The cost of high-quality materials like PIR and PUF panels can be prohibitive, especially for small businesses looking to build or expand their cold storage capabilities.

Supply Chain Disruptions: The construction of cold storage facilities relies on a steady supply of raw materials, skilled labor, and transportation. Supply chain disruptions, as witnessed during the COVID-19 pandemic, can lead to delays in panel production and installation. Such disruptions can increase costs and affect project timelines, impacting market growth.

Environmental Concerns Over Insulating Materials: Although polyurethane and polyisocyanurate offer excellent thermal properties, their production involves chemicals that may have environmental impacts. As more companies seek eco-friendly alternatives, the market may need to adapt by developing sustainable insulation materials or focusing on recyclable options.

Limited Awareness in Developing Regions: While developed markets in North America and Europe have widely adopted hook type cold room panels, awareness and adoption remain limited in certain developing regions. This lack of awareness can limit the market’s growth in areas where cold storage demand is on the rise but where companies have yet to invest in advanced cold storage solutions.

Future Outlook and Opportunities in the Hook Type Cold Room Panels Market

Technological Advancements in Insulation: The development of advanced insulating materials, such as vacuum insulation panels and aerogel, could enhance the thermal efficiency of hook type cold room panels. These materials could offer improved insulation with thinner panels, saving space and reducing material costs.

Expansion into Emerging Markets: As developing countries invest in cold storage infrastructure to meet rising food and healthcare demands, there is a significant opportunity for growth in regions like Asia-Pacific, Africa, and parts of Latin America. Expanding distribution channels and educating potential customers on the benefits of hook type cold room panels could help manufacturers tap into these emerging markets.

Focus on Sustainability and Energy Efficiency: With sustainability becoming a priority, companies are exploring ways to make cold storage solutions more eco-friendly. Hook type cold room panel manufacturers are increasingly using eco-friendly materials and focusing on reducing carbon footprints during production. Innovations in recyclable insulation materials or low-emission production processes could position these panels as a more sustainable choice in cold storage construction.

Integration with IoT and Smart Technologies: Smart cold storage facilities are becoming more common, with IoT sensors used to monitor temperature, humidity, and energy consumption in real-time. Hook type cold room panels with embedded sensors or smart capabilities could further enhance the efficiency of cold storage facilities, providing insights into energy usage and enabling predictive maintenance.

Conclusion: A Market Primed for Growth and Innovation

The global hook type cold room panels market is poised for significant growth as industries continue to invest in cold storage solutions to meet the needs of a globalized and health-conscious consumer base. Driven by demand from the food, pharmaceutical, and logistics sectors, hook type cold room panels offer a cost-effective and energy-efficient solution for companies looking to maintain temperature-controlled environments. While challenges such as high initial costs and environmental concerns remain, ongoing advancements in insulation technology and sustainable practices present opportunities for innovation and market expansion.

As the world increasingly prioritizes food safety, healthcare access, and environmental sustainability, hook type cold room panels are set to play a central role in the future of cold storage solutions worldwide.

MORE ABOUT REPORT: https://www.xinrenresearch.com

0 notes

Text

Astaxanthin Market Size & Share | Statistics Report 2030

The global astaxanthin market reached a valuation of USD 2.34 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 17.1% from 2024 to 2030. This growth is driven by a rising demand for astaxanthin across various industries, including aquaculture, animal feed, nutraceuticals, cosmetics, pharmaceuticals, and food and beverages. Astaxanthin’s role in aquaculture is significant, where it is commonly used to enhance the coloration of species such as prawns, salmon, trout, and ornamental fish, increasing their market value. Additionally, astaxanthin offers numerous health benefits to aquatic animals, improving stress tolerance, performance, immune-related gene expression, reproductive capacity, survival rates, and disease resistance. To meet the rising demand in aquaculture, major industry players are focusing on product development and collaborative agreements.

Market growth is further supported by organizations that actively promote awareness of astaxanthin's diverse applications. For example, the Natural Algae Astaxanthin Association (NAXA) is influential in promoting, protecting, and educating the public on the benefits of natural astaxanthin across various industries. NAXA also supports relevant research and offers the NAXA Verification Seal to certify natural astaxanthin products.

To increase the penetration of natural astaxanthin-based products, companies are engaging in strategies such as new product launches and partnerships with influential players in related industries. For instance, Algalif partnered with Divi’s Nutraceuticals in May 2022 to release high-concentration astaxanthin beadlets called AstaBeads, targeting sports nutrition and healthy aging markets. Similarly, The Lubrizol Corporation launched ASTAGILE microcapsules in October 2020, focusing on enhancing cognitive and mental agility for both young and senior adults.

Gather more insights about the market drivers, restrains and growth of the Astaxanthin Market

The astaxanthin market showcases a high degree of innovation, with companies developing novel formulations and sustainable production methods. For example, Sirio Europe (SIRIO) revealed in August, 2023, its plan to introduce two new softgel products targeting the pharmaceutical sector during the CPHI Barcelona 2023 event.

The astaxanthin market is also characterized by a high level of merger and acquisition (M&A) activity by the leading players In January 2022, ENEOS Corporation disclosed its acquisition of Ecocert Inputs Attestation, a globally recognized certification organization. This strategic move strengthens ENEOS' position in the astaxanthin market, particularly for Panaferd-AX. The merger reflects the company's commitment to quality and international standards, contributing to the evolution of the industry.

Product Segmentation Insights:

In 2023, dried algae meal or biomass dominated the market with a share of 25.26%. This significant share is attributed to its applications in biomass production for other forms, such as capsules and tablets, minimal downstream processing, convenient bulk production, and a higher demand for use as animal feed. New product launches in the sector, such as Solabia-Algatech Nutrition Ltd’s AstaPure Arava gummies in October 2022, highlight the growing demand for algal astaxanthin. Additionally, in May 2022, Algalif collaborated with start-up company Marea to create a biodegradable coating using residual algae biomass. These advancements are anticipated to support growth in this segment over the forecast period.

The softgel segment is expected to experience strong growth in the coming years, as softgels are widely favored by consumers for their convenience and suitability for the geriatric population. Veggie softgels, derived from modified cornstarch and glycerin, are particularly popular among nutraceutical companies due to their plant-based origin and minimal side effects. Regulatory approvals are further boosting this segment; for example, in September 2021, NextFerm Technologies obtained regulatory approval in the U.S. to market Astaferm, an innovative antioxidant in oil form for softgels.

These factors collectively contribute to the expansion of the global astaxanthin market across various segments and applications.

Order a free sample PDF of the Astaxanthin Market Intelligence Study, published by Grand View Research.

#Astaxanthin Industry#Astaxanthin Market Research#Astaxanthin Market Forecast#Astaxanthin Market Overview

1 note

·

View note

Text

Astaxanthin Market – Industry Trends and Forecast Report 2030

The global astaxanthin market reached a valuation of USD 2.34 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 17.1% from 2024 to 2030. This growth is driven by a rising demand for astaxanthin across various industries, including aquaculture, animal feed, nutraceuticals, cosmetics, pharmaceuticals, and food and beverages. Astaxanthin’s role in aquaculture is significant, where it is commonly used to enhance the coloration of species such as prawns, salmon, trout, and ornamental fish, increasing their market value. Additionally, astaxanthin offers numerous health benefits to aquatic animals, improving stress tolerance, performance, immune-related gene expression, reproductive capacity, survival rates, and disease resistance. To meet the rising demand in aquaculture, major industry players are focusing on product development and collaborative agreements.

Market growth is further supported by organizations that actively promote awareness of astaxanthin's diverse applications. For example, the Natural Algae Astaxanthin Association (NAXA) is influential in promoting, protecting, and educating the public on the benefits of natural astaxanthin across various industries. NAXA also supports relevant research and offers the NAXA Verification Seal to certify natural astaxanthin products.

To increase the penetration of natural astaxanthin-based products, companies are engaging in strategies such as new product launches and partnerships with influential players in related industries. For instance, Algalif partnered with Divi’s Nutraceuticals in May 2022 to release high-concentration astaxanthin beadlets called AstaBeads, targeting sports nutrition and healthy aging markets. Similarly, The Lubrizol Corporation launched ASTAGILE microcapsules in October 2020, focusing on enhancing cognitive and mental agility for both young and senior adults.

Gather more insights about the market drivers, restrains and growth of the Astaxanthin Market

The astaxanthin market showcases a high degree of innovation, with companies developing novel formulations and sustainable production methods. For example, Sirio Europe (SIRIO) revealed in August, 2023, its plan to introduce two new softgel products targeting the pharmaceutical sector during the CPHI Barcelona 2023 event.

The astaxanthin market is also characterized by a high level of merger and acquisition (M&A) activity by the leading players In January 2022, ENEOS Corporation disclosed its acquisition of Ecocert Inputs Attestation, a globally recognized certification organization. This strategic move strengthens ENEOS' position in the astaxanthin market, particularly for Panaferd-AX. The merger reflects the company's commitment to quality and international standards, contributing to the evolution of the industry.

Product Segmentation Insights:

In 2023, dried algae meal or biomass dominated the market with a share of 25.26%. This significant share is attributed to its applications in biomass production for other forms, such as capsules and tablets, minimal downstream processing, convenient bulk production, and a higher demand for use as animal feed. New product launches in the sector, such as Solabia-Algatech Nutrition Ltd’s AstaPure Arava gummies in October 2022, highlight the growing demand for algal astaxanthin. Additionally, in May 2022, Algalif collaborated with start-up company Marea to create a biodegradable coating using residual algae biomass. These advancements are anticipated to support growth in this segment over the forecast period.

The softgel segment is expected to experience strong growth in the coming years, as softgels are widely favored by consumers for their convenience and suitability for the geriatric population. Veggie softgels, derived from modified cornstarch and glycerin, are particularly popular among nutraceutical companies due to their plant-based origin and minimal side effects. Regulatory approvals are further boosting this segment; for example, in September 2021, NextFerm Technologies obtained regulatory approval in the U.S. to market Astaferm, an innovative antioxidant in oil form for softgels.

These factors collectively contribute to the expansion of the global astaxanthin market across various segments and applications.

Order a free sample PDF of the Astaxanthin Market Intelligence Study, published by Grand View Research.

#Astaxanthin Industry#Astaxanthin Market Research#Astaxanthin Market Forecast#Astaxanthin Market Overview

1 note

·

View note

Text

Cold Form Blister Packaging Market Size, Share, Trends, Growth, Key Players, Report and Forecast 2024-2036

Research Nester assesses the growth and market size of the global cold form blister packaging market which is anticipated to be on account of the growing investment in the healthcare sector.

Research Nester’s recent market research analysis on “Cold Form Blister Packaging Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitors analysis and a detailed overview of the global cold form blister packaging market in terms of market segmentation by material, application, and by region.

Growing Demand in the Pharmaceutical Industry Global Market Share of Cold Form Blister Packaging

The expanding demand for cold-form blister packaging is driven by its remarkable qualities, including effortless sealing and providing a robust barrier against oxygen, water, light, and moisture. Cold-form blister packaging involves the use of specialized cold-forming foil, which eliminates the need for heat during the packaging process. This technique is primarily used for packaging pharmaceuticals such as tablets and capsules, providing a secure and protective enclosure for these sensitive medical products.

Request Free Sample Copy of this Report @ https://www.researchnester.com/sample-request-6334

Therefore, the surge in the demand for blisters and the maximizing research and development activities in the pharmaceutical industry are boosting the market growth. Also, the pharmaceutical sector has witnessed sustained growth over the decades, due to the geriatric population, growing healthcare awareness, and the demand for numerous medications. According to WHO, one in six individuals on the globe will be 60 years of age or older by 2030.

Some of the major growth factors and challenges that are associated with the growth of the global cold form blisters market are:

Growth Drivers:

Surge in the adoption of cold form aluminum blister packs

Exceptional features than the alternative packaging types

Challenges:

The most popular type of blister pack is thermoformed, which employs clear PVC material provides a variety of seal options, and safeguards the goods during travel as it is strong, resilient, and impervious to tampering. Besides this, heat seal blister cards, a form of blister packing produced by applying heat, are the perfect packaging option for pharmacies to shield food items and medications from impurities, moisture, and air. All these factors may limit the adoption of cold form blister packaging.

Moreover, the fluctuating prices of raw materials and a lack of advanced infrastructure in emerging nations are some other challenges that may hamper the growth of the cold form blister packaging market.

Request for customization @ https://www.researchnester.com/customized-reports-6334

By material, the global cold form blisters market is segmented into aluminum, PVC, and PET. The PVC segment is expected to gain a significant market share during the forecast period. The main advantage of PVC is its affordability. PVDC, or polyvinylidene chloride, is mixed with PVC sheets to improve the packaging's barrier properties. This provides outstanding protection against moisture and oxygen.

By region, the Europe cold form blister packaging market is expected to garner notable market revenue. The region's market is expanding due to the growing emphasis on child-resistant packaging and the rising need for unit-dose packaging provided by cold-form blister packaging solutions. Furthermore, the need for sustainable cold-form blister packaging solutions built with recyclable PET materials that support the region's sustainability goals is being driven by a shift in consumer preference for eco-friendly packaging options in the healthcare sector.

This report also provides the existing competitive scenario of some of the key players of the global cold form blister packaging market which includes company profiling of Amcor plc, Constantia Flexibles, Sonoco Products Company, WINPAK LTD, Bilcare Limited, Honeywell Internatonal Inc., TekniPlex, Liveo Research AG, R-Pharm Germany GmbH, Wasdell Group, UFlex Limited, and others.

Access our detailed report @ https://www.researchnester.com/reports/cold-form-blister-packaging-market/6334

About Research Nester-

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

#Cold Form Blister Packaging Market#Cold Form Blister Packaging Market analysis#Cold Form Blister Packaging Market segment

0 notes

Text

Vacuum Packaging Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Global Vacuum Packaging Market – Industry Trends and Forecast to 2029

Global Vacuum Packaging Market, By Material Type (Polyethylene, Polypropylene, Polyamide, Ethylene Vinyl Alcohol, Others), Machinery (Thermoformers, External Vacuum Sealers, Tray Sealing Machines, Others), Process (Skin Vacuum Packaging, Shrink Vacuum Packaging, Others), Packaging (Rigid Packaging, Flexible Packaging, Semi-Rigid Packaging), Application (Food, Pharmaceuticals, Industrial Goods, Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2029

Access Full 350 Pages PDF Report @

The global vacuum packaging market is experiencing significant growth due to the increasing demand for convenience foods, technological advancements in packaging materials, and the need for extended shelf life of food products. Vacuum packaging helps in preserving the freshness and quality of products by removing oxygen from the packaging, thereby reducing the growth of bacteria and mold. This market analysis will focus on key metrics such as market size, growth drivers, challenges, and trends shaping the vacuum packaging industry.

**Segments**

- **By Packaging Type**: The vacuum packaging market can be segmented into rigid packaging, flexible packaging, and semi-rigid packaging. Rigid packaging includes trays and containers, flexible packaging comprises pouches and bags, while semi-rigid packaging includes vacuum skin packaging. - **By Application**: The market can be segmented into food packaging, pharmaceutical packaging, industrial packaging, and consumer goods. Food packaging accounts for the largest market share due to the growing demand for processed and convenience foods. - **By Region**: Geographically, the market is segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific is expected to witness the fastest growth due to the rapid industrialization and increasing disposable incomes in countries like China and India.

**Market Players**

- Cryovac Inc. (Sealed Air Corporation) - Amcor plc - Berry Global Inc. - Mondi - Winpak Ltd. - ULMA Packaging - Coveris - LINPAC Packaging - Klöckner Pentaplast - MULTIVAC

These market players are focusing on product innovations, strategic mergers & acquisitions, and partnerships to gain a competitive edge in the global vacuum packaging market. The increasing emphasis on sustainable packaging solutions and the adoption of recyclable materials are also driving market growth. However, challenges such as high initial investment costs and stringent regulations regarding food safety and packaging materials could hinder market growth in the coming years.

For more insights and in-depth analysis, refer to https://www.databridgemarkThe global vacuum packaging market is witnessing a surge in demand owing to the rising need for convenience and packaged foods worldwide. Technological advancements in packaging materials have significantly contributed to the growth of this market by enhancing the preservation of freshness and quality of products. By removing oxygen from the packaging, vacuum packaging helps in reducing bacterial and mold growth, thereby prolonging the shelf life of various food products. As consumers increasingly opt for processed and convenience foods, the demand for vacuum packaging solutions continues to escalate, driving the market forward.

In terms of packaging types, the market can be segmented into rigid, flexible, and semi-rigid packaging. Rigid packaging, which includes trays and containers, offers sturdy protection to the packaged goods. On the other hand, flexible packaging, such as pouches and bags, provides convenience and ease of use for consumers. Semi-rigid packaging, like vacuum skin packaging, combines elements of both rigidity and flexibility to cater to specific product requirements. Each packaging type serves a unique purpose in meeting the diverse needs of different industries, contributing to the overall growth of the vacuum packaging market.

The applications of vacuum packaging span across various industries, including food, pharmaceutical, industrial, and consumer goods packaging. Among these, food packaging holds the largest market share, driven by the escalating demand for processed and convenience foods globally. The pharmaceutical industry also presents significant opportunities for vacuum packaging solutions, as they help in maintaining the efficacy and safety of medical products. Industrial packaging and consumer goods packaging segments are also witnessing growth due to the benefits offered by vacuum packaging in extending the shelf life of products and ensuring their integrity during transit and storage.

Geographically, the vacuum packaging market is segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. The Asia Pacific region is poised to experience rapid growth driven by factors such as industrialization, urbanization, and increasing disposable incomes in countries like China and India. The region's expanding food and beverage sector, coupled with the growing demand for packaged goodsThe global vacuum packaging market is witnessing a surge in demand owing to the rising need for convenience and packaged foods worldwide. Technological advancements in packaging materials have significantly contributed to the growth of this market by enhancing the preservation of freshness and quality of products. By removing oxygen from the packaging, vacuum packaging helps in reducing bacterial and mold growth, thereby prolonging the shelf life of various food products. As consumers increasingly opt for processed and convenience foods, the demand for vacuum packaging solutions continues to escalate, driving the market forward.

In terms of packaging types, the market can be segmented into rigid, flexible, and semi-rigid packaging. Rigid packaging, which includes trays and containers, offers sturdy protection to the packaged goods. On the other hand, flexible packaging, such as pouches and bags, provides convenience and ease of use for consumers. Semi-rigid packaging, like vacuum skin packaging, combines elements of both rigidity and flexibility to cater to specific product requirements. Each packaging type serves a unique purpose in meeting the diverse needs of different industries, contributing to the overall growth of the vacuum packaging market.

The applications of vacuum packaging span across various industries, including food, pharmaceutical, industrial, and consumer goods packaging. Among these, food packaging holds the largest market share, driven by the escalating demand for processed and convenience foods globally. The pharmaceutical industry also presents significant opportunities for vacuum packaging solutions, as they help in maintaining the efficacy and safety of medical products. Industrial packaging and consumer goods packaging segments are also witnessing growth due

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Vacuum Packaging Market Landscape

Part 04: Global Vacuum Packaging Market Sizing

Part 05: Global Vacuum Packaging Market Segmentation By Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

Key takeaways from the Vacuum Packaging Market report:

Detailed considerate of Vacuum Packaging Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the Vacuum Packaging Market-leading players.

Vacuum Packaging Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of Vacuum Packaging Market for forthcoming years.

Browse Trending Reports:

Regenerated Fiber Market Cardiac Resynchronization Therapy Crt Devices Market Electronic Trial Master File Etmf Systems Market Starch Processing Market Acute Myeloid Testing Market Food Inclusions Market Industrial Dryers Market Neurosurgery Market Viral Hepatitis Market Glass Bottle Market Reclaimed Rubber Market Modified Wheat Starch Market Plant Genomics Market Digital Pump Controller Market Tofu And Tempeh Market Non Gmo Certification Market Linear Low Density Polyethylene Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Rigid Plastic Packaging Market Size $262.5 billion by 2027

The report "Rigid Plastic Packaging Market Industry by Type, Application (Food, Beverages, Healthcare, Cosmetics, Industrial), Raw Material (Bioplastics, PE, PET, PS, PP, PVC, EPs, PC, Polyamide), Production Process, and Region - Global Forecast to 2027 ", is projected to grow from USD 207.8 billion in 2022 to USD 262.5 billion by 2027, at a CAGR of 4.7% between 2022 and 2027. The growth of the Rigid plastic packaging market is attributed towards growing of food, beverages, healthcare, cosmetics, Industrial and others. Rigid plastic packaging is widely used in the food & beverage industries as it increases the shelf life of the products, thus preventing food loss. The market for rigid plastic packaging in the healthcare segment is also projected to grow at a high rate, owing to the increase in consumption of pharmaceutical products due to the aging population and growth in incidence rates of chronic diseases. Rigid plastic packaging offers aesthetic appeal and durability to the product, which increases its marketability; hence, it is used in the cosmetics & toiletries industry

Download PDF Brochure at https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=178852016

Browse 203 market data Tables and 52 Figures spread through 225 Pages and in-depth TOC on "Rigid Plastic Packaging Market by Type, Application (Food, Beverages, Healthcare, Cosmetics, Industrial), Raw Material (Bioplastics, PE, PET, PS, PP, PVC, EPs, PC, Polyamide), Production Process, and Region - Global Forecast to 2027 " View detailed Table of Content here - https://www.marketsandmarkets.com/Market-Reports/rigid-plastic-packaging-market-178852016.html

Tube, Cups and Pots to be the fastest growing type in Rigid Plastic Packaging during forecast period

Rigid plastic tubs, cups, and pots are used in the food service and retail industry to package anything from cream and dips to insecticides. Cups are precision thermoformed, which are sealed using a heat sealable flexible lid. These cups generally have flat edges for perfect seals. Some rigid cups also have rolled rims. These products are generally used to pack dairy products such as cream, yogurt, and dairy desserts. The segment is projected to witness the highest growth rate as a result of the growing demand for single-serve packs and properties such as cost-effectiveness, portion control, and less environmental impact.

Healthcare is to be the 3rd largest markets share segment in the Rigid Plastic Packaging Market during the forecast period

Healthcare products, which include pharmaceutical and medical products, are required to be protected from light, moisture, contamination, physical damage, or anything that can alter the quality of the products. The packaging quality of healthcare products plays a vital role in ensuring their protection. It involves the manufacture of a wide range of packaging materials such as paper, paperboard, cardboard, and rigid plastic packaging material. The growth in rigid plastic packaging is estimated to continue in global medication consumption, which is expected to be significantly driven by the aging demographic, leading to the increasing number of diseases and disorders. This will increase the demand for pharmaceutical products, which will further support the growth in rigid plastic packaging.

By raw material, Polyethylene Terephthalate (PET) to be the 3rd largest share in the Rigid Plastic Packaging Market during the forecast period

Polyethylene Terephthalate (PET) is a general-purpose thermoplastic polymer that belongs to the polyester family of polymers. Polyester resins are known for their excellent combination of properties such as mechanical, thermal, chemical resistance as well as dimensional stability attributes include superior transparency equal to that of glass, high mechanical strength, high rigidity at lower wall thickness, high flexibility, and high puncture resistance. These attributes enable the production of dimensionally stable rigid packaging with relatively small wall thickness and excellent oxygen barrier qualities, which make it suitable for packaging fresh foodstuffs. The application of polyethylene terephthalate takes place in industries such as food packaging, pharmaceutical packaging, box making, and electronics.

By Production Process, Blow Molding is to be the fastest growing in Rigid Plastic Packaging market during forecast period

Injection blow molding is used for the production of hollow plastic quantities. Products such as small medical and single-serving bottles are prepared using injection blow molding. Extrusion blow molding can be used to process different polymers such as polyethylene and polyvinyl chloride. Stretch blow molding applications include jars, bottles, and similar containers because it produces items of excellent visual and dimensional quality compared to extrusion blow molding. Many of the same materials used in blow molding are also good choices for injection molding, including HDPE, PS, PU, PP, and LDPE. There is a range of additional materials that are more uniquely suited for the solid products produced with injection molding. HDPE is the most commonly blow-molded plastic material. It is used in a vast array of products, including bottles for consumer liquids such as shampoos and motor oils, coolers, play structures, fuel tanks, industrial drums, and carrying cases.

Request For FREE Sample of Report at https://www.marketsandmarkets.com/requestsampleNew.asp?id=178852016

North America to be the 3rd largest share in the Rigid plastic packaging market during the forecast period

The rigid plastic packaging market in North America is expected to grow steadily during the forecast period. The market in this region is driven by technological advancements in the packaging industry. The demand for rigid plastic packaging will also be driven by factors such as increasing sales of consumer durables, high disposable income, and increasing demand for packaged foods. The US held a major share of the North American rigid plastic packaging market The rigid plastic packaging market in the US is mature and is expected to progress with a steady growth rate, mainly due to increasing sales of consumer durables in the country. As rigid plastic packaging finds application in consumer durables, the increasing demand for consumer durables will drive the market for rigid plastic packaging in the US. The growth in the rigid plastic packaging market in the US will be supported by the increased spending on healthcare products, as the healthcare industry is one of the largest consumers of rigid plastic packaging. This will boost the demand for pharmaceutical and medical products, further supporting the growth in the packaging industry.

Rising food production levels highlight the need for rigid plastic packaging. Moreover, the improvement of the US economy and the rising disposable income will increase the consumption level in the country, further supporting the growth of the rigid plastic packaging market. The growing trend of retail shopping is also responsible for the increasing demand for rigid plastic packaging in the US.

Amcor Plc(Switzerland), SIG Berry Global Group Inc.(US), Pactiv LLC(US), Silgan Holdings Inc.(US), Sonoco Products Company(US), DS Smith Plc(UK), ALPLA(Austria), Takween Advanced Industries(Saudi Arabia), SABIC.( (Saudi Arabia)), Al Jabri Plastic Factory(UAE), Nuplas Industries Ltd.(UAE), Altium Packaging LP (US)and Plastipak Holdings, Inc.(US) among others are the key players operating in the Rigid plastic packaging market . Acquisitions, expansions, contracts, agreements & partnerships, and new product developments are some of the major strategies adopted by these key players to enhance their positions in the Rigid plastic packaging market .

Don’t miss out on business opportunities in Rigid Plastic Packaging Market. Speak to our analyst and gain crucial industry insights that will help your business grow.

#Rigid Plastic Packaging#Rigid Plastic Packaging Market#Rigid Plastic Packaging Industry#Plastic Packaging#Plastic#Packaging

1 note

·

View note

Text

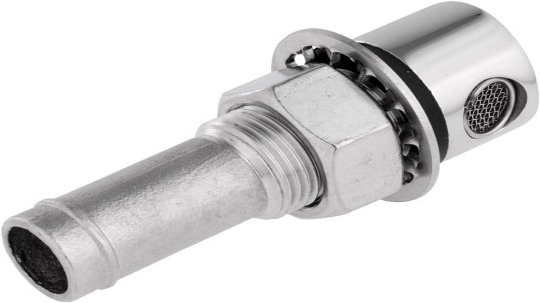

Breather Vent Market Size, Share, Analysis and Opportunities by 2024-2032