#Pesticides Manufacturers

Explore tagged Tumblr posts

Text

And from having large dogs. And a lot of them seem to require spraying chemicals on lawns.

HOAs sound awful, how do people deal with strangers telling them what color to paint their house and shit I would start throwing rocks

#if I ran the world I would force pesticide manufacturers to make their products smell like skunk#or turn brown on contact with air

25K notes

·

View notes

Text

SSCL: Pioneering Organic Solutions in Sanitation & Agriculture

In today's time a lot of demand for sustainable and organic products. People are becoming more inclined towards organic therefore it could be either about keeping our daily hygiene neat and clean or about the health of animals. SSCL (Sustainable Solutions Company Limited) is one such company offering a range of innovative products in the domain of sanitary and agricultural for these purposes.

Trailblazing Organic Sanitizers

When it comes to leading a healthy life hygiene is an integral factor and one who understands this the most is SSCL. With a variety of Organic Sanitizers the firm came forward to redefine cleaniliness in a very eco-friendly manner Unlike the ordinary chemical based sanitizers the SSCL has made organic sanitizers out of natural substances, thereby making it safe for us, our pet and our surrounding nature. These sanitizers are plant-based and help in killing dangerous pathogens in an effectual manner without harming your skin. SSCL’s organic sanitizers are perfect whether for your personal use or the commercial purposes and act as epitome of consistency in hygeine practices.

Making Organic Sanitization Products a Revolutionary Goal

SSCL certainly did not stop by giving just basic sanitizers when they made provision for a variety of Organic Sanitization Products aswell. These products are useful across a wide array of sectors such as medical, hotels and in households. We make sure that constituents for these sanitation solutions come from nature, are so they are ecofriendly which means that they are made up of elements which will break down and will not cause harm to the planet and at the same time saving us from harm.

Lending a Helping Hand to Domestic Stock by Supplying Premium Cattle Feed

After making its own products ultra-sustainable SSCL is also into agriculture and animal care now. The company is a trustworthy Cattle Feed Manufacturer, providing quality organic fodder which is to keep livestock in a healthier shape. These animal feeds are fortified with the essentials so that livestock is well fed which adds to their well being and productivity.

SSCL’s cattle feed manufacturing is free of any harmful chemicals thus promote animal well-being and contribute in the production of more healthy dairy and meat products.

Animal Feed Manufacturer With Care for Quality

Besides animal feed for cattle SSCL also manufacture feeds for other domestic stocks like poultry, sheep and goat breeds. These organic feed compositions are specially formulated by the firm depending on the kind of animal each is made for. The use of plants constituents and evading use of unnatural elements make the animals strong and prevent diseases making life easier for farmers and improving the agriculture ecosystem as a whole.

Why Choose SSCL?

SSCL is committed to leaving as little as possible environmental impact with every product we produce.

Everything on SSCL is 100% organic, safe and effective for things from cleaning to animal nutrition.

Innovation and Research: SSCL invests in research so that we can continue to bring you solutions to your problems now and into the future.

Trusted by Industries: With products across Agriculture, Healthcare, Hospitality & Cleaning SSCL products have gained a trust of best quality and reliability.

Changing Lives - One Product at a Time

For SSCL, it’s not only about making products. For them, it’s about leading the way towards a healthier, sustainable agriculture. By offering Organic Sanitation Products and top quality animal feed, SSCL wants to enable communities towards adopting eco-friendly practices that are beneficial both for health and environment.

The Future with SSCL

The future is all about embracing organic and SSCL is leading the organic revolution. When you choose for SSCL’s organic sanitizers and animal feed, you opt for a healthier living, improved animal welfare and an Earth that’s sustainable.

If you are making a purchase decision, consider SSCL and be a part of the change. Together, we can create a cleaner, greener and healthier place to live.

#organic waste decomposer#humic acid manufacturer#rabbit feed manufacturer#organic pesticide manufacturer#bio fertilizer manufacturer#animal feed manufacturer#cattle feed manufacturer#organic sanitizer#organic sanitation product#pig feed manufacturer

0 notes

Text

Bio Pesticides Company in India: Driving Sustainable Agriculture

Bio pesticides have gained significant traction in India as an environmentally friendly alternative to chemical pesticides. With the rising demand for organic farming and sustainable agricultural practices, bio pesticides companies in India are playing a pivotal role in transforming the farming landscape. These companies are focused on developing and delivering innovative products that help farmers protect crops from pests and diseases while maintaining soil and environmental health.

Bio pesticides are derived from natural sources such as plants, bacteria, fungi, and minerals. They are safe for human health, non-toxic to beneficial organisms, and biodegradable, making them an integral part of sustainable farming practices. Leading bio pesticides companies in India offer a range of products, including microbial pesticides, plant-based extracts like neem oil, and pheromone traps, tailored to the diverse needs of Indian farmers.

The government’s push for integrated pest management (IPM) and organic certification has further boosted the growth of bio pesticides in the Indian agricultural sector. Prominent bio pesticides companies in India, such as Kay Bee Bio Organics, is at the forefront of this movement. They invest in research and development to create innovative solutions that address pest management challenges effectively.

By adopting bio pesticides, Indian farmers can reduce their dependency on chemical pesticides, enhance crop productivity, and cater to the increasing global demand for organic produce. The efforts of bio pesticides company in India are not only contributing to healthier farming practices but also ensuring long-term agricultural sustainability.

0 notes

Text

Hydrogel usage reduces water stress when mixed with a substrate. Enhances plant growth by providing water and nutrients right at the root zone of the plants, reducing wastage. Reduces erosion and water runoff. Enhances plant performance, especially in arid areas. Protects the environment against drought and groundwater contamination. Acts as an insulating material for plant roots in frosty winter conditions. Reduces fertilizer usage by 15 – 30%.

1 note

·

View note

Text

Unveiling the Strength and Versatility of Resol Phenolic Resin: A Bond of Innovation

In the realm of materials science, resol phenolic resin emerges as a stalwart champion of strength, durability, and versatility. Born from the alchemy of chemical synthesis and human ingenuity, this remarkable substance has revolutionized industries ranging from automotive to construction. Let us embark on a journey to discover the extraordinary properties and myriad applications of resol phenolic resin, exploring the human intelligence and emotion that underpin its creation and utilization.

Exceptional Properties:

High Strength: Resol phenolic resin boasts exceptional mechanical strength, making it an ideal choice for applications where durability and reliability are paramount. Its ability to withstand extreme temperatures and harsh environmental conditions sets it apart as a material of choice in demanding engineering applications.

Fire Resistance: One of the hallmark properties of resol phenolic resin is its superior fire resistance. With a low flammability and high char yield, it serves as a critical component in fire-retardant materials for buildings, aircraft interiors, and other safety-critical applications.

Chemical Stability: Resol phenolic resin exhibits excellent resistance to a wide range of chemicals, acids, and solvents, making it suitable for use in corrosive environments such as chemical processing plants and offshore oil platforms.

Diverse Applications:

Composite Materials: Resol phenolic resin is widely used as a matrix material in the production of composite materials such as fiberglass reinforced plastics (FRP) and carbon fiber composites. Its ability to bond with reinforcing fibers creates lightweight yet strong structures for applications ranging from aerospace to sporting goods.

Insulation Products: The thermal and electrical insulation properties of resol phenolic resin make it a popular choice for manufacturing insulation products such as foam boards, pipe insulation, and electrical laminates. Its low thermal conductivity and high dielectric strength contribute to energy efficiency and safety in various industries.

Adhesives and Binders: As a versatile adhesive and binder, resol phenolic resin finds use in wood panels, plywood, particle boards, and foundry sand molds. Its strong bonding capabilities and heat resistance ensure the structural integrity and performance of bonded assemblies in diverse applications.

Innovative Manufacturing:

Precision Synthesis: The production of resol phenolic resin involves precise control over chemical reactions and process parameters to achieve desired properties such as molecular weight, viscosity, and curing characteristics. Advanced synthesis techniques and quality control measures ensure consistency and reliability in the final product.

Custom Formulations: Manufacturers tailor resol phenolic resin formulations to meet specific performance requirements for different applications. By adjusting resin composition, additives, and curing conditions, they optimize properties such as viscosity, tack, and flow behavior to suit diverse processing techniques and end-use conditions.

Human Ingenuity and Emotion:

Scientific Discovery: The development of resol phenolic resin is a testament to the curiosity, creativity, and perseverance of scientists and researchers who explore the frontiers of materials science. Their quest for innovation drives breakthroughs that unlock new possibilities and applications for this versatile material.

Engineering Excellence: Behind every application of resol phenolic resin lies the expertise and craftsmanship of engineers and technicians who harness its properties to solve real-world challenges. Their dedication to quality, safety, and performance ensures the integrity and reliability of structures and products made with this remarkable material.

Conclusion: Resol phenolic resin embodies the union of human intelligence and emotion in the pursuit of innovation and progress. From its exceptional properties to its diverse applications, it serves as a testament to the ingenuity and creativity of those who explore the boundaries of materials science. As we continue to unlock the potential of resol phenolic resin in various industries, let us celebrate the collaborative spirit and passion for discovery that drive its evolution and adoption.

In a world where challenges abound and solutions are sought, resol phenolic resin stands as a shining example of the transformative power of human ingenuity and emotion in shaping the materials that shape our world.

0 notes

Text

Understanding the Use and Need of HDPE Plastic Bottles

Have you ever wondered about the sturdy plastic bottles that house a myriad of chemicals in industries ranging from pharmaceuticals to agriculture? The answer lies in High-Density Polyethylene (HDPE), a versatile and durable plastic material that has become the backbone of chemical packaging. In this blog, we’ll take a deep dive into the making of chemical HDPE bottles, exploring their use, need, and the numerous benefits they offer to various industries.

1. What is HDPE?

High-Density Polyethylene (HDPE) is a type of thermoplastic polymer with a high strength-to-density ratio. It is known for its toughness, resistance to chemicals, and durability. These properties make HDPE an ideal material for the production of containers, including bottles, used in the storage and transportation of various chemicals.

2. Why Choose HDPE for Chemical Bottles?

a. Chemical Resistance: HDPE exhibits excellent resistance to a wide range of chemicals, making it suitable for storing corrosive substances without the risk of degradation or contamination.

b. Durability: The robust nature of HDPE ensures that the bottles can withstand the rigors of transportation, handling, and storage, providing a secure containment for diverse chemical products.

c. Versatility: HDPE bottles come in various shapes and sizes, catering to the specific needs of different industries. From small pharmaceutical bottles to large agricultural containers, HDPE is adaptable to a multitude of applications.

d. Cost-Effectiveness: HDPE is a cost-effective material, making it an attractive choice for industries seeking a balance between performance and budget considerations.

Manufacturing Process of HDPE Bottles

Now, let’s delve into the intricate process behind the scenes that transforms raw HDPE material into the chemical bottles we encounter in our daily lives.

1. Raw Material Preparation:

The journey begins with the collection of raw HDPE resin pellets. These pellets are typically produced through the polymerization of ethylene, a hydrocarbon gas derived from crude oil or natural gas. The quality and properties of the resin depend on the specific manufacturing process and additives used.

2. Extrusion:

The raw HDPE resin pellets are then melted and extruded into a continuous parison — a tube-like structure with an opening at one end. This process is known as extrusion and is facilitated by heating the resin to its melting point.

3. Extrusion Blow Moulding:

The extruded parison is transferred to a mould, and a controlled amount of air is injected into the parison, forcing it to take the shape of the mould. This process, known as extrusion blow moulding, results in the creation of the bottle’s basic form. The mould dictates the final shape and size of the bottle.

4. Cooling and Trimming:

Once the bottle shape is formed, it undergoes a cooling process to solidify the plastic. After cooling, excess material is trimmed, leaving behind a seamless and uniform HDPE bottle.

5. Quality Control:

Quality control measures are implemented throughout the manufacturing process to ensure that the produced bottles meet industry standards. This includes checks for thickness, dimensions, and overall structural integrity.

6. Packaging:

After undergoing rigorous quality checks, the finished HDPE bottles move on to the packaging stage. To maintain product integrity, bottles are carefully sorted, grouped, sealed, and labelled for identification. By ensuring that the containers are distribution-ready, this procedure helps to preserve their quality throughout storage and transportation. It is the last stage of production, preparing the carefully constructed HDPE bottles to be delivered to customers, where they will be safely used to carry and hold various chemicals used in many different sectors.

Benefits of HDPE Plastic Bottles in Chemical Industries

1. Chemical Compatibility:

HDPE exhibits exceptional resistance to a wide range of chemicals, making it an ideal choice for packaging chemicals such as acids, bases, and solvents. This ensures that the integrity of both the container and its contents is maintained, preventing leaks, spills, and contamination.

2. Lightweight and Durable:

HDPE bottles are lightweight yet durable, making them easy to handle and transport while providing robust protection for the chemicals they contain. This characteristic is particularly crucial in industries where ease of handling and cost-effective transportation is paramount.

3. Environmental Considerations:

HDPE is a recyclable material, contributing to sustainability efforts in reducing plastic waste. Many industries are increasingly adopting recycling programs, allowing used HDPE bottles to be transformed into new products, reducing their environmental impact.

4. Versatility in Design:

The versatility of HDPE allows for the creation of bottles in various shapes and sizes, catering to the specific requirements of different industries. Whether it’s a small pharmaceutical vial or a large agricultural container, HDPE can be moulded to suit diverse applications.

5. Cost-Effective Packaging:

The cost-effectiveness of HDPE makes it an economical choice for packaging in chemical industries. Its affordability, coupled with its performance characteristics, makes it a preferred material for businesses seeking to balance functionality and budget considerations.

READ MORE-https://regentplast.com/making-of-chemical-hdpe-bottles-behind-the-scenes/

0 notes

Text

Video of Pesticide Liquid Filling Machine | Gear pump Filling Machine | Shiv Shakti Machtech

youtube

#manufacturer#shivshaktimachtech#filler#capper#Labeller#manufacturing#pesticides#fillingmachines#fillingmachine#liquidfillingmachinemanufacturer#liquidfillingmachine#automaticfillingmachine#oilfillingmachine#edibleoil#gearpumpfillingmachine#servofillingmachine#lubricants#Youtube

1 note

·

View note

Text

Monsanto was literally my gateway into eco feminism

#poisoning land then sueing the plaintiffs back#wdym thay you sell the most harmful seeds to plant that cause so much trouble to take care of#then also become the only manufacturer of said pesticide to help get rid of the harmfulness of the seeds#just pure evil and you will ROT

0 notes

Text

Best Pesticides Manufacturer in Ethiopia in India

Pesticides Manufacturer in Ethiopia are chemical substances or mixtures of chemicals that are used to control, repel, mitigate, or kill pests. Pests can include a wide range of organisms such as insects, weeds, fungi, rodents, nematodes, and other undesirable organisms that can negatively impact agriculture, public health, or the environment. Pesticides are designed to protect crops, control disease vectors, manage pests in homes and gardens, and address various pest-related issues.

Visit Us: Pesticides Manufacturer in Ethiopia

ADDRESS:

Office No - 704, 7th Floor, Akashdeep Building, Barakhamba Road, New Delhi - 110001

EMAIL:

PHONE:

+91 98370 22119

0 notes

Text

Top manufacturer of pest control in Gujarat

The top manufacturer of pest control chemicals in Gujarat is Dharmaj Crop Guard Ltd.

Dharmaj Crop Guard Ltd. is constantly trying to find new ways to solve the problems that Indian farmers are facing. For the sake of their farming community, they are committed to making the greatest use of available resources and making innovative initiatives. The business has developed a strategy of constant growth and development of high-value brands with an emphasis on registration and marketing, to which it is totally committed.

#top manufacturer of pest control#top pest control manufacturer in gujarat#agro chemical#insecticide manufacturer#agrochemicals#dharmaj crop#fungicide manufacturer in gujarat#pesticide manufacturer in Gujarat#agriculture#farmer

0 notes

Text

Introducing SSCL, a trusted animal feed manufacturer dedicated to providing high-quality and nutritious feed for your livestock. With a commitment to excellence and innovation, we strive to meet the unique nutritional needs of animals to ensure their health and well-being.

Visit here: https://www.sscl.in/animal-feed.aspx

#humic acid manufacturer#rabbit feed manufacturer#organic sanitation product#organic pesticide manufacturer#bio fertilizer manufacturer#organic waste decomposer#organic sanitizer#animal feed manufacturer#pig feed manufacturer#cattle feed manufacturer

0 notes

Text

Safeguarding Agricultural Yield: Exploring the Crop Protection Chemicals Market

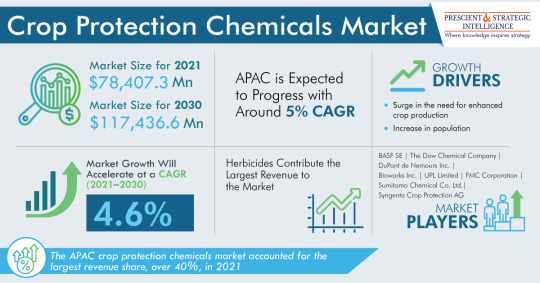

The total size of the crop protection chemicals market in the recent past was USD 78,407.3 million, and will reach USD 117,436.6 million by 2030, propelling at a rate of 4.6% in the years to come, as per a report published by a market research firm, P&S Intelligence. Herbicides had the largest revenue in the industry of around USD 40 billion, as these are employed for the manipulation or…

View On WordPress

#agriculture#applications#crop protection chemicals#crop yield#fungicides#Growth#herbicides#industry#insecticides#manufacturers#market#market analysis#pest control#pesticides#trends

0 notes

Text

Factors to consider while choosing the best agrochemical packaging machines for your industry

For over four decades, Nichrome has established itself as a renowned provider of high-quality and innovative packaging solutions across a range of industries. With its extensive expertise in the packaging field, Nichrome has become a leading name in agrochemical packaging, delivering exceptional solutions to meet the needs of this specialized industry. Agriculture and farming have been essential…

View On WordPress

#agrochemical packaging#agrochemical packaging machine#coffee pacakging machine#innovative packaging solutions#packaging machine manufacture#pesticide filling machine

0 notes

Text

What are health effects on humans from exposure to pesticide-contaminated water?

The health effects of consuming water contaminated with pesticide residue is a serious issue that no one should take lightly. Pesticides are designed to kill insects, weeds, and other pests, but they can also be hazardous to humans and other animals if exposed in high concentrations or over extended periods of time.

Pesticide-contaminated water can have serious consequences for human health, ranging from minor illnesses to long-term chronic conditions. Understanding the potential dangers of pesticide exposure is essential for protecting the health of those who live near areas where pesticides are in use.

In this blog we are going to discuss some of the health effects on humans from the exposure of pesticide-contaminated water so as to safeguard ourselves by fixing the issue at the source. So, let’s get going…

The health effects of exposure to pesticide-contaminated water can be devastating. While the effects vary depending on the type and amount of pesticide present, long-term exposure to contaminated water can lead to serious health problems. Below we provide a list of common health effects on humans from exposure to pesticide-contaminated water.

1. Cancer: Exposure to pesticides in drinking water has been linked to an increased risk of certain types of cancer, such as bladder cancer and leukemia.

2. Respiratory Problems: Pesticides can cause irritation in the lungs and throat, leading to coughing, wheezing and difficulty breathing.

3. Neurological Effects: Long-term exposure to pesticides has been associated with neurological damage, including reduced intellectual performance, memory loss and changes in behavior.

4. Reproductive Problems: Both men and women exposed to contaminated water have an increased risk for reproductive issues such as infertility or miscarriage in pregnant women.

5. Gastrointestinal Symptoms: Ingesting contaminated water can lead to vomiting, diarrhea or abdominal pain due to irritation from the chemicals present in the water supply.

6. Immune System Suppression: Exposure can weaken your immune system’s ability to fight off infections or diseases over time due to chemical interference with normal bodily functions like white blood cell production or liver enzyme regulation.

7. Birth Defects: Pesticide contamination in drinking water is associated with a higher rate of birth defects, including cleft palate, heart defects, neural tube defects, spina bifida, clubfoot, Down syndrome and more.

8. Allergic Reactions: Prolonged exposure has also been linked with increases in allergic reactions ranging from mild skin rashes or headaches all the way up through life threatening anaphylaxis.

9. Kidney Damage: The kidneys are especially sensitive when it comes contaminants like those found in pesticide -contaminated drinking water; prolonged exposure may result in kidney damage that is irreversible without dialysis treatments or a transplant.

10. Liver Disease: The liver plays a key role in cleansing toxins from your body, so when it is overburdened by regular ingestion of pesticides it can lead not only inflammation but also permanent damage that leads eventually leads cirrhosis or other forms of liver disease.

Conclusion:

The potential health effects of exposure to pesticide-contaminated water are serious and far-reaching. From neurological damage, fertility issues, gastrointestinal symptoms, immune system suppression and birth defects to allergic reactions, kidney damage, and liver disease – the risks associated with drinking contaminated water should not be taken lightly. It’s important to always be aware of what is going into your drinking water supply so you can take steps necessary for your family’s safety against these potential health risks!

Why choose Netsol!

In conclusion, although pesticide contamination is becoming an increasingly pressing issue in many areas across the world, there are thankfully solutions available through Netsol water solutions that can help protect us from its potentially dangerous effects on our health and environment. Homeowners should take steps to test their home wells regularly for contaminants such as pesticides if possible and contact Netsol, if elevated levels are detected so that appropriate action can be taken quickly before any long-term harm occurs due to ongoing exposure over time.

You may call/WhatsApp us at +91-9650608473 for any questions you may have about health effects of pesticide-contaminated water, or you can send an email to [email protected]

#What are health effects on humans from exposure to pesticide-contaminated water?#industrial ro plant manufacturers#commercial ro plant manufacturer

0 notes

Text

HDPE Pesticide Bottle Manufacturers & Exporter|RegentPlast

In the realm of agriculture and pest control, the significance of high-quality pesticide bottles cannot be overstated. These vessels play a crucial role in preserving the efficacy of pesticides while ensuring the safety of users and the environment. Among the notable players in the industry, Regent Plast emerges as a distinguished name, standing out as one of the leading pesticide bottle manufacturers and exporters, specializing in HDPE pesticide bottles.

Regent Plast takes pride in its commitment to delivering top-notch products that meet the stringent standards of the agricultural sector. The company's expertise lies in the production of high-density polyethylene (HDPE) pesticide bottles, which are renowned for their durability, chemical resistance, and eco-friendly nature. These bottles serve as a reliable and secure packaging solution for various types of pesticides, safeguarding their potency and preventing any potential harm to the environment.

The use of HDPE in pesticide bottle manufacturing is a strategic choice made by Regent Plast. HDPE is a robust and versatile material known for its strength and resistance to chemicals. This makes it an ideal choice for containers that house potentially hazardous substances like pesticides. Regent Plast ensures that its HDPE pesticide bottles provide a reliable barrier against external elements, maintaining the integrity of the contained pesticides throughout storage and transportation.

As a prominent player in the industry, Regent Plast goes beyond just manufacturing. The company has positioned itself as a key pesticide bottle exporter, catering to the global demand for quality packaging solutions in the agriculture and pest control sectors. By exporting their HDPE pesticide bottles, Regent Plast contributes to the international efforts aimed at promoting safe and efficient pesticide usage.

One of the distinguishing features of Regent Plast's HDPE pesticide bottles is their design, which prioritizes user convenience and safety. The bottles are crafted with precision to facilitate easy pouring and application of pesticides, minimizing the risk of spills and exposure. Additionally, the secure caps and closures on these bottles prevent leakage and ensure that the potency of the pesticides remains intact.

Regent Plast understands the importance of sustainability in the current environmental landscape. In response to this, the company ensures that its pesticide bottles are not only durable but also recyclable. This aligns with the global push towards eco-friendly practices in packaging and waste management. By choosing Regent Plast's HDPE pesticide bottles, consumers contribute to reducing the environmental impact associated with single-use plastics.

The success of Regent Plast as a pesticide bottle manufacturer and exporter can be attributed to its unwavering commitment to quality, innovation, and customer satisfaction. The company's products have earned the trust of agricultural professionals and businesses worldwide, making Regent Plast a preferred choice in the competitive market.

In conclusion, Regent Plast stands tall among pesticide bottle manufacturers, excelling in the production and export of HDPE pesticide bottles. With a focus on quality, safety, and sustainability, the company plays a pivotal role in supporting the agriculture and pest control sectors globally. Choosing Regent Plast means choosing reliability and responsibility in pesticide packaging.

0 notes