#Pcb Assembly

Explore tagged Tumblr posts

Text

Thank you for the super positive feedback on my PC setup!! I'm glad I could share a slice of my passion with so many people:)

Here's a landscape style shot of the inside of a Coleco Gemini, an atari 2600 knockoff that was quite popular in Canada!

41 notes

·

View notes

Text

So excited to have my hands of the first proper prototype of my NuaCam project. It's crazy to see just how far I have come in a few short months, growing this from a simple idea to a functional device. The goal is to build a camera which utilising ai stylisation to capture reality in a new light. Now I can focus on improving the ai side to try and create exciting styles to use. The first prototype was causing lots of lost hours debugging due to lose wires, so I bite the bullet and designed this pcb to help me develop the software side.

#embedded#technology#electronic project#electronics#startup#camera#ai photography#hobby#pcb#pcb assembly#electronic engineering#project#nuacam

17 notes

·

View notes

Text

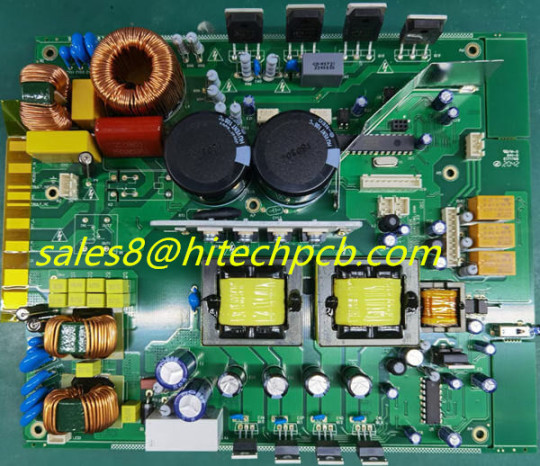

PCB Manufacturing-PCB Assembly-Hitech Circuits

Hitech Circuits is a lеаding PCB Manufacturing & PCB Assembly company with more than 20 years experience in the electronics manufacturing industry. We focus on PCB Design, PCB Layout, Circuit board fabrication, Turnkey PCB assembly, and electronic parts sourcing services.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

We offer a full range of Electronic manufacturing services.

-LED PCB

-Heavy Copper PCB

-Multilayer PCB

-HDI PCB

-Flexible PCB

-Rigid-Flex PCB

-High Speed PCB

-High Frequency PCB

-PCB Reverse Engineering

7 notes

·

View notes

Text

I designed a custom circuit board for a dual-channel Bluetooth speaker module and chose to place the order with GreatPCB. After uploading all the files, I received all the components in just a few days. The inspiration for the 3D-printed color module came from Japanese anime. Overall, I’m really satisfied with the result.

2 notes

·

View notes

Text

hi,I'm zoe,a sales engineer in the Shenzhen STHL Electronics Co.,Ltd.we are a professional PCB & PCBA manufacturing servicer with more than 18 years of experience located in Shenzhen, China. Mainly provide services of electronic components sourcing + PCB fabrication + PCB Assembly + Housing assembly + Function testing services.

Our factory covers 7000+ square meters, has 5 (Panasonic) high-speed SMT production lines, 2 DIP lines, 2 testing lines, and 180+ workers, passed ISO9001, ISO14001, ISO13485 and IATF 16949 certifications, win recognization by Littelfuse, Hisense,Surfilter, etc.

2 notes

·

View notes

Text

PCB schematic/design/fabrication/assembly

MPN TECH Pte Ltd provides One-Stop PCBA Solutions in Singapore, which support from R&D prototype to mass production. We have built long-term collaborations with many local startups, SIMES, MNCS, etc. We also have lots of overseas PCBA projects in Europe and the US. If any questions feel free to let me know.

Our Solutions:

PCB Design;

PCB Fabrication;

Components souring;

PCB Assembly;(SG Local machine Assembly)

3 notes

·

View notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

What is a Printed Circuit Board?

Printed Circuit Boards are boards that connect various points together through lines and pads. They allow signals and power to connect between two separate physical devices. While the term “printed circuit board” is typically used, other terms to describe these include “printed wiring board” and “printed wiring card.”

#marketing#investing#finance#branding#pcb circuit#pcb#pc build#pcb assembly#flexible circuit board#pcb board fabrication#pcb circuit design#pcb circuit in Gujarat#pcb design company#Printed Circuit Boards

3 notes

·

View notes

Text

Die fünf Hauptfunktionen von Lötstopp-Lochverschlüssen

1️⃣ Verhindern des Fließens von Lötzinn durch die Durchkontaktierungen und Vermeidung von Kurzschlüssen während des PCB-Wellenlötens, insbesondere wenn die Durchkontaktierungen auf BGA-Pads platziert sind. Es ist notwendig, die Löcher vor der Vergoldung zu verschließen, um das BGA-Löten zu erleichtern.

2️⃣ Vermeiden von Flussmittelrückständen innerhalb der Durchkontaktierungen.

3️⃣ Nach der Oberflächenmontage und Bauteilplatzierung muss die Leiterplatte auf einer Testmaschine einem Vakuumsaugtest unterzogen werden, um einen Unterdruck für die Fertigstellung zu erzeugen.

4️⃣ Verhindern des Fließens von Lötpaste in die Löcher und Vermeidung von Lötfehlern, die die Lötung während der Montage beeinträchtigen könnten.

5️⃣ Verhindern des Herausspringens von Lötkugeln während des Wellenlötens, was zu Kurzschlüssen führen könnte.

2 notes

·

View notes

Text

What is PCB Assembly ?

PCB Assembly manufacturer - Hitech Circuits Co., Limited

It’s the step in the manufacturing process in which you populate a blank board with the electronic components needed to make it into a functional printed circuit board. It’s these components that make a board into the circuit that enables an electronic product to function. PCB assembly typically takes place via one of two processes:

1. Surface-mount technology

SMT: SMT stands for “Surface Mount Technology“. The SMT components are very small sizes and comes in various packages like 0201, 0402, 0603, 1608 packages for resistors and capacitors. Similarly for Integrated circuits ICs we have SOIC, TSSOP, QFP and BGA.

The SMT components assembly is very difficult for human hands and can be time taking process so it is mostly done by automated pick and place machine.

2. Through-hole manufacturing

THT: THT stands for “Through hole Technology”. The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Printed Circuit Board Assembly Techniques

There are only two common PCBA techniques available for use by a PCB designer. The methods are:

1. Automated PCB Assembly Techniques

Generally, this technique employs the use of state of the art machines, which are fully automatic. For example, the surface mount components are worth positioning with the aid of an automated pick and place machine.

Again, reflow soldering is commonly for surface mount components usually done in a reflow oven. An automated solder stencil is also used to apply the solder paste on the PCB.

Finally, high tech inspection machines are used to confirm and check the quality of the PCBA. Some of which include: Automated optical inspection machine (AOI), X-ray inspection machines, etc.

Above all, due to the precise monitoring, control of soldering, no human input and versatile machines.

This technique ensures utmost efficiency, output consistencies, and limits defects.

2. Manual PCB Assembly Techniques

This method is favorite for use with through-hole parts, which needs manual placement on the board. Besides, with these through-hole parts, it’s advisable you use wave soldering. Note that in the through- hole assembly process, you need to place the components and electronics on the PCB.

After that, you use wave soldering to solder the leads. Typically, you will need an individual to insert a component into a marked PTH. Once done, transfer the PCB to the next station where the next person will be on standby tasked with fixing another part.

What are the Benefits of SMT PCB Assembly?

SMT assembly provides many benefits and some of them are as follows:

It can be used to incorporate small components.

In SMT, the components can be placed on both sides of the board.

It assures high component densities.

Fewer holes need to be drilled for surface mounting than through-hole.

It require low initial costs and time for setting up the mass production.

SMT is the simpler and faster-automated assembly when compared to through-hole.

Errors regarding the component placement can be easily rectified.

Surface mount PCBs feature strong joints, which can easily withstand vibrations.

What are the techniques used in Surface Mount Technology?

There are several techniques for the reflow process. After applying the solder paste or a flux mixture on the board and after placing the components, the boards are conveyed to a reflow soldering oven. The techniques used for reflowing soldering include infrared lamps, hot gas convection, fluorocarbon liquids with a high boiling point, and so on.

What are the different testing methods used in SMT PCB Assembly?

Hitech Circuits as the PCB assembly manufacturer, we perform the following testing and inspection to ensure the quality of surface mount PCBs.

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

What type of files or documents should I send for SMT PCB Assembly?

Gerber Files: The file contains all details of physical board layers including solder masks, copper layers, drill data, legends, and so on.

Bill of Materials (BOM): This contains information on the list of items needed for the PCB manufacturing and the instructions of manufacturing.

Pick and Place File: This file contains information on all components to be used in the PCB design and their rotation and X-Y coordinates.

The whole process of PCB Assembly

1. Bare board loader machine

The first step in the PCB assembly is to arrange the bare boards on the rack, and the machine will automatically send the boards one by one into the SMT assembly line.

2. Printing solder paste

When PCB on the SMT production line, firstly, we have to print solder paste on it, and the solder paste will be printed on the pads of the PCB. These solder pastes will be melt and solder the electronic parts to the circuit board when it passes through the high-temperature reflow oven.

In addition, when testing new products, some people will use film board/adhesive cardboard instead of solder paste, which can increase the efficiency for adjusting the SMT machines.

3. Solder paste inspection machine(SPI)

Since the quality of solder paste printing is related to the quality of welding of subsequent parts, some SMT factories will use optical machine to check the quality of solder paste after printed the solder paste in order to ensure stable quality. If there any poorly printed solder paste board, we will wash off the solder paste on it and reprint, or remove the excess solder paste if there is redundant solder paste on it.

4. High speed SMT machine

Usually, we will put some small electronic parts (such as small resistors, capacitors, and inductors) to be printed on the circuit board first, and these parts will be slightly stuck by the solder paste just printed on the circuit board, so even if the speed of printing is very fast and the parts on the board will not fall away. But large parts are not suitable for use in such high speed SMT machines, which will slow down the speed of small parts assembly. And the parts will be shifted from the original position due to the rapid movement of the board.

5. Universal SMT machine

Universal SMT machine is also known as "slow machine", it will be assembled some large electronic components, such as BGA IC, connectors, etc., these parts need more accurate positions, so the alignment is very important. Use a camera to take a picture to confirm the position of the parts, so the speed is much slower than High speed SMT machine we taked before. Due to the size of the components here, not all of them are packed in tape and reel, and some may be packed in trays or tubes. But if you want the SMT machine to recognize the trays or tube-shaped packaging materials, you must configure an additional machine.

Generally, traditional SMT machines are using the principle of suction to move electronic parts, and in order to place the parts successfully, and there must be the flat surface on these electronic components for the suction nozzle of the SMT machine to absorb. However, for some electronic parts don’t have a flat surface for these machines, and it is necessary to order special nozzles for these special-shaped parts, or add a flat tape on the parts, or wear a flat cap for thees electronic parts.

6. Manual parts or visual inspection

After assembled all parts by the high speed SMT machine or Universal SMT machine and before going through the high-temperature reflow oven, and we will set up a visual inspection station here and to pick out the deviation parts or missing components boards etc., because we have to use a soldering iron to repair if there are still defectives boards after passing the high-temperature oven, which will affect the quality of the product and will also increase the cost. in addition, for some larger electronic parts or traditional DIP parts or some special reasons cannot be processed by the SMT machine before, they will be manually placed on pcb here.

7. Reflow oven

The purpose of reflow oven is to melt the solder paste and form a non-metallic compound on the component feet and the circuit board, that means to solder electronic components on the circuit board. The temperature rise and fall curves often affect the soldering quality of the entire circuit board. According to the characteristics of the solder materials, usually the reflow oven will set the preheating zone, soaking zone, reflow zone, and cooling zone to achieve the best soldering effect.

For example, the melting point for SAC305 solder paste with lead-free is about 217°C, which means that the temperature of the reflow oven must be higher than the melting points to remelt the solder paste. What's more, the maximum temperature in the reflow furnace should not exceed 250°C, otherwise many parts will be deformed or melted because they cannot withstand such a high temperature.

Basically, after the pcb passed through the reflow oven, the assembly for the entire circuit board is almost complete. If there are hand-soldered parts, we need to transfer to DIP process, and then we have to check the quality after reflow oven by QC department.

8. Automatic optical inspection(AOI)

The main purpose of setting up AOI is because some high density boards can’t be process the following ICT test, so we used AOI inspection to replace it. But even using AOI inspections, there still have the blind spots for such checking, for example, the solder pads under the components cannot be checked by AOI. At present, it can only check whether the parts have side standing issue, missing parts, displacement, polarity direction, solder bridges, lack of soldering etc., but cannot checking the BGA solderability, resistance value, capacitance value, inductance value and other components quality, so far AOI inspection can’t completely replace ICT test.

Therefore, there is still some risk if only AOI inspection is used to replace ICT testing, but ICT test is also not 100% make sure the good quality, we suggest these two ways can be combined with together to make sure the good quality.

9. PCB unloader machine

After the board is fully assembled, it will be retracted to the unloder machine, which has been designed to allow the SMT machine to automatically pick and place the board without damaging the quality for PCB.

10. Visual inspection for finished products

Normally there will be a visual inspection area in our SMT production line whether there is an AOI station or not, and it will help to check if there are any defectives after completed assembled the pcbs. If there is an AOI station, it can reduce the visual inspection worker on our SMT line, and to reduce the potential cost, and because it is still necessary to check some places that cannot be judged by AOI, many SMT factories will provide the mainly visual inspection templates at this station, which is convenient for visual inspection worker to inspect some key parts and polarity for components.

11. DIP process

DIP process is a very important process in the whole PCBA processing, and the processing quality will directly affect the functional for PCBA boards, so it is necessary to pay more attention to the DIP process. There are many preliminary preparations for DIP process. The basic process is to re-process the electronic components first, like to cut the extra pins for some DIP components, our staff received the components according to the BOM list, and will check whether the material part numbers and specifications are correct or not, and performs pre-production pre-processing according to the PCBA samples. The steps are: Use various related equipment (automatic capacitor pins cutting machine, jumper bending machine, diode and triode automatic forming machine, automatic belt forming machine and other machines) for processing.

12. ICT test

Printed Circuit board open/short circuit test (ICT, In-Circuit Test), The purpose of ICT test is mainly to test whether the components and circuits on the printed circuit board are open or short issues. It can also measure the basic characteristics of most components, such as resistance, capacitance, and inductance values to judge whether the functions of these parts are damaged, wrong parts or missing parts etc. after passing through the high-temperature reflow oven.

ICT test machines are divided into advanced and basic machines. The basic ICT test machines are generally called MDA (Manufacturing Defect Analyzer). It’s just to measure the basic characteristics of electronic components and judge open and short circuits issue we talked above.

In addition to all the functions of the basic ICT test machines, for advanced ICT test machine can also test the whole PCBA by using power, start to testing the PCBA boards by setting the program in the test machine. The advantage is that it can simulate the function of the printed circuit board under the actual power-on condition, this test can partly replace the following functional test machine (Function Test). But the cost for the test fixture of this advanced ICT test can probably buy a car, it’s too expensive and we suggest it can be used in mass production products.

13. PCBA function test

Functional testing is to make up for the ICT test, because ICT only tests the open and short circuits on the the PCBA board, and other functions such as BGA and other fuctions are not tested, so it is necessary to use a functional testing machine to test all functions on the whole PCBA board.

14. Cutting board (assembly board de-panel)

Normally, printed circuit boards will be produced in panel, and it will be assembled to increase the efficiency of SMT production. It means several single boards in one panel, such as two-in-one, four-in-one etc. After finished all the pcb assembly process, it needs to be cut into single boards, and for some printed circuit boards with only single boards also need to cut off some redundant board edges.

There are several ways to cut the printed circuit board. You can design the V-cut using the blade cutting machine (Scoring) or directly manually break off the board (not recommended). For more high density circuit boards, it will be used the professional splitting machine or the router to split the board without any damage the electronic components and printed circuit boards, but the cost and working hours will be a little longer.

Why Choose Hitech Circuits PCB Assembly Manufacturer for Your PCB Assembly Projects?

There are several PCB manufacturers specializing in PCB assemblyservices. However, Hitech Circuits PCB Assembly stands out owing to the following:

Assistance in Material Procurement:

Technically, in PCB assembly services, the quality of parts is the responsibility of the OEM; however, we ease your job by assisting you to make the right selection. We can help you procure all your parts of the same type own a single part number, thanks to our supply chain and vendor network as well as experience. This saves time and cost that goes in ordering single parts as you plan.

Testing procedures:

We are very focused on quality and thus implement stringent testing procedures at each stage of the assembly and after completion.

Fast Turnaround Times:

Our well-equipped facility and the right tools enable us to complete your requirements well before time, and without compromising on the quality or functioning of the PCBs. For simple designs we revert in 24 to 48 hours.

Cost Effectiveness:

While PCB assembly is a cost-effective alternative, we go a step further and assure that the parts you list are of a good quality and suitable for your requirement. Also, you can control the part flow and replenish them as needed. This eliminates the need to buy extra stock and store it.

Quick Quote:

We offer a quick quote based on your BOM. All you need is a detailed BOM, Gerber files, your application requirement sheet, and quantity.

We’re not one to stand still, which is why we use the latest equipment and the finest minds to create your PCB projects. We’re constantly keeping our finger on the pulse of the latest trends. And as a result, we know how to deliver the highest standards of PCB assembly to meet all your requirements.

Our dedicated, friendly customer service team also means that we support you every step of the way. Offering our expert guidance to ensure a complete PCB project that you’re happy with.

Contact us today

No matter what your printed circuit board assemblyneeds are, we always aim to deliver efficient, dependable solutions. For more information about our services, do not hesitate to get in touch with us today for a no-obligation quote

2 notes

·

View notes

Text

Printed circuit board manufacturing which is our major business, I think you already know, we are a PCB manufacturer. We have 3 branch factories dedicated to Quick Turn PCB Prototypes Manufacturing, Small and Medium-volume Printed Circuit Board, FPC Manufacturing services and PCB assembly services. Our market target is the High Multilayer PCB, High Density PCB, Flexible PCB, Rigid-flex PCB, Heavy copper PCB, Rogers PCB, Ceramic PCB and Special Materials Printed Circuit Boards.

Also, we can help customer sourcing components, wire PCB assembly and provide one-stop service.

Hitech Group is capable of providing full turn-key and partial turn-key PCB assembly services. For full turn-key, we take care of the entire process, including manufacture of Printed Circuit Boards, procurement of components, order tracking, continuous monitoring of quality and final board assembly. Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

4 notes

·

View notes

Text

PCBA assembly manufacturing services provides by Hitech provides, from PCBA sample to medium or mass production volume. Our professional SMT factory has advanced equipments help us to offer rich experience in various PCBA manufacturing. Contact susie [email protected]

3 notes

·

View notes

Text

One-stop PCB assembly service and PCB manufacturing supplier -- Hitechpcba

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

4 notes

·

View notes

Text

#hardware design#hardware design services#pcb assembly#pcb design#pcb manufacturer#pcba#pcbassembly#electronics design#automotive electronics

2 notes

·

View notes

Text

The Essentials of PCB Design: Techniques and Best Practices

Introduction

This carries basic sense in the electronic world. PCB design basically forms the infrastructural skeleton of any devices for powering our day-to-day life. In consumer electronics and industrial systems, optimized PCB ensures efficient performance in terms of circuit along with size, heat, and manufacturability issues. Whether it's a simple two-layer or complex multi-layered board, the principle of PCB design makes equal importance to come up with reliable products.

We're going to go through the critical phases of a PCB design, really getting into the advanced features of a multilayer PCB layout design and then to the important details of DFM, DFT, DFA, and thermal analysis. Meanwhile, on the importance of a professional PCB design service, which may be what will ensure your design meets the highest standards of performance and reliability.

In short words, the overall meaning of PCB design is that it is the planning and designing of a layout of a printed circuit board that serves as an electronic device foundation. In general, the board usually consists of a network of copper traces. The traces connect all other components like resistors, capacitors, ICs, and transistors. This will ensure that the components are properly communicated to the PCB and achieve the purpose, with the overhead efficiency of the product, durability, and size all well in balance.

Critical Objectives of a PCB Design:

Signal Integrity: Small signal loss and interference.

Thermal Management: Must be able to dissipate the heat created by the elements efficiently.

Manufacturability: A PCB that would reliably be produced in volume.

Electrical Performance: Optimizes the circuit's performance on power and speed.

In the course of evolution, electronic devices have had to keep abreast of increased functional requirements within ever smaller spaces. Thus came PCB layout design with compactness yet complexity in circuitry.

What is a Multilayer PCB

A multilayer PCB has more than three layers of conductive material separated by insulating layers. Such layers allow designers to design complex layouts since they would allow routing a significant number of signals across multiple layers without over saturating the surface. The design of a multilayer PCB is considered crucial in industries like telecommunications, aerospace, automobile, and consumer electronics where signal integrity is paramount while available space must be maximized.

PCB design services? Lanjekar Manufacturing take care of everything from schematic to the multilayer layout PCB design, to make sure that your design is ready for production.

Advantages of Multi-layer PCB Design Layout

More components in a smaller area can be accommodated.

Breaking of signal paths across different layers will reduce the interference caused by electromagnetic rays. High signal integrity .

Multilayer PCB boards help in denser designs, and hence the footprint of the overall product is reduced.

Compact Board size.

It is a little bit complicated to design the multilayer PCB layout; however, the challenges are associated with this. Signals cross-talk or interference do not make it easy to route across multiple layers while thermal integrity is also of great challenge. Professional PCB design services can take advantage of understanding in balancing these factors for maximized performance.

DFM, DFT, DFA Analysis: Manufacturability and Testability

When a PCB is to be designed, electrical performance would not be the only matter of concern but rather ease and efficiency in manufacturing and testing the board. That's where DFM, DFT, and DFA analysis comes into play.

DFM (Design for Manufacturability)It ensures the PCB can be manufactured within an error range that is not costly. It checks the design for trace spacing, trace width, copper pathways, size, and locations of vias along with materials. The success of DFM analysis helps reduce the chances of possible manufacturing mistakes and lead times since it smoothes the transition from design to manufacture.

DFT (Design for Testability)DFT analysis tries to make the PCB testable for defects or failures during and after production. In this, the testing points are included in the designing into which automatic test equipment can probe shorts, opens, and other possible reasons that may jeopardize the board functionality. With DFT analysis included in the designing process of a PCB, designers save test time and money, avoid costly rework, and save on failures during and even after the manufacturing process.

DFA (Design for Assembly)Design for DFA ensures that the PCB could be assembled without much trouble. DFA assures that components are sited such that they can be mounted simply through soldering, and there should be sufficient clearance for a robotic assembly tool. This gives assurance that such design does not produce an assembly flaw. Optimal DFA-ing increases the reliability of the product but it decreases labor costs to a minimum.DFM, DFT, and DFA analysis in the design of a PCB may ensure that the final product meets certain technical specifications while also remaining easy to manufacture and test. Professional services for the design of PCB would be invaluable here because both have the experience performing such analyses and possess all the tools necessary in doing so.

Looking for professional PCB design services? Lanjekar Manufacturing delivers comprehensive solutions, ensuring your design is ready for production.

What is Thermal Analysis?

Thermal analysis is the checking of heat being distributed on a printed circuit board and how it spreads out to be dissipated correctly. Overheated specific portions of the board might damage components, interfere with signals, or even cause failure of the overall system.

Thermal Analysis in PCB Design: Controlling Heat for Longevity

Thermal management possibly represents probably one of the important aspects of PCB design, particularly when high power applications, such as power supplies, industrial systems, and communication devices, are taken into account. Performance and reliability outcome can be severely affected if too much heat begins to emanate from the electronic components.

Types of thermal management in PCB design:

Copper Pour and Heat Sink: Application for copper pours is the areas where extensive areas of copper are utilized for absorbing heat and letting it dissipated. In such application, high power components may be mounted on heat sinks, therefore, making them cool better.

Component Placement: Sensitive components should be placed away from the source of generation of heat. Overheating is thus avoided, Advanced simulation tools are used by the professional PCB design services; hence, ideal heat is managed in the product designed and also ensuring that the final product achieved meets all its requirements for performance.

Why Choose Professional PCB Design Services?

Though it might seem like circuitry know-how is all one needs for designing modern PCBs, the realities of the business are far removed from that. Functionality, manufacturability, testability, and thermal management all need to be balanced quite heavily. That's where professional PCB design services come in-they make all the difference.

Here's why you must opt for professional PCB design services:

Access to State-of-the-Art Tools: Professional services guarantee that the design and simulation tools are state-of-the-art for building accuracy and performance in your PCB design.

Handling Complex Design: Whether it is multilayer PCB layout design, DFM, DFT, DFA analysis, or thermal analysis, any expertise can handle it.

Market Sooner: Outsourcing the PCB design service will save your cycle going shorter than you expect and readying for the marketplace sooner.

Conclusion

PCB designing forms the heart of modern electronics, and proper understanding requires the amalgamation of technical and manufacturing considerations. Whether you are working with a very simple two-layer board or a complex multi-layer PCB layout design, you have to integrate DFM, DFT, DFA analysis, and rigorous thermal analysis into the process of PCB designing to be successful. Association with professional PCB design services will make sure your product meets the highest possible standards for performance, reliability, and manufacturability.

Need help with PCB design? Lanjekar Manufacturing offers full end-to-end PCB design services to optimize your design towards all factors with respect to performance and manufacturability.

Also read:

Know Electronics Manufacturing: The Total Guide

Firmware Development: Where Software Meets Hardware

The Essentials of PCB Design: Techniques and Best Practices

The Complete Guide to Hardware Development: From Design to Deployment

0 notes

Text

The Ultimate Guide to PCB SMT Assembly in Industrial Manufacturing

In the rapidly evolving world of industrial manufacturing, printed circuit board (PCB) surface mount technology (SMT) assembly plays a critical role in the production of electronic products. This comprehensive guide delves into the complexities of PCB SMT assembly within the industrial manufacturing space, providing valuable insights into processes, equipment, best practices, and emerging technologies that improve PCB production efficiency and quality. From understanding the basics of PCB assembly to exploring the latest advances and environmental considerations, this guide serves as a roadmap for navigating the complexities of SMT assembly in an industrial setting.

Introduction to PCB SMT Assembly

If you’ve ever wondered how those tiny components magically assemble onto your circuit board, welcome to the world of PCB SMT assembly! This article will walk you through the ins and outs of this fascinating process.

Learn the Basics of PCB Assembly

Let’s start with the basics - PCB assembly is like putting together a high-tech puzzle, but we’re not talking about your grandma’s kitchen table, we’re talking about precision machines and cutting-edge technology.

Types of PCB Assembly Processes

There’s more than one way to skin a circuit board - from surface mount technology (SMT) to through-hole assembly, each process has its own characteristics and advantages. Let’s delve into the world of PCB assembly processes and uncover the differences.

Overview of Industrial Manufacturing Processes

Industrial manufacturing is the backbone of turning circuit designs into tangible products. Let’s peek behind the scenes and see the magic that happens in the world of PCB assembly.

Overview of Industrial Manufacturing for PCB Assembly

Imagine a symphony of machines, skilled technicians, and some futuristic technology - that’s industrial manufacturing in a nutshell. We’ll explore how this orchestra works together to create the perfect circuit board.

Comparison of SMT vs. Through-hole Assembly

It’s a battle between SMT and through-hole assembly - the dynamic duo of PCB assembly. In a battle of efficiency and reliability, which one comes out on top? Let’s find out.

Importance of SMT Assembly in PCB Manufacturing

SMT assembly is the unsung hero of PCB manufacturing, bringing efficiency and miniaturization. But like any superhero, it also comes with its own set of challenges. Let’s uncover the hidden strengths and weaknesses of SMT assembly.

Advantages of SMT Assembly

Why do manufacturers swear by SMT assembly? Faster production speeds, smaller form factors, and better performance are just the tip of the iceberg. Get ready to learn why SMT assembly is the golden child of PCB manufacturing.

Challenges and Limitations of SMT Assembly

Not everything is smooth sailing in the world of SMT assembly. From component placement accuracy to thermal issues, there are obstacles to overcome. Let’s take a look at the challenges and limitations that keep manufacturers on their toes.

Key Components and Equipment for SMT Assembly

You can’t bake a delicious cake without the right ingredients and tools, and the same is true for SMT assembly. Let’s explore the essential components and equipment that work wonders in the world of PCB manufacturing.

Overview of SMT Components

From resistors to capacitors, SMT components are the building blocks of modern electronics. Get ready to enter the world of tiny but mighty components that make your gadgets tick.

0 notes