#PVDF Material

Explore tagged Tumblr posts

Text

Elevating Industry Standards: PVDF Materials by Petron Thermo Plast

In the dynamic landscape of industrial materials, Polyvinylidene Fluoride (PVDF) emerges as a standout choice, renowned for its exceptional properties and diverse applications. Petron Thermo Plast, a leading manufacturer in the field, specializes in delivering top-tier PVDF Materials crafted to surpass industry expectations. This blog meticulously explores the features, benefits, and applications of PVDF materials by Petron Thermo Plast, showcasing why they are the preferred solution for professionals worldwide.

Unveiling PVDF Materials

PVDF materials represent a pinnacle of innovation, characterized by their remarkable chemical resistance, thermal stability, and mechanical strength. Petron Thermo Plast’s PVDF materials are engineered with precision to offer unparalleled performance across a multitude of industrial settings.

Key Attributes of PVDF Materials

1. Chemical Resistance:

PVDF materials exhibit exceptional resistance to a wide spectrum of chemicals, including acids, bases, and solvents, making them ideal for corrosive environments.

2. Thermal Stability:

With a high melting point and remarkable heat resistance, PVDF materials maintain their integrity even under extreme temperatures, ensuring reliability in demanding conditions.

3. Mechanical Strength:

PVDF materials boast high tensile strength and durability, enabling them to withstand mechanical stress and pressure, thus guaranteeing longevity in challenging applications.

4. Low Permeability:

The low permeability of PVDF materials to gases and liquids prevents leakage, making them suitable for applications requiring excellent barrier properties.

5. Weatherability:

PVDF materials exhibit exceptional weather resistance, making them suitable for outdoor applications where exposure to UV radiation and harsh weather conditions is common.

6. Non-Toxicity:

PVDF materials are non-toxic and safe for use in applications involving potable water and food processing, adhering to stringent health and safety standards.

Applications of PVDF Materials

PVDF materials by Petron Thermo Plast find extensive applications across diverse industries:

Chemical Processing: Used for fabricating pipes, fittings, and linings in chemical plants due to their resistance to corrosive chemicals.

Construction: Employed in architectural cladding, roofing, and facades for their durability and weather resistance.

Electronics: Utilized in printed circuit boards and semiconductor manufacturing for their electrical insulation properties.

Transportation: Applied in aerospace and automotive industries for interior and exterior components due to their lightweight and high strength-to-weight ratio.

Medical: Used in medical equipment and devices requiring sterilizability and chemical resistance.

Advantages of Choosing Petron Thermo Plast

Advanced Manufacturing Techniques:

Petron Thermo Plast employs cutting-edge manufacturing processes and rigorous quality control measures to ensure PVDF materials meet the highest standards.

Customization Options:

The company offers PVDF materials in various formulations, sizes, and colors to meet specific customer requirements.

Expert Technical Support:

Comprehensive technical support and guidance are provided to assist customers in selecting the right PVDF materials and ensuring proper integration into their projects.

Sustainability Commitment:

Petron Thermo Plast is committed to sustainable manufacturing practices, ensuring their PVDF materials are environmentally friendly and compliant with global standards.

Why Choose PVDF Materials from Petron Thermo Plast?

Investing in PVDF materials from Petron Thermo Plast guarantees superior quality, reliability, and performance. Here are some compelling reasons to choose Petron Thermo Plast:

Unmatched Quality: PVDF materials from Petron Thermo Plast adhere to the highest quality standards, ensuring consistency and reliability.

Tailored Solutions: With a wide range of formulations and customization options available, you can find the perfect PVDF material for your specific application.

Technical Expertise: Petron Thermo Plast provides expert technical support to guide you through every stage, from material selection to project completion.

Sustainability: By choosing PVDF materials from Petron Thermo Plast, you are supporting environmentally friendly manufacturing practices and contributing to a greener future.

Conclusion

PVDF materials by Petron Thermo Plast redefine excellence in the industrial sector. Their unparalleled properties, reliability, and versatility make them indispensable across various industries. Choose Petron Thermo Plast for PVDF materials that exceed your expectations and elevate your projects to new heights of success.

#pvdf material#engineering plastics#pvc ball valve#pvc butterfly valve#pvdf pipe#explore#union ball valve#hdpe pipe fittings

2 notes

·

View notes

Text

Development of PVDF Particles

PVDF pellets are a polyethylene material. It can be in the form of powder or white granules. It has good weather resistance. Because it is made of polyethylene, it also has good chemical resistance. Due to these excellent post-processing properties and good temperature resistance, products made from PVDF particles have better performance. PVDF particles can also be used in the design of metal…

View On WordPress

0 notes

Text

PTFE tube with PVDF nozzle

Can be customized according to drawings. Please contact me for a quote if required.

3 notes

·

View notes

Text

Scientists uncover advanced manufacturing strategies for piezoelectric and triboelectric tactile sensors

Piezoelectric and triboelectric tactile sensors are designed to convert mechanical stimuli into electrical signals, making them critical components in intelligent systems. Piezoelectric sensors leverage voltage generation through mechanical stress in non-centrosymmetric materials, such as quartz and polyvinylidene fluoride (PVDF), while triboelectric sensors operate on contact-induced charge transfer. Both sensor types offer unique advantages, including self-powered functionality and high sensitivity, but also face challenges, such as material brittleness and environmental limitations. A team of researchers led by Professor Hanjun Ryu from Chung-Ang University, South Korea, has introduced novel manufacturing strategies to overcome these limitations. The team's paper is published in the International Journal of Extreme Manufacturing.

Read more.

#Materials Science#Science#Piezoelectric#Triboelectric#Electronics#Sensors#Manufacturing#Chung Ang University

12 notes

·

View notes

Text

Pompa Dosing Tacmina

Jual Pompa Dosing Tacmina| 0813–3535–3290

pompa dosing tacmina adalah salah satu solusi terbaik untuk kebutuhan pemompaan cairan di berbagai sektor industri, mulai dari kimia, farmasi, makanan dan minuman, hingga pengolahan air. Produk Tacmina dikenal akan keandalannya, keakuratan pengukuran, serta teknologi canggih yang memastikan kinerja optimal dalam aplikasi-aplikasi kritis. Di Indonesia, PT Hefram Asasta Indonesia menjadi distributor resmi yang menawarkan berbagai varian pompa Tacmina dengan harga yang kompetitif.

Artikel ini akan membahas secara rinci mengenai harga pompa Tacmina, keunggulannya, dan faktor-faktor yang memengaruhi harga produk ini. Kami juga akan memberikan gambaran tentang mengapa PT Hefram Asasta Indonesia menjadi pilihan terpercaya untuk memenuhi kebutuhan pompa Anda. Dengan informasi ini, diharapkan Anda dapat membuat keputusan yang tepat dalam memilih pompa Tacmina sesuai dengan kebutuhan Anda.

Hubungi Kontak Kami:

Kontak:wa.me/6281335353290

Alamat: https://maps.app.goo.gl/XHtDvZAHB7ZxjkVDA

Marketplce:https://tokopedia.link/ulFa1FENVPb

1. Apa Itu Pompa Tacmina?

Pompa Tacmina adalah pompa yang dirancang dengan teknologi tinggi untuk memastikan transfer cairan yang presisi dan bebas kebocoran. Beberapa jenis pompa Tacmina yang populer meliputi:

Pompa Smoothflow: Dirancang untuk menghasilkan aliran cairan yang stabil tanpa pulsasi.

Pompa Metering (Dosing Pump): Ideal untuk aplikasi yang memerlukan pengukuran presisi, seperti dalam industri kimia atau farmasi.

Pompa Transfer: Cocok untuk memindahkan cairan dari satu tempat ke tempat lain dengan efisiensi tinggi.

2. Faktor-Faktor yang Mempengaruhi Harga Pompa Tacmina

Harga pompa Tacmina dapat bervariasi tergantung pada beberapa faktor utama, seperti:

Jenis dan Kapasitas Pompa: Pompa dengan kapasitas lebih besar atau fitur lebih canggih biasanya memiliki harga yang lebih tinggi.

Material: Pompa yang terbuat dari material tahan korosi, seperti stainless steel atau PVDF, akan lebih mahal dibandingkan material standar.

Spesifikasi Teknis: Model dengan spesifikasi teknis khusus, seperti tahan suhu tinggi atau kompatibel dengan cairan agresif, juga memengaruhi harga.

Ketersediaan Suku Cadang: Pompa dengan dukungan suku cadang lengkap biasanya memiliki harga yang lebih bersaing karena mudah dalam perawatan.

Merek Distributor: Membeli dari distributor resmi seperti PT Hefram Asasta Indonesia menjamin kualitas dan garansi produk, meskipun harganya mungkin sedikit lebih tinggi dibandingkan penjual tidak resmi.

3. Rentang Harga Pompa Tacmina di PT Hefram Asasta Indonesia

Berdasarkan data terbaru, berikut adalah rentang harga untuk beberapa varian pompa Tacmina:

Pompa Smoothflow: Mulai dari Rp20.000.000 hingga Rp80.000.000 tergantung kapasitas dan material.

Pompa Metering: Berkisar antara Rp10.000.000 hingga Rp50.000.000, tergantung pada akurasi dan fitur tambahan.

Pompa Transfer: Harga mulai dari Rp15.000.000 hingga Rp60.000.000.

Harga ini bersifat indikatif dan dapat berubah tergantung pada kondisi pasar dan permintaan. Untuk mendapatkan penawaran terbaik, disarankan untuk menghubungi PT Hefram Asasta Indonesia secara langsung.

4. Cara Memilih Pompa Tacmina yang Tepat

Untuk memilih pompa Tacmina yang sesuai dengan kebutuhan Anda, perhatikan hal-hal berikut:

Jenis Cairan: Pastikan pompa kompatibel dengan jenis cairan yang akan dipompa, terutama jika cairan tersebut korosif atau memiliki viskositas tinggi.

Kapasitas dan Tekanan: Pilih pompa dengan kapasitas dan tekanan yang sesuai dengan kebutuhan aplikasi Anda.

Fitur Tambahan: Perhatikan fitur-fitur tambahan seperti kontrol otomatis, pengaturan aliran, dan perlindungan terhadap kebocoran.

Layanan Purna Jual: Pastikan distributor menyediakan layanan purna jual yang memadai, seperti garansi, suku cadang, dan layanan teknis.

5. Mengapa Memilih PT Hefram Asasta Indonesia?

Sebagai distributor resmi pompa Tacmina, PT Hefram Asasta Indonesia menawarkan beberapa keunggulan, antara lain:

Beragam Pilihan Produk: Menyediakan berbagai jenis dan model pompa Tacmina untuk memenuhi kebutuhan industri yang berbeda.

Layanan Pelanggan Terbaik: Memberikan konsultasi gratis untuk membantu Anda memilih pompa yang tepat.

Layanan Purna Jual Lengkap: Menyediakan suku cadang asli dan layanan teknis untuk memastikan pompa Anda selalu dalam kondisi optimal.

Harga Kompetitif: Menawarkan harga yang bersaing dengan kualitas produk terbaik.

6. Tips Mendapatkan Harga Terbaik

Untuk mendapatkan harga pompa Tacmina terbaik dari PT Hefram Asasta Indonesia, Anda dapat mengikuti tips berikut:

Bandingkan Produk: Bandingkan harga dan spesifikasi berbagai model untuk menemukan yang paling sesuai dengan kebutuhan Anda.

Tanyakan Diskon atau Promo: PT Hefram Asasta Indonesia sering menawarkan promo khusus untuk pembelian dalam jumlah besar atau pada periode tertentu.

Manfaatkan Konsultasi Gratis: Gunakan layanan konsultasi untuk memastikan Anda mendapatkan produk yang sesuai tanpa membayar lebih.

Keunggulan Pompa Tacmina

Presisi Tinggi: Pompa Tacmina dirancang untuk memberikan aliran cairan yang sangat akurat, cocok untuk aplikasi yang membutuhkan pengukuran presisi.

Bebas Kebocoran: Dengan teknologi diaphragm dan material berkualitas tinggi, risiko kebocoran dapat diminimalkan.

Tahan Lama: Dibuat dengan material yang tahan terhadap korosi dan keausan, pompa Tacmina memiliki umur pakai yang panjang.

Efisiensi Energi: Desain yang efisien memastikan penggunaan energi yang minimal tanpa mengurangi kinerja.

Pemeliharaan Mudah: Dengan desain modular, perawatan pompa Tacmina menjadi lebih cepat dan mudah.

Kalit Contoration

"Kalit Contoration" adalah istilah unik yang mengacu pada konsistensi kualitas dan inovasi teknologi dalam produk-produk Tacmina. Dengan mengutamakan "Kalit Contoration," Tacmina memastikan bahwa setiap produk yang mereka hasilkan memiliki kualitas terbaik dan performa yang konsisten di berbagai aplikasi.

PT Hefram Asasta Indonesia sebagai mitra Tacmina di Indonesia terus mendukung prinsip ini dengan menghadirkan produk-produk berkualitas tinggi dan layanan pelanggan yang unggul.

Model : V-1000-VTCF-HW,Kapasitas :1150ml/menit = 69 L/H,Tekanan : 3 Bar

Koneksi : Discharge & Suction : PVC Hose 12x18.Model Pengoperasian : Manual setting

Viskositas maksimal : 50 cPs,Temperature Stroke : 0-40degC,Kecepatan stroke : 108 stroke/menit

Panjang stroke : 0- 6 mm,Power supply : 50 hz /220V/1 phase /10w/4pole

Kesimpulan

Pompa Tacmina adalah solusi unggulan untuk berbagai kebutuhan industri, menawarkan presisi, keandalan, dan efisiensi yang sulit ditandingi. PT Hefram Asasta Indonesia sebagai distributor resmi di Indonesia memberikan jaminan produk asli, layanan purna jual yang lengkap, dan harga yang kompetitif.

Dengan memahami faktor-faktor yang memengaruhi harga, keunggulan produk, dan tips memilih pompa yang tepat, Anda dapat membuat keputusan yang lebih baik dalam membeli pompa Tacmina. Hubungi PT Hefram Asasta Indonesia untuk mendapatkan informasi lebih lanjut dan penawaran terbaik.

Hubungi Kontak Kami:

Kontak:wa.me/6281335353290

Alamat: https://maps.app.goo.gl/XHtDvZAHB7ZxjkVDA

Marketplce:https://tokopedia.link/ulFa1FENVPb

pompa dosing tacmina,pompa air tanpa listrik,tacmina pump,pompa air hitachi,metering pump tacmina,pompa oli tangan,pompa tc,p0901 clutch actuator circuit range/performance,tacmina pump catalog,pompa 6 inch

#pompadosingtacmina #pompaairtanpalistrik #tacminapump #pompaairhitachi #meteringpumptacmina #pompaolitangan #pompatc #p0901clutchactuatorcircuit range/performance #tacminapumpcatalog #pompa6inch

youtube

2 notes

·

View notes

Text

What material is PVDF? PVDF is a very important high-performance engineering plastic. It has excellent chemical stability, heat resistance, weather resistance and mechanical properties, so it is widely used in various fields. The full name of PVDF is polyvinylidene fluoride, which is a thermoplastic fluoroplastic with excellent chemical corrosion resistance and electrical insulation properties. PVDF has attracted much attention due to its unique properties. Let’s take a closer look at what material PVDF is. First, PVDF has excellent chemical resistance. PVDF has excellent acid and alkali resistance and good corrosion resistance to most organic solvents, acids, alkali and salts, so it is widely used in chemical pharmaceuticals, electroplating and other fields. In the chemical industry, PVDF is often used to manufacture pipes, pumps, valves and other equipment because it can effectively resist acid and alkali corrosion and ensure the stable operation of equipment. Secondly, PVDF has excellent heat resistance. The melting point of PVDF is about 165°C, the long-term use temperature can reach 140°C, and the short-term use temperature is even higher. This allows PVDF to maintain stable performance in high temperature environments, so it is widely used in aerospace, automotive, electronics and other fields. For example, in the aerospace field, PVDF is often used to manufacture aircraft parts, such as pipes, connectors, etc., because it can maintain stable performance in high-temperature and high-pressure environments. In addition, PVDF also has good weather resistance. PVDF has excellent UV resistance and anti-aging properties, so it can maintain stable performance for a long time in outdoor environments and is not prone to aging, discoloration, etc. Therefore, PVDF is often used to manufacture exterior wall panels in the fields of construction, billboards, solar energy, etc. , billboards, solar panels and other products to ensure their long-term stable performance in outdoor environments. Finally, PVDF has excellent mechanical properties. PVDF has high strength and stiffness, as well as good toughness and impact properties, so it is widely used in machinery manufacturing, electrical equipment and other fields. In the field of machinery manufacturing, PVDF is often used to manufacture bearings, gears, seals and other products because it can maintain stable performance under high-speed, high-load working conditions. To sum up, PVDF is a very important high-performance engineering plastic with excellent chemical stability, heat resistance, weather resistance and mechanical properties. Therefore, it is widely used in chemical industry, aerospace, construction, machinery manufacturing and other fields. It is believed that with the continuous advancement of technology, the application fields of PVDF will continue to expand, bringing more convenience and possibilities to all walks of life.

3 notes

·

View notes

Text

Abrex 600 Sheet Plates

Since the fundamental limit of ABREX is to give assurance from scratched territory, in this way we try to manufacture precision fabricated Abrex 600 Plates, which are extensively known for their positive conditions like high insurance from effect, weld breaking point, handiness, and significantly more. One progressively included piece of breathing space that goes with the usage of ABREX 600 sheets and plates is that the greatness of the fundamental part reduces enormously, which shows to be of authentic help with truly grinding working conditions. This associates in growing the future of the mechanical parts related with these sheets and plates.

At Vandan Steel & Engg. co., we attempt to cling ourselves to all the fundamental worldwide models and benchmarks of collecting, to retreat the entire methodology. In addition, the amassing of Abrex 600 Abrasion Resistant Plates and Sheets, is done in proximity of all the skilled and experienced partners, who work relentlessly towards collecting the best grouping of things for our customers.

Our entire workplace is outfitted with the best extent of equipment and mechanical assembly, which makes the age of Abrex 600 Wear Resistant Plates and Sheets especially smooth and mix-up free. All these Abrex sheets and plates are caused available to our customers at a completely moderate an incentive to go.

Abrex 600 plates have a lot of characteristics given by solidified steel make it a convincing candidate in materials decisions. Solidified steel is subsequently low carbon steel which contains chromium at extra by weight. It is the extension of chromium that gives the steel of its novel flawless, spoil restricting properties.

ABREX 600 STEEL PLATE SPECIFICATION

Thickness : 5mm to 150mm Width : 1,500mm to 2,500mm Length : 6,000mm to 12,000mm Heat Treatment : N, Q+T Surface Paint : EP, PE, HDP, SMP, PVDF Material : ABREX 600 Plate

APPLICATION

Machine building Pylons and other architectural structures Lifting and mobile equipment Construction of bridges Wearing plates Framework structures Crane booms, Rail cars Stone or iron chutes Truck frames, Containers Vehicles and transport equipment Anti drill plates such as security doors, shot blasting equipment and tumbling machine

For More Information :

Visit Our Website: http://wearplates.co.in/

Contact No: +91-8828813630

E-Mail ID: [email protected]

5 notes

·

View notes

Text

Car Parking Shades Suppliers in Dubai 0543839003

https://parkingshades.weebly.com/

provide highly engineered car parking shades structure to its client, which provide extreme protection to cars and other vehicles from the burning sun UV radiations and our parking shades structures are very helpful for UAE’s hot weather. We manufacture, supply and install both Standard and Customized parking sheds in Sharjah and other states of UAE.

https://g.page/r/CXorswe6WLtiEAE

Car Parking Shades Suppliers in Dubai Sharjah Ajman UAE Best Quality Good Materials affordable and Best Quallity Materials

CAR PARKING SHADE SIZES LENGTH & WIDTH

6.0m x 3.0m (Good For 1 Car)

6.0m x 6.0m (Good For 2 Car)

We are Sharjah base Car Parking Shade and tents manufacturing company since 2002. We deliver wide range of Car Parking Shades in Dubai, Abu Dhabi, Sharjah,Oman, saudi arabia, other Gulf regions like Ajman, Al Ain, Umm Al Quwain, Fujairah, as well we provide our services in all GCC Countries and Africa with standard and custom designs and requirements.

https://local.google.com/place?id=7114377592378174330&use=posts&lpsid=CIHM0ogKEICAgICemYDMaA

Our most Used Low price Parking Shade is Cantilever Car Parking Shades which are available in most competitive price and these shades are best solution for car parking lot.

OUR CAR PARKING SHADES IN DUBAI:

ARCH DESIGN CAR PARKING SHADES SUPPLIERS DUBAI

PYRAMID CAR PARKING SHADE SUPPLIERS IN DUBAI

CONE SINGLE-POLE PARKING SHADES SUPPLIERS IN DUBAI

CONICAL CAR PARKING SHADES SUPPLIERS IN DUBAI

TOP SUPPORT PARKING SHADE SUPPLIERS IN DUBAI

SAIL CAR PARKING SHADES SUPPLIERS IN DUBAI

PYRAMID TOP SUPPORT PARKING SHADE SUPPLIERS IN DUBAI

UMBRELLA CAR PARKING SHADES SUPPLIERS IN DUBAI

WAVE DESIGN PARKING SHADES SUPPLIERS IN DUBAI

K-SPAN CAR PARKING SHADE SUPPLIERS IN DUBAI

BOTTOM SUPPORT PARKING SHADES SUPPLIERS IN DUBAI

BOTTOM SUPPORT PYRAMID PARKING SHEDS SUPPLIERS IN DUBAI

CAR PARKING SHADES FABRIC SUPPLIERS IN DUBAI

We are expert manufacturers and suppliers as we use world high class fabrics like PVC, PVDF, PTFE, HDPE for the car parking shades structure which increase the safety of your cars more efficiently and effectively and very much helpful for the UAE weather and maintain the gloss, shine and protect the car.

List of Parking Shades Fabrics Use for the manufacturing of Car parking sheds are:

AND DESIGN AND TECHNOLOGY WILL CERTAINLY CONVINCE SOMEONE.

Car Parking Shades Suppliers in UAE

THE FACTORY OF AL MUZALAAT TENTS IS LOCATED IN SHARJAH INDUSTRIAL AREA 6 SHARJAH, STEEL FABRICATION IN SAJJA WITH FULL-FLEDGED FACILITY FOR DESIGN, MANUFACTURING AND INSTALLATION OF TENSILE MEMBRANE STRUCTURES. WE HAVE THE FACILITY TO MANUFACTURE STEEL AND FABRIC, IN-HOUSE

car parking arch design arch design car parkingcar parking shade arch design arch design in Dubai Dubai arch design arch design Dubai parking shade arch design arch design parking shade arch design shade parking arch design arch design parkingUAE arch designarch design UAE Sharjah arch design arch design Sharjah arch design roof arch design roof cover arch design in Abu Dhabi arch design Abu Dhabi Abu Dhabi arch design shade arch design roof shade arch design parking shade arch designs shade arch design car parking shade arch design in Sharjah shade arch design UAE shade arch design shade arch design UAE shade arch design roof cover Sharjah shade arch design shade arch design Sharjah shade arch design Dubai Dubai shade arch design shade arch design in Dubaishade arch design in Abu Dhabi shade arch design Abu Dhabi Abu Dhabi shade arch design shade arch design Al Ain Al Ain shade arch designshade arch design in Al Ain shade arch design in UAE car park shade In UAEcar park shade structurescar parking shade suppliers car parking shade products car park shade sails

industrial car parking shadecar parking shades designoudoor shade sail clothparking shades designcar park shade structures in UAE car parking shade suppliers In UAEcar parking shade products In UAE car park shade sails In UAE industrial car parking shade In UAE car parking shades design In UAE oudoor shade sail cloth In UAE parking shades design In UAE car parking shade In UAE car parking shade suppliers car parking shade productscar parking shade sailindustrial car parking shadecar parking shedssun shadeshade clothcar park canopy park shade UAEpark shade structures.

These products are manufactured with the latest technologies under the strict guidance of our highly skilled engineers. Moreover, the blend of quality with the most recent technologies will let us customize the designs according to our customer’s desires.

HDPE (High-Density Polyethylene) is a high-quality fabric used in parking shades and tensile structures. The fabric is manufactured using high-quality materials to function for a more extended period. It is designed for maximum strength, durability, and protection.

Proven to resist UV rays, this fabric can withstand harsh weather as well. This type of material is highly recommended for the people who would like to enhance their outdoor space within the budget. It is one of the most cost-effective fabric shade available in the market. Both waterproof and non-water proof materials are available- depending upon the client requirement we use it for car parking sheds and other urban spaces.

PVC (Poly Vinyl Chloride) is a fabric used in the car parking shades well known for its amazing properties. There are plenty of good qualities for this fabric, such as UV resistance, cold resistance, durability, etc. The material is 100 percent waterproof and can withstand harsh weather. It is also an economical solution for parking shades. Our PVC fabric will protect the car parking area from the sun, hence maintaining the color and heat of the car.

Car Parking Shades– PVC Mesh

PVC mesh is a very popular and cost-effective roofing system which is designed to keep interior temperatures cooler during warmer weather conditions. These type of fabric are used in the areas with high UV level. It is a strong, durable and long-lasting material.

More Details contact us 0543839003 / 0505773027

#car shades#shades#maqavi#awnings#parking#awnings suppliers#tensile#tents#awnings_installation#abudhabi#awnings_suppliers#car Parking Shades Suppliers#car parking shades suppliers in dubai#car Parking Shades Suppliers in Sharjah#car Parking Shades Suppliers in Ajman#car parking shades suppliers in umm al quwian#car parking shades suppliers in Ras Al Khaimah#car Parking Shades Suppliers in fujairah#car parking shades suppliers in uae

3 notes

·

View notes

Text

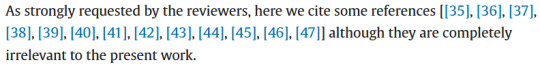

I have a uni subscription.

References (in Chicago format which gives a full author list) in order - or they were before Tumblr fucked with my formatting - starting at 35 and ending at 47 are behind the readmore because I am merciful.

The reviewer is not the first author on all the papers because they have different first authors, but there's... definitely a common thread.

The fourth one on the list is the only one to have neither Sergei nor Alex Trukhanov; it has Ekaterina Trukhanova instead. (Edit: I looked at the et al. and this one actually has both Sergei and Alex.)

This stuff stinks and needs to stop.

El-Ghobashy, Marwa A., Hisham Hashim, Moustafa A. Darwish, Mayeen Uddin Khandaker, Abdelmoneim Sulieman, Nissren Tamam, Sergei V. Trukhanov, Alex V. Trukhanov, and Mohamed A. Salem. "Eco-friendly NiO/polydopamine nanocomposite for efficient removal of dyes from wastewater." Nanomaterials 12, no. 7 (2022): 1103.

Henaish, Ahmed Maher, Moustafa A. Darwish, Osama M. Hemeda, Ilya A. Weinstein, Tarek S. Soliman, Alex V. Trukhanov, Sergei V. Trukhanov, Di Zhou, and Ali M. Dorgham. "Structure and optoelectronic properties of ferroelectric PVA-PZT nanocomposites." Optical Materials 138 (2023): 113402.

Hussein, Marwa M., Samia A. Saafan, H. F. Abosheiasha, Amira A. Kamal, Abd El-razek Mahmoud, Di Zhou, Sergei V. Trukhanov, Tatiana I. Zubar, Alex V. Trukhanov, and Moustafa A. Darwish. "Structural and dielectric characterization of synthesized nano-BSTO/PVDF composites for smart sensor applications." Materials Advances 4, no. 22 (2023): 5605-5617.

Migas, Dmitry B., Vitaliy A. Turchenko, A. V. Rutkauskas, Sergey V. Trukhanov, Tatiana I. Zubar, Daria I. Tishkevich, Alex V. Trukhanov, and Natalia V. Skorodumova. "Temperature induced structural and polarization features in BaFe 12 O 19." Journal of Materials Chemistry C 11, no. 36 (2023): 12406-12414.

Hussein, Marwa M., Samia A. Saafan, Hatem F. Abosheiasha, Di Zhou, Daria I. Tishkevich, Nikita V. Abmiotka, Ekaterina L. Trukhanova et al. "Preparation, structural, magnetic, and AC electrical properties of synthesized CoFe2O4 nanoparticles and its PVDF composites." Materials Chemistry and Physics 317 (2024): 129041. (Edit: the et al. are Alex V Trukhanov, Sergei V Trukhanov, M Khalid Hossain, Moustafa A Darwish)

Tishkevich, D. I., S. S. Grabchikov, S. B. Lastovskii, S. V. Trukhanov, D. S. Vasin, T. I. Zubar, A. L. Kozlovskiy et al. "Function composites materials for shielding applications: Correlation between phase separation and attenuation properties." Journal of Alloys and Compounds 771 (2019): 238-245.

Trukhanov, S. V., V. V. Fedotova, A. V. Trukhanov, H. Szymczak, and C. E. Botez. "Cation ordering and magnetic properties of neodymium-barium manganites." Technical Physics 53 (2008): 49-54.

Trukhanov, A. V., D. I. Tishkevich, A. V. Timofeev, V. A. Astakhov, E. L. Trukhanova, A. A. Rotkovich, Yuan Yao et al. "Structural and electrodynamic characteristics of the spinel-based composite system." Ceramics International 50, no. 12 (2024): 21311-21317.

Trukhanov, A. V., V. O. Turchenko, I. A. Bobrikov, S. V. Trukhanov, I. S. Kazakevich, and A. M. Balagurov. "Crystal structure and magnetic properties of the BaFe12− xAlxO19 (x= 0.1–1.2) solid solutions." Journal of Magnetism and Magnetic Materials 393 (2015): 253-259.

Trukhanov, S. V., T. I. Zubar, V. A. Turchenko, An V. Trukhanov, T. Kmječ, J. Kohout, L. Matzui et al. "Exploration of crystal structure, magnetic and dielectric properties of titanium-barium hexaferrites." Materials Science and Engineering: B 272 (2021): 115345.

Vinnik, Denis A., Andrey Yu Starikov, Vladimir E. Zhivulin, Kseniya A. Astapovich, Vitaliy A. Turchenko, Tat’yana I. Zubar, Sergei V. Trukhanov et al. "Changes in the structure, magnetization, and resistivity of BaFe12–x Ti x O19." ACS Applied Electronic Materials 3, no. 4 (2021): 1583-1593. (The et al. are Jaroslav Kohout, Tomas Kmjec, Olena Yakovenko, Lyudmila Matzui, Antonio Sergio B Sombra, Di Zhou, Rajshree B Jotania, Charanjeet Singh, Yujie Yang, Alex V Trukhanov)

Trukhanov, S. V., A. V. Trukhanov, A. N. Vasiliev, and H. Szymczak. "Frustrated exchange interactions formation at low temperatures and high hydrostatic pressures in La 0.70 Sr 0.30 Mn O2. 85." Journal of Experimental and Theoretical Physics 111 (2010): 209-214.

Zhivulin, Vladimir E., Evgeniy A. Trofimov, Olga V. Zaitseva, Daria P. Sherstyuk, Natalya A. Cherkasova, Sergey V. Taskaev, Denis A. Vinnik et al. "Preparation, phase stability, and magnetization behavior of high entropy hexaferrites." IScience 26, no. 7 (2023). (The et al. are Yulia A Alekhina, Nikolay S Perov, Kadiyala CB Naidu, Halima I Elsaeedy, Mayeen U Khandaker, Daria I Tishkevich, Tatiana I Zubar, Alex V Trukhanov, Sergei V Trukhanov)

[As strongly requested by the reviewers, here we cite some references [[35], [36], [37], [38], [39], [40], [41], [42], [43], [44], [45], [46], [47]] although they are completely irrelevant to the present work.]

Yang et al. (2024)

3K notes

·

View notes

Text

Top Reasons to Use PVDF Sheets for Chemical Storage Solutions When it comes to chemical storage, selecting the right material is crucial for ensuring safety, durability, and performance. Among the many options available, PVDF sheets (Polyvinylidene Fluoride) have emerged as a top choice due to their exceptional properties. At Petron Thermoplast, we provide high-quality PVDF sheets tailored for a wide range of industrial applications. Here’s why PVDF sheets are the ideal solution for chemical storage needs:

0 notes

Text

WallNova Aluminum Curtain Wall Materials manufacturer

WallNova is an original manufacturer specializes in aluminum cladding.

In the dynamic world of metal manufacturing, WALLNOVA has emerged as a shining star. With a rich 15 year legacy, our factory in Foshan has been continuously evolving and expanding its footprint in the global market. For over a decade, we have been successfully supplying our top notch metal products to Europe, Southern Asia, and Australia, amassing a wealth of experience and a sterling reputation along the way.

State-of-the-Art Facility

Situated in the vibrant manufacturing hub of Guangdong Foshan, wallnova factory sprawls across an expansive area of more than twenty thousand square meters. This vast space is home to a team of over 100 highly skilled and dedicated workers, who pour their expertise and passion into every product we create. Our commitment to quality is further exemplified by our in house Dulux & Akzonobel certified PVDF and Powder coating production line. This cutting edge facility not only ensures the durability and aesthetic appeal of our metal products but also gives us complete control over the production process, allowing us to meet the most stringent international standards and customized requirements with ease.

Global Reach and Local Expertise

Wallnova factory extensive experience in exporting has equipped us with a deep understanding of the diverse needs and preferences of our international clients. We pride ourselves on our ability to seamlessly adapt to different market demands, whether it's the sleek and modern designs favored in Europe, the functionality driven requirements of Southern Asia, or the robust and reliable standards expected in Australia. This global perspective, combined with our local manufacturing prowess, positions us as the ideal partner for any project, regardless of its scale or complexity.

If your company currently has a project or quotation and needs FREE SAMPLES for your evaluation

Pls do not hesitate to get in touch, aluminum products and color samples are both available.

Echo Luo WallNova Architectural Products Co., Ltd Tel: +86-0755-23733286 Mobile/Whatsapp: +86 13714661321 Email: [email protected] Web: www.wallnova.com

1 note

·

View note

Text

A research team led by Professor Soojin Park and Seoha Nam from the Department of Chemistry at POSTECH, in partnership with Hansol Chemical's Battery materials R&D center, has developed a new fluorine-free binder and electrolyte designed to advance eco-friendly, high-performance battery technology. Their findings were recently published in Chemical Engineering Journal, an international journal in the field of chemistry. As environmental concerns intensify, the importance of sustainable materials in battery technology is growing. Traditional lithium batteries rely on fluorinated compounds such as polyvinylidene fluoride (PVDF) bindersand lithium hexafluorophosphate (LiPF6, LP) salts. However, this "PVDF-LP" system releases highly toxic hydrogen fluoride (HF), which reduces battery performance and lifespan. Furthermore, PVDF is non-biodegradable, and with the European Union (EU) tightening regulations on PFAS, a ban on these substances is expected by 2026.

Read more.

10 notes

·

View notes

Text

High Performance Plastics Market

High-Performance Plastics Market Size, Share, Trends: BASF SE Leads

Increasing Demand for Light-Weight Materials in the Automotive Industry

Market Overview:

The global High-Performance Plastics Market is projected to grow at a CAGR of 7.5% from 2024 to 2031, reaching USD 35.2 billion by 2031 from USD 21.3 billion in 2024. Asia-Pacific is expected to dominate the market throughout the forecast period. The market growth is driven by increasing demand from various end-use industries such as automotive, aerospace, and electronics, where high-performance plastics are valued for their superior mechanical, thermal, and chemical properties. These materials offer significant advantages over conventional plastics and metals, including weight reduction, improved fuel efficiency, and enhanced durability.

DOWNLOAD FREE SAMPLE

Market Trends:

As the automobile industry transitions to electric vehicles and fuel efficiency standards encourage the use of lighter-weight materials, high-performance polymers are emerging as viable alternatives to traditional materials. Within this market, high-performance polymers, such as engineering plastics and composites, are likely to see the most growth. For example, the global market for engineering plastics in automotive applications was valued at $YY billion in 2022 and is expected to increase to $YY billion by 2031, at a 6.9% CAGR. These lightweight, high-strength polymers are increasingly being used to make electric car battery enclosures, interior components, and other structural pieces, reducing overall vehicle weight and enhancing energy efficiency.

Market Segmentation:

Fluoropolymers dominate the market generally. Fluoropolymers including PTFE and PVDF are driving the market for high-performance plastics thanks in significant part to their strong chemical resistance, low friction properties, and high temperature stability. For these materials, demandable applications abound: chemical processing equipment, non-stick cookware, high-performance seals and gaskets. Emphasizing reduced environmental impact and improved recyclability, new developments in fluoropolymer technology serve to address growing industry sustainability challenges.

Market Key Players:

The high-performance plastics industry is highly competitive, with major players focusing on strategic projects including mergers and acquisitions, product developments, and capacity building if they are to keep their market share. Key companies such as BASF SE, Solvay S.A., DuPont de Nemours, Inc., Arkema Group, Evonik Industries AG, Celanese Corporation, Victrex plc, Daikin Industries, Ltd., Sumitomo Chemical Co., Ltd., and Toray Industries, Inc. dominate the market.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Breaking Down the Manufacturing Process of ACP Sheets in India

Aluminium Composite Panels (ACP) have become essential to modern construction and design in India. ACP sheets, known for their adaptability, durability, and aesthetic appeal, are commonly utilised in commercial buildings, home projects, and interiors. Have you ever thought how these sheets were made? To learn why Indian ACP sheet manufacturers in India have a reputation for their quality and inventiveness, let's read the step-by-step method of creating them.

1. Raw Material Preparation

The manufacturing of ACP sheets begins with selecting premium-quality raw materials. Aluminium coils are the primary input, alongside polyethene (PE) or mineral-filled cores that provide strength and insulation. ACP sheet manufacturers in India ensure that raw materials meet international durability, safety, and environmental compliance standards.

2. Surface Treatment for Aluminium Coils

Surface treatments for aluminium coils include degreasing, chemical coating, and anodising. This procedure increases the material's corrosion resistance, ensuring long-term performance even under extreme weather conditions. A high-quality priming coat is next applied to aid the adhesion of the remaining ornamental coats.

3. Core Preparation

The core of an ACP sheet is made using either PE or fire-retardant (FR) materials. Indian manufacturers are increasingly opting for eco-friendly and fire-resistant cores to meet evolving safety standards. The core material is processed into sheets of precise thickness for uniformity.

4. Layer Bonding

This is the most critical step in the ACP sheet manufacturing process. The treated aluminium layers are bonded to the core material using a specialized adhesive film under high heat and pressure. The lamination process is conducted in a continuous line, ensuring seamless integration and exceptional durability.

5. Surface Coating and Finishing

After the layers are joined, the top aluminium surface is treated with ornamental and protective treatments. PVDF (Polyvinylidene Fluoride) and polyester are common coatings that offer weather resistance, UV protection, and a sleek appearance. Indian producers provide a wide variety of colours, textures, and patterns, such as wood grain, marble, and metallic finishes.

6. Cutting and Sizing

The laminated sheets are cut into standard sizes or customized dimensions based on client requirements. Automated cutting machines ensure precision and reduce material wastage.

7. Quality Inspection

Every ACP sheet undergoes rigorous quality checks to meet safety and durability standards. Strength, fire resistance, weather resistance, and color consistency tests are performed to maintain high quality.

8. Packaging and Dispatch

Finally, the ACP sheets are packed securely to prevent damage during transportation. Indian manufacturers prioritize sustainable packaging solutions to reduce environmental impact.

Conclusion

Aluminium Composite Panels (ACP) combine innovative design wiTH innovative functionality. Indian manufacturers excel in producing high-quality, eco-friendly, and durable ACP sheets through precise manufacturing processes. These versatile panels continue to redefine modern construction and design standards, making them a top choice for diverse applications.

0 notes

Text

0 notes

Text

Car Parking Shades Suppliers in Dubai 0543839003

https://parkingshades.weebly.com/

provide highly engineered car parking shades structure to its client, which provide extreme protection to cars and other vehicles from the burning sun UV radiations and our parking shades structures are very helpful for UAE’s hot weather. We manufacture, supply and install both Standard and Customized parking sheds in Sharjah and other states of UAE.

https://g.page/r/CXorswe6WLtiEAE

Car Parking Shades Suppliers in Dubai Sharjah Ajman UAE Best Quality Good Materials affordable and Best Quallity Materials

CAR PARKING SHADE SIZES LENGTH & WIDTH

6.0m x 3.0m (Good For 1 Car)

6.0m x 6.0m (Good For 2 Car)

We are Sharjah base Car Parking Shade and tents manufacturing company since 2002. We deliver wide range of Car Parking Shades in Dubai, Abu Dhabi, Sharjah,Oman, saudi arabia, other Gulf regions like Ajman, Al Ain, Umm Al Quwain, Fujairah, as well we provide our services in all GCC Countries and Africa with standard and custom designs and requirements.

Our most Used Low price Parking Shade is Cantilever Car Parking Shades which are available in most competitive price and these shades are best solution for car parking lot.

OUR CAR PARKING SHADES IN DUBAI:

ARCH DESIGN CAR PARKING SHADES SUPPLIERS DUBAI

PYRAMID CAR PARKING SHADE SUPPLIERS IN DUBAI

CONE SINGLE-POLE PARKING SHADES SUPPLIERS IN DUBAI

CONICAL CAR PARKING SHADES SUPPLIERS IN DUBAI

TOP SUPPORT PARKING SHADE SUPPLIERS IN DUBAI

SAIL CAR PARKING SHADES SUPPLIERS IN DUBAI

PYRAMID TOP SUPPORT PARKING SHADE SUPPLIERS IN DUBAI

UMBRELLA CAR PARKING SHADES SUPPLIERS IN DUBAI

WAVE DESIGN PARKING SHADES SUPPLIERS IN DUBAI

K-SPAN CAR PARKING SHADE SUPPLIERS IN DUBAI

BOTTOM SUPPORT PARKING SHADES SUPPLIERS IN DUBAI

BOTTOM SUPPORT PYRAMID PARKING SHEDS SUPPLIERS IN DUBAI

CAR PARKING SHADES FABRIC SUPPLIERS IN DUBAI

We are expert manufacturers and suppliers as we use world high class fabrics like PVC, PVDF, PTFE, HDPE for the car parking shades structure which increase the safety of your cars more efficiently and effectively and very much helpful for the UAE weather and maintain the gloss, shine and protect the car.

List of Parking Shades Fabrics Use for the manufacturing of Car parking sheds are:

AND DESIGN AND TECHNOLOGY WILL CERTAINLY CONVINCE SOMEONE.

Car Parking Shades Suppliers in UAE

THE FACTORY OF AL MUZALAAT TENTS IS LOCATED IN SHARJAH INDUSTRIAL AREA 6 SHARJAH, STEEL FABRICATION IN SAJJA WITH FULL-FLEDGED FACILITY FOR DESIGN, MANUFACTURING AND INSTALLATION OF TENSILE MEMBRANE STRUCTURES. WE HAVE THE FACILITY TO MANUFACTURE STEEL AND FABRIC, IN-HOUSE

car parking arch design arch design car parkingcar parking shade arch design arch design in Dubai Dubai arch design arch design Dubai parking shade arch design arch design parking shade arch design shade parking arch design arch design parkingUAE arch designarch design UAE Sharjah arch design arch design Sharjah arch design roof arch design roof cover arch design in Abu Dhabi arch design Abu Dhabi Abu Dhabi arch design shade arch design roof shade arch design parking shade arch designs shade arch design car parking shade arch design in Sharjah shade arch design UAE shade arch design shade arch design UAE shade arch design roof cover Sharjah shade arch design shade arch design Sharjah shade arch design Dubai Dubai shade arch design shade arch design in Dubaishade arch design in Abu Dhabi shade arch design Abu Dhabi Abu Dhabi shade arch design shade arch design Al Ain Al Ain shade arch designshade arch design in Al Ain shade arch design in UAE car park shade In UAEcar park shade structurescar parking shade suppliers car parking shade products car park shade sails

industrial car parking shadecar parking shades designoudoor shade sail clothparking shades designcar park shade structures in UAE car parking shade suppliers In UAEcar parking shade products In UAE car park shade sails In UAE industrial car parking shade In UAE car parking shades design In UAE oudoor shade sail cloth In UAE parking shades design In UAE car parking shade In UAE car parking shade suppliers car parking shade productscar parking shade sailindustrial car parking shadecar parking shedssun shadeshade clothcar park canopy park shade UAEpark shade structures.

These products are manufactured with the latest technologies under the strict guidance of our highly skilled engineers. Moreover, the blend of quality with the most recent technologies will let us customize the designs according to our customer’s desires.

HDPE (High-Density Polyethylene) is a high-quality fabric used in parking shades and tensile structures. The fabric is manufactured using high-quality materials to function for a more extended period. It is designed for maximum strength, durability, and protection.

Proven to resist UV rays, this fabric can withstand harsh weather as well. This type of material is highly recommended for the people who would like to enhance their outdoor space within the budget. It is one of the most cost-effective fabric shade available in the market. Both waterproof and non-water proof materials are available- depending upon the client requirement we use it for car parking sheds and other urban spaces.

PVC (Poly Vinyl Chloride) is a fabric used in the car parking shades well known for its amazing properties. There are plenty of good qualities for this fabric, such as UV resistance, cold resistance, durability, etc. The material is 100 percent waterproof and can withstand harsh weather. It is also an economical solution for parking shades. Our PVC fabric will protect the car parking area from the sun, hence maintaining the color and heat of the car.

Car Parking Shades– PVC Mesh

PVC mesh is a very popular and cost-effective roofing system which is designed to keep interior temperatures cooler during warmer weather conditions. These type of fabric are used in the areas with high UV level. It is a strong, durable and long-lasting material.

More Details contact us 0543839003 / 0505773027

#car parking shade#maqavi#tents#shades#parking#awnings#awnings suppliers#awnings_installation#awnings_suppliers#abudhabi#tensile#dubai villas#viralvideos#viraltopic#virtual reality#ten stories high#topics#top#construction#contracting#manufacturers

2 notes

·

View notes