#PLC in India

Explore tagged Tumblr posts

Text

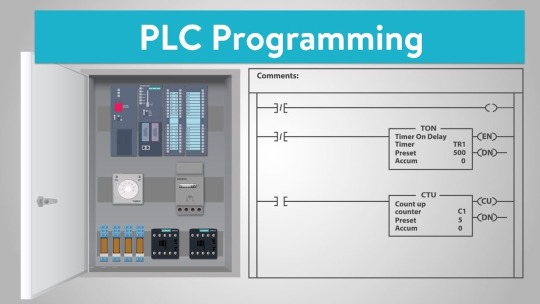

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Public Limited Company Registration in Rajasthan

Starting a Public Limited Company (PLC) in India may sound complicated, but with the right guidance, it becomes smooth and simple. At E Accountax Manager, we’re here to make the entire registration process of public limited company in Rajasthan stress-free—from choosing your company name to getting your Certificate of Incorporation.

#Public Limited Company Registration Rajasthan#PLC registration India#company registration Jaipur#start public company Rajasthan#register business India#public company legal process#company formation Rajasthan#company law compliance#company incorporation Jaipur#online company registration India

1 note

·

View note

Text

Authorized Siemens PLC Dealer – Reliable Automation Solutions

Get high-quality Siemens PLCs from an authorized dealer. We offer advanced automation solutions with expert support for seamless industrial control.

0 notes

Text

PLC splitter suppliers | PLC splitter suppliers in Noida | PLC splitter suppliers in Noida India

NexTik, the leading PLC splitter supplier in Noida, offers high-quality fiber optic solutions for FTTH networks. With a wide range of durable and efficient PLC splitters, NexTik ensures seamless signal distribution, superior performance, and expert support for businesses. Contact us today! +91 8130608406

0 notes

Text

Some of y'all call way too many things colonialism. The Celtic areas of the British isles falling under what was/is largely English control wasn't colonialism, it was imperialism. The three partitions of Poland weren't colonialism, they were imperialism.

Colonialism implies the conquered peoples were much more significantly oppressed and alienated from the people of the conquering state than what occurred in those examples.

#sure the irish were treated like shit#but that treatment was much more comparable to that of english peasantry than to native peoples of north america‚ india‚ and africa#and the PLC was fucking *incorperated* into Austria Russia and Prussia#that's not very alienated if you ask me

1 note

·

View note

Text

https://aknitech.in/blog/the-role-of-plcs-in-industry-top-plc-manufacturers/

Programmable Logic Controllers (PLCs) play a pivotal role in modern industrial applications, acting as the brain behind the automated manufacturing processes. With the rapid advancement of Industry 4.0, the importance of PLCs has grown exponentially, driving efficiency, reliability, and scalability in various sectors.

0 notes

Text

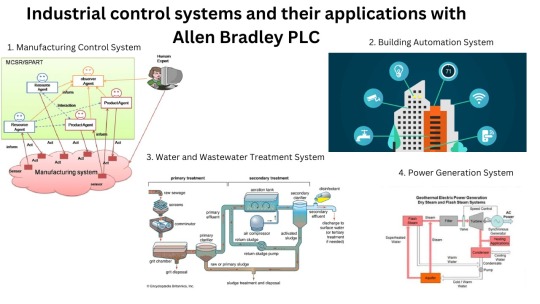

Industrial control systems and their applications with Allen Bradley PLCs

To manage and observe industrial processes, a variety of applications use industrial control systems. A common brand of Programmable Logic Controllers (PLCs) used in industrial control systems is Allen Bradley.

1.Manufacturing Control System:

2. Building Automation System:

3. Water and Wastewater Treatment System:

4. Power Generation System:

#trending#tumblr trends#viralpost#automation#allen bradley#rockwell automation#tech#technology#automotive#industrial#india#plc#viral#trendingnow

0 notes

Text

Expert PLC Repair Services for Seamless Operations

In today’s fast-paced industrial landscape, automation plays a vital role in enhancing productivity and efficiency. Programmable Logic Controllers (PLCs) serve as the backbone of automation systems, ensuring smooth operations and precise control of machinery and processes. However, like any complex electronic device, PLCs are subject to wear and tear, malfunctions, and occasional breakdowns. When these issues arise, it is crucial to have access to expert PLC repair services to minimize downtime and restore operations promptly.

Unique Power Technologies understands the importance of reliable automation systems and offers comprehensive PLC repair services. With their expertise and industry-leading solutions, they ensure seamless operations for businesses across various sectors.

Why Choose Unique Power Technologies for PLC Repairs?

Technical Expertise: Unique Power Technologies boasts a team of highly skilled technicians with extensive knowledge of PLCs from various manufacturers. They are proficient in diagnosing and resolving a wide range of PLC issues, from programming errors to hardware failures. With their technical expertise, they can quickly identify the root cause of the problem and implement effective repairs.

Quick Turnaround Time: Downtime can be costly for businesses. Unique Power Technologies prioritizes efficient and timely service. Their experienced technicians work diligently to minimize repair time without compromising on quality. By swiftly addressing PLC issues, they help businesses resume operations and avoid prolonged disruptions.

OEM-Approved Solutions: As an authorized service provider, Unique Power Technologies strictly adheres to original equipment manufacturer (OEM) guidelines for repairs. They use genuine parts and components to ensure compatibility and optimal performance. By relying on OEM-approved solutions, businesses can trust in the reliability and longevity of the repaired PLCs.

Comprehensive Testing and Calibration: Unique Power Technologies goes beyond mere repairs. They conduct comprehensive testing and calibration to ensure that the repaired PLCs meet or exceed industry standards. Through rigorous testing procedures, they verify the functionality and accuracy of the PLCs, ensuring they are ready to perform flawlessly in real-world applications.

Preventive Maintenance Services: In addition to repairs, Unique Power Technologies offers preventive maintenance services for PLCs. They conduct regular inspections, cleanings, and system optimizations to identify and address potential issues before they escalate into major problems. By implementing preventive measures, businesses can extend the lifespan of their PLCs and minimize unexpected failures.

Customized Solutions: Unique Power Technologies understands that every business has unique requirements. They provide customized solutions tailored to specific industry needs. Whether it’s PLC programming, system upgrades, or troubleshooting complex network configurations, their team has the expertise to deliver personalized solutions that align with business goals.

Dedicated Customer Support: Exceptional customer support is at the core of Unique Power Technologies’ services. They prioritize clear communication, responsiveness, and transparency throughout the repair process. Their team is readily available to answer queries, provide updates, and address any concerns, ensuring a smooth and satisfactory customer experience.

Conclusion

When PLC issues occur, timely and expert repairs are essential to maintain seamless operations and avoid costly downtime. Unique Power Technologies stands as a reliable partner, offering expert PLC repair services that meet the specific needs of businesses across industries. With their technical expertise, quick turnaround time, OEM-approved solutions, and comprehensive testing, they ensure that repaired PLCs function optimally and reliably. By choosing Unique Power Technologies, businesses can count on seamless automation and uninterrupted productivity.

#PLC repair services#PLC repairing services#PLC repairing services in India#PLC repairing services in Gujarat#Best PLC repairing services#Best PLC repairing services in India

0 notes

Text

Leading Indigenous Plc Manufacturer In India: Messung

Introduction

In the realm of industrial automation, Programmable Logic Controllers (PLCs) play a vital role in controlling and monitoring complex machinery and processes. One notable player in this field is Messung, a leading indigenous PLC manufacturer based in India. With a rich history and expertise in PLC technology, Messung has established itself as a trusted name in the industry. Want to explore the various aspects of Messung's PLCs? Read on to learn about how your business is at an advantage if you opt for Messung’s PLC services.

Messung's PLC Expertise

Messung has been at the forefront of the industrial automation industry for over four decades. With a strong focus on innovation and cutting-edge technology, they have built a reputation for delivering reliable and efficient PLC solutions. Their extensive experience in designing, manufacturing, and supporting PLCs has made them a preferred partner for numerous businesses in India and beyond.

Messung offers a diverse range of Programmable Logic Controllers (PLCs) that cater to the specific needs of different industries. Let's explore some of the noteworthy PLCs provided by Messung:

NX-ERA PREMIUM PLC

The NX-ERA PREMIUM PLC is a flagship offering by Messung, designed to deliver exceptional performance and versatility. This advanced PLC boasts a powerful processor and ample memory capacity, allowing for seamless multitasking and complex control applications. The NX-ERA PREMIUM PLC supports multiple communication protocols, enabling easy integration with other automation devices and systems. Equipped with high-speed counters and advanced motion control capabilities, this PLC is ideal for applications requiring precise motion control, such as robotics and material handling systems.

NX-ERA XPRESS PLC

The NX-ERA XPRESS PLC is a compact and cost-effective solution designed for applications where space is a constraint. Despite its small size, the NX-ERA XPRESS PLC doesn't compromise on performance and functionality. It offers a wide range of built-in I/Os and supports expansion modules for additional flexibility. The NX-ERA XPRESS PLC provides reliable and precise control for various applications, such as conveyor systems, lighting control, and small-scale process automation.

XM-PRO 10 PLC

The XMPRO-10 PLC from Messung is a versatile, flexible, and easy-to-use PLC that has found its applications in a wide range of industries. The XMPRO-10 PLC offers a range of applications in various industries, such as food and beverage, chemical, automotive, textile, and pharmaceutical industries. Developed under Messung’s ‘Navonmesh-Make in India initiative’, XM-PRO 10 is a compact, capable and customisable PLC. The XM-PRO 10 PLC offers scalability, allowing businesses to expand their automation systems as per their requirements. It supports a wide range of I/O modules, communication protocols, and expansion options, providing flexibility and future-proofing.

Advanced Features and Benefits

Messung's PLCs are equipped with advanced features that enhance operational efficiency and productivity. These include high-speed processing capabilities, extensive memory capacity, and robust communication protocols. Their PLCs also offer easy programming options, enabling users to quickly develop and modify control strategies. Moreover, the rugged design and superior build quality of Messung's PLCs ensure reliable performance even in harsh industrial environments.

Diverse Applications

Messung's PLCs find applications across a wide range of industries, including manufacturing, automotive, pharmaceuticals, food processing, and energy. In manufacturing plants, Messung's PLCs are employed to automate assembly lines, monitor production processes, and control quality parameters. In the automotive industry, their PLCs help streamline assembly operations, ensuring precise control and synchronization of complex machinery. The pharmaceutical sector benefits from Messung's PLCs for precise dosage control and monitoring critical processes.

Customization and Integration

One of the key strengths of Messung is their ability to customize PLC solutions to meet specific industry requirements. They work closely with clients to understand their unique needs and develop tailored solutions that seamlessly integrate with existing infrastructure. This flexibility allows businesses to optimize their automation systems, achieve higher productivity, and reduce downtime.

Comprehensive Support and Service

Apart from their cutting-edge PLC technology, Messung stands out for its commitment to customer support. They offer comprehensive service and maintenance programs, ensuring minimal disruptions and prompt assistance when needed. Their dedicated team of engineers and technicians provides training, troubleshooting, and on-site support, guaranteeing smooth operation and maximum uptime for their clients.

Conclusion

Choosing Messung as your PLC partner offers numerous advantages. Their extensive experience and expertise in the field, coupled with advanced features and customization options, make them a reliable and trusted choice. From enhancing efficiency and productivity to ensuring precise control and seamless integration, Messung's PLCs cater to diverse industrial requirements. With a focus on customer support and service, Messung goes the extra mile to ensure client satisfaction. So, whether you are a business owner or an industry professional, considering Messung's PLC solutions is a prudent decision that can propel your automation processes to new heights.With innumerable use cases, it is no surprise that Messung is the preferred choice for businesses across different sectors. Messung's position as a leading indigenous PLC manufacturer in India is well-deserved, given their proven track record, advanced technology, and commitment to customer satisfaction. When it comes to PLCs, Messung sets the bar high, offering reliable and customized solutions that empower businesses across various industries.

#Plc Manufacturer In India#plc#programmable logic controller#plc automation#plc controller#industrial automation

0 notes

Text

Siemens PLC Dealer: Your Reliable Industrial Automation Partner

Automation has a very significant role in raising efficiency, eliminating the occurrence of errors on a human scale, and ensuring trouble-free running in the industrial scene today. Siemens is amongst the most reputable companies in industrial automation. Programmable Logic Controllers (PLCs) by Siemens can be located in most sectors of industry to carry out automation. For the best Siemens PLC purchase, there is a need to buy from a reputable Siemens PLC dealer. In this blog, we will learn why Siemens PLCs are so important, where they are used, and how to select the most suitable Siemens PLC dealer.

What is a Siemens PLC?

A Siemens PLC is an industrial heavy-duty computer used to operate equipment and processes within industries. The PLCs are programmed to carry out complex automation functions and provide smooth operations. Siemens provides numerous PLCs, with the SIMATIC S7 series being the most used one in the industry.

Why Use Siemens PLC?

Siemens PLCs are reputed to be technologically sound, long-lived, and stable. They have some superb advantages:

High Performance: Siemens PLCs are capable of handling high-speed processes with high accuracy.

Flexibility: They can be easily programmed based on any particular industry requirement.

User-Friendly Interface: Siemens offers simple-to-use programming software for PLCs.

Robust Design: Siemens PLCs have a robust design that can operate in rugged industrial environments.

Seamless Integration: They can be easily integrated with other automation products and systems.

Applications of Siemens PLCs

Siemens PLCs are extensively used in various industries such as:

Manufacturing: In order to mechanize the production lines for better efficiency.

Automotive Industry: To control robotic systems in order to manufacture automobiles.

Food and Beverages: In order to maintain quality checks at food processing factories.

Energy Sector: In order to control power generation and distribution.

Pharmaceuticals: In order to control and monitor drug production processes.

Water Treatment Plants: For automating the process of clean water treatment.

Building Automation: For controlling lighting, HVAC, and security systems in buildings.

How to Select the Best Siemens PLC Dealer

It is very important to find a trustworthy Siemens PLC dealer to get original products and quality service. The following are some of the key factors to consider when selecting a Siemens PLC dealer:

1. Authorized Dealer

Always go to an authorized Siemens PLC dealer. Authorized dealers offer authentic Siemens products with warranty and technical support.

2. Experience and Reputation

A reputed Siemens PLC dealer must be operational for decades. Verify the ratings and reviews from customers to ascertain their genuineness.

3. Product Availability

The dealer must maintain a good inventory of Siemens PLCs. In this manner, you will receive the correct PLC model appropriate for your requirements on schedule.

4. Technical Support

A good Siemens PLC dealer must provide technical assistance, such as installation, programming, and support for troubleshooting.

5. Competitive Pricing

Compare prices from various dealers to enjoy the best price without sacrificing quality.

6. Post-Sales Service

Good dealers offer post-sales service, maintenance, and software updates.

7. Training and Consultancy

A few Siemens PLC dealers also provide training sessions to educate customers on how to properly use and operate the PLCs.

Advantages of Buying from a Siemens PLC Dealer

Buying from a reputable Siemens PLC dealer has a lot of advantages:

Original Products: You receive original Siemens PLCs with documents and warranty.

Professional Advice: Dealers can assist you in selecting the appropriate PLC for your industry needs.

Prompt Support: Receive professional support for repairs and installation.

Better Pricing: Authorized distributors have better prices and deals.

Best Siemens PLC Models Available with Dealers

Some of the best Siemens PLC models that you can avail with a Siemens PLC distributor include:

Siemens SIMATIC S7-1200: Suitable for small and medium-sized automation applications.

Siemens SIMATIC S7-1500: High-performance automation for demanding applications.

Siemens LOGO!: A space-saving and low-cost solution for basic automation requirements.

Siemens SIMATIC S7-300: The most popular PLC used in every industry.

Siemens SIMATIC S7-400: Suitable for industrial automation at a higher level.

How to Purchase Siemens PLCs from a Dealer?

It is simple to purchase a Siemens PLC from a dealer if you do the following:

Know Your Needs: Determine the kind of PLC you desire according to your needs for automation.

Find a Good Dealer: Look for an authorized Siemens PLC distributor near you.

Get a Quote: Call the dealer for quotations and availability.

Check Warranty and Support: Ensure the dealer gives a warranty and technical support.

Order: Complete your purchase and have Siemens PLC shipped to you.

Obtain Installation Assistance: Take the assistance of the dealer for installation and programming, if needed.

Conclusion

Siemens PLCs play a vital role in industrial automation, and the right choice of a Siemens PLC dealer will provide you with original products, great support, and competitive pricing. Whether you are in manufacturing, automotive, energy, or any other kind of business, a trusted Siemens PLC dealer will provide the ideal automation solution. Always look at authorization, experience, product supply, and after-sales service when choosing a dealer. This will ensure seamless industrial processes with high-performance Siemens PLCs. Originally Published Here:-https://nmagroup.in/siemens-plc-dealer-industrial-automation/

0 notes

Text

PLC Control Panel Manufacturers

We are counted as the Top PLC Control Panel Manufacturers & Suppliers in Uttar Pradesh, India. Working with our engineering team, who ensure only the fine quality material are used in the manufacturing Process. The company's aim is to provide all kinds of PLC Control Panel in India.

If you have any special requirements then contact us @ +91- 9999596127, Our products are provided as per the requirements of the customers. Visit Here - https://www.krdelectrical.com/plc-panels-scada-system.html

0 notes

Text

Exploring the Role of a Public Limited Company: Understanding its Purpose in the Business World

Overview of Public Limited Company's Purpose: Limited companies are a type of general incorporation that place limits on the level of responsibility that the company's owners are willing to assume. This expression refers to a legal system that ensures that the amount of a company member's or subscriber's liability is limited to the extent of their contractual or financial investment in the company.

Assets and liabilities of a limited corporation are separate from those of the shareholders. As a result, if the company runs into financial trouble as a result of normal business operations, the shareholders' personal assets won't be in danger of being confiscated by creditors. It is simple to transfer ownership of a limited business.

The objectives of a public limited company

Expanding the business

Because their products and services are in greater demand, businesses require more funding to fund new initiatives. To generate additional money, many businesses are forced to go public. An organization that is publicly traded is more likely to raise equity to support a disproportionately larger amount of its needs. Equity financing reduces the company's ownership, but it also helps its finances by reducing debt and removing high-interest charges.

Maintaining the Company

It's possible for a firm to occasionally need more money to survive. Businesses that wish to stay in business frequently need to expand their operations. So, another important reason for a company to go public is to survive.

Gaining Profit

The main goal of Public Limited businesses is to increase shareholder wealth through profit. The company's founders could, for instance, concentrate on increasing the company's annual revenue or market share.

Increasing earnings by cutting costs and boosting sales is a typical goal. A public limited company (PLC) has the ability to raise more money than any other type of corporate entity. By expanding into new areas and creating new products, the company is able to grow quickly thanks to the additional investment.

Brand awareness

Brand recognition is valued by many public limited firms. Once a company is listed on the stock exchange, it is thought to have more prestige. As a result, it is easier to recruit top talent, draw in investors, and increase customer confidence.

In addition to going public, a business can increase brand awareness by getting involved in charitable causes, developing high-caliber goods that meet consumer needs, or having a solid marketing strategy.

Advantages of Public Limited Company

Public Shares Are Issued

A public company may issue shares to the general public in order to raise funds. It can also borrow money from a bank by putting up assets as security. It offers potential investors the possibility to buy company stock.

Shareholders may gain from liquidity as a result of being able to sell their shares on the open market. Because public corporations are also subject to greater levels of public scrutiny, the public can have more faith in the management team of a company.

Rising Financial Opportunities

Public companies have access to a wider range of financial instruments than private organizations do. This is due to the fact that public firms are subject to more scrutiny from regulators and the general public.

A public corporation has two ways to make money: selling shares to the general public and using its assets as collateral to get a loan from a bank or other financial institution, all the while providing shareholders with the opportunity to buy stock in the company.

More chances to develop and expand

The use of a public limited company is one of the most common methods for smaller businesses to go public. They can raise capital for expansion by selling shares to the general public and taking on debt. The operational and managerial accountability of public firms is also higher than that of smaller private companies.

The exchangeability of shares

A public limited company has open shareholders who are allowed to buy or sell the company's stock without the directors' consent. The freedom to transfer shares is known as "transferability of shares," and it makes it easier for public companies to attract investors than for private ones, which place restrictions on share transfers.

Public Limited Company Drawbacks

More stringent regulatory requirements

Public limited companies are subject to additional regulations than private companies. The public limited company must also hold an annual general meeting where shareholders can vote on important matters.

Ownership Issues

Shareholders of private enterprises frequently know the founders or directors. The company will be selective in who it lets become a shareholder, making sure that they support the objectives and business plans of the company.

Controlling who owns a corporation and what the directors are responsible for is substantially more complex than it is with a private limited company. This suggests that the original owners or directors of the company might no longer have control over it, might encounter difficulties, or might have to devote a lot more time to managing shareholder expectations.

Possibility of Taking Over

A small percentage of your corporation is owned by shareholders. But if they get along, they may have an impact on the strategic decisions made by your company. This implies that if a different organization decides it wants to take over your business, it may gradually buy up shares until it owns a majority of it. Once they have a decision to sell your business to the company, they will be able to compel that decision.

Conclusion

Public limited Company benefit from a variety of advantages, including the freedom to choose how they might raise capital and the enviable reputation that comes with being a public company. However, they are also subject to more regulation and inspection, which can be onerous for some organizations. Due to their greater openness to takeover offers compared to private limited corporations, they might be less long-term focused.

Read our Other Blogs on Public Limited Company to know More About it- Understanding the GST Registration Process for Public Limited Companies

#plc#public limited company#companyregistration#company#companyformation#public limited company registration#company registration in India

0 notes

Text

Company Registration in India by Mercurius & Associates LLP

Starting a business in India requires a proper legal structure, and registering a company is the first crucial step. Mercurius & Associates LLP offers seamless company registration services to help entrepreneurs establish their business with ease. Whether you are a startup or an established entity, understanding the company registration process is essential to ensure legal compliance and business growth.

Why Register a Company in India?

Registering a company in India provides several benefits, such as:

Legal Recognition – A registered company enjoys legal status and credibility.

Limited Liability Protection – Shareholders' liability is limited to their shares.

Easy Fundraising – Registered entities can raise funds from banks and investors.

Perpetual Succession – The company continues to exist even if ownership changes.

Tax Benefits – Companies can avail of various tax incentives and exemptions.

Types of Companies You Can Register

Mercurius & Associates LLP provides assistance in registering different types of companies based on business needs:

Private Limited Company (PLC) – Ideal for startups and small businesses seeking investment.

Public Limited Company – Suitable for large-scale businesses planning to raise capital from the public.

Limited Liability Partnership (LLP) – A mix of partnership and corporate structure with limited liability.

One Person Company (OPC) – Best for solo entrepreneurs wanting limited liability.

Sole Proprietorship & Partnership Firm – Suitable for small businesses with fewer compliance requirements.

Step-by-Step Process of Company Registration

Mercurius & Associates LLP ensures a hassle-free company registration process, which includes:

Step 1: Choosing the Right Business Structure

Select the company type that aligns with your business goals and legal requirements.

Step 2: Obtaining Digital Signature Certificate (DSC)

DSC is required for digitally signing incorporation documents.

Step 3: Applying for Director Identification Number (DIN)

Every director must have a unique DIN issued by the Ministry of Corporate Affairs (MCA).

Step 4: Name Approval

Propose and reserve a unique company name through the MCA’s RUN (Reserve Unique Name) service.

Step 5: Drafting & Filing Incorporation Documents

Submit essential documents, including the Memorandum of Association (MoA) and Articles of Association (AoA).

Step 6: Company Incorporation Certificate

Once approved by the MCA, you will receive a Certificate of Incorporation (COI) along with a Corporate Identity Number (CIN).

Step 7: PAN, TAN & Bank Account Setup

Post-registration, apply for PAN (Permanent Account Number) and TAN (Tax Deduction & Collection Account Number), and open a business bank account.

Documents Required for Company Registration

To register your company, you need the following documents:

PAN Card and Aadhaar Card of directors

Address proof (Utility bills, Bank statements)

Registered office address proof (Rental agreement, Electricity bill)

MoA & AoA

Passport-size photographs of directors

Why Choose Mercurius & Associates LLP?

With years of expertise, Mercurius & Associates LLP provides end-to-end assistance in company registration. Here’s why you should choose us:

Expert Guidance – Our professionals simplify legal procedures.

Quick & Hassle-Free Process – Ensuring smooth registration with minimal paperwork.

Affordable Pricing – Transparent and cost-effective solutions.

Post-Incorporation Support – Assistance with GST registration, tax filing, and compliance.

Conclusion

Registering a company in India is an essential step towards building a legally recognized business. Mercurius & Associates LLP offers expert guidance to ensure a seamless company registration process. Whether you need help with legal formalities, documentation, or compliance, our team is here to assist you at every step.

#accounting & bookkeeping services in india#audit#businessregistration#chartered accountant#foreign companies registration in india#income tax#taxation#auditor#ap management services

3 notes

·

View notes

Text

Conventional or Online? Sourcing Dilemma in the Industrial Automation Industry Resolved !

The internet has taken the world by storm. With online ordering from e-commerce retailers becoming the new norm, sourcing of components online was not to be left far behind. Here, we compare the traditional and online modes of procurement in the industrial automation industry that can enable organizations to make an informed choice.

#industrial automation#industrial control systems#plc system#industrial cellular modems#plc systems in india#industrial automation services#allen bradley products#controllogix#allen bradley plc

1 note

·

View note

Text

Sports Betting Market 2024-2032 Report Size, Share, Trends, Growth, Demand and Price

“ Sports Betting Market Research Report 2024” provides a unique tool for evaluating the Market, highlighting opportunities, and supporting strategic and tactical decision-making. The Sports Betting market research report serves as a cornerstone for the advancement of businesses, irrespective of their scale. Employing unparalleled and established methodologies like SWOT analysis and Porter’s Five Forces analysis, the report facilitates forecasting, analysis, and estimations. It encompasses competitive analysis of key market players, empowering businesses to make informed decisions to bolster their products and sales. Grounded in SWOT analysis, the market insights and analysis provided in the Sports Betting market survey report instill confidence in businesses.

Get Full PDF Sample Copy of Report (Including Full TOC, List of Tables & Figures, Chart) https://www.econmarketresearch.com/request-sample/EMR00547/

The global Sports Betting Market report by wide-ranging study of the Sports Betting industry which covers comprehensively all aspects of the different industry verticals. This includes its past performance analysis, latest market performance estimation for the current year based on the Drivers, Challenges & Trends.

Global Sports Betting Market Breakdown:

By Type:

Based on type, the global sports betting market is divided into fixed odds wagering, exchange betting, live/in-play betting, pari-mutuel, e-sports betting, and others. The fixed odds wagering category dominates the market with the largest revenue share in 2023. Bettor placement at predefined odds established by the bookmaker is known as fixed odds wagering. Regardless of future fluctuations in the odds, the possible payoff is known at the time the wager is made and cannot be altered.

By Applications:

Based on application, the global sports betting market is segmented into draw games, instant games, lotto, number games, and others. The draw games segment dominates the sports betting market. Participants in draw games choose numbers or combinations, and random drawings are used to determine the winners. Instant games usually use scratch-off tickets or their digital equivalents to deliver outcomes instantly. In order to be eligible to win rewards, players of lotto games usually have to choose a certain set of numbers.

Based on regions, Sports Betting Market is classified into North America, Europe, Asia- Pacific, Middle East & Africa, and Latin America

Middle East and Africa (GCC Countries and Egypt)

North America (United States, Mexico, and Canada)

South America (Brazil, Argentina etc.)

Europe (Turkey, Germany, Russia UK, Italy, France, etc.)

Asia-Pacific (Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia)

This Free report sample includes:

A brief introduction to the Sports Betting Market research report.

Graphical introduction of the regional analysis.

Top players in the Sports Betting Market with their revenue analysis.

Selected illustrations of Sports Betting Market insights and trends.

Example pages from the Sports Betting Market

Who are the key Top Competitors in the Global Sports Betting Market?

Following are list of players:

888 Holdings Plc

Bet365

Betsson AB

Churchill Downs Incorporated

Entain plc

Flutter Entertainment Plc

IGT

Kindred Group Plc

Sportech Plc

William Hill Plc, and various others

Crucial Research:

During the first survey, we interviewed various key sources of supply and demand to obtain qualitative and quantitative information related to Sports Betting report. Key supply sources include key industry participants, subject matter specialists from key companies, and consultants from several major companies and organizations active in the Sports Betting market.

Minor Research:

The second study was conducted to obtain key information on the supply chain of the Sports Betting industry, the market’s currency chain, pools of major companies, and market segmentation, with the lowest level, geographical market, and technology-oriented perspectives. Secondary data was collected and analyzed to reach the total Global Sports Betting market size, which was verified by the first survey.

Competitive Landscape:

Mergers & Acquisitions, Agreements & Collaborations, New Product Developments & Launches, Business overview & Product Specification for each player listed in the study. Players profiled in Sports Betting market are

Some Notable Report Offerings:

– We will provide you an analysis of the extent to which the global Sports Betting acquires commercial characteristics along with examples or instances of information that helps you to understand it better.

– We will also help to identify customary/ standard terms and conditions, as like offers, worthiness, warranty, and others for the Sports Betting industry.

– Also, this report will help you to identify any trends to forecast Sports Betting growth rates.

– The analysed report will forecast the general tendency for supply and demand in Sports Betting market.

For More Information or Qurey, Visit @ https://www.econmarketresearch.com/industry-report/sports-betting-market/

Key Highlights of Report

Overview of key market forces propelling and restraining market growth

Offers a clear understanding of the competitive landscape and key product segments

An analysis of strategies of major competitors

Detailed analyses of industry trends

A well-defined technological growth map with an impact-analysis

Provides profiles of major competitors of the market.

Details of their operations, product and services.

Recent developments and key financial metrics.

Browse Related Reports:

Computer Aided Design (CAD) Market Size

Smart Agriculture Market Share

Vertical Farming Market Growth

Automotive Motors Market Analysis

ISO Tank Container Market Revenue

Semiconductor Market Rate

Medical Devices Market Forecast

Biotechnology Market Industry

Hydrogen Compressor Market Size

Cold Chain Logistics Market Share

SOC Containers Market Growth

System On Chip (SoC) Market Analysis

Digital Forensics Market Revenue

Material Handling Equipment Market Rate

Floating Solar Panels Market Forecast

Agriculture Equipment Market Industry

AI Training Dataset Market Size

Automated Data Platform Market Share

Cancer Supportive Care Drugs Market Growth

Medical Coating Market Analysis

Portable Oil-Free Air Compressor Market Revenue

Modular Data Center Market Rate

Electric Generator Market Forecast

Golf Simulator Market Industry

Automotive Infotainment Market Size

Vegan Food Market Share

2D Barcode Reader Market Growth

Artificial Intelligence In Agriculture Market Analysis

Coiled Tubing Market Revenue

Distributed Antenna System Market Rate

EV Charging Infrastructure Market Forecast

Food Coating Ingredients Market Industry

Artificial Intelligence Sensors Market Size

Deception Technology Market Share

Forklift Market Growth

Silicon Battery Market Analysis

Solid State Battery Market Revenue

Intelligent Transportation System Market Rate

Network Switches Market Forecast

Perovskite Solar Cell Market Industry

Quantum Computing Market Size

Thermal Management Market Share

Application Delivery Controller Market Growth

Bioinsecticides Market Analysis

Compressor Oil Market Revenue

Connected Mining Market Rate

Cosmetic Antioxidants Market Forecast

Digital Dentistry Market Industry

Edible Offal Market Size

Fire Truck Market Share

Food Antioxidants Market Growth

#Sports Betting#Sports Betting Market#Sports Betting Market 2024#Sports Betting Market Analysis#Sports Betting Market Analysis in Developed Countries#Sports Betting Market by Application#Sports Betting Market by Type#Sports Betting Market Development#Sports Betting Market Forecast#Sports Betting Market Forecast to 2026#Sports Betting Market Future Innovation#Sports Betting Market Future Trends#Sports Betting Market in Asia#Sports Betting Market in Australia#Sports Betting Market in Europe#Sports Betting Market in France#Sports Betting Market in Germany#Sports Betting Market in Key Countries#Sports Betting Market in United Kingdom#Google News#Sports Betting Market is Booming#Sports Betting Market Latest Report#Sports Betting Market Rising Trends#Sports Betting Market Size#Sports Betting Market Size in United States#Sports Betting Market SWOT Analysis#Sports Betting Market Updates

2 notes

·

View notes