#PCBA manufacturer

Explore tagged Tumblr posts

Text

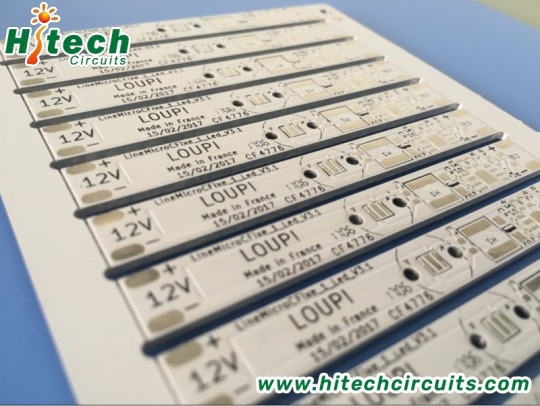

PCB Manufacturing-PCB Assembly-Hitech Circuits

Hitech Circuits is a lеаding PCB Manufacturing & PCB Assembly company with more than 20 years experience in the electronics manufacturing industry. We focus on PCB Design, PCB Layout, Circuit board fabrication, Turnkey PCB assembly, and electronic parts sourcing services.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

We offer a full range of Electronic manufacturing services.

-LED PCB

-Heavy Copper PCB

-Multilayer PCB

-HDI PCB

-Flexible PCB

-Rigid-Flex PCB

-High Speed PCB

-High Frequency PCB

-PCB Reverse Engineering

7 notes

·

View notes

Text

hi,I'm zoe,a sales engineer in the Shenzhen STHL Electronics Co.,Ltd.we are a professional PCB & PCBA manufacturing servicer with more than 18 years of experience located in Shenzhen, China. Mainly provide services of electronic components sourcing + PCB fabrication + PCB Assembly + Housing assembly + Function testing services.

Our factory covers 7000+ square meters, has 5 (Panasonic) high-speed SMT production lines, 2 DIP lines, 2 testing lines, and 180+ workers, passed ISO9001, ISO14001, ISO13485 and IATF 16949 certifications, win recognization by Littelfuse, Hisense,Surfilter, etc.

2 notes

·

View notes

Text

#pcb#pcba#pcbassembly#pcb manufacturer#pcb board#pcb factory#pcb fabrication#aluminum pcb#pcb design#pcb prototype

2 notes

·

View notes

Text

What is PCB Assembly ?

PCB Assembly manufacturer - Hitech Circuits Co., Limited

It’s the step in the manufacturing process in which you populate a blank board with the electronic components needed to make it into a functional printed circuit board. It’s these components that make a board into the circuit that enables an electronic product to function. PCB assembly typically takes place via one of two processes:

1. Surface-mount technology

SMT: SMT stands for “Surface Mount Technology“. The SMT components are very small sizes and comes in various packages like 0201, 0402, 0603, 1608 packages for resistors and capacitors. Similarly for Integrated circuits ICs we have SOIC, TSSOP, QFP and BGA.

The SMT components assembly is very difficult for human hands and can be time taking process so it is mostly done by automated pick and place machine.

2. Through-hole manufacturing

THT: THT stands for “Through hole Technology”. The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Printed Circuit Board Assembly Techniques

There are only two common PCBA techniques available for use by a PCB designer. The methods are:

1. Automated PCB Assembly Techniques

Generally, this technique employs the use of state of the art machines, which are fully automatic. For example, the surface mount components are worth positioning with the aid of an automated pick and place machine.

Again, reflow soldering is commonly for surface mount components usually done in a reflow oven. An automated solder stencil is also used to apply the solder paste on the PCB.

Finally, high tech inspection machines are used to confirm and check the quality of the PCBA. Some of which include: Automated optical inspection machine (AOI), X-ray inspection machines, etc.

Above all, due to the precise monitoring, control of soldering, no human input and versatile machines.

This technique ensures utmost efficiency, output consistencies, and limits defects.

2. Manual PCB Assembly Techniques

This method is favorite for use with through-hole parts, which needs manual placement on the board. Besides, with these through-hole parts, it’s advisable you use wave soldering. Note that in the through- hole assembly process, you need to place the components and electronics on the PCB.

After that, you use wave soldering to solder the leads. Typically, you will need an individual to insert a component into a marked PTH. Once done, transfer the PCB to the next station where the next person will be on standby tasked with fixing another part.

What are the Benefits of SMT PCB Assembly?

SMT assembly provides many benefits and some of them are as follows:

It can be used to incorporate small components.

In SMT, the components can be placed on both sides of the board.

It assures high component densities.

Fewer holes need to be drilled for surface mounting than through-hole.

It require low initial costs and time for setting up the mass production.

SMT is the simpler and faster-automated assembly when compared to through-hole.

Errors regarding the component placement can be easily rectified.

Surface mount PCBs feature strong joints, which can easily withstand vibrations.

What are the techniques used in Surface Mount Technology?

There are several techniques for the reflow process. After applying the solder paste or a flux mixture on the board and after placing the components, the boards are conveyed to a reflow soldering oven. The techniques used for reflowing soldering include infrared lamps, hot gas convection, fluorocarbon liquids with a high boiling point, and so on.

What are the different testing methods used in SMT PCB Assembly?

Hitech Circuits as the PCB assembly manufacturer, we perform the following testing and inspection to ensure the quality of surface mount PCBs.

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

What type of files or documents should I send for SMT PCB Assembly?

Gerber Files: The file contains all details of physical board layers including solder masks, copper layers, drill data, legends, and so on.

Bill of Materials (BOM): This contains information on the list of items needed for the PCB manufacturing and the instructions of manufacturing.

Pick and Place File: This file contains information on all components to be used in the PCB design and their rotation and X-Y coordinates.

The whole process of PCB Assembly

1. Bare board loader machine

The first step in the PCB assembly is to arrange the bare boards on the rack, and the machine will automatically send the boards one by one into the SMT assembly line.

2. Printing solder paste

When PCB on the SMT production line, firstly, we have to print solder paste on it, and the solder paste will be printed on the pads of the PCB. These solder pastes will be melt and solder the electronic parts to the circuit board when it passes through the high-temperature reflow oven.

In addition, when testing new products, some people will use film board/adhesive cardboard instead of solder paste, which can increase the efficiency for adjusting the SMT machines.

3. Solder paste inspection machine(SPI)

Since the quality of solder paste printing is related to the quality of welding of subsequent parts, some SMT factories will use optical machine to check the quality of solder paste after printed the solder paste in order to ensure stable quality. If there any poorly printed solder paste board, we will wash off the solder paste on it and reprint, or remove the excess solder paste if there is redundant solder paste on it.

4. High speed SMT machine

Usually, we will put some small electronic parts (such as small resistors, capacitors, and inductors) to be printed on the circuit board first, and these parts will be slightly stuck by the solder paste just printed on the circuit board, so even if the speed of printing is very fast and the parts on the board will not fall away. But large parts are not suitable for use in such high speed SMT machines, which will slow down the speed of small parts assembly. And the parts will be shifted from the original position due to the rapid movement of the board.

5. Universal SMT machine

Universal SMT machine is also known as "slow machine", it will be assembled some large electronic components, such as BGA IC, connectors, etc., these parts need more accurate positions, so the alignment is very important. Use a camera to take a picture to confirm the position of the parts, so the speed is much slower than High speed SMT machine we taked before. Due to the size of the components here, not all of them are packed in tape and reel, and some may be packed in trays or tubes. But if you want the SMT machine to recognize the trays or tube-shaped packaging materials, you must configure an additional machine.

Generally, traditional SMT machines are using the principle of suction to move electronic parts, and in order to place the parts successfully, and there must be the flat surface on these electronic components for the suction nozzle of the SMT machine to absorb. However, for some electronic parts don’t have a flat surface for these machines, and it is necessary to order special nozzles for these special-shaped parts, or add a flat tape on the parts, or wear a flat cap for thees electronic parts.

6. Manual parts or visual inspection

After assembled all parts by the high speed SMT machine or Universal SMT machine and before going through the high-temperature reflow oven, and we will set up a visual inspection station here and to pick out the deviation parts or missing components boards etc., because we have to use a soldering iron to repair if there are still defectives boards after passing the high-temperature oven, which will affect the quality of the product and will also increase the cost. in addition, for some larger electronic parts or traditional DIP parts or some special reasons cannot be processed by the SMT machine before, they will be manually placed on pcb here.

7. Reflow oven

The purpose of reflow oven is to melt the solder paste and form a non-metallic compound on the component feet and the circuit board, that means to solder electronic components on the circuit board. The temperature rise and fall curves often affect the soldering quality of the entire circuit board. According to the characteristics of the solder materials, usually the reflow oven will set the preheating zone, soaking zone, reflow zone, and cooling zone to achieve the best soldering effect.

For example, the melting point for SAC305 solder paste with lead-free is about 217°C, which means that the temperature of the reflow oven must be higher than the melting points to remelt the solder paste. What's more, the maximum temperature in the reflow furnace should not exceed 250°C, otherwise many parts will be deformed or melted because they cannot withstand such a high temperature.

Basically, after the pcb passed through the reflow oven, the assembly for the entire circuit board is almost complete. If there are hand-soldered parts, we need to transfer to DIP process, and then we have to check the quality after reflow oven by QC department.

8. Automatic optical inspection(AOI)

The main purpose of setting up AOI is because some high density boards can’t be process the following ICT test, so we used AOI inspection to replace it. But even using AOI inspections, there still have the blind spots for such checking, for example, the solder pads under the components cannot be checked by AOI. At present, it can only check whether the parts have side standing issue, missing parts, displacement, polarity direction, solder bridges, lack of soldering etc., but cannot checking the BGA solderability, resistance value, capacitance value, inductance value and other components quality, so far AOI inspection can’t completely replace ICT test.

Therefore, there is still some risk if only AOI inspection is used to replace ICT testing, but ICT test is also not 100% make sure the good quality, we suggest these two ways can be combined with together to make sure the good quality.

9. PCB unloader machine

After the board is fully assembled, it will be retracted to the unloder machine, which has been designed to allow the SMT machine to automatically pick and place the board without damaging the quality for PCB.

10. Visual inspection for finished products

Normally there will be a visual inspection area in our SMT production line whether there is an AOI station or not, and it will help to check if there are any defectives after completed assembled the pcbs. If there is an AOI station, it can reduce the visual inspection worker on our SMT line, and to reduce the potential cost, and because it is still necessary to check some places that cannot be judged by AOI, many SMT factories will provide the mainly visual inspection templates at this station, which is convenient for visual inspection worker to inspect some key parts and polarity for components.

11. DIP process

DIP process is a very important process in the whole PCBA processing, and the processing quality will directly affect the functional for PCBA boards, so it is necessary to pay more attention to the DIP process. There are many preliminary preparations for DIP process. The basic process is to re-process the electronic components first, like to cut the extra pins for some DIP components, our staff received the components according to the BOM list, and will check whether the material part numbers and specifications are correct or not, and performs pre-production pre-processing according to the PCBA samples. The steps are: Use various related equipment (automatic capacitor pins cutting machine, jumper bending machine, diode and triode automatic forming machine, automatic belt forming machine and other machines) for processing.

12. ICT test

Printed Circuit board open/short circuit test (ICT, In-Circuit Test), The purpose of ICT test is mainly to test whether the components and circuits on the printed circuit board are open or short issues. It can also measure the basic characteristics of most components, such as resistance, capacitance, and inductance values to judge whether the functions of these parts are damaged, wrong parts or missing parts etc. after passing through the high-temperature reflow oven.

ICT test machines are divided into advanced and basic machines. The basic ICT test machines are generally called MDA (Manufacturing Defect Analyzer). It’s just to measure the basic characteristics of electronic components and judge open and short circuits issue we talked above.

In addition to all the functions of the basic ICT test machines, for advanced ICT test machine can also test the whole PCBA by using power, start to testing the PCBA boards by setting the program in the test machine. The advantage is that it can simulate the function of the printed circuit board under the actual power-on condition, this test can partly replace the following functional test machine (Function Test). But the cost for the test fixture of this advanced ICT test can probably buy a car, it’s too expensive and we suggest it can be used in mass production products.

13. PCBA function test

Functional testing is to make up for the ICT test, because ICT only tests the open and short circuits on the the PCBA board, and other functions such as BGA and other fuctions are not tested, so it is necessary to use a functional testing machine to test all functions on the whole PCBA board.

14. Cutting board (assembly board de-panel)

Normally, printed circuit boards will be produced in panel, and it will be assembled to increase the efficiency of SMT production. It means several single boards in one panel, such as two-in-one, four-in-one etc. After finished all the pcb assembly process, it needs to be cut into single boards, and for some printed circuit boards with only single boards also need to cut off some redundant board edges.

There are several ways to cut the printed circuit board. You can design the V-cut using the blade cutting machine (Scoring) or directly manually break off the board (not recommended). For more high density circuit boards, it will be used the professional splitting machine or the router to split the board without any damage the electronic components and printed circuit boards, but the cost and working hours will be a little longer.

Why Choose Hitech Circuits PCB Assembly Manufacturer for Your PCB Assembly Projects?

There are several PCB manufacturers specializing in PCB assemblyservices. However, Hitech Circuits PCB Assembly stands out owing to the following:

Assistance in Material Procurement:

Technically, in PCB assembly services, the quality of parts is the responsibility of the OEM; however, we ease your job by assisting you to make the right selection. We can help you procure all your parts of the same type own a single part number, thanks to our supply chain and vendor network as well as experience. This saves time and cost that goes in ordering single parts as you plan.

Testing procedures:

We are very focused on quality and thus implement stringent testing procedures at each stage of the assembly and after completion.

Fast Turnaround Times:

Our well-equipped facility and the right tools enable us to complete your requirements well before time, and without compromising on the quality or functioning of the PCBs. For simple designs we revert in 24 to 48 hours.

Cost Effectiveness:

While PCB assembly is a cost-effective alternative, we go a step further and assure that the parts you list are of a good quality and suitable for your requirement. Also, you can control the part flow and replenish them as needed. This eliminates the need to buy extra stock and store it.

Quick Quote:

We offer a quick quote based on your BOM. All you need is a detailed BOM, Gerber files, your application requirement sheet, and quantity.

We’re not one to stand still, which is why we use the latest equipment and the finest minds to create your PCB projects. We’re constantly keeping our finger on the pulse of the latest trends. And as a result, we know how to deliver the highest standards of PCB assembly to meet all your requirements.

Our dedicated, friendly customer service team also means that we support you every step of the way. Offering our expert guidance to ensure a complete PCB project that you’re happy with.

Contact us today

No matter what your printed circuit board assemblyneeds are, we always aim to deliver efficient, dependable solutions. For more information about our services, do not hesitate to get in touch with us today for a no-obligation quote

2 notes

·

View notes

Text

Printed circuit board manufacturing which is our major business, I think you already know, we are a PCB manufacturer. We have 3 branch factories dedicated to Quick Turn PCB Prototypes Manufacturing, Small and Medium-volume Printed Circuit Board, FPC Manufacturing services and PCB assembly services. Our market target is the High Multilayer PCB, High Density PCB, Flexible PCB, Rigid-flex PCB, Heavy copper PCB, Rogers PCB, Ceramic PCB and Special Materials Printed Circuit Boards.

Also, we can help customer sourcing components, wire PCB assembly and provide one-stop service.

Hitech Group is capable of providing full turn-key and partial turn-key PCB assembly services. For full turn-key, we take care of the entire process, including manufacture of Printed Circuit Boards, procurement of components, order tracking, continuous monitoring of quality and final board assembly. Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

4 notes

·

View notes

Text

Aluminium PCB

Aluminium PCB are metal-based, copper-clad laminates with a good heat dissipation function. Usually, Aluminium PCB is refer to LED PCB board, which is the most important part of LED display and lighting products, etc.

Hitech Circuits Co., Limited is a professional aluminum pcb board, LED PCB manufacturer in China. Through 10 years of aluminum pcb board designing and manufacturing experience, Hitech are able to provide high quality and cost effective single layer, double layer and multi layer aluminum pcb boards to global customers. For any of your requirements regarding aluminum pcb board, please don’t hesitate to contact [email protected]

#Aluminium PCB#aluminum pcb#pcb assembly#pcb#engineering#technology#pcba#pcb manufacturer#pcbassembly#pcb design#hardware

5 notes

·

View notes

Text

One-stop PCB assembly service and PCB manufacturing supplier -- Hitechpcba

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

4 notes

·

View notes

Text

📢 Elecrow #PartnerSeller Program Product #Newarrival 🔥 🔱 Introducing the #EncoderCounter, meticulously designed by Y2Kb! This advanced device accurately displays and outputs the count of incremental output encoder pulses. 😻 #ElecrowPCB 🚀 #PCBA, selling, and shipping services provided by #Elecrow. For more info 👇 https://www.elecrow.com/encoder-counter.html?utm_source=tumblr&utm_term=idd=2

2 notes

·

View notes

Text

#hardware design#hardware design services#pcb assembly#pcb design#pcb manufacturer#pcba#pcbassembly#electronics design#automotive electronics

2 notes

·

View notes

Text

We are a 20 years PCB&PCBA factory.

4 notes

·

View notes

Text

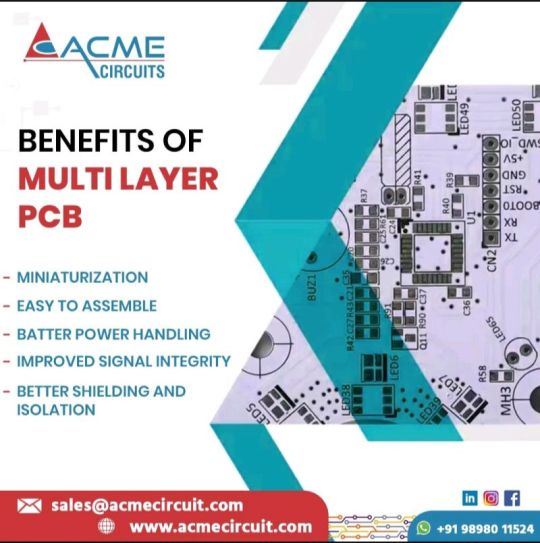

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

#pcb#pcba#pcbassembly#aluminum pcb#pcb design#pcb fabrication#pcb factory#pcb manufacturer#pcb board#pcb prototype

2 notes

·

View notes

Text

Electronic Manufacturing Services

Hitech Circuits has always been focused on electronic manufacturing services for over 15 years with much experience for design and production in the PCBA field. We provide one-stop services, including SMT mounting, plug-in (THT), electronic component procurement and sourcing, finished product assembly, testing, and other comprehensive services.

From the introduction of new products to the provision of customized components, to stable production, we provide solutions for the entire product lifecycle, enabling our customers to achieve success. Hitech Circuits creates value for customers through advanced value engineering services, customized component solutions, global factory layout, and high-level supply chain management.

We have introduced advanced imported production and testing equipment, and have been committed to the development of new technologies for a long time, implementing comprehensive quality management and environmental management. Therefore, we have become an industry leader with highly competitive prices, ultra-high product stability, reliable delivery guarantee, and excellent service.

One stop electronics manufacturing service

One stop electronic manufacturing service: providing agency component procurement, circuit board supply, and design and application of built-in electronic devices for brand electronic equipment manufacturers.

Provide and solve the entire process from electronic consumer goods to electronic circuit assembly. At the same time, it is equipped with some warehouse logistics management, quality control, and technical services.

Hitech Circuits provides customized services to every customer, forming a professional team to serve a single customer, from sample production, trial production, to mass production, aiming to help customers' products go public in the shortest possible time. Please refer to the one-stop service process we provide for customers as shown in the diagram:

Engineering Services

NPI New Product Introduction

A professional team composed of departments such as engineering, quality assurance, materials, and production management, serving a single customer, strictly overseeing every step of production for the customer.

Provide DFM and DFT reports for customer new product development

The product engineer acts as the communication coordinator for engineering related issues between the customer and the internal team, integrating internal information to help the customer eliminate problems as soon as possible.

Based on the trial production results, discuss and propose improvement measures and suggestions in the trial production report to assist customers in rapid mass production and marketing of their products.

Design Optimization for DFM/DFT Manufacturability and Testability

DFM (Design for Manufacturing)

DFM refers to the consideration of manufacturing capabilities during product design. Through Hitech Circuits electronics' DFM report, it can assist customers in early detection of design issues, reduce the time for repeated trial production verification, save material and labor costs, improve product production quality, and accelerate mass production speed.

Design For Testing

In the PCB layout stage of the product, the Hitech Circuits Electronic Engineering team can analyze the Gerber files and make empirical judgments through software to determine the testing coverage of the PCB and the potential risk of failure during the testing phase. This allows customer RD personnel to modify the circuit diagram as soon as possible, reducing the difficulty of future release engineering design changes.

ECO/ECR/ECN Engineering Specification Change Management

Engineering change management services include:

ECO Engineering Change Order: usually initiated by customer RD to correct design issues.

ECR Engineering Change Request: typically initiated by the process engineer of the OEM factory, such as requesting customers to change parts to improve SMT/DIP/assembly yield.

ECN Engineering Change Notice: usually issued by the DCC (Document Control Center) document management center to notify relevant units that the BOM has been changed.

Supplier management includes:

Control the quality and cost of key materials for strategic planning.

Establish good relationships with suppliers to achieve stable supply.

Understand supplier quality systems and production processes to ensure material quality.

Regularly audit the quality, price, and delivery time of suppliers.

Improve communication efficiency between customers, Hitech Circuits and suppliers through the delivery platform.

Exchange experience and resources with suppliers to establish a win-win partnership.

Always rely on unparalleled quality to meet your EMS needs on time. Our core point is always to deliver quality on time, as Hitech Circuits 's core belief is that each functional department and its related processes must be integrated throughout the entire enterprise. An integrated product delivery system method for managing.

Always rely on unparalleled quality to meet your any EMS needs on time.

Always delivering quality on time is our top priority. We start with Hitech Circuits 's core belief that each functional discipline and its related processes must be integrated throughout the entire enterprise. The integrated product delivery system approach for managing business helps to ensure that each customer's plan meets or exceeds all technical and commercial requirements of the customer. In order to successfully become an electronic manufacturing service (EMS) provider among today's competition, the factory must be able to do all of this and do it well throughout the entire product lifecycle. Hitechpcba will try the best to meet different customers’ requirements.

Why are more and more customers choosing PCBA one-stop service?

More and more customers are asking if their suppliers can provide PCBA one-stop service. Many of them purchased these two types of circuit boards and components separately after discovering them.

Therefore, more and more customers are choosing Printed circuit board & electronic components one-stop procurement services for the following reasons.

Firstly, the sales channels for components are networked, and prices tend to be transparent.

At present, the entire component sales network is actually available. You can find any type of material by entering the online model, price, manufacturer's production status, and whether there is inventory. In fact, the entire process is very simple. If the company purchases on its own, it needs to ask someone who knows the materials if the component supplier is genuine and when it can be shipped. But in this way, the final purchased materials may have the same price as the supplier, which is equivalent to spending more money on the same thing.

Secondly, labor costs increase and own cost decrease to cope with uncertainty

Faced with the current unstable situation, we can indeed feel that orders are not actually increasing, but decreasing. It is absolutely impossible to reduce labor costs without increasing orders. The entire PCBA one-stop service includes the entire budget, with controllable prices and no other costs, reducing uncertainty.

Thirdly, delegate professional affairs to a more professional team for handling

Compared to General Solutions, it may not have much understanding of the current price trends of PCB boards and components, as well as new SMT technologies, as it does not involve specific backend production processes. But PCBA manufacturers have to handle these backend processes every day. The engineers at the PCBA processing plant are very clear about what type of board and solder paste to use in what industry.

The most important point is that PCBA manufacturers have many customers and there is also a high demand for parts procurement. Correspondingly, you can obtain more terminal channels, thereby obtaining more products, so the price will definitely be lower and the quality will definitely be guaranteed. After all, end distributors do not want to lose their main customers. If you purchase from one company, you may not be able to meet the lowest quotation from other companies.

Are you looking for a reliable one-stop PCB assembly services provider for the electronic product of you company?

Hitech Circuits, an advanced PCB one-stop-shop solution provider, will show what is the one-stop electronic assembly services in this article below.

Chapter 1: What does it have in One-Stop PCB Assembly Services?

Chapter 2: One-Stop PCB Assembly Services Provider - HITECH CIRCUITS

Part 1: What does it have in One-Stop PCB Assembly?

One-stop PCB assembly belongs to electronics manufacturing services, and it includes PCB design, PCB manufacturing, electronic components sourcing, and PCB assembly.

The collaboration model between electronics solution companies and the one-stop PCB assembly service provider Hitech Circuits is:

Electronics solution companies work on project designs for product research and development > Hitechpcba reduces the project costs through appropriate PCB design > PCB manufacturing, assembly, test, and other services > shipping.

One-Stop PCB assembly specific process of Hitech Circuits:

Step 1. PCB board designing (optional) and PCB reverse

HITECH CIRCUITS can help the customers to improve the PCB design. If you have completed the PCB design, our professional engineers will check carefully your design to make sure everything is OK. We also can design the board for the customers. we need schematic source files or netlists, structure diagrams (dxf) and design requirements. If no schematic source files or netlists, it needs to provide a package library (if no package, need to provide a component data manual).

Besides, we also can do the PCB reverse engineering. if you can send me 2 good sample boards.

1.Tell me these details (Layers, board size, raw materials.) then we can give you a quote about making Gerber files and BOM.

this is the first step. If you agree with the quote, then you can send me board;

2.after making files, then we quote production cost for you. If you don't agree the production cost, then you just need to pay us the cost of making files.

Step 2. PCB board manufacturing

Before bulky PCB manufacturing, HITECH CIRCUITS can manufacture samples according to customers’ requirement and do the DFM, DFT, and DFX (design for manufacturing, test, excellence).

The PCB manufacturing process is:

PCB material preparation and processing > laminate PCB layers on the core > generate circuits on PCB layers > AOI (automatic optical inspection) > mechanical and laser drill on PCB layers > electroplate PCB holes by VCP (vertical continuous plating) > print solder mask and surface finishes > process the PCB edges > four-terminal sensing test (for boards of defense, aerospace, medical, automotive uses)

Meanwhile, we manufacture the SMT stencils for PCB assembly.

Step 3. Electronic components sourcing

HITECH CIRCUITS has its electronic component warehouse, with commonly-used components and some discontinued ST/TI components in stock. According to your BOM, we provide all components you want.

We source the components from local and reliable electronic components factories and direct suppliers from the globe. Through regional price differences, we can provide the best prices for you. All the electronic parts components are original ones.

Step 4. PCB assembly service

Before bulky PCBA manufacturing, we assemble 5 PCB boards and randomly choose one for the first article inspection (FAI). We generate an FAI report and send it to our client. We will start bulky PCB assembly when the client reviews and approves it.

The PCB assembly process is: solder paste printing > solder paste inspection > SMT assembly (high-speed assembly and function assembly) > X-ray inspection if there is BGA > reflow soldering > AOI > THT assembly > wave soldering > functional test (optional) > IC programming (optional) > thermal aging (optional) > conformal coating (optional) > box-built assembly (optional)

Step 5. Final shipping

We have our warehouse for printed circuit boards and PCBA. We will use FedEx, DHL, or UPS to deliver the boards to you as soon as possible. (Usually, we recommend FedEx. since it is cheaper). We also have our own forwarder which can provide competitive price.

Part 4: One-Stop PCB Assembly Services Provider – Hitech Circuits

HITECH CIRCUITS is a leading and professional one-stop solution provider of electronics manufacturing services for the customers around the world. Hitech Circuits can provide good services with good quality on time

Our one-stop PCB assembly services target clients are from the industry of automotive, industrial, medical, defense, aerospace, communications, and consumer electronics, etc.

Here are the reasons to work with Hitech Circuits for one-stop PCB assembly:

One-stop PCB assembly certified with ISO, IATF, REACH, UL, RoHS, and IPC standards

Complex PCB manufacturing and assembly from design and prototypes to bulky production

One-on-one engineering support with free DFM, DFT, and DFX for one-stop PCB assembly projects

Electronic components sourcing for one-stop PCB assembly without profit from

Complete PCB/PCBA tests and services available, such as four-terminal sensing, IC programming, conformal coating

Electronics manufacturers need a dependable partner to supply the electronic chip that goes into all our smart electronic gadgets. Whether it’s a luxury car or smartwatch, a remote-controlled child’s toy or a glucose monitoring kit at your local health store, the crucial printed circuit board (PCB) is an essential component.

Manufacturing a PCB involves a series of complex steps: printing and storing circuit boards, procuring electronic components, assembly, and testing to ensure functionality to specifications. Traditionally, OEMs used a multi-vendor, multi-partner approach to PCB sourcing, manufacturing, assembly, and testing. However, this method was too cumbersome, slow, expensive and error-prone. As a result, the demand for ready-to-use PCBs snowballed, and one-stop PCB assembly services became the preferred choice for electronics manufacturers and designers.

The importance of a one-stop PCB assembly services provider

End-to-end service providers give OEMs a competitive edge. They can turn their ideas into efficient electronics products, get them out into the market before their competition, and achieve early monetization.

When working with a one-stop PCBA (printed circuit board assembly) service provider, the same vendor sources components and assembles the PCB. Maintaining a single point of contact for the entire manufacturing process eases communication in case of any problems, changes, or modifications. As a result, you can resolve issues quickly and efficiently, eliminate bottlenecks in the production process, and significantly reduce PCB production lead times.

Hitech Circuits is your ideal partner for one-stop PCB assembly services. We procure high-quality electronic components based on your PCB design. Our advanced electronics assembly solutions and superior customer service support you throughout the assembly process till the PCB board is tested and shipped to your promises.

HITECH CIRCUITS turnkey PCB solutions: Contributing to every stage of PCB production

OEMs prefer to work with one-stop PCB assembly manufacturers to provide services at every production stage:

Components procurement: Careful selection and timely procurement of components are key to an efficient PCB assembly process. The HITECH CIRCUITS procurement team studies details of the PCB design and layout before placing the orders for components to avoid problems in the layout later on.

Component placement: If the electronic components are not placed correctly on a blank circuit board, it can cause problems during assembly. It may result in incorrect soldering and can even cause shorts and failures in some or all of the automated processes.

PCB board layout: The schematic layout of the circuit board is decided during the PCB design process. Design choices affect the cost and delivery schedule of PCBs. Complex PCBs require longer procurement lead times and fabrication time. Therefore, coordination with the design team is critical to meeting cost and delivery targets. A one-stop provider can keep track of all the connections or interfaces that the design may require and accommodate them in the manufacturing schedule and costs.

Testing: HITECH CIRCUITS provides comprehensive testing services for PCB components and functionality. Our powerful tests include Automated Optical Inspection (AOI), X-Ray tests, in-circuit tests, flying probe, Jtag. We will not let any board pass through unless it’s perfect!

Hitech Circuits partners with you from the PCB design phase to maximize the benefits of DFM for product development, including making the right components selection and placement decisions, and finally through to production and testing.

The advantages of using one-stop PCB assembly services

There are many advantages to using a single company like HITECH CIRCUITS for end-to-end PCB manufacturing and assembly:

Reduce PCB fabrication and assembly costs: Since our one-stop PCB services cover all processes, including fabrication and assembly, there is no need for shipping components and boards from one vendor to another. Your Bill of Materials (BOM) cost is also optimized as we efficiently source difficult-to-find and long lead-time components. With all processes under one roof, you save on production costs.

Detect errors and issues early: An end-to-end service can spot potential errors and detect potential issues very early in the PCB assembly project. This saves time and gives you a chance to modify the design and reduce wastage, resulting in substantial cost savings.

Ensure higher quality of parts and production: It is best to get a single outsourced company to manage the entire production process for quality assurance. With multiple vendors, errors at one stage may not get communicated to the next, leading to quality issues in the end product. We provide comprehensive SMT assembly services (surface mount technology) at HITECH CIRCUITS with high-quality, ISO9001-certified equipment. We constantly review our quality management system to enhance service delivery. We select only high-quality components from proven suppliers.

Maintain easy communication with a single point of contact: When you have a single point of contact, there is better collaboration between designers, engineers, and testing teams. You don’t need to circulate design files with multiple vendors—one error in a chain of vendors can cause delays and quality issues in the final assembly phase. A single point of contact makes it easy to initiate change order changes with a simple phone call or email.

Develop, test and take products to market faster: To compete in today’s fast-paced market, you need to turn your ideas into thoroughly tested and functional products in the quickest time possible. Work with a single partner for shorter procurement lead times, smoother production, and a faster time-to-market while delivering quality products to your customers. We handle all aspects of the PCB manufacturing process so you can focus on improving the performance of your final product and designing better products!

Partner with HITECH CIRCUITS for end-to-end PCB assembly services

Hitech Circuits is committed to fulfilling customer requirements in a way that exceeds expectations. We understand that producing high-quality circuit boards requires an end-to-end approach.

With years of experience providing PCB prototype design, parts procurement, testing, and assembly, we have developed strong relationships with major North American partners and distributors. Our team has secured ties with component vendors and shipping partners so that we can negotiate the best rates for you.

At HITECH CIRCUITS, we can meet all your requirements for quick turn PCB manufacturing.

Contact us freely, Email add: [email protected]

0 notes

Text

Your Trusted Partner for High-Reliability Electronic Manufacturing--Hitech Circuits

Printed Circuit Boards (PCBs) play a vital role in modern technology, serving as the foundation for nearly every electronic device we rely on daily. From smartphones and medical equipment to automotive systems and industrial machinery, PCBs are at the heart of innovation, enabling seamless functionality and advanced capabilities.

At Hitech Circuits, we specialize in providing high-quality PCB manufacturing and assembly services designed to meet the needs of diverse industries. With state-of-the-art technology, strict quality control, and a highly skilled team, we deliver solutions that combine reliability, precision, and efficiency.

We can provide turnkey electronic manufacturing services. The services include:

PCB Manufacturing from Prototyping to Mass Production

Components Purchasing at competitive prices

PCB Assembly(Mechanical & Electronic Components)

Shell customization and assembly

Function Testing

PCB Reverse Engineering

With the experiences of over 20 years in the electronics manufacturing industrial, we are devoted to providing superior services and have cooperated with many famous brands. The end customers we serve are in industries such as aerospace, medical & life sciences, industrial,military & defence.

If you want to know the prices from us, please email Pelina--Hitechpcb<[email protected]> Below is the guideline of basic information you are supposed to provide or specify:

Complete GERBER files including the Excellon Drill File

Quantities

Need expedited service or not(for PCB prototype onlly)

Panelization Requirements

Materials Requirements

Surface Finish Requirements

Board Thickness

Copper Thickness

Assembly Requirements (including full turn key)

Any Other Requirements

Don't know what any of these items are? Call us. We can help.(Phone Number: 86-18033061378 )

Your custom quote for PCB or PCBA usually will be delivered within 24 hours(working day). We will always do our best to meet your needs and get your quote returned to you as soon as possible.

0 notes

Text

LHD Technology participated in the 17th AES UAE Home Appliances and Consumer Electronics Show 2024-Made in China Goes Global

At the upcoming 17th AES UAE Home Appliances and Consumer Electronics Show, we will showcase our expertise in the PCB and PCBA field. As a company with more than 20 years of experience in R&D, production and sales. The following is a detailed introduction of our company, as well as our highlights and expectations at the exhibition.

Company Background

Our company was established in 2003 and is committed to providing customers with high-quality PCB (printed circuit board) and PCBA (printed circuit board assembly) solutions. With many years of industry experience, we have accumulated rich technical knowledge and production capabilities to meet the needs of different customers. Our factory is equipped with advanced production equipment and adopts strict quality control processes to ensure that every product meets international standards.

Main industries

Our products mainly cover the following industries:

Security: Provide reliable circuit board solutions for monitoring equipment.

New energy: Meet the renewable energy developed and utilized based on new technologies.

Home appliances: Provide high-efficiency PCB design and manufacturing for various home appliances.

Military industry: Meet the high standards and high reliability requirements of military equipment.

Exhibition highlights

At this exhibition, we will focus on the following aspects:

Latest technologies and products

We will display the latest PCB and PCBA products, including:

High-frequency and high-speed PCB: Suitable for 5G communication and high-frequency applications.

Flexible circuit board: Suitable for application scenarios with limited space and bending.

Environmentally friendly materials: In response to the global environmental protection trend, lead-free materials and recyclable materials are used.

Live Demonstration and Interaction

We will conduct live product demonstrations and factory video playback at the booth. Welcome all customers to experience our one-stop service. At the same time, we will also arrange professional technicians to answer customers' questions and provide customized solutions.

Business negotiation opportunities.

We also participated in exhibitions in India, Iran, and Hong Kong, serving many customers from all over the world, answering their questions and providing professional services.

This exhibition is a good business negotiation platform. We look forward to establishing connections with potential customers from Dubai and surrounding countries to explore cooperation opportunities. Whether you are looking for new suppliers or want to learn about the latest technology, we welcome you.

Future Outlook

With the development of science and technology, the PCB and PCBA markets are facing new opportunities and challenges. We will continue to be committed to technological innovation and continuously improve production efficiency to meet the growing market demand. At the same time, we also hope to further expand the international market through this exhibition and establish long-term cooperative relationships with more customers.

Conclusion

Thank you for reading our introduction. We look forward to seeing you at the 17th AES UAE Home Appliances and Consumer Electronics Show! Please feel free to visit our booth to talk to our team and learn more about our products. If you have any questions or need further information, please feel free to contact us. Let us work together to create a better future!

Phone:+8615337485501 Email: [email protected]

0 notes