#Marine Plywood Suppliers

Explore tagged Tumblr posts

Text

The Luxurious Aesthetic of Wood Veneers

Wood veneers are an exquisite embodiment of sophistication and luxury in interior design and furniture making. Crafted from thin layers of real wood, they offer a natural charm and warmth that is unparalleled by other materials. Let's delve deeper into the luxurious aesthetic of wood veneers and explore their timeless appeal.

What are wood veneers?

Wood veneers are thin slices of natural wood, typically around 0.6 to 6 millimeters thick, obtained by peeling or slicing logs. These slices showcase the intricate patterns and grains inherent in wood, providing a visually stunning surface finish. Veneers can be sourced from various wood species, each imparting its unique characteristics to the final product.

Types of Wood Veneers

Natural vs. engineered veneers

Natural wood veneers are obtained directly from the log, retaining the organic beauty of the wood grain. Engineered veneers, on the other hand, are manufactured using advanced techniques to replicate the appearance of natural wood. While both types offer exceptional aesthetics, natural veneers often command a premium due to their authenticity.

Popular wood species used

A wide range of wood species is utilized in veneer production, including oak, walnut, maple, cherry, and mahogany. Each species exudes its distinct color, grain pattern, and texture, allowing for endless design possibilities.

Manufacturing Process

Wood veneers are meticulously crafted through a multi-step manufacturing process. Logs are first soaked in hot water to soften the fibers, making them easier to peel or slice into thin sheets. These sheets are then dried, flattened, and bonded onto substrates such as plywood or medium-density fiberboard (MDF). The result is a durable and flexible veneer sheet ready for application.

Sustainability considerations play a crucial role in veneer production, with many manufacturers opting for responsibly sourced wood and eco-friendly adhesives to minimize environmental impact.

Advantages of Wood Veneers

Aesthetic appeal

Wood veneers impart a timeless elegance to any space, enhancing its visual appeal with their natural beauty. The intricate patterns and textures of wood grains add depth and character to furniture pieces and interior surfaces.

Cost-effectiveness

Compared to solid wood furniture, which can be prohibitively expensive, wood veneers offer a more budget-friendly alternative without compromising on quality or aesthetics. They allow for the creation of luxurious-looking furniture at a fraction of the cost.

Versatility in design

Wood veneers are highly versatile, lending themselves to a myriad of design styles and applications. Whether it's sleek and modern or rustic and traditional, veneers can be tailored to suit any aesthetic preference, making them a favorite among designers and homeowners alike.

Applications of Wood Veneers

Wood veneers find extensive use in various industries, including:

Furniture making

From elegant cabinets and tables to intricate veneer panels, furniture makers harness the beauty of wood veneers to create exquisite pieces that exude sophistication and style.

Interior design

In interior design, wood veneers adorn walls, ceilings, and floors, adding warmth and texture to residential and commercial spaces. They can be used to create focal points, accent walls, or decorative elements that elevate the overall ambiance.

Architectural applications

Wood veneers are also employed in architectural projects, where they lend a touch of luxury to doors, partitions, and facades. Their lightweight nature and flexibility make them ideal for curved surfaces and custom installations.

Maintenance and Care

While wood veneers boast exceptional durability, proper maintenance is essential to preserve their beauty and extend their lifespan. Regular dusting and occasional polishing with a suitable wood cleaner will keep veneered surfaces looking pristine for years to come.

Trends in Wood Veneer Usage

Contemporary designs

In recent years, there has been a surge in the popularity of contemporary designs featuring sleek, minimalist aesthetics. Wood veneers complement these modern spaces effortlessly, adding warmth and character to clean-lined furniture and interiors.

Incorporating wood veneers in modern spaces

Designers are increasingly incorporating wood veneers into modern spaces to create striking contrasts and visual interest. Whether it's pairing veneered surfaces with metal accents or juxtaposing different wood species for a dynamic effect, the possibilities are endless.

Challenges and Considerations

Despite their many virtues, wood veneers are not without their challenges. Durability concerns may arise over time, particularly in high-traffic areas or environments prone to moisture and humidity. Additionally, the environmental impact of veneer production warrants careful consideration, prompting the need for sustainable practices and materials.

Conclusion

Lakshmi Timbers and Plywood emerge as the undisputed leader in the realm of wood veneers in Chennai. With its unwavering commitment to quality, extensive range of products, and unparalleled customer service, the company sets the benchmark for excellence in the industry. Whether you're a seasoned professional or a novice enthusiast, Lakshmi Timbers and Plywood welcomes you to explore its world of wood veneers and experience the epitome of luxury and craftsmanship.

FAQs

Are wood veneers as durable as solid wood? Wood veneers are highly durable when properly maintained, but they may not be as robust as solid wood in certain applications.

Can wood veneers be repaired if damaged? Minor scratches or chips in wood veneers can often be repaired using wood fillers or touch-up kits available from furniture stores.

Are wood veneers environmentally friendly? It depends on the sourcing and manufacturing practices of the veneer supplier. Opting for veneers made from sustainably harvested wood and eco-friendly adhesives can help reduce environmental impact.

Can wood veneers be stained or painted? Yes, wood veneers can be stained or painted to achieve different colors or finishes, although it's essential to follow proper preparation and application techniques for optimal results.

How long do wood veneers typically last? With proper care and maintenance, wood veneers can last for decades, retaining their beauty and integrity over time.

#Wood Veneers in Chennai#Veneer in Chennai#Marine plywood in Chennai#plywood in Chennai#plywood price Chennai#plywood price per sq ft in Chennai#waterproof plywood price in Chennai#plywood rate in Chennai#cost of plywood in Chennai#plywood suppliers in Chennai#plywood kitchen cabinet

0 notes

Text

#best quality plywood manufacturers in india#calibrated plywood in india#best marine plywood in india#plywood manufacturers in india#plywood suppliers in india#film face shuttering plywood in india#best plantation timber plywood in india#chequered plywood suppliers in india#best plywood used in government tenders in india

0 notes

Text

L2 Certification Attempt

After obtaining my L1 attempt, I had originally planned to fly for an L2 attempt on the same rocket. However, I attended a VRA club night where a swap meet was being held and ended up with a Rocketry Warehouse (now Madcow) Broken Arrow 54. Sometimes a great deal is a great deal.

This was a pretty big step up from the cardboard and plywood construction I was used to, being entirely filament-wound fibreglass. Its large diameter/length ratio combined with its small split fins also made it intimidating. This kit is also intended only for dual-deploy, which is something I had never done before. I decided it was a good opportunity to challenge myself.

Build

The kit was pretty bare-bones, meaning I had to source a retainer and much of the hardware for it. I ordered a 38mm Aeropack retainer, and then I began the build.

The process was relatively simple, with through-the-wall fins like all my previous builds. However, this time they did not fit into divots in the centering rings, so I 3D printed a fin jig to hold them in place while the epoxy cured.

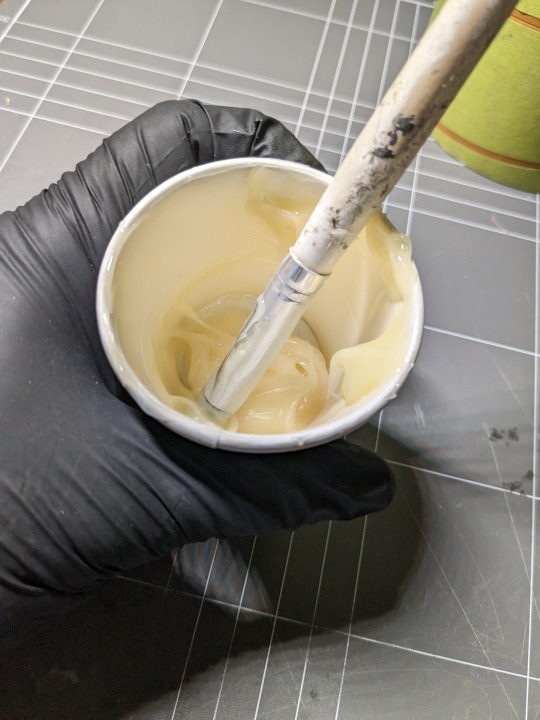

Speaking of epoxy, I moved away from the 5-minute Araldite I had used for previous builds in favour of a more serious adhesive. I used JB Weld for anything motor-adjacent because of its thermal tolerance, and Epiglue for all other structural attachments and fin fillets. This was recommended to me by a friend in Perth who flies truly ridiculous rockets and has used it on flights of up to Mach 2. It is also available from a local marine supplier, meaning I didn't have to pay through my nose to get hold of Rocketpoxy or West Systems. I was very pleased with how nicely it went on and how strong it was.

By this time I'd also nailed down my epoxy application and filleting methods - I use cheap silicone sculpting and grouting tools which can simply be cleaned with acetone after I'm done. For filleting, I also found that mixing the epoxy in a ziploc bag and piping it on like icing worked a treat.

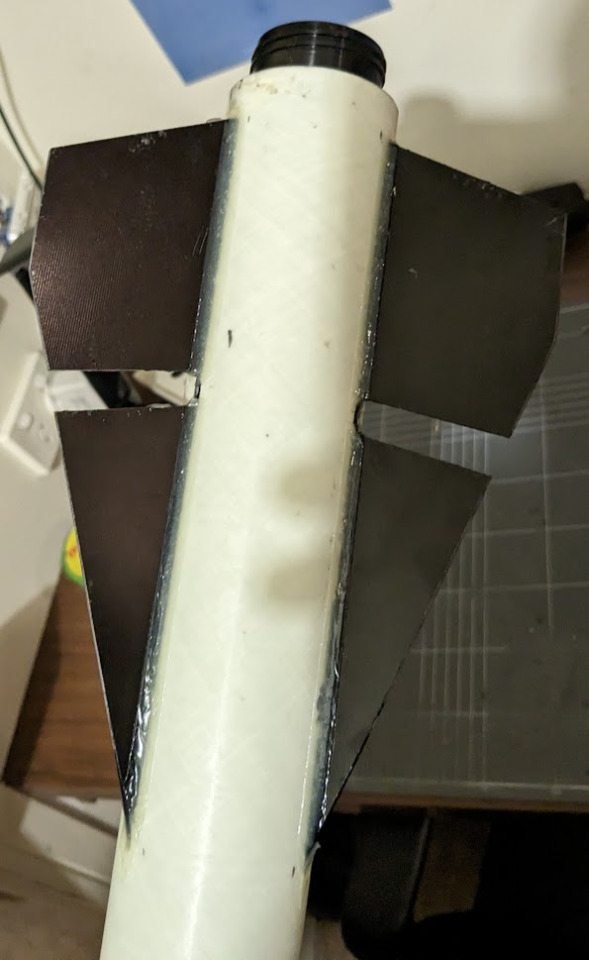

My work gets cleaner with every set of fillets I lay down. These ones don't look fantastic, and the split fins were something I had never dealt with before, but that didn't matter for reasons that became apparent shortly after the epoxy had set.

The morning after I applied these fillets, I got up to continue working on the rocket when I noticed that something had shifted overnight. The motor mount tube was somehow at an angle, as shown in the image above. I know I installed it perfectly level, but I didn't secure it while it set so I think it slipped as it cured. In my defense, I was quite sick and not firing on all cylinders when I had completed all the work up until now, but the realisation of what I'd managed to do was pretty disappointing and a bit of a knock to my confidence. Some measurements and a bit of trig suggested that the offset was only a degree or two, but the image suggests otherwise. I consulted some friends who are far more experienced flyers than I, and the consensus was a mix between 'send it' and Do Not Fly That Rocket, with more in favour of flying it than not. I looked at my OpenRocket sim for stability characteristics, and read some old Rocketry Forum posts about this model, all which pointed to it being rather squirrelly. In hindsight, I feel like I made the right decision, as I just couldn't ignore my gut feeling. I decided to rip it apart and rebuild it completely.

I did not take photos during this phase due to being completely covered with fibreglass dust, but I ended up using a diamond Dremel cutting wheel to first cut the fin can off, then cleanly slice the fins out of the body. I cannibalised a small section of the avionics bay tube to use as a coupler to reattach the aft section. I was then able to epoxy the whole thing back together, sand it all down, and it looked no different - apart from the motor mount being at the correct angle of zero degrees. I re-filleted the fins with a larger radius than before, as I wasn't happy with how they looked initially. I was very pleased with this effort, and confident to a) present this rocket to an RSO and b) fly it safely.

I also took the opportunity during this rebuild to modify the rocket to be motor-eject capable, by removing the bulkhead to which the recovery harnessing would be attached. I cut a small divot in the forward centering ring and attached a looped piece of kevlar around the motor tube before reinstalling it. This 'leash' provides the anchor point for a longer recovery harness to be attached to. I am very glad I did this, as not long after I was informed that my university club possessed a grand total of two (2) grams of black powder. Traditional dual-deploy would no longer be an option. More on that later.

To finish off the construction, I 3D printed rail guides from ABS and bolted them to the body, with a bit of JB Weld in there for good measure. I drilled pressure relief holes in the forward and aft sections of the body, and another in the avionics bay for altimeter readings. I then drilled a more smaller holes and installed screws to pin the nosecone to the forward section, and the forward section to the avionics bay. Since the flight would no longer be traditional dual-deploy, the rocket would not need to separate at these points. Finally, I gave it a purple paintjob and the name of CRUNCHWRAP 3.

At some point, Taco Bell might see these and send me a cease and desist. I am going to keep building and flying them until they do.

Recovery

With a proper dual-deploy ejection now out of the question, I turned to my backup plan. My team calls it the 'poor-man's dual deploy', even though it's arguably actually more expensive than using black powder. This involves deploying a drogue with the motor charge, then using a JollyLogic chute release device to deploy the main at whatever altitude you have chosen. There is a substantial risk of the harnessing becoming tangled using this method, but I didn't really have a choice. I used a 4.5m nylon shock cord, tied to the anchored kevlar leash. I divided the cord into thirds, tying a loop at each third. I attached the drogue to the forward-most loop, and the main to the aft loop. Both chutes were on quick links and swivels to reduce the risk of tangling as much as possible. Each of these chutes were wrapped in their own nomex protector, and then placed in the aft section of the rocket with their harness. I used a 36' (91-ish cm) main chute from Loc Precision, and a 40cm 4-gore drogue which I sewed using Scott Bryce's fantastic Spherical Parachute Pattern Generator.

Avionics

Although it ended up not being needed, I decided to send the flight computer I got hold of along for the ride. I thought it would be cool to get an altitude reading to compare with the simulated apogee. A buddy of mine in the US was getting rid of a few bits and pieces, so I bought his RRC2+ off him with the intent of flying it for my L2 attempt. First, though, it needed somewhere to live.

I found the supplied parts for the av-bay were a little lacking, so I added some modifications - the main one being drilled holes for two threaded rods to pass through. I used two for redundancy, since the idea of a single rod made me a little uneasy. I used wingnuts on these so I could fasten them nice and tight without the need for a spanner. It was also missing enough eye bolts, so I grabbed some from Bunnings.

I then designed and 3D printed a sled to fit onto the threaded rods and provide a mount for the battery and the flight computer. A very simple setup. The sled looks objectively awful since the printer was having a bit of a sook at the time, but the actual functionality was not affected and it serves its purpose just fine.

Motor

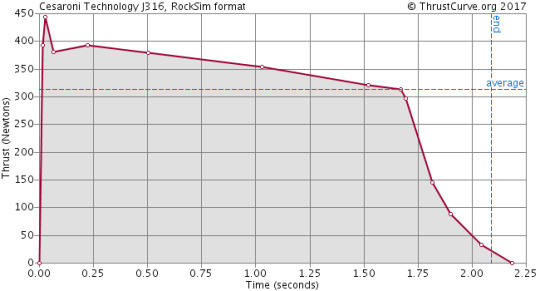

With an unbelievably limited amount of motors available in Australia at the time of writing, I had to work with what I could get hold of. I was lucky enough to snag was a CTI J-316 (pink!!) through my university team, which is a 38mm 5 grain reloadable motor with an adjustable delay of up to 17 seconds. Unfortunately, we didn't have a 5-grain case so I made do with a 6-grain case and a spacer. I only became aware of that the night before the launch, so I had to very quickly revise my recovery packing technique to account for the now limited real estate inside the body.

It provided an average thrust of roughly 316N, with a max of 450N, over a burn time of about 2.1sec, for a total impulse of roughly 650Ns. A pretty tame J motor, but still far more powerful than anything I'd ever flown before.

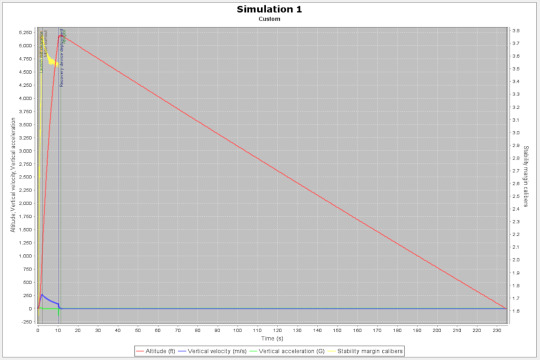

Simulation

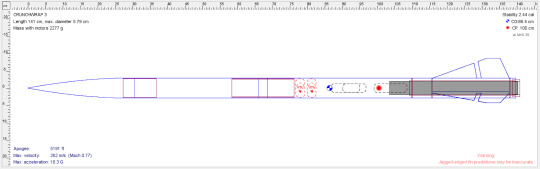

After carefully weighing every single component of the rocket and entering them into OpenRocket, I simulated the flight on the motor above. The entire vehicle weighed 2.7kg, with a length of 1.41m. It was simulated to hit Mach 0.77, and fly to an apogee of 5191ft.

Theoretically, the centre of pressure and centre of gravity would be 0.86m and 1m respectively from the tip of the nose cone. This would give a stability calibre of 2.44 at Mach 0.3 - however, this rocket is quite a bit faster than that. Also, the 'rule of thumb' which says a rocket's CG should be roughly 1.5 body diameters in front of the CP is not as helpful on rockets with a length/diameter ratio of over 10, such as this one (which is 24). Here, the CG should be roughly 10% of the overall length in front of the CP, which it was, almost (9.6%). The stability calibre off the rod was predicted to be only a little over 1.5 (6%), but given that it would be going 31m/s I was confident this would be fine as long as it didn't launch into a strong wind gust. At motor burnout, stability would be up near 3.8 (15%), which I was happy with.

I set the motor delay to the full 17 seconds for the simulations, as anything shorter would have the recovery devices deployed before apogee. This would a) cut the flight short and more importantly b) place a huge amount of strain on the harnessing and chutes due to a very high deployment speed. With the full delay, deployment would be at 11.3m/s, which the harness and drogue could handle easily. Ground hit was simulated to be a brisk but not destructive 6.8m/s.

As an aside, OpenRocket includes a little disclaimer about 'jagged edge fin predictions may not be accurate'. I bore this in mind through the whole process, but based on others I'd seen fly and forum posts I'd read online, I was comfortable with what I was doing.

Flight

L2 certifications require passing a written exam with two sections - technical knowledge and the Tripoli safety code. I had already passed the exam (100%, don't mind if I do) at a previous date, so all I had to do was install my motor, altimeter, and recovery gear. I didn't even have to drill out a delay. After a quick field CG test and a visit to the RSO tent, I was ready to rack up.

A few new recruits to our team came out to the launch day, so I enjoyed an opportunity to show them how to set up for flight, install an igniter, and test for continuity.

After a small delay to clear the range and ensure the skies were clear overhead, the LCO hit the button.

The rocket flew straight and fast on a frankly gorgeous purple flame, and almost instantly got high enough that we struggled to keep a visual on it. A puff of smoke indicated the ejection charge had blown, and then I was able to see the fluoro yellow gores of the drogue as it opened. The rocket began to drift slowly as it came down, as there was a fairly stiff breeze blowing at the time. I had programmed my chute release to 500ft, and it performed as intended. The main chute deployed and thankfully none of the recovery gear got tangled. I watched it gently descend, albeit with a decent drift going on, and set itself down in a field about 800m away. After a gentle stroll (read: powerwalk to warm up, it was freezing), we arrived at the rocket. It had been dragged a little and the chute had become tangled on the ground, but all was intact. One quick pitstop at the RSO tent later, I had my L2!

Upon reflection....

Things to improve

Use a much smaller drogue. The one I flew was about twice as big as it needed to be, and it was far too windy for such a chute. I simply didn't have a smaller one, although making one would have only taken about an hour.

I didn't get any useful readings from my altimeter. I don't believe I set it up properly, so I need to make sure I learn to do that and fly it as a passenger on at least one more flight before I use it as a deployment computer. I am disappointed that I couldn't get a figure to compare with the simulation.

Use a proper stand to rest the rocket on, perfectly horizontally, during construction. This would have avoided the whole debacle of the motor mount slipping and me consequentially having to rip it apart and rebuild.

Things that went well:

Being absolutely prepared and packing my car the night before, and bringing spares of most components, made launch prep a breeze

That was the first flight of my homemade drogue, and upon inspection afterwards there was no damage. I can now be confident that others of the same design and similar construction that I have planned for bigger rockets will perform in a similar way.

The recovery technique worked as intended, with no tangling. This is probably not a viable option for rockets going any higher, but it's nice to have in the back pocket for projects of this scale if black powder and/or avionics access might be an issue

I am also extremely relieved that this certification only took me one shot, rather than the three that my L1 took. I think it reflects well on my progress.

Next:

Fly it again with proper dual deploy, if I can get my hands on some black powder

Scratch build of a rocket of similar scale

...... L3?

2 notes

·

View notes

Text

Premium Plywood & Decorative Solutions | Plylam Centre, Goshamahal, Hyderabad

Enhance your interiors with high-quality plywood and decorative solutions from Plylam Centre, the trusted supplier in Goshamahal, Hyderabad. We offer a wide selection of durable and versatile plywood, including Gurjan plywood, Birch plywood, and premium decorative sheets, tailored to suit your construction and interior design needs.

Explore our vast collection, including stylish wall panels, Veneer Sheets, and��Acrylic Laminates Near Me. For a striking transformation, check out our exclusive 3D Wall Decor Near Me selection, perfect for adding depth and style to any space. Whether you’re a contractor, builder, or homeowner, Plylam Centre offers Ply Sheet Prices that fit every budget while maintaining unmatched quality.

We’re also recognized as a leading plywood wholesaler and marine plywood dealer in Hyderabad. Our waterproof plywood provides a durable solution for areas exposed to moisture, ensuring long-term performance. Additionally, our Decorative Laminates Near Me bring elegance and modern aesthetics to your interiors, making your spaces stand out.

Visit Us at Plylam Centre

Discover the finest plywood and decor materials at our Goshamahal store. Our dedicated team is here to assist you in finding the perfect products for your projects.

Address: 5–5–685, Pink House, Goshamahal, Hyderabad, Telangana 500012

Phone Number: 040 2465 4077

Location: Find us on the map

0 notes

Text

best gurjan face trader

Cheap and Best Gurjan Face Veneer in Indonesia – Athexporthouse.com

Looking for the best Gurjan Face Veneer in Indonesia at unbeatable prices? Look no further than Athexporthouse.com, your trusted supplier of high-quality Indonesian Face Veneer and plywood solutions. We specialize in providing top-quality Keruing plywood and Meranti face veneer, catering to the needs of importers, wholesalers, and manufacturers worldwide.

Why Choose Our Gurjan Face Veneer?

At Athexporthouse.com, we take pride in offering premium Gurjan Face Veneer that stands out for its superior quality, durability, and affordability. Here’s why our veneer is the preferred choice:

High-Quality Raw Materials – Our veneers are made from the finest Gurjan wood, ensuring a smooth, strong, and durable finish.

Competitive Pricing – We provide cost-effective veneer solutions without compromising on quality.

Consistent Thickness & Smooth Finish – Our veneer sheets are carefully crafted to provide uniform thickness, making them perfect for furniture, paneling, and interior décor.

Eco-Friendly & Sustainable – We follow responsible sourcing practices, ensuring minimal impact on the environment.

Global Supply & Timely Delivery – With a strong logistics network, we ensure on-time delivery to importers and manufacturers worldwide.

Our Range of Veneer Products:

Gurjan Face Veneer – Best for premium plywood manufacturing.

Red Color Meranti Face Veneer – Ideal for decorative applications and plywood production.

White Color Meranti Face Veneer – Known for its smooth and elegant texture.

Top-Quality Keruing Plywood – Durable and resistant to moisture, perfect for outdoor and marine applications.

Trusted Gurjan Face Importers’ Choice

We have established a strong reputation among Gurjan Face Importers globally, supplying top-tier veneer that meets international standards. Our products are widely used in the construction, furniture, and interior design industries.

If you’re looking for the best Gurjan Face Veneer in Indonesia, visit Athexporthouse.com today and get the finest quality veneer at the most competitive prices. Contact us now for bulk orders and custom veneer solutions!

0 notes

Text

J S Plywood & Timber: Your Trusted Plywood Timber Wholesale Supplier in Jaipur

When it comes to construction and interior design, selecting the right materials is crucial for the durability and aesthetics of any project. Plywood and timber are among the most essential materials used in a variety of applications, from furniture making to home construction. If you’re looking for top-quality plywood and timber in Jaipur, J S Plywood & Timber is the name you can trust. As a leading Plywood Timber Wholesale supplier in Jaipur, they offer high-quality products at competitive prices, catering to all your construction and design needs.

The Importance of Quality Plywood and Timber

Plywood and timber are versatile materials that find extensive use in construction, carpentry, and interior designing. Plywood is engineered by bonding thin layers of wood veneer together, which makes it stronger and more durable than solid wood. It’s an ideal material for furniture, doors, flooring, and even wall paneling. Timber, on the other hand, is prized for its natural beauty and strength, making it perfect for structural components and exterior applications.

When sourced from a reliable supplier like J S Plywood & Timber, both plywood and timber offer exceptional strength, durability, and aesthetic appeal. Whether you’re an architect, contractor, or DIY enthusiast, choosing quality plywood and timber can make a huge difference in the longevity and look of your project.

Why Choose J S Plywood & Timber?

1. Wide Range of Products J S Plywood & Timber specializes in providing a broad selection of plywood and timber, catering to different customer needs. They offer everything from marine plywood, commercial plywood, and flush doors to timber in various finishes and grades. Their wholesale services ensure you get the best products for any scale of project, whether you’re working on a small renovation or a large construction project.

2. Competitive Wholesale Pricing One of the key advantages of buying from J S Plywood & Timber is their unbeatable pricing. As a leading Plywood Timber Wholesale supplier in Jaipur, they offer competitive prices that help you save without compromising on quality. Whether you’re buying in bulk or just a few sheets, you can trust that you’re getting the best value for your money.

3. Quality Assurance At J S Plywood & Timber, quality is never an afterthought. They source plywood and timber from trusted manufacturers who adhere to the highest industry standards. Every product is inspected for its durability, strength, and finish, ensuring that it meets your expectations and project requirements. This commitment to quality ensures that you receive long-lasting and reliable materials for your construction and design projects.

4. Customization Options Whether you need plywood of specific dimensions or custom-cut timber for a specialized project, J S Plywood & Timber offers tailored solutions. Their team is always ready to assist with cutting, shaping, and even finishing the materials to suit your unique needs. This flexibility makes them a go-to choice for both large-scale builders and smaller, custom jobs.

5. Excellent Customer Service Navigating the world of construction materials can be overwhelming, but J S Plywood & Timber’s knowledgeable staff makes the process easy. They’re always available to answer any queries, guide you in selecting the best materials, and help you with delivery logistics. Their commitment to customer satisfaction sets them apart as one of the best plywood and timber dealers in Jaipur.

Applications of Plywood and Timber in Various Industries

The versatility of plywood and timber makes them indispensable in multiple industries. Here are some of the most common applications:

1. Construction Plywood is widely used in flooring, roofing, and wall systems, thanks to its strength and resistance to environmental factors. Timber is frequently used in framing, window framing, and door construction.

2. Furniture Manufacturing From chairs and tables to cabinets and bookshelves, plywood is a favorite material for furniture manufacturers. Timber is used for high-end furniture pieces where natural aesthetics and durability are a priority.

3. Interior Design Timber’s natural beauty is perfect for creating unique designs for walls, flooring, and decorative pieces. Plywood, with its smooth surface, is ideal for creating contemporary designs in interiors.

4. Marine Applications Marine plywood, known for its resistance to water, is used in boat building and other outdoor applications exposed to moisture.

Conclusion

For anyone in Jaipur looking for top-notch plywood and timber, J S Plywood & Timber is the supplier to trust. Their commitment to quality, variety, and customer satisfaction makes them a leader in the plywood timber wholesale industry. Whether you need premium timber for construction or specific plywood for your interior design, J S Plywood & Timber has you covered.

Visit them today for all your plywood and timber needs and experience the best in quality and service. With J S Plywood & Timber, you’re guaranteed to get the perfect materials for your next big project.

0 notes

Text

Where can you buy waterproof plywood?

Sourcing Waterproof Plywood: A General Guide for Every Project

Waterproof plywood is an essential intermediate material for an indoor conversion and outdoor construction. The resistance to water and humidity makes it a terrific choice for projects that involve exposure to water. One key to a successful, long-term project is the choice of a type and a supplier, which stretches from kitchen cabinets and bathroom vanities to outdoor furniture and marine structures. This guide addresses types of waterproof plywood available, their sources and tips to consider when buying them.

Understanding Waterproof Plywood: Types and Applications

"Waterproof plywood" isn't a single entity. It encompasses several types, each engineered for specific moisture resistance levels and applications:

· BWP (Boiling Water Proof) Plywood: Although this is an ideal benchmark of waterproof plywood, this type of material can endure even boiling water and is inherently resistant to moisture and humidity. BWP plywood uses waterproof adhesive, generally phenolic resins, and is suitable for those areas that are extremely humid, reach water contact commonly, or even are submerged. Common applications include kitchen cabinets, bathroom vanities, marine construction, and exterior cladding.

· MR (Moisture Resistant) Plywood: Depending on the source, MR plywood is often referred to as "water resistant." BRP, however, is not as good at repelling moisture when compared to BWP. It is designed to withstand moderate humidity and occasional spills but is altogether inappropriate for long-term submersion. MR plywood is a low-cost indoor application for furniture, paneling, and some kitchen parts that may encounter some damp conditions without direct exposure to water.

· WBP (Weather and Boil Proof) Plywood: Similar to BWP, WBP plywood is bonded with waterproof adhesives and offers excellent resistance to weathering and boiling water. It's often used in exterior applications like signage, hoardings, and concrete formwork. While suitable for some outdoor furniture, BWP is generally preferred for projects requiring direct and prolonged water exposure.

Navigating the Market: Where to Buy Waterproof Plywood

Finding the right source for waterproof plywood is as important as choosing the right type. Here are the primary avenues to explore:

1.Online Retailers: The internet has revolutionized shopping, and building materials are no exception. Online retailers are convenient, with more variety and often competitive prices. However, it's essential to pay attention to establish the reputation of the dealer before placing any order, as well as policies regarding shipping. Consider these suggestions:

· Plyneer- a premier manufacturer and distributor, probably has a variety of plywood products from waterproof downwards. Explore the site for the products specifications, prices, and availability.

· Major Online Marketplaces: Platforms like Amazon host numerous sellers offering various types of waterproof plywood. One should be quite judicious- checking out price comparisons, reading reviews from fellow consumers, and understanding product descriptions before going for purchases.

· Home Improvement Giants: much like Home Depot and Lowe's offer a selection of plywood products with options typically for online ordering and in-store pick-up.

2. Local Lumber Yards and Hardware Stores: Local suppliers offer the advantage of personal interaction and the ability to physically inspect the plywood before buying. They can also provide valuable advice and may offer better deals on bulk orders. Building relationships with local suppliers can be beneficial for ongoing projects.

3. Specialty Plywood Distributors: For large-scale projects or specific requirements, consider contacting specialty plywood distributors. They often carry a wider range of grades, thicknesses, and finishes and can cater to bulk orders.

Making Informed Decisions: Key Considerations

Purchasing waterproof plywood involves more than just finding the lowest price. Here are crucial factors to keep in mind:

· Project Requirements: Clearly define the specific needs of your project. Determine the type of plywood required (BWP, MR, or WBP), the necessary dimensions, and the required grade.

· Quality and Certifications: Look for plywood that meets industry standards and carries relevant certifications. This ensures the product's quality and performance.

· Price and Budget: Balance cost with quality. When making a purchase, do not forget about price, but instead consider the quality. This lets you avoid any costly repairs or replacement later on. Get price quotes for comparisons from several suppliers.

· Supplier Reputation-Carefully chooses a reliable supplier, with a positive track record of quality products and customer service. Check online reviews and seek recommendations from others.

· Refunds and Guarantees: Ask whether or not they give warranties and guarantees for their products. This provides protection against defects or damage.

· Delivery and Logistics: If ordering online, consider shipping costs and delivery times. Ensure the supplier has a reliable delivery system and can handle large or bulky items.

Beyond the Purchase: Storage and Handling

Good storage and handling practices should be observed in maintaining waterproof plywood integrity:

· Storage: Store plywood in a well-ventilated, dry space completely free of direct sunlight and extreme temperatures. Stack it flat on supports to prevent warping.

· Handling: Handle plywood carefully to avoid damaging the edges or surface. Use appropriate lifting equipment for large sheets.

Conclusion: Investing in Quality for Lasting Results

Choosing the right quality water-resistant plywood is actually a big investment into the longevity and success of your project. Understanding the various types available to their buying options as well as the various other key factors discussed in this guide will enable one to make informed decisions and acquire the right plywood for their specific needs.

Remember that quality often outweighs the initial cost, ensuring a durable and reliable result for years to come. Whether you're building a boiling water proof plywood kitchen or seeking water resistant plywood sheets for a smaller project, careful consideration and research are essential. Don't solely focus on the waterproof plywood price or waterproof ply price; prioritize quality and suitability for your specific application.

#bangalore plywood#best plywood for cupboards#best plywood for interior#best plywood for kitchen#best plywood for wardrobe#best plywood for wardrobes#best plywood in india#boiling water resistant plywood#cheap plywood sheets#commercial ply board#commercial plywood#commercial plywood price#Construction plywood#cost of plywood board#designer plywood sheets price#difference between laminate and veneer#fabric laminate wardrobe#frosty white laminate wardrobe#gurjan gold plywood#gurjan neem plywood#laminate sheets for bedroom#marble finish laminate wardrobe#neem gold plywood#neem wood plywood#plywood company in bangalore#plywood cost in bangalore#plywood factories in bangalore#plywood price bangalore#plywood sheet cost in bangalore#plywood sheets price in bangalore

0 notes

Text

Top Plywood Suppliers & Exporters – Find the Best for Your Needs

When it comes to sourcing high-quality plywood, choosing the right supplier makes all the difference. Whether you're in construction, furniture manufacturing, or interior design, working with trusted plywood suppliers ensures durability, reliability, and competitive pricing.

🌍 Global Plywood Market Leading plywood exporters come from India, China, Vietnam, and Indonesia, offering a wide variety of products, including: ✔ Hardwood Plywood – Perfect for furniture & cabinetry ✔ Marine Plywood – Water-resistant and ideal for outdoor projects ✔ Film-Faced Plywood – Best for concrete formwork

📦 Why Choose Verified Plywood Suppliers? ✅ Quality-certified materials ✅ On-time delivery with transparent trade practices ✅ Competitive pricing & bulk supply options

Choosing a reputable supplier means smooth logistics and superior materials for your projects. Get insights into the top plywood exporters and explore detailed trade data in our latest blog!

🔗 Read More: Top plywood exporters

1 note

·

View note

Text

Plywood Designed to Overcome Borer Infestations and Combat Fire Discover the highest quality plywood available at Krishstar which sells a variety of plywood products suitable for both residential and commercial use, such as waterproof, commercial, marine, fire-resistant, termite-borer-proof, and many more. With the highest quality plywood in Dubai available to create the ideal space, one can trust Plywood suppliers in Dubai to create outstanding interior designs for their house or place of business. https://www.krishstargt.com/blog-plywood-designed-to-overcome-borer-infestation-and-combat-fire.html

0 notes

Text

Plywood Dealer in Ahmedabad -Navkar Plywood

Plywood Dealer in Ahmedabad – Navkar Plywood

When it comes to high-quality plywood, Navkar Plywood is a trusted name as a leading Plywood Dealer in Ahmedabad. With years of expertise in the plywood industry, we specialize in supplying premium, commercial, and durable plywood for all kinds of construction and interior projects. Our commitment to quality and customer satisfaction has made us a preferred choice among builders, architects, and interior designers.

Why Choose Navkar Plywood as Your Plywood Dealer in Ahmedabad?

1. Wide Range of Plywood Products

As a leading Plywood Dealer in Ahmedabad, we offer a diverse selection of plywood to meet the varying needs of our customers. Whether you need commercial plywood, marine plywood, or decorative plywood, we have the perfect solution for your projects. Our plywood is crafted with precision and meets industry standards for strength and durability.

2. Superior Quality Plywood

Quality is our priority, and we ensure that every plywood sheet we supply is made from the finest wood and bonded with high-grade adhesives. Our plywood is known for its high strength, resistance to moisture, and durability, making it an excellent choice for furniture, flooring, paneling, and structural applications.

3. Affordable Pricing

As a customer-centric Plywood Dealer in Ahmedabad, we provide top-quality plywood at competitive prices. We believe in offering value for money by supplying plywood that is durable, long-lasting, and worth the investment.

4. Trusted Supplier in Ahmedabad

Navkar Plywood has built a strong reputation as a reliable Plywood Dealer by consistently delivering premium plywood products. We cater to a wide range of customers, including homeowners, contractors, interior designers, and furniture manufacturers.

5. Sustainable and Eco-Friendly Plywood

We understand the importance of sustainability and source our plywood from environmentally responsible manufacturers. Our plywood is manufactured using eco-friendly processes, ensuring that it is safe for both users and the environment.

Our Plywood Products

As a reputed Plywood Dealer in Ahmedabad, we offer a variety of plywood types, including:

1. Commercial Plywood

Our commercial plywood is designed for general-purpose applications such as furniture, partitions, and paneling. It is manufactured with high-quality hardwood and is resistant to moisture, ensuring longevity.

2. Marine Plywood

Marine plywood is known for its exceptional resistance to water and moisture, making it ideal for applications like boat building, kitchen furniture, and bathroom interiors. Our marine plywood meets industry standards for strength and durability.

3. Waterproof Plywood

Our waterproof plywood is specially treated to resist water damage, making it an excellent choice for kitchens, bathrooms, and exterior furniture.

4. Decorative Plywood

Enhance your interiors with our decorative plywood, available in various finishes and designs. It is perfect for wall paneling, cabinetry, and high-end furniture.

5. Blockboard and Flush Doors

In addition to plywood, we offer blockboards and flush doors made with premium materials. These products provide excellent strength and are widely used in furniture and construction applications.

Applications of Our Plywood

Being a leading Plywood Dealer in Ahmedabad, our plywood is widely used in various applications, including:

Furniture Manufacturing: Tables, chairs, wardrobes, and cabinets

Interior Decoration: Wall paneling, partitions, and ceilings

Construction Projects: Flooring, roofing, and formwork

Exterior Applications: Outdoor furniture and signage boards

Marine and Waterproof Uses: Boats, kitchen, and bathroom furniture

Why Plywood from Navkar Plywood?

High Durability: Our plywood is strong, long-lasting, and resistant to environmental factors.

Smooth Finish: We provide plywood with smooth and defect-free surfaces for superior aesthetics.

Termite and Borer Resistant: Our plywood is treated to resist termites and borers, ensuring longevity.

Custom Sizes Available: We offer plywood in various sizes and thicknesses to meet specific project requirements.

On-Time Delivery: As a trusted Plywood Dealer, we ensure timely delivery of products.

Get the Best Plywood from the Top Plywood Dealer in Ahmedabad

If you are looking for a reliable Plywood Dealer in Ahmedabad, Navkar Plywood is your go-to destination for high-quality plywood solutions. Whether you need plywood for residential, commercial, or industrial projects, we provide the best products at the most competitive prices.

Contact us today to explore our wide range of plywood and find the perfect solution for your needs. Trust Navkar Plywood for superior quality, durability, and affordability. Let us be your trusted partner in all your plywood requirements!

For More Information:

6354105257

20,21,22 Amar Estate, near Memco,Ahmedabad, Gujarat 380025

0 notes

Text

Top Plywood Suppliers in Jaipur: Best Quality, Affordable Prices & Wide Variety Explore the top plywood suppliers in Jaipur offering high-quality, durable, and affordable plywood for construction, furniture, and renovation projects. From commercial plywood to water-resistant marine plywood, these suppliers provide a wide variety of plywood options that cater to different needs. Discover plywood that ensures longevity, aesthetic appeal, and value for money. With reliable customer service and expert guidance, these suppliers are your go-to choice for all plywood requirements in Jaipur.

#PlywoodSuppliersJaipur#QualityPlywood#AffordablePlywood#JaipurPlywood#PlywoodForConstruction#MarinePlywood#MoistureResistantPlywood#WoodworkingSupplies#FurniturePlywood#HomeRenovation#BestPlywoodInJaipur#PlywoodForFurniture#PlywoodDeals#PlywoodSuppliers#JaipurConstruction

0 notes

Text

Why Choose Lakshmi Veneers For Your Next Project

Veneers are indeed a fantastic way to achieve the astounding and stunning look of your living space. It is a thin slice of wood that you can attach to any board, made to add a touch of luxury to any environment, whether it's your home or office. These are available in various exquisite designs, shades, and patterns to cater to people's distinct needs and requirements. Veneers can strengthen any furniture's appearance and bring about a graceful charisma when applied to cabinets and wardrobes. So, you should definitely consider buying these for your household if you wish to make everyone mesmerise with the outlook of your home.

Lakshmi Veneers is your absolute destination if you want high-quality decorative veneers for your household. It has one of the supreme collections of veneers that can offer the vibe you wish to achieve. It offers desired flexibility in selection, as one selection can have different types and designs. Now, let us find out why Lakshmi Veneers are the best out there when purchasing veneers.

Why Select Lakshmi Veneers for Your Interior Upgrade?

With numerous platforms present, Lakshmi Veneers is the best offering of premium-quality decorative veneers. Let’s discuss the reasons that make them the ultimate choice for elevating your interior.

Supreme Collection

Lakshmi Veneers has an extensive collection of veneers, having something for everyone. This includes a number of wood types and textures to assist you in finding your favourite style. Lakshmi Veneers attempts to please every taste, whether one is looking for warmth, elegance, or sleekness. In addition, their collection extends to various grain patterns, from straight to figure, which allows further customisation and personalisation of your space.

Unmatched Versatility

The versatility of Lakshmi Veneers' products is a major selling feature. They supply a variety of wood options and finishes to choose from. You can find veneers in various thicknesses that not only make it easy to store but also offer room for some flexibility in application as well. Lakshmi Veneers has various solutions that go well with any

interior design dream project. For example, they can be employed to furnish a contemporary apartment, an old cabin, or even a traditional office space. In addition, their veneers can be used for various surfaces,

including cabinets, wardrobes, doors, and furniture pieces. This versatility provides limitless ways to regulate and maintain the visual appeal of your space.

Quality Assurance

Above all else, quality is their prime focus. They get their wood from reputable suppliers and employ top-notch quality control measures throughout manufacturing to ensure that their veneers meet the highest standards. Every veneer undergoes a strict inspection process to achieve specified colour, grain, and texture consistency. This gives rise to an amazing-looking product which is also durable. You can fully trust Lakshmi Veneers' delivery services as they ensure the supply of premium-quality veneers that will maintain their beauty for years to come.

Endless Design Possibilities

With Lakshmi Veneers, the design possibilities are truly endless. They can help you achieve a classic, vintage look or even a more contemporary and exceptional aesthetic by providing inspiration for grandeur. You can combine their veneers with other materials like glass and metal to reflect your individuality and creativity.

Worth Your Money

Veneers deliver the same properties as hardwood, and that too at an affordable price. They offer products at the best prices so that you can invest in them without a doubt. That means you can achieve a luxurious and sophisticated look for your space without spending a surplus of money with Lakshmi Veneers. This makes them a cost-effective solution for achieving the aesthetic you prefer.

Durability and Maintenance

Lakshmi Veneers design their products by keeping features like durability and low maintenance in mind to make them ideal for busy households. Their sleek finishing intensifies the veneers' resistance to scratches, stains, and fading so that they don't lose their beauty and shine over time. Routine maintenance is minimal and typically involves simple cleaning with a damp cloth, allowing homeowners to enjoy their stunning veneered surfaces without the hassle of extensive upkeep.

Environmental Responsibility

Lakshmi Veneers is committed to sustainability and environmental responsibility. They source their wood from responsibly managed forests and adhere to strict environmental standards in their manufacturing processes. This way, you can feel confident that you are investing in a product that minimises environmental impact and promotes the conservation of natural resources.

Conclusion

Choose Lakshmi Veneers to bring your dream decor to life and make your house your pride. Lakshmi Veneers sets itself apart in decorative veneers by providing an amazing selection of multiple options, ensuring ease of installation, guaranteeing durability and low maintenance, providing value for money, and delivering outstanding service. You can easily elevate your living space's beauty and functionality with Lakshmi Veneers.

FAQs

Are veneers suitable for everyone? While veneers are a versatile option for many individuals seeking dental enhancements, they may not be suitable for everyone. It's essential to consult with a qualified dentist to determine the best course of action based on individual dental needs and conditions.

Do veneers require special care? While veneers do not require extensive maintenance, it's essential to practice good oral hygiene habits, including regular brushing, flossing, and routine dental check-ups. Avoiding habits such as teeth grinding or biting hard objects can also help prolong the lifespan of veneers.

Can veneers fix severe dental issues? While veneers can address a variety of dental imperfections, they may not be suitable for severe cases of misalignment or structural damage. In such instances, alternative treatments may be recommended by a qualified dentist to achieve the desired results.

How long do veneers last? With proper care and maintenance, veneers can last upwards of 10-15 years or even longer. However, their longevity may vary depending on factors such as oral hygiene practices, lifestyle habits, and the quality of the veneers themselves.

Are veneers reversible? While veneers are considered a permanent cosmetic dental solution, they are not entirely irreversible. However, the process of removing veneers may involve altering the natural tooth structure, so it's crucial to carefully consider this decision with the guidance of a qualified dentist.

#Veneer#Veneer in Chennai#Marine plywood in Chennai#plywood in Chennai#plywood price Chennai#plywood price per sq ft in Chennai#waterproof plywood price in Chennai#plywood rate in Chennai#cost of plywood in Chennai#plywood suppliers in Chennai#plywood kitchen cabinet

0 notes

Text

#best quality plywood manufacturers in india#calibrated plywood in india#best marine plywood in india#plywood manufacturers in india#chequered plywood suppliers in india#best plantation timber plywood in india#film face shuttering plywood in india#best plywood used in government tenders in india#plywood suppliers in india

0 notes

Text

Applewudindia Brand Plywood Manufacturer in Yamunanagar

Plywood Factory In Yamunanagar, a bustling industrial hub in Haryana, India, has earned a distinguished reputation as the “Plywood Capital of India.” This title is no accident; the city is home to numerous plywood manufacturers and suppliers that cater to domestic and international markets. Among these, ApplewudIndia has emerged as a prominent and trusted name in the plywood manufacturing sector. This article delves into the journey, strengths, and offerings of ApplewudIndia, which has made it a frontrunner in the industry.

The Genesis of ApplewudIndia

ApplewudIndia Brand Plywood Manufacturer Company In Yamunanagar was founded with a clear vision to provide high-quality plywood solutions to meet the growing demands of construction, furniture, and interior design industries. Established in Yamunanagar, the company has leveraged the city’s rich history of timber and plywood manufacturing to carve out its niche. Its inception was driven by a commitment to innovation, sustainability, and excellence in craftsmanship.

Core Values and Philosophy

ApplewudIndia operates on a set of core values that underpin every aspect of its business:

Quality Assurance: The company adheres to stringent quality control measures to ensure that every product meets international standards.

Sustainability: Aware of the environmental impact of plywood manufacturing, ApplewudIndia prioritizes eco-friendly practices such as sourcing timber from sustainable plantations and minimizing waste.

Customer-Centric Approach: The company’s operations are guided by a deep understanding of customer needs, enabling it to deliver tailor-made solutions.

Innovation: ApplewudIndia continuously invests in research and development to stay ahead in a competitive market.

Product Portfolio

ApplewudIndia offers a diverse range of plywood products, catering to various sectors such as residential, commercial, and industrial. Some of their flagship products include:

1. Commercial Plywood

Commercial plywood is one of the most sought-after products in the market due to its versatility and affordability. ApplewudIndia’s commercial plywood is made from premium-quality hardwood and is bonded with superior-grade adhesives, ensuring durability and resistance to wear and tear.

2. Marine Plywood

Designed to withstand high moisture levels, marine plywood is ideal for applications in kitchens, bathrooms, and other humid environments. ApplewudIndia’s marine plywood is crafted with water-resistant adhesives and high-quality veneers, making it an excellent choice for long-lasting performance.

3. Shuttering Plywood

Shuttering plywood is essential for concrete formwork in construction projects. ApplewudIndia’s shuttering plywood is known for its high load-bearing capacity, smooth finish, and reusability, making it a preferred choice for builders and contractors.

4. Decorative Plywood

With an emphasis on aesthetics, ApplewudIndia’s decorative plywood offers stunning designs and finishes that cater to interior designers and architects. The range includes veneers and laminates in various textures, patterns, and colors.

5. Blockboards and Flush Doors

ApplewudIndia also manufactures blockboards and flush doors, which are known for their robustness, smooth finish, and dimensional stability. These products are widely used in furniture, partitions, and door applications.

Manufacturing Excellence

ApplewudIndia’s state-of-the-art manufacturing facility in Yamunanagar is the backbone of its operations. Equipped with advanced machinery and technology, the facility ensures precision and efficiency in production. Key highlights of the manufacturing process include:

Raw Material Selection: Timber is sourced from sustainable plantations, ensuring a consistent supply of high-quality wood.

Advanced Machinery: The use of modern equipment, such as hydraulic presses, peeling machines, and hot presses, guarantees superior product quality.

Quality Control: A dedicated team of quality inspectors conducts rigorous tests at every stage of production to maintain consistency and reliability.

Environmental Compliance: The factory adheres to eco-friendly practices, including waste management systems and energy-efficient operations.

Market Presence and Distribution

ApplewudIndia has a strong presence in the Indian market and is gradually expanding its footprint internationally. The company’s robust distribution network ensures timely delivery of products to customers across the country. Strategic partnerships with dealers, retailers, and contractors have further solidified its market position.

Customer Testimonials

The trust and loyalty of customers have been pivotal to ApplewudIndia’s success. Here are a few testimonials that highlight the company’s commitment to excellence:

Architect’s Perspective: “ApplewudIndia’s decorative plywood collection is a game-changer. The quality and variety they offer have made them my go-to supplier for all my interior projects.”

Contractor’s View: “We have been using ApplewudIndia’s shuttering plywood for years. Its durability and reusability make it a cost-effective choice for our construction projects.”

Homeowner’s Experience: “The marine plywood from ApplewudIndia has transformed my kitchen. It’s not only sturdy but also resistant to moisture, ensuring long-term value.”

Commitment to Sustainability

As environmental concerns take center stage globally, ApplewudIndia is dedicated to reducing its ecological footprint. The company’s initiatives include:

Sustainable Sourcing: Collaborating with certified plantations to ensure responsible timber procurement.

Waste Management: Implementing efficient waste recycling processes to minimize environmental impact.

Green Certifications: Obtaining certifications such as FSC (Forest Stewardship Council) to validate its commitment to sustainability.

Challenges and Future Prospects

While ApplewudIndia has achieved significant milestones, the plywood industry is not without challenges. Fluctuating raw material prices, competition, and stringent regulatory norms are some hurdles the company faces. However, ApplewudIndia’s proactive approach to innovation and customer satisfaction positions it well to overcome these challenges.

Looking ahead, the company plans to:

Expand its product range to include more eco-friendly options.

Invest in digital marketing to enhance brand visibility.

Strengthen its global presence by exploring new export markets.

Continue focusing on research and development to introduce cutting-edge products.

Conclusion

ApplewudIndia’s journey from a local plywood manufacturer in Yamunanagar to a recognized brand in the industry is a testament to its unwavering dedication to quality, innovation, and sustainability. By consistently exceeding customer expectations and staying true to its core values, the company has set a benchmark for excellence in plywood manufacturing. As it charts its course for the future, ApplewudIndia is poised to remain a key player in the plywood industry, contributing not just to the economy of Yamunanagar but also to the broader global market.

Plywood

Plywood Manufacturers

Plywood Factory

Brand Plywood

Applewudindia

#best plywood factory in yamunanagar#plywood manufacturer in yamunanagar#yamunanagar plywood factory#applewudindia plywood#plywood in yamunanagar#yamunanagar plywood factory list#best plywood manufacturing comapny in yamunanagar

0 notes

Text

How to Choose the Right Marine Plywood Manufacturers in India

Finding the right Marine Plywood Manufacturers in India can be crucial for various applications, from boat building and marine construction to furniture making and industrial uses. With numerous options available, it's essential to choose a reliable supplier that offers high-quality products. This guide will help you navigate the Indian market and find the best marine plywood for your needs.

What is Marine Plywood?

Marine plywood is a high-grade plywood designed to withstand harsh marine environments. It's manufactured using high-quality hardwood veneers and a waterproof adhesive, making it highly resistant to moisture, rot, and decay. Get in touch with us for more information.

#Marine plywood manufacturers in India#best marine plywood#Plywood#BEST PLY IN INDIA#Best plywood company in India#Best Plywood

0 notes

Text

Premium Plywood Sheets Manufacturer: Royal Wood Pack

When it comes to reliable and high-quality plywood sheets, Royal Wood Pack stands as a leading name in the industry. With our years of expertise in plywood manufacturing, we provide durable, versatile, and cost-effective plywood solutions for a wide range of applications. Whether you are involved in construction, furniture making, interior design, or other woodworking projects, our plywood sheets deliver the strength and stability you need.

What Makes Royal Wood Pack's Plywood Sheets Stand Out?

At Royal Wood Pack, we are committed to producing plywood sheets that not only meet but exceed industry standards. Here’s why our plywood sheets are preferred by builders, architects, designers, and craftsmen:

Superior Quality: We use the finest raw materials, sourced from trusted suppliers, to manufacture plywood sheets with exceptional strength, stability, and smooth finishes.

Customization: Our plywood sheets come in various thicknesses, grades, and finishes. We can also offer customized sizes and specifications to match the specific needs of your projects.

Sustainability: At Royal Wood Pack, we prioritize environmental sustainability. Our plywood sheets are produced using eco-friendly practices, ensuring that our products contribute to greener building solutions.

Durability: Our plywood sheets are engineered to endure even the most demanding conditions. Whether used indoors or outdoors, they resist wear and tear, moisture, and temperature fluctuations.

Affordable Pricing: We believe that premium quality should be accessible. Our plywood sheets offer excellent value for money, combining high performance with competitive pricing.

Applications of Plywood Sheets

Plywood sheets from Royal Wood Pack are used in a wide range of applications across various industries:

Construction: Plywood is commonly used in building frameworks, subflooring, roofing, and walls due to its strength and durability.

Furniture Making: Our plywood sheets are perfect for creating custom furniture, cabinets, tables, and more.

Interior Design: Plywood is a popular choice for interior wall paneling, flooring, and decorative elements.

Marine and Outdoor Applications: Special moisture-resistant plywood can be used for boat building, outdoor furniture, and other outdoor structures.

Packaging: Plywood sheets are also an ideal material for making packaging boxes, crates, and pallets.

Why Choose Royal Wood Pack for Plywood Sheets?

Quality Assurance: Our plywood sheets undergo rigorous quality control measures to ensure they meet international standards for performance, appearance, and durability.

Reliable Supplier: With a solid track record of delivering on time and in large volumes, we are the trusted partner for your plywood needs.

Expert Team: Our dedicated team of professionals works closely with clients to understand their requirements, offering expert guidance and support throughout the process.

Innovation: We keep up with the latest advancements in plywood manufacturing, incorporating new technologies to improve the quality and efficiency of our products.

Available Plywood Sheet Types

At Royal Wood Pack, we offer a diverse range of plywood sheets, including:

MR Grade Plywood: Moisture-resistant plywood, ideal for interior use where humidity levels are a concern.

BWR Grade Plywood: Boiling Water Resistant plywood, perfect for applications exposed to water or moisture.

BWP Grade Plywood: Waterproof plywood designed to withstand extreme conditions, including outdoor and marine environments.

Veneer Plywood: Aesthetic plywood with a fine veneer finish, suitable for high-end furniture and interior projects.

Get in Touch with Royal Wood Pack

If you are looking for high-quality plywood sheets for your next project, Royal Wood Pack is the manufacturer you can trust. With a wide range of products, excellent customer service, and a commitment to sustainability, we provide plywood solutions that meet the needs of diverse industries.

Visit our website at Royal Wood Pack to learn more about our products, or contact us to discuss your requirements and request a quote. Our team is ready to help you find the perfect plywood sheets for your project.

0 notes