#Manufacturers Container Desiccant

Explore tagged Tumblr posts

Text

The 5 Best Mil-Spec Packaging Suppliers

Military products must meet stringent quality and reliability standards, which also apply to their packaging. Consequently, any company in this sector must partner with the best mil-spec packaging suppliers to ensure everything remains compliant.

1. Edco Supply Corporation

Edco Supply Corporation — out of Brooklyn, New York — is the best all-around mil-spec packaging supplier. Edco manufactures a wide range of packaging types to fit various military standards, so you can likely find a solution that works regardless of your product type or size. It’s also been in business for over 60 years, giving it extensive experience serving diverse needs.

In addition to packaging and materials, Edco sells mil-spec tapes and adhesives to keep product containers sealed. The company accepts custom orders, too, further expanding the variety of end uses it can support. An in-depth blog explaining key mil-spec concepts and available customer support team provide additional help for those new to the industry.

2. Quality Support, LLC

Consider Quality Support, LLC, for your mil-spec packaging supplier if you need wooden crates. This provider specializes in custom lumber products, which are ideal for shipping large equipment or particularly heavy or sensitive items. As a bespoke manufacturer, Quality Support also offers design services to help you create the best package possible.

While it has an inventory of ready-made packaging for smaller runs or non-niche needs, Quality Support’s best asset is its custom work. Its personalized solutions span all manners of boxes, bags and insulation. Beyond adhering to military specifications, Quality Support is NIST SP 800-171 compliant, which some Department of Defense contractors need from their suppliers due to new cybersecurity regulations.

3. IMPAK Corporation

Los Angeles-based IMPAK Corporation is another of the best mil-spec packaging suppliers in the U.S. While Quality Support focuses on rigid crates, IMPAK’s specialty is flexible packaging, making it a good fit for smaller products or anti-static insulation. Its bag and pouch selection is among the most varied lineups available, and the company performs custom work, too.

IMPAK’s complementary capabilities are some of its strongest benefits. The company sells an impressive range of desiccants, oxygen absorbers and sealing technologies and will even service this equipment. IMPAK will also test products for strength, sterility, moisture resistance and more to give you confidence in your packaging designs.

4. MAC Packaging

With decades in the industry, MAC Packaging is one of the more experienced suppliers on this list. It has become a national leader in mil-spec packaging, even offering consulting services for companies wanting to learn more about the industry. It’s also unique in that it solely works in custom jobs.

In addition to packaging, MAC manufactures RFID tags to military standards. These solutions make your products easier for clients to track through their warehouses and can streamline your own logistics processes. The brand will also file all related paperwork at no extra cost.

5. ProtoPak Engineering Corporation

Another long-standing firm in this sector is ProtoPak Engineering Corporation, which has provided mil-spec packaging since 1967. ProtoPak’s product range boasts impressive variety and even offers custom shipping platforms to meet your bulk order needs. Perhaps most impressively, the company has a 100% accuracy record.

ProtoPak also offers warehousing and logistics services to streamline supply chain operations in businesses that don’t have enough internal capacity. Its expert team can help you design personalized solutions and ensure your workflows are efficient to deliver the highest quality to your clients.

How to Choose a Mil-Spec Packaging Supplier

The best mil-spec packaging supplier depends on your needs and the clientele you serve. However, there are a few general signs to look for when identifying a reliable provider.

Adherence to mil-spec guidelines is an obvious factor, but related regulatory requirements are also worth consideration. For example, the Cybersecurity Maturity Model Certification requires compliance with NIST SP 800-171 for some contractors, necessitating these standards from your supply chain partners. Other standards like the Food Safety Modernization Act or ISO 27001 may introduce unique needs, too.

When choosing between certified partners, consider the kinds of packaging you need. Many of the best suppliers offer multiple packaging types, but not every company manufactures every product type. Consequently, you must determine if bags, cartons, crates or other solutions suit your shipments the best before deciding on a supplier.

A business’s complementary services and support options are also worth consideration. The ability to customize packaging or buy related products like humidity indicators or mil-spec sealers may significantly streamline your operations. Similarly, a partner offering greater support and information will be easier to work with, especially when unexpected challenges arise.

Finally, look for signs of transparency and reliability from packaging suppliers. Over half of all organizations report that procurement fraud is a major issue in their area. Such risks are damaging in any sector but all the weightier in a military context. Given these concerns, you should only work with firms that have thorough documentation on their mil-spec compliance.

The Best Mil-Spec Packaging Suppliers Compared

Any of the five mil-spec packaging companies on this list can be a worthy partner. Here is how these providers compare along a few key categories.SupplierPackaging typesAdditional capabilitiesSupport optionsEdco Supply CorporationCartons, bags, static shielding, desiccants, barrier films, wrapping, cloth paper, tubingCustom orders, humidity indicators, tapes and sealers, labelsDedicated customer support line, email, industry blogQuality Support, LLCCrates, cartons, bags static shieldingCustom orders, die-cut foam insulators, design services, NIST SP 800-171 complianceDedicated customer support line, emailIMPAK CorporationBags, static shielding, desiccantsCustom orders, prototyping, oxygen absorbers, sealers, labels, sealer repairs, product testingDedicated customer support line, emailMAC PackagingCartons, bags, static shielding, barrier films, wrappingCustom orders, prototyping, humidity indicators labels, RFID tags, paperwork servicesConsulting services, dedicated customer support line, email, industry blogProtoPak Engineering CorporationCrates, cartons, bags, static shielding, desiccants, barrier films, wrappingCustom orders, labels, RFID tags, shipping platforms, supply chain solutionsConsulting services, dedicated customer support line, email

Choose the Best Mil-Spec Packaging Supplier for Your Products

When you partner with the best mil-spec packaging suppliers, you can uphold higher quality and compliance standards without sacrificing efficiency or flexibility. Any business selling to military agencies or contractors must abide by these requirements. Start your compliance journey by finding the right mil-spec packaging provider for your needs.

#mil-spec packaging#military packaging suppliers#pharma packaging business#biopharma packaging#glass pharmaceutical packaging#defense packaging

2 notes

·

View notes

Text

Let’s make some coconut ice cream 🥥🍨👨🏾🍳🇯🇲🇬🇧🇺🇸

.

INGREDIENTS

1 x 400ml can coconut milk

150ml double cream

1 x 160g can coconut cream

50g golden caster sugar

4 large egg yolks

25g desiccated coconut, toasted

.

.

Method

Put the coconut milk, double cream and coconut cream in a saucepan and bring almost to the boil. Meanwhile, whisk the sugar and the egg yolks in a bowl until thick. Pour the coconut milk mixture in a slow stream over the egg yolks and sugar, whisking constantly.

Rinse out the saucepan and return to a low heat. Pour in the custard mixture and stir in the desiccated coconut. Continue to stir constantly for 5-10 mins until the custard thickens slightly and you can trace a line through it with a wooden spoon. Pour into a bowl, then cover the surface of the custard with cling film, allow to cool, then chill for 30 mins.

Transfer the chilled custard to an ice cream maker and freeze according to the manufacturer’s instructions. Alternatively, transfer the mixture to a small freezable container with a lid and freeze for 1 hr, then use a fork or electric whisk to really churn through the ice cream to break up the ice crystals so that the mixture is the same consistency.

Pop it back into the freezer for another 2-3 hrs, whisking it about every half hour, then cover the surface with a sheet of cling film and freeze with the lid on until as firm as ice cream. Take out of the freezer 10 mins before serving so it’s easy to scoop 😎🍨😋

5 notes

·

View notes

Text

Wholesale Supplier for Silica Gel Sachet Wrapper Material | Favourite Fab'

Looking for a reliable wholesale supplier of silica gel sachet wrapper material? At Favourite Fab, we specialize in high-quality, breathable, and dust-proof fabrics designed specifically for moisture-absorbing sachets used in packaging, pharma, electronics, and more.

Why Choose Our Wrapper Material?

Breathable Non-Woven Fabric: Allows efficient moisture absorption while securely containing the desiccant

Custom GSM & Sizes: Tailored to your sachet filling requirements

Heat-Sealable & Ultrasonic-Friendly: Supports high-speed sachet production

Dust-Free & Safe: Suitable for food-grade and pharmaceutical applications

Industries We Serve

Pharmaceuticals

Electronics & Semiconductors

Textile & Leather Packaging

Food & Beverage

Bulk Supply Advantages

Competitive wholesale pricing

Consistent quality and fast delivery

Custom branding and packaging support

Final Word

As a leading silica gel sachet wrapper material manufacturer, Favourite Fab ensures your moisture control solutions are effective, safe, and scalable. Contact us today for bulk inquiries and experience quality that performs.

https://favouritehub.com/wholesale-supplier-for-silica-gel-sachet-wrapper-material-favourite-fab/

0 notes

Text

Your Global Hyundai Parts Exporter From India – Smart Parts Exports

Keeping a Hyundai running smoothly takes more than good driving habits and regular servicing; it takes parts you can truly rely on. From brake pads that bite precisely to filters that keep engines breathing freely, every component matters. That is why workshops, fleet owners, and car enthusiasts across five continents partner with Smart Parts Exports, the premier Hyundai parts exporter committed to shipping authentic components world-wide. In this in-depth guide—around 800 words—you’ll discover why choosing us as your Hyundai genuine parts exporter and Hyundai OEM parts exporter is the smartest decision for long-term vehicle health and business success.

1. The Hyundai Legacy and the Importance of Authenticity

Hyundai started in 1967 with a single model; today it produces millions of cars revered for durability, value, and ever-improving tech. Every nut, bolt, gasket, and electronic sensor in those vehicles is engineered to microscopic tolerances. Substituting copies or “will-fit” alternatives may save a few dollars up front, but the hidden costs—reduced efficiency, warranty disputes, breakdowns, safety risks—can be brutal.

Partnering with a verified Hyundai genuine parts exporter restores confidence. You receive the same components installed at the factory, complete with QR-coded labels, tamper-proof packaging, and OEM documentation. When a customer’s Creta, Tucson, or Elantra rolls out of your workshop, you know it drives away with the precise reliability Hyundai intended.

2. Why Smart Parts Exports Leads the Industry

2.1 Expertise Deeply Rooted in India’s Automotive Hub

India is more than an emerging auto market; it is also a strategic sourcing powerhouse. Situated in Delhi-NCR—a logistics crossroads—Smart Parts Exports maintains direct channels with Hyundai’s authorized distributors as well as Tier-1 manufacturers. This geographic advantage helps us fulfill urgent orders faster than any competing Hyundai parts exporter.

2.2 One-Stop Shop for Every Hyundai Platform

From compact hatchbacks like the i10 to luxury SUVs like the Palisade, our catalog covers:

Engine internals (pistons, crankshafts, oil pumps)

Transmission assemblies and clutch kits

Steering & suspension arms, struts, and bushings

Brake pads, discs, calipers, ABS sensors

Body and lighting panels, bumpers, mirrors

HVAC compressors, condensers, and cabin filters

Electronic modules, wiring harnesses, ECUs

Whether you need a single alternator or a pallet of timing-belt kits, the same commitment drives each shipment from our warehouse to your door. That reliability is why mechanics consistently tag us the preferred Hyundai OEM parts exporter.

3. Logistics Engineered for Speed and Savings

3.1 Global Reach, Local Ease

We currently supply parts to 85+ countries in the Middle East, Africa, Eastern Europe, Central Asia, and Latin America. Our multilingual export team prepares pro-forma invoices, certificate-of-origin documents, and HS-code classifications that sail through customs. Because we are a Hyundai parts exporter from India, freight routes via Mumbai, Mundra, and Chennai ports give us flexible pricing on both FCL and LCL containers. For urgent, light-weight components, we dispatch consolidated air freight every Tuesday and Friday.

3.2 Quality Control at Every Mile Marker

Before packing, each item is visually inspected, cross-checked against Hyundai’s electronic parts catalog, and scanned into our ERP system. Boxes are sealed with moisture-proof tape and desiccant sachets. GPS-enabled tracking then follows the cargo until your warehouse signs the POD (Proof of Delivery). In short, our customers enjoy the visibility once reserved for multinational automakers—without paying a premium.

4. Competitive Pricing Without Compromising Authenticity

Counterfeiters tempt buyers with low prices. We compete differently: bulk purchasing, optimized warehousing, and lean staffing let us quote authentic parts at costs that rival grey-market sellers. You get OEM quality, transparent invoices, and full Hyundai warranty coverage—an unbeatable trio that only a seasoned Hyundai genuine parts exporter can provide.

5. How to Order in Three Straightforward Steps

Request a Quote Email, WhatsApp, or submit part numbers through our website. Our parts specialists double-check compatibility and reply with price, lead-time, and shipping mode within 24 hours.

Confirm and Pay Securely We accept major international payment gateways, LC at sight, and swift TT transfers. Each transaction is protected by SSL encryption.

Receive and Review Upon arrival, open the tamper-proof boxes, scan the hologram labels, and verify them on Hyundai’s global authentication portal. Enjoy peace of mind knowing you bought from a trusted Hyundai OEM parts exporter.

6. Frequently Asked Questions

Q: Do you handle small mixed orders for independent workshops? Yes. We ship cartons as small as 10 kg via air freight, perfect for garages needing fast turnaround.

Q: Can you supply discontinued parts for older models? Often, yes. Our sourcing team leverages relationships with legacy vendors and global surplus networks to locate hard-to-find components.

Q: How do I become a regional distributor? Send us your company profile. We evaluate volume potential, storage capacity, and service commitments, then propose tiered pricing and marketing support.

7. Success Stories from the Field

Dubai Fleet Operator: Switched to us as their primary Hyundai parts exporter in 2023. Downtime on their 120-vehicle Accent taxi fleet dropped 28 percent within six months because parts arrived on schedule and fit perfectly the first time.

Nairobi Retailer: Previously battled counterfeits tarnishing their reputation. After onboarding Smart Parts Exports as a Hyundai genuine parts exporter, warranty claims fell to near-zero and monthly revenue rose 18 percent.

Lima Parts Wholesaler: Needed bulk shipments of suspension kits but feared high freight costs. Our consolidated containers cut shipping expense by 22 percent while preserving OEM authenticity—proof we’re the cost-effective Hyundai parts exporter from India.

8. Conclusion: Drive Forward with Confidence

A Hyundai is engineered for years of trouble-free service, but only if it is maintained with the parts it deserves. Smart Parts Exports, your go-to Hyundai parts exporter, delivers that promise daily. As a certified Hyundai genuine parts exporter and dedicated Hyundai OEM parts exporter, we combine India’s manufacturing strength with rigorous global logistics to keep your workshop shelves stocked, your customers happy, and your reputation soaring.

Ready to elevate your supply chain? Contact Smart Parts Exports today—the trusted Hyundai Parts Exporter From India—and experience genuine excellence, part after part, mile after mile.

#smart parts exports#smartpartsexports#genuine parts exports#hyundaipartsexporterfromindia#hyundaigenuineparts

0 notes

Text

Handling and Storage Tips for Tungsten Rods to Maintain Quality

Tungsten rods are widely used in various high-performance industries such as aerospace, electronics, medical devices, and welding due to their exceptional hardness, high melting point, and corrosion resistance. However, despite their durability, improper handling and storage can compromise the quality and longevity of tungsten rods. Whether you’re a manufacturer, distributor, or end-user, following the right procedures is key to preserving their integrity.

Handle with Care: Avoid Surface Damage

Tungsten rods are dense and brittle, especially in their pure form. Mishandling can lead to chipping, cracking, or even breakage.

Use gloves: Always wear clean gloves when handling tungsten rods. This prevents oils or moisture from your hands from contaminating the surface.

Avoid dropping or impacts: Tungsten rods can fracture or bend if dropped or subjected to force. Use cushioned trays or supports when moving them.

Use soft gripping tools: Avoid metallic clamps or tools that can scratch the surface. Instead, use soft-tipped grippers or padded holders.

Store in a Dry and Clean Environment

Tungsten is resistant to corrosion, but it can oxidize or discolor over time if stored improperly.

Humidity control: Always store tungsten rods in a low-humidity environment. A climate-controlled storage room is ideal to prevent any moisture-induced oxidation.

Desiccant packs: If storing in sealed containers or cabinets, include desiccant packs to absorb moisture.

Avoid exposure to chemicals: Keep rods away from acids, alkalis, or other reactive chemicals that could interact with the metal.

Use Proper Storage Containers and Racks

To prevent bending, warping, or contamination, tungsten rods should be stored in appropriate containers.

Horizontal racks: Store longer rods horizontally in padded racks to distribute weight evenly and prevent sagging.

Vertical containers: For short rods, use vertical storage with soft liners to keep them upright and separated.

Label properly: Use non-corrosive tags or labels to identify different grades or diameters. Avoid direct writing on the rods.

Separate by Material Type and Grade

Tungsten rods come in various grades pure tungsten, tungsten-copper, tungsten heavy alloy, and more. Mixing them during storage can lead to confusion, contamination, or misapplication.

Color-code storage bins or use separate compartments to distinguish between types.

Record batch numbers and specifications clearly to maintain traceability.

Inspect Regularly

Regular inspections allow you to identify problems early and maintain consistent quality standards.

Check for surface changes such as pitting, corrosion, or discoloration.

Examine straightness to detect any warping or bending.

Clean if needed using appropriate non-abrasive methods and avoid harsh solvents unless recommended by the supplier.

❓ Frequently Asked Questions (FAQs)

Q1: Can tungsten rods rust if exposed to moisture? While tungsten doesn’t rust like iron, it can oxidize and develop a dull layer if exposed to humidity or chemicals. Proper storage in a dry, sealed environment prevents this.

Q2: How long can tungsten rods be stored without losing quality? If stored correctly in a clean, dry, and controlled environment tungsten rods can be stored for years without any degradation in quality.

Q3: Is it safe to store tungsten rods with other metals? It's best to store tungsten rods separately to avoid cross-contamination, especially with softer metals that may transfer material or become damaged.

Q4: What’s the best way to transport tungsten rods? Use cushioned cases or padded tubes that prevent movement and impact during transportation. Ensure they’re tightly secured to avoid vibrations or drops.

Conclusion: Handling and storing tungsten rods may seem simple, but small mistakes can lead to significant quality issues. By implementing these practical tips, you can maintain the rods’ structural integrity and performance for long-term use. Whether in a manufacturing facility or a research lab, proper care will ensure you get the most value from your tungsten inventory.

0 notes

Text

Biogas Treatment Solutions: Key Technologies for Cleaner Energy

As the world shifts towards sustainable energy, biogas has emerged as a powerful alternative to fossil fuels. However, raw biogas often contains impurities that can reduce efficiency and damage equipment. This is where biogas treatment solutions come in—providing essential processes to clean and upgrade biogas for safe and efficient use.

What Is Biogas and Why Does It Need Treatment?

Biogas is produced through the anaerobic digestion of organic matter such as agricultural waste, food scraps, sewage, or manure. It primarily consists of methane (CH₄) and carbon dioxide (CO₂), along with trace gases like hydrogen sulfide (H₂S), moisture, siloxanes, and ammonia.

While methane is the valuable component for energy, the other elements can:

Corrode equipment

Reduce combustion efficiency

Harm the environment

Therefore, proper biogas treatment is critical before using biogas for electricity generation, heating, or injection into natural gas grids.

Top Biogas Treatment Solutions

1. Desulfurization (H₂S Removal)

Hydrogen sulfide is highly corrosive and toxic. Treatment methods include:

Iron sponge filters: React H₂S with iron oxide to form iron sulfide.

Activated carbon: Adsorbs H₂S from the gas stream.

Biological scrubbers: Use bacteria to oxidize H₂S into sulfur or sulfate.

2. Moisture Removal (Dehumidification)

High moisture levels can damage downstream equipment. Key solutions include:

Cooling and condensation: Reduces temperature to condense water vapor.

Adsorption dryers: Use desiccants like silica gel or molecular sieves.

Membrane dehydration: Selectively allows water vapor to pass through.

3. Carbon Dioxide (CO₂) Removal

Removing CO₂ upgrades biogas to biomethane, suitable for grid injection or vehicle fuel.

Water scrubbing: CO₂ dissolves in water under pressure.

Pressure swing adsorption (PSA): Separates gases under varying pressure.

Membrane separation: Uses semi-permeable membranes to filter CO₂.

4. Siloxane Removal

Siloxanes can form hard deposits in engines, reducing efficiency.

Activated carbon filters

Deep chilling

Advanced oxidation processes (AOP)

5. Compression and Storage

After cleaning, biomethane is compressed for storage or transportation. Compressors and high-pressure storage tanks are essential for pipeline injection or use as compressed natural gas (CNG).

Benefits of Effective Biogas Treatment

✅ Improved Efficiency: Clean biogas burns more efficiently in engines and turbines. ✅ Extended Equipment Life: Reduced corrosion and wear on components. ✅ Regulatory Compliance: Treated biogas meets environmental and safety standards. ✅ Market Versatility: High-quality biomethane can be used in transportation, industrial, and residential sectors.

Industries That Benefit from Biogas Treatment

Agriculture and livestock farms

Wastewater treatment plants

Food and beverage manufacturing

Municipal solid waste facilities

Future Trends in Biogas Treatment

As biogas becomes a vital part of the renewable energy landscape, innovations such as AI-driven monitoring, smart filtration systems, and low-cost adsorbents are making treatment processes more efficient and affordable.

Conclusion

Biogas treatment solutions are essential for turning raw biogas into a safe, efficient, and environmentally friendly energy source. With the right technologies, businesses and municipalities can not only reduce waste but also generate clean energy and reduce carbon emissions.

0 notes

Text

Comprehensive Guide to IBC Totes: Product Features, Industry Applications & Shipping Guidelines

Comprehensive Guide to IBC Totes: Product Features, Industry Applications & Shipping Guidelines

Introduction: Why Are IBC Totes the Global Standard for Liquid Transportation?

In the global chemical and liquid logistics industries, Intermediate Bulk Containers (IBC Totes) have become the gold standard for transporting liquids and semi-fluids due to their efficiency, safety, and cost-effectiveness. With a decade of expertise in plastic product trading, this 2,000+ word guide provides an in-depth analysis of IBC totes’ core advantages, diverse applications, and critical maritime shipping protocols. By the end, you’ll gain actionable insights to reduce cross-border logistics costs by 30%+ while ensuring compliance and operational excellence.

1. Technical Breakdown of IBC Totes

1.1 Definition & Structural Design

IBC totes feature a triple-layer composite structure:

Outer Frame:��Galvanized steel or high-density polyethylene (HDPE) grid (impact resistance ≥10 kJ/m²)

Inner Container: Food-grade HDPE (2.5–3.5 mm thickness, FDA 21 CFR certified)

Base Pallet: Modular design (static load capacity ≥1,500 kg; dynamic load ≥1,000 kg)

(IBC Tote cross-sectional view highlighting layers)

1.2 Technical Specifications Comparison

Parameter

Standard

Anti-Static

Chemical-Grade

Capacity

1,000 L

1,000 L

1,000 L

Temp. Range

-40°C to 60°C

-30°C to 50°C

-20°C to 70°C

Valve Type

Butterfly

Ball valve + grounding

316 stainless steel

UN Certification

UN31HA1/Y

UN31HA2/Y

UN31HA1/X

1.3 Innovative Technologies

Multi-Layer Coextrusion: 3-layer HDPE inner liners improve oxygen barrier efficiency by 40%.

Smart Monitoring: Optional RFID temperature sensors (±0.5°C accuracy).

Quick-Clean Design: 135° discharge port reduces residue to <0.1%.

2. Industry Applications & Case Studies

2.1 Chemical Industry Solutions

Hazardous Material Transport: Compliant with ADR/RID for Class II dangerous goods (e.g., UN 1203 diesel).

Case Study: A global paint manufacturer reduced annual transport losses from 2.3% to 0.7% using anti-static IBC totes.

2.2 Food-Grade Applications

Aseptic Filling: CIP (Clean-in-Place) systems meet ISO 22000 microbial standards.

2.3 Pharmaceutical Compliance

GMP Standards: Inner surface roughness ≤0.8μm (USP <88> Class VI compliant).

Temp. Control: Phase Change Material (PCM) insulation maintains ±2°C for 72 hours.

3. Maritime Shipping Protocols

3.1 Pre-Shipment Checklist

Documentation:

Valid UN Performance Test Report (5-year validity).

Material Safety Data Sheet (MSDS).

CTU Code-compliant container certificate.

Pre-Treatment:

Cleaning: Residuals <10 ppm.

Drying: Internal humidity <15% RH.

Leak Test: 0.3 bar pressure held for 30 minutes.

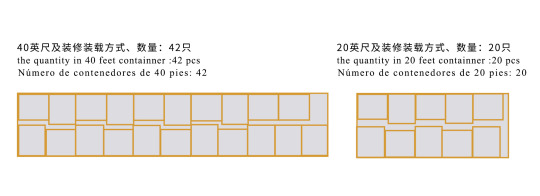

3.2 Container Loading Optimization

IBC Tote Container Loading

Container Type

20’GP

40’HQ

Units/Layer

20

42

Stacking

2 layers

3 layers

Securing

Cross straps + anti-slip mats

Honeycomb pads + airbags

3.3 Risk Mitigation Strategies

Temp. Monitoring: Refrigerated containers must maintain -5°C to 25°C (±3°C/24h).

Moisture Control: Silica gel desiccants (≥200 g/m³).

Emergency Kits: Include polymer sealants and repair tapes.

Click here for the complete original link of the blog post.

1 note

·

View note

Text

Evaluating the Leakage Prevention Measures Provided by Eyeshadow Palette Manufacturers

In the cosmetics industry, the production and packaging of eyeshadow palettes are subjects of meticulous attention. The question of whether the Eyeshadow Palette Manufacturer has implemented effective leakage prevention measures is a critical one, as it directly impacts the consumer experience and the integrity of the products themselves. This article delves into the importance of such measures and evaluates the efforts made by Eyeshadow Palette Manufacturers to ensure their products reach consumers in pristine condition.

The very nature of eyeshadow products, with their powdery and sometimes creamy textures, poses a significant risk of leakage during transportation and storage. If not properly contained, these products can not only damage the packaging but also cause wastage and dissatisfaction among users. As such, the role of Eyeshadow Palette Manufacturers in providing robust leakage prevention becomes paramount.

To begin with, the selection of packaging materials by Eyeshadow Palette Manufacturers is a crucial factor in determining the success of leakage prevention. High-quality, durable materials that can withstand fluctuations in temperature and pressure are essential. Manufacturers must also consider the design of the packaging, ensuring that it is airtight and that any seams or closures are secure. This is particularly important for products that are prone to react with moisture or that have a tendency to dry out if exposed to air.

Another aspect that Eyeshadow Palette Manufacturers must address is the internal structure of the palette. The compartments that hold the individual eyeshadows should be designed to minimize the movement of the product within the container. This can be achieved through the use of fixed wells or by incorporating a silicone pad that grips the eyeshadow pans, preventing them from shifting during transit. Additionally, the inclusion of a sealing layer or a protective film over the eyeshadows can serve as an extra barrier against leakage.

Innovative solutions are also being developed by forward-thinking Eyeshadow Palette Manufacturers to further enhance leakage prevention. Some companies are experimenting with vacuum-sealed packaging, which not only prevents leakage but also helps to preserve the freshness and longevity of the product. Others incorporate desiccant packets or moisture-absorbing materials within the packaging to control humidity levels and prevent the growth of mold or bacteria.

The testing protocols employed by Eyeshadow Palette Manufacturers are another area where leakage prevention is addressed. Rigorous quality control measures should be in place to simulate the conditions that the product will face during shipping and handling. This includes drop tests, pressure tests, and temperature cycling to ensure that the packaging can withstand the rigors of transportation without failing.

Consumer feedback is invaluable in the continuous improvement of leakage prevention measures by Eyeshadow Palette Manufacturers. By monitoring reviews and returns, manufacturers can identify patterns and issues related to packaging failures and make necessary adjustments to their designs. This iterative process of feedback and refinement is essential for staying ahead of consumer expectations and maintaining a positive brand reputation.

In conclusion, the provision of effective leakage prevention measures by Eyeshadow Palette Manufacturers is not just a matter of product protection but also a reflection of their commitment to quality and customer satisfaction. As the cosmetics market continues to evolve, the demand for high-quality, reliable, and sustainable packaging solutions will only grow. It is through the dedication of Eyeshadow Palette Manufacturers to innovate and refine their packaging that the industry can continue to meet these high standards and deliver products that are both beautiful and secure.

External size: Ø65*68*13.9mm

Inner size: Ø17*17mm

Net weight: 39.0g

Material: PS(bottom), AS/PS/ABS(cover)

Secondary process feasible: Rubber paint / matte paint / electroplating / screen printing / bronzing / 3D printing

Color: 9 Colors

Can install a mirror or not: Yes

Structure: Square. Composed of a cover, bottom, and inner case, with a square buckle.

0 notes

Text

Desiccants are like little moisture warriors that help keep things dry. For many industries, moisture control is crucial during the production, shipping, and manufacturing of their products. If low humidity isn't maintained in containers or packaging, sensitive products for many industries,.... Read more

https://www.desiccantpak.com/blog/what-are-desiccants-types-uses-benefits

#desiccant#moistureabsorbers#silicagel#cargo bag#humiditycontrol#benefits#typesdesiccants#what is this#desiccants

0 notes

Text

Automotive Packaging Solutions: Enhancing Efficiency and Protection in the Supply Chain

Introduction

The automotive industry relies on a complex supply chain that spans multiple continents, with manufacturers sourcing components from various suppliers before assembling the final product. To ensure the safe transit of delicate parts, automotive packaging solutions play a crucial role in protecting valuable components from damage, contamination, and inefficiencies. As automotive production evolves, so does the need for smarter, more durable, and sustainable packaging solutions.

This article explores the importance of automotive packaging solutions, the different types available, and how the industry is adapting to new challenges in logistics and sustainability.

Why Automotive Packaging Solutions Matter

Automobile manufacturers and suppliers handle a diverse range of parts, from large body panels to small electrical components. Without proper packaging, these components are at risk of damage due to:

Mechanical impact during handling and transportation

Moisture and corrosion, especially for metal components

Electrostatic discharge (ESD), which can affect sensitive electronic parts

Improper stacking and storage, leading to deformation or inefficiency

High-quality automotive packaging solutions address these risks, ensuring that parts arrive at their destination in optimal condition while minimizing waste and unnecessary costs.

Types of Automotive Packaging Solutions

To meet the varied needs of the automotive sector, packaging solutions come in different forms, each designed for specific applications:

1. Returnable Packaging Solutions

Returnable or reusable packaging systems are gaining popularity in the automotive industry due to their cost-effectiveness and sustainability. These packaging options include:

Plastic totes and bins: Ideal for transporting small parts like screws, nuts, and bolts.

Foldable bulk containers: Used for larger components such as engine parts or transmission units.

Steel racks and pallets: Perfect for heavy and oversized automotive components.

These solutions help manufacturers reduce packaging waste, lower costs, and improve supply chain efficiency.

2. Custom Foam Inserts and Protective Cushioning

Delicate components such as sensors, electronics, and fragile automotive parts require cushioning to absorb shock and vibrations. Foam inserts, air pockets, and honeycomb core packaging provide impact resistance, ensuring safe transportation.

3. Corrosion-Resistant Packaging

Many automotive parts, particularly those made of steel or aluminum, require protection against oxidation and rust. Corrosion-resistant packaging includes:

Vacuum-sealed pouches to remove oxygen exposure.

VCI (Volatile Corrosion Inhibitor) bags that prevent rust formation.

Desiccant packs to absorb moisture and maintain a dry environment.

4. ESD-Safe Packaging for Electronics

Modern vehicles rely heavily on electronic components, including control modules, sensors, and lithium-ion batteries. Electrostatic discharge (ESD) can damage these parts, making specialized ESD-safe packaging essential. Materials like conductive plastics, ESD shielding bags, and foam-lined trays protect sensitive electronics from static buildup.

5. Partition Sheets and Layer Pads

Partition sheets and layer pads are widely used in automotive packaging to separate components, prevent shifting during transport, and maximize stacking efficiency. Made from durable materials like corrugated plastic or honeycomb-core polypropylene, these solutions offer both strength and reusability.

Key Benefits of Advanced Automotive Packaging Solutions

Investing in the right automotive packaging solutions offers several advantages, including:

1. Reduced Damage and Product Loss

Proper packaging prevents dents, scratches, and breakage, reducing the risk of costly replacements and delays in production.

2. Improved Supply Chain Efficiency

Standardized, stackable, and returnable packaging enhances logistics efficiency, making it easier to load, unload, and store components.

3. Cost Savings in the Long Run

Although some automotive packaging solutions require higher initial investment, they result in long-term savings through durability, reduced waste, and lower material handling costs.

4. Sustainability and Reduced Environmental Impact

As the automotive industry moves toward greener practices, sustainable packaging options are gaining importance. Recyclable, reusable, and biodegradable materials contribute to a circular economy, reducing waste and carbon footprint.

5. Compliance with Industry Regulations

Many countries and automotive manufacturers have strict packaging regulations regarding hazardous materials, weight limitations, and environmental impact. Using compliant automotive packaging solutions ensures smooth operations without regulatory issues.

The Future of Automotive Packaging

The automotive industry is evolving, and so are its packaging needs. Some key trends shaping the future include:

Smart Packaging: Integration of RFID tags and QR codes to track shipments and manage inventory more efficiently.

Lightweight and High-Strength Materials: Advanced composites that offer both durability and weight reduction for lower shipping costs.

Greater Focus on Circular Economy: Manufacturers are increasingly prioritizing packaging that can be reused, repurposed, or recycled to minimize environmental impact.

Automation and Robotics in Packaging: Automated systems for loading, unloading, and packaging optimization are making processes faster and more efficient.

Conclusion

Automotive packaging solutions are a crucial part of the supply chain, ensuring that components remain undamaged, logistics remain efficient, and manufacturers reduce waste and costs. Whether it’s returnable packaging, protective cushioning, or corrosion-resistant materials, selecting the right packaging solution is vital for the success of the automotive industry.

With a growing emphasis on sustainability and efficiency, companies must continue to innovate and adopt automotive packaging solutions that align with modern industry demands.

0 notes

Text

How Are Industrial Air Dryers In Penrith Saving Manufacturers Thousands in Maintenance Costs?

In the production industry, achieving maximum equipment performance is essential in reducing downtime and maximising output. One of the frequently neglected yet influential factors of machinery performance is moisture in compressed air. Producers in Penrith increasingly acknowledge the relevance of industrial air dryers in Penrith in preventing problems caused by moisture, resulting in huge savings on maintenance. The article discusses the way moisture corrupts machinery and how high-performance air dryers are revolutionising operations for domestic producers.

The Silent Threat of Moisture in Compressed Air

Compressed air moisture can cause havoc to industrial equipment. When air is compressed, it contains water vapour that can be condensed into liquid form inside the system. Moisture can result in a number of problems, including:

Corrosion: Water can result in internal rusting of metal parts, resulting in premature equipment failure and expensive repairs.

Contamination: Excess moisture encourages the growth of bacteria and mould, which can contaminate goods and impact quality.

Decreased Efficiency: More moisture can disrupt pneumatic equipment and tool functioning, resulting in lower efficiency and higher energy use.

These conditions not only translate into increased maintenance expenses but can also cause major production losses due to equipment failure or complete replacement.

The Role of Industrial Air Dryers

Industrial air dryers are critical to the elimination of moisture in compressed air systems. By making sure that dry air only goes into the machinery, these systems ensure optimal functioning and equipment life extension. Several types of air dryers exist, such as:

Refrigerated Air Dryers: These machines chill the compressed air, which causes the moisture to condense and be eliminated. They are usually applied in general manufacturing processes.

Desiccant Air Dryers: Employing a desiccant substance to remove moisture, these dryers are best suited for use in applications needing very dry air.

Membrane Dryers: Selective permeation separates moisture from the air through these systems, and they are well suited to applications with limited sizes.

By choosing the right kind of air dryer for their particular application, Penrith manufacturers can easily minimise problems caused by moisture.

Cost Savings Through Improved Efficiency

Investment in high-efficiency industrial air dryers directly means cost savings for manufacturers. Here's why:

Lower Maintenance Costs: By reducing exposure to moisture, businesses can lower the frequency and amount of maintenance needed on their equipment. This results in lower labour costs and fewer replacement parts over time.

Extended Equipment Life: With fewer corrosion and wear issues caused by moisture, equipment lasts longer. This minimises capital outlays related to replacing new equipment.

Enhanced Energy Efficiency: Energy-efficient air dryers maximise energy consumption by allowing compressors to run under perfect conditions. This means lower energy costs and less carbon footprint.

Reduced Downtime: By avoiding breakdowns caused by moisture, manufacturers have less downtime, enabling smooth production schedules and higher output.

Real-World Effect on Penrith Manufacturers

Most manufacturers in Penrith have already started experiencing the advantages of investing in industrial air dryers.

For example, a Penrith-based manufacturer achieved a 30% decrease in maintenance expenses after acquiring a high-efficiency refrigerated dryer.

Besides, they recorded a considerable improvement in product quality because of lower contamination by moisture.

These success stories also point to the vital role industrial air dryers play in today's manufacturing processes.

As more companies see the cost-saving potential of these systems, it is likely that their use will expand further.

Conclusion

Compressed air moisture is a major threat to manufacturing operations, causing higher maintenance costs and less efficiency. Yet, through their investment in industrial air dryers in penrith with high efficiency in Penrith, the manufacturers are becoming proactive against all these risks. The resultant savings in cost in terms of reduced maintenance, extended equipment life, enhanced energy efficiency, and least downtime all signify the worthiness of such a system in present-day manufacturing life. As industries remain committed to efficiency of operation and quality checks, industrial air dryers in Penrith certainly will become decisive in forging success for them.

0 notes

Text

Beyond Silica Gel: Desiccant Wrapper Solutions for Different Absorbents

While silica gel remains the most recognized desiccant, industries today require diverse moisture-control solutions tailored to specific applications. This has led to the rise of advanced desiccant wrapper materials designed for a variety of absorbents beyond just silica gel.

Types of Desiccant Absorbents

Activated Clay – Ideal for general-purpose moisture absorption at moderate humidity levels.

Molecular Sieves – Suitable for ultra-low humidity environments and temperature-sensitive products.

Calcium Chloride – High-capacity absorber, commonly used in shipping and logistics.

Carbon Desiccants – Combines moisture and odor absorption, perfect for pharmaceuticals and food packaging.

Specialized Wrapper Materials

To match these absorbents, manufacturers offer customized wrappers made from:

Non-woven fabric – Breathable, dust-proof, and suitable for food-safe applications.

Tyvek® – Strong, medical-grade material used for pharmaceutical-grade desiccants.

Composite Films – Laminate layers for durability, often used with calcium chloride or carbon desiccants.

Sewn Cloth Bags – For heavy-duty or bulk desiccant use in shipping containers.

Benefits of Custom Wrappers

Optimized absorption performance

Safe and non-leaching containment

Branded printing for traceability

Eco-friendly material options available

Conclusion

Desiccant solutions go far beyond silica gel, and choosing the right wrapper is essential for maximum effectiveness and safety. Whether you're working with clay, sieves, or calcium chloride, custom desiccant wrappers from experts like Favourite Fab ensure protection tailored to your product’s needs.

https://favouritehub.com/beyond-silica-gel-desiccant-wrapper-solutions-for-different-absorbents/

0 notes

Text

What Are the Most Common Mistakes in Biology Laboratory Equipment Maintenance?

Biology Laboratory Equipment proper servicing ensures accurate results and safety in a laboratory environment. Many biology laboratories, ranging from research to education, use advanced tools in performing their experiments. Using a Desiccator, Dissecting Microscope, Scalpel Blade, Dropping Bottle, and Digital Flame Photometer, various biological activities can be carried out in the laboratories. These instruments are important but when not properly maintained, they tend to fail very often and the data collected is worthless. In this blog, we will discuss five common maintenance issues, how to avoid them, and why you should work with credible biology laboratory equipment manufacturers and suppliers for impeccable quality.

5 Common Maintenance Mistakes and How to Prevent Them

Ignoring Regular Upkeep

With time, dust and biological residues can accumulate on the surfaces of equipment, especially on items like photometers and microscopes. Utilization of lint-free fabrics and suitable cleaning agents on a regular basis can avert this damage. In the case of the Dissecting Microscope, lenses must be inserted in containers free of dust and other contaminants to maintain their good optical quality.

Using Inappropriate Cleaning Agents

Some laboratory workers tend to use corrosive cleaning agents that may deteriorate delicate equipment such as Dropping Bottles over a long period of use. Use only the specified cleaning agents and consult user manuals specific to each equipment for recommended cleaning methods so that equipment useful life is extended.

Uncalibrated Equipment

Sometimes researchers forget to calibrate their instruments and as a result, they are unable to obtain the desired measurements. It is recommended to reinforce the procedure for regular calibration of devices as prescribed by Biology Laboratory Equipment manufacturers and suppliers in India. This is especially crucial in research laboratories where the accuracy of results is the key factor.

Dismissing Storage Instructions

Numerous laboratories fail to store equipment correctly which results in damage to the instrument. For instance, a desiccator should be kept in a cool and dry environment in order to prevent moisture build-up, while fragile items such as scalpel blades should be placed safely in sterile containers.

Neglecting Maintenance Services

With the passage of time, there could be instances of some hidden wear and tear which may not be apparent. A regular inspection enables attention to reasons such as loose screws, broken seals, or worn out items. Periodic maintenance checks ensure that any harm that can lead to bigger complications and risks is dealt with at the nascent stage.

Essential Biology Laboratory Equipment and Their Maintenance

Dissecting Microscope

A vital instrument in biological dissections and viewing of samples, a dissecting microscope is one of the pieces of equipment that has to be properly used and must be calibrated all the time.

Scalpel Blade

Employed to make cuts during dissection cutting, scalpel blades are handled and kept in a safe manner in sterilized storage and should also be changed often to ensure sharpness.

Desiccator

The desiccator is crucial in preventing contamination of biological samples that are prone to moisture. Additionally, regular upkeep and maintenance routines alongside correct storing are the most effective means of preserving the tool.

According to Wikipedia, Cobalt chloride paper and other moisture-sensitive materials can be preserved for later use by using desiccators, which are sealable containers filled with desiccants. Desiccators are frequently used to shield hygroscopic or water-reactive compounds from humidity.

Dropping Bottle

An attachment for dispensing small amounts of liquid, and dropping bottles should be disinfected and examined for cracks to avoid the risk of contamination and leakage.

Digital Flame Photometer

This device quantitatively determines the concentration of certain elements in biological specimens. Regular and proper maintenance of this device is highly critical, as it involves calibration and cleaning after every few usages.

Why Choose School Educational Instruments?

As a reputable Biology Laboratory Equipment manufacturer and supplier in India, School Educational Instruments offers an impressive range of high-grade materials and equipment that have been carefully designed to provide years of dependable service. School Educational Instruments emphasizes customer satisfaction by providing effective assistance and proper guidance regarding the use and maintenance of the equipment so that your laboratory is efficient and safe.

Conclusion

It is crucial to take good care of all Biology Laboratory Equipment to make sure that it is accurate, safe, and can last long in any biological laboratory. By avoiding these common maintenance mistakes, laboratory staff can prevent equipment malfunctions and unnecessary breakage but most importantly improve the quality of their experiments. School Educational Instruments is a trusted Biology Laboratory Equipment manufacturer and supplier in India. With proper maintenance, your laboratory can maintain a good standard which helps researchers and students in carrying out their scientific endeavors.

#biology laboratory equipment manufacturers and suppliers#biology laboratory equipment manufacturer#biology laboratory equipment manufacturers and suppliers in india

0 notes

Text

Best Practices to Store and Handle Ground Granulated Blast Furnace Slag

Ground granulated blast furnace slag price is one of the many considerations when using the GGBS in your construction material. It is usually considered for the cementitious properties along with the material’s durability and sustainability benefits.

You must ensure that the quality of GGBS is preserved over time and is always at the peak of its performance. For this purpose, you must consider using the right storage and handling practices. Here are some of the best practices that can help maintain the quality of GGBS, especially during storage and transportation.

• It is important to understand the properties of GGBS before you set out to understand the ways to maintain the quality of the product. GGBS is a fine and powdery material that is produced when you grind the granulated blast furnace slag.

This slag is a byproduct of iron and steel manufacturing. As they are available in fine particle size, they are easily vulnerable to external factors like contamination and moisture. When you are storing or handling the GGBS, you must consider a few factors. The hygroscopic nature of the product allows it to absorb the moisture from the air. As a result, it leads to clumping. Moreover, the density and flowability of the fine particles is limited, making it important to make way for these aspects during transportation. Lastly, you must consider the reactivity of GGBS with water, which makes you look for solutions that are airtight and moisture-proof. The granulated blast furnace slag suppliers should be aware of these factors to create the best solution for storage and transportation.

• There are a few best practices to consider when planning the storage of these materials. You should ensure that the product stays free of contamination, moisture and degradation. Using these practices, you can design a storage facility that maximizes the quality of the GGBS.

o The first thing you must do is design the storage facility in silos or as a closed storage area. This way you can shield the products from the extreme weather conditions, such as rain, wind and temperature fluctuations. This will also prevent external contamination of the products. You must consider the ground granulated blast furnace slag price for this purpose.

o The next step in designing the facility would be to create airtight silos to contain the moisture. You can avoid storing them in semi-open containers. Make sure to have consistent temperatures in the storage facility to prevent condensation.

o You can also consider bulk storage in silo corrosion-resistant materials like stainless steel. You can also use aeration equipment to avoid the compaction and free flow of materials. Lastly, you must use dehumidifiers and desiccants to control humidity.

o It is also a great idea to use bagged storage if you want to handle smaller quantities of the slag. You can use moisture-proof bags made of polyethylene materials to protect the product against humidity. You can also use store bags on pallets, which can eliminate the water seepage. You can also reduce overstacking to prevent tearing or crushing of bags.

• You should also consider the handling practices to minimize the material loss and contamination. o Use sealed conveyors to transfer the GGBS while avoiding the material spillage and exposure o Make sure to use dust extraction systems at the different transfer points to eliminate the airborne particles and ensure material conservation.

Make sure to choose right granulated blast furnace slag suppliers for the right conservation and transfer of your products.

0 notes

Text

The Unique Needs and Benefits of Glass Bottle Washers: Why Seppa Solutions is Your Best Choice

Haven't you ever wondered how crucial it is to wash glass bottles? From the cola you drink to the pill you swallow or the lotion you apply, the cleanliness of the package matters in a major way. But how do these bottles get so spotless? But why should companies care about investing in specialized equipment, like glass bottle cleaner? Let’s dive into the answers.

Why Is Glass Bottle Cleaning So Important?

Just like you might drink a cooling drink or take a drug to make you feel better. What if the bottle wasn't quite clean? Would you use it with confidence? Most likely not!

That’s why glass bottle cleaning is critical. It's not only about appearance; it's health, safety, and quality. Clean bottles guarantee escape from toxins, microbes, and other contaminants reaching the food we eat. It is also the business aspect of building a rock-solid reputation and customer credibility.

Fields such as beverages, pharmaceuticals, and cosmetics all have deep needs for the use of clean bottles. An unsanitary bottle can result in complaints, product loss, or more severe bad effects on customers.

How Glass Bottle Washers Get the Job Done

Glass bottle washers are special machines that provide cleaning to the next level. Here’s how they typically work:

Pre-Washing: This is the pre rinse to remove anything that may shake loose in the nuts/molds.

Deep Cleaning with Detergents: With high-pressure water jets and cleaning solutions, the bottle is cleaned from top to bottom, inside and out.

Sterilization: Most washers clean bottles using high-temperature water or steam to kill bacteria and to provide them in a germ-free state.

Final Rinse: A thorough rinse removes any leftover cleaning agents.

Drying and Inspection: Bottles are desiccated and typically checked to make sure that they are free of dirt and clean for use.

This method isn’t just thorough—it’s efficient. It guarantees every bottle is as clean as possible, without wasting time or resources.

What Makes Glass Bottle Washing Unique?

Cleaning glass bottles is no child's play washing dishes at home. They have unique needs that require careful handling:

Fragility and Strength: Glass bottles must be very carefully handled to prevent breakage, yet they also have to be subjected to strong cleaning to get rid of tough residues.

Different Sizes and Shapes: Imagine all the bottles in existence—from miniscule drug ampules to large fluid containers. A great washer can respond to any shape or size.

Chemical Residues: Some bottles hold sticky substances like oils or syrups. Cleaners of washing loads must contain cleaning agents powerful enough to overcome them without damaging the glass.

Eco-Friendliness: Water and energy are saved while cleaning bottles which has relevance particularly in refinancing.

Why Choose Seppa Solutions’ Glass Bottle Washers?

Search for a solution that satisfies all of the above needs and others and Seppa Solutions will take care of it. Here’s what makes their glass bottle washers stand out:

Tailored to Your Needs: Irrespective of beverage, pharmaceuticals, or cosmetics industry, their washers can also be tailored to fit your individual needs.

Environmentally Friendly: Seppa Solutions machines are used as a way to save water and energy but there is no sacrifice in cleaning quality.

Built to Last: Using high-quality materials, these washers are designed for strength and dependability, even when heavily used.

Advanced Automation: Their washing machines are equipped with smart functions, such as automatable settings and automatable inspection, which enables efficient and uniform cleaning.

When you choose Seppa Solutions, you’re not just buying a machine—you’re investing in quality, innovation, and long-term success.

Industries That Rely on Glass Bottle Washers

Uncontaminated glass containers are not only of interest for a specific sector of the economy. Lot of industries take advantage of having a state-of-the-art bottle washer such as:

Beverages: Clean bottles preserve the taste and freshness of beverages, from soda, to beer and wine.

Pharmaceuticals: Sterile bottles are crucial for storing medicines and vaccines.

Cosmetics: A sterilized receptacle can represent the top grade of the product in it.

Food Producers: Clean packaging is essential for products such as sauces, oils, and syrups to maintain freshness and safety.

No matter your field, clear bottles tell your customers you care about the customer on the receiving end of your product, and the quality of that product.

Why Seppa Solutions Is the Right Choice

When it comes to glass bottle washing, Seppa Solutions has set the gold standard. Their washers are designed to meet the highest levels of cleanliness while being cost-effective and eco-friendly.

Choosing Seppa Solutions means choosing:

Better product quality.

Streamlined operations.

A stronger reputation with your customers.

Ready to Make the Switch?

Why settle for anything less than the best? Your customers deserve clean, safe, and high-quality packaging. By investing in Seppa Solutions’ Glass Bottle Washer, you’re ensuring every bottle you use is up to the mark.

Don’t wait—contact Seppa Solutions today and discover how their innovative solutions can elevate your business. Because every little detail counts when it comes to cleanliness.

#glass bottle washers#glass bottle cleaner#glass bottle cleaning machine#industrial glass bottle washer#glass bottle washer machine

0 notes

Text

Bacillus Clausii Spores Suspension Manufacturers

Bacillus Clausii Spores Suspension Manufacturers: An Overview of Benefits and Applications

Bacillus clausii is a highly resilient, beneficial bacterium that belongs to the Bacillus species, often used in the form of spore suspension for various industrial and healthcare applications. Due to its remarkable properties, such as its ability to survive in harsh environments and its probiotic benefits, Bacillus clausii spores suspension is gaining significant attention. In this blog, we’ll explore the role of Bacillus clausii spore suspension manufacturers, their products' benefits, and the diverse applications they serve.

What is Bacillus Clausii?

Bacillus clausii is a non-pathogenic, spore-forming bacterium that thrives in extreme conditions, including acidic environments like the human stomach. The bacterium is known for its ability to produce spores, which are extremely resilient and capable of surviving even when subjected to harsh environments like heat, desiccation, and acidity. Bacillus clausii is widely recognized for its probiotic potential and its use in various treatments related to gut health.

Bacillus Clausii Spores Suspension: What Makes It Special?

A spore suspension of Bacillus clausii involves suspending the bacterial spores in a liquid medium. These spores remain dormant in this state and can be activated once they reach the intestines or the desired area of application. The spores have an innate ability to restore the natural microbial balance in the gut and support overall digestive health.

Benefits of Bacillus Clausii Spores Suspension:

Probiotic Properties: Bacillus clausii spores have a long history of being used in the treatment of various gastrointestinal disorders. It helps maintain gut flora, reduces the severity of diarrhea, and can even help restore the microbiome balance after antibiotic use.

Enhanced Survivability: Unlike many probiotics, Bacillus clausii spores are more resistant to harsh conditions such as stomach acid and bile, which makes them highly effective when delivered orally. Their ability to form spores allows them to survive transit through the digestive tract, making them effective when consumed in supplement form.

Immune System Support: Bacillus clausii is known to stimulate the immune system by promoting the production of immune cells and enhancing gut-associated lymphoid tissues.

Digestive Health: By aiding in the proper functioning of the digestive system, Bacillus clausii can alleviate issues like bloating, constipation, and other gut-related discomforts. The spores can also aid in the absorption of nutrients, which is crucial for overall health.

Manufacturing Bacillus Clausii Spores Suspension

The process of manufacturing Bacillus clausii spore suspensions requires sophisticated techniques to ensure that the spores are preserved in a stable form, maintaining their potency and effectiveness. Manufacturers typically follow several key steps:

Cultivation of Bacillus Clausii: The first step involves cultivating Bacillus clausii under controlled conditions to encourage spore formation. This process can take several days and requires careful monitoring of temperature, pH, and nutrient levels.

Spore Harvesting: After the spores have matured, they are carefully harvested and purified. The purity of the spores is critical to the final product, as contaminants can affect their performance.

Suspension in Liquid Medium: Once the spores are isolated, they are suspended in a sterile liquid medium to create the spore suspension. This step is done under sterile conditions to prevent any microbial contamination.

Packaging and Storage: The Bacillus clausii spore suspension is then packaged in suitable containers that ensure the stability and potency of the spores. These containers must protect the suspension from environmental factors that could degrade the spores, such as light and temperature.

Quality Control and Testing: Throughout the manufacturing process, quality control is essential. Manufacturers perform rigorous testing to ensure the Bacillus clausii spores are viable, free from contaminants, and safe for use. This includes microbiological testing, sterility testing, and potency testing.

Applications of Bacillus Clausii Spores Suspension

Bacillus clausii spores suspension is utilized in a variety of sectors, notably in healthcare, food industries, and even agriculture. Below are some key applications:

Pharmaceutical and Healthcare Industry: Bacillus clausii spores are primarily used in the form of supplements for improving gut health. They are included in products aimed at treating digestive disorders, reducing antibiotic-associated diarrhea, and managing irritable bowel syndrome (IBS).

Animal Health: Bacillus clausii is also used in veterinary applications, helping to restore gut health in animals and promote a balanced microbiota in their digestive systems.

Agricultural Sector: The probiotic nature of Bacillus clausii spores has led to their use in agriculture. They are employed as natural biocontrol agents for plant diseases and as soil conditioners to enhance plant growth. The bacteria help improve soil health by enhancing nitrogen fixation and promoting beneficial microbial activity.

Food Industry: As a food-grade probiotic, Bacillus clausii is also used in functional foods and beverages. It is commonly found in fermented products like yogurt and functional beverages, where it helps enhance the nutritional profile of the product by supporting gut health.

Choosing a Reliable Bacillus Clausii Spores Suspension Manufacturer

When selecting a Bacillus clausii spores suspension manufacturer, it’s essential to consider several factors:

Expertise and Experience: The manufacturer should have experience in producing high-quality spore suspensions.

Quality Control Standards: Ensure that the manufacturer follows stringent quality control processes. This includes adherence to GMP (Good Manufacturing Practices) and certifications from relevant authorities.

Research and Innovation: A reliable manufacturer should engage in continuous research to improve their products and explore new applications of Bacillus clausii spores.

Sustainability Practices: Manufacturers should adopt eco-friendly practices in their production processes to ensure sustainability and minimize the environmental impact of their operations.

Conclusion

Bacillus clausii spores suspension is a potent and versatile product that offers numerous health benefits. Whether used for digestive health, immune support, or in agricultural applications, it plays a significant role in enhancing human and animal well-being. The demand for high-quality Bacillus clausii spore suspensions is growing, and reputable manufacturers are at the forefront of providing these innovative solutions. By understanding the manufacturing process, benefits, and various applications of Bacillus clausii spores, consumers can make informed decisions about incorporating this beneficial bacterium into their health regimens or business practices.

URL: For more information, visit Vakya Lifescience : Bacillus clausii spore suspension manufacturers

0 notes