#Manufacturer of Mica Powder

Explore tagged Tumblr posts

Note

your stuff looks very cool! can you please explain more about the materials & what you mean by bodysafe?

Thank you! And absolutely, safety is so important to me!

We make all of our toys with platinum cure silicone. The specific silicones we use are tested and certified skin safe by our manufacturer, meaning it won't cause irritation or reactions with skin and is totally safe to be in contact with for prolonged periods. Platinum cure silicone is hypoallergenic, phthalate free, nonporus, and hydrophobic making it an ideal material for sex toys when treated properly!

For our pigments we use mica powders that are certified by US and EU standards to be safe to use near eyes and on mucus membranes that won't cause irritation. These are double safe because they're encapsulated in the silicone. For non mica powder pigments we use pigments designed to be used with silicone that also has the same body safe certification!

20 notes

·

View notes

Text

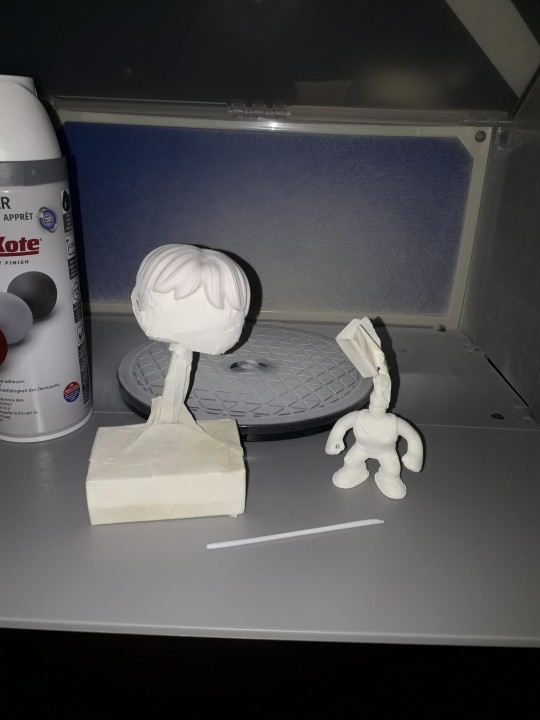

How to Build Your Own 'Augmented Super Wife Supersoldier From The Future' Funko Pop.

A Semi-Coherent Guide By RC.

This is a long one. A loooooooong one.

I meant to do this like two and a half years ago, but in the spirit of keeping this fandom's head above water, and the fact I'm at the hospital (nothing serious!) with nothing to do for the next couple of hours, I'm doing it now.

So if, like me, you are still bitter that Grace and Dani didn't get official Funkos, or official *anything* due to manufacturer short-sightedness, why not say 'fuck it' and build yer own?

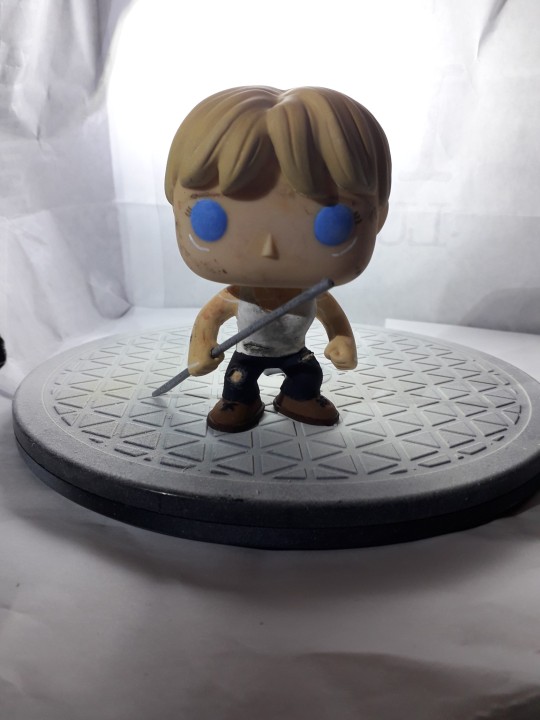

This rambling tutorial will attempt to demonstrate how to build Grace from the 'when they start to kill me, run' scene.

Like, literally that bit 😋.

Anywho. Let's do this!

You will need:

- Funko Pop DIY (female)

- Polymer clay (eg. Sculpy, Fimo, CosClay). I'd advise against cheapo no-name alternatives purely because in my experience the baking times/temperatures stated are absolute garbo. Also, polymer clay will give off quite gnarly fumes while curing, so better to use a trusted source. But if cheapo's all ya got, it's all ya got.

Other modeling materials you might consider instead of polymer clay include...

Epoxy clay (eg. Milliput, Apoxie Sculpt, The Army Painter 'Green Stuff', even something like J-B Weld or similar 2 part plumber's/repair putty).

Plain ol' air drying clay (eg. DAS, FimoAir, Gedeo).

You could even whip up a batch of 'cold porcelain', or an oven cure salt dough from ingredients you probably already have at home. Make sure you clear coat any salt dough creations properly after curing as over time ambient moisture may mess with it.

Each option above has its own pros and cons. Do your research if you aren't sure. Me? I used Fimo.

*ahem* Carrying on...

- Masking tape

- Hobby knife

- Pin vice

- Kebab skewer (wooden), or styrene rod

- Paint brushes

- Primer (plus dust mask if you're using a rattle can indoors)

- Sandpaper (around 400 grit oughta do it but you could probably go 200 either side of that and get a good result)

- Acrylic paints (optional: Posca PC-1MR pens in black and white for fine detail).

- Crafter's heat gun, or a hairdryer

- Varnish/clear coat.

Optional extras: Airbrush, spray booth/cardboard box, rotary tool, oven thermometer, artist's/cake decorating turntable, UV resin, silver leafing pen, jeweller's files, jeweller's wire, acetone, superglue or 5 minute epoxy, a lil piece of sponge, pearl mica powder, scavenged Funko Pop head 😈.

Step One: Grab your Funko DIY and separate the head from body using heat to soften the vinyl enough to wangle it off the neck post. Shoving it in a mug of hot water for a few minutes should do the trick. Make sure to dry out the head as much as possible. Last thing you want is mould growing inside it. This is Terminator, not The Last Of Us 😉. Alternatively you could use your heat gun/hairdryer, but I explain in Step Six why the water bath approach is a better option (imho) at this early stage.

(You are giving this entire thing a quick read through before you start, right? I dunno about the rest of you but I like to have at least a basic idea of the work ahead before I get stuck in. Saves finding out you're missing a necessary tool/material at an inopportune moment and all).

Stop rambling, RC. Sorry. It's easier to be succinct when you haven't lost half your photos 🤦♀️. Moving on...

If you don't wanna attempt to sculpt the hair yourself you can, as I did, take a kitbashing approach instead of using the supplied DIY head. Grab one of the many commercially available Funkos with a decent approximation of the hairstyle you want and then go Step One on em. Buy 'pre-loved', buy BNIB, dig one out of a dumpster, steal one from your lil cousin, it doesn't matter. Procure as your time/budget/situation dictates. Improvise where necessary.

Sorry, Ron. I need your floppy hair. I do not need your clothes.

Or your boots. Or your motorcycle.

...😋

Step Two: Take the body of the Funko DIY and mark out the position of the tank top and the cuffs of the jeans. These will be used as guides for when you add the clay.

At this point I used a pin vice to drill the hole thru the fist for the rebar. If you're a crazy person you could use a rotary tool with an appropriately sized bit attached.

To make the rebar I fashioned a mould from a drinking straw and filled it with UV resin. Because I'm awkward. A wooden kebab skewer, or some hobbyist's styrene rod (eg. Evergreen Scale Models) would work just as well. Just cut it to size, paint it silver and you're golden. I used a metallic leafing pen. You use whatever you've got handy. Doesn't have to be shiny. A flat grey acrylic would work just fine.

Use jeweller's files and sandpaper to make small adjustments to the hand hole and rebar respectively in order to get a good press fit. There's always glue if you overdo it 😉. But don't add the rebar to the model just yet, as you're gonna need room to manoeuvre for the next bit.

Step Three: How do you make it look like your figure is wearing clothes when you don't have much real estate to work with?

You fake it, that's how.

You do not need to model an entire set of clothes! It's an arse ache, and we're all about working smarter not harder on the RC channel.

So, take your modeling compound of choice, roll a chunk of it out to the desired thickness, and then cut into strips, say 2-3mm wide. Use your best judgement here.

Now, using the jeans as our example, wrap a strip around the bottom of the leg where the cuff would sit. Cut off any excess and blend out the join. Just give it a lil rub and it's like it was never there. Like magic! You should have a nice defined edge at the bottom, just above the foot. Now see the top edge of your lil clay strip? Well, you wanna start pushing and flattening the clay to blend the edge right out so it fades back into the body.

Repeat for the other leg, and the bottom of the tank top. The straps are relatively simple, tho the bits that pass under the arms can be fiddly due to lack of space. Use a hobby knife to shape and crisp up those edges and then blend out the extraneous edge. Same thing with the neckline.

Run a strip around each foot to form the soles of the boots, and a lil 'x' on the top of the feet to give the impression of laces.

For the rips in the clothing you can simply gouge out a little of the clay. If there isn't any on that part of the model (the knee for example) roll out a little wormy dealie (for you North of the Border fans 😉), position it as needed, blend out the edges, then gouge as required.

If you're playing on hardcore mode, this might be the time to start piling clay on the Funko DIY head and sculpting the hair. You may prefer to leave it til the head's re-attached tho. It depends on the material you're using. If you don't think it'll stand up to a bit of manhandling while pushing the head back onto the body, save this step til that bit's done.

Cure according to the clay manufacturer's instructions. The vinyl will not melt at the temperatures required to cure polymer clay, but if you don't wanna risk it or you don't wanna use your food oven to cook plastic, with all the gnarly fumes and stuff, I've given you plenty of air dry and/or non toxic alternatives. Consistent temperature is key with polymer clay. Undercooked, it's quite brittle. An oven thermometer comes in handy here if you've got one.

Step Four: Primetime!!! Some like to brush on primer, which is fine if you're painting a fence or throwing gesso on a canvas. Not so fine if you're painting a figurine imho. I mean, unless it's Cassandra from Doctor Who. A good rattle can of spray paint is what you want ideally, but again, it's about what you can afford/wangle/manage with your crafting space, so feel free to ignore me and brush away!

First rule of Primer Club: several light coats are better than one heavy coat. Second rule of Primer Club: knock each coat back a lil with sandpaper before applying the next one. Third rule of Primer Club: sit your rattle can in a warm water bath for five minutes before shaking it up to improve flow.

You can get primer specifically for plastics but while I would recommend it, it's not absolutely necessary.

A scavenged head may need masking off if the base colour already matches the skin colour of your character. Save yourself a bit of painting innit. You can get really tight, clean edges against the hairline with a hobby knife. If the hairstyle, hair colour, and skin colour match straight outta the box? Congrats! Why are you even reading this? 😜.

That thing in the background is a portable spray booth (that other thing is a turntable). A cardboard box is also a portable spray booth if you want it to be. Only thing it doesn't have is an extractor fan. So put on a dust mask, and open a window or work outside.

The DIY figure comes primed outta the box, so if you're using the DIY head and are planning on sculpting the hair after re-attachment you don't need to prime it. Unless you want to.

Step Five: Time to paint that shizz. You don't need me to walk you thru this bit, right?

Right?...

Masking is your friend if you don't trust your ability to freehand with a brush. If you're masking over a part you've already painted and are afraid of pulling the paint off, you can knock the level of tack on the tape down by sticking it to yourself (or your clothes) a couple of times before applying it. Some prefer to add a light layer of clear coat to 'lock in' the underlying paint. It's like a real life 'save point'. Some people do both. Some use masking fluid. Some use silly putty/blu-tac/plasticine. Play around, see what works. You do you.

I painted Grace's eyes blue coz Grace is extra and so am I. I threw a lil bit of pearl powder in there to add a subtle shimmer, as I thought going full metallic blue might be a bit too extra.

Lady Funkos have eyelashes. Don't forget the eyelashes.

(I nearly forgot the eyelashes).

A fine tipped Posca pen comes in handy here if you've got one.

Ditto the eyebrows, tho those aren't just for the ladies obvs.

For Grace's augmentation scars, again I recommend a Posca pen but a brush will do.

DO NOT PAINT THE NECK POST. Don't even varnish the neck post. Keep that bitch masked up until you're ready to reattach the head. Like, you can get away with painting the very bottom if you're worried the bare plastic will show even with the head attached, but that's it. Any more will be making a rod for your own back.

You have a choice now. Whether to weather your figure. I chose to add that extra level of detail as it made sense to me. Use a combination of dark washes, dry brushing, and/or sponge stipling to add dirt, blood etc. If ya want.

When you're happy with your paint job, give everything (except the neck post!!!!) a couple of layers of clear coat.

Step Six: When it comes to reattaching the head you probably don't wanna be dunking anything in water by this point, just in case. So we're gonna soften the neck post (and around the base of the head if necessary) with hot air instead. Use a hairdryer if you don't have a heat gun. DO NOT use an industrial or decorator's heat gun for the love o' god. That shit's meant for stripping paint, not gently warming vinyl figurines. It'd be like using a nuke to shake a cherry tree, and you'd likely burn yourself. A hairdryer is more than capable of doing the job.

Why did we not use the hairdryer for Step One? To be honest there's nothing stopping you if that's what you wanna do, but as you don't have direct access to the bits that need softening at that point you will have to wait for the heat to penetrate. You could be doing other things in that time by letting a water bath do the work for you.

Now, however, you do have direct access, so you'll probably find you only need to blast the hot air for 10 seconds or so.

Step Seven: So, you've got the head re-attached, and your paint job is finished and clear coated. That means it's time to add the rebar. If you went a bit too far with the drilling or sanding now's the time to get your glue on. As an final extra touch you can spiral some thin jeweller's wire around the length of the rebar to make it look more rebar-y. I didn't do this bit as the wire I had in my possession at the time was too thick for my tastes.

But whether you opt for that or not, congratulations on making your very own Grace Funko Pop!

I'm still planning on making security guard and future war versions of Grace, and at least one version of Dani. Yeah, I've been saying that for the last two years, but it's still absolutely happening, trust me.

Anyway. That'll do it. If you have any questions, or you need further explanations or recommendations etc. y'all know where to find me.

8 notes

·

View notes

Text

Heatmaster International: Your Trusted Partner for Industrial Heating Solutions

At Heatmaster International, located in Bahrain, we are committed to delivering high-quality, efficient, and durable industrial heating solutions. With years of expertise, we provide a wide array of products tailored to meet the specific needs of various industries. Our products, including open coil heaters, dehydrators, heat exchangers, mica band heaters, powder coating ovens, calorifier heaters, material handling systems, turnkey projects, and process equipment, are designed to ensure optimum performance and efficiency.

Open Coil Heaters: Reliable and Efficient Heating

Open coil heaters are essential for many industrial applications. Their open design allows for efficient heat transfer, making them ideal for air or liquid heating. As a leading open coil heater manufacturer, Heatmaster International offers products designed for longevity, versatility, and easy integration into various systems. Whether you're in need of a heater for your ventilation system or a more complex industrial application, our open coil heaters deliver reliable and consistent heating power.

Dehydrators: Perfect for Moisture Removal

Our dehydrators are perfect for industrial applications requiring moisture removal. Whether you're in the food, pharmaceutical, or chemical industry, dehydrators help to preserve products by efficiently reducing moisture levels. Heatmaster International’s dehydrators are built with advanced technology to ensure faster and more energy-efficient drying, making them an invaluable tool for manufacturers who need to reduce moisture content in their products.

Heat Exchangers: Boosting Efficiency

A heat exchanger is a critical component in industrial heating and cooling systems. At Heatmaster International, our heat exchangers are designed to transfer heat efficiently between two or more fluids, ensuring that industrial processes run smoothly and cost-effectively. We manufacture heat exchangers that are durable, easy to maintain, and perform exceptionally well in high-demand environments.

Mica Band Heaters: High Performance for Precision Heating

Mica band heaters are widely used for precision heating applications, especially in industries where controlled heat is essential. Heatmaster International’s mica band heaters provide uniform heat distribution, ensuring efficiency and consistency in industrial processes. These heaters are ideal for heating barrels, tanks, and other cylindrical equipment, providing an effective solution for your heating needs.

Powder Coating Ovens: Advanced Heating for Coating Processes

For industries involved in powder coating, our powder coating ovens are an essential piece of equipment. These ovens are designed to cure powder coatings evenly and effectively, ensuring the highest quality finish. Heatmaster International’s powder coating ovens provide excellent temperature control, energy efficiency, and durability to meet the demands of modern manufacturing processes.

Calorifier Heaters: Efficient Hot Water Solutions

At Heatmaster International, we offer calorifier heaters designed to provide reliable hot water for industrial processes. These heaters are used to efficiently heat water, providing a steady supply of hot water for various applications such as heating, cleaning, and other industrial needs. Our calorifier heaters are designed with advanced technology to ensure energy efficiency and long-lasting performance.

Material Handling Systems: Improving Productivity

A material handling system is an essential part of any industrial facility, and at Heatmaster International, we provide innovative and efficient solutions. Our material handling systems are designed to improve productivity, reduce labor costs, and streamline operations. We manufacture systems that can handle a wide range of materials, from raw goods to finished products, ensuring that your business operates efficiently and safely.

Turnkey Projects: Complete Solutions for Your Business

At Heatmaster International, we offer turnkey projects that provide comprehensive solutions from design to implementation. Whether you need a complete heating system, a custom-designed production line, or a full-scale industrial project, our team has the expertise to deliver results. Our turnkey projects include everything from initial consultation and design to installation and maintenance, ensuring a smooth and hassle-free experience for our clients.

Process Equipment: Tailored for Your Industrial Needs

Heatmaster International offers high-quality process equipment that is designed to meet the specific requirements of your business. Our process equipment is built to enhance productivity, reduce downtime, and ensure consistent performance. From heating systems to custom equipment, we provide solutions tailored to your industry, ensuring that every piece of equipment meets your operational standards.

Why Choose Heatmaster International?

As a Bahrain-based manufacturer, Heatmaster International is known for providing top-tier industrial heating solutions, including open coil heaters, dehydrators, heat exchangers, mica band heaters, powder coating ovens, calorifier heaters, material handling systems, turnkey projects, and process equipment. Our products are designed to maximize efficiency, reduce energy consumption, and improve the overall performance of your operations.

We pride ourselves on offering durable, reliable, and energy-efficient solutions that meet the unique needs of every client. Whether you need heating for industrial processes, moisture removal, or complete turnkey solutions, Heatmaster International is your trusted partner for all your industrial heating needs.

Contact Heatmaster International today to learn more about our products and services. Let us help you optimize your industrial processes with the best heating and equipment solutions in the market.

0 notes

Text

Enhancing Idols and Sculptures with Premium Pigments by SP Colour & Chemicals

SP Colour & Chemicals Mica powders and pigments covered with metallic oxides, such as titanium dioxide, metal flakes are used to create pearl pigments, which are fine powders. These pigments produce stunning pearlescent, metallic, or iridescent effects by reflecting light. Pearl pigments do not produce solid hues like regular pigments do. Rather, they give every surface they adorn a dazzling shine that delicately changes depending on the angle of the light, giving it refinement and fascination.

Why Choose Pearl Pigments by SP Colour & Chemicals for Sculptures and Idols?

There are numerous benefits of using our pearl pigments:

Aesthetic Appeal: Pearl pigments give sculptures and idols an opulent sheen that enhances their visual appeal and makes them appropriate for both classic and contemporary designs.

Versatility: Our Pearlescent pigments perform well with a wide range of materials, including metal, wood, clay, plaster, and resin.

Durability: The sculptures will continue to shine over time because of SP Colour & Chemicals’ pigments’ lightfastness, resistance to weather, and non-toxicity.

Cultural Significance: Pearl pigments by SP Colour & Chemicals can replicate the appearance of valuable metals and stones in religious and cultural idols, giving them a regal or hallowed atmosphere.

How to Apply SP Colour & Chemicals’ Pearl Pigments on Sculptures and Idols?

Step 1: Preparing the Surface of your products

Make sure your idols and sculptures surface is clean, smooth, and primed if needed before adding pearl pigments. A primer improves the colors’ adhesion and brightness on materials like clay or plaster.

Step 2: Applications used on your products

Dry Brushing: This technique is ideal for emphasizing fine details since it uses a gentle, dry brush to apply pigments to the surface.

Mixing with Mediums: For painting or pouring applications, mix pigments with transparent binders such as varnish, resin, or acrylic medium.

Layering: To achieve a rich, multi-tonal appearance, apply several layers of color.

Step 3: Finish Sealing

Apply a clear coating, like epoxy resin or spray varnish, to the pigments to seal them. This stage guarantees longevity and improves the pigments’ sheen in addition to protecting them.

How to Use Pearl Pigments in Candle Making?

Pearl pigments are simple to use, but meticulous attention to detail is necessary to achieve professional effects. Here are some pointers:

Preparation: Melt the wax to the temperature specified for the type you have selected (paraffin, soy, etc.). For best results, measure out the appropriate amount of AMP Pigments, usually 1% to 2% of the wax weight.

Mixing: To guarantee even distribution of coloring effect, gently add the premium pigment to the heated wax while mixing constantly.

Pouring: Before pouring, divide the pigmented wax into pieces and work as required to create layered or marbled effects. To avoid the wax cooling too soon, work swiftly.

Final Details: After the candle has set, you can use a soft brush to add more pigment to the surface for more glitter effect.

Creative Applications for Pearl Pigments

Combination of Colors: To create distinctive hues with delicate sheen, mix SP Colour & Chemicals pearl pigments with any color pigments.

Glow-in-the-Dark Effects: To create idols that glow in low light and have a mysterious appearance, combine pearl paints with phosphorescent powders.

Antique Finishes: Ideal for classic idols with a historic appearance, metallic pearl colors can be used to simulate aged gold or bronze.

Why Choose SP Colour & Chemicals’ Pearl Pigments?

We at SP Colour take great satisfaction in manufacturing high-quality varieties of pearl pigments that are specific to the requirements of both manufacturers and artists. The pigments we use are:

High Quality: Constructed from premium materials for exceptional durability and brilliance.

Broad Variety: Every artistic vision can be satisfied with our selection of metallic golds and color-shifting iridescents.

Sustainable and Safe: They are perfect for use in religious and decorative objects because they are non-toxic and environmentally friendly.

The pearl pigments from SP Colour offer the ideal finish to make your creations come to life, whether you are making a massive sculpture for public display or a tiny handcrafted idol.

To know more: Visit us : www.spcolour.in | www.amppigments.com OR Contact us: +91 9990286664

0 notes

Text

A Comprehensive Guide to Selecting the Best Mica Powder Supplier

Mica powder, known for its various applications and distinctive qualities, has become a significant raw material across multiple sectors. From cosmetics to electronics and construction, its value is unrivaled. Knowing the characteristics, uses, and sourcing requirements of mica powder is crucial for making wise choices when looking for a trustworthy provider.

Understanding Mica Powder

Mica is a mineral that occurs naturally and breaks into thin, pliable sheets. Supplier of Mica Powder is a popular option in sectors that require longevity and visual appeal since it maintains its gloss and superior insulating qualities when ground into powder. Depending on its intended use, purity, and fineness, mica powder comes in a variety of grades.

Among the notable characteristics of mica powder are:

Thermal and Electrical Insulation: Mica is a natural insulator, frequently employed in electrical equipment and high-temperature environments.

Durability: Its robust nature ensures longevity, making it a cost-effective solution.

Aesthetic Appeal: The glittering quality of mica powder lends a beautiful finish to cosmetic goods and paintings.

Mica Powder's Industrial Uses

Mica powder's versatility allows it to meet a variety of industrial needs:

Cosmetics: Mica's smooth texture and sheen make it a popular element in makeup such as highlighters, lipsticks, and foundations.

Construction: Used in plasters, mortars, and paints, mica powder enhances strength and provides a smooth finish.

Electronics: Mica powder is a critical component in insulating materials for electrical appliances due to its heat-resistant properties.

Rubber and plastics use it as a filler to increase stability and mechanical strength.

Automotive: Mica boosts the endurance and aesthetic appeal of paints used in vehicles.

Important Things to Look for in a Mica Powder Supplier

The performance of mica powder in the intended application is greatly influenced by its quality. Therefore, one of the most important steps for businesses is selecting the right supplier. Here are some factors to consider:

Purity and Quality: Ensure the provider supplies high-purity mica powder free from impurities. Impurities might damage the performance and durability of the final product.

Range of Grades: A reputable provider provides a range of grades to meet various industrial requirements. Because of this flexibility, firms can choose the best course of action.

Sustainability: Since careless sourcing can damage ecosystems and communities, ethical mining and ecologically friendly processing are important factors to take into account.

Packaging and Delivery: Proper packaging guarantees that the mica powder preserves its quality during transit. Meeting manufacturing schedules also requires dependable delivery dates.

Customer Support: To help organizations make the most of mica powder, a trustworthy provider will offer technical support and advice.

Why Mica Powder is a Preferred Choice in Modern Applications

Mica powder's versatility and distinctive qualities have led to its increasing demand across numerous sectors. Its performance is unmatched because of its capacity to tolerate high temperatures, withstand water, and produce a smooth finish. Additionally, its natural availability guarantees a steady supply for businesses dedicated to environmentally beneficial operations.

Top Provider of Mica Powder

Pratibha Refractory Minerals is a well-known brand in the sector and a reliable source of premium mica powder. With an emphasis on client satisfaction, quality control, and sustainable methods, the company serves varied industrial requirements. They are a dependable partner for companies looking for premium mica powder for their applications because of their dedication to quality.

Mica Powder's Prospects in Industry

As industries continue to innovate, the demand for versatile raw materials like mica powder is only expected to grow. From enhancing the performance of electronics to revolutionizing beauty products, its applications are set to expand. Suppliers who value quality and sustainability will play a major role in influencing the future of this indispensable commodity.

Conclusion

Selecting the best mica powder supplier is a critical step for businesses looking to improve customer happiness and product performance. With its unequaled qualities and extensive applications, mica powder remains a cornerstone for current industrial needs. By cooperating with a trustworthy source like Pratibha Refractory Minerals, businesses can access the full potential of this unique material while ensuring sustainable practices and high-quality output.

0 notes

Text

Testing all my brush pens full of fountain pen ink and 7 are more stubbornly cloggy out of 40 pens. 2 were leaky, but fixable.

Also no pattern whatsoever on what ink clogs my pens. I thought mica powder shimmer inks might be more problematic, but I guess the powder is small enough. So I guess it's just mild manufacturing errors and general disuse letting ink find somewhere to settle.

Occurs to me I have enough pens to do every day of October in a different color.

Me: I will save money and use less plastic filling these pens with fountain pen ink instead of using cartridges!

Angel On My Shoulder: Yes, but you need to stop buying all these shimmer inks

Devil On My Shoulder: No, you should have more shimmer inks.

0 notes

Text

High-Quality Mica Pearl Powder for Cosmetics, Plastics, and Coatings | SP Colour & Chemicals

SP Colour & Chemicals is among the leading manufacturers of top-quality Mica Pearl Powder which is Most effective for its shine, durability as well as versatility in many applications. We have over 26 years of experience in Mica Pearl pigments manufacturing, allowing them perfect for applications for cosmetics, plastic, automotive, Soap, Coatings, Oil etc. Various shades and Different particle sizes of Mica Pearl powder are available.

Many uses of Mica Pearl Powder:

Cosmetics Industry: Our Cosmetic Grade Mica Pearl Powder is Nontoxic and can be used in lipsticks, eyeshadows, nail lacquers and other cosmetic products providing a shine that makes them better.

Plastics Manufacturing: Mica Pearl Powder provides a bright and glittering coating for plastic products, enhancing the looks of items such as bottles, household products and components for the automobile industry.

Coating & Paints: We use Mica Pearl powder pigments, color pigments which give metallic and pearlescent effect widely used in Automotive paints, Industrial coatings, powder coatings to enhance the appearance at the end of the product.

Printing and Packaging: Apart from that, Mica Pearl Powder is used in screen printing and packing to produce captivating aspects and special effects.

Mica Pearl Powder Advantages:

High Luster: Yield a rich reflective surface finish.

Wide Range of Colors: Comes in both earthy tones and man made colors.

Durability: Good resistance to overheating and fading.

At SP Colour & Chemicals, we ensure that our Mica Pearl Powder meets the highest industry standards for quality, safety, and performance. Whether you're in the cosmetics, plastics, or coatings industry.

To know more

Visit Website : www.spcolour.in | www.amppigments.com

OR

Contact us : +91 9990286664

0 notes

Text

VedaOils is a prominent producer and seller of Natural Soap Colorants for soap making. It is used in a variety of products like candles, cosmetics, skincare, etc. We are recognized for offering cost-effective natural products since we manufacture them in bulk quantities and distribute them throughout the United States at Wholesale Prices.

0 notes

Text

Buy Pigment Powder Online in India – VedaOils

Buy Pigment Powder Online at Wholesale Prices in India. Shop Mica Powder for Resin, Paint Work, Nail Art, Lip Care & Cosmetics Products. Order Dry Pigment Powder in Bulk Quantity directly from Wholesale Manufacturers & Suppliers. Check Mica Powder Prices, Specifications, Shipping, Discounts, and Offers on Vedaoils.

1 note

·

View note

Text

Pearl Pigments and Pearl Powders | SP Colour & Chemicals | AMP Pigments

In the vibrant landscape of India's chemical industry, SP Colour & Chemicals has emerged as a distinguished manufacturer, specialising in the manufacturing of Pearl Pigments and Pearl Powders.AMP Pigments has established itself as a frontrunner in the realm of colour and cosmetic additives.https://spcolour.in/pearl-pigment-powder-manufacturer/

SP Colour & Chemicals takes pride in its extensive expertise in the formulation and manufacturing of pearl pigments, which are known for imparting a luminous and iridescent quality to various products. These pigments are manufactured with precision, utilising advanced techniques and technology to ensure optimal performance and visual appeal.https://spcolour.in/pigment-paste/

Pearl pigments manufactured by SP Colour & Chemicals are versatile and find applications in diverse industries, including cosmetics, automotive coatings, plastics, printing inks, and more. The pigments are characterised by their ability to create a pearlescent effect, enhancing the aesthetics of the final product. With a wide range of colours and particle sizes available, clients have the flexibility to achieve their desired visual effects, be it a subtle shimmer or a bold, eye-catching sparkle.https://spcolour.in/pigment-powder/

SP Colour & Chemicals manufacturing landscape, offering a spectrum of possibilities with its pearl pigments and powders. AMP Pigments continue to seek brilliance and sustainability, SP Colour & Chemicals remains at the forefront, delivering solutions that captivate the senses and respect the planet.

0 notes

Text

Heatmaster International: Your Premier Partner for Industrial Heating Solutions

In the heart of Bahrain, Heatmaster International has established itself as a leader in the manufacturing of industrial heaters and equipment. With a robust commitment to quality and innovation, Heatmaster provides a comprehensive range of heating solutions that cater to various industrial needs.

Extensive Product Line of Industrial Heaters

At Heatmaster International, you will find an impressive array of industrial heaters designed for efficiency and durability. Their extensive product line includes:

Open Coil Heaters

As a distinguished open coil heater manufacturer, Heatmaster specializes in open coil heaters that are highly effective for rapid heating applications. These heaters are particularly well-suited for integration into industrial ovens and industrial dryers, providing reliable performance and quick heating capabilities.

Flanged Tubular Heaters

For processes that demand precise temperature control, Heatmaster’s flanged tubular heaters are the ideal solution. Known for their reliability and efficiency, these heaters serve a wide variety of process equipment, ensuring optimal performance across multiple industries.

Industrial Immersion Heaters

Heatmaster International also offers a range of industrial immersion heaters designed to heat liquids efficiently within tanks and vessels. These industrial immersion heaters are essential for applications in sectors such as food processing, chemicals, and pharmaceuticals, where consistent temperature control is crucial.

Nozzle Heaters

In situations where space is limited, Heatmaster’s nozzle heaters provide compact and effective heating solutions. Widely used in the plastics industry, these heaters maintain the necessary temperatures for materials, enhancing overall processing efficiency.

Specialized Heating Solutions for Diverse Applications

Heatmaster International goes beyond standard offerings, providing specialized heating solutions that include:

Industrial Furnaces and Ovens

From industrial ovens to powder coating ovens, Heatmaster designs and manufactures equipment tailored to meet specific operational requirements. Their gas-fired pit furnace and roller hearth furnace exemplify energy efficiency and robust design, making them ideal for a variety of industrial applications.

Industrial Dryers and Dehydrators

Heatmaster’s industrial dryer and dehydrator solutions are crucial for effective moisture removal in manufacturing processes. These products are engineered to create optimal drying conditions, thereby preserving product quality and enhancing productivity.

Heat Exchangers and Calorifier Heaters

Integral to many industrial processes, Heatmaster’s heat exchangers and calorifier heaters facilitate energy conservation and improve process efficiency. By optimizing heat recovery, these systems help reduce operational costs while ensuring high performance.

Comprehensive Turnkey Projects and Material Handling Systems

One of Heatmaster’s notable services is its ability to deliver turnkey projects. This all-inclusive approach means clients receive tailored solutions, encompassing design, manufacturing, installation, and maintenance. Additionally, Heatmaster’s expertise in material handling systems ensures seamless integration with their heating solutions, enhancing overall operational efficiency.

Unwavering Commitment to Quality and Innovation

Heatmaster International is dedicated to maintaining the highest quality standards in all its products, from open coil heaters to industrial immersion heaters. Each product is crafted using state-of-the-art technology, and the company continuously innovates to provide the most effective heating solutions available.

Conclusion

For businesses in search of reliable and efficient industrial heating solutions, Heatmaster International in Bahrain is the go-to partner. With a broad range of offerings—including mica band heaters, rotary kiln direct firing, and a variety of industrial heaters—Heatmaster is equipped to meet the unique demands of any industry. Whether you require industrial ovens, industrial dryers, or specialized process equipment, Heatmaster International is committed to delivering excellence and enhancing your operations. Discover how their advanced heating solutions can transform your processes today!

0 notes

Text

SP Colour & Chemicals — Supplier of Plenty Solutions in Pearl & Pigments

SP Colour & Chemicals is one of the Top manufacturers in the volume of Pearl Pigments and industrial pigments with an extensive range of products suitable to the requirements of the industries across the globe.

With our 26 + years of experience we are determined to maintain the quality of our pigments so that it meets the demand of enhancing the aesthetics of the products and performing more in several uses.

Choosing SP Colour & Chemicals — Why Worry about Quality?

From the color stability of our pigments — one of the most severe tests, to pigments adhesion — the final test — all pigment characteristics of our products conform to the highest completeness of Colour requirements.

If it’s Automotive, Articles of Plastic, Cosmetics, Coatings, Printing Inks or any other industry, our pigments are here to provide you with the best of results to all your applications.

Range of Pigments

Pearl Pigments: The most stunning and extremely popular in use pearl pigments catch many smiles only because of their captivating effects of shimmer. These are mainly used in cosmetics, automotive paints and packaging materials. We have Wide Range of Pearl Pigments like Mica, Synthetic, Diamond, Iridescent, Chameleon and more.

Chameleon Pigments: Our exclusive chameleon pigments change colors according to angle, creating eye catching stunning visual effects on the products, surfaces or for coatings & films.

Glow Powder: Our brand has 15 different shades of glow in the dark pigments which make the perfect for safety signs, toys, textiles and many more.

Aluminum Metal Pigments: Suitable for metallic coatings and industrial paints, our pigments create smooth effects on your products.

Carbon Black: Carbon black are for their good dispersion and high saturation color and are used for printing inks, plastics, and rubber products. We have a wide range of Carbon Black.

To get more Information about us

Visit us : www.spcolour.in | www.amppigments.com

OR

Contact us : +91 9990286664

0 notes

Text

Pratibha Refractory: Your Trusted Supplier of High-Quality Mica Powder

When it comes to sourcing premium-grade mica powder, Pratibha Refractory stands out as a leading Supplier of Mica Powder dedicated to delivering superior quality and unmatched usability. Our commitment to excellence ensures that industries relying on mica powder can achieve optimal performance in their products and processes.

Why Choose Pratibha Refractory for Your Mica Powder Needs?

Superior Quality Mica Powder

At Pratibha Refractory, quality is our top priority. We understand that the effectiveness of mica powder in various applications depends significantly on its quality. That’s why we source the best raw materials and employ rigorous quality control measures to produce mica powder that meets the highest industry standards. Our mica powder is known for its purity, consistency, and superior properties, making it an essential component in numerous industrial applications.

Versatile Applications

Mica powder is a versatile material used in various industries, including cosmetics, electronics, construction, and more. At Pratibha Refractory, we provide mica powder that enhances the performance and quality of products in these industries. Our mica powder offers excellent thermal and electrical insulation properties, making it ideal for use in electronic components. It also provides a shimmering effect in cosmetics and serves as a filler in construction materials, improving their durability and performance.

Commitment to Customer Satisfaction

At Pratibha Refractory, we place a strong emphasis on understanding and meeting our customers’ needs. We recognize that each industry has unique requirements, and we are dedicated to providing mica powder that precisely meets those specifications. Our team works closely with clients to ensure they receive the right product for their specific applications. With our expertise and customer-centric approach, we have established long-term relationships with clients who trust us for their mica powder needs.

Sourcing the Best Raw Materials

The quality of mica powder is highly dependent on the raw materials used in its production. At Pratibha Refractory, we source high-quality mica from trusted suppliers to ensure that our products meet the highest standards. Our rigorous selection process guarantees that the mica we use is free from impurities and possesses the desired properties for various industrial applications. This commitment to sourcing the best raw materials sets us apart as a reliable supplier of mica.

Advanced Manufacturing Processes

Our state-of-the-art manufacturing facility is equipped with advanced technology and machinery to produce mica powder of consistent quality. We follow stringent manufacturing processes to ensure that our mica powder retains its beneficial properties and performs effectively in different applications. Our dedicated team of experts oversees every stage of the production process, from raw material selection to final packaging, to maintain the highest standards of quality and purity.

Customization Options

We understand that different industries have specific requirements for mica powder. At Pratibha Refractory, we offer customization options to meet these unique needs. Whether you require mica powder with specific particle sizes, chemical compositions, or other properties, we can tailor our products to suit your specifications. Our flexibility and commitment to customization make us the preferred supplier of mica powder for a wide range of industrial applications.

Conclusion

Pratibha Refractory is your trusted supplier of high-quality mica powder, offering superior products that enhance the performance of various industrial applications. With our commitment to quality, customer satisfaction, and sustainable practices, we stand out as a leading provider in the industry. For all your mica powder requirements, turn to Pratibha Refractory and experience the difference in quality and service. Contact us today to learn more about our products and how we can meet your specific needs.

0 notes

Text

The Beauty and Utility of Indian Soapstone Powder

Soapstone powder, a versatile mineral, has been a significant resource in various industries for centuries. This finely ground stone, often referred to as talcum powder, is valued for its myriad applications. Among leading Manufacturer of Soapstone Powder in India is A.N. Enterprises, a company with a rich history and an unblemished reputation for delivering superior products. Their products find applications in a wide range of industries, making them a trusted choice for businesses seeking top-quality soapstone powder. It is composed primarily of talc, chlorite, pyroxenes, micas, amphiboles, carbonates, and other minerals. The softness, heat resistance, and smooth texture of soapstone make it an ideal candidate for transformation into fine powder.

The Manufacturing Process

1. Extracting Soapstone: The journey of soapstone powder begins with the extraction of soapstone from quarries. We select the finest soapstone with high talc content to ensure the best quality end product.

2. Crushing and Grinding: Once extracted, the soapstone is subjected to a meticulous crushing and grinding process to create the fine powder. The consistency and purity of the powder are closely monitored throughout this phase.

3. Quality Control: Quality assurance is at the heart of our operations. Their rigorous testing processes ensure that the soapstone powder meets the highest industry standards.

Applications of Soapstone Powder

Soapstone powder finds its way into various industries due to its remarkable properties.

1. Cosmetics and Personal Care: The pharmaceutical and cosmetic industry often uses soapstone powder in talcum powders, soaps, and other skincare products.

2. Paper Industry: In the paper industry, soapstone powder serves as an excellent filler and coating material, enhancing the texture and finish of paper products.

3. Paints and Coatings: The paint and coatings industry utilizes soapstone powder as a cost-effective extender, improving the durability and finish of paint products.

4. Plastics: In plastics, it acts as a functional filler and reinforcement material, enhancing mechanical properties.

Why Choose A.N. Enterprises for Soapstone Powder?

1. Quality Assurance: A.N. Enterprises place a strong emphasis on quality control, ensuring that their soapstone powder consistently meets the highest standards.

2. Competitive Pricing: Their commitment to providing cost-effective solutions makes them a preferred choice for businesses seeking quality and affordability.

3. Ethical Practices: The company is dedicated to ethical and sustainable practices, ensuring that their operations have a minimal impact on the environment.

The Versatility of Soapstone Powder

Soapstone powder's versatility extends beyond its industrial applications. It has found its way into various art forms and crafts due to its softness and ease of carving. Artists and sculptors appreciate soapstone's workability, and the powder can even be mixed with water to create sculpting clay. Its natural color variations also add aesthetic value to sculptures and carvings, making it a preferred choice in the world of art.

Exporting Excellence

We aren't just a local supplier; they have gained recognition on the global stage for their superior soapstone powder. Their commitment to quality, consistency, and ethical practices has earned them a solid reputation among international clients. Many industries worldwide rely on us for their soapstone powder needs, acknowledging their contributions to global manufacturing and production.

If you're ready to explore the world of high-quality soapstone powder and experience the excellence of A.N. Enterprises, don't hesitate to get in touch with us today. Our team is eager to assist you with your specific needs and inquiries. Contact us to discover how our soapstone powder can enhance your industry or creative projects. Let's embark on a journey of innovation and reliability together. Your satisfaction is our priority, and we're here to meet your requirements and exceed your expectations.

0 notes

Text

AMP Pigments are better than other Pigments Manufacturer in India

AMP Pigments differentiates itself from other manufacturers of pigments through a number of key distinctions that highlight its dedication to quality, innovation, and customer satisfaction. AMP Pigments offers a thorough determination of pearl pigments, including Gold Pearl Pigments, Mica Pearl Pigments, Glow in the Dark Pigments (Radium Powder), and Carbon Black Powder. Visit our website: www.spcolour.in

AMP Pigments are well known for their consistent performance and exceptional visual appeal are ensured by manufacturing each product to strict quality standards. The core of AMP Pigments' operations is innovation. To develop new pigment formulations and enhance existing ones, the company makes significant investments in R&D. AMP Pigments is able to keep up with industry trends and meet the changing needs of its customers because of this focus on innovation. Understanding that various businesses have novel prerequisites, AMP Pigments offers customization choices for its colors. AMP Pigments collaborates closely with customers to develop bespoke solutions that are precisely tailored to their requirements, be they in the form of a particular shade, particle size, or special effect. https://spcolour.in/pearl-pigment-powder-manufacturer/

AMP Pigments, which has its head branch office in India, has a significant global presence by exporting its goods to a number of continents. A robust logistics network supports this international reach, ensuring prompt delivery and dependable service to worldwide customers. Contact for Bulk orders in India: +91-999028664 and mail: [email protected] and in for International orders: +91-9310048024 and mail: [email protected]

1 note

·

View note

Text

VedaOils is a prominent producer and seller of Soap Colors for soap making. It is used in a variety of products like candles, cosmetics, skincare, etc. We are recognized for offering cost-effective natural products since we manufacture them in bulk quantities and distribute them throughout the United States at Wholesale Prices.

Our Best Colors for Soap Making are created in laboratories using only Organic Materials to assure maximum accuracy and flexibility. These colors do not bleed from soaps once they have been added since they are totally absorbed in the solution. We can also provide them at low prices since we buy in bulk quantities without sacrificing quality.

0 notes