#Manganese Wear Parts

Explore tagged Tumblr posts

Text

Round one of the species introduction!!!!

Prectikar Master Post:

Here's some info on them, and if you want to see some other drawings I've done of them (albeit some occasionally older n crustier ones), check out my deviantart: https://www.deviantart.com/blasho

Anyway let's get into a terribly long string of paragraphs about some of their info:

Prectikar are a large sentient species, usually standing at around 8-9 feet tall when fully upright and weighing anywhere close to or upwards if 1000 pounds

They are covered in feather-like fur (or is it fur-like feathers? They're occasionally branched like feathers, and all have quills, but some are more hairlike) due to the cold climate they evolved in, though length and thickness of it now varies by region.

They are omnivorous, and while they have many traits to help them hunt and kill, most of their diet tends to be plants.

Originally rush-down predators, they use their considerable strength to move in quick bursts and their specialized tusks to either ram prey to death or gouge into it as they grapple it.

Their jaw strength is also insane,with their skull actually sacrificing brain space in favor of it, which helps them eat pretty much anything they come across. They pay a lot of attention to food and cooking because of their high calorie needs and very sensitive nose/tongue.

They have manganese as an oxygen carrier is a result of the scarcity of other metals in their environment and potentially because of its general affinity for oxygen.

This causes their blood to be an amber/orange brown and shades of pink depending on its exposure to oxygen.

Through a network of cooperative bonding and other adaptations (like better oxygen retention in muscles and the easily carried size and longevity of the molecule) they’ve managed to bring this manganese transport molecule close to hemoglobin in terms of effectiveness, though they can also make use of manganese’s catalyst properties to temporarily push it to bring lots more oxygen to their tissues at a time (used for short bursts of speed and strength that allow them to take down large prey and plants for food).

their large body size (selected by their colder environment) lets them use their own high body heat to keep the O2 fixation and liberation going in their highly effective lungs.

An extensive understanding of their internal chemistry is unknown (aka gatekept by their colonizers/"uplifters" who ill get to later) but it seems like they also have a network of bacteria in their body just to manage the more reactive and damaging oxides that form, and to remove/convert the spent manganese into connective tissue and aid in bone maintenance.

They have higher calorie needs from keeping up the body temp and recycling/removing all that stuff, alongside just being big in general. Alongside a lot of sleeping, they also basically just eat all the time (compared to other species) to compensate, though their mammal-like fat retention and other metabolic adaptations for scarcity mean that they can handle long periods without resources(though this causes increasingly compounded problems for them)

Some other downsides include low tolerance of changes in oxygen levels (particularly low) and temperature levels, and poor adaptation to environments outside of their biosphere/without all the microorganisms since these things upset their delicate balance.

(part of why so many tribes were nomadic was/is to chase temperate and ‘warm’ seasons, even though to us that’s still cold. Prectikar living in human dominated areas often just take a lot of supplements with beneficial bacteria in them to cope with thr lack of that in their environent, and any food printers need an 'ink' cartridge containing these things or else theyre basically useless.),

They also experience faster general wear and tear from having constant complex and intensive chemical reactions(sometimes with dangerous chemicals) going on in their bloodstream and tissues.

( I’m not a biochemist, so if there’s any glaring issues with this then just explain it away to yourself with ‘they have a gland for that’ or ‘just don’t think about it actually’ which is what I did. I just wanted the fun color with a metal that can reversibly bond with oxygen :). )

They have one nasal passageway for smell/air and a second, bigger cavity for just vocalization (which they can’t breathe in from as easily).

This second cavity is between their first set of eyes, and has a phonic lip structure inside to produce higher pitched sounds.

The upper nasal opening has muscled nostrils that act as lips to further help control sound. The noise coming from here sounds very high to them, but to us it sounds like a nasally human voice, broken uobhere and there with squeaks, buzzes, and clicks).

They can pitch this nose voice very high, closer to dolphin-like clicking noises but not quite echolocation level.

Their throat vocal cords by their air sac are very long and thick, used for making very deep noises that carry long distances.

However, the vocal control they have through their mouth is very poor due to this and the inarticulate lips and tongue they have, and due to the more limited air they can bring in and out of it, so when speaking only through their mouth they sound a lot like seals or dogs and can only really go in short bursts before having to refill the sac.

Most of their languages are spoken with the nose and mouth sounds in tandem, where the high and low mix to make a more even sounding voice.

It’s fairly easy to understand them, but nearly impossible for us to truly speak any of their native languages, and if they wanted to they could also just start making sounds we cant hear.

They see it as strange that humans and other species speak with a single tone without difficulty.

The red flaps pictured on the drawing of their mouth and nasal passages can be moved to seal off the passage and direct airflow elsewhere.

The big red one in their throat acts as a “diaphragm” to fill and empty the air sac (which is left over from when their digestive and respiratory tracts were more connected like ours, but time in the water heavily shifted it to a more ‘blowhole’ type outline to help them breathe and vocalize from the surface).

The other flap by the air sac and its vocal cords moves upwards to block off the digestive tract whenever the mouth or nose is opened to allow air to be drawn in by this diaphragm.

The two red flaps making a pinched shape can move independently or with the other red flap, but never at the same time with each other. The main airway is always separate from the digestive tract, though the flap to the middle, non vocal nasal passage can be moved so that it’s a part of either the vocal nasal passage to draw in air or the air sac part to act as another resonance chamber.

Air can be drawn in by the diaphragm via open mouth and through the nose via open top red flap at the same time, and can be released at the same time, resulting in their near continuous double speak sound they use for their own language.

Their characteristic large tusks are retractable and housed in a cone-shaped bony socket on the side of their jaw.

A muscle is attached to the bony root of the tooth, and pushes it out. As it slides towards the front of the mouth, the cone socket narrows and wedges a protrusion on the tooth into a hole in the socket, and then the muscle stiffens, locking it in there.

When the tusk retracts, the muscle quickly jimmies the tooth forward then draws it back to get it out of the hole, and then pulls it back into the wider part of the socket.

This is mainly because their tusks are ever growing (but very slowly) but not great at self sharpening, and are their main weapon in self defense and hunting,so it seems this just happened to keep them safe.

If a tusk is broken, as long as it was not cracked at the root, it can be regrown with extensive time in the socket, but otherwise they stay safely stowed in da socket where the majority of its sharp edge can stay protected from chewing and other mouth stuff. Tusks won't start growing in until their teenage years.

They are primarily bipedal/ quadrupedal and switch between the two occasionally.

Knuckle walking helps distribute their top-heavy weight and give them more balance for long and short distance, while walking upright gives them better visibility, less stress on their neck/upper back, and quicker but unsteadier movement.

Their gallop/sprint utilizes both arms and legs to propel them forward in a gait halfway between a bear and a gorilla (since their big mid arms are set like a bears) to overtake prey after an ambush or drive them into the rest of the pack waiting elsewhere. Quad walking also helps them get around in buildings meant for species half their size.

Their hands are some of their only places without hair, but as they age, they loose it on their arms and face too.

Prectikar have different uses for each of their pairs of limbs, and have for all stages of their evolution.

The front ones specialized for grappling prey and grabbing things, and so have a ‘sprawling’ shoulder position like humans and have hands with relatively nimble fingers, the outer two are angled inwards but can also move in a pamprodactyl ish fashion (which acts as their version of a thumb, and lets them switch from big to little grabbing motions) .

Their mid limbs used to be wings with hands, and still have a basically zygodactyl finger position that was helpful for holding onto branches (with the backwards facing finger), but over time they have been converted into terrestrial knuckle-walking limbs, with the one that swings back and forth being brought forwards to walk or swung back to adjust grip on big things they want to move or for balance on unstable terrain like ice . The fingers on this one are big and clumsy, pretty much only useful for digging, walking, or slashing.

Their back limbs also used to be for grasping but were mainly counterbalances, but have now turned into plantigrade walking limbs (and much like humans, that’s pretty much all they use them for). All have nonretractable claws.

Prectikar are viviparous and usually give birth to litters of up to 8.

They have a specific mating season, where their dimorphic traits will become more pronounced.

Males in rut will shed the feathers on their throat sac region and it will become a bright ambery yellow color, and they will also grow in longer feathers on their butt region (in a fan shape for display purposes. The dont have a true post anal tail like humans).

They will also develop some of that pinkish orange/yellow on their chest skin. Females go throguh estrus cycles and will also grow a more prominent butt feather crest, as well as some very long feathers around their neck, shoulders, and abdomen for babies to hold onto.

Their skin patches turn a much brighter shade of yellow to help direct newborns to where they can feed from. Once they give birth, they will start making an oily and thick secretion across the skin patch which is collected into a divot which the infant licks from. Part of why the babies hold onto them is so they can constantly lick the 'milk'so they can grow.

Newborns come out blind and hairless, but quickly grow in a thick down and open their eyes so they can climb on mom.

Once they're weaned, they'll drop off and use the muscles they gained hanging on and climbing to start moving with the adults. They grow very fast, and canes are a common sight in teens to help deal with the rapid bone and muscle growth.

Usually, it is only during this season where chest/skin related nudity standards change to be more conservative, since showing those colors means youre down to fuck and so doing that is usually restricted to in private with their partner or for bachelors.

They have very strict binaries for sex and gender based on this seasonal divide and religion.

Most tribes show gender identity through a piercing on their lower nose for male or chin for female (so dont worry, the main guy up there is showing some male presenting chest outside of the mating season, so hes fine).

Normally, only some cultures pierce their ears, which are like if owls had a little mobile flap of outer ear to swivel I stead of their whole head. Very little of it is actually flesh, and the sound is mainly captured by the feathers around it.

While they have a reputation otherwise, Prectikar are highly social within their tribal/family groups.

They regularly allogroom, greet each other with hugs, and usually travel in sibling groups. Households are multi generational.

They have a reputation as standoffish or irritable because they take things very differently and have other standards/specific body language truggers. also most other species treat them differently/with fear by default.

their upper pair of eyes is larger and focused on long distance vision while their lower pair is for close up vision, creatign a bifocal effect for them when using both at once.

Aaaaaand that oretty much everything, I think. I'll post some other arts related to them soon, but consider this the Master Post on the things you should know about them!!

#spec evo#worldbuilding#alien species#xenobiology#drawing#illustration#original species#prectikar#lore stuff

167 notes

·

View notes

Text

The Challenge {2/2}

Aemond Targaryen x fem!bladesmith!reader Summary: It is time to deliver the sword to the prince. Warnings: 18+ only, nsfw, jousting, smut, caught in the act WC: 3.9k

HOTD Masterlist || Part One || Part Two

Two weeks passed quickly as you worked tirelessly on Prince Aemond’s sword.

You had not heard from him since he left that morning and you were not sure whether or not you had expected him to send a message of some kind before you made the journey to King’s Landing. You couldn’t deny you were a little disappointed he hadn’t sent a raven - if for no other reason than to check in on the progress of your work.

Nevertheless, you had gone above and beyond to create the masterpiece before you.

It was by far the most expensive piece you had invested in and the twin sapphires alone had cost a small fortune but after being inset into the eyes of the dragon on the pommel you knew it was worth it.

The sword was made of manganese steel imported from Dothraki, which was far lighter than iron, and had been folded with carbon dozens of times over to increase the tensile strength of the metal. The fierce dragon had been carved into the manganese steel and then dipped in gold but the snarling teeth were made of white gold and polished to perfection.

There was no way to mistake this for any common blade and it was truly fit for royalty.

A local leatherworker had taken the measurements of the sword and made a scabbard that would protect it while it was not in use and you slid the sword into the sheath before locking it into a travel box.

“Your carriage is ready to leave, mistress,” Gerry said after knocking at your bedroom door. “Oh, you look lovely.”

The dress was stiff and uncomfortable and you wished you could travel in more sedate clothes but in public such a scandal could lead to incarceration and that would be bad for business. The other option was to wear the heavy cloaks of your work attire but even after a thorough washing they never smelt or looked very pleasant.

“I look like a meringue,” you murmured, shrugging the puffy sleeves that capped just above your elbow.

“Nonsense,” Gerry said with a giggle, taking it upon herself to straighten the layers of skirts so they hung neatly. “The prince will be lost for words, mistress.”

You narrowed your eyes at your housemaid. “What makes you say that?”

She couldn’t suppress the smile that she tried to hide behind her hand and shook her head. “The girls talk, mistress. Kasia and Tiff heard from Kyron, the stable boy, that the prince and his guard were arguing before they left.”

You shouldn't have been interested in gossip but you were leaning forward in anticipation as her smile grew. Finally you lost patience and huffed as she forced you to ask, “Arguing about what?”

“You, of course.”

“Me?”

“Aye, the prince confessed he had fallen to temptation of the flesh. That had to be you, right, mistress,” she said with a wink. “I imagine his highness has a date with the High Septon on his return. You were careful, right?”

You rolled your eyes and gave a droll nod. “Yes, mother.”

“Don’t bite my head off, I promised your ma I would watch over you, bless her soul. Now be on your way, it is a long ride.”

Kasia was already waiting at the front of the house with the carriage and you climbed into the cab before making space for her. You would have preferred for Gerry to make the three day journey with you but she wasn’t comfortable going anywhere near the capital, and you didn’t pry to find out why.

The carriage driver whipped the reins and you jostled with the movement, eventually falling into a routine sway as the horses ambled along the road that would take you south to King's Landing.

The noise of the crowd was unlike anything you had heard and the musicians playing an upbeat tune only added to the cacophony. Peddlers worked the stands around the stadium, selling their merchandise to the viewers, while food stalls were erected outside with the scent of their goods almost eradicating the smell from the horse stables beyond.

Finding space on a bench seat, you pulled Kasia down beside you and stilled her leg that kept bouncing excitedly with every match that went by. You had arrived later than expected when the wheel of the carriage broke outside of Rosby and so far Ser Criston hadn’t lost a match in both jousting and sword fighting, but you were hoping to catch the next one.

You were beginning to tire of the harsh sun that beat down, the temperature enough to rival your workshop, and ready to find some solace in the shade when the next trumpets fared for the jousting final.

“Mistress, that is Prince Jacaerys,” Kasia gasped as she pointed to the house flag that had been raised and a chestnut steed trotted into the lists with a helmeted rider upon its back. “Who would dare strike a prince?”

You had an inkling as you looked to the other side of the arena and saw the flag of House Cole being draped onto the rung. “Unbelievable.”

A white stallion leisurely walked into the lists and you were the only one who wasn’t surprised to see Prince Aemond riding atop with his helmet tucked under his arm. Whispers began to spread along the rows of viewers as they realised it had been the One-Eyed Prince fighting under his knight’s banner the entire time.

“What is the meaning of this, Aemond?” King Viserys asked as he rose slowly from the royal box.

“It was pointed out that fighting as a prince may lead my opponents to go easy on me, and I would not have that shame,” he said with a smirk thrown Jacaerys’ way. “That need not be a problem now will it, nephew?”

Prince Jacaerys pushed his visor up over his helmet and dark hair tumbled out to frame his face. Even from so far away you could see his brown eyes were full of disdain and his jaw was clenched as he spoke through his teeth, “No problem, Uncle.”

It would have been embarrassing should he have said otherwise, he would have been practically admitting he only reached the finals because of his royal title whether or not it was true.

“Well played,” you chuckled to yourself as you watched Prince Aemond place his helmet on his head and shove a gloved hand out for his steward to give him the lance.

In the royal box the mothers, Queen Alicent and Princess Rhaenrya, shot to their feet and rushed to the edge balustrade with concern etched into their faces. The look they shared both held reprehension for the other and you briefly wondered what it was about before a cheer erupted and your attention was brought back to the match.

The princes spurred their horses forward with a kick of the stirrups and you leaned forward in your seat with the rest of the crowd.

There was not a whisper in the air as anticipation held the spectators in silent suspension. To cheer either prince would be to insult the other so not a sound was made.

The horses reached the fence and raced towards each other with thundering hoofbeats. The distance narrowed and no one took a breath as they lowered their lances, the blunt tips aimed at the other.

From your vantage point in the stands you could see how Prince Aemond’s head was turned far more than Prince Jacaerys’ to account for the lost vision in his left eye but his aim was still well positioned. With the extra height he had over his nephew, Aemond’s reach was greater and his lance smashed into the Velaryon’s chest, glancing off the armour and under the shoulder plate.

A collective wince hissed across the crowd and the younger prince screamed as he was thrown from his horse. The scream was echoed by his mother and Princess Rhaenyra rushed from the royal box to check on his welfare along with the maesters. At least given the painful squirming on the ground, he was certainly alive.

Prince Aemond tore his helmet off and his silver hair shimmered in the brutal sunlight, it was almost too bright to look at directly but even with the glare there was no hiding the smirk on his face. Dismounting to the dirt, he sauntered over to his nephew and dropped to one knee beside him, his hand hovering over the wound he had dealt.

How you wished to be close enough to hear what he said, because although he looked like he was offering condolences there was no mistaking the disdain on his face or the amusement when Jacaerys weakly tried to push him away.

Looking up, Aemond saw his half sister nearing and rose to his feet, swiftly leaving the arena without a care for the splatterings of polite clapping for his win.

“That is my queue,” you said to Kasia as you grabbed the boxed sword from where you had kept it safely hidden beneath your skirts and rose to your feet. “I shall see you back at the inn for dinner.”

It wasn’t difficult to find Prince Aemond with his hair like a beacon. Everyone gave him a wide berth in the streets except for his trusted knight who noticed your approach first and sighed heavily. It was the sigh that caught Aemond’s attention and he turned to see what had elicited the annoyed sound from his friend.

The surefooted prince stumbled as he spotted you and his eye travelled your body from head to toe twice before he blinked and recovered.

“I almost didn’t recognise you,” he admitted and nodded his head to Ser Criston. “You may leave, I am sure my mother will want to accost you for the role you played today.”

The white cloak knight didn’t look pleased but nodded back before casting a glance your way and shaking his head. You couldn’t help but send him a sweet smile and bat your lashes at him with a dainty wave of your fingers, earning a chuff of a laugh from the prince.

“Blessed name day, my prince,” you greeted him when you were alone and once more walking towards the Red Keep. You held the box out for him, grateful you no longer had to lug it around the city. “As requested.”

“Do you have a sister?” he asked, taking it from your hands and tucking it under one arm. “You look rather similar to a woman I met a few weeks ago, though she was a little more scrappy and rather filthy.”

“Ha ha,” you exaggerated with a roll of your eyes. “Here I thought you were a prince but I have been fooled by a court jester. Funny how one and two are the same.”

“There she is.” He grinned and opened a door that led to a courtyard but the small joy he had disappeared in the company of the few people milling about. They shifted uncomfortably in his presence and the place fell silent until he had passed under an archway and turned down a corridor.

You were utterly lost by the many turns it took to come to the room he eventually led you, closing the door behind with a click of the lock.

The box thudded as he placed it on a writing desk that was covered with books and letters with the dragon crest drawn upon. They couldn’t have been important as he shoved them aside and unlatched the lid.

“Congratulations on your win,” you said as he opened the reward. “You must be proud.”

“I don’t give a shit about tourneys,” Prince Aemond retorted as he unsheathed the sword before twirling it in his hands. “I just wanted to see the look on that bastard's face when he lost.”

He continued to inspect the weapon, staring down its length to ensure it was straight before pricking his finger on the tip to test how sharp it was. He gave a satisfied hum at the conclusion and you bit your lip at the reminder of the similar sounds he had made.

Finally he brought the pommel closer and peered at the intricate dragon with intense scrutiny. “Incredible.”

“I’m almost reluctant to part ways with it,” you teased and he gripped the handle tighter as if he were prepared to fight you for it. “But you seem rather attached already and I’m feeling charitable.”

“How generous of you.” He rolled his eye and sheathed the sword before buckling the scabbard to his belt and pointing to a large purse on the table. “I suppose that means I can return that small fortune to the coffers then.”

You scoffed and crossed your arms over your chest. “I’m not that charitable.”

Unaccustomed to wearing dresses, you hadn’t realised crossing your arms had pushed your breasts up dangerously high and they were barely contained by the corset. It was only the lingering stare of the prince and the widening of his eye that drew your attention down where he was fixated.

“Not one raven, not even a ‘hello, how have you been?’” you tutted and ran your fingertips teasingly over the skin of your bosom. “I should be insulted.”

His eye followed the movement hungrily. “You have the attention of a prince, insulted is not the word that comes to mind.” One long stride closed the distance and you craned your head back to hold his stare.

“Did you confess your sins to the Septon?” you had to know as you felt the heat of his armour warming your skin. “Did you repent for the sordid touch?”

“I did. And I swore I would banish all thoughts of you from my mind.” He swallowed deeply and reached for the bowtie that held the laces of your corset together. “I did so knowing it was a lie.”

You cursed under your breath as his words affected you more than you expected and you covered his hand with yours, guiding it to the delicate laces so he would hurry up and free you from the constraints of the dress. You could finally breathe liberally and you inhaled deeply as the heavy materials fell to the floor but there wasn’t time to waste as you reached for his armour.

Your deft fingers made quick work of the buckles and Aemond caught the heavy plates before they could clatter to the floor, instead depositing them to the side where they wouldn’t cause an accident.

Next went his damp clothes, the material strewn across the room as you wrapped each layer like a gift - eager to get to the prize that waited beneath.

“I’ve heard men fuck like a lion after fighting in a tourney, like the sweat gets their blood pumping,” you stated as you push him into the chair in front of his desk and straddled his lap.

He grabbed your hips and lined himself up with your entrance, pulling up down his length until you couldn’t take anymore and gasped at the fullness. He still wasn’t done, not when he wanted to tease you with more than his body, his lips following the line of your jaw until he reached your ear and whispered, “Lions are nothing compared to a dragon.”

Your nails dug into his shoulders as you held on tight and rolled your hips to take your pleasure from him. He let you have your moment, enjoying the warmth of your cunt as it tightened around him and the press of your breasts to his skin, but then he wanted to chase his own ecstasy and gripped your hips. His arms should have been weak and trembling from the day spent fighting but they were still strong as he guided you up and down his cock.

“Fuck, Aemond, you feel so good.”

“Hmm,” he growled in your ear, “I am your prince.”

“You can be my prince out there but right now you are just a man, now fuck me like one.”

In an instant you were empty and he was on his feet, spinning you around and bending you over his desk. The void you were missing was filled with one rough thrust and his hand slapped over your mouth to muffle the cry of dark pleasure that erupted.

Gone was the restraint, gone was the control. Prince Aemond was unleashed.

The wood cut into your hips and his ink pot spilled, books tumbled to the floor and the armour resting against the table leg toppled over. The clatter of metal was like the herald bells being struck and shouts came from outside the door.

“Fuck,” Aemond growled at the knock that quickly followed. “Go away.”

“My prince, it is your mother,” Ser Criston called out.

“Fuck.” This time the sound wasn’t from frustration but fear and he pulled out in a rush to find his clothes scattered around the room. “Give me a minute.”

“Cole, move,” a surprisingly stern order came from a gentle feminine voice and the lock on the door was opened from the outside before the door swung open.

“Mother,” Aemond greeted quietly as he covered his manhood and bowed his head.

“I expect this unbecoming behaviour from your brother but,” she sighed dramatically and Aemond’s head dipped further at the disappointment radiating from his mother, “not my sweet Aemond.”

You coughed a laugh and covered your mouth as the sound drew her attention to you. You didn’t have enough hands to cover your nakedness and your dress was inconveniently in a head at her feet.

“Who are you?”

“I’m no one, your highness,” you said as you shifted on your feet and tried to shimmy across to hide behind the prince.

“Her name is Y/N,” Ser Criston said without even stepping into the room.

“The bladesmith you visited, who is also the daughter of the metal merchant?” she confirmed as she took a second look at you before turning her back. “Cover yourselves.”

“Yes, mother.” Aemond grabbed your dress first and tossed it with more force than necessary before swiping his own undershorts up from the floor. “I will go to the Sept and confess.”

“Don’t bother,” Alicent scoffed with a toss of her head. “You are not contrite. No, I have another way for you to repent and save your honour.”

It was far harder to get the dress back on than it was to get off, especially since it had taken the help of Kasia last time. You were still busy trying to thread the laces back through the eyelets when the Queen dropped the bomb.

“You will wed her, Aemond. I won’t have any more shame on this house.”

“Mother,” Aemond interrupted but she held up a hand to silence him, something that wasn’t going to stop you.

“Beg your pardon, majesty, but fuck that. I’ll take a vow of silence and be on my way out of this dreadful city.”

“Silence? From you?” she said with a humourless laugh. “If the people weren't still watching the tourney the entire residence would have heard your filth. No, I’ve made up my mind.”

“More like lost it,” you uttered before Aemond pinned you with a glare that had you closing your mouth once again.

“Cole, make sure my son’s betrothed finds her way to her own room. Alone.” With that she departed and Aemond’s posture slumped.

The moment she was out of hearing range you turned to him. “I’m serious, I’m not marrying you, or anyone for that matter.”

“I don’t believe we have a choice.”

“I do.” You tied a knot in the lace just enough to be sure it wouldn’t suddenly come apart as you stormed out of the room and straight into that bothersome guard. “Move.” Ser Criston looked at the prince but you snapped your fingers in front of his face. “I’m talking to you, so don’t look at him.”

“Let her pass,” Aemond said and your head spun incredulously towards him to find him already dressed. “I’ll escort her.”

“To the ladies wing?” he asked as he moved aside and let you through.

“To the stables.” Aemond caught your arm and turned away from his guard to head in the other direction. “I’ll not marry a stranger because I wanted to wet my prick.”

“How uncouth,” you teased as you hurried to match his pace through the Red Keep. “Such a filthy mouth, Prince Aemond.”

He growled as he pushed you against the cold stone wall and caged you between his arms, his erection hard against your hip through the layers of cloth separating you. “Now is not the time to tease me.”

“Yeah?” you pushed back, grinding yourself shamelessly against him in the empty hall. “Or what?”

Aemond’s fist hit the stone with a groan before his hand circled your wrist and tugged you with a renewed pace. “You were born of the Seven Hells, I swear.”

“What makes you say that, my prince?” I asked sweetly. “My devilish good looks or what was it my stable boy overheard…oh yes, my tempting flesh?”

Aemond opened a door and the irritating smell of stale dust told you the storage room was not often used before he pushed you inside and closed the door behind him. “This is the last time,” he promised himself as he bunched the material of your skirt up over your waist and freed himself from his trousers.

You knew you would miss the feeling of him stretching your cunt with each thrust and the way he stroked your walls until they clenched around him. None of your past lovers had been able to fill you quite like he did, or take your attitude either.

“You can always visit me,” you offered in a moment of weakness as the tension of the oncoming orgasm built, “when your sword needs taking care of.”

The sounds of your bodies slapping together filled the room and the table you were sitting upon rocked as Aemond filled the space between your legs. His hand dropped your skirts so he could cradle your face, his thumb tracing your lips. “The bladesmiths here will suffice.”

“I wasn’t talking about that sword.” You nipped at his thumb and smirked, feeling him react instantly as he rutted harder against you. Your legs wrapped around his and your hands slipped under his shirt as you pulled him closer, chasing the high that was cresting inside you.

Your orgasm erased your ability to think and your body jerked as wave after wave of pleasure washed over you. The feel of your cunt pulsing around him tipped the prince over the edge and he released a shuddering breath as he spilled himself within you.

There was no time to enjoy the afterglow and Aemond tucked himself back into his trousers before pulling your skirt down over your legs that were still dangling off the table.

“I doubt my mother will let me leave the keep for a while after this,” he said as he helped you off the table and onto shaking legs.

“Do you always do what your mother says?” You asked him, fixing one of the clasps of his vest that had come undone.

“Don’t.”

Your lips twitched as you saw the fire in his eye. “Don’t what, my prince?”

“Don’t challenge me.”

“Afraid to lose?”

He chuckled and caught your chin between his thumb and forefinger. His teeth bared as he leaned closer and his silver hair brushed your shoulder while his hot breath kissed your skin.

“You should know by now…I never lose.”

Tagging: @hopebaker , @padfooteyes , @fan-goddess , @whitefang1919 , @drinking-tea-and-be-obsessed , @let-love-bleeds-red , @raven1234321

#aemond targaryen x reader#aemond targaryen x you#aemond targaryen x y/n#aemond x y/n#aemond x reader#aemond x you#aemond smut#aemond imagine#hotd fanfic

422 notes

·

View notes

Text

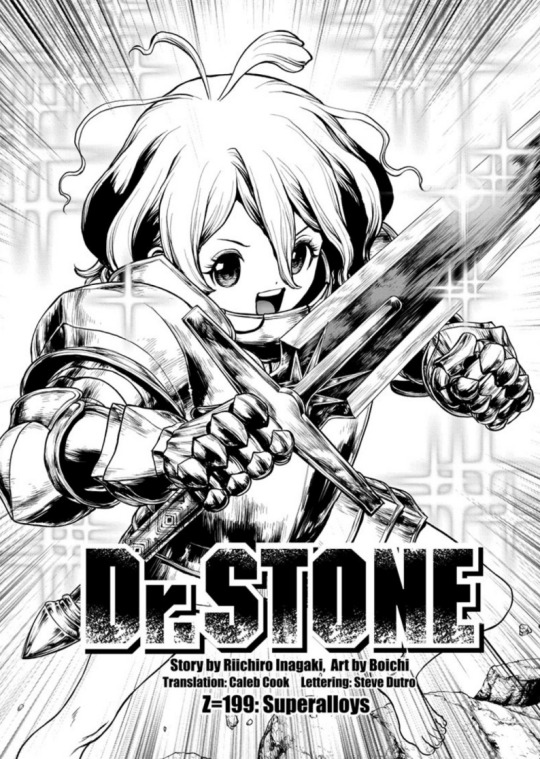

Chapter 199 Trivia (Part 1)

Are we reaching a second Age of Exploration?

The cover page may be a reference to Berserk, as it's been exactly a month since the writer for it, Kentaro Miura, died.

Why Suika is only half-armored I'm not sure.

The first device Xeno makes is for cryogenic fractional distillation. As he says, it cools air to separate the elements within.

Think of it as the reverse of alcohol distillation: rather than boiling it to separate the gases, you cool it to separate the liquids!

I don't really understand why Kohaku is so confused by argon specifically, as she knows someone who was named after it. Ginro even fought Argo(n) in the Grand Bout!

Geiger counters work as Xeno says: an inert gas becoming conductive when a particle of radiation ionizes the gas, allowing a current to pass. This is either connected to a display to show the readout or something that makes the iconic clicks.

Chrome loves his rock-detecting devices!

Also the sound effects here are literally "gaigā". Very Pokémon.

This boat is definitely made by the villagers, likely by Kaseki himself, due to the design. He was the one to make all the boats for them, after all.

Ilmenite is the most important ore of titanium, formula FeTiO3. Molybdenite is a common ore of molybdenum, formula MoS2. Chrome ore (probably chromite) is self-explanatory, but can be found in oxide form with several other metals such as iron or manganese.

Pyrochlore ore is actually a mineral group, but in Araxá, it's all about getting niobium. Nickel comes in many ores due to how common it is, and can be found in laterite (laterite is a soil/rock type, not an ore).

Alloyed together, these metals make the strong, lightweight materials needed for aircraft and spacecraft.

Most of them are also either radioactive (pyrochlore) or have radioactive inclusions (rhenium-187 in molybdenite) which is why the Geiger counter works!

Also, Gen is wearing shoes!

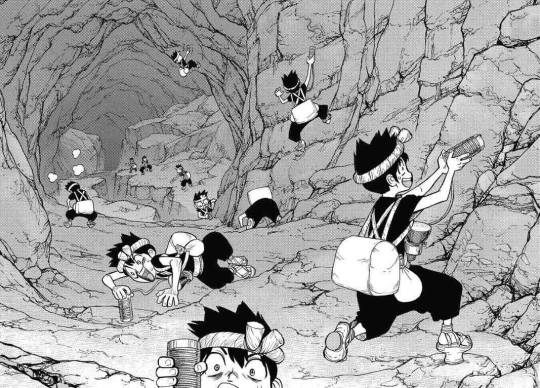

This isn't the first time Monster Hunter has been referenced! The first one is way back in chapter 19, which helped Senku realise that something fishy was going with in the village...

A compilation of Senku getting excited about large collections of rocks:

(Next part)

4 notes

·

View notes

Text

Abrasion Resistance Plate Exporters

Abrasion resistant steel is used every bit as a part of regions where there is prone to be a high degree of abrasion area or wear of the steel plate. Average applications are in truck couches, connections to diggers and earth movers and in preparing applications in the mining business.

The key quality for wear resistant steels is their hardness. We offer wear plate as per its hardness measured on the Brinnell Hardness Test- for the most part in 400HB evaluations.

Abrasion resistance plates, also known as wear-resistant plates, are specially engineered metal plates designed to withstand the mechanical wear and tear caused by friction, impact, and scraping. These plates are critical in industries where materials undergo high-intensity interactions with abrasive surfaces. The primary purpose of abrasion-resistant plates is to reduce the degradation of machinery and equipment by offering superior resistance to abrasive forces.

400 HB steel is in excess of 3 times harder than soft steel (120HB), even only a third as strong as stainless steel (1250HB). Sample exercises are for development apparatus, skips, bulldozers and excavators, buckets and conveyors.

Steels with a high HB rating (Briness Hardness) are proposed for applications where wear or scraped area safety is critical. The profit of utilizing abrasion resistant steel is that the plant, apparatus or developments working life can be amplified extensively. This can fundamentally enhance the unwavering quality, toughness and well being of structures and gear. It additionally helps to diminish the support expenses connected with wear and breakdown of plant.

The steel is extinguished which gives wear safety; to enhance hardness, it might also be tempered. Bring down HB's for the most part give great cool twisting properties and great weldability. Weldability is not, by and large lessened as the hardness increments.

Abrasion resistance plates are typically made from high-carbon steel or alloys with a combination of other elements like manganese, chromium, and molybdenum. These elements enhance the hardness and strength of the plates, ensuring they can withstand harsh conditions. The plates are commonly available in various hardness levels, which are measured in Brinell hardness, ranging from 400 HB to 600 HB.

The properties of abrasion-resistant plates include:

High Hardness: The high hardness of the plate prevents wear caused by constant friction or impact.

Durability: These plates are designed to last longer compared to regular steel, reducing the frequency of replacements and maintenance costs.

Toughness: While they are hard, abrasion-resistant plates also offer a degree of toughness, allowing them to absorb impact without cracking.

Corrosion Resistance: Some types of abrasion-resistant plates are treated to resist rust and corrosion, extending their service life in harsh environments.

Wear resistant steels are not fitting for utilization at temperatures in excess of 250 degree C as the hotness can result in changes to the material properties.

Yields for 400HB steel are in the region of 100MPA with tough qualities of around 1250MPA.It is not enrolled at universal standard affiliation, for example, ASTM Jin, Din so each one production has their Brand name like Rockhard 400, ABREX, SUMIHARD, RAEX, JFE, XAR, BIS.

Applications of Abrasion Resistance Plates

Abrasion-resistant plates are widely used across various industries where high wear and tear are common. Some key applications include:

Mining and Construction: In mining and construction, heavy machinery is often exposed to abrasive materials like gravel, sand, and ore. These plates are used in the construction of hoppers, chutes, and conveyor systems.

Steel Mills: In steel production, abrasion resistance plates are used in the lining of chutes, hoppers, and crushers where friction from metal fragments and slag can be intense.

Agriculture: Agricultural machinery such as plows, tillers, and harvesters also benefit from abrasion-resistant plates, which enhance their longevity when working with soil and crops.

Material Handling: In industries where materials are transported or processed on conveyors or chutes, abrasion resistance plates are used to line these areas, minimizing wear on machinery parts.

Scrap Handling: Plates are used in equipment that processes scrap metal or other hard materials. These plates ensure that the equipment can withstand the heavy-duty impact and friction encountered during operations.

Benefits

Extended Equipment Life: By using abrasion-resistant plates, machinery and equipment are protected from premature wear and tear, thus reducing downtime and maintenance costs.

Cost Efficiency: While the initial investment in abrasion-resistant plates can be higher, their ability to increase the longevity of equipment makes them cost-effective in the long run.

Improved Safety: By ensuring equipment is less likely to break down or malfunction due to excessive wear, abrasion-resistant plates contribute to a safer working environment.

Performance Enhancement: These plates help maintain the operational efficiency of equipment by reducing friction and damage, leading to smoother operations.

Conclusion

Abrasion resistance plates are a vital component in many industries where machinery is exposed to high levels of wear and tear. They are engineered to provide superior hardness, toughness, and durability, ensuring that industrial processes can continue without unexpected breakdowns. From mining and construction to agriculture and steel mills, abrasion-resistant plates are indispensable for maintaining the efficiency, safety, and longevity of equipment. Investing in these high-performance plates ensures that businesses can reduce costs, enhance productivity, and protect valuable machinery from the harsh effects of abrasion.

For more information

Contact: 8828813630

Email id: [email protected]

Address: Vandan Steel & Engg. co. 359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai-400 004.

0 notes

Text

Comprehensive Guide to Swimming Pool Water Testing Services in the UAE | +971 554747210

Swimming pools are an integral part of the UAE’s luxurious lifestyle, providing a respite from the region's hot climate. However, maintaining the cleanliness, safety, and quality of pool water is paramount. Swimming pool water testing services ensure that water is not only safe for swimmers but also compliant with health and safety standards. In this comprehensive guide, we will explore the importance of swimming pool water testing, the services offered by testing labs in the UAE, and how they contribute to maintaining optimal water quality.

Why Swimming Pool Water Testing is Essential

Swimming pool water testing is more than a routine maintenance task; it is a critical measure to ensure safety and comfort for users. Here are the key reasons why regular testing is indispensable:

1. Health and Safety

Improperly treated pool water can harbor harmful microorganisms such as E. coli, Cryptosporidium, and Legionella, which can cause severe illnesses. Ensuring that water is free of pathogens is essential for protecting swimmers' health.

2. Chemical Balance

Unbalanced water chemistry can lead to issues like skin irritation, eye discomfort, and even damage to pool surfaces and equipment. Proper testing ensures that the pH, chlorine levels, and other chemical parameters are within acceptable ranges.

3. Regulatory Compliance

The UAE has stringent guidelines for swimming pool water quality to safeguard public health. Regular testing helps pool operators comply with these regulations, avoiding penalties and ensuring their facilities remain open.

4. Equipment Longevity

Balanced water reduces wear and tear on pool systems such as filters, pumps, and heating equipment. Testing prevents scaling, corrosion, and blockages, extending the life of these components.

Parameters Tested in Pool Water

Comprehensive swimming pool water testing services in the UAE evaluate several critical parameters to ensure water quality:

1. pH Levels

Ideal range: 7.2 – 7.8.

Affects swimmer comfort and the efficiency of disinfectants.

2. Chlorine Levels

Ideal range: 1.0 – 3.0 ppm (parts per million).

Ensures effective disinfection of water.

3. Alkalinity

Ideal range: 80 – 120 ppm.

Stabilizes pH levels, preventing sudden changes.

4. Calcium Hardness

Ideal range: 200 – 400 ppm.

Prevents scaling and etching of pool surfaces.

5. Total Dissolved Solids (TDS)

Maximum recommended level: 2,000 ppm.

Ensures water clarity and chemical stability.

6. Microbial Contamination

Detects harmful bacteria, viruses, and fungi.

7. Heavy Metals

Ensures levels of metals like iron, copper, and manganese are within safe limits to prevent staining and health risks.

Types of Swimming Pool Water Testing Services

Testing labs in the UAE offer a range of services tailored to the specific needs of pool owners and operators:

1. Routine Testing

Regular checks for chemical balance and basic parameters.

Ideal for residential pools and smaller facilities.

2. Comprehensive Testing

In-depth analysis of chemical, microbial, and physical parameters.

Recommended for commercial pools, hotels, and resorts.

3. Emergency Testing

Rapid response testing to address contamination issues or unexpected changes in water quality.

4. Pre-Opening Testing

Ensures water quality is safe and compliant before opening a new pool.

5. Custom Testing Packages

Tailored testing solutions based on specific requirements, such as saltwater pools or high-usage facilities.

How Accredited Labs Enhance Pool Water Testing

Accredited testing labs in the UAE adhere to internationally recognized standards, such as ISO/IEC 17025. Here’s how they ensure superior testing services:

1. High-Quality Equipment

Accredited labs utilize state-of-the-art technology for precise measurements.

2. Skilled Professionals

Experienced technicians and chemists conduct tests, ensuring accuracy and reliability.

3. Standardized Procedures

Rigorous protocols ensure consistent and reproducible results.

4. Comprehensive Reporting

Detailed test reports include results, interpretations, and actionable recommendations.

5. Regulatory Expertise

Labs stay updated with UAE regulations, ensuring their clients remain compliant.

Best Practices for Pool Water Testing

To get the most out of swimming pool water testing services, follow these best practices:

1. Regular Testing Schedule

Conduct daily checks for pH and chlorine levels.

Schedule weekly or bi-weekly comprehensive tests.

2. Prompt Action on Results

Address any imbalances or issues immediately based on lab recommendations.

3. Collaborate with Professionals

Work with lab experts to understand test results and implement corrective measures.

4. Maintain Records

Keep detailed records of all test results and maintenance activities for reference and compliance audits.

5. Train Staff

Educate pool maintenance teams on the importance of water testing and proper handling of chemicals.

Choosing the Right Testing Lab in the UAE

When selecting a swimming pool water testing service provider, consider the following factors:

Accreditation and Certification

Ensure the lab is accredited to ISO/IEC 17025 or equivalent standards.

Reputation

Look for labs with positive reviews and a proven track record.

Range of Services

Choose a lab that offers comprehensive and customizable testing solutions.

Turnaround Time

Opt for labs that provide timely results to minimize downtime.

Cost-Effectiveness

Compare pricing and packages to find the best value.

Conclusion

Swimming pool water testing is a critical aspect of maintaining safe, clean, and compliant pools in the UAE. By partnering with accredited labs, pool owners and operators can ensure accurate results, expert guidance, and adherence to health and safety standards. Whether it’s a residential pool or a high-traffic facility in a luxury resort, regular and comprehensive water testing safeguards the well-being of swimmers and protects the reputation of the establishment. Invest in professional testing services to create a safe and enjoyable swimming experience for everyone.

0 notes

Text

Alloy Steel Sheets & Plates Exporters

Alloy Steel Plates Supplier is defined as having 1.5% to 5% total alloy content. Its common alloying elements are manganese, silicon, chromium, nickel, molybdenum, and vanadium, which contain as many as four or five of these alloys in varying amounts. which is been used by the manufacturers who works with petrochemical industries, oil and gas industries, chemical industries, shipbuilding etc. Alloy steel wear plates is a smooth, chromium carbide rich overlay plate manufacturers and Supplier by a patented production process maximizing abrasion resistance and reducing hang up.

Alloy Steel Sheet is been designed from alloys such as chromium, molybdenum, nickel, manganese, silicon so on, they are industrial product that is generally used in various industries applications. 4130 alloy steel sheet is low-alloy steels containing chromium and molybdenum as strengthening agents. It provides good strength and toughness, weldability and machinability. Alloy steel 4340 sheet is a heat treatable low alloy steels which contains nickel, chromium, molybdenum, they are commonly used for heavy duty industrial, aerospace and automotive applications.

It has high strength and toughness in heat treated condition. 6150 alloy steel sheet is useful in heavily stressed machinery parts including gears, shafts, hand tool components and pinions. It is a fine grained, highly abrasion resistant carbon-chromium alloy steel. Alloy Steel Plates Grades are ASTM A387 Gr 5, ASTM A387 Gr 9, ASTM A387 Gr 11, ASTM A387 Gr 12, ASTM A387 Gr 22 and ASTM A387 Gr 91.

Specification Schedule of Alloy Steel Sheets & Plates

SpecificationsASTM A387 / ASME SA387Thickness1mm-300mmWidth 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, 4050mm etcLength2000mm, 2440mm, 3000mm, 5800mm, 6000mm, 12000mm, 15000mm etcSurface2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching Manufacturer and SupplierFinishHot rolled plate (HR), Cold rolled sheet (CR)FormCoils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip Manufacturer and Supplier

Chemical Properties of Alloy Steel Sheets & Plates

GradesCMnPSSICrMoASTM A387 Grade 50.15 max0.3 – 0.60.0350.030.5 max4.00 – 6.000.45 – 0.65ASTM A387 Grade 90.15 max0.30 – 0.60.030.031.0 max8.0 – 10.00.9 – 1.1ASTM A387 Grade 110.05 – 0.170.4 – 0.650.0350.0350.5 – 0.801.0 – 1.50.45 – 0.65ASTM A387 Grade 120.05 – 0.170.4 – 0.650.0350.0350.15 – 0.40.8 – 1.150.45 – 0.6ASTM A387 Grade 220.05 – 0.150.3 – 0.60.0350.0350.5 max2.0 – 2.50.9 – 1.1

Mechanical Properties of Alloy Steel Sheets & Plates

Tensile StrengthYield StrengthElongationin 200mm (%)Elongation in 50mm (%)70-90 ksi, 485-620 MPa45 Ksi, 310 MPa1822

Equivalent Standard of Alloy Steel Sheets & Plates

Material GroupCommon NameTypeUNSForging Spec.Casting Spec. EquivalentDINDIN W. NoApplicationLow ASMoly SteelC-1/2MoK12822A182-F1 cl2A217-WC115M031.5415Up to 470ºC* (875ºF)AS Chrome Moly1.1/4Cr-1/2MoK11572A182-F11 cl2A217-WC613CRM0441.7335Up to 593ºC (1100ºF)2.1/4Cr-1MoK21590A182-F22 cl3A217-WC910CRM09101.7380Up to 593ºC (1100ºF), HP steam5Cr-1/2MoK41545A182-F5/F5aA217-C512CRMO1951.7362High temp refinery service9Cr-1MoK90941A182-F9A217-C12X 12 CrMo 9 11.7386High temp erosive refinery service9Cr-1Mo-VA182-F91A217-C12AX 10 CrMoVNb 9 11.4903High pressure steam

0 notes

Text

Comprehensive Guide to Manganese Phosphating: Enhancing Metal Durability with Dekem India

Explore the benefits of manganese phosphating with Dekem India, your trusted partner for high-quality Manganese Phosphate Coating solutions. Our advanced coatings offer superior corrosion resistance, wear protection, and enhanced adhesion for various industrial applications.

Understanding Manganese Phosphating Manganese phosphating is a widely used surface treatment process that improves the durability and functionality of metal components. This chemical treatment forms a crystalline phosphate layer that enhances corrosion resistance, reduces friction, and provides excellent adhesion for subsequent coatings or lubricants.

Benefits of Manganese Phosphate Coating

Superior Corrosion Protection:

The manganese phosphate coating creates a protective barrier, shielding metal parts from environmental degradation and rust.

Increased Wear Resistance:

Ideal for high-friction applications, manganese phosphating reduces surface wear, ensuring longer component lifespan.

Enhanced Lubricant Retention:

The porous nature of the coating allows for better lubricant retention, improving performance in critical applications.

Improved Adhesion:

Ensures strong bonding with paints and sealants, providing better finishing and long-lasting results.

The Manganese Phosphating Process at Dekem India Our step-by-step manganese phosphating process includes:

Surface Preparation:

Thorough cleaning and degreasing to remove contaminants.

Phosphating Treatment:

Immersion in a specially formulated solution to form a crystalline phosphate layer.

Post-Treatment:

Application of protective coatings or lubricants for enhanced performance.

Quality Inspection:

Rigorous testing to ensure coating uniformity and adherence to industry standards.

Get in Touch with Dekem India Ensure the longevity and performance of your metal components with our expert Manganese Phosphate Coating solutions.

Contact Dekem India today! to discuss your requirements and get customized solutions tailored to your needs.

Visit: https://www.dekemindia.com/mn-phosphating.php

Contact: +91 0253 2941600

0 notes

Text

Aluminium Bronze Fasteners — Manufacturer, Specifications, and Applications

Introduction

Aluminium Bronze fasteners are widely recognized for their exceptional strength, corrosion resistance, and durability. They are used in various industrial applications, especially in marine, aerospace, and oil & gas sectors, due to their high-performance characteristics.

Aluminium bronze fasteners are highly valued in various industries due to their exceptional strength, corrosion resistance, and excellent mechanical properties. They are primarily used in demanding environments where superior performance and durability are essential. Aluminium bronze fasteners find applications in marine, aerospace, automotive, and industrial sectors due to their high strength-to-weight ratio and resistance to corrosion.

What are Aluminium Bronze Fasteners?

Aluminium Bronze fasteners are metal components made primarily from a combination of aluminium and copper, with minor additions of iron, nickel, or manganese. These fasteners exhibit remarkable mechanical properties, such as high tensile strength, excellent corrosion resistance, and enhanced wear resistance. Due to these properties, Aluminium Bronze fasteners are highly sought after in demanding environments.

Key Properties:

Strength & Durability: Aluminium Bronze offers superior tensile strength, fatigue resistance, and excellent wear properties.

Corrosion Resistance: Provides outstanding resistance to seawater, oxidizing environments, and industrial chemicals.

Heat Resistance: Performs well at elevated temperatures.

Non-Magnetic: Ideal for applications requiring non-magnetic materials.

Specifications of Aluminium Bronze Fasteners

Aluminium Bronze fasteners adhere to various international standards such as ASTM (American Society for Testing and Materials) and BS (British Standards). The key specifications include:

Chemical Composition: Aluminium Bronze fasteners typically consist of:

Mechanical Properties:

Standards:

Grades of Aluminium Bronze Fasteners

Aluminium Bronze fasteners come in various grades, each designed to cater to specific applications based on their chemical composition and mechanical properties. Some of the commonly used grades include:

Aluminium Bronze C95400 (9% Aluminium): Suitable for marine, aerospace, and structural applications due to high corrosion resistance.

Aluminium Bronze C95410 (10% Aluminium): Offers enhanced wear resistance, making it ideal for pumps, marine components, and mining equipment.

Aluminium Bronze C95200 (11% Aluminium): Known for exceptional corrosion resistance, especially in harsh environments like seawater.

Aluminium Bronze C63000 (Iron Aluminium Bronze): Offers improved corrosion resistance and strength, particularly in offshore oil platforms and chemical processing plants.

Applications of Aluminium Bronze Fasteners

Known for their strength and corrosion resistance, Aluminium Bronze fasteners are utilized in a variety of industries.

Marine Industry: Ideal for shipbuilding, offshore platforms, and subsea components due to their excellent corrosion resistance.

Aerospace Industry: Used in aircraft engine parts, landing gear systems, and heat exchangers for their high strength and heat resistance.

Oil & Gas Industry: Commonly used in pipelines, valves, and drilling equipment due to their corrosion resistance in harsh environments.

Construction & Structural Applications: Used in high-stress environments such as bridges, towers, and industrial machinery.

Aluminium Bronze Fasteners Manufacturer & Exporter

Ananka Group is a trusted manufacturer and exporter of high-quality Aluminium Bronze fasteners. With years of expertise, we produce fasteners that meet international standards (ASTM, BS, etc.) and are widely appreciated for their superior quality, durability, and performance.

Key Features of Ananka Group:

Custom Manufacturing: We offer customized fasteners tailored to specific customer requirements.

Global Export: Our Aluminium Bronze fasteners are exported to countries such as the USA, UK, Europe, the Middle East, and Asia.

Quality Assurance: Our fasteners undergo rigorous quality control processes to ensure they meet the highest standards.

Technical Support: We provide expert guidance on material selection, application suitability, and customization.

Conclusion

Aluminium Bronze fasteners are essential components in demanding environments that require strength, corrosion resistance, and durability. From marine and aerospace applications to industrial machinery and structural components, Aluminium Bronze fasteners offer unmatched performance.

At Ananka Group, we pride ourselves on delivering top-grade Aluminium Bronze fasteners, ensuring that industries worldwide benefit from our high-quality products. For any inquiries or custom requirements, feel free to get in touch with us.

Frequently Asked Questions (FAQ)

Q1: What are the key benefits of Aluminium Bronze fasteners?

A1: Aluminium Bronze fasteners offer high corrosion resistance, excellent strength, durability, and heat resistance, making them ideal for demanding environments like marine, aerospace, and oil & gas industries.

Q2: Which industries commonly use Aluminium Bronze fasteners?

A2: Industries such as marine, aerospace, oil & gas, construction, and industrial machinery rely heavily on Aluminium Bronze fasteners due to their corrosion resistance and strength.

Q3: How can I purchase Aluminium Bronze fasteners from Ananka Group?

A3: You can contact us directly via email or through our website for inquiries related to custom manufacturing, bulk orders, and export requirements.

Q4: What grades of Aluminium Bronze are suitable for marine applications?

A4: C95400 and C95200 grades are commonly used in marine applications due to their excellent corrosion resistance in seawater.

Q5: Are Aluminium Bronze fasteners resistant to high temperatures?

A5: Yes, Aluminium Bronze fasteners exhibit excellent heat resistance, making them suitable for high-temperature applications like aerospace and industrial processes.

#Ananka#fasteners#fastenersmanufacturer#manufacturer#aluminiumbronze#bronze#linkedin#Article#anankafasteners#supplier#mumbai#hex#bolt#usa

0 notes

Text

Optimizing Bucket Elevator Discharge Chutes

In 2022, a cement plant initiated a project to renovate its bucket elevator discharge chutes. They entrusted Nantong Darko Building Materials Machinery Co., Ltd. with the entire process, from production to equipment installation and operation. Darko quickly dispatched technicians to the site for an on-the-spot evaluation. They identified several key issues with the discharge chutes.

Main Issues

1.Insufficient Wear Resistance: The discharge chutes used wear-resistant manganese steel plates, which had poor durability. This led to multiple wear-through points and material leakage. The worn manganese steel plates became uneven, causing material to stick.

2.Unreasonable Structural Design: The angle in the middle of the discharge chutes was too steep, failing to effectively cushion the material. As a result, the lower part of the chute experienced severe wear.

3.Uneven Design of the Sloped Chute: The design of the sloped section was uneven. Material concentrated on one side, while the other side showed little wear. This uneven force distribution caused severe wear on the side in contact with the material and led to material accumulation.

Solutions

To address these issues, Darko's technicians proposed practical solutions:

1.Optimize Overall Structure: They adjusted the angle in the middle of the discharge chutes to reduce the impact force of the material. This modification effectively slows down and cushions the material.

2.Redesign the Sloped Chute: They changed the lower sloped section from an irregular rhomboid shape to a parallelogram. This design distributes the impact force more evenly across the bottom and sides, extending the equipment's lifespan.

3.Replace Wear Materials: They substituted wear-resistant ceramic liners for the manganese steel plates. The ceramic liners offer superior wear and corrosion resistance, and their smooth surface reduces material buildup.

Simulation Testing and Expected Results

Darko's technicians conducted simulation tests using the new solutions. They expect to increase the lifespan of the bucket elevator discharge chutes by 3 to 5 times, improve work efficiency by 3% to 12%, and reduce the likelihood of material blockage by 20% to 30%.

These design optimizations will significantly enhance the performance of the discharge chutes. They will ensure the cement plant's production efficiency and the long-term stability of the equipment. If you are facing similar issues, feel free to contact us. We are ready to provide you with professional solutions.

0 notes

Text

The Importance of Ferrous Metals in Modern Industries

Ferrous metals, which primarily consist of iron, are fundamental to many of the industries that drive modern economies. Their combination of strength, versatility, and cost-effectiveness makes them indispensable in everything from construction and infrastructure to manufacturing and transportation. In this article, we explore the importance of ferrous metals in modern industries and how they continue to shape the world we live in.

What Are Ferrous Metals?

Ferrous metals are metals that contain iron as a primary element. The term "ferrous" comes from the Latin word ferrum, meaning iron. These metals typically have iron as the base metal, with small amounts of carbon or other alloying elements, such as chromium, nickel, or manganese, added to enhance certain properties. The most common examples of ferrous metals include steel, cast iron, and wrought iron.

Why Are Ferrous Metals Important?

Ferrous metals are crucial to modern industries because of their strength, durability, and widespread availability. Here are some key reasons why ferrous metals are so important in today's world:

1. Strength and Durability

One of the defining characteristics of ferrous metals is their strength. Steel, the most common ferrous metal, is highly durable and resistant to wear and tear. This makes it ideal for heavy-duty applications, such as the construction of buildings, bridges, and machinery. Ferrous metals can withstand significant stress and are highly reliable, which is why they are used in the manufacture of products that need to endure harsh conditions.

2. Versatility and Adaptability

Ferrous metals can be easily shaped, molded, and welded, making them incredibly versatile for a wide range of applications. Steel, for instance, can be alloyed with other elements like chromium (to form stainless steel) or carbon (to make carbon steel) to create materials with specific properties suited for particular uses. Whether it’s lightweight alloys for automotive applications or heavy-duty steel for construction, ferrous metals can be tailored to meet the unique demands of any industry.

3. Cost-Effectiveness

Compared to non-ferrous metals (which do not contain iron), ferrous metals are generally more affordable. This is primarily due to the abundance of iron, which makes the extraction and production process more cost-efficient. The low cost of ferrous metals allows industries to produce large quantities of materials at a competitive price, making them essential in sectors like construction and manufacturing where budget constraints are often a factor.

4. Recycling Potential

One of the biggest advantages of ferrous metals is their ability to be recycled. Steel, in particular, is one of the most recycled materials in the world. Recycling ferrous metals reduces the need for raw materials, conserves energy, and lowers greenhouse gas emissions, contributing to sustainability efforts. This makes ferrous metals a key player in circular economies, where products are reused, repaired, and recycled rather than disposed of.

Key Applications of Ferrous Metals in Modern Industries

1. Construction

The construction industry is one of the largest consumers of ferrous metals, particularly steel. Steel is used extensively in the construction of buildings, bridges, roads, and infrastructure projects due to its high strength and resistance to structural fatigue. Ferrous metals provide the durability needed to withstand harsh weather conditions and heavy loads, making them essential for the creation of long-lasting, safe, and reliable structures.

2. Automotive Industry

The automotive sector relies heavily on ferrous metals, especially steel and cast iron, for manufacturing vehicle components. Steel is used for car frames, engines, and body parts, while cast iron is often used in engine blocks and other high-strength components. The strength-to-weight ratio of steel allows for the production of safer and more durable vehicles, and its recyclability makes it a preferred choice in the industry.

3. Manufacturing and Machinery

Ferrous metals are foundational in the production of machines, tools, and equipment across various industries. Steel, in particular, is used to make everything from hand tools and industrial machinery to large-scale equipment in factories. The ability to alloy steel with other elements allows manufacturers to create materials suited for a wide variety of applications, from cutting tools to high-performance machinery.

4. Energy and Power Generation

In the energy sector, ferrous metals are used in the construction of power plants, wind turbines, and other energy infrastructure. Steel, for example, is used to build the frames and structures of wind turbines, as well as the boilers and pipes in power plants. The strength and durability of ferrous metals make them essential for equipment that must endure high-pressure conditions and extreme temperatures.

5. Shipbuilding and Aerospace

Ferrous metals, particularly high-strength steel alloys, are used in the construction of ships, aircraft, and other heavy transport vehicles. Steel provides the necessary strength to support large structures, whether it’s a cargo ship navigating the oceans or an airplane withstanding the pressures of flight. The ability to alloy steel for specific applications makes it a versatile choice for these industries.

Ferrous Metals in the Metal Trade

The global metal trade plays a vital role in the distribution of ferrous metals to industries worldwide. Metal trading companies facilitate the buying and selling of ferrous metals, ensuring that manufacturers and industries have access to the raw materials they need for production. The high demand for ferrous metals means that the metal trade is a dynamic and essential industry, with metals like steel being continuously traded, recycled, and repurposed for various applications.

Conclusion

Ferrous metals are integral to modern industries, offering strength, durability, and cost-effectiveness in a wide range of applications. From construction and automotive to manufacturing and energy, ferrous metals are the backbone of many key sectors that power economies around the world. Their recyclability also makes them a key part of sustainable industrial practices. As we continue to innovate and expand in various industries, the importance of ferrous metals will remain a cornerstone of modern society and economic development.

1 note

·

View note

Text

NITRONIC 50 ROUND BARS: PROPERTIES, CHARACTERISTICS, AND APPLICATIONS

The industrial sector constantly seeks durable and corrosion-resistant materials that withstand harsh environments, extreme temperatures, and highly corrosive chemicals. Nitronic 50 is a highly sought-after alloy that finds immense use in several industries due to its exceptional characteristics. Nitronic 50-round bars, in particular, are highly popular and in demand due to their unique properties. In this post, we will discuss some of the characteristics of Nitronic 50-round bars and their applications across various industries.

WHAT ARE NITRONIC 50-ROUND BARS?

Nitronic 50-round bars are high-strength, corrosion-resistant stainless steel produced by the austenitic family of alloys. It has excellent mechanical properties at low and elevated temperatures and superior galling and wear resistance. These round bars are commonly used in marine environments, structural components for vehicles, pumps and valves, fasteners, springs, cookware, and trimming for architectural applications. They offer excellent weldability with their uniform grain structure and good machinability.

PROPERTIES OF NITRONIC 50-ROUND BARS

Nitronic 50 is a nitrogen-strengthened austenitic stainless steel alloy that contains 20-23% chromium, 11-13% nickel, and 4-6% manganese. Some of the most prominent properties of Nitronic 50 round bars include:

• High Strength: Nitronic 50-round bars have a higher tensile strength than conventional stainless steel alloys and can be used in critical applications.

• Exceptional Corrosion Resistance: Nitronic 50-round bars resist pitting, crevice corrosion, and chloride stress corrosion cracking. As a result, they find applications in marine and chemical industries.

• High Wear Resistance: Nitronic 50-round bars resist galling and exhibit excellent wear resistance. This property makes them ideal for use in industries requiring high wear and tear.

APPLICATIONS OF NITRONIC 50-ROUND BARS

Nitronic 50-round bars are extensively used across various industries. Some of the applications of Nitronic 50-round bars include:

• Aerospace Industry: Nitronic 50-round bars manufacture engine components, landing gear, fasteners, and other critical parts that require high strength, corrosion resistance, and fatigue resistance.

• Chemical Industry: Nitronic 50-round bars can withstand extreme environments, high acidity, and saltwater exposure and thus find use in the manufacturing of storage tanks, chemical processing equipment, and valves.

• Marine Industry: Nitronic 50-round bars are highly resistant to pitting and crevice corrosion and hence are used to manufacture marine hardware, shafts, and fasteners.

CONCLUSION

Nitronic 50-round bars are a versatile and durable alloy widely used across various industries. Their exceptional properties, such as high strength, corrosion, and wear resistance, make them ideal for critical applications. Nitronic 50-round bars have several applications across the aerospace, chemical, marine, oil and gas, and medical industries and find use in manufacturing critical components such as engine parts, fasteners, storage tanks, valves, and implants, for anyone who requires an alloy highly resistant to corrosion, wear, and tear, Nitronic 50-round bars should be on their list of materials to consider.

To Know More https://www.smmindustriesllp.com/nitronic-50-round-bars-properties-characteristics-and-applications/

0 notes

Text

Cone crushers for high-hardness materials

Cone crushers are widely used in industries for crushing high-hardness materials such as granite, basalt, quartz, and hard ores like iron ore, copper ore, and manganese ore. These crushers are known for their robust design, high performance, and adaptability to challenging material processing requirements. In this article, we will explore the benefits, working principles, benefits, and key considerations for choosing cone crushers for high-hardness materials.

Working Principle of Cone Crushers

A cone crusher operates on the principle of compressing and crushing materials between a rotating mantle and a stationary concave. The material enters the crusher chamber at the top, where it is subjected to pressure and friction as the mantle moves. The compression reduces the size of the material until it passes through the narrow gap between the mantle and the concave. This crushing action continues until the material is sufficiently reduced to the desired size.

Benefits of Cone Crushers for High-Hardness Materials

High Crushing Efficiency: Cone crushers are efficient at reducing the size of hard materials due to their crushing mechanism, which applies pressure from all directions. This helps in producing finer products in a single pass.

Versatility: Cone crushers can handle a wide range of materials, from soft rocks to hard ores. Their ability to crush high-hardness materials makes them ideal for industries like mining, quarrying, and construction.

Excellent Product Shape: Cone crushers are known for producing cubic-shaped aggregate, which is essential for certain applications, such as road construction and asphalt production.

Adjustable Output Size: Many cone crushers, especially hydraulic models, allow for easy adjustment of the product size, enabling flexibility in meeting the specific requirements of different projects.

Long Wear Life: The design of cone crushers ensures that the wear parts, such as the mantle and concave, last longer under heavy-duty operations, reducing downtime and maintenance costs.

Considerations When Choosing a Cone Crusher

When selecting a cone crusher for high-hardness materials, several factors should be considered:

Material Characteristics: Understanding the hardness, abrasiveness, and moisture content of the material to be crushed is crucial for selecting the appropriate cone crusher.

Crushing Capacity: The crusher’s capacity should match the throughput required for the application. High-hardness materials may require larger or more powerful crushers.

Adjustability and Control: Hydraulic cone crushers offer more precise control over the output size and adjustments to suit different needs.

Maintenance and Serviceability: High-hardness materials can cause wear, so it’s important to choose crushers that are easy to maintain and service.