#Low Smoke Zero Halogen

Explore tagged Tumblr posts

Text

youtube

🔥 LSZH Conduit Ultimate Video Guide 🔥

Ever wondered about LSZH conduit and why it's essential for safety-critical environments? 🤔 This is the ultimate guide you've been waiting for! We're breaking down everything you need to know about LSZH conduit: Don't miss out on this comprehensive video guide!

#lszh conduit#electrical conduit#hft conduit#lsoh conduit#halogen free conduit#low smoke zero halogen conduit#plastic conduit#electrical piping#electrical wiring pipe#rigid conduit#wholesale conduit#bulk conduit#conduit manufacturer#Youtube

0 notes

Text

Low Smoke Halogen Free Cables

LAPP Olflex Low smoke halogen zero free cables (LSHF), (LSOH), and (LSZF) are commonly used in public buildings, airports, railway stations, and areas.

0 notes

Text

Are you searching a best 12 Fiber Pigtail

A 12-fiber pigtail refers to a fiber optic cable terminated on one end with a connector, typically used for splicing or connecting to other fiber optic cables or devices. In the case of a 12-fiber pigtail, it means that there are 12 individual optical fibers within the cable, each terminated with its connector.

Here are some key points about 12-fiber pigtails:

Number of Fibers: As the name suggests, a 12 fiber pigtail contains 12 individual optical fibers within a single cable assembly. These fibers are typically color-coded for identification purposes.

Connector Type: The connector termination at the end of the pigtail can vary depending on the application and compatibility requirements. Common connector types include LC, SC, ST, and MTP/MPO connectors.

Applications: 12 fiber pigtails are commonly used in data centers, telecommunications networks, and other fiber optic installations where high-density fiber connections are required. They are often used for splicing to distribution or breakout cables, connecting to patch panels, or interfacing with active network equipment.

Splicing: In many cases, the individual fibers within a 12 fiber pigtail are spliced to corresponding fibers in other cables or devices using fusion splicing or mechanical splicing techniques. This allows for the creation of permanent connections between fibers without the need for connectors.

Color Coding: Each fiber within the pigtail may be color-coded to facilitate identification and ensure proper alignment during splicing or connection. Common color codes include blue, orange, green, brown, gray, white, red, black, yellow, violet, rose, and aqua.

Jacketing and Protection: The fibers within the pigtail are typically enclosed in a protective jacket to provide mechanical protection and prevent damage to the individual fibers. The jacket may be made of materials such as PVC, LSZH (Low Smoke Zero Halogen), or plenum-rated materials for use in different environmental conditions.

Overall, 12 fiber pigtails provide a convenient and efficient solution for establishing multiple fiber connections in various fiber optic applications, offering high-density connectivity and reliable performance in optical networks.

Next: Buy Quality 12 LC Cable for Seamless Connectivity

2 notes

·

View notes

Text

High-Performance Fiber Optic Cables for the FTTH Access Network Application

With the continuous development of FTTH (Fiber-to-the-Home) network construction, there will be more and more new varieties of fiber optic cables for the FTTH access network application. This article will discuss the three types of fiber optic cables for FTTH in detail.

Fiber Optic Cables for FTTH Access Network

FTTH is an access network architecture that allows deploying xPON technology to provide high speeds of Internet access downstream (from the network to the end-user) and upstream (from the user to the network) over optical fiber from the operator’s switching equipment to an individual home. The main fiber optic cables implemented to build up the FTTH access network are the FTTH feeder cable, FTTH distribution cable, and FTTH drop cable.

FTTH Feeder Cable

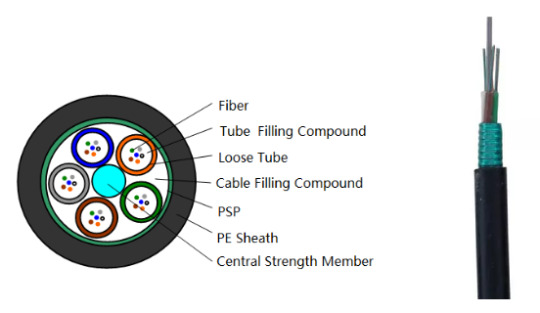

FTTH feeder cable, such as stranded loose tube light-armored cable connects the central office/hut to the fiber distribution hub (FDH). It is ideal for duct and aerial installations. This cable has good mechanical and temperature performance, high hydrolysis resistance, high strength loose tube, good crush resistance and flexibility, high tensile strength ensured by steel wire, and good moisture-proof ensured by PSP (steel tape).

Stranded loose tube light-armored cable construction is that 250um fibers are positioned in a loose tube which is made of high modulus plastic and filled with a water-resistant filling compound; A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member; Tubes are stranded around the strength member into a compact and circular cable core; The PSP is longitudinally applied over the cable core which is filled with the filling compound to protect it from water ingress; The cable is completed with a PE sheath.

FTTH Distribution Cable

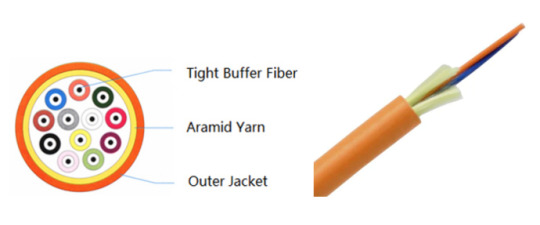

FTTH distribution cable connects the FDH to the fiber access termination (FAT). FTTH distribution cable, such as indoor distribution cable uses φ900um tight buffer fibers as an optical communication medium and aramid yarn strength member. It is compliant with a PVC or LSZH jacket. Generally, FTTH distribution cable is available in fiber counts ranging from 2 to 144 fibers. It has excellent stripping performance of tight buffer fiber, good tensile strength, and small size. FTTH distribution cable is used in indoor /outdoor and backbone cable distribution in building applications.

FTTH Drop Cable

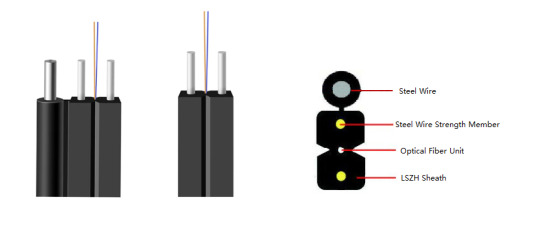

FTTH drop cable is used between the fiber terminal and the building or home. It is ideal for aerial, direct buried, and ducted installations. FTTH drop cable has good crush resistance ensured by parallel strength member, good tensile strength ensured by single steel wire, low smoke, small diameter, zero halogen sheath, simple structure, lightweight, and high practicability.

FTTH drop cable construction is that the optical fiber unit is positioned in the center. Two parallel steel wire strength members are placed at the two sides; A steel wire as the additional strength member is also applied. The cable is completed with an LSZH sheath.

Things to Consider When Choosing Fiber Optic Cables for FTTH Access Network

When choosing the three fiber optic cables for the FTTH access network, there are some general elements that you should pay attention to that influence the method of cable deployment.

Type of FTTH Architecture: The FTTH architecture implemented will influence the data rate and the optical power budget, which will affect the choice of fiber optic cable for the FTTH access network.

Fiber Type of Existing Network: If an existing network is expanded, you must add hardware that can integrate seamlessly with the existing infrastructure.

Installation Environment: No matter the indoor or outdoor applications, there are always different environments where the cable will be installed. For instance, in rugged spaces where your cable may suffer damage, such as basements or in conduits sharing space with electrical or other wirings, you may choose a rugged sheathed cable that is flexible and crush resistant.

Conclusion

FTTH allows a fiber optic cable to be laid from the provider’s equipment directly to the user’s home. Choosing the correct fiber optic cables for FTTH access networks will directly affect network reliability, operational flexibility, and the economics of FTTH deployment.

Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if you have any needs.

#suntelecom#fiberoptic#telecommunications#fttx#telecomengineering#cabling#osp#fiberopticcable#catv#telecomconsult

3 notes

·

View notes

Text

The Importance of Low Smoke Zero Halogen (LSZH) in Modern Construction

With modern construction paving its way into the world, safety has become a primary concern of the occupants. To ensure this, most modern systems have been built with safety standards that aim to protect them from potential hazards. One of the key components in enhancing safety in the building is the use of Low Smoke Zero Halogen cables.

These cables will not only help in figuring out a way to enhance your personal safety but also work towards a better and sustainable future. While keeping your safety in mind, this blog enlightens you about the importance of these cables and why they are important in modern construction.

What is LSZH?

Used in the insulation and sheathing of cables and other electrical components, LSZH cables stands for Low Smoke Zero Halogen, which maintains their safety standards as they do not contain halogens like chlorine, fluorine, bromine, and iodine, which emit toxic gases when exposed to incidents like a fire breakout. Materials made up of LSZH cables are designed to mitigate these risks by producing smoke and non-toxic emissions.

Importance of LSZH in Construction

1. Enhanced Fire Safety

One of the most important benefits of using LSZH materials is their contribution to fire safety. As these gases produce significantly less smoke, they help in enhancing visibility during the incident of a fire making it easier for people to find escape routes. The absence of these toxic halogens means that the smoke produced is less harmful to humans, thus reducing the risk of any injuries and fatalities.

2. Protection of Electronic Equipment

A fire breakout can cause significant damage to the electronic equipment along with the structure of the building. Since traditional cables release corrosive gases that can damage sensitive electronic components, it is vital to install LSZH cables in places like data centres, hospitals, and commercial buildings, where the integrity of electronic systems is crucial.

3. Compliance with Safety Regulations

Using LSZH cables allows companies to follow safety regulations and standards that construction projects must adhere to. These materials help builders and developers to comply with these regulations without any difficulty. Using them will help in assuring you that the buildings meet the safety standards, reduce legal liabilities, and enhance the overall safety profile of the construction.

Application of LSZH Materials

1. Residential Buildings

In your residential homes, the safety of the members is the most important. LSZH cables are the ones that can help you in such a case. They will help in reducing the release of smoke filled with toxic gases thus minimizing the risks of any further damage through the inhalation of these gases. These cables are particularly important in high-rise apartment complexes, where evacuation can be challenging.

2. Commercial Buildings

For buildings that consist of many electronic products and are associated with a large amount of electronic equipment, using LSZH is an absolute requirement. These materials are designed in such a way that they would be crucial in building a safe environment for both human lives and valuable assets.

3. Public Infrastructure

As public infrastructure products, including transportation systems, hospitals, and educational institutions, include a large number of occupants, ensuring the highest level of safety is crucial for these services. Thus, choosing LSZH cables can benefit these infrastructures in case of a fire from causing any extravagant damage.

Challenges and Considerations

1. Cost

Due to their specialised material and manufacturing processes involved, LSZH cables are costlier than other traditional cables. This could be one of the challenges that could cause an obstruction. However, these costs only matter in the beginning; if you think about long-term solutions, these investments will feel worth it in terms of safety and compliance with regulations.

2. Performance Characteristics

Before investing in one, you must ensure that your LSZH cables cater to your requirements. Since these cables are different from the traditional ones, their performance may vary, with respect to different mechanical properties such as flexibility and durability for the cables.

The Future of LSZH in Construction

As people grow aware of fire safety and environmental concerns, adopting LSZH materials will become mandatory. Hence, its use in construction is going to significantly increase. Technological advancements are going to make these cables more cost-effective and improve their performance characteristics. Furthermore, stricter safety regulations and standards will drive the demand for safer construction materials, making LSZH a preferred choice for modern buildings.

Conclusion

Low Smoke Zero Halogen (LSZH) materials are a must in modern construction and are in demand for their ability to enhance fire safety, protect electronic equipment, and ensure compliance with safety regulations. As we move forward towards a sustainable environment while safeguarding lives and properties, investing in LSZH cables will become an essential equipment for every industry to flourish. Therefore, we advise you to hire professionals who will ease the process for you.

Greenbuild has been serving people with the best-quality cable management system for 75 years and is worthy of the trust you will bestow on them. Contact Greenbuild Supply on 0370085086 or write a mail on [email protected]

0 notes

Text

High-Quality Communication Cables: Reliable, Durable, and Efficient Connectivity Solutions

In today’s fast-paced digital world, high-quality communication cables play a crucial role in ensuring reliable, durable, and efficient connectivity solutions for various applications. Whether for residential, commercial, or industrial use, these cables are fundamental in establishing robust networks that support data transmission, voice communications, and multimedia services. The demand for seamless connectivity has led to significant advancements in cable technology, allowing manufacturers to develop products that meet the evolving needs of modern communication systems.

High-quality communication cables are designed with superior materials and manufacturing processes that enhance performance and longevity. For instance, cables constructed from high-grade copper or fiber optics are favored for their excellent conductivity and minimal signal loss, ensuring that data transmission remains clear and uninterrupted over long distances. Additionally, advanced shielding techniques are employed to protect against electromagnetic interference (EMI) and radio frequency interference (RFI), which can compromise signal integrity. This shielding not only enhances the cable's performance but also contributes to its durability, making it suitable for installation in various environments, including those with harsh conditions.

Durability is a key factor in the selection of communication cables, especially in settings that require reliable long-term performance. High-quality cables are engineered to withstand physical stress, temperature fluctuations, and exposure to environmental factors such as moisture and dust. For example, cables with robust outer jackets made from materials like PVC or LSZH (Low Smoke Zero Halogen) provide added protection, ensuring that the cables can endure installation in challenging locations while maintaining their structural integrity. This durability translates into reduced maintenance costs and fewer disruptions in service, which are vital for businesses that rely on continuous connectivity.

Efficiency is another important characteristic of high-quality communication cables. Efficient cables facilitate faster data transfer rates and reduced latency, which are essential for applications such as video conferencing, online gaming, and cloud computing. The rise of smart homes and IoT (Internet of Things) devices has further increased the demand for cables that can support multiple devices without compromising speed or performance. Innovations such as Cat 6 and Cat 7 Ethernet cables offer enhanced bandwidth capabilities and faster transmission speeds, accommodating the growing number of connected devices and the increasing need for high-speed internet access.

Moreover, selecting the right type of communication cable is critical for optimizing network performance. Options such as coaxial, twisted pair, and fiber optic cables each serve specific purposes and are suited for different applications. For instance, fiber optic cables are ideal for long-distance data transmission, while twisted pair cables are commonly used for local area networks (LANs) due to their balance of performance and cost-effectiveness. By understanding the unique attributes of each cable type, users can make informed decisions that align with their connectivity needs.

In conclusion, high-quality communication cables are indispensable in today’s interconnected world. Their reliable, durable, and efficient design ensures seamless communication across various platforms, making them essential for homes, businesses, and industries alike. As technology continues to advance, the importance of investing in top-tier communication cables will only grow, driving the demand for solutions that can support the ever-expanding digital landscape. Whether for upgrading existing networks or planning new installations, choosing the right communication cables is vital to achieving optimal connectivity and performance.

1 note

·

View note

Text

Why use LSZH cables, and where do you use them?

Why use LSZH cables, and where do you use them?

Why use LSZH cable?

Where do you use LSZH cables?

LSZH (Low-Smoke Zero Halogen) cables are used in various applications where fire safety and the reduction of smoke and toxic fumes are critical. These cables are designed to minimize the release of smoke and halogens when exposed to heat or fire. Here are some common applications where LSZH cables are used:

Public Buildings: LSZH cables are commonly used as power and control cables in public buildings such as airports, bus stations, railway stations, shopping malls, state buildings, hospitals, schools, and universities. Data Centers: LSZH cables are suitable for use in data centers, where there are many cables and the risk of fire spreading quickly is high. Industrial Buildings: LSZH cables are used in industrial buildings where fire safety is crucial. These cables help minimize the release of smoke and toxic fumes, reducing the risk to personnel and equipment. Aircraft and Ships: LSZH cables are used in the aviation and marine industries, where fire safety is of utmost importance. These cables help prevent the spread of fire and minimize the release of smoke and toxic gases in confined spaces. Construction: LSZH cables are suitable for use in any construction where it may be difficult to escape in the event of a fire. These cables help protect people and property by reducing the release of smoke and toxic fumes. Other Settings: LSZH cables can be used in any setting where regular cables are used, but fire safety and the reduction of smoke and toxic fumes are concerns.

It’s important to note that LSZH cables have some differences compared to other types of cables:

LSZH vs. PVC Cable: LSZH cables produce no halogens and emit less smoke during a fire, making them less toxic for humans and the environment. In contrast, PVC cables release harmful black smoke and chemicals, including halogens, which can be more dangerous than the fire itself .

LSZH vs. LSF Cable: LSZH cables should not be confused with LSF (Low Smoke and Fume) cables. LSF cables are altered PVC cables that produce fewer harmful gases and smoke when burning, but they still emit gases and do not have the same low-smoke zero-halogen properties as LSZH cables.

0 notes

Text

Zero Halogen Cables: Ensuring Safety and Reliability

In the world of modern infrastructure and technology, safety and reliability are paramount. One innovation that significantly enhances both is the use of zero halogen cables. These cables are designed to reduce the risks associated with fire hazards and improve environmental safety. In this blog, we will explore the benefits, applications, and features of zero halogen cables, and why they are the preferred choice for many industries.

What are Zero Halogen Cables?

Zero halogen cables are made from materials that do not contain halogens, such as chlorine, fluorine, bromine, iodine, and astatine. When exposed to high temperatures or flames, these cables emit minimal smoke and no toxic or corrosive gases. This makes them an ideal choice for environments where safety is a critical concern.

Benefits of Zero Halogen Cables

Reduced Toxicity:

Traditional cables made with halogens can release harmful gases when burned, posing significant health risks. Zero halogen cables mitigate this danger by emitting low levels of smoke and toxic substances.

Improved Fire Safety:

Zero halogen cables are designed to be flame-retardant, reducing the spread of fire. This feature is crucial in maintaining the integrity of safety systems during emergencies.

Environmental Safety:

Halogens can be harmful to the environment, particularly when cables are disposed of or incinerated. Zero halogen cables are more eco-friendly, contributing to a safer and healthier planet.

Corrosion Resistance:

In the event of a fire, halogen-free cables produce non-corrosive gases, protecting nearby equipment and structures from damage.

Applications of Zero Halogen Cables

Zero halogen cables are used in various industries and settings where safety and reliability are of utmost importance:

Public Buildings:

In places like schools, hospitals, and airports, the use of zero halogen cables ensures the safety of occupants by reducing the risks associated with toxic smoke and fire spread.

Transportation:

Railways, subways, and ships often use zero halogen cables to enhance passenger safety and protect critical infrastructure from fire hazards.

Industrial Facilities:

Factories and plants with sensitive equipment and materials benefit from the use of zero halogen cables due to their low smoke emission and non-corrosive properties.

Data Centers:

Protecting valuable data and ensuring uninterrupted service is vital in data centers. Zero halogen cables provide a safer environment for both equipment and personnel.

Key Features of Zero Halogen Cables

Low Smoke Emission:

In the event of a fire, zero halogen cables produce significantly less smoke, improving visibility and reducing the risk of inhalation injuries.

Flame Retardant:

These cables are designed to resist ignition and prevent the spread of fire, enhancing overall fire safety.

Non-Toxic Gases:

By eliminating halogens, these cables do not emit harmful gases, ensuring the safety of people and equipment in the vicinity.

Durability and Reliability:

Zero halogen cables are built to withstand harsh conditions, making them a reliable choice for critical applications.

Why Choose Qflx Zero Halogen Cables?

At Qflx, we prioritize safety, quality, and performance. Our zero halogen cables are engineered to meet the highest industry standards, ensuring they deliver exceptional safety and reliability. Whether you are looking to upgrade your current infrastructure or planning a new installation, Qflx zero halogen cables provide the peace of mind that comes with superior fire safety and environmental responsibility.

Conclusion

Zero halogen cables are a crucial advancement in ensuring the safety and reliability of electrical systems across various industries. By reducing the risks associated with fire hazards and toxic emissions, these cables offer unparalleled protection for both people and equipment. At Qflx, we are committed to providing top-quality zero halogen cables that meet the diverse needs of our clients. Contact us today to learn more about our products and how they can enhance the safety and performance of your systems.

0 notes

Link

$4.05 $ Digitus DK-1617-005 UTP CAT6 Patch Lead - 0.5M Grey https://nzdepot.co.nz/product/digitus-dk-1617-005-utp-cat6-patch-lead-0-5m-grey/?feed_id=153270&_unique_id=6643364a9c29c Features: CAT 6 U-UTP patch cable, Cu, LSZH AWG 26/7, length 0.50 m, color grey Future-oriented standards and high-end quality for your network. – With LSZH (Low Smoke Zero Halogen) sheath for best fire behaviour and low smoke emissions. – Transparent red colored plug for easy identification of Category 6 (250 MHz) – Conductor: Copper (Cu) – PoE+ ready The DIGITUS® Category 6 Class E patch cords are manufactured and tested to the ISO/IEC 11801 and DIN EN 50173 Category 6 specifications. They will guarantee the installed cabling system is compliant with the ISO & EN channel specification requirements and […] #

0 notes

Text

Aptek Cables: Revolutionizing the World of Specialized Cables

Introduction:

In today's interconnected www.aptekcables.com/ world, the demand for specialized cables capable of meeting unique industry requirements is on the rise. Aptek Cables, a leading manufacturer in the field, has emerged as a key player in providing tailored cable solutions. With a commitment to innovation, quality, and customer satisfaction, Aptek Cables has revolutionized the industry with its extensive range of specialized cables. In this article, we delve into the world of Aptek Cables, exploring their history, product offerings, technological advancements, and the impact they have on various industries.

Aptek Cables: A History of Excellence:

Founded several decades ago, Aptek Cables has established a strong reputation as a reliable manufacturer of high-quality specialized cables. The company's journey began with a vision to address the unique needs of industries requiring cables with exceptional performance characteristics. Over the years, Aptek Cables has developed a deep understanding of various sectors, allowing them to design and manufacture cables that excel in demanding environments.

Wide Range of Specialized Cables:

Aptek Cables offers an extensive portfolio of specialized cables, catering to diverse industries such as aerospace, defense, automotive, telecommunications, and more. Their product range covers a wide spectrum of cable types, including:

High-Temperature Cables: Aptek Cables specializes in manufacturing high-temperature cables capable of withstanding extreme heat conditions. These cables are designed to maintain their electrical and mechanical properties even in environments with elevated temperatures, making them ideal for aerospace, automotive, and industrial applications.

Low-Smoke Zero-Halogen (LSZH) Cables: LSZH cables are vital in applications where fire safety is a concern. Aptek Cables offers LSZH cables that emit minimal smoke and do not produce toxic halogen gases when exposed to fire. These cables find application in transportation, marine, and building infrastructure where safety is of paramount importance.

Shielded and Armored Cables: In industries where electromagnetic interference (EMI) and mechanical protection are critical, Aptek Cables provides shielded and armored cables. These cables offer enhanced protection against EMI, ensuring reliable signal transmission, and are capable of withstanding harsh conditions, such as those encountered in defense and industrial applications.

Fiber Optic Cables: Aptek Cables also manufactures fiber optic cables, which are essential for high-speed data transmission and telecommunications applications. These cables provide efficient and secure connectivity, supporting the ever-growing demand for bandwidth in industries such as telecommunications, data centers, and networking.

Technological Advancements and Innovation:

Aptek Cables is at the forefront of technological advancements in the specialized cable industry. They continuously invest in research and development to push the boundaries of cable performance, ensuring their products meet the evolving needs of industries. Some notable technological advancements by Aptek Cables include:

Materials and Insulation: Aptek Cables utilizes advanced materials and insulation technologies to enhance cable performance. They employ innovative polymers and coatings that offer superior electrical properties, temperature resistance, and mechanical strength, ensuring optimal performance in challenging environments.

Customization: Aptek Cables recognizes the importance of customization to meet specific industry requirements. They work closely with customers to understand their unique needs and provide tailored cable solutions. This customization capability allows industries to optimize cable performance and reliability for their specific applications.

Signal Integrity: With the increasing demand for high-speed data transmission, Aptek Cables focuses on maintaining signal integrity throughout their cable designs. They employ advanced techniques to minimize signal loss, crosstalk, and distortion, ensuring reliable data transmission in critical applications.

Impact on Industries:

Aptek Cables plays a significant role in various industries, enabling reliable and efficient connectivity in critical applications. Some notable industries influenced by Aptek Cables' specialized cables include:

Aerospace and Defense: In aerospace and defense applications, where reliability and performance are paramount, Aptek Cables' specialized cables provide critical connectivity for avionics systems, military equipment, radar systems, and communication networks. These cables withstand extreme temperatures, vibrations, and harsh environments, ensuring secure and uninterrupted communication.

Automotive: The automotive industry relies on specialized cables to power advanced systems, such as engine management, safety systems, infotainment, and electric vehicle components. Aptek Cables' high-temperature cables and EMI shielded cables provide the necessary reliability and performance for these demanding automotive applications.

Telecommunications: With the exponential growth of data transmission and the demand for high-speed connectivity, the telecommunications industry heavily relies on fiber optic cables. Aptek Cables' fiber optic cables enable efficient data transmission, supporting the expansion of telecommunications networks, data centers, and high-speed internet connections.

Industrial Automation: Specialized cables from Aptek Cables play a crucial role in industrial automation, providing reliable connectivity for sensors, actuators, motors, and control systems. These cables ensure seamless communication within automated processes, contributing to increased productivity, efficiency, and safety in manufacturing environments.

Conclusion:

AptekCables has emerged as a pioneering force in the world of specialized cables, offering tailored solutions for industries with unique requirements. With a history of excellence, a wide range of specialized cables, and a commitment to technological advancements, Aptek Cables has made a significant impact on various sectors.

Their high-temperature cables, LSZH cables, shielded and armored cables, and fiber optic cables address the specific needs of industries such as aerospace, defense, automotive, telecommunications, and more. Through continuous research and development, Aptek Cables has introduced innovative materials, insulation technologies, and customization options, ensuring their cables deliver optimal performance in challenging environments.

The impact of Aptek Cables can be seen across industries. Their specialized cables provide reliable connectivity for critical applications in aerospace, defense, automotive, telecommunications, and industrial automation. By enabling secure and efficient communication, Aptek Cables empowers these industries to operate at their best, supporting advancements in technology, safety, and efficiency.

As industries continue to evolve and demand specialized cable solutions, Aptek Cables remains at the forefront of innovation, driving the industry forward. With their unwavering commitment to quality, customer satisfaction, and technological advancements, Aptek Cables is poised to shape the future of specialized cables, meeting the ever-changing needs of industries and contributing to connectivity and innovation across the globe.

0 notes

Text

Low Smoke Zero Halogen conduit (LSZH conduit) is a specialized type of electrical conduit designed to minimize the release of toxic gases and smoke during a fire. This makes it a safer and more environmentally friendly alternative to traditional PVC conduits.

#electrical conduit#lszh conduit#plastic conduit#plastic conduit pipe#hft conduit#electrical tubing#halogen free conduit#lsoh conduit#low smoke zero halogen conduit#electrical pipe#conduit pipe

0 notes

Text

9 tiêu chuẩn cáp điện chống cháy quan trọng cho các hệ thống điện

Cáp điện chống cháy là thiết bị được sử dụng rộng rãi trong các công trình xây dựng, nhà ở và các khu công nghiệp hiện nay. Trong bài viết này, Ame Group s�� tìm hiểu về 9 tiêu chuẩn cáp điện chống cháy cần nắm rõ để đảm bảo hiệu suất và tuân thủ các quy định an toàn trong lĩnh vực điện.

Tìm hiểu về cáp chống cháy

Cáp chống cháy là một loại cáp điện được thiết kế đặc biệt để giảm nguy cơ cháy hoặc hạn chế sự lan truyền của ngọn lửa trong trường hợp xảy ra cháy. Trong các hệ thống điện, nơi có khả năng cháy nổ hoặc cần đảm bảo an toàn cao, sử dụng cáp chống cháy là cực kỳ quan trọng.

Cáp chống cháy thường được sản xuất bằng cách sử dụng các vật liệu chống cháy, chẳng hạn như vỏ bọc bằng chất liệu không cháy hoặc có khả năng tự dập lửa. Một số vật liệu thông dụng được sử dụng trong cáp chống cháy bao gồm PVC không chứa chì, LSZH (Low Smoke Zero Halogen), XLPE (Cross-linked Polyethylene) và các chất liệu chống cháy khác.

Các cáp chống cháy có khả năng chịu được nhiệt độ cao hơn, không lan truyền cháy và giảm thiểu sự phát sinh khói độc hại khi bị cháy. Điều này giúp ngăn chặn sự lan truyền của ngọn lửa và giảm thiểu nguy cơ gây hại cho con người và tài sản.

9 tiêu chuẩn cáp điện chống cháy phổ biến

Tiêu chuẩn IEC 60331: Đây là tiêu chuẩn quốc tế về cáp chống cháy. Cáp được kiểm tra để chịu được nhiệt độ lên tới 750 độ C trong ít nhất 90 phút.

Tiêu chuẩn CNS 11174: Điều kiện cháy cáp ở nhiệt độ 840 độ C trong 30 phút.

Tiêu chuẩn BS 6387 loại A: Cáp chống cháy ở nhiệt độ 650 độ C trong 3 giờ.

Tiêu chuẩn BS 6387 loại B: Cáp chống cháy ở nhiệt độ 750 độ C trong 3 giờ.

Tiêu chuẩn BS 6387 loại C: Cáp chống cháy ở nhiệt độ 950 độ C trong 3 giờ.

Tiêu chuẩn BS 6387 loại W: Cáp chống cháy khi có nước ở nhiệt độ 650 độ C trong 15 phút. Sau đó, cáp sẽ tiếp tục chịu được thêm 15 phút nữa khi có nước phun tác động lên cáp.

Tiêu chuẩn BS 6387 loại X: Cáp chống cháy khi có lực va chạm tác động ở điều kiện nhiệt độ 650 độ C trong 15 phút.

Tiêu chuẩn BS 6387 loại Y: Cáp chống cháy khi có lực va chạm tác động ở điều kiện nhiệt độ 750 độ C trong 15 phút.

Tiêu chuẩn BS 6387 loại Z: Cáp chống cháy khi có lực va chạm tác động ở điều kiện nhiệt độ 950 độ C trong 15 phút.

Cáp chậm cháy

Cáp chậm cháy là một loại cáp thông thường nhưng có tính chất khó cháy và giới hạn sự lan truyền của ngọn lửa, tương tự như cáp chống cháy. Tuy nhiên, khi bị cháy, cáp chậm cháy vẫn có thể gây ngắn mạch và chập điện như các loại cáp thông thường.

Một số tiêu chuẩn liên quan đến cáp chậm cháy:

Tiêu chuẩn CNS 11175: Đối với cáp có đường kính ngoài ≤ 15mm, tiêu chuẩn này yêu cầu cáp có khả năng chịu nhiệt lên tới 300 độ C trong 15 phút. Đối với cáp có đường kính ngoài > 15mm, tiêu chuẩn yêu cầu cáp có khả năng chịu nhiệt lên tới 380 độ C trong 15 phút.

Tiêu chuẩn IEC 60332-1: Tiêu chuẩn này liên quan đến khả năng lan truyền của ngọn lửa trên dây đơn và cáp đơn cách điện theo hướng thẳng đứng. Khoảng cách từ đầu kẹp xuống phía dưới mà vỏ bọc cháy xém phải lớn hơn hoặc bằng 50mm. Nếu áp dụng tiêu chuẩn IEEE 383, phần cháy không được lan lên đỉnh của cáp.

Tiêu chuẩn IEC 60332-3-22 Loại A: Tiêu chuẩn này yêu cầu vỏ bọc cáp được làm từ vật liệu không chứa kim loại tương đương với 7l/m, và được xếp thành bó trong khoảng thời gian là 40 phút.

Tiêu chuẩn IEC 60332-3-23 Loại B: Tiêu chuẩn này yêu cầu vỏ bọc cáp được làm từ vật liệu không chứa kim loại tương đương với 3.5l/m, và được xếp thành bó trong khoảng thời gian là 40 phút.

Tiêu chuẩn IEC 60332-3-24 Loại C: Tiêu chuẩn này yêu cầu vỏ bọc cáp được làm từ vật liệu không chứa kim loại tương đương với 1.5l/m, và được xếp thành bó trong khoảng thời gian là 40 phút.

Nên mua cáp chống cháy, chậm cháy ở đâu?

Bạn cần tìm mua cáp chống cháy, chậm cháy phải đảm bảo các yếu tố như chất lượng, an toàn khi dụng, truyền tải điện năng tốt, chính hãng và giá tốt? Hãy lựa chọn ngay Ame Group, chúng tôi cung cấp và phân phối trực tiếp từ thương hiệu Cadivi, cam kết chính hãng 100%, uy tín và chất lượng đặt lên hàng đầu. Liên hệ ngay với chúng tôi qua Hotline: 0353.228.666 để được gái giá ưu đãi nhất trong hôm nay.

0 notes

Text

Types of commercial electrical wiring

Commercial electrical wiring encompasses various systems and methods designed to meet the unique demands of various businesses and industries. This type of wiring is crucial for powering lighting, machinery, and electronic devices in commercial establishments. Understanding the different types of commercial electrical wiring is essential for ensuring safety, reliability, and compliance with electrical codes. Here, we'll explore some common types of commercial electrical wiring:

1. Non-Metallic Sheathed Cable (NM Cable):

NM cable, commonly known as Romex, is a popular choice for commercial electrical wiring. It consists of insulated copper conductors encased in a plastic sheath, protecting against moisture and physical damage. NM cable is cost-effective and easy to install, making it suitable for various commercial applications, such as lighting and general power distribution.

2. Armored Cable (AC):

Armored cable, or BX cable, features insulated conductors encased in a flexible metal armor. This metal armor provides additional protection against physical damage and can be preferred in areas where the wiring may be exposed to potential hazards. AC is commonly used in commercial settings where durability is a key consideration.

3. Conduit Systems:

Conduit systems comprise metal or plastic pipes that house and protect individual conductors. Conduits are available in various types, including rigid metal conduit (RMC), intermediate metal conduit (IMC), and electrical metallic tubing (EMT). Conduits offer excellent protection against moisture, chemicals, and physical damage, making them suitable for demanding commercial environments.

4. Metal-Clad Cable (MC Cable):

Metal-clad cable combines the benefits of a metallic sheath with individual insulated conductors. This type of cable is often used in commercial buildings where the commercial electrical wiring needs extra protection against physical damage and interference. MC cable is commonly employed in applications requiring a high degree of reliability and durability.

5. Mineral-Insulated Copper-Clad Cable (MICC):

MICC is a specialized type of commercial electrical wiring that consists of copper conductors surrounded by a layer of magnesium oxide insulation, all encased in a copper sheath. MICC provides exceptional fire resistance and is commonly used in critical applications where maintaining functionality during a fire event is crucial, such as in emergency systems.

6. Low Smoke Zero Halogen (LSZH) Cable:

LSZH cable is designed to minimize the release of toxic and corrosive gases in the event of a fire. This makes it suitable for commercial settings where the safety of occupants is a top priority. LSZH cable is commonly used in areas with limited ventilation, such as tunnels and enclosed spaces.

7. Twisted Pair Cable:

Twisted pair cables are commonly used for data transmission in commercial settings. They consist of insulated copper wires twisted together to reduce electromagnetic interference. This type of wiring is prevalent in commercial applications such as Ethernet networks and telephone systems.

8. Fiber Optic Cable:

Fiber optic cables use light signals to transmit data and are commonly employed in commercial settings where high-speed and high-bandwidth communication is essential. They are widely used in networking, telecommunications, and data centers. In addition to these common types, commercial electrical wiring includes specialty cables like power-limited tray cables (PLTC) for control systems, thermocouple extension cables for temperature sensing, and high-temperature cables for demanding industrial processes.

The choice of wiring depends on factors such as load capacity, environmental conditions, and safety regulations. Regular inspections and maintenance are essential to ensure commercial electrical systems' continued efficiency and safety, underscoring the importance of professional expertise in designing and managing these intricate networks.

In Conclusion

Understanding the specific requirements of a commercial space is essential for selecting the appropriate type of electrical wiring. Consulting with a qualified commercial electrical wiring professional such as Advanced Electric Servicing LLC and adhering to local electrical codes is crucial to ensure the safety and reliability of the electrical system in commercial buildings.

0 notes

Text

Flame Retardants ATM & MDH Low Smoke & Zero Halogen Free Compounds

ATH Alumina Trihydrate and MDH Magnesium Hydroxide Are widely used to make low-smoke and halogen-free flame retardant wire and cable compounds for a range of insulation and jacketing applications. ATH and MDH serve to retard both flame and smoke via an endothermic reaction that releases water when heated to decomposition. The metal oxide by-product from decomposed ATH and MDH, Al2O3 and MgO respectively, also helps form a char on the polymer, which insulates the polymer from heat and oxygen. For More Information Visit: https://20microns.com/blogs/flame-retardants-atm-mdh-low-smoke-zero-halogen-free-compounds/

0 notes

Text

Reducing Halogen Exposure: Tips for a Safer Home and Workplace

Building a home should feel easy and safe, but how do you understand what is safe for you and what isn’t? For example, exposure to chemicals. We deal with this in our day-to-day lives in different forms, such as cleaning powder, cookware, water, cables, and many other types of equipment, but how do you understand the right amount to use it?

In this blog, we talk about halogens, a group of elements that include chlorine, bromine, iodine, and astatine, and how they can affect your household and workplace by making the air around you toxic through cables.

Understanding Halogens in Cables

Cables in the workplace and household often contain halogens, particularly chlorine and bromine, in their materials. These halogens can be released in any mishap by fire, posing serious health risks and environmental damage. As an alternative, one can use Low Smoke Zero Halogen (LSZH) cables, which are safer and reduce the breakout of harmful gases when exposed to high temperatures.

Tips for Reducing Halogen Exposure from Cables at Home

1. Choose LSZH Cables

Designed to emit minimal smoke and no halogenated gases, these cables are the perfect fit to build safe homes for yourself. These cables are both safe for your homes and for the environment. Therefore, while installing new electrical systems or replacing old ones, choose LSZH cables from a trusted brand.

2. Check existing Installations

For the cables that are already present at home, you can try checking if they are halogen-free or not. In case they consider Halogens, consider replacing them with LSZH substitutes, especially if the area is highly prone to risks by fire, such as in kitchens, attics, and basements.

3. Use cable management solutions

If you regularly check for signs of wear and tear and replace cables when necessary, you can easily avoid any damage caused by overloading electrical outlets and by using cable organisers to prevent tangling and damage. Following these would prevent risks of overheating and fire in your homes.

Tips for reducing Halogen exposure from cables in the workplace

1. Contact regular inspections

In the workplace, one should schedule routines and maintain checks to identify and replace halogen-containing cables with safer alternatives. Regularly inspecting and keeping detailed records about them would help you keep track of any signs of degradation or damage. To make it easier, try maintaining accounts of where the cables are present to streamline this process.

2. Enhance fire safety measures

Along with implementing LSZH cables, you should also be careful about the use of comprehensive safety measures that would reduce the risks of any damage. Keep track that the fire detection systems, sprinklers, and extinguishers are in place and are regularly maintained. In addition to this, employees should be trained on the procedures and fire drills.

3. Implement LSZH cables in new installations

Using LSZH cable wires in your workplace can help in reducing the risks of fire. Traditional cables often contain halogens; thus, while implementing new installations, use LSZH wires as your alternative, which offers a safer environment around you. These cables are particularly significant in high-density environments, like data centres, commercial buildings, and industrial facilities, where the risk of fire can have substantial consequences.

4. Promoting safe cable handling practices

To follow the above procedures, one must train their employees properly with instructions on how to handle these cables, encouraging a culture of safety surrounding you at the workplace. Since improper procedure or handling can lead to severe damage, it is necessary to educate employees on how to mitigate the dangers.

Conclusion

Following these tips can help you promote a safe cable handling process that is essential for protecting your employees from any hazard that might occur. By adapting to LSZH wires, you can foster a safer and more efficient workplace and home. In the end, what is necessary along with these installations, is being able to choose the proper brand with professional help, which will help you in easing up the process. An enterprise that provides you with the best quality LSZH cables is Greenbuild Supply. With over 75 years of experience, we will help you in creating a safer and more sustainable environment. Therefore, before it's too late, contact us to protect your homes and workplaces from jeopardy.

0 notes

Text

🆙Indoor Cable ✅1. The duplex flat indoor cable is a kind of 2core cable that uses the buffered fiber as its basic element. ✅2. The multi-fiber distribution indoor cable is used for bundle fan-out pigtail and patch cord, it uses the buffered fiber as its basic element. ✅3. The duplex round indoor cable is a kind of 2core cable that uses buffered fiber as its basic element. ✅4. The simplex round indoor cable is a kind of single-core cable that uses buffered fiber as its basic element. ✅5. Tight-buffered fiber is the basic element of various indoor cables, with tight-buffered cable designs, the buffering material is in direct contact with the fiber. This design is suited for "jumper cables" which connect outside plant cables to terminal equipment, and also for linking various devices in a premises network. 🔸🔹🔸🔹🔸🔹🔸🔹🔸🔹🔸🔹🔸🔹🔸🔹🔸🔹🔸🔹🔸🔹 ➡️Fiber type: G.652A/B/C/D,G.657A/B/C single-mode fiber,A1a or A1b multimode fiber, or other types ➡️Jacket material: Environmental flame-retardant polyvinyl chloride (PVC), environmental low smoke zero halogen flame retardant polyolefin (LSZH), environmental thermoplastic polyurethane (TPU), or other contracted material.

#Fiberopticcable #FTTH #FTTX #Cable #PVC #LSZH #TPU #Fiberoptic #ISP #Internerserviceprovider #Opticalfiber #December #factory #wholesale #China #MadeinChina #5G

1 note

·

View note