#Lean six sigma green belt certification

Explore tagged Tumblr posts

Text

Six Sigma Training and Certification Online

With online Six Sigma training and certification, start your path to greatness. Get access to in-depth courses that will provide you the know-how and abilities required to promote process improvement and accomplish operational excellence. Get ready for certifications that are accepted by the industry and open up new quality management career options.

0 notes

Text

#lean six sigma green belt certification#lean six sigma green belt#six sigma green belt#green belt certification

0 notes

Text

#lean six sigma#six sigma green belt certification#lean six sigma online course#lean six sigma yellow belt certification

0 notes

Text

Unlocking Career Growth with Lean Six Sigma Green Belt Certification

In today's competitive business landscape, organizations are constantly seeking ways to improve efficiency, reduce waste, and enhance overall quality. Professionals equipped with Lean Six Sigma skills are at the forefront of driving these improvements, making them invaluable assets to their companies. One of the most recognized credentials in this field is the Lean Six Sigma Green Belt certification. But what exactly does this certification entail, and how can it benefit your career? Let's dive in.

What is Lean Six Sigma Green Belt?

Lean Six Sigma is a methodology that combines the principles of Lean and Six Sigma to eliminate waste and reduce variation in processes. While Lean focuses on maximizing value by minimizing waste, Six Sigma emphasizes the reduction of defects and inconsistencies. A Lean Six Sigma Green Belt certification demonstrates that you have a solid understanding of these concepts and are capable of leading small to medium-sized projects that drive process improvements.

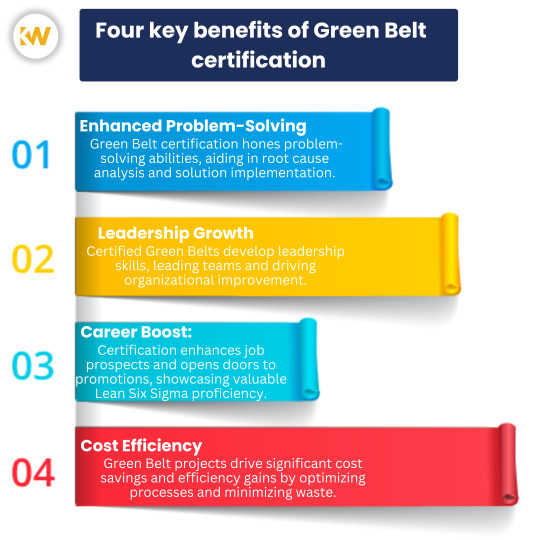

Why Pursue a Lean Six Sigma Green Belt Certification?

Enhance Your Skill Set: The Green Belt certification equips you with a powerful toolkit for problem-solving and process improvement. You'll learn to use data-driven methods to identify inefficiencies, streamline operations, and deliver better results. These skills are highly sought after in industries ranging from manufacturing to healthcare, finance, and beyond.

Boost Your Career Prospects: With a Lean Six Sigma Green Belt certification, you'll stand out in the job market. Employers value professionals who can lead initiatives that improve quality, reduce costs, and increase customer satisfaction. This certification can open doors to new opportunities, promotions, and higher earning potential.

Lead with Confidence: As a Green Belt, you'll be qualified to lead process improvement projects within your organization. You'll gain the confidence to take on leadership roles, guiding teams to achieve significant results. Whether you're working on reducing production defects, improving customer service, or optimizing supply chain processes, your skills will make a tangible impact.

Contribute to Organizational Success: Organizations that adopt Lean Six Sigma principles often experience improved efficiency, higher quality products, and greater customer satisfaction. By applying your Green Belt knowledge, you can help your company achieve these outcomes, making you a key contributor to its success.

The Certification Process

Obtaining a Lean Six Sigma Green Belt certification typically involves completing a training course and passing an exam. The training covers a range of topics, including process mapping, data analysis, statistical tools, and project management. You'll also have the opportunity to apply what you've learned to real-world scenarios, often through a hands-on project that demonstrates your ability to lead and deliver results.

Is Lean Six Sigma Green Belt Right for You?

If you're a professional looking to advance your career, improve your problem-solving skills, and contribute to your organization's success, then the Lean Six Sigma Green Belt certification could be the right choice for you. Whether you're in manufacturing, healthcare, finance, or any other industry, the principles of Lean Six Sigma can be applied to improve processes and achieve excellence.

Conclusion

In a world where efficiency and quality are paramount, the Lean Six Sigma Green Belt certification offers a pathway to career growth and organizational success. By mastering the tools and techniques of Lean Six Sigma, you'll be well-equipped to lead process improvement initiatives that deliver measurable results. Take the next step in your professional journey by pursuing a Lean Six Sigma Green Belt certification and unlock new opportunities for growth and leadership.

0 notes

Text

#lean six sigma green belt#six sigma green belt#six sigma certification#green belt certification#six sigma green belt certification

0 notes

Text

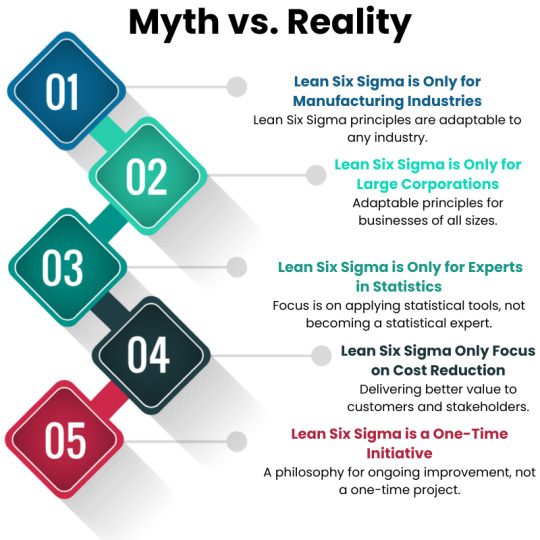

Addressing Common Misconceptions About Lean Six Sigma Green Belt Certification

Introduction

The Lean Six Sigma Green Belt certification is powerful and can significantly enhance one’s professional skills and career prospects. But like any widely recognized certification, it often comes with many misconceptions. In this blog post, we aim to dispel some common myths surrounding Lean Six Sigma Green Belt certification and provide a clearer understanding of its value and benefits.

Myth 1: Lean Six Sigma Green Belt is Only for Manufacturing Industries

Fact: The principles of Lean Six Sigma originated in manufacturing, but have proven to be versatile and applicable to a variety of industries. Greenbelt certification provides professionals with problem-solving skills and valuable process improvement strategies in areas such as healthcare, finance, IT, and service industries.

Myth 2: Lean Six Sigma Certification is Time-Consuming

Fact: Although Lean Six Sigma certification requires time and effort, the length of time varies depending on the activity and methodology. Many popular internship programs offer flexible programs, allowing individuals to balance their professional and personal commitments while pursuing certification. In addition, the benefits of a certificate often outweigh the validity period.

Myth 3: Lean Six Sigma is Only for Experts in Statistics

Fact: Although statistical skills are part of Lean Six Sigma Green belt candidates do not have to be statisticians. They focus on practical applications and problem solving using mathematical tools rather than extensive theoretical skills. The training programs are designed to teach participants how to use statistical methods to improve the effectiveness of the programs.

Myth 4: Lean Six Sigma is Only for Large Corporations

Fact: The principles of Lean Six Sigma can be scaled up to suit organizations of all sizes, including small and medium enterprises. Small businesses benefit greatly from the cost savings and productivity improvements that Lean Six Sigma techniques bring. The principles are flexible and can be tailored to the specific needs and size of an organization.

Myth 5: Lean Six Sigma Green Belts Only Focus on Cost Reduction

Fact: While cost reduction is a common outcome of Lean Six Sigma projects, it is not the only focus. Greenbelts have been trained to identify and eliminate waste, increase efficiency and improve overall efficiency. These improvements often result in cost savings, but the ultimate goal is to deliver better value for customers and stakeholders.

Myth 6: Lean Six Sigma is a One-Time Initiative

Fact: Lean Six Sigma is a continuous improvement philosophy. Greenbelts are trained to embed a culture of continuous improvement in their organizations. Certification empowers individuals to lead and participate in a variety of projects, ensuring continued program efficiency and effectiveness.

Myth 7: Lean Six Sigma Green Belt Certification Guarantees a Promotion

Fact: While Lean Six Sigma certification is a valuable addition to your skill set, it is not an instant promotion. The impact of career advancement depends on a variety of factors, including skills to use in real-world jobs, organizational culture, and individual performance but certification enhances your potential and makes you a candidate for leadership roles.

Conclusion

In conclusion, Lean Six Sigma Green Belt certification is a valuable asset that goes beyond the surrounding misconceptions. By understanding the truth behind these myths, individuals can make informed decisions about pursuing certification and leveraging its benefits to make a positive difference in their career journey.

#Lean Six Sigma#Green Belt Certification#Process Improvement#Professional Development#Continuous Improvement#Business Transformation

0 notes

Text

Six Sigma Green Belt Certification Training | Lean Six Sigma Green Belt?

IselGlobal is a training and consulting organization that offers Six Sigma Green Belt certification and training programs. Six Sigma is a set of techniques and tools used for process improvement, and Green Belt certification indicates a level of expertise in applying these principles to improve processes within an organization.

Here are some key points about the Six Sigma Green Belt certification at IselGlobal:

Curriculum: The Lean Six Sigma Green Belt program at IselGlobal typically covers the fundamentals of Six Sigma, statistical analysis, process improvement methodologies, and project management. Participants learn how to use tools like DMAIC (Define, Measure, Analyze, Improve, Control) to drive process improvements.

Training: IselGlobal provides training through various formats, including in-person classes, online courses, and blended learning options. The training is designed to help participants understand and apply Six Sigma concepts effectively.

Certification: Upon successful completion of the training and passing an exam, participants receive a Six Sigma Green Belt from IselGlobal. This certification can be a valuable credential for individuals looking to advance their careers in process improvement and quality management.

Practical Projects: Often, Six Sigma Green Belt programs include practical projects where participants apply their knowledge to real-world scenarios within their organizations. These projects help reinforce the learning and demonstrate the ability to make tangible improvements.

Duration: The duration of the Green Belt certification program at IselGlobal can vary depending on the format and intensity of the training. Some programs may be completed in a few weeks, while others may span several months.

Trainers: IselGlobal typically employs experienced instructors who have a background in Six Sigma and can provide valuable insights and guidance throughout the training program.

Cost: The cost of the Lean Six Sigma Green Belt certification program at IselGlobal can vary, so it's best to contact them directly or visit their website for the most up-to-date information on pricing and course availability.

Before enrolling in any certification program, it's a good idea to research the organization, read reviews, and consider your career goals to ensure that the program aligns with your needs and aspirations. Additionally, you may want to inquire about any specific requirements or prerequisites for the Green Belt certification program at IselGlobal.

#six sigma green belt#lean six sigma green belt certification#green belt certification#lean six sigma certification

1 note

·

View note

Text

Learn Value Stream Mapping and Its Essentials for Success

Organizations are continuously looking for methods to increase customer value, reduce waste, and improve efficiency. Value stream mapping is an effective technique for accomplishing these goals (VSM). A visual technique called value stream mapping is used to examine and enhance the movement of data and materials through a system or process. We'll go through the essential ideas and factors for value stream mapping success in this blog, emphasizing the role it plays in promoting operational excellence and process improvement.

Understanding Value Stream Mapping

At its core, value stream mapping is a lean management technique that helps organizations identify and eliminate non-value-added activities, reduce lead times, and optimize process flow. The process involves creating a visual representation of the current state of a process, identifying areas of waste and inefficiency, and designing a future state that maximizes value for the customer. You can learn more about it by enrolling in top lean six sigma green belt certification courses to enhance your knowledge about VSM lean six sigma.

Key Concepts in Value Stream Mapping

Current State Map: The current state map provides a snapshot of the existing process, including all steps, activities, and flows from raw materials to finished product or service. It helps identify bottlenecks, delays, and waste in the process.

Value-Added and Non-Value-Added Activities: Value-added activities are those that directly contribute to meeting customer requirements and are willing to pay for. Non-value-added activities, on the other hand, do not add value to the product or service and should be eliminated or minimized.

Process Flow: Understanding the flow of materials and information through the process is critical for identifying opportunities for improvement. Process flow analysis helps identify areas of congestion, duplication, or inefficiency.

Future State Map: The future state map represents the desired state of the process after implementing improvements. It outlines the ideal flow of materials and information, as well as the elimination of waste and inefficiency.

Considerations for Success

Leadership Support: VSM lean six sigma requires strong leadership support to drive change and ensure that resources are allocated effectively. Leaders must champion the value stream mapping process and provide the necessary support and resources for implementation.

Cross-Functional Collaboration: Value stream mapping involves multiple stakeholders from different departments and functions. Effective collaboration and communication are essential for identifying opportunities for improvement and implementing changes across the organization.

Data Accuracy and Analysis: Accurate data collection and analysis are critical for identifying patterns, trends, and opportunities for improvement. Organizations must ensure that they have access to reliable data and the analytical capabilities to interpret it effectively.

Continuous Improvement Mindset: Value stream mapping is not a one-time exercise but rather an ongoing process of continuous improvement. Organizations must foster a culture of continuous improvement. They should empower employees to identify problems, propose solutions, and implement changes to drive positive outcomes.

Measurement and Monitoring: Establishing key performance indicators (KPIs) and metrics is essential for measuring the success of VSM lean six sigma initiatives. Organizations must monitor progress against established targets and adjust strategies as needed to achieve desired outcomes. Conclusion

Value stream mapping is a powerful tool for driving process improvement and operational excellence in organizations. By understanding current state mapping, value-added activities, process flow, and future state mapping, organizations can identify opportunities for improvement. Organizations should consider factors like leadership support, data accuracy, continuous improvement mindset, and measurement and monitoring. It ensures the success of their VSM lean six sigma initiatives and achieve improvements in performance and customer satisfaction.

Do you want to learn more about Lean and six sigma green belt certification courses? You can enroll at MindCypress, an upskilling platform that supports professionals by providing personalized upskilling courses for career growth.

Resource: https://www.mindcypress.com/blogs/quality-management/learn-value-stream-mapping-and-its-essentials-for-success

0 notes

Text

Understanding Effectiveness: A Handbook for Lean Six Sigma Green Belt Accreditation

Organizations are continuously looking for ways to improve productivity, reduce waste, and streamline operations because they know that efficiency is essential for success in today's world. Lean Six Sigma is a potent combination of Six Sigma techniques and Lean principles that has become a game-changing strategy for attaining operational excellence. The Green Belt accreditation, a highly sought-after title that denotes competence in promoting process changes, is the foundation of this system. Let's examine what it means to get certified as a Lean Six Sigma Green Belt and why it's an advantageous skill in the current competitive environment.

Knowing Lean Six Sigma

Let's first discuss the basics of Lean Six Sigma before delving into the importance of the Green Belt certification. The Toyota Production System is the source of lean concepts, which emphasize reducing waste, maximizing flow, and increasing value for customers. The goal of Six Sigma, which was developed by Motorola and made popular by General Electric, is to attain near-perfect quality by minimizing errors and variance in processes. Lean Six Sigma provides an all-encompassing strategy to continuous improvement by combining speed and precision through the integration of various approaches.

The Green Belt's Function

As front-line issue solvers and project managers, Green Belts are essential members of the Lean Six Sigma hierarchy. These people can spearhead improvement projects in their respective fields because they have a strong grasp of Lean Six Sigma principles and technologies. Green Belts oversee initiatives targeted at raising productivity, quality, and customer happiness. These initiatives may involve reducing production procedures, boosting service delivery, or strengthening administrative workflows.

Green Belt Certification: Obtaining this certification demonstrates that one has mastered the principles of Lean Six Sigma and is adept at implementing them in practical settings. Essential topics including process mapping, data analysis, root cause analysis, statistical tools, and the DMAIC (Define, Measure, Analyze, Improve, Control) methodology are typically covered in Green Belt training programs. After a demanding training program, candidates take a certification exam to evaluate their knowledge and problem-solving abilities.

Advantages of Becoming a Certified Green Belt:

1. Improved Ability to Solve Problems:

With the help of green belt training, people may solve problems more methodically by determining the underlying causes of issues, evaluating the facts, and putting workable solutions into place. These abilities are extremely valuable in all fields, enabling businesses to take on challenging tasks and promote long-term progress.

2. Leadership Development

Earning a Green Belt credential develops leadership qualities in addition to technical proficiency. In order to support change projects, Green Belts get experience leading cross-functional teams, communicating clearly, and influencing stakeholders. Fostering a culture of continuous improvement and accelerating organizational transformation require these qualities in a leader.

3. employment Advancement

A Green Belt certification will greatly improve employment possibilities in the competitive work market of today. Professionals with Lean Six Sigma experience are highly valued by employers, who see them as catalysts for achieving measurable outcomes and advancing operational excellence. Certified Green Belts are in a good position to grow in their careers, whether they're looking to move up the corporate ladder or take advantage of new chances.

4. Cost Savings and Efficiency benefits

Green Belt initiatives frequently result in significant cost savings and efficiency benefits because they optimize processes and minimize waste. Lean Six Sigma programs have an influence that goes beyond individual projects and improves customer happiness, cycle times, and product quality while also generating financial gains for businesses.

In summary,

companies need to continuously pursue excellence in a fast-paced business climate that is marked by intense competition and changing client needs. Professionals with a Lean Six Sigma Green Belt certification are prepared to create operational improvements and provide measurable business outcomes because they have the necessary knowledge, abilities, and credentials. Whether you are a rising star in your area or a seasoned industry veteran, investing in Green Belt training can open doors for career advancement, personal development, and organizational success. In today's changing environment, embrace the path to mastery and realize Lean Six Sigma's full potential.

Lean Six Sigma Green Belt certification is a lighthouse of expertise in the quest of excellence and efficiency, pointing people and organizations in the direction of a better, more productive future.

#lean#lean six sigma green certification#gree#lean six sigma green belt certification#green belt#green belt certification

0 notes

Text

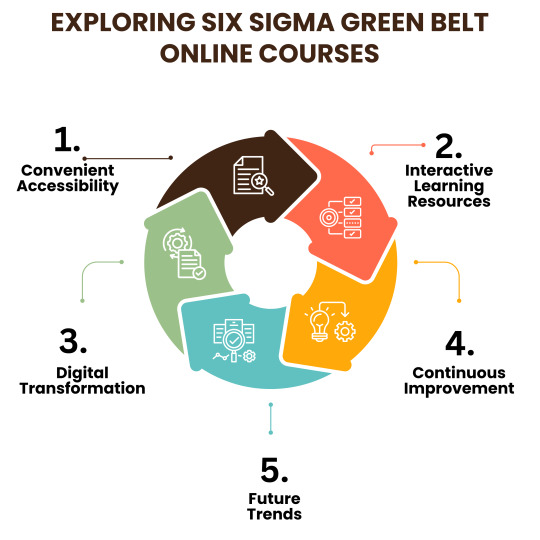

Master Efficiency: Lean Six Sigma Green Belt Certification Course Online

The Lean Six Sigma Green Belt Certification Course Online offers a comprehensive training program aimed at equipping learners with the skills and knowledge necessary to drive process improvement and waste reduction in their organization. Participants will gain access to a vast library of 450+ courses that cater to individuals at all levels and are compatible with all major browsers and devices. The engaging learning materials range from 10-minute micro-learning videos to 40-hour full courses, guaranteeing broad coverage of crucial concepts and tools.Here is the course link:https://lead-academy.org/course/lean-six-sigma-green-belt-certification

0 notes

Text

Lean Six Sigma Green Belt Training and Certification

#Lean Six Sigma#Green Belt Certification#Process Improvement#DMAIC#Lean Principles#Operational Excellence#Continuous Improvement#Waste Reduction#Efficiency#Statistical Analysis#Project Leadership#Professional Development#Quality Management#Six Sigma Training.

1 note

·

View note

Text

The Lean Six Sigma Certification Course: Your Ultimate Guide to Success

All the knowledge required to earn a certified Lean Six Sigma Green Belt is taught in the extensive online course, MITSkills Lean Six Sigma Certification. Project management, leadership and communication, Six Sigma tools and techniques, and the DMAIC process are all covered in the course. A project component of the course allows you to apply the knowledge you have gained to a real-world problem, and it is taught by seasoned Six Sigma specialists.

Six Sigma initiatives employ a five-step approach called the DMAIC process:

Define the problem or opportunity.

Measure the current state of the process.

Analyze the data to identify the root causes of the problem or opportunity.

Improve the process by addressing the root causes.

Control the improved process to ensure that it continues to perform as expected.

The DMAIC process is covered in great detail in the MITSkills Lean Six Sigma Certification Course, which also gives you the skills and information you need to apply it to any process.

To find and remove waste from operations, Six Sigma employs a range of instruments and methods. Among the most often used Six Sigma methods and instruments are:

Process mapping

Cause-and-effect diagrams

Pareto charts

Histograms

Scatter plots

Control charts

Using these instruments and strategies to enhance processes is what the MITSkills Lean Six Sigma Certification Course teaches you.

Project management principles are generally applied in the administration of Six Sigma initiatives. Project management fundamentals are covered in the MITSkills Lean Six Sigma Certification Course, including:

Project planning

Risk management

Communication management

Stakeholder management

Applying project management concepts to Six Sigma initiatives is another skill you will learn in this course.

Leading and overseeing Six Sigma initiatives is the responsibility of Six Sigma Green Belts. You may learn how to be a great leader and communicator with the MITSkills Lean Six Sigma Certification Course.

Topics covered in the course include:

Motivating and engaging team members

Managing conflict

Giving and receiving feedback

Communicating with stakeholders

A project component of the MITSkills Lean Six Sigma Certification Course gives you the chance to put your newly acquired knowledge to use in solving a practical issue.

Choosing a project and creating a project plan will be done in collaboration with your mentor. Data collection and project plan implementation will follow.

To determine the underlying reasons of the issue or opportunity, you will examine the data after you have gathered it. Next, in order to address the underlying problems, you will create and implement solutions.

Lastly, you will maintain control over the enhanced procedure to make sure it keeps operating as planned.

Enrolling in the MITSkills Lean Six Sigma Certification Course has numerous advantages, such as:

Comprehensive coverage of the Lean Six Sigma methodology

Experienced instructors

Project component

Affordable and accessible

Preparation for the Six Sigma Green Belt certification exam

For anyone seeking to gain knowledge of the Lean Six Sigma methodology and obtain certification as a Lean Six Sigma Green Belt, the MITSkills Lean Six Sigma Certification Course is an invaluable asset. It is a reasonably priced, thorough, and expertly taught course.

The MITSkills Lean Six Sigma Certification Course is highly recommended if you are serious about learning Lean Six Sigma.

#six sigma#6 sigma#six sigma certification#lean six sigma#green belt#six sigma black belt#six sigma belts#six sigma process#lean six sigma black belt#mit skills india#skills#upskilling#mit skills#mitskills#career upskilling#upskill

0 notes

Text

Everything You Need to Know About Lean Six Sigma Certification

Organizations are continuously looking for ways to increase overall quality, reduce waste, and improve operational efficiency in today's competitive business environment. This is where having a Lean Six Sigma certification is essential. Lean Six Sigma experts are in high demand as companies look to streamline their operations and provide more value to their clients. We'll go over the importance of Lean Six Sigma certification, its advantages, and how to get this important certification in this article.

Knowing Lean Six Sigma

Combining the data-driven technique of Six Sigma, which aims to reduce faults and variations, with the lean principles of improvement and waste elimination, Lean Six Sigma is a potent methodology. Using a holistic strategy enables firms to improve customer happiness, streamline processes, and make long-term gains.

The Significance of Certification in Lean Six Sigma

1. employment Advancement: By proving a professional's capacity to spearhead process improvements and provide measurable outcomes inside a company, Lean Six Sigma certification improves employment chances.

2. Organizational Impact: By spearheading process optimization initiatives, cutting expenses, and improving overall operational efficacy, certified professionals help an organization succeed.

3. Worldwide Recognition: The Lean Six Sigma certification is widely regarded and recognized worldwide, making certified professionals in great demand on the job market.

Advantages of Certification in Lean Six Sigma

1. Improved Problem-Solving Skills: Professionals who have earned certification have increased data analysis and problem-solving abilities, which help them spot and resolve process inefficiencies.

2. Competitive Advantage: Those with certifications have an advantage in the labor market and are frequently given preference for strategic and leadership positions inside companies.

3. Quality Improvement: By putting Lean Six Sigma ideas to use, product and service quality is raised, which increases client happiness and loyalty.

Getting Certified in Lean Six Sigma

Select the Appropriate Certification Level: Yellow, Green, Black, and Master Black Belt are the many levels of Lean Six Sigma certifications that are available. Choose the level that corresponds with your experience and professional objectives.

2. Register for Accredited Training: Look for respectable training organizations that conduct Lean Six Sigma courses. These courses offer thorough instruction in Lean Six Sigma approaches and help applicants get ready for certification tests.

3. Get Practical Experience: Use the knowledge you've learned to work on real-world projects. Gaining practical experience is essential to understanding Lean Six Sigma principles and techniques.

4. Certification Exam: To demonstrate your mastery of the technique and its application, be ready for and pass the Lean Six Sigma certification exam.

5. employment Growth: Professionals can pursue a variety of employment options in process improvement, quality management, supply chain optimization, and other fields with a Lean Six Sigma certification in hand.

In summary

To sum up, for individuals looking to progress their careers and have a big influence in their organizations, a Lean Six Sigma certification is a great tool. People may drive positive change, cultivate a culture of continuous improvement, and contribute to the overall success of their organizations by becoming proficient in Lean Six Sigma approaches. The demand for certified Lean Six Sigma specialists is anticipated to stay high as long as organizations continue to value quality and efficiency. Obtaining this certification is a prudent investment in one's professional development.

#lean six sigma#lean six sigma green belt#six sigma green belt#six sigma course#six sigma certification

0 notes

Text

Green Belt Certification Training Online Course - [2023]

In today's competitive business environment, organizations strive to optimize processes, improve quality, and enhance efficiency. Lean Six Sigma methodologies have emerged as a powerful toolset to achieve these goals. If you aspire to become a certified Lean Six Sigma Green Belt, enrolling in a reputable online training course is a strategic step toward professional growth. In this blog, we will explore the significance of Lean Six Sigma Green Belt certification, the benefits it offers, and why ISEL Global's online training course is the ideal choice for aspiring Green Belts in 2023.

Lean Six Sigma Green Belt Certification: A Catalyst for Career Advancement - Lean Six Sigma Green Belt certification is highly valued in the industry. It equips professionals with the knowledge and skills required to identify process inefficiencies, reduce waste, and improve overall performance. Holding this certification not only demonstrates your expertise in process improvement but also enhances your career prospects. Employers recognize Lean Six Sigma Green Belts as valuable assets capable of driving continuous improvement initiatives and delivering measurable results.

The Benefits of Lean Six Sigma Green Belt Certification - Obtaining a Lean Six Sigma Green Belt certification offers numerous advantages. Firstly, it equips you with a structured approach to problem-solving, enabling you to analyze complex issues and implement effective solutions. Secondly, the certification enhances your ability to work collaboratively within cross-functional teams, leading to improved teamwork and increased productivity. Moreover, Lean Six Sigma Green Belt certification demonstrates your commitment to quality and process excellence, setting you apart from your peers and positioning you as a sought-after professional in the industry.

#green belt certification#six sigma green belt#six sigma green belt certification#lean six sigma green belt certification

0 notes

Text

TIMWOOD Analysis: Identifying and Eliminating Waste in Business Processes

The business landscape is heavily competitive today. Organizations have started focusing on ways that can help improve efficiency, save expenditures and increase customer satisfaction. To achieve this goal, businesses use TIMWOOD analysis, a crucial part under Lean Six Sigma. TIMWOOD analysis is helpful for organizations in identifying and eliminating lean six sigma waste in business processes.

In this blog, we will understand the fundamentals, principles and importance of TIMWOOD analysis along with effective strategies for it.

Understanding TIMWOOD Analysis

There are seven types of waste in Lean Six Sigma and TIMWOOD is an acronym derived from the same. It refers to the waste that business processed commonly consist:

Transportation: Movement of materials for no reason or information between workstations or locations. Inventory: Excess inventory that ties up capital and leads to storage costs, obsolescence, and waste. Motion: Non-essential movement of people, equipment, or machinery. Waiting: Time spent waiting for materials, information, equipment, or approvals for next steps. Overproduction: Producing more than necessary or before it is needed. Over processing: Performing unnecessary or redundant steps in a process. Defects: Errors, defects, or rework that result in scrap, rejections, customer complaints, and additional costs.

The goal of TIMWOOD analysis is to identify and eliminate these forms of waste. Thereby, improving process efficiency, reducing costs, and enhancing overall performance. You can enroll for a lean six sigma green belt certification course to learn more about TIMWOOD Analysis.

Importance of TIMWOOD Analysis in Lean Six Sigma

TIMWOOD analysis is a foundational concept in Lean Six Sigma methodology, which aims to minimize waste and maximize value for the customer. By conducting TIMWOOD analysis, organizations can:

Identify Opportunities for Improvement: TIMWOOD analysis helps organizations identify inefficiencies, bottlenecks, and areas of waste in their processes, providing insights into opportunities for improvement.

Streamline Operations: By eliminating waste, organizations can streamline their operations, reduce cycle times, and improve throughput, leading to increased productivity and efficiency.

Enhance Customer Satisfaction: By delivering products or services more quickly, reliably, and cost-effectively, organizations can enhance customer satisfaction and loyalty.

Reduce Costs: Eliminating waste reduces costs associated with excess inventory, unnecessary processing, defects, and rework, leading to improved profitability.

Drive Continuous Improvement: TIMWOOD analysis is not a one-time exercise but rather an ongoing process of continuous improvement. By continually monitoring and optimizing their processes, organizations can maintain a competitive edge and adapt to changing market conditions.

Practical Strategies for Identifying and Eliminating Waste

Value Stream Mapping: Conducting value stream mapping exercises to visualize and analyze end-to-end processes, identify waste, and design future state maps that optimize flow and efficiency.

Kaizen Events: Organizing Kaizen events or rapid improvement workshops to engage cross-functional teams in identifying and implementing solutions to eliminate waste and improve processes.

Standard Work: Establishing standard work procedures and work instructions to ensure consistency, reduce variability, and eliminate waste in processes.

Error-Proofing (Poka-Yoke): Implementing error-proofing techniques to prevent defects and errors from occurring in processes, thereby reducing waste and rework.

Continuous Monitoring and Improvement: Continuously monitoring process performance metrics, soliciting feedback from stakeholders, and implementing incremental improvements to eliminate waste and optimize processes over time. Conclusion:

TIMWOOD analysis is a powerful tool for identifying and eliminating waste in business processes. It drives efficiency, reduces costs, and enhances customer satisfaction. Organizations can streamline their operations by understanding the seven types of waste and applying practical strategies for waste elimination. They can also improve productivity, and achieve sustainable competitive advantage in today's competitive business environment. By incorporating TIMWOOD analysis into their Lean Six Sigma initiatives, organizations can unlock new opportunities for process improvement and drive continuous innovation and excellence.

To get a better understanding of TIMWOOD Analysis or Lean Six Sigma waste, it is best to learn from professionals. Enroll in Lean Six Sigma Green Belt Certification course by MindCypress. It is a learning platform that helps individuals gain new skills or hone existing one. The certifications can increase your value in the market, wherever you go. Resource: https://www.mindcypress.com/blogs/quality-management/timwood-analysis-identifying-and-eliminating-waste-in-business-processes

0 notes