#Laboratory Water Heater

Text

Choosing the Right Water Heater: A Guide to 316 Stainless Steel Electric Water Heaters

Laboratories often require precise temperature control for experiments and processes. A laboratory water heater must provide consistent and accurate heating, as well as resist corrosion from chemicals and other substances that may come into contact with the heating element or tank. A reliable water heater is essential for ensuring the integrity of experiments and research.

0 notes

Text

NASA scientists recreate Mars's spider-shaped geologic formations in lab for the first time

Tests on Earth appear to confirm how the red planet's spider-shaped geologic formations are carved by carbon dioxide.

Since discovering them in 2003 via images from orbiters, scientists have marveled at spider-like shapes sprawled across the southern hemisphere of Mars. No one is entirely sure how these geologic features are created. Each branched formation can stretch more than a half-mile (1 kilometer) from end to end and include hundreds of spindly "legs." Called araneiform terrain, these features are often found in clusters, giving the surface a wrinkled appearance.

The leading theory is that the spiders are created by processes involving carbon dioxide ice, which doesn't occur naturally on Earth. Thanks to experiments detailed in a new paper published in The Planetary Science Journal, scientists have, for the first time, re-created those formation processes in simulated Martian temperatures and air pressure.

"The spiders are strange, beautiful geologic features in their own right," said Lauren Mc Keown of NASA's Jet Propulsion Laboratory in Southern California. "These experiments will help tune our models for how they form."

The study confirms several formation processes described by what's called the Kieffer model: Sunlight heats the soil when it shines through transparent slabs of carbon dioxide ice that built up on the Martian surface each winter.

Being darker than the ice above it, the soil absorbs the heat and causes the ice closest to it to turn directly into carbon dioxide gas—without turning to liquid first—in a process called sublimation (the same process that sends clouds of "smoke" billowing up from dry ice). As the gas builds in pressure, the Martian ice cracks, allowing the gas to escape. As it seeps upward, the gas takes with it a stream of dark dust and sand from the soil that lands on the surface of the ice.

When winter turns to spring and the remaining ice sublimates, according to the theory, the spiderlike scars from those small eruptions are what's left behind.

Recreating Mars in the lab

For Mc Keown and her co-authors, the hardest part of conducting these experiments was re-creating conditions found on the Martian polar surface: extremely low air pressure and temperatures as low as minus 301 degrees Fahrenheit (minus 185 degrees Celsius). To do that, Mc Keown used a liquid-nitrogen-cooled test chamber at JPL, the Dirty Under-vacuum Simulation Testbed for Icy Environments, or DUSTIE.

"I love DUSTIE. It's historic," Mc Keown said, noting that the wine barrel-size chamber was used to test a prototype of a rasping tool designed for NASA's Mars Phoenix lander. The tool was used to break water ice, which the spacecraft scooped up and analyzed near the planet's north pole.

For this experiment, the researchers chilled Martian soil simulant in a container submerged within a liquid nitrogen bath. They placed it in the DUSTIE chamber, where the air pressure was reduced to be similar to that of Mars's southern hemisphere. Carbon dioxide gas then flowed into the chamber and condensed from gas to ice over the course of three to five hours. It took many tries before Mc Keown found just the right conditions for the ice to become thick and translucent enough for the experiments to work.

Once they got ice with the right properties, they placed a heater inside the chamber below the simulant to warm it up and crack the ice. Mc Keown was ecstatic when she finally saw a plume of carbon dioxide gas erupting from within the powdery simulant.

"It was late on a Friday evening and the lab manager burst in after hearing me shrieking," said Mc Keown, who had been working to make a plume like this for five years. "She thought there had been an accident."

The dark plumes opened holes in the simulant as they streamed out, spewing simulant for as long as 10 minutes before all the pressurized gas was expelled.

The experiments included a surprise that wasn't reflected in the Kieffer model: Ice formed between the grains of the simulant, then cracked it open. This alternative process might explain why spiders have a more "cracked" appearance. Whether this happens or not seems dependent on the size of soil grains and how embedded water ice is underground.

"It's one of those details that show that nature is a little messier than the textbook image," said Serina Diniega of JPL, a co-author of the paper.

What's next for plume testing

Now that the conditions have been found for plumes to form, the next step is to try the same experiments with simulated sunlight from above, rather than using a heater below. That could help scientists narrow down the range of conditions under which the plumes and ejection of soil might occur.

There are still many questions about the spiders that can't be answered in a lab. Why have they formed in some places on Mars but not others? Since they appear to result from seasonal changes that are still occurring, why don't they seem to be growing in number or size over time? It's possible that they're left over from long ago, when the climate was different on Mars—and could therefore provide a unique window into the planet's past.

For the time being, lab experiments will be as close to the spiders as scientists can get. Both the Curiosity and Perseverance rovers are exploring the red planet far from the southern hemisphere, which is where these formations appear (and where no spacecraft has ever landed). The Phoenix mission, which landed in the northern hemisphere, lasted only a few months before succumbing to the intense polar cold and limited sunlight.

TOP IMAGE: Spider-shaped features called araneiform terrain are found in the southern hemisphere of Mars, carved into the landscape by carbon dioxide gas. This 2009 image taken by NASA’s Mars Reconnaissance Orbiter shows several of these distinctive formations within an area three-quarters of a mile (1.2 kilometers) wide. Credit: NASA / JPL-Caltech / University of Arizona

CENTRE IMAGE: These formations similar to the Red Planet’s “spiders” appeared within Martian soil simulant during experiments in JPL’s DUSTIE chamber. Carbon dioxide ice frozen within the simulant was warmed by a heater below, turning it back into gas that eventually cracked through the frozen top layer and formed a plume. Credit: NASA / JPL-Caltech

LOWER IMAGE: Dark splotches seen in this example of araneiform terrain captured by NASA’s Mars Reconnaissance Orbiter in 2018 are believed to be soil ejected from the surface by carbon dioxide gas plumes. A set of experiments at JPL has sought to re-create these spider-like formations in a lab. Credit: NASA / JPL-Caltech / University of Arizona

BOTTOM IMAGE: Here’s a look inside of JPL’s DUSTIE, a wine barrel-size chamber used to simulate the temperatures and air pressure of other planets – in this case, the carbon dioxide ice found on Mars’ south pole. Experiments conducted in the chamber confirmed how Martian formations known as “spiders” are created. Credit: NASA / JPL-Caltech

2 notes

·

View notes

Text

Features of Eco-Friendly Homes in Durango

Energy Efficiency

Energy-efficient homes are a cornerstone of green living in Durango. These homes often include high-efficiency HVAC systems, insulation, and windows that reduce energy consumption.

Double-pane windows with low-E (low emissivity) coatings help maintain indoor temperatures and reduce energy loss.

Source: Learn more about energy-efficient windows from the Department of Energy.

Renewable Energy Sources

Many eco-friendly homes in Durango utilize renewable energy sources, such as solar or wind power. These energy sources reduce reliance on fossil fuels and lower greenhouse gas emissions.

A home equipped with solar panels and a solar water heater significantly reduces its carbon footprint.

Source: Explore renewable energy options from the National Renewable Energy Laboratory.

Water Conservation

Water conservation is another critical aspect of green living in Durango. Eco-friendly homes often feature water-saving appliances and fixtures, as well as systems for rainwater harvesting and greywater recycling.

Installing low-flow showerheads, faucets, and toilets can reduce water usage by up to 50%.

Source: Find out more about water conservation techniques from WaterSense.

Sustainable Materials

Using sustainable building materials is essential for eco-friendly homes. These materials are often sourced locally and have a lower environmental impact than traditional building materials.

Bamboo flooring is a popular sustainable choice due to its rapid growth and minimal environmental footprint.

For more information: please visit our website at https://www.destinationdro.com/

0 notes

Text

Purpose Of Using Odor Removal Service in Fort Worth and Dallas, TX

A home that stinks cannot be healthy. Unfortunately, most people get used to foul smells and think nothing of them until it is too late. A bad odor indicates health hazards, and the homeowner or its occupants may be affected with health issues before long. While one may pick up a pest carcass or vacuum the more obvious contaminants away, deep and proper cleaning to get rid of all foul smells requires the intervention of individuals adept at odor removal services in Fort Worth and Dallas, TX.

Guessing the source of malodors is not enough. It is important to be convinced about it before taking pains to clean it once and for all. It is also interesting to note that a foul smell emanating from inside the home may be caused by any of the following:-

· Washing Machine

· Sewer

· Garbage Disposal System

· New Furniture

· Dirty Floor Coverings

· Unclean Fridge

· Wet Towels

· Dead Animal

· Dirty Bedclothes

· Smelly Dishwasher

· Hidden Mold & Mildew

· Dander

· Water Heater

· Leaking Gas

The professional team will arrive fully prepared to tackle this unknown or hidden threat to the health. While investigating the home to find the source of the malodor is essential, the professionals are sure to have the required knowledge about chemistry to understand the reason behind the foul smell, too. Sure, the professionals will utilize varied resources & methods to eliminate the smell, namely the following:-

· Engineering- The professionals are sure to advise using multiple engineering controls to thwart the possibility of stinky smells. They recommend the installation of multiple odor controls such as biofilters, chemical scrubbers, activated carbon filters, or thermal oxidizers. The controls work by neutralizing the chemical components that spread the odor before they are released into the surrounding air

· Chemical- The chemical agents used are oxidizing agents like hydrogen peroxide, chlorine dioxide, ozone, and other odor-masking agents such as diverse fragrances or essential oils.

· Biological Approach—The professionals will spray a good amount of neutralizing compounds that react with the odoriferous substances to mask or eliminate the odor. Introducing specific odor-eliminating bacteria or enzymes, known as bioaugmentation, is often employed. The team may decide on biofiltration, which utilizes microorganisms in biofilters to metabolize the gases that spread the foul smell.

Just spraying the compounds in the air is not enough. The residents will be advised to keep a close watch and note the control's efficacy. The professional team may consider repeat visits for assessments, evaluation of controls, and analysis.

It is important to engage professionals to find and abate the malodors to ensure the complete elimination of the stink right at its source. Doing it as soon as possible can also ensure good health for all concerned!

Healthcare facilities, laboratories, and vet clinics generate huge amounts of biohazardous waste. Using professional services for medical waste removal in Dallas and Fort Worth, TX, not only ensures a healthy environment but also helps the facilities remain compliant with regulatory standards.

0 notes

Text

Immersion Water Heater

An immersion water heater is a highly efficient device used for heating liquids directly in tanks or containers. It consists of a heating element that is immersed in water, providing rapid and even heating. Ideal for domestic and industrial use, immersion water heaters are perfect for applications such as heating water in homes, laboratories, and industrial processes. Their compact design and ease of use make them a convenient solution for on-demand hot water, ensuring energy savings and reliable performance.

0 notes

Text

Top 5 Steam Boiler Manufacturers in India

What is Steam Boiler?

A steam boiler is a closed vessel designed to convert water into steam through the application of heat. This process typically involves the combustion of fuels such as coal, natural gas, or biomass, generating thermal energy that heats water within the boiler’s chamber. As the water reaches its boiling point, steam is produced under high pressure, ready to be harnessed for various applications.

Types of Steam Boiler:

1. Fire-Tube Boilers:

Fire-tube boilers have a cylindrical shell containing water and tubes running through it. Hot gases from combustion pass through these tubes, heating the water and generating steam. They are typically used for low to medium pressure applications such as heating buildings, processing plants, and small industrial processes.

2. Water-Tube Boilers:

Water-tube boilers have water-filled tubes that are heated externally by combustion gases. These boilers can withstand higher pressures and temperatures, making them suitable for power generation, large-scale industrial processes, and applications requiring high steam output.

3. Electric Boilers:

Electric boilers use electricity to generate steam. They are clean, quiet, and efficient, making them suitable for applications where emissions must be minimized, such as hospitals, laboratories, and residential buildings. Electric boilers are also commonly used in areas where natural gas is not readily available.

4. Biomass Boilers:

Biomass boilers use organic materials such as wood chips, agricultural residues, or biogas to generate steam through combustion. They offer a sustainable alternative to fossil fuels and are commonly used in industries such as forestry, agriculture, and waste management.

5. Hybrid Boilers:

Hybrid boilers combine different technologies, such as fire-tube and water-tube designs, to optimize performance and efficiency. They are versatile and can be customized to meet specific requirements, making them suitable for a wide range of applications, including heating, power generation, and industrial processes.

6. Condensing Boilers:

Condensing boilers are designed to maximize energy efficiency by recovering heat from exhaust gases that would otherwise be lost. They achieve this by condensing water vapor in the exhaust gases, releasing latent heat and increasing overall efficiency. Condensing boilers are commonly used in residential and commercial heating systems.

7. Package Boilers:

Package boilers are factory-assembled units that come pre-wired, pre-piped, and pre-tested, making them easy to install and operate. They are often used in temporary or remote locations, as well as in industries where space is limited or where rapid deployment is required.

8. Modular Boilers:

Modular boilers consist of multiple smaller units that can be combined to meet fluctuating steam demand or provide redundancy in critical applications. They offer flexibility, scalability, and ease of maintenance, making them well-suited for industries with varying steam requirements.

Applications of Steam Boiler:

1. Power Generation:

Steam turbines powered by steam boilers are used in thermal power plants to generate electricity. The steam produced by the boiler drives the turbine, which converts thermal energy into mechanical energy, powering electrical generators.

2. Industrial Processes:

Steam boilers are integral to numerous industrial processes, including chemical manufacturing, petrochemical refining, pulp and paper production, textile manufacturing, and food processing. They provide heat for reactors, distillation columns, dryers, sterilizers, and other equipment.

3. Heating and HVAC Systems:

Steam boilers are used for space heating and domestic hot water production in residential, commercial, and institutional buildings. They provide warmth through radiators, baseboard heaters, and underfloor heating systems, and they can also be used in HVAC systems for air humidification and dehumidification.

4. Cogeneration and Combined Heat and Power (CHP):

Steam boilers are often employed in cogeneration systems, where they simultaneously produce steam for process heating or power generation and capture waste heat for other applications, such as space heating, water heating, or absorption cooling. CHP systems improve overall energy efficiency and reduce utility costs.

5. District Heating:

Steam boilers play a crucial role in district heating systems, where steam or hot water is distributed from a central energy plant to multiple buildings or residential complexes for space heating, water heating, and other thermal energy needs. District heating systems improve energy efficiency and reduce greenhouse gas emissions compared to individual heating systems.

6. Agricultural Applications:

Steam boilers are used in agricultural operations for tasks such as soil sterilization, greenhouse heating, and grain drying. They provide heat for crop drying to preserve quality and reduce moisture content, enhancing storage and transportation efficiency.

7. Marine Propulsion:

Steam boilers power steam turbines in marine propulsion systems, driving ships and maritime vessels across oceans and waterways. Marine boilers produce steam to turn the ship’s propeller, providing propulsion for cargo ships, passenger vessels, and naval ships.

8. Pharmaceutical and Healthcare Facilities:

Steam boilers are essential in pharmaceutical manufacturing for sterilizing equipment, sanitizing surfaces, and producing purified water for injection. They are also used in healthcare facilities for autoclaving medical instruments, sterilizing surgical equipment, and providing steam for laundry and sanitation purposes.

9. Environmental Remediation:

Steam boilers are utilized in environmental remediation projects for soil vapor extraction, steam stripping, and thermal desorption. They provide heat for treating contaminated soil and groundwater, removing volatile organic compounds (VOCs) and hazardous substances from the environment.

Best Steam Boiler Manufacturer in India

If you are looking for Best Steam Boiler manufacturer in India, look no further than Steamax Energy India, we are a leading manufacturer and supplier of Industrial Steam Boiler in India. For more details, please contact us!

Website :- https://www.steamaxenergyindia.com/

Contact No. :- 7053901803

Email :- [email protected]

#steam boiler manufacturer#steam boiler manufacturer in India#Top steam boiler manufacturer in India#Best steam boiler manufacturer in India#steam boiler supplier#steam boiler supplier in India#Top supplier of steam boiler in India#steamax energy india

1 note

·

View note

Text

Dry Bath

A dry bath, also known as a dry block heater or a thermal cycler, is a laboratory instrument used to heat samples in various vessels such as tubes, microplates, or vials. Unlike water baths, dry baths use metal blocks to evenly distribute heat to the samples without the need for liquid immersion. They are commonly used in molecular biology, biochemistry, and microbiology applications for tasks such as DNA amplification (PCR), enzyme reactions, and incubation of samples at specific temperatures.

0 notes

Text

STONYLAB Ultrasonic Cleaner with Mechanic Control Panel of Heating and Timer

4 Capacities: 2L; 3L; 6L; 10L

2 Power supplies: 110V; 220V

Price as low as $74.47 USD

StonyLab Ultrasonic Cleaner is professional designed to provide effective and efficient cleaning of laboratory glassware and instruments with simply, user-friendly operation

Supplied with heater and timer in knob control panel, ensuring precise cleaning temperature and time control; heating could reduce the adhesion of stains and boost the cleaning power

Operation frequency: 40kHz; temperature is adjustable up to 80°C (176℉)

Made of 304 stainless steel, our safe, reliable ultrasonic cleaner is corrosion and high temperature resistant; FCC, CE and ROHS certified

🧪An ultrasonic cleaner in a chemistry lab is a device that utilizes high-frequency sound waves (ultrasonic waves) to clean various laboratory equipment, glassware, and samples. The cleaner consists of a tank filled with a cleaning solution, typically water or a solvent, in which the items to be cleaned are submerged.

Find the other type with digital display at

#stonylab#stonylabproducts#stonylabglass#stonylabus#labsupplies#labequipment#chemistrylab#ultrasoniccleaner#ultrasoniccleanerchemistry#ultrasoniccleaning#ultrasoniccleaningmachine#ultrasoniccleanermachines#ultrasoniccleanerdigital#ultrasoniccleaningequipment

0 notes

Text

Testing for Hard Water in Your Home

Introduction

Hard water, characterized by high mineral content, can have detrimental effects on plumbing fixtures, appliances, and the overall quality of water in your home. Testing for hard water is essential for identifying potential issues and implementing appropriate solutions. In this guide, we'll discuss how to test for hard water in your home, explore its effects, and provide solutions to mitigate its impact.

Testing for Hard Water

Follow these steps to test for hard water in your home:

1. DIY Testing Kits

- Step 1: Purchase a DIY hard water testing kit from a home improvement store or online retailer.

- Step 2: Follow the instructions provided with the testing kit to collect a water sample from your tap.

- Step 3: Use the testing strips or reagents included in the kit to analyze the water sample for hardness levels.

- Step 4: Compare the color or results on the testing strips to the scale provided to determine the hardness level of your water.

2. Professional Testing

- Step 1: Contact a water testing laboratory or local water treatment company to schedule a professional water test.

- Step 2: Collect a water sample according to the laboratory's instructions and submit it for analysis.

- Step 3: Receive the test results from the laboratory, indicating the hardness level and any other water quality parameters tested.

3. Visual Indicators

- Step 1: Look for visual indicators of hard water, such as white scale buildup on faucets, showerheads, and fixtures.

- Step 2: Check for soap scum or film residue on surfaces, dishes, and glassware after washing.

- Step 3: Examine the performance of plumbing fixtures and appliances for signs of reduced efficiency or premature failure, which may indicate hard water issues.

Effects of Hard Water

Understanding the effects of hard water can help you identify and address potential issues in your home:

- Scale Buildup: Hard water can lead to the accumulation of mineral deposits, or scale, in plumbing fixtures, pipes, and appliances, reducing water flow and efficiency.

- Soap Scum: The presence of minerals in hard water can interfere with the lathering ability of soap, leading to the formation of soap scum on surfaces, dishes, and laundry.

- Appliance Damage: Hard water can cause premature wear and damage to water-using appliances such as water heaters, dishwashers, and washing machines, resulting in decreased lifespan and efficiency.

- Skin and Hair Issues: The minerals in hard water can strip moisture from the skin and hair, leading to dryness, irritation, and dullness.

Solutions for Hard Water

Address hard water issues in your home with these effective solutions:

- Water Softeners: Install a water softener system to remove minerals from the water and reduce hardness levels.

- Water Filtration: Use water filtration systems or reverse osmosis systems to remove impurities and improve water quality.

- Regular Maintenance: Perform regular maintenance on plumbing fixtures and appliances to remove scale buildup and prolong their lifespan.

- Soft Water Products: Use soft water products such as soaps, shampoos, and laundry detergents designed for use with hard water to minimize the effects of mineral deposits.

FAQs

- How does hard water affect plumbing fixtures and appliances? Hard water can lead to scale buildup in plumbing fixtures and appliances, reducing water flow, efficiency, and lifespan.

- Can hard water affect the taste and odor of drinking water? Yes, hard water may have a noticeable taste or odor due to the presence of minerals, but it's typically safe to drink.

- Are there health risks associated with hard water? While hard water isn't considered harmful to health, it can contribute to skin and hair issues due to its drying effects.

- Can I install a water softener myself, or do I need professional installation? Installing a water softener typically requires professional installation to ensure proper setup and functionality.

- How often should I test for hard water in my home? It's recommended to test for hard water periodically, especially if you notice signs of scale buildup or reduced water quality.

Conclusion

Testing for hard water in your home is essential for identifying potential issues and implementing effective solutions to improve water quality and protect plumbing fixtures and appliances. By following the testing methods outlined in this guide and consulting the accompanying FAQs, you can effectively address hard water issues and enjoy cleaner, better-tasting water throughout your home.

Learn more from Plumbnerd

Read the full article

0 notes

Text

Choosing the Right Water Heater: A Guide to 316 Stainless Steel Electric Water Heaters

When choosing a water heater for laboratory or commercial kitchen applications, opting for a 316 stainless steel electric water heater is a wise decision. The corrosion resistance, hygienic properties, high temperature tolerance, durability, and energy efficiency of these units make them a reliable choice for environments where precision, cleanliness, and reliability are paramount.

0 notes

Text

NASA’s Europa Clipper Gets Set of Super-Size Solar Arrays

The largest spacecraft NASA has ever built for planetary exploration just got its ‘wings’ — massive solar arrays to power it on the journey to Jupiter’s icy moon Europa.

NASA’s Europa Clipper spacecraft recently got outfitted with a set of enormous solar arrays at the agency’s Kennedy Space Center in Florida. Each measuring about 46½ feet (14.2 meters) long and about 13�� feet (4.1 meters) high, the arrays are the biggest NASA has ever developed for a planetary mission. They have to be large so they can soak up as much sunlight as possible during the spacecraft’s investigation of Jupiter’s moon Europa, which is five times farther from the Sun than Earth is.

The arrays have been folded up and secured against the spacecraft’s main body for launch, but when they’re deployed in space, Europa Clipper will span more than 100 feet (30.5 meters) — a few feet longer than a professional basketball court. The “wings,” as the engineers call them, are so big that they could only be opened one at a time in the clean room of Kennedy’s Payload Hazardous Servicing Facility, where teams are readying the spacecraft for its launch period, which opens Oct. 10.

Flying in Deep Space

Meanwhile, engineers continue to assess tests conducted on the radiation hardiness of transistors on the spacecraft. Longevity is key, because the spacecraft will journey more than five years to arrive at the Jupiter system in 2030. As it orbits the gas giant, the probe will fly by Europa multiple times, using a suite of science instruments to find out whether the ocean underneath its ice shell has conditions that could support life.

Powering those flybys in a region of the solar system that receives only 3% to 4% of the sunlight Earth gets, each solar array is composed of five panels. Designed and built at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, and Airbus in Leiden, Netherlands, they are much more sensitive than the type of solar arrays used on homes, and the highly efficient spacecraft will make the most of the power they generate.

At Jupiter, Europa Clipper’s arrays will together provide roughly 700 watts of electricity, about what a small microwave oven or a coffee maker needs to operate. On the spacecraft, batteries will store the power to run all of the electronics, a full payload of science instruments, communications equipment, the computer, and an entire propulsion system that includes 24 engines.

While doing all of that, the arrays must operate in extreme cold. The hardware’s temperature will plunge to minus 400 degrees Fahrenheit (minus 240 degrees Celsius) when in Jupiter’s shadow. To ensure that the panels can operate in those extremes, engineers tested them in a specialized cryogenic chamber at Liège Space Center in Belgium.

“The spacecraft is cozy. It has heaters and an active thermal loop, which keep it in a much more normal temperature range,” said APL’s Taejoo Lee, the solar array product delivery manager. “But the solar arrays are exposed to the vacuum of space without any heaters. They’re completely passive, so whatever the environment is, those are the temperatures they get.”

About 90 minutes after launch, the arrays will unfurl from their folded position over the course of about 40 minutes. About two weeks later, six antennas affixed to the arrays will also deploy to their full size. The antennas belong to the radar instrument, which will search for water within and beneath the moon’s thick ice shell, and they are enormous, unfolding to a length of 57.7 feet (17.6 meters), perpendicular to the arrays.

“At the beginning of the project, we really thought it would be nearly impossible to develop a solar array strong enough to hold these gigantic antennas,” Lee said. “It was difficult, but the team brought a lot of creativity to the challenge, and we figured it out.”

More About the Mission

Europa Clipper’s three main science objectives are to determine the thickness of the moon’s icy shell and its interactions with the ocean below, to investigate its composition, and to characterize its geology. The mission’s detailed exploration of Europa will help scientists better understand the astrobiological potential for habitable worlds beyond our planet.

Managed by Caltech in Pasadena, California, NASA’s Jet Propulsion Laboratory leads the development of the Europa Clipper mission in partnership with APL for NASA’s Science Mission Directorate in Washington. APL designed the main spacecraft body in collaboration with JPL and NASA’s Goddard Space Flight Center in Greenbelt, Maryland, NASA’s Marshall Space Flight Center in Huntsville, Alabama, and Langley Research Center in Hampton, Virginia. The Planetary Missions Program Office at Marshall executes program management of the Europa Clipper mission.

NASA’s Launch Services Program, based at Kennedy, manages the launch service for the Europa Clipper spacecraft, which will launch on a SpaceX Falcon Heavy rocket from Launch Complex 39A at Kennedy.

TOP IMAGE: NASA’s Europa Clipper is seen here on Aug. 21 at the agency’s Kennedy Space Center in Florida. Engineers and technicians deployed and tested the giant solar arrays to be sure they will operate in flight. Credit: NASA/Frank Michaux

CENTRE IMAGE: NASA’s Europa Clipper is seen here on Aug. 21 in a clean room at Kennedy Space Center after engineers and technicians tested and stowed the spacecraft’s giant solar arrays. Credit: NASA/Frank Michaux

LOWER IMAGE: This artist’s concept depicts NASA’s Europa Clipper spacecraft in orbit around Jupiter. The mission’s launch period opens Oct. 10. Credit: NASA/JPL-Caltech

3 notes

·

View notes

Text

had a dream i was venturing through a great forest with a group of people. we were following a particular person who knew the way.

upon reaching civilization we split up and the group i was in was now just a trio. the guide, my friend, and me.

the guide did a flourish and introduced us to her hometown. Enhou, China.

The city was beautiful, like a gentle mishmash of modern buildings and plants making small alleyways. A habitable self made maze.

We followed out guide deeper into Enhou as we arranged to stay at her house. Another group member found us and tagged along.

Arriving to a nondescript building in the fork between a road, we were led up into its also maze like interior. Hastily but lovingly tiled paths. We stopped before 2 apartment doors for a bit. Our guide knocked and spoke with the residents inside. The guy tagging along got distracted by this and I could see the guide gesture to leave while he spoke with them.

We are glad to be rid of the guy bc he was really fucking annoying. But I can tell the guide wanted to leave me behind as well. Only wanted my friend.

Going further up into the building we find a courtyard? mezzanine? With 2 more doors here.

We lay out blankets in this courtyard and set up to sleep here. Guide engages the friend in conversation while i pull out my journal to write.

I don't remember exactly what happens next but we find out that the residential part of this building is complicated not only because of Enhou architecture but it's built around a laboratory. Our guide's mother works there. And there is serious interpersonal issues causes by the fact that the guide's mother is a slightly modified clone of some dude.

----------------

The next dream starts in a large area, built around a waterway at what might be the bottom of a canyon.

I am close to the leadership here so I am appointed in accompanying this visiting important girl. But she's nice and I find us making an actual bond of friendship.

Things happen and we find her adoptive father/butler is super sick. We have him set up with the best of our medical knowledge and I go to visit him. The butler's wife is weeping sadly by his side and a power outage happens.

I'm worried about him so I run the bath he's sitting in, happy that the water heater runs on gas instead. I get this poor comatose man in a hot bath and leave him with his wife watching. I go to investigate the electricity but it comes back as im on my way.

So I turn around to check on him again. The EKG and other machines are all flatlined now and the wife is gone. No where to be seen as her husband floats in the bath.

He looks peaceful, if I'm sure he wasn't dead. I pull him to the back wall of the tub and stick my hands in his armpits, hooking my thumbs up into the tender flesh. I can see his face closely. He really would be asleep if not for the fact that I can't feel his pulse at all.

The young lady finds us like this and before I can react, gasps and runs off.

Then a timeskip happens. I had followed the young lady to her home and was welcomed. Though she was trapped here. Turns out she wasn't supposed to have left and they consider it her fault that the servant she cherished was killed.

So the young lady and I plan an escape back to my home. We have different abilities but should be able to keep up with each other.

Getting through the castle itself is easy but its the exterior and moat that would be hard. A large fortress of dark grey stone surrounded by a deep, swampy moat.

We manage to find an exit to a side entrance. On a patch of land before the moat starts. She takes off with her enhanced stealth abilities and as I have a more physical form it'll be harder for me to follow.

I do get out far but end up running into a guard robot. It's vaguely hound shaped if hounds were made of triangular welded red beams and also twice as high. I feel insulted and drop down into the bushes to try and escape notice.

I do but a guy on the walls spots me instead. I book it and see a jetski parked nearby. Bright red, it kind of screams trap but I have to.

So I zoom off into the water and it's fast enough that I catch up to her. I let her know we'be been spotted. We gun it and race through the moat heading for a building on the other shore. However its quite far from us the long way as well but it'll lead to a passage where we can get lost in town.

In the water we dodge large nets containing water beasts her family has raised and also shrimp farms. They take up large circles with a path only big enough for one at a time so we have to ensure we don't crash while pulling off high speed turns.

It's several of these before we finally arrive at the building. It's big and brutalist and we make our way in. I see a path and I lift up the young lady to take it, hoping she can pull me up with her weak arms- but a wall slides closed separating us.

I feel a chill down my spine and look behind me and up. On the roof I see the lord of the vampires, his thick goth boots, and unmistakable cloak. I book it going downwards and then out a doorway I find there. I round a corner into a garage which has a hall I follow into a brutalist staircase.

As I climb I see the vampire lord again, the young lady's true father, and I taunt him with something about his funeral.

He gives chase and we end up amongst the rooftops. As he's after me I'm dodging without much care. He can't kill me as I'm important to the werewolves so is trying for capture.

We run and I pull off these strange purple tiles leaking some kind of energy I can detect. Just 2 tiles every so often. Once I have about 10 of them I stop.

I look over to the lord who seems befuddled.

'That wasn't the real Serenata, here.' I hand him the tiles. 'The magic is drained but it should have enough traces for you to tell.'

It turns out I knew the young lady I'd been with here wasn't the real one the whole time. But I didn't have the resources to interrogate the imposter without issue so I provoked this capture so the vampires would do it for me.

The purple tiles sustain the imposter's disguise spell which is why, I explained, she pretended to want to rest in the city before entering the castle. So it would be reinforced.

Now the disguise would fall and the vampires on her tail would be less reluctant to capture. We haven't seen the real Serenata since she ran off at her butler's death.

0 notes

Text

Dry Bath

A dry bath, also known as a dry block heater or a dry heat block, is a laboratory instrument used to heat samples in tubes or microplates. Unlike water baths, which use water as a heat transfer medium, dry baths utilize metal blocks with wells or holes to hold the sample containers. These metal blocks are typically made of aluminum or aluminum alloy and are designed to evenly distribute heat throughout the sample.

0 notes

Text

AMAN REFRIGERATION - YOUR EXPERT IN AIR COOLING SOLUTIONS

Aman Refrigeration introduces an extensive range of industrial AIR COOLING UNITS tailored for diverse applications. Our portable AIR COOLERS provide a swift and cost-effective solution for spaces requiring substantial cooling capacity. Whether you need an efficient air conditioning solution suitable for various climates or an environmentally friendly, low CO2-emission evaporative cooler, we possess the expertise to deliver top-notch commercial air coolers customized to meet your specific needs.

Our product portfolio includes evaporative coolers, air conditioners, container coolers, and tent coolers. The choice of an AIR COOLING SYSTEM depends on the specific area to be cooled and the environmental conditions it will encounter. For example, expansive open spaces like factories and warehouses benefit from a cost-effective evaporative cooling solution, while enclosed settings like laboratories, requiring precise temperature and humidity control, may find air-conditioning to be a more suitable alternative.

KEY FEATURES:

• Robust outer frames crafted from high-quality powder-coated GI sheets or SS casing ensure heavy-duty construction.

• Carefully selected axial flow fans provide higher static pressure and superior air throw.

• State-of-the-art IP-protected fan motors, featuring low-temperature grease, guarantee optimal performance.

• Various defrosting systems, including water, hot gas, and heater options, are available based on specific applications.

• Well-designed drain pans with a sloped end ensure efficient water drainage.

0 notes

Text

Steam turbine oil analysis practices

Introduction:

The market studies done by the various analyst on “Global market analysis on Turbine oil “forecast that the global turbine oil market to grow at a CAGR of 3.498% during the period 2017-2021 and the market size has a potential to grow by 1500.05 K MT during 2020-2024, and its momentum will accelerate during the forecast period. Turbine oil manufacturers are continuously working with OEMs to provide high-performance turbine oils to meets the rising demands globally. Nowadays the industries are more focused on extending the life of both lubricants and the equipment by implementing a robust Reliability lubrication Program.

In this article, we have tried to cover the maximum information about turbine oil which could help the power generation & manufacturing industries to move further with a cost-effective sustainable solution.

Turbine & it's lubrication system:

The turbine which is the heart of the power plant extracts thermal energy from high-pressure steam and converts it into mechanical energy on a rotating output shaft. This mechanical energy is used to drive rotating equipment like pumps, compressors, fan, blower, and ultimately to drive a generator for the production of electricity.

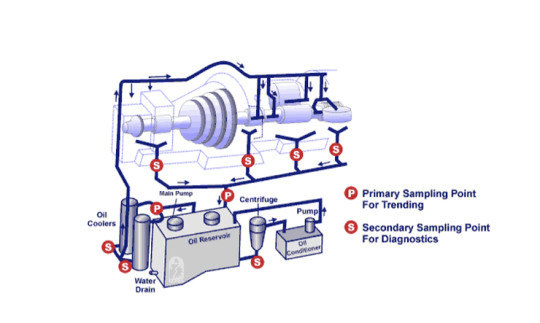

Let’s understand a brief of oil flow along with major component and its function in the lubrication system of the turbine with the following steps:

Oil system which is composed of an oil tank (with a heater for a start-up)

Oil pumps to provide the necessary level of oil pressure

Oil coolers to dissipate the heat from the oil during operation

Oil filters to remove erosional debris from the circulating oil

Pressure control valve to regulate an exact and constant supply oil pressure to the bearings

In addition, one pressure relief valves to protect the pumps from overpressure (usually rotary type)

An accumulator for minimizing pressure surge when any operational change occurs, like switching-over between main and stand-by equipment.

A Temperature Control Valve (TCV) is provided to by-pass the coolers when the oil temperature is low, to ensure correct oil viscosity and efficient lubrication. Sometimes it is done by controlling water flow through oil coolers.

Importance of turbine oil:

In this growing modern world where electricity has become the most important part of our life and spending a day without it could slow down our lifestyle, productivity and overall impacting the global economy; then the generation of electricity indeed became fundamental to us. To meet this ever-increasing demand, power plants are delicately performing to improve their output and reliability. In the Power plants, Turbine is the most crucial machine which is the prime movers for other rotating equipment and hence the generation of electricity. Its reliability and availability critically depend on the turbine oil, which makes the lubricant selection very important part in the reliability program. However, the OEM of the turbine carefully specifies the characteristic of the lubricants, laboratory test for oil analysis and standard references for the best performance of the turbine.

Turbine oil has to undergo through an adverse condition like large temperature fluctuation, heavy load, ingress of contamination, moisture, entrained air, heat and many physical & chemical changes. Important roles of oil are cooling of bearings & journals, flushing contaminants away from rotating parts, preventing in leakage of gases, providing hydrostatic lift for shafts, actuating valves in the hydraulic circuit, and protecting lube-system internals.

Modern technologies in lubrication science show clearly a great advancement in the formulation of the turbine oil. Almost 90-95% of turbine oil is a base oil with additives making up the remaining per cent which includes antioxidants, rust inhibitors, metal deactivators, antifoam agents, demulsifier, pour depressants and antiwear additives.

To learn more visit: www.minimacsystems.com

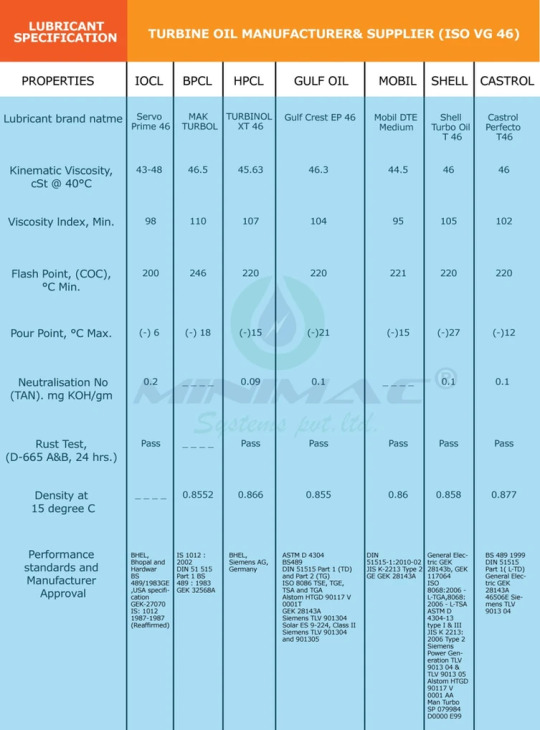

Turbine oil properties, type and brand:

Integral properties of the steam turbine oil are to allow uniform lubricating performance over a wide range of ambient and operating temperatures, to reduce hydrolysis, to reduce the formation of varnish, sludge, emulsion & entrained gas/foam, to prevent rust, minimize acid attack on copper alloy parts, improves lubricity, minimize oxidation, good oil degradation solubility improves filtration, etc. The oil which meets all these mentioned properties is of ISO VG 46.

We at Minimac study your maintenance needs and provide the best solution. We believe in Discern, Design & Deliver.

Lubricant supplier selection and brands:

Selecting a suitable supplier who can meet the performance requirement for the turbine is a vital part of the reliability lubrication program. While finalizing the vendors, many points should be considered like lubricant quality & services, technological advancement, troubleshooting support, emergency preparedness, technical support, laboratory support, price, and delivery capacity.

Turbine oil maintenance (sampling points, testing standards, testing schedule)

Sampling points:

Maximize data density of oil information

Minimize the distortion of information

Designated sampling location of primary points (return line or drain valve, elbow, turbulent area) and secondary points (anywhere on the system to isolate upstream component)

Proper frequency

Proper sampling hardware

Sample when the machine is running at normal operating temperature

Sample after flushing a small quantity of oil (0.5 - 1.0l) through the sampling point

Use only dedicated clean and dry sampling equipment intended for the sampling of used oils.

Samples should be sent to the lab or processed for on-site analysis before 24 hours from the time the sample was extracted.

To avoid leakage, fill the sample bottle to 90% capacity and ensure it is properly sealed before despatch to the laboratory.

Below images are illustrating both primary sampling points and secondary sampling points of turbine lube oil system:

Primary Sampling Point: Location where regular routine oil samples are taken for monitoring and trending wear metal debris, oil condition, and oil contamination.

Testing Standards:

Power Plant lubrication monitoring is broadly specified under ASTM D4378 and ASTM D6224, and these define almost every test used to qualify lubricants for new and in-service monitoring for power plants. Following are major standards and OEM approval standards

ASTM D4378, "Standard Practice for In-Service Monitoring of Mineral Turbine Oils for Steam, Gas, and Combined Cycle Turbines"

ASTM D6224, "Standard Practice for In-Service Monitoring of Lubricating Oil for Auxiliary Power Plant Equipment", focuses on auxiliary equipment that supports power-generating turbines.

FED-STD-791D (testing method of lubricants, liquid fuels, and related products)

Ahlstom - Gas and Steam - HTGD901117

GE - Gas - GEK 32568f

GE - Steam - GEK 46506D

Solar - ES9-224

MHI - Steam & Gas - MS04-MA- CL001 and CL002

Siemens/ Westinghouse - K-8962-11

Testing schedule with standard reference:

Watch our Low Vacuum Dehydration System video: Click here

Steam turbine breakdown problems:

1. Bearing Failure

Bearing & Journal related issues are one of the main causes of turbine generator outages. While faulty design or manufacturing can be occasionally responsible, the most frequent cause of these problems is improper operating conditions. A turbine trip is likely to occur when any bearing/shaft vibration reaches the trip limit. Major operational causes of accelerated wear and failure of turbine generator bearings are:

Improper lubrication (inadequate flow, dirty oil, improper oil temperature)

Excessive load (ie. the force pressing the shaft against the bearing)

Prolonged operation at high vibration levels which can result in fatigue cracking of the bearing lining.

Insufficient oil flow and pressure causes wiping off of babbitt material

Such operating conditions can result in bearing overheating, scoring, or erosion of bearing surfaces by oil contaminants, or fatigue damage.

2. Blade Failure

Turbine blade failure is a nightmare for any power player. It is another major problem and typical operational issues responsible for it are deposits, erosion, corrosion and vibration, fatigue, and manufacturing defect. The most common causes of blade failures are stress corrosion cracking and fatigue cracking due to excessive blade vibration.

Blade failure can cause large scale damage to the turbine. In the worst case, one or more of the long moving blades in an LP turbine may pierce the casing and become turbine missiles. In a less severe case, the broken blade (interfering with the motion of other blades, can shear off or bend some of them. The resultant very high vibration can destroy turbine generator bearings, seals, oil lines, etc. This type of case happened in 2014 at one of the large power generation stations in India where 600 MW LP turbine last stage blade broken at lacing wire area and subsequently damaged 5 more blades. It caused a unit outage of more than 90 days!

The serious consequences of such breakdowns, determination of the causes of bearing failure, and methods of effective repair are of paramount importance. Sublevel maintenance practices or overextending the life of the oil are also important factors for the breakdown of the turbine *A very common myth with lubrication system is that “keeping filters in line with oil circuits will prevent failures due to contamination”. This is the paradox of the situation where emergency oil supply systems bypass all the filters and obstacles in the circuit to fulfill the demand, but contaminants use it as an opportunity to fail the emergency system itself. (Bases on the facts when DC pumps started and failed due to oil contamination).

Turbine bearing failure is not only limited to bearing replacement cost and time but results in rotor damage as well. In 2017, in India, one 300 MW Chinese supplied machine encountered oil starvation during a blackout and resulted in rotor damage which further cost billions of rupee revenue loss to the company.

Consolidated turbine oil care and maintenance points:

Apart from the oil analysis, below lubrication practices should be followed for best performance of Steam Turbine:

Keep oil clean, cool, and dry

Inspect bulk delivery of new oil before acceptance

Maintain proper alignment

Perform regular oil analysis

Install high-capture-efficiency breathers

Inspect for signs of foaming and/or air entrainment

Install primary and secondary sampling points

Routinely inspect sight glasses for level, foam, and water

Keep tank headspace dry using blowers, condensers, or instrument air

Use off-line fluid conditioning for precision contamination control

Regularly inspect for varnish, especially in gas turbines

Analyze the oil periodically

Keep temperature and operation records

Install filter and strainers to retain solid contaminants

Install a multipurpose oil purification unit to prevent solid and liquid contaminants

Check oil filter cartridges or elements periodically

During inspection and overhauls, the turbine oil must be drained from the main oil tank, oil cooler, and the bearing pedestals

Reuse the oil only after ensuring all the parameters within the prescribed limits

Any small change in vibration must be considered on priority

Keep a close view on condition monitoring results and repeat the test in case of any deviation

Call +91 7030901266 for Mechanical Maintenance & Oil Check.

About the Author: Ms. Preeti Prasad associated as Technical Consultant and Business Development Manager with Minimac system Pvt Ltd. She is a chemical engineer with work experience in Oil Refinery and also providing lubrication consultancy services to many companies/sectors. She holds Level I Machine Lubrication Technician(MLT) certification through the International Council for Machinery Lubrication (ICML).

Reference Taken:

Machinery Lubrication India- Noria Corporation Ltd

Monitoring and Optimizing life of Turbine Oil by Analyst, Inc

Troubleshooting bearing and lube oil system problems by Thomas H.McCloseky

BHEL documents on Stem Turbine Maintenance and Turbine oil care maintenance

Turbine Operational Problem (module 234-14)

PDS of mentioned oil manufacturer

#oil flushing#minimac systems#frf#power#minimac#hydraulic oil#oil & gas#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#transformation oil purification#transformers#electrostatics lube cleaner#coalescer separator#metal#mining#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre

1 note

·

View note

Text

Fluid Facilities The Role of Commercial Plumbing in New Jersey Business Success

In the intricate tapestry of New Jersey businesses, one essential thread weaves through the foundation of success – commercial plumbing services. Beyond the visible pipelines and fixtures, these unsung heroes play a crucial role in maintaining the fluidity of operations, ensuring a seamless flow that underpins the success of businesses across the state.

1. Precision Installations:

At the heart of commercial plumbing excellence is precision in installations. Whether it's a new construction project or a renovation, commercial plumbing services in New Jersey meticulously plan and execute installations. From water supply systems to drainage networks, every element is strategically placed to optimize functionality and longevity.

2. Uninterrupted Operations:

The seamless flow of water and the efficient disposal of waste are paramount for uninterrupted business operations. Commercial plumbing services ensure that businesses can operate without disruptions caused by plumbing issues. This reliability is particularly crucial for industries where downtime translates to financial losses.

3. Responsive Repairs:

When plumbing issues arise, time is of the essence. Commercial plumbers in New Jersey understand the urgency and provide responsive repair services. From leaky pipes to malfunctioning fixtures, they swiftly diagnose and remedy issues, minimizing downtime and preventing potential damage to property and inventory.

4. Sustainable Solutions:

In an era where sustainability is a business imperative, commercial plumbing services New Jersey contribute by implementing eco-friendly solutions. This includes water-saving fixtures, energy-efficient water heaters, and environmentally conscious practices that align with businesses' commitment to reducing their ecological footprint.

5. Compliance with Codes and Regulations:

Navigating the intricate web of plumbing codes and regulations is a specialized task. Commercial plumbing services ensure strict adherence to these standards, safeguarding businesses from legal issues and potential penalties. Compliance is not just a legal requirement but a foundation for ethical and responsible business practices.

6. Tailored Maintenance Programs:

Preventive maintenance is the backbone of reliable plumbing systems. Commercial plumbers design tailored maintenance programs that suit the unique needs of businesses. Regular inspections, cleaning, and proactive repairs ensure that potential issues are identified and addressed before they escalate into major problems.

7. Emergency Response Expertise:

Plumbing emergencies can strike at any time, posing immediate threats to businesses. Commercial plumbing services in New Jersey are equipped with emergency response expertise. Whether it's a burst pipe, a sewage backup, or a malfunctioning water heater, they are on standby to address crises promptly and effectively.

8. Upgrading Infrastructure for Efficiency:

As businesses evolve, so do their plumbing needs. Commercial plumbers play a pivotal role in upgrading plumbing infrastructure to accommodate growth and enhance efficiency. This includes installing advanced technologies, optimizing layouts, and integrating smart systems that align with the technological advancements of the business landscape.

9. Ensuring Hygiene and Sanitation:

In businesses where hygiene and sanitation are paramount, such as restaurants and healthcare facilities, commercial plumbing services play a critical role. They design and maintain plumbing systems that meet stringent hygiene standards, ensuring a clean and safe environment for customers, employees, and patients.

10. Supporting Specialty Industries:

Certain industries have unique plumbing requirements. Commercial plumbers in New Jersey are adept at supporting specialty industries such as laboratories, manufacturing plants, and research facilities. They understand the specific needs of these businesses and provide tailored plumbing solutions to meet industry standards.

11. Cost-Effective Solutions:

Commercial plumbing services prioritize cost-effective solutions. By identifying and addressing plumbing issues in their early stages, businesses can avoid costly repairs and replacements. This proactive approach not only saves money in the long run but also contributes to the overall financial health of the business.

12. Partnering in Business Success:

In essence, commercial plumbing services in New Jersey emerge as true partners in business success. Their role extends beyond fixing leaks and unclogging drains; they contribute to the overall functionality, sustainability, and resilience of businesses. By ensuring a reliable and efficient plumbing infrastructure, they become integral contributors to the seamless operations that drive success.

In conclusion, commercial plumbing services in New Jersey are the silent architects of business success. Their expertise, responsiveness, and commitment to excellence create a foundation upon which businesses can thrive. As businesses evolve, so do their plumbing needs, and these professionals stand ready to adapt, ensuring a continuous flow that supports the growth and prosperity of enterprises across the state.

1 note

·

View note