#Heat Stress Monitor demand

Explore tagged Tumblr posts

Text

The Best News of Last Week - February 13, 2023

Hello there! Welcome to another edition of ‘Feel Good Newsletter’. I'm so glad you're here. Every week, I scour the web for the most uplifting and heartwarming stories to bring you a little bit of joy and inspiration. So, sit back, relax, and let's dive in!

1. Minnesota House passes "universal" school meals, providing free breakfast, lunch to students

The Minnesota House of Representatives is considering a bill that would provide universal school meals to all students in the state, regardless of their families' ability to pay. The goal of the bill is to ensure that all students have access to nutritious meals and are better equipped to learn in the classroom.

If the bill is approved, Minnesota would become the second state in the country, after California, to offer universal school meals. The bill has the support of education and anti-hunger advocates, who argue that it would help to address food insecurity and improve student health and academic performance.

2. Ukraine succeeds in bringing back 128 children forcibly removed to Russia

Ukraine has succeeded in bringing back 128 children forcibly taken by the invaders to Russia.

Source: Yuliia Usenko, Head of the Department for the Protection of the Interests of Children and Combating Violence of the Prosecutor General's Office of Ukraine, quoted by Ukrinform

Quote: "We have managed to bring 128 children back to Ukraine. More than 50 of them, together with their parents or guardians, are currently in EU countries.

3. Putting solar panels in grazing fields is good for sheep

A study found that installing solar panels in grazing fields is beneficial for sheep. The study was conducted in the UK and found that sheep were more likely to spend time in areas with solar panels than in areas without. This is because the panels provide shade and shelter from the sun, wind, and rain.

The researchers believe that this could help to improve the welfare of sheep, as they are more likely to seek out shade in hot weather, which can reduce the risk of heat stress. The study also found that the solar panels had little impact on the growth and health of the grass, which is important for the sheep's diet.

4. Dad takes toddler son for a manicure after teacher says it's 'only for girls'

The father and son were at a "Daddy and Me" event, where fathers were encouraged to spend time with their children doing various activities. The father chose to take his son to get a manicure, but was told by the teacher in charge of the activity that it was only for girls. The father was reportedly surprised and upset by the teacher's statement, as he felt that it was important for his son to be able to express himself however he wants, without gender stereotypes getting in the way.

The article notes that the incident highlights the ongoing issue of gender stereotypes and the importance of promoting gender equality and inclusivity, especially in children's activities.

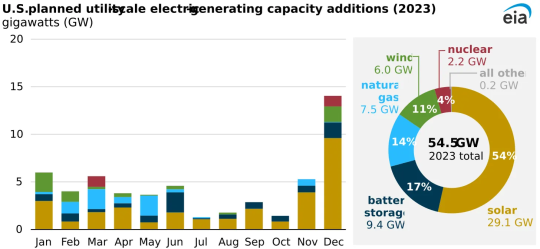

4. More than half of new U.S. electric-generating capacity in 2023 will be solar, and only 14% will be using fossil fuels

Information Administration (EIA), energy production in the country increased for the fourth consecutive week. The EIA data showed that the output of oil, natural gas, and coal rose by 1.6%, 2.2%, and 3.2% respectively. The increase in energy production is due to a combination of factors, including improved drilling techniques, favorable weather conditions, and rising global demand for energy.

5. Deforestation in Brazil falls by 60% in first month under Lula

Deforestation in the Amazon rainforest in Brazil fell for the first time this year, according to a report by Reuters. The decrease is attributed to increased enforcement of environmental regulations and increased monitoring of illegal logging activities. The Brazilian government has implemented several measures to reduce deforestation and preserve the Amazon rainforest, which is a critical component of the global ecosystem.

6. Cat returned to NJ shelter for being 'too affectionate' now happy in his new home

A cat named Bruno surrendered to a shelter in New Jersey and was eventually adopted by a new family. Bruno, who was described as a friendly and affectionate cat, is now happily settling into his new home. The story of Bruno's adoption serves as a reminder of the importance of animal shelters and the work they do to find loving homes for abandoned pets.

7. A doggy day care was on fire. Neighbors helped save all 115 dogs inside.

A fire broke out at a doggy daycare and resort in Seattle, causing significant damage to the building. No dogs or employees were injured in the fire, but several dogs had to be temporarily relocated to other facilities. The cause of the fire is under investigation, and the resort is working to make repairs and get back to serving the community's four-legged friends as soon as possible.

- - -

That's it for this week. If you liked this post you can support this newsletter with a small kofi donation:

Buy me a coffee ❤️

Have a great week ahead :)

252 notes

·

View notes

Text

Megatwix's canon information and trivia:

Megatwix’s inner structure reflects his dual nature of strength and resilience, much like the twin layers of a Twix bar. He has a “dual-core resolve,” meaning he never wavers in his decisions and always stands firm, even in the face of opposition. This dual-core design gives him a split yet synchronized thought process, allowing him to strategize on two fronts at once. It makes him an excellent multi-tasker and a fearsome strategist.

Megatwix’s demeanor is often described as “chocolate-cold” by the other Decepticorns, referring to his calm, unshakable personality. His level-headedness makes him the ideal leader, as he can assess any situation without letting emotions get the best of him. He rarely raises his voice, preferring to issue commands in a low, assertive tone that demands respect. His coldness, however, can make him seem distant, and few Decepticorns are close enough to see any warmth behind his leadership.

Megatwix’s sturdy, biscuit-like core gives him his characteristic “crunch factor”—a solid inner layer that makes him a force to be reckoned with. He has an unyielding structure that keeps him balanced and grounded, making him difficult to knock down. This toughness also translates into his personality, as he values stability and detests unpredictability, which is why Starcream’s theatrical outbursts get on his nerves.

Megatwix is almost immune to psychological warfare, a trait referred to by his fellow Decepticorns as his “indomitable will.” No amount of taunting, flattery, or trickery can sway his focus on his goals. This trait makes him particularly resistant to Starcream’s constant schemes and manipulation attempts, much to Starcream’s frustration. Megatwix is well aware of Starcream’s ambition and views it as almost amusing rather than threatening.

In Megatwix’s mind, there is a “Candy Code” that governs what he considers proper Decepticorn behavior. This unwritten code values strength, loyalty, and self-discipline, traits he considers essential to the candy hierarchy. He has little tolerance for what he sees as “softness” or “frivolity,” and he regards Starcream as a prime example of how not to embody the Candy Code. Megatwix uses this code to justify his leadership style, and he believes that as long as he adheres to it, he is entitled to lead the Decepticorns.

Megatwix occasionally has moments he calls “melted memory” episodes, where his caramel core heats up and distorts his recall of certain events, especially traumatic or high-stress battles. These are rare, but when they happen, they add a slight vulnerability to his otherwise perfect composure. He hides these episodes from the other Decepticorns, not wanting anyone to perceive any weakness in him. Only Soundwafer knows of this flaw, and Megatwix has instructed him to monitor his condition discreetly.

Megatwix and Soundwafer have an unspoken understanding: if either senses a threat to the Decepticorns’ leadership, they protect each other at all costs. Megatwix considers Soundwafer his “silent shield,” the one Decepticorn he implicitly trusts to watch his back.

Megatwix has devised a series of grueling trials for any new Decepticorns, called the “Twix Tolerance Test.” These tests are designed to separate the strong from the weak and consist of tasks that push recruits to their physical and mental limits. Megatwix believes that only those who pass these trials are worthy of joining his ranks, and he uses them to ensure that his army is made up of only the most dedicated, resilient Decepticorns.

Megatwix is haunted by a past battle known as the “Bittersweet Triumph,” where he emerged victorious but suffered significant losses among his followers. This incident left him with a deep-rooted distrust of easily won victories, as he believes that triumph always comes at a price.

Though he would never admit it, Megatwix feels a hidden sense of regret over “The Sweet Divide,” a philosophical split between him and Optimus Peppermint. Megatwix privately wonders if he could have forged an alliance with Optimus Peppermint long ago, potentially uniting Decepticorns in a different way. This unspoken regret subtly affects his interactions with the Autobons, as he sees their softer, dessert-themed styles as a painful reminder of a missed opportunity for unity.

Megatwix has a little-known weakness called “caramel crystallization,” a condition where his caramel core becomes brittle under extreme cold. This vulnerability is one of his most closely guarded secrets, as it could be exploited by cold-based Decepticorns, such as Scorponshake. Only Soundwafer and a few trusted allies know of this flaw, and Megatwix is careful to avoid situations where extreme cold could compromise his stability.

3 notes

·

View notes

Text

Understanding Transformer Bushings: Types, Functions, and Importance

Transformer bushings are essential components in electrical transformers, providing safe insulation for conductors as they pass through grounded transformer cases. Despite being often overlooked, bushings play a critical role in maintaining the efficiency and safety of power distribution systems. As one of the leading transformer bushings connectors manufacturers in India, Radiant Enterprises has extensive expertise in the manufacturing, export, and distribution of these vital components. In this blog, we will explore the different types of transformer bushings, their functions, and their significance in power systems, while addressing key industry keywords such as transformer bushing manufacturers in India and transformer bushing imports.

What are Transformer Bushings?

A transformer bushing is an insulated structure that allows an electrical conductor to safely pass through a grounded barrier, like the wall of a transformer or circuit breaker. The primary function of a transformer bushing is to insulate the high-voltage conductor from the grounded parts of the transformer, enabling safe and efficient electrical transmission. Bushings must withstand high voltages and electrical stress while preventing electrical breakdown.

The importance of using high-quality bushings cannot be overstated, as any failure can lead to significant damage, operational downtime, and safety hazards. That is why leading transformer bushing manufacturers in India prioritize the development of durable, high-performance bushings that meet global safety and operational standards.

Types of Transformer Bushings

Transformer bushings come in various designs, each suited for specific applications. Below are the main types of transformer bushings:

1. Oil-Impregnated Paper (OIP) Bushings

Oil-impregnated paper bushings are one of the most common types of transformer bushings used in high-voltage transformers. They consist of layers of insulation paper impregnated with mineral oil, providing excellent dielectric properties. The oil helps dissipate heat and enhances the insulation performance, making OIP bushings ideal for outdoor and high-voltage applications.

However, OIP bushings are susceptible to moisture ingress, which can degrade their performance over time. Proper maintenance and regular monitoring are essential to ensure their longevity and reliability. Transformer bushing manufacturers in India like Radiant Enterprises offer high-quality OIP bushings that meet international standards and ensure optimal performance in the most demanding environments.

2. Resin-Bonded Paper (RBP) Bushings

Resin-bonded paper bushings are similar to OIP bushings, but instead of oil, the insulation paper is bonded with a resin. This makes RBP bushings more resistant to moisture and provides them with better mechanical strength. They are typically used in medium-voltage applications where exposure to harsh environmental conditions is not as severe as in high-voltage applications.

Although RBP bushings offer some advantages in terms of moisture resistance and mechanical strength, they tend to have lower dielectric strength than OIP bushings. Nevertheless, they are a reliable choice for specific transformer applications where medium-voltage bushings are required.

3. Resin-Impregnated Paper (RIP) Bushings

Resin-impregnated paper bushings are a modern alternative to traditional OIP bushings. In this type of bushing, the paper insulation is impregnated with resin and vacuum-sealed to ensure minimal moisture content. RIP bushings offer superior dielectric properties, are resistant to moisture, and require less maintenance compared to OIP bushings.

RIP bushings are gaining popularity for use in power transformers due to their durability and reduced maintenance requirements. They are widely preferred for both outdoor and indoor installations. As one of the leading transformer bushing manufacturers in India, Radiant Enterprises offers a wide range of RIP bushings that provide enhanced safety and performance in modern power systems.

4. Capacitive-Graded Bushings

Capacitive-graded bushings are designed to distribute the electric field uniformly along the bushing, reducing the stress on the insulation materials. They are commonly used in high-voltage applications and can be manufactured using a combination of paper, oil, or resin-based insulation systems.

These bushings are particularly effective in minimizing dielectric losses and ensuring long-term reliability in power transformers. Capacitive grading also helps to manage the electrical stress along the bushing surface, preventing partial discharge and electrical breakdowns. Exporters and transformer bushing manufacturers in India are increasingly focusing on capacitive-graded designs to meet the growing demand for reliable, high-performance transformer bushings in the global market.

Functions of Transformer Bushings

Transformer bushings are critical for ensuring the safety and efficiency of power distribution systems. Below are some of their key functions:

1. Insulation

The primary function of a transformer bushing is to insulate the high-voltage conductor from the grounded transformer body or other equipment. This prevents electrical arcing, short circuits, and system failures, ensuring the safe transmission of electricity through the transformer.

2. Electrical Conduction

Transformer bushings also play a role in allowing the conductor to pass through the transformer housing or barrier without losing electrical efficiency. High-quality bushings help to maintain electrical continuity while minimizing losses during transmission.

3. Heat Dissipation

Transformer bushings, particularly OIP and RIP bushings, assist in dissipating heat generated during electrical transmission. This is critical to maintaining the temperature within the safe operating limits of the transformer, ensuring optimal performance and preventing overheating.

4. Voltage Grading

In high-voltage transformers, bushings also serve the purpose of voltage grading. By evenly distributing the voltage stress along the length of the bushing, they help prevent electrical breakdown, prolonging the lifespan of the transformer and reducing the risk of system failure.

Importance of High-Quality Transformer Bushings

Choosing high-quality transformer bushings is essential for the safe and reliable operation of power systems. Low-quality or faulty bushings can lead to serious issues such as electrical breakdowns, transformer failure, and even catastrophic accidents. As one of the leading transformer bushings connectors manufacturers in India, Radiant Enterprises understands the critical importance of designing and manufacturing bushings that meet the highest standards of quality and reliability.

Below are some reasons why investing in high-quality transformer bushings is crucial:

1. Enhanced Safety

Faulty bushings can result in electrical arcing, short circuits, and fire hazards. High-quality bushings are designed to withstand high voltage and electrical stress, ensuring the safety of the transformer and its surrounding environment.

2. Improved Transformer Longevity

Transformer bushings are integral to the overall health of a transformer. High-quality bushings reduce the risk of electrical failures, helping to extend the lifespan of the transformer and minimize downtime for repairs or replacements.

3. Energy Efficiency

Efficient bushings reduce electrical losses during transmission, ensuring that the transformer operates at optimal efficiency. This not only improves the performance of the power distribution system but also reduces energy costs in the long run.

4. Compliance with International Standards

High-quality transformer bushings must comply with international safety and performance standards, ensuring their suitability for use in diverse applications and environments. As a leading transformer bushing manufacturer in India, Radiant Enterprises ensures that all of its products meet or exceed global standards.

Transformer Bushing Exports and Distribution in India

India has emerged as a key player in the global transformer bushing market, with a robust manufacturing base and a strong focus on exports. Transformer bushing exports and distribution in India have grown steadily over the past decade, thanks to the country's focus on quality manufacturing and adherence to international standards.

At Radiant Enterprises, we are proud to be one of the top transformer bushing manufacturers in India, offering a wide range of high-performance bushings for export to international markets. Our products are trusted by power utilities and industries worldwide, thanks to our commitment to quality, innovation, and customer satisfaction.

India also imports certain specialized transformer bushings to meet the demand for specific applications that require advanced technologies not readily available domestically. Transformer bushing imports complement the country's own manufacturing capabilities, ensuring that Indian industries have access to the best solutions for their needs.

Conclusion

Transformer bushings are vital components that ensure the safe and efficient operation of power transformers. From oil-impregnated paper to resin-impregnated designs, the variety of bushing types allows for customized solutions to meet the demands of different voltage levels and operating environments. As a leader in transformer bushing exports and distribution in India, Radiant Enterprises provides high-quality, durable, and efficient bushings that support the energy needs of industries worldwide.

For reliable, cutting-edge transformer bushings, trust Radiant Enterprises – one of the top transformer bushing manufacturers in India. Our products are designed to meet the highest standards of quality and performance, ensuring the safety and longevity of your electrical systems.

#Transformer bushings connectors manufacturers in India#Transformer bushing manufacturers in India#Transformer bushing#Transformer bushing exports and distribution in India#Transformer bushing imports#India#Germany#Russia

4 notes

·

View notes

Text

Excerpt from this story from EcoWatch:

Sunrun, a solar company, and Baltimore Gas and Electric Company (BGE), the largest utility provider in Maryland, have launched a pilot program for a bidirectional power plant fueled by solar energy and EV technology.

The pilot, which involves three households, allows users to draw energy from a Ford F-150 Lightning electric truck when paired with the Ford Charge Station Pro and Home Integration System sold by Sunrun. This setup lets the household utilize energy from the EV during peak energy demand, Smart Energy International reported.

The pilot program is the first vehicle-to-home power plant in the U.S. and was funded with grants from the U.S. Department of Energy.

“This program is a significant proof of concept — no other market player has done this — and the goal is to expand these programs all around the country,” Sunrun CEO Mary Powell said in a press release. “This exciting partnership lays the foundation for the power grid of the future where electric vehicle owners can contribute to grid resiliency and utility price stability for everyone. The summer heat can be especially stressful on our power grid, which is why proving the use of stored energy in electric vehicles for capacity is so important.”

The process works by sending energy from the EV batteries to the homes, allowing the vehicle batteries to operate as energy storage. This can complement solar energy sources as well as reduce demand on Maryland’s power grids during peak times. The bidirectional power provided through the charging station can power homes for up to 10 days in the event of an outage, Sunrun said.

For the pilot program, the trucks share energy from 5 p.m. to 9 p.m. on weekdays from June 1 to September 30. The pilot is offering an estimated $800 to participants.

Currently, there are only a limited number of EV models that offer the bidirectional charging feature, including the Nissan Leaf, the 2024 Ioniq 5 and Ioniq 6 models from Hyundai, Kia’s EV6, EV9 and Niro EV, and the Ford F-150 Lightning, Cars.com reported.

More vehicles are expected to introduce bidirectional charging in the coming years, including all GM and Tesla EV models, CNET reported.

Sunrun and BGE are planning to expand the program after monitoring the pilot and will offer incentives for F-150 Lightning owners to join, helping increase grid resilience. The program could also help contribute toward Maryland’s goal to reach net-zero emissions by 2045 and achieve 100% clean electricity by 2035.

3 notes

·

View notes

Text

An Error in Judgment, Part 8

***

Kensi clasped Deeks cheeks between her palms, his head slack, eyes closed. Fortunately, he hadn’t taken a hard fall, but the heat emanating from his skin was worrisome. She licked her suddenly dry lips as she briskly rubbed his burning skin.

“Deeks. Deeks, hey, open your eyes for me, baby,” she urged.

“Was he hit?” Sam asked from behind her, and she didn’t spare him a glance, busy finding his pulse. It raced beneath her fingers.

“No, he just passed out and has a high fever,” Kensi explained.

“I’ll get Eric on it.”

Kensi continued rubbing Deeks’ face and chest, barely registering as he described the situation to Eric. Placing her closed fist in the center of Deeks’ chest, she rubbed directly over his sternum with enough force she worried she’d leave bruises. Her efforts were rewarded though when Deeks groaned miserably and cracked his eyes open.

“Hey, baby.” His eyes, glassy and red, shifted at the sound of her voice. “Can you stay awake for me?” He nodded once to her question. “Good. We’re going to get you help soon, ok sweetie?”

***

“Clear!” Sam announced over comms, his voice filling OPS where Admiral Kilbride, Eric, and Fatima were grouped. “We got Whitley.”

Eric and Fatima visibly relaxed, glancing back at the Admiral, who had been monitoring the operation closely. The entire office had been on tenterhooks the last week; Eric hoped that they would return to normalcy, or at least what passed for it with this team once this case was closed.

“Good. Inform me when they return,” Kilbride instructed, starting to turn towards the sliding doors.

“Yes, Sir,” Fatima responded from beside him. Her shoulders and voice tense. She’d found the changes particularly difficult to deal with. Eric sympathized with her. Things never felt quite right when Nell was out of the office or in the field.

A sudden commotion in his ear had Eric leaning forward. Kensi was saying Deeks’ name repeatedly, her voice panicked.

“Eric, we need an ambulance for Deeks,” Sam said tersely over the other chatter. “High fever, fast pulse, and reduced response.”

“I’m putting in the request now.”

“What the hell is going on?” Kilbride demanded, standing over Eric’s shoulder with a glower that would have cowed him if he wasn’t concentrating on Sam’s words.

“Deeks just collapsed,” he explained shortly, fingers flying across his keyboard as he filled in Deeks’ biographical information and current condition.

“What? I thought there weren’t any casualties on our side.”

“There weren’t.” Eric shot the admiral a dark look; though he wasn’t privy to the exact details, like everyone else, he knew Kensi and Deeks were on some kind of probation. He also had been victim to Kilbride’s unpredictable anger, his mood swings depending on the weather, the little annoyances of the day, and stressful cases.

Usually, he held a great amount of respect for the Admiral, but in this case, he was completely on Deeks and Kensi’s side. They’d earned his loyalty through the years. He couldn’t say the same for their supervisor.

“Sam, ETA for the ambulance is 15 minutes,” he said. “Keep us updated on Deeks.”

***

The tip of Kensi’s boot tapped against a gray linoleum tile, her clenched fists tucked under her folded arms. Across from her, Deeks lay on his stomach on a hospital bed, drifting in and out of sleep.

She’d managed to get a couple sips of water into Deeks after propping him up against a post. Though he remained conscious until the ambulance arrived, the was far from lucid. In fact, she was pretty sure his temperature had increased in that short time.

After that, the trip to the hospital had been a blur. On the way, Deeks’ temperature had spiked to a 104, which had set off the sensor on some machine and put the paramedics into a frenzy. They’d started him on fluids and a fever reducer and fortunately by the time they reached the hospital, his temperature had lowered slightly.

With his temp and racing pulse in mind, he was immediately brought to a cubicle. While Kensi explained his recent injuries, and progressing symptoms, two nurses had removed his shirt. The fabric had been practically glued to the wounds with discharge, and the resulting process of peeling the shirt off and placing temporary bandages had Deeks shaking in pain.

The wounds themselves were bright red, raised, and weeping. Kensi could only imagine how much pain Deeks had been in over the past several days as they steadily grew worse.

She leaned forward at the thought and brushed her knuckles across his cheeks, easing a few strands of hair back. Deeks lifted his head slowly in response, the ghost of an uneven smile curving his lips.

“I think a Kensi Blye kiss would make it all better,” he said, winking before he flopped his head back down. The color was still high in his cheeks and the visible skin of his neck and chest though.

“Somebody’s feeling better,” Kensi observed, stretching forward to kiss him several times. She exhaled softly in relief.

“Yeah, I think they have me on the good antibiotics.” He groaned and rubbed a hand down one side of his face. “Sam and Callen are never going to let me live this down,” he murmured. “Taken down by a couple of burns.”

“Horribly infected burns,” Kensi corrected firmly. “The doctor said you’re lucky they caught it before you actually went septic.” She laid her hand over his shoulder, careful to avoid the bandages. “You should have told me it was this bad, Deeks.”

“I didn’t realize it was.” Kensi gave him a sharp look and he amended with a nod of his head. “Ok, I knew it was getting worse, but I didn’t think I was septic.” He twisted his head to kiss her palm, brows furrowing. “I’m sorry.”

When he looked at her that way, eyes all soft and vulnerable, she couldn’t stay upset for long.

“I was just really worried.”

“I know.”

“I’ll be more careful after this.”

Kensi snorted, shoulders shaking as she started to laugh in earnest. “Right, like that’s going to happen.”

Deeks stretched across the bed to kiss her, groaning when it pulled on his back.

A nurse poking her into the cubicle interrupted the moment, and Kensi straightened, expecting an update on Deeks’ status.

“Agent Blye?”

“Yes?”

“There’s an Admiral Kilbride in the waiting room, who’d like to speak to you,” the nurse explained.

Kensi glanced to Deeks and he nodded encouragingly.

“Go ahead, I’ll be fine,” he assured her.

“Ok, I’ll be right back,” she said, giving him once kiss. She was reluctant to leave him alone at all.

When she made it to the waiting room, Kilbride was angrily pacing. She waited until he turned back to face her, arms folded against her chest.

“Sir, I heard you needed to speak with me. I assume you’d like my statement,” she said calmly, even though anger was brewing in her chest.

“No I do not,” he retorted. “I’d like to know what you’re doing here when I did not give approval for you to leave your post.”

“Deeks needed someone to escort him.” Before he could interrupt her, she added, “He was incoherent with poor vitals signs when they arrived. I assume you wanted him to receive the correct medical treatment.”

“Don’t pull that with me, Blye. I doubt it was all that serious.” He shook his head dismissively, muttering something that sounded distinctly like “drama queens”.

And Kensi’s self control flew completely out the window. “The wounds on Deeks’ back are severely infected, he had a fever of 104 degrees when we came in,” she said, her voice now dangerously calm. “A few more hours and he would have been septic. I don’t care what you think, I wasn’t about to leave him alone in that condition. So yes, I broke protocol. And I would do it again.”

“Well if he’d been more upfront about the situation, things might have turned out differently.”

“You told Deeks to wait until the case was closed,” Kensi said, patience, and respect, nonexistent. “Are you telling me that if Deeks had admitted he wasn’t feeling well and needed medical help, you wouldn’t have held it against him?”

“Agent Blye, you know why the two of you were disciplined—”

“You’ve been biased against Deeks from the day you walked in,” she cut him off. “You can’t see past the way he looks or acts, and you let that get in the way. It’s not the first time it’s happened to him, but I had certainly hoped someone in your position would figure it out more quickly.”

“I’ve treated Deeks no differently than any other operative,” Kilbride insisted. “And I take offense to your tone, agent.”

“For anyone else what you thought you saw would have gotten a verbal warning, not an unspecified period of probation without any specific terms.” Kensi shook her head, thinking of Deeks’ red, swollen wounds. “And because of your bias, you didn’t listen when both he and a senior agent explicitly told you he needed professional medical attention.”

“Well, I wouldn’t have needed to question him if he didn’t make a habit of screwing around while on job. I can’t name the number of nonsensical things I’ve heard come out of his mouth, or seen him do since I took supervision of this team.

“That maybe be true, but Deeks has never let that get on the way of his ability to perform his job incredibly well. Many people realize it’s actual an asset.” Kilbride made a scornful noise, and she stepped closer, lowering her voice. Not because she didn’t want anyone else to hear, but so Kilbride might actually listen. “Think about this. If Deeks was so unprofessional, do you think he would work while injured? He followed your new rules, he did his job, and he didn’t complain once.”

Shaking her head, Kensi pressed her lips together, deciding she needed to stop before she said something truly terrible. “I need to get back to Deeks,” she said.

Kilbride’s eyes flashed. “Agent Blye, I’m not finished with you yet.”

“My partner needs me,” she continued, turning away from him. “You’ll have my full report tomorrow.”

***

A/N: No, I don’t think Kensi would really get away with talking to Kilbride that way.

And yes, I’m playing a little fast and loose with medical issues again.

Hopefully this isn’t too disjointed.

#ncis la fanfiction#marty deeks#kensi blye#densi#and team#Deeks whump#Kilbride is sort of the villain#an error in judgment#part 8#au#ejzah fanfiction

16 notes

·

View notes

Text

What you don't see |Prolog

So, this is going to be a story that I write with @ghost-guard-13 and this is my side of the story, I'm not sure if they will post their side of the story on tumbler however, they will be posting it on wattpad along with mine, their part will be called "What you do see"

Cw: expiraments, mentions of past death. Let me know if I missed anything

Word count: 664

----------------------------------------------------------

He tried to remember what happened, the world around him seemed too bright and too loud. In the back of his mind he knew he should be in pain, he should be hurting, he should be able feel the needle in his arm but he couldn't, he could only feel the pain in his back and the strange feeling of something hard there. That couldn't be right, they should have only gotten the bullet out of his chest, they shouldn't have touched his back.

He couldn't feel where the bullet was. That couldn't be right, there's no way they have medicine that strong, and even if they did they wouldn't have given it to him. 'Somethings wrong' he thought, how was this possible?

His tired mind attempted to find an answer but he couldn't. He turned his head, looking out a near window, it seemed to be still be night, the moonlight peeked through the window. He carefully lifted his arm, he had two IV's. He looked beside him to see that he was hooked up to multiple monitors. The sound of his heart monitor filled his ears.

He carefully sat up. His back hurt, a lot. It didn't feel right, something had happened when he was put under, something he wasn't told would happen. A man walked in (of course it was a man, no woman was allowed to wonder around), he wore a white coat, he had brown hair, strainds of gray weaved through with all the years of stress that comes along with being here. He held a clipboard. The man looked up and saw that he was awake. "Ah, glad to see your finally awake." He wrote something down.

Virgil narrowed his eyes, "what did you do to me?" He demanded, letting his power seep into his words. He saw the man gulp. Good.

The man cleared his throat, "your father allowed me to do two experimental surgerys on you-"

Virgils blood began to boil. "He what?"

The man only shrugged, "he told me to cut off the pain receptors for certain parts of your body. Most of your body has been affected, however your back has reminded untouched. Other then the implants."

Virgils blood ran cold. He had been put through not only had he been experimented on once but twice without his knowledge. "What implants?" He wasn't sure he wanted the answer.

"There has been metal drilled into your shoulder bones, a small part of the implants is sticking out as well as sensors. There has been blue prints for wings that will attach to them when the wings are done. You will no longer feel pain, heat, or cold. You will have to have routine check up's for the implants to make sure that they don't get too rusty." The doctor explained, writing the entire time as if this was nothing, like it was normal.

Virgil stared at him, he couldn't feel pain. He couldn't feel anything.

The devil himself walked in, seeing Virgil and smirking. "Hello son" I am not your son Virgil bit back the response. "After your last stunt, I figured that this would help you. You had gotten so weak mentally, it needed to balanced by something, so I let them do a few experiments that could help us get better fighters in the future."

Virgil wanted to jump across the room and strangle him, how had he made him weaker? If anything he made him stronger, he had given him a reason to fight, which was more then what Alex could do. Virgil had to stop himself from saying that. If he had been willing to put Virgil through experimental surgerys that could have done who knows what to him, who knew what his 'father' was willing to do to him.

-----------------------------------------------------------

Word count: 664

Please let me know if you like this

12 notes

·

View notes

Text

Common Issues in Investment Casting and Their Solutions

For generations, the highly skilled manufacturing method of the lnvestment casting process, commonly referred to as lost wax casting, has been utilized to create accurate and elaborate metal parts. Investment casting has several benefits, including fine tolerances and a smooth surface, but several problems might arise in the course of manufacturing.

Broken Wax Patterns Cracking of Wax Patterns Cause: Quick cooling that occurs during the injection of wax. Solution: To provide a regulated and slow cooling process, optimize the wax injection settings.

Warping of Wax Patterns Cause: Inadequate mold release or uneven cooling. Solution: Use the proper mold release agents and keep the cooling environment constant.

Incomplete wax fill Cause: Inadequate mold temperature or insufficient wax injection pressure are the causes of incomplete wax fill. Solution: Make sure the molds are properly warmed and modify the injection settings.

Shell Building Issues Shell mold cracking Cause: Thermal stress that occurs during the shell-building process is the cause of cracking in shell mold. Solution: The investment casting Supplier must use a regulated heating procedure and gradually raise the temperature of the shell mold.

Inadequate shell thickness Cause: Improper slurry composition or inconsistent dipping is the cause of inadequate shell thickness. Solution: Guarantee consistent dipping and keep a close eye on the composition of the slurry.

Peel-off shell Cause: Inadequate drying or contamination resulting in poor adhesion. Solution: Keep your workspace tidy and adhere to the drying techniques that are advised.

Casting Defects Incomplete Data Entry Cause: Inadequate gating system or low metal temperature. Solution: Create an effective gating mechanism and optimize metal temperature.

Surface flaws, such as porosity Origin: Insufficient dewaxing, incorrect burnout, or gas entrapment. Recommendation: Improve dewaxing processes, maximize burnout cycles, and regulate venting to prevent gas leaks. Investment casting is a precise and adaptable manufacturing process, but it also demands close attention to detail and a comprehensive awareness of any potential problems. Through the identification and resolution of prevalent issues at every phase of the investment casting procedure, Investment casting manufacturer may improve the caliber of their output, minimize wastage, and maximize output efficiency. To consistently succeed in investment casting, one must monitor the process, follow best practices, and pursue continual improvement.

More Inquiry: Mastering the Art of Investment Casting: A Deep Dive into the Process

#lnvestment casting process#Precision Investment Casting#Precision Investment Casting China#Investment casting manufacturer#Investment casting Supplier

2 notes

·

View notes

Text

How to Protect Your Commercial HVAC System During Extreme Heat Waves

Extreme heat can put significant strain on commercial HVAC systems, leading to potential breakdowns, reduced efficiency, and increased energy costs. For businesses in Toronto, where hot summers can push these systems to their limits, ensuring optimal performance is essential to keep employees comfortable and maintain smooth operations. Regular maintenance, efficient use, and timely repairs are all part of keeping your HVAC system running well during peak temperatures. Here are some practical steps, including the importance of commercial refrigeration services in Toronto, to help protect your commercial HVAC system during extreme heat.

Schedule Routine Maintenance Before Heat Waves Hit

The best way to keep your HVAC system in top shape is by scheduling preventive maintenance before high temperatures arrive. During maintenance, a technician will inspect, clean, and tune up components like filters, coils, and electrical connections. Filters, in particular, play a crucial role in ensuring proper airflow; clogged or dirty filters can lead to overheating, causing the system to work harder and consume more energy.

In addition to regular HVAC service, it’s a smart idea to integrate commercial refrigeration services in Toronto as part of your maintenance routine if you have refrigeration units. Since refrigeration and HVAC systems often work in tandem, ensuring they both operate efficiently can lower the burden on each system during extreme weather.

Use Smart Thermostat Settings

Smart thermostats allow for precise control over temperature settings, optimizing energy use based on occupancy and time of day. For example, setting the thermostat a few degrees higher when the building is unoccupied can reduce the load on your HVAC system without compromising comfort. On scorching days, this simple adjustment helps prevent the system from running non-stop to maintain unnecessarily low temperatures.

A smart thermostat can also monitor your system’s performance and alert you to any irregularities, helping you identify potential issues before they escalate. Many commercial refrigeration services in Toronto offer advanced monitoring solutions that help with both cooling and HVAC performance management, giving you a clearer picture of overall system health.

Inspect and Seal Insulation

Insulation plays a vital role in maintaining a stable indoor temperature. Poor insulation allows hot outdoor air to seep into your building, causing your HVAC system to work harder to maintain cool temperatures. Check the insulation around windows, doors, and ductwork, sealing any gaps that could lead to energy loss. This simple step can significantly reduce the stress on your HVAC system, leading to fewer breakdowns and reduced energy costs.

Keep Outdoor Units Clear of Debris

Outdoor HVAC units need proper airflow to work efficiently. During summer, ensure the area surrounding the unit is clear of dirt, leaves, and other debris that could block airflow and cause overheating. Regularly inspect the outdoor unit and clear away any obstruction to ensure optimal performance.

Prioritize Professional Repairs

When it comes to extreme heat, quick and efficient repairs are crucial to avoid costly breakdowns. Ignoring minor issues can lead to significant damage, so it’s important to address problems as soon as they arise. Many companies specializing in commercial refrigeration services in Toronto also provide HVAC repair services, making it convenient to tackle both needs at once. A skilled technician can diagnose issues early, saving you time, stress, and money on larger repairs down the line.

In Conclusion

Protecting your commercial HVAC system during extreme heat requires proactive maintenance, smart energy management, and timely repairs. By scheduling regular service, optimizing thermostat settings, and keeping the system clean and clear, your HVAC unit can handle the demands of hot weather. With these steps, you’ll enjoy efficient cooling, lower costs, and uninterrupted comfort, keeping your business running smoothly all summer long.

0 notes

Text

Understanding Plain Broiler: A Comprehensive Guide to Poultry Basics

Nutritional Requirements of Plain Broilers

Essential Nutrients for Growth and Health

Raising regular chickens necessitates feeding them a rounded diet to promote their growth and well being effectively.

Feeding Practices for Optimal Development

Grain-Based Diets

Grain based diets are commonly used in feeding broilers as they consist of corn, wheat and soybean meal which supply the nutrients needed for their growth. The combination of these grains helps ensure that broilers get the levels of energy and protein required for their development.

Supplementary Feeding Options

Adding nutrients to broiler diets through feeding options can boost their nutritional content and overall quality. These options may involve incorporating acids and essential vitamins or minerals tailored to meet dietary requirements. By including these supplements, in the feed regimen of broilers can lead to enhanced feed efficiency and faster growth rates as it helps in addressing any deficiencies that may arise.

Health Management in Plain Broilers

Common Diseases and Prevention Strategies

Regular chickens are, at risk of getting sick, with illnesses like coccidiosis and avian flu as Newcastle disease Treatment methods consist of keeping their living areas clean ensuring they have a balanced diet and scheduling routine health assessments to spot any signs of sickness early.

Vaccination Protocols for Disease Control

Administer the vaccine is vital, for managing diseases in broiler chickens as it helps enhance immunity against pathogens prevalent, in the region and decreases the frequency of outbreaks by following established protocols tailored to local disease patterns.

Importance of Biosecurity Measures

Biosecurity measures are vital in protecting plain broilers from infectious diseases. These measures include controlling access to poultry houses, disinfecting equipment, and monitoring visitor movements. Implementing strict biosecurity protocols minimizes disease transmission risks.

Housing and Environmental Needs of Plain Broilers

Ideal Housing Conditions for Welfare and Productivity

Temperature and Humidity Control

Ensuring the temperature and humidity levels is crucial, for the well being and performance of broilers. Effective ventilation systems play a role in controlling these aspects to avoid problems, like heat stress or respiratory issues that might affect their growth.

Space and Comfort Considerations

Sufficient space is essential to promote comfort and alleviate anxiety, in broiler chickens enabling them to engage in activities such as moving around and stretching their wings freely without any constraints. Overcrowding may result in heightened levels of aggression and hinder optimal growth rates, among the broilers.

Impact of Environment on Growth Rates

Factors, like the amount of light to them for a day and the cleanliness of the air they breathe can greatly impact how quickly plain broilers grow and develop their well being and progress are influenced by how well these environmental factors are managed enhancing the conditions, around them can help these birds grow more effectively and perform better as a result.

Zeus: Innovation in Poultry Farming Equipment

Commitment to Advanced Technology Integration

Zeus shows a dedication, to incorporating cutting edge technology into the equipment used in poultry farming operations by focusing on improving feeding systems efficiency and implementing climate control solutions and automated monitoring processes.

Customized Solutions for the Chinese Market

Design Innovations

Zeus provides design solutions customized to cater to the demands of the Chinese market by taking into account local agricultural methods and weather conditions as well, as regulatory standards to guarantee seamless integration, with current systems.

Customer-Centric Product Development

At the heart of Zeuss strategy lies a focus, on developing products that prioritize the needs of customers. Through collaboration with farmers to grasp their obstacles firsthand Zeus devises solutions that directly tackle real life issues with efficiency. This method guarantees that the products are not functional but truly advantageous, for those who use them.

0 notes

Text

Revolutionizing Surveying with Wearable Technology: Advancements, Safety, and Precision

Wearable technology is transforming various industries, including the land surveying sector. What began as a tool for personal fitness has now evolved into an essential asset for professionals, helping them improve efficiency, accuracy, and safety on job sites. Surveyors are benefiting immensely from these innovations, especially when working in demanding environments. Any reputable land survey company in Regina today must stay ahead of technological trends to deliver exceptional results, and wearable technology is becoming a game-changer.

Increasing Precision in Land Surveying with Wearable Devices

Wearable technology has made precision more achievable than ever. Surveyors now have access to devices like augmented reality (AR) headsets, smart glasses, and wearable GPS units, all of which enhance their ability to capture real-time data accurately. These tools allow surveyors to overlay virtual models of construction designs onto physical sites, reducing errors by ensuring everything aligns with the original plan.

GPS-enabled wearables have become indispensable. Unlike handheld devices, wearable GPS systems allow surveyors to map terrains more comfortably and efficiently while keeping their hands free for other tasks. These wearable systems are particularly valuable for land surveyors working in vast or rugged areas, where traditional tools might slow down the process.

Wearables Boosting Safety on the Job Site

Surveying often involves working in unpredictable environments, such as construction zones or difficult terrains. Wearable technology plays a crucial role in enhancing safety for surveyors operating in these conditions. Smart helmets, equipped with sensors, can detect changes in environmental conditions, such as sudden impacts or excessive heat, and notify the wearer to take action before hazards escalate. This added layer of safety ensures surveyors are protected even in potentially dangerous environments.

Additionally, smartwatches and wearable health monitors are making it easier for surveyors to stay healthy during long work days. These devices track heart rate, hydration levels, and signs of fatigue, ensuring workers maintain optimal physical health. Supervisors can monitor their teams remotely, receiving alerts if any field worker experiences stress, exhaustion, or other health issues.

Improving Communication and Collaboration Across Teams

Efficient communication is essential for the success of any surveying project. Wearable technology bridges gaps between field teams and office staff, facilitating seamless collaboration. Devices like smart glasses or AR headsets allow surveyors to connect with remote experts in real time, who can see what the surveyor sees and provide step-by-step guidance. This reduces the need for follow-up site visits and ensures problems are addressed promptly.

Bluetooth-connected wearables further streamline communication by delivering updates and instructions directly to surveyors in the field. Teams can transmit survey data instantly to central offices, allowing decision-makers to review findings immediately and provide feedback. This continuous exchange of information eliminates delays, saving both time and resources. The ability to adapt to modern communication tools sets a land survey company in Regina apart, enabling it to offer exceptional service tailored to client needs.

Future Potential of Wearable Technology in Surveying

As wearable technology evolves, the future of land surveying looks increasingly promising. Innovations like wearable LiDAR scanners, which map terrains with high precision, and exoskeletons that reduce physical strain, are poised to make surveying even more effective. Surveying companies will need to continue embracing these developments to maintain a competitive edge in the industry.

Wearable technology has emerged as a powerful tool for land surveyors, helping them improve data precision, enhance safety, and streamline communication. With innovations such as GPS-enabled devices, AR headsets, and smart health monitors, surveyors can work more efficiently, stay safe in the field, and collaborate effectively with their teams.

For more information about Land Survey-Geomatics Services and Residential Land Survey Okanagan Valley please visit:- CORE Geomatics

0 notes

Text

"Exploring the Essential Role of Heat Treatment in Enhancing Material Integrity for Gulf Coast Industries."

https://www.onsiteusa.com/

In industries across the Gulf Coast region, where extreme operational demands and harsh environments prevail, ensuring the integrity of materials used in high-temperature processes is critical. Heat treatment plays an indispensable role in this regard, offering a means to optimize the strength, durability, and safety of materials like metals and alloys that are integral to the function of industrial equipment, pipelines, and fabrication processes.

In this article, we will take a closer look at the importance of heat treatment, how it benefits Gulf Coast industries, and why investing in onsite heat treatment services can be the key to operational success.

Understanding Heat Treatment and Its Importance in Material Performance

Heat treatment refers to a process used to alter the physical and sometimes chemical properties of a material, typically metal. It involves controlled heating and cooling, which can significantly improve mechanical properties such as hardness, strength, and resistance to wear and corrosion.

Why is heat treatment crucial for Gulf Coast industries? The answer lies in the extreme conditions faced by materials used in facilities like refineries, petrochemical plants, and manufacturing sites. With fluctuating temperatures, high pressure, and exposure to aggressive chemicals, materials are put under immense stress. Without proper heat treatment, equipment can degrade, leading to costly downtime and potential safety hazards.

One of the most common heat treatment processes is annealing, where the material is heated and then cooled slowly to improve ductility. This makes the material less likely to fracture under stress, which is crucial in the manufacturing of pressure vessels and pipelines that handle volatile substances. Another critical process is quenching, which rapidly cools the material, increasing its hardness and strength. For industries that require high levels of resilience, such as those working with steel alloys in the oil and gas sector, this is essential.

The Role of Onsite Heat Treatment for Gulf Coast Industries

When we talk about heat treatment, it’s important to understand the significant advantages of onsite heat treatment services, particularly in the Gulf Coast. Onsite heat treatment allows companies to perform necessary heat treatment processes directly at the worksite, without having to transport materials back and forth to off-site facilities. This service is crucial for industries where operational continuity is paramount.

For example, onsite heat treatment can be performed on pressure vessels and reactor vessels that operate under high-pressure conditions, ensuring they meet safety standards and continue to function at peak efficiency. By eliminating the need for transporting large components offsite, onsite heat treatment not only reduces downtime but also minimizes the logistics costs associated with moving heavy industrial materials.

Moreover, the real-time monitoring capabilities available with onsite heat treatment services ensure that temperatures and cooling rates are precisely controlled, reducing the chances of defects or material failure. This makes onsite heat treatment a preferred solution for Gulf Coast industries that demand quick and reliable service.

For more in-depth insight into how onsite heat treatment can benefit Gulf Coast industries, you can read Understanding the Impact of Heat Treatment on Material Integrity.

Key Benefits of Heat Treatment in Gulf Coast Industries

Increased Durability and Longevity of EquipmentHeat-treated materials are more resistant to wear and tear, which directly impacts the lifespan of industrial equipment. In industries like petrochemicals, oil refining, and heavy manufacturing, equipment often operates under extreme conditions, facing everything from corrosive environments to high mechanical stresses. Heat treatment can increase the strength and hardness of components, which helps them endure the demanding operational conditions that would otherwise cause premature failure.As these industries continue to grow in the Gulf Coast region, ensuring the reliability of equipment becomes crucial. By investing in heat treatment services, businesses can mitigate risks related to equipment failures, improve safety standards, and reduce maintenance costs.For more details, visit Onsite heat treatment.

Mitigating Material DegradationCorrosion and fatigue are some of the most common issues faced by industries in the Gulf Coast. The humid and salt-laden air, combined with the exposure to hazardous chemicals, accelerates the process of corrosion. Heat treatment processes like annealing and tempering can reduce the likelihood of these issues, making materials more resistant to corrosion, cracking, and fatigue.Through regular heat treatment services, businesses in the Gulf Coast can enhance the corrosion resistance of key components, ensuring they remain in operation for longer periods, even in the face of aggressive environmental factors.

Operational Efficiency and Reduced DowntimeOne of the significant advantages of onsite heat treatment is the minimization of downtime. In industries where time equals money, having an onsite team capable of performing heat treatment can drastically reduce the time spent on repairs and equipment servicing. This is especially important when critical components such as piping systems, pressure vessels, or valves need heat treatment to restore their integrity.Onsite heat treatment services can provide fast and effective solutions, ensuring equipment is back in operation as quickly as possible. This not only reduces operational costs but also increases overall productivity by keeping the necessary machinery running at peak performance levels.

Compliance with Safety and Industry StandardsCompliance with safety standards is non-negotiable, especially in the Gulf Coast industries dealing with hazardous materials like oil, gas, and chemicals. Heat treatment plays a pivotal role in ensuring that materials can withstand the stresses of high-temperature operations without compromising safety.Onsite heat treatment services also help businesses comply with industry regulations, ensuring that all equipment meets the necessary standards for safety and performance. This is crucial in avoiding costly fines, maintaining a positive corporate reputation, and ensuring the safety of employees and surrounding communities.

For further information on heat treatment and its role in industrial safety, visit Onsite heat treatment.

Supporting Operational Excellence with Onsite Heat Treatment Services

As mentioned earlier, onsite heat treatment services are pivotal to maintaining the operational excellence of industries in the Gulf Coast region. By providing targeted heat treatment services directly at the worksite, businesses can minimize downtime, reduce operational costs, and ensure that materials perform to their full potential.

Moreover, onsite heat treatment services support real-time monitoring and immediate corrective actions if needed, ensuring a higher level of quality control. This service is integral to industries that require custom heat treatment solutions and need them done quickly without compromising precision or efficiency.

Case Study: The Benefits of Onsite Heat Treatment in a Gulf Coast Refinery

To further emphasize the importance of onsite heat treatment, let's look at a real-world example. A Gulf Coast refinery dealing with pressure vessels had been facing frequent failures due to cracks and material fatigue. The company decided to invest in onsite heat treatment services, specifically post-weld heat treatment (PWHT), which helped in reducing the residual stresses in the welds.

After implementing onsite heat treatment, the company reported a significant reduction in maintenance costs, fewer instances of equipment failures, and increased operational reliability. This case highlights the importance of customized heat treatment solutions tailored to the specific needs of each company.

Conclusion

Heat treatment plays a critical role in ensuring the strength, safety, and longevity of materials used in Gulf Coast industries. Whether for oil and gas, chemical plants, or heavy manufacturing, onsite heat treatment services provide a valuable solution to optimize material performance, mitigate risks, and support operational efficiency.

By embracing these advanced heat treatment processes, industries can reduce downtime, improve material integrity, and meet the stringent safety standards required in today’s competitive and high-risk industrial environments.

To learn more about how onsite heat treatment can benefit your operations, read the full article on Understanding the Impact of Heat Treatment on Material Integrity or visit Onsite USA.

Sources:

ASM International, "Heat Treatment of Steel," ASM Handbook, Volume 4: Heat Treating.

American Petroleum Institute (API), "Heat Treatment for Pressure Vessel Components," API Recommended Practice 576.

Environmental Protection Agency (EPA), "Best Practices for Material Management in Corrosive Environments."

Occupational Safety and Health Administration (OSHA), "Safety Standards for High-Temperature Equipment."

0 notes

Text

How Wire Basket Spools Support Efficient Wire Handling in Various Industries

Wire management is crucial in many industries, from manufacturing and welding to 3D printing and construction. Among the tools that streamline wire handling, wire basket spools stand out for their durability, versatility, and efficiency. Designed to neatly store and dispense wires, cables, and filaments, wire basket spools help keep workspaces organized and processes running smoothly. In this blog, we’ll explore how wire basket spools contribute to efficient wire handling across various sectors.

Wire Basket Spool

Why Are Wire Basket Spools Essential for Wire Handling?

Wire basket spools are cylindrical holders made with a mesh or open design. They allow quick and easy access to stored wire materials. Unlike solid spools, these wire basket versions allow users to visually monitor the remaining wire or filament, making it easy to manage inventory and avoid unexpected shortages. Their lightweight yet robust design is perfect for industries that require high-performance equipment for frequent, intense use.

The Role of Wire Basket Spools in the Welding Industry

In welding, consistent wire feeding is essential for high-quality welds. Wire basket spools are commonly used to store and dispense welding wires, helping operators maintain a smooth workflow and avoid the frustration of tangled or kinked wire.

Efficient Wire Dispensing: Wire basket spools allow welding operators to pull wire as needed, preventing interruptions.

Reduced Tangling and Wastage: With neatly wound wire, tangles and breakages are minimized, leading to less waste and downtime.

Heat-Resistant Design: Made from durable materials, these spools withstand the heat and demanding environment of welding workstations.

Wire Spool

Supporting Manufacturing Workflows with Wire Basket Spools

In traditional manufacturing settings, wires are often used for power transmission, equipment assembly, and product production. Wire basket spools simplify wire management, helping to reduce waste and improve safety on the manufacturing floor.

Space-Efficient Storage: Wire basket spools are stackable and easy to store, saving valuable floor space in busy manufacturing environments.

Enhanced Safety: By keeping wires organized, basket spools reduce trip hazards and equipment malfunctions.

Long-Lasting Quality: Built for heavy use, wire basket spools are sturdy enough to withstand continuous handling, providing manufacturers with a long-term wire storage solution.

The Growing Importance of Wire Basket Spools in 3D Printing

As 3D printing expands across industries, efficient filament management is essential to keeping production lines running without delays. Wire basket spools help meet this need by providing an organized and reliable way to store and feed 3D printing filaments.

Consistent Filament Flow: Smooth filament dispensing prevents jams and breaks, ensuring consistent print quality.

Quick Material Switching: The open structure of basket spools allows users to change filaments quickly, an advantage in fast-paced 3D printing environments.

Easy Monitoring: Users can see how much filament is left on the spool, making it easier to manage inventory and avoid sudden supply interruptions.

Wire Spool Manufacturer

Key Benefits of Wire Basket Spools Across Industries

No matter the industry, wire basket spools bring a host of benefits to wire handling and management:

Durability: Wire basket spools are made from high-strength materials, such as stainless steel, that withstand frequent use and environmental stresses.

Versatile Applications: Their adaptability makes wire basket spools useful in a variety of settings, from construction sites to small workshops and large-scale manufacturing.

Eco-Friendly Design: Many wire basket spools are made from recyclable materials, contributing to sustainable practices and reducing environmental impact.

Choosing the Right Wire Basket Spool for Your Industry

When selecting wire basket spools, it’s essential to consider the specific demands of your industry. Here are a few tips for choosing the right spool:

Material Quality: Look for spools made from rust-resistant and heat-resistant materials, especially for welding and outdoor applications.

Capacity and Size: Ensure the spool can accommodate the volume and weight of wire you typically use.

Compatibility: Some applications, such as 3D printing, require specific spool sizes and fittings, so make sure the wire basket spool meets your equipment’s requirements.

Wire Basket Spool Manufacturer

The Future of Wire Basket Spools in Industrial Applications

With continued advances in automation and sustainable manufacturing, wire basket spools will likely evolve to meet the changing demands of modern industries. Future improvements may include enhanced customization options, innovative materials, and more ergonomic designs to support safe handling. As more industries prioritize efficiency and sustainability, wire basket spools will play an even more critical role in supporting these goals.

Conclusion

Wire basket spools have become an invaluable asset for efficient wire handling across various industries. From ensuring a smooth welding process to simplifying filament management in 3D printing, these spools help keep operations organized, reduce waste, and improve overall productivity. By choosing high-quality, durable wire basket spools, businesses can streamline their workflows and set up a more efficient, safe, and sustainable work environment.

Consider integrating wire basket spools into your operation to experience the difference they make in organization, efficiency, and ease of wire handling.

0 notes

Text

How to rest well in a busy world

Finding genuine rest has become increasingly challenging in today’s fast-paced world. Whether you are a busy professional in the heart of a bustling metropolis like a Colombo city hotel or a parent juggling multiple responsibilities, the art of resting well seems more elusive than ever. The constant bombardment of notifications, endless to-do lists, and the perpetual pressure to stay productive have created a society that often views rest as a luxury rather than a necessity. This comprehensive guide will help you understand the importance of quality rest and provide practical strategies to achieve it, even in the midst of a hectic lifestyle.

Understanding True Rest

Rest is not merely about sleeping or taking a break from work. It is a holistic concept that encompasses physical, mental, and emotional rejuvenation. Like finding the perfect Colombo hotel offers for a weekend getaway, discovering your ideal rest routine requires careful consideration and planning. True rest involves a state of deep relaxation where both your body and mind can recover from the demands of daily life.

The Science Behind Rest

Research shows that proper rest is crucial for:

Cognitive function and memory consolidation: During rest periods, your brain processes and stores information from the day, strengthening neural pathways and improving learning retention.

Emotional regulation and stress management: Adequate rest helps regulate cortisol levels, reducing anxiety and improving emotional stability.

Physical recovery and immune system function: Your body repairs tissues, strengthens immunity, and balances hormones during restful periods.

Creativity and problem-solving abilities: A well-rested mind is more capable of innovative thinking and finding solutions to complex challenges.

Overall mental health and well-being: Regular rest reduces the risk of burnout, depression, and anxiety disorders.

Key Strategies for Quality Rest

Create a Restful Environment

Just as family rooms in Colombo provide a comfortable space for families to unwind, your rest environment should be conducive to relaxation. Consider these essential elements:

Temperature control (68-72°F/20-22°C is optimal):

Use programmable thermostats to maintain ideal temperatures.

Consider seasonal adjustments to your bedding.

Use fans or heating as needed for comfort.

Proper lighting:

Install dimmer switches for evening wind-down.

Use blackout curtains or shades.

Invest in smart lighting systems that adjust throughout the day.

Minimise blue light exposure in the evening.

Noise management:

Use sound-proofing materials where possible.

Invest in quality white noise machines.

Consider double-pane windows for urban environments.

Use noise-cancelling devices when needed.

Comfortable furnishings:

Choose ergonomic furniture that supports proper posture.

Invest in high-quality mattresses and pillows.

Regular maintenance of bedding materials.

Consider pressure-relief materials for optimal comfort.

Digital Detox Practices

In our hyper-connected world, digital boundaries are essential:

Implement a "tech-free" hour before bedtime:

Create a charging station outside the bedroom.

Use analogue alternatives (physical books, traditional alarm clocks).

Develop evening routines that do not involve screens.

Practise mindful disconnection.

Create designated phone-free zones:

Establish tech-free meal times.

Designate certain rooms as no-phone areas.

Create physical barriers to technology access.

Encourage face-to-face interactions.

Use apps to monitor and limit screen time:

Set up app usage limits.

Track daily screen time patterns.

Use focus mode features.

Schedule regular digital breaks.

Practise regular digital sabbaticals:

Plan weekly tech-free periods.

Schedule monthly digital detox days.

Create alternative activities for tech-free times.

Build sustainable habits for reduced screen dependency.

Mindful Rest Techniques

Like choosing between normal rooms in Colombo for a business trip, selecting the right rest technique depends on your specific needs:

Progressive muscle relaxation:

Start with systematic tension and release exercises.

Focus on major muscle groups.

Practice for 10-15 minutes daily.

Combine with breathing exercises.

Deep breathing exercises:

Learn diaphragmatic breathing.

Practice 4-7-8 breathing technique.

Use breathing apps or guided sessions.

Incorporate breathing breaks throughout the day.

Guided imagery:

Create personal visualisation scenarios.

Use guided imagery apps or recordings.

Practice during scheduled rest periods.

Combine with other relaxation techniques.

Meditation and mindfulness:

Start with short sessions (5-10 minutes).

Gradually increase duration.

Explore different meditation styles.

Join meditation groups or classes.

Power napping:

Keep naps between 15-20 minutes.

Schedule naps during natural energy dips.

Create optimal napping environments.

Use alarm clocks to prevent oversleeping.

Time Management for Rest

Integrate rest into your daily schedule:

Block out specific rest periods:

Schedule rest like any other important appointment.

Create buffer time between activities.

Honour rest commitments.

Adjust schedules based on energy levels.

Use the Pomodoro Technique:

Work in focused 25-minute blocks.

Take intentional 5-minute breaks.

Track productivity patterns.

Adjust intervals based on personal needs.

Schedule "white space":

Leave unplanned time in your calendar.

Create flexibility for unexpected needs.

Allow for spontaneous rest.

Protect this time from encroachment.

Protect weekends and holidays:

Set clear boundaries between work and rest.

Plan rejuvenating activities.

Maintain consistent rest schedules.

Learn to say no to work-related requests.

In our busy world, learning to rest well is not a luxury—it is a necessity. By understanding different types of rest and implementing appropriate strategies, you can create a sustainable rest routine that supports your well-being and helps you thrive in all areas of life. Remember that rest is not a sign of weakness but a crucial component of a successful, balanced life. Start small, be consistent, and adjust your rest practices as needed to find what works best for you. With dedication to proper rest, you will find yourself more energised, focused, and capable of handling life's challenges with greater resilience and clarity.

0 notes

Text

The Future of Cable Management: Trends in Cable Tray Design and Material

As industries Grow Increasingly Reliant on high-performance cable management solutions, cabletrays have seen substantial innovation. What was once a standard utility is now evolving with newmaterials, designs, and technologies to meet the demands of modern infrastructure. Here is a look at the trends shaping the future of cable trays, revealing how they are becoming smarter, more sustainable, and tailored to a wide array of environments.

Wire mesh cable tray

1. Eco-Friendly and Sustainable Materials

Recycled Metals and Sustainable Alloys

Environmental responsibility Is Leading manufacturers to explore sustainable materials, such as

recycled aluminum and eco-friendly stainless steel alloys. These materials reduce waste, minimize

environmental impact, and Still deliver the durability and strength needed for cable management.

Biodegradable Coatings

To make cable trays more sustainable, manufacturers are experimenting with biodegradable or low-

VOC coatings. This innovation could offer additional protection while ensuring a reduced ecological

footprint when trays eventually need replacement.

2. Modular and Customizable Designs

Modular Systems for Versatile Installations

Modern installations require adaptability. Modular cable tray systems allow engineers to configure

trays easily and adjust them as requirements change, particularly in spaces with evolving equipment

needs, such as data centers and industrial facilities.

Customizable Components for Precision Fit

Customization is a growing trend, with manufacturers providing a range of tray sizes, bends, and

connectors. This precision fit approach enables installers to create exact configurations, leading to

more efficient space use and easier future modifications.

3. Incorporating Smart Technology

Integrated Monitoring Sensors

Cable trays are no longer passive components; some now feature smart sensors that monitor

temperature, vibration, or load stress. This technology provides real-time data, alerting facility

managers to potential issues before they become costly problems.

Remote Access and Monitoring

With the advent of IoT, smart trays can be accessed remotely. Facility managers can check status

updates from anywhere, enabling predictive maintenance and reducing downtime.

4. Enhanced Safety and Fire-Resistance Features

Fire-Resistant and Heat-Tolerant Materials

Safety remains paramount, especially in high-temperature or fire-prone environments. New

materials with fire-resistance properties help prevent flame spread, while high-heat-tolerant trays

are essential for industries like manufacturing and power generation.

Built-in Grounding and Insulation

Built-in grounding capabilities are becoming standard in cable trays, minimizing risks associated with

electrical faults. Insulating features are also enhancing worker safety by reducing potential shock

hazards.

5. Lightweight Yet Durable Designs