#Halogen Free Flame Retardant Industry

Explore tagged Tumblr posts

Text

Halogen-Free Cables: Everything You Need to Know

As we prioritize safety and sustainability in electrical installations, halogen-free cables have emerged as a vital component in modern wiring systems. These cables not only improve safety but also comply with stringent environmental standards. In this blog, we’ll explore what halogen-free cables are, their advantages, and why they are essential for the future of wiring.

What Are Halogen-Free Cables?

Halogen-free cables are designed to eliminate the release of harmful halogen gases during combustion. Traditional cables, when exposed to fire, can emit toxic fumes that pose serious health risks. In contrast, halogen-free cables use materials such as thermoplastic elastomers (TPE) and polyolefins, ensuring safer conditions in the event of a fire. This unique feature makes them ideal for various applications, especially in safety-sensitive environments.

Flame Retardant Low Smoke Halogen-Free Cables

One of the most significant advancements in halogen-free cable technology is the creation of flame retardant low smoke halogen-free cables, commonly known as FR cables. These cables are engineered to resist ignition and limit flame spread, significantly reducing smoke production when exposed to fire. This characteristic is crucial in high-occupancy buildings like schools, hospitals, and offices, where smoke inhalation can be even more dangerous than fire itself. By incorporating FR cables, construction projects can enhance safety and meet regulatory requirements.

Growing Demand for Safety and Compliance

The global emphasis on safety and environmental compliance has fueled the adoption of halogen-free cables. Regulatory bodies are tightening fire safety and emission standards, making it essential for industries to adapt. Halogen-free cables are no longer just an option; they are becoming a necessity to ensure the safety of occupants and workers. As we focus more on building safety, integrating halogen-free cables into electrical installations is a proactive step toward a safer future.

Innovations in Cable Design

The future of halogen-free cable technology is marked by ongoing innovation. Manufacturers are continually enhancing the durability and flexibility of these cables, making them suitable for a wide range of applications. Recent advancements in materials science have led to cables that can withstand extreme temperatures and harsh conditions. This versatility is invaluable, allowing for use in industrial machinery, outdoor installations, and complex building systems.

Enhanced Performance Characteristics

Modern halogen-free cables offer improved performance characteristics that expand their usability. These cables now feature enhanced resistance to chemicals, abrasion, and UV light, making them ideal for outdoor and industrial environments. Their resilience ensures they maintain performance over time, even under challenging conditions. This durability makes halogen-free cables a wise investment for any wiring project.

Integration with Smart Technologies

As smart building technologies evolve, the importance of halogen-free cables becomes increasingly evident. Smart buildings require reliable and efficient wiring solutions to support advanced technologies like IoT devices and automation systems. Halogen-free cables provide the necessary safety and performance features to support these innovations, establishing them as a crucial component of future smart infrastructure.

Eco-Friendly Alternatives

Sustainability is now a requirement in the manufacturing landscape. Manufacturers of halogen-free cables are increasingly focused on using recyclable materials and environmentally responsible production methods. This commitment to sustainability aligns with consumer preferences and sets a standard for responsible product development. As demand for greener options grows, the shift towards eco-friendly alternatives in halogen-free cable technology becomes more critical.

Conclusion

Halogen-free cables, particularly flame retardant low smoke options, are leading the way in modern electrical wiring solutions. Their safety benefits, regulatory compliance, and compatibility with advanced technologies make them indispensable in today’s construction and manufacturing environments. As the industry continues to innovate, we can anticipate further advancements that will enhance the performance and sustainability of these cables. For anyone involved in electrical installations, understanding the importance of halogen-free cables is essential for ensuring safety, compliance, and efficiency in projects.

0 notes

Text

Electric Wire and Cable Burning Tester: Efficient Tool for Assessing Cable Non-Propagation of Flames

The electric wire and cable burning tester is a precision instrument specifically designed to determine the non-propagation of flames of cables under fire conditions. This equipment is suitable for various cable types including single plastic wires, control cables, cross-linked cables, elevator cables, ship cables, and mining cables. Additionally, it can conduct vertical burning tests for high self-extinguishing low smoke halogen-free flame-retardant polyolefin insulation materials and 105°C low smoke halogen-free flame-retardant irradiated polyolefin insulation materials. The design of the electric wire and cable burning tester adheres to the following national standards: • GBT 18380.11-2008 “Tests on electric cables and optical cables under fire conditions – Part 11: Test for vertical flame propagation for a single insulated wire or cable – Apparatus” • GBT 18380.12-2008 “Tests on electric cables and optical cables under fire conditions – Part 12: Test for vertical flame propagation for a single insulated wire or cable – 1 kW pre-mixed flame test method” Furthermore, this equipment is effectively compliant with the international standard IEC 60332-1/2, ensuring international applicability and accuracy of test results. RSB-WC Wire Cable Flame Tester Key Features • Automatic Ignition: Utilizes a high-voltage igniter for automatic ignition, ensuring ease of operation. Corrosion Resistance Design: Designed with a structure resistant to smoke corrosion, enhancing longevity. • High-Quality Components: Critical components are imported to ensure stability and reliability of the equipment. • Digital Display and Automatic Control: Equipped with digital display timing functions, the test procedure is fully automated for convenient operation. Operating Principle The electric wire and cable burning tester employs a control circuit to manage the application time of the flame and operational procedures. The device provides a flaming combustion source to ensure the accuracy and repeatability of tests. Applications The vertical burning tester for electric wires and cables finds wide application in the cable manufacturing industry, construction industry, and quality inspection organizations. Through vertical burning tests, it effectively assesses the safety performance of electric wires and cables under emergency conditions, providing essential guidelines for design, production, and usage. Moreover, this equipment is used for researching new flame-retardant materials, developing high-performance electric wire and cable products, and establishing relevant industry standards. Continual optimization and improvement of testing methods by the vertical burning tester contribute to enhancing the safety performance of electric wires and cables, reducing fire risks, and safeguarding life and property. Testing Procedure • Preparation: Ensure a safe test environment free of flammable materials and check the burning tester for integrity. Prepare the cable samples by cutting them to specified lengths and diameters. • Sample Installation: Secure the cable samples on the fixture of the burning tester in a vertical position. Adjust the burner position to a certain height above the cable. • Start the Test: Ignite the burner to initiate the cable burning. Observe and record parameters such as burning time, burning length, smoke density, etc. Maintain a safe distance during the test to avoid injury from sparks. • End the Test: Once the cable has burned completely or reached the predetermined time, turn off the burner and allow the sample to cool. Compile test data for analysis and evaluation of the cable’s burning performance. This systematic approach ensures thorough assessment of electric wire and cable fire safety characteristics, contributing to enhanced product reliability and safety in various applications. Read the full article

0 notes

Text

Flexible Packaging Market by Regions, Type & Applications During 2024-2030

Flexible Packaging Industry Overview

The global flexible packaging market size was estimated at USD 270.96 billion in 2023 and is expected to expand at a CAGR of 4.8% from 2024 to 2030. Increasing consumption of flexible packaging products in medical and pharmaceutical sectors is driving their demand. These products offer various advantages, such as container variety, need for less raw materials, ease of disposal, and lightweight nature, which are expected to fuel their demand over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Flexible Packaging Market

According to the Flexible Packaging Association, nearly 34.7 million tons of all produced food is sent to landfills annually. Food waste generates 27.0 million tons of carbon dioxide. In addition, there are other indirect effects of food production on the environment, which include the greenhouse gases generated from cattle breeding, farm machinery, vehicles that transport food, and nutrient runoff from fertilizers that often lead to water pollution.

Extending food shelf life is necessary to reduce the amount of food waste dumped in landfills. Oxygen and moisture affect the freshness of food products, thereby rendering them unsafe for consumption due to mold formation on food products. The shelf life of food products depends on factors such as storage conditions, packaging material, and exposure to microorganisms, oxygen, light, and moisture.

The flexible packaging consists of plastic films with high barrier properties. The high-barrier properties efficiently block the transmission of moisture, light, and oxygen from contacting sensitive foods. Furthermore, the reseal closure products featured by flexible packaging allow users to securely close the bags or pouches, ensuring the freshness of the packaged food products over several uses.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global phthalic anhydride market size was valued at USD 4.52 billion in 2023 and is projected to grow at a CAGR of 3.8% from 2024 to 2030. This growth is driven by significant industrial chemicals used as starting materials for manufacturing various chemicals and polymers.

• The global low smoke halogen free flame retardant polypropylene market size was valued at USD 637.1 million in 2023 and is projected to grow at a CAGR of 9.5% from 2024 to 2030. The market growth is attributed to the increased adoption of low-smoking halogen-free flame retardant polypropylene due to its low-smoking emission and environment-favoring properties.

Flexible Packaging Market Segmentation

Grand View Research has segmented the global flexible packaging market report based on material, product, application, and region

Flexible Packaging Material Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • Plastics o Polyethylene (PE) o Polypropylene (PP) o Polyamide (PA) o Polyvinyl Chloride (PVC) o Polystyrene (PS) o Others • Paper • Metal • Bioplastics

Flexible Packaging Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • Bags • Pouches o Retort Pouches o Refill Pouches • Rollstock • Films & Wraps • Others

Flexible Packaging Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • Food • Beverages • Pharmaceutical & Healthcare • Personal Care & Cosmetics • Others

Flexible Packaging Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • North America o US o Canada o Mexico • Europe o Germany o UK o France o Italy o Spain • Asia Pacific o China o India o Japan o South Korea o Australia o Indonesia o Malaysia o Philippines o Thailand o Vietnam o Myanmar • Central & South America o Brazil o Argentina • Middle East & Africa o Saudi Arabia o UAE o South Africa

Order a free sample PDF of the Flexible Packaging Market Intelligence Study, published by Grand View Research.

Key Companies profiled: • Amcor plc • Mondi Group • Huhtamaki Flexible Packaging • Sonoco Products Company • Sealed Air • DS Smith • Berry Global • Constantia Flexibles • Bemis Manufacturing Company • UkrMetal • ProAmpac • Wipak Group • FlexPak Services • Transcontinental Inc. • Coveris Holdings • American Packaging Corporation • InterFlex Group • FLEX-PACK ENGINEERING, INC. • Innovia Films • Cosmo Films • Novolex • Sigma Plastics Group • Graphic Packaging International, LLC • Bischof+Klein SE & Co. KG • Südpack

Recent Developments

• In May 2024, Amcor and AVON both combinedly launch the AmPrima Plus refill pouch for the AVON Little Black Dress classic shower gels in China. The recycle-ready packaging will result in an 83% reduction in carbon footprint, and 88% and 79% reduction in water consumption and renewable energy respectively when it's recycled.

• In August 2023, Amcor acquired Phoenix Flexibles, expanding its capacity in Indian market. Phoenix Flexibles is situated in Gujarat, India, and generates revenue of approximately USD 20 Mn per year from the sale of flexible packaging for food, home care and personal care applications. The acquisition also adds advanced film technology, enabling local production of a broader range of more sustainable packaging solutions, and brings capabilities allowing Amcor to expand its product offering in attractive high-value segments.

• In February 2023, Sealed Air acquired Liquibox for a purchase price of USD 1.15 Bn on a cash and debt-free basis. Liquibox is a pioneer, innovator and manufacturer of Bag-in-Box sustainable fluids & liquids packaging and dispensing solutions for fresh food, beverage, consumer goods and industrial end-markets.

0 notes

Text

Zero Halogen Cables: Ensuring Safety and Reliability

In the world of modern infrastructure and technology, safety and reliability are paramount. One innovation that significantly enhances both is the use of zero halogen cables. These cables are designed to reduce the risks associated with fire hazards and improve environmental safety. In this blog, we will explore the benefits, applications, and features of zero halogen cables, and why they are the preferred choice for many industries.

What are Zero Halogen Cables?

Zero halogen cables are made from materials that do not contain halogens, such as chlorine, fluorine, bromine, iodine, and astatine. When exposed to high temperatures or flames, these cables emit minimal smoke and no toxic or corrosive gases. This makes them an ideal choice for environments where safety is a critical concern.

Benefits of Zero Halogen Cables

Reduced Toxicity:

Traditional cables made with halogens can release harmful gases when burned, posing significant health risks. Zero halogen cables mitigate this danger by emitting low levels of smoke and toxic substances.

Improved Fire Safety:

Zero halogen cables are designed to be flame-retardant, reducing the spread of fire. This feature is crucial in maintaining the integrity of safety systems during emergencies.

Environmental Safety:

Halogens can be harmful to the environment, particularly when cables are disposed of or incinerated. Zero halogen cables are more eco-friendly, contributing to a safer and healthier planet.

Corrosion Resistance:

In the event of a fire, halogen-free cables produce non-corrosive gases, protecting nearby equipment and structures from damage.

Applications of Zero Halogen Cables

Zero halogen cables are used in various industries and settings where safety and reliability are of utmost importance:

Public Buildings:

In places like schools, hospitals, and airports, the use of zero halogen cables ensures the safety of occupants by reducing the risks associated with toxic smoke and fire spread.

Transportation:

Railways, subways, and ships often use zero halogen cables to enhance passenger safety and protect critical infrastructure from fire hazards.

Industrial Facilities:

Factories and plants with sensitive equipment and materials benefit from the use of zero halogen cables due to their low smoke emission and non-corrosive properties.

Data Centers:

Protecting valuable data and ensuring uninterrupted service is vital in data centers. Zero halogen cables provide a safer environment for both equipment and personnel.

Key Features of Zero Halogen Cables

Low Smoke Emission:

In the event of a fire, zero halogen cables produce significantly less smoke, improving visibility and reducing the risk of inhalation injuries.

Flame Retardant:

These cables are designed to resist ignition and prevent the spread of fire, enhancing overall fire safety.

Non-Toxic Gases:

By eliminating halogens, these cables do not emit harmful gases, ensuring the safety of people and equipment in the vicinity.

Durability and Reliability:

Zero halogen cables are built to withstand harsh conditions, making them a reliable choice for critical applications.

Why Choose Qflx Zero Halogen Cables?

At Qflx, we prioritize safety, quality, and performance. Our zero halogen cables are engineered to meet the highest industry standards, ensuring they deliver exceptional safety and reliability. Whether you are looking to upgrade your current infrastructure or planning a new installation, Qflx zero halogen cables provide the peace of mind that comes with superior fire safety and environmental responsibility.

Conclusion

Zero halogen cables are a crucial advancement in ensuring the safety and reliability of electrical systems across various industries. By reducing the risks associated with fire hazards and toxic emissions, these cables offer unparalleled protection for both people and equipment. At Qflx, we are committed to providing top-quality zero halogen cables that meet the diverse needs of our clients. Contact us today to learn more about our products and how they can enhance the safety and performance of your systems.

0 notes

Text

Global Bio-based Polycarbonate Market Assessment, Opportunities and Forecast, 2030

Bio-based Polycarbonate Market size was valued at USD 75.28 million in 2022, expected to reach USD 145.65 million in 2030 with a CAGR of 8.6% for the forecast period between 2023 and 2030. Conventional polycarbonate resins are made from bisphenol A, which raises the concerns of sustainable goals and innovation shifted to derive alternate polycarbonate from bio or natural resources. Polycarbonates have many applications used alone or blended for numerous sectors like electronics, automotive, housewares, etc. Being produced from natural resources, the features of polycarbonates got enhanced, like delivering excellent optical properties, chemical & UV resistance, higher surface resistance, etc.

Sample report- https://www.marketsandata.com/industry-reports/bio-based-polycarbonate-market/sample-request

Electronics Industry is Augmenting the Bio-based Polycarbonate Market While Concerning the Sustainable Goals

Bio-based polycarbonate copolymer drives the electronics industry by providing sustainable materials and achieving net-zero carbon emissions. It is successively used as a smartphone battery cover, which should be certified by prominent certifications. The bio-based polycarbonate is made of a minimum composition of natural polymers and a maximum content of post-consumer products. Such effective polycarbonates assist in thin-wall injection molding for numerous applications, including electrical housings or health care. SABIC has developed high-performance bio-based polycarbonate that comprises around 21% natural polymers (like vegetable oils) and over 50% post-consumer recycled resin, along with pre-consumer recycled carbon fibers. Substantially the product is halogen free and PIN flame retarded and progressively used for electronics packaging.

Data released by the Static PIB states that the global market industry in 2020 is dominantly estimated at around USD 2.9 trillion, which is almost equivalent to India’s economy. India is growing exponentially, creating a huge production potential of around USD 25 billion in the electronics industry, around 12% of global investment. A survey data published by the Japan Electronics and Information Technology Industries Association JEITA states that the global electronics and IT industries are estimated to rise 5% in 2022, total to USD 3,536.6 billion.

Automotive Industry is Propelling Exceptionally using Bio-based Polycarbonates

Bio-based polycarbonate possesses unique features like incredible optical properties, high transparency, and phenomenal scratch resistance. These properties are substantially important in the perspective of automotive vehicles. Plant-derived polycarbonates are contributing to developing enhanced vehicle features and appearance with extended durability. These polymer formulations develop additional sustainable benefits supporting the economy and reducing product carbon footprint. Mitsubishi Chemical has developed excellent plant-based bicarbonate resin extensively used for automotive exterior and interior parts. Plant-based isosorbide polycarbonates have excellent optical properties and retain high surface hardness and transparency characteristics, imparting vivid colors in the transparent panels.

The demand for cars in South America has increased by 1.8%, accounting for 2.8 million units sold in 2022, where Brazil is contributing majorly to such a segment. In 2022, Indian passenger car sales rose by 23.1%, achieving 3.8 million units due to effective measures taken by the Indian government like lower interest rates. Taking account of 2023, the outlook for the European market is convincingly showing positive trends to create huge growth for the automotive industry.

Roofing Solutions has Effectively Improved by Incorporating Bio-based Polycarbonates

Bio-based Polycarbonate have successively enhanced the roofing and sliding solution from huge malls to large stadiums. The selection of high-strength and durable panels that enable varying heat and light intensity can lead to the proper architecture of such massive constructions. Palram Industries Ltd. is successfully manufacturing polycarbonate flat and corrugated panels for a wide range of applications. Its unique roofing and sliding solutions use proprietary SolarSmart technology which effectively facilitates light penetration selectively. From building huge malls to advancing world-class Olympic stadiums, they have numerous accountings of such projects that provide thermal insulation, heat blocking, chemical resistance, light transmission, and diffusion.

Annual report published by Stadiums Queensland (SQ) stated that during 2021-2022, Stadiums Queensland (SQ) hosted more than 3.4 million patrons across entire venues that substantially contributed more than USD 646 million in economic benefit to the Queensland economy and created around 5,717 FTE jobs for various event-related industries including cleaning, catering, and security.

Impact of COVID-19

The outbreak of COVID-19 has severely impacted numerous sectors and human livelihoods, where every person was vulnerable to infectious disease. The fight against COVID-19 was a challenging operation that evolved every sector to contribute their practices and eradicate the impact. Bio-based polycarbonates are important for developing effective solutions in numerous applications, especially automotive and construction. The pandemic impact was extended to these significant sectors, leading to a complete shutdown of manufacturing units and the delivery of new cars. But after the pandemic, companies invested more to recover the loss during a pandemic, and construction practices also resumed. Therefore, the market for bio-based polycarbonates is on the verge of growing exponentially with such enormous applications.

Bio-based Polycarbonate Chemical Market: Report Scope

“Bio-based Polycarbonate Market Assessment, Opportunities and Forecast, 2016-2030F”, is a comprehensive report by Markets and data, providing in-depth analysis and qualitative & quantitative assessment of the current state of the Bio-based Polycarbonate Market, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities and forecast between 2023 and 2030. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/bio-based-polycarbonate-market

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

0 notes

Text

TSTCABLES 10 Tips for B-Side Purchasing Demystifying High Temperature Cable Shopping Tips

I. High temperature cable Overview

High temperature cable is a special type of cable that can work normally in a high-temperature environment, and can usually withstand high temperatures above 200°C. Even some types of high-temperature cables can safely and stably transmit power signals and data signals at temperatures as high as 600°C or higher. Such cables have the following characteristics and uses:

Second, high temperature cable product characteristics

High temperature resistance: can operate stably in environments up to hundreds of degrees Celsius.

Anti-corrosion and anti-corrosion: Long-term performance in corrosive environments.

High efficiency and low consumption: special design to reduce energy consumption and enhance energy efficiency.

Strong anti-interference: Super anti-interference (EMI) shielding ability to ensure stable signal transmission in high temperature and electromagnetic interference environment.

High safety: low smoke and halogen-free flame retardant, reducing fire and other safety risks.

Long life: reduce the frequency of replacement, reduce maintenance costs.

Third, high temperature cable product standards

The production and testing of high-temperature cables follow strict standards. For example, according to the national standard GB12666.6-90, the long-term use of high-temperature cables can reach a working temperature of 200 ℃, and the short-term use of the temperature can even reach 1000 ℃. In addition, the products have passed a number of international certifications, such as CE, EN (EN 50264, EN50382, EN50306) certification, etc., to ensure their quality and safety.

Four, High-temperature cable application cases and scenes

Industrial production of High-temperature cable

Iron and steel smelting: high-temperature cables transmit power and data in steel furnaces and high-temperature production lines to ensure continuous production. Glass manufacturing: used in high-temperature furnaces to ensure the stability and safety of the production process.

Petrochemical High-temperature cable

Chemical reactors: connecting high-temperature reaction equipment and control systems to ensure precise control of chemical reactions.

Pipeline Conveying: Used in high temperature fluid conveying and monitoring systems.

Power and Energy High Temperature Cables

Solar power generation: connecting solar panels and inverters for efficient transmission of electricity.

Wind power generation: in wind turbines to ensure stable transmission of power in high temperature and high humidity environments.

Aerospace High Temperature Cables

Aero-engine: Ensure stable transmission of power and signal under extreme high temperature and vibration environment.

Satellite communication: in the space environment, to provide stable power and data transmission support.

Transportation High Temperature Cables

High-speed trains: Ensure stable power and signal in high temperature, high humidity and vibration car environment.

Electric Vehicle Charging: Support high temperature environment power transmission in fast charging station.

Medical Equipment High Temperature Cables

Medical equipment connection: Ensure stable power and signal transmission in high temperature sterilization and surgical equipment.

Military & Defense High Temperature Cables

Missile Systems: Ensure stable operation of missile systems under extreme conditions.

Mobile equipment: provide stable power support for military mobile equipment.

high temperature resistant cables

V. B-end buyers procurement to avoid the pit guide: High Temperature Cables 10 purchase skills

TST CABLES(www.tstcables.com) senior engineers summarized ten tips for you, I hope to help you choose high-quality high-temperature cables, if you want to buy cables do not step on the pit, pay attention to TST CABLES on the line.

Define the temperature range of high-temperature cables: Need to understand the maximum temperature and duration of the required high temperature cable can withstand, to ensure the safe operation of the cable in a high temperature environment.

Select the appropriate high temperature cable material: According to the different needs of the use of the environment, select the appropriate high temperature cable insulation materials and sheath materials, such as silicone rubber, graphitized polyimide, fluoroplastics, etc. These materials can maintain excellent electrical properties and mechanical strength at high temperatures.

Consider high temperature cable structure and size: The structure of high-temperature cables should meet the requirements of specific environments, such as high-temperature resistance and corrosion resistance.

The size and length of the cable should ensure that it can be adapted to the requirements of the equipment, while taking into account the bending radius and installation space.

High-temperature cable core number and cross-sectional area: According to the specific needs of the appropriate number of cores and cross-sectional area to meet the needs of high-power electrical equipment.

Focus on the safety of high-temperature cables: Select high temperature cables that meet the relevant standards and regulations, such as with UL, CE, EN and other certifications to ensure the safety performance of the cable.

Understand the high-temperature cable technical standards: Familiarize yourself with the relevant technical standards at home and abroad, such as IEC or specific national standards, to ensure that the cable purchased meets the specification requirements.

Consider the special environmental conditions of high-temperature cables: Cables used in special environmental conditions (such as high temperature, high humidity, corrosion, etc.) need special attention to their weather resistance and corrosion resistance.

High-temperature cable packaging and transportation: For high temperature cables exported or transported over long distances, the packaging should be tight and in accordance with international transportation standards to reduce the risk of damage during transportation.

High-temperature cable supplier technical information and certification: Ensure that high temperature cable suppliers provide complete technical information and certification documents, so that there is a clear reference and guidance in the process of use.

Consider High Temperature Cables supplier after-sales service: Choose high temperature cable manufacturer with good after-sales service, TST CALBES is a one-on-one engineer to provide full after-sales guidance, so that when problems arise during the use of the cable can be resolved in a timely manner.

TST CALBES engineers suggest that you need to consider many aspects when purchasing high-temperature cables, including the temperature range of the cable, the choice of materials, structure and size, safety, and the supplier’s after-sales service. Through careful comparison and selection, you can ensure that you get the right high temperature cable for your specific working environment, thus guaranteeing the stability and safety of power transmission.

High Temperature Cables Manufacturer TST CABLES

TST CABLES High Temperature Cables, stable transmission, in control! TST CABLES High Temperature Cables are made of high standard military materials, with excellent moisture-proof, anti-corrosion, anti-damage, anti-radiation, low-smoke, halogen-free, flame-retardant characteristics, to ensure stable and error-free signal transmission. The multi-core design meets the needs of complex circuits, making your industrial automation, energy transportation, aviation, nuclear power, wind power, ships and other projects more reliable and efficient. Strictly enforcing several national standards and passing multiple quality tests, it guarantees the stable operation of your project.

TST CABLES–Specializing in high temperature resistant cable applications and solutions.

For more information on railway cables, Silicone Cables, marine cables, low-smoke, halogen-free, flame-retardant, high temperature resistant cables or to customize cables for your machinery or system, visit https://www.tstcables.com/product/ orsend an e-mail to:[email protected]

0 notes

Text

Alumina Trihydrate, Global Market Size Forecast, Top 5 Players Rank and Market Share

Alumina Trihydrate Market Summary

Alumina trihydrate is produced synthetically from bauxite. The outstanding features of aluminium hydroxide are flame retardance (dehydration at 200°C), high whiteness and low hardness. Alumina trihydrate is regarded as being the most important mineral flame retardant in the world and, thanks to its freedom from halogens, it is environmentally friendly and is characterized by its high efficiency as a smoke gas suppressant. This mineral is made from bauxite in accordance with the Bayer process.

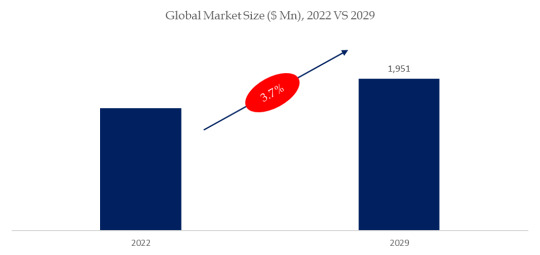

According to the new market research report “Global Alumina Trihydrate Market Report 2023-2029”, published by QYResearch, the global Alumina Trihydrate market size is projected to reach USD 1951.2 million by 2029, at a CAGR of 3.7% during the forecast period.

Figure. Global Alumina Trihydrate Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

Market Drivers:

Growing economies in regions like Asia-Pacific and Latin America are driving increased construction and industrial production, which, in turn, boosts the demand for alumina trihydrate.

There is a growing trend towards using halogen-free flame retardants, including alumina trihydrate, due to concerns about the toxicity and environmental impact of halogenated flame retardants. This shift is driven by regulatory changes and consumer preferences for safer materials.

Restraint:

Alumina trihydrate is typically produced from bauxite ore, and its cost is influenced by fluctuations in the prices of bauxite and other raw materials. Price volatility can affect the profitability of manufacturers and make it difficult to plan for stable production costs.

The alumina trihydrate market is competitive, with several key players operating globally. Intense competition can lead to price wars and reduced profit margins for manufacturers.

Increasing health risks, primarily due to exposure to aluminium trihydrate, are expected to hinder the growth of the market studied.

Opportunity:

Alumina trihydrate is widely used as a flame retardant in plastics, textiles, and other materials. With increasing awareness of fire safety and stricter regulations, the demand for flame retardant materials has been on the rise. This trend is expected to continue as safety standards become more stringent.

Environmental regulations and consumer preferences for eco-friendly products have put pressure on manufacturers to develop more sustainable processes for producing alumina trihydrate. This includes reducing emissions, minimizing waste, and sourcing raw materials responsibly.

Innovations in production technologies have led to more efficient and cost-effective methods of producing alumina trihydrate. These advancements can impact the industry by improving product quality and reducing production costs.

Figure. Alumina Trihydrate, Global Market Size, The Top Five Players Hold 57% of Overall Market

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

This report profiles key players of Alumina Trihydrate such as Huber, CHALCO, Nabaltec, Luoyang Zhongchao, KC Corp.

In 2022, the global top five Alumina Trihydrate players account for 57% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Alumina Trihydrate.

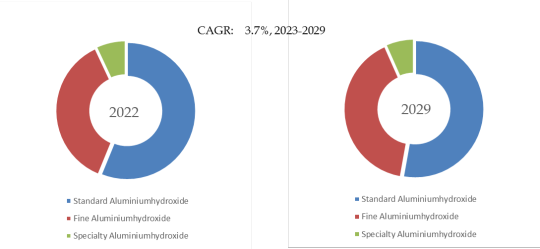

Figure. Alumina Trihydrate, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

In terms of product type, Standard Aluminiumhydroxide is the largest segment, hold a share of 56.2%.

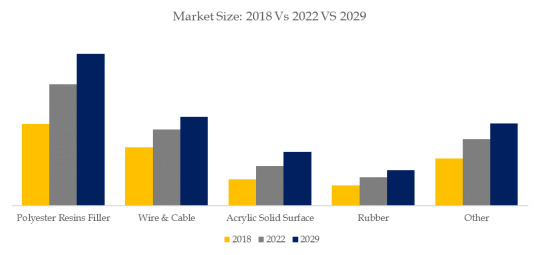

Figure. Alumina Trihydrate, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

In terms of product application, Polyester Resins Filler is the largest application, hold a share of 36.5%.

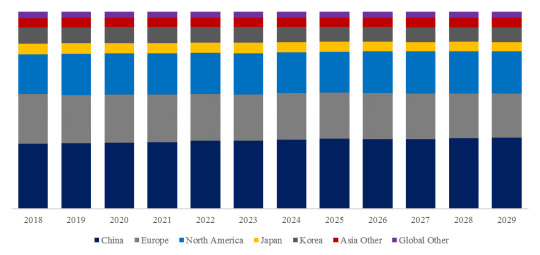

Figure. Alumina Trihydrate, Global Market Size, Split by Region (Production)

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

About The Authors

Lu Jing - Lead Author

Email: [email protected]

Lu Jing is a technology & market senior analyst specializing in chemical, advanced material, and component. Lu has 9 years’ experience in chemical and focuses on catalyst and additive, metal and plastic materials, waste recycling, daily chemicals. She is engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

SINOYQX Launches Melamine Foam in Rolls for Electronic Precision Manufacturing Industry

SINOYQX, on 30th, 10, 2023 launches melamine foam in rolls for thermal insulation, flame retardant and heat preservation application on electronic precision manufacturing industry.

The Melamine Foam in Rolls by SINOYQX's innovative processing technology, has a uniform appearance, and high open cell ratio. It is widely used in the electronic precision manufacturing industry, providing excellent thermal insulation, flame retardant, heat preservation, and the material in rolls, which facilitates the customer's post-processing adhesive laminating process, and improves the production efficiency.

Typical Properties of SINOYQX Melamine Foam in Rolls:

Permanent flame retardancy (UL94 V-0, HF-1, B1 grade) ;

Excellent acoustic performance (0.95NRC) ;

Excellent thermal insulation (thermal conductivity, 0.035 W/ (m*K)) ;

Permanent and stable three-dimensional mesh structure (99% open-cell) ;

Wide range of weathering (minus 180 degrees Celsius to 200 degrees Celsius, up to 240 degrees Celsius, with a wide range of weathering resistance (minus 180 degrees Celsius to 200 degrees Celsius, up to 240 degrees Celsius, with a maximum resistance of 240 degrees Celsius, with a wide range of weathering resistance) ;

Lightweight (8.5KG/cubic meter) ;

Environmentally friendly (does not contain any halogenated hydrocarbons, flame retardants and/or toxic heavy metals; does not emit toxic or harmful gases when burnt in a flame);

Environmentally stable (resistant to acids, alkalis, antibacterials and molds) .

Typical Specifications for SINOYQX Rolled Melamine Foam:

Thickness: 0.3mm to 3mm

Width: 100mm to 600mm

Length: 20m/roll to 300m/roll

In addition to its properties advantages, SINOYQX melamine foam in rolls have many other merits, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

SINOYQX is looking for partners and distributors of its melamine foam in rolls products globally.

About SINOYQX

SINOYQX is a huge chemical entity based on natural gas production chain, manufacturing urea (AdBlue), melamine(powder), melamine foam, melamine cyanurate (MCA), polyphosphate (MPP), polyvinyl butyral resin (low-polymerization PVB resin), modified melamine formaldehyde resins, and other chemical products. The annual capacity of AdBlue is 150,000Litters and 600,000Tons of Granule; Melamine, 50,000Tons; Melamine foam, 200,000M3, the Melamine Cyanurate (MCA) is 50,000Tons. And the Transulate (an Equivalent of 3M Thinsulate) is 20,000 Sqm, per day.

For more information about SINOYQX's rolled melamine foam products, please call us at 028-8411-1861 or write to us at [email protected] for free samples or quotes, or for more innovative solutions.

#melamine foam in rolls#melamine foam#rolled melamine foam#electronic rolls#permanent flame retardant#excellent acoustic performance#thermal insulation#three-dimensional mesh structure#broad weather resistance#lightweight#flame retardants#toxic heavy metals#acid resistance#alkali resistance#antimicrobial#anti-mold

1 note

·

View note

Text

0 notes

Text

Unveiling the Future of Low Smoke Halogen Free Flame Retardant Agent Market: Global Analysis & Projection (2019 - 2030)

Introduction:

The introduction to the report serves as a gateway into the comprehensive world of the low smoke halogen free flame retardant agent market. As industries continue to evolve and adapt to changing consumer demands and technological advancements, understanding the market dynamics becomes paramount for industry stakeholders. The report takes on the responsibility of offering a profound and all-encompassing analysis of the low smoke halogen free flame retardant agent market, catering to the needs of a diverse audience that includes manufacturers, suppliers, distributors, and investors.

Scope and Purpose:

The report's primary goal is to provide invaluable insights that empower industry stakeholders to make informed decisions. Whether it's manufacturers seeking to refine their product offerings, suppliers strategizing their supply chain management, distributors gauging market trends, or investors evaluating potential opportunities, the report aims to be a comprehensive guide. It endeavors to illuminate the current status of the low smoke halogen free flame retardant agent market while projecting its future trends.

Request for Sample Report:

Value to Industry Stakeholders:

Recognizing that knowledge is power, the report promises to deliver a wealth of information encompassing various aspects of the low smoke halogen free flame retardant agent market. By delving into the intricacies of market dynamics, competition, growth avenues, challenges, and regional variations, the report seeks to equip its readers with an arsenal of insights. This information is not merely descriptive; rather, it's intended to be actionable, aiding stakeholders in making critical decisions that can shape their strategies and endeavors in the market.

Promising Comprehensive Analysis:

To fulfill its promises, the report assures a comprehensive analysis that leaves no stone unturned. It pledges to unravel the factors propelling the market's growth, dissecting shifts in consumer preferences and technological breakthroughs that are driving the demand for low smoke halogen free flame retardant agent products. Simultaneously, it acknowledges that challenges and obstacles are part of any industry landscape, and it vows to illuminate these hurdles, be it economic uncertainties or the intense competition that often characterizes such markets.

Guiding the Path Forward:

As the report extends an invitation to its readers to explore its contents, it sets the stage for uncovering the competitive landscape. It introduces the major players in the low smoke halogen free flame retardant agent market and their strategies, offering insights into what makes them thrive. This insight-rich analysis is meant to guide others on their path forward – whether it's to navigate the competition more effectively or to find inspiration in successful strategies.

Anticipation of Insights:

With an awareness that the market is not monolithic but rather a composition of various segments, the report pledges to provide a nuanced understanding of these segments. It promises to detail their sizes, potential growth trajectories, and key trends. This targeted knowledge assists stakeholders in carving out specialized strategies and ensuring optimal resource allocation.

Market Dynamics:

Factors Driving Market Growth: The section dedicated to the factors driving the growth of the low smoke halogen free flame retardant agent market provides a comprehensive overview of the key forces propelling its expansion. It delves into a multi-dimensional analysis that underscores the multifaceted nature of this growth. The following aspects are discussed in detail:

Changing Consumer Preferences: The report recognizes that consumer preferences are ever-evolving, influenced by shifting lifestyles, demographics, and societal trends. It highlights how low smoke halogen free flame retardant agent products are witnessing increasing demand due to consumers' heightened awareness of environmental sustainability and their preference for more efficient and eco-friendly solutions. As consumers increasingly seek products that align with their values, the market experiences a surge in demand.

Technological Advancements: A prominent driver of market growth is technological progress. The report emphasizes how advancements in manufacturing processes, materials, and product designs are enhancing the appeal and performance of low smoke halogen free flame retardant agent products. These innovations lead to improved product efficiency, durability, and functionality, thereby attracting both consumers and industry players.

Government Regulations and Initiatives: The report recognizes the influential role of governments in shaping the market landscape. It details how regulatory frameworks and initiatives that promote the adoption of sustainable and environmentally friendly products are fostering the growth of the low smoke halogen free flame retardant agent market. These regulations incentivize manufacturers, suppliers, and consumers to opt for low smoke halogen free flame retardant agent products, driving their adoption and market penetration.

Potential Hindrances to Market Growth: In a balanced assessment, the report acknowledges that alongside growth drivers, there are potential impediments that can affect the trajectory of the low smoke halogen free flame retardant agent market's expansion. These include:

Economic Uncertainty: Economic fluctuations and uncertainties can impact consumer spending patterns and investment decisions. The report discusses how economic downturns or uncertainties may lead to cautious spending behavior, affecting the demand for non-essential products such as low smoke halogen free flame retardant agent goods. This economic sensitivity can create fluctuations in market growth rates.

Supply Chain Disruptions: The global supply chain is subject to various risks, including natural disasters, geopolitical tensions, and pandemics. The report highlights how disruptions in the supply chain can lead to production delays, shortages, and increased costs. Such disruptions can hinder the consistent availability of low smoke halogen free flame retardant agent products in the market.

Intense Market Competition: The report acknowledges that as the low smoke halogen free flame retardant agent market gains traction, competition among market players intensifies. It explores how the proliferation of products and companies in this sector can lead to price wars, reduced profit margins, and the need for innovative marketing and differentiation strategies to stand out.

Balancing Forces and Strategic Implications: By elucidating both the driving forces and potential obstacles, the report paints a holistic picture of the market dynamics. It enables industry stakeholders to navigate the competitive landscape with a deeper understanding of the forces at play. Manufacturers can align their innovation efforts with consumer preferences and regulatory trends, thereby enhancing their market position. Investors and decision-makers can be better prepared to address economic uncertainties and supply chain vulnerabilities. Overall, this section equips readers with insights to make strategic decisions that account for both growth opportunities and challenges in the low smoke halogen free flame retardant agent market.

Experience Our Sample Report:

Exploring the Competitive Landscape:

The section dedicated to the competitive landscape of the low smoke halogen free flame retardant agent market offers an intricate exploration of the market's key players, their strategies, and their impact on the industry. This segment aims to provide a comprehensive understanding of the market's dynamics, the role of major companies, and the strategies they employ to thrive. The analysis encompasses several critical aspects:

Major Players Introduction: The report begins by introducing the major companies that play a significant role in the low smoke halogen free flame retardant agent market. These players are identified as key influencers within the industry and are pivotal in shaping its direction. The inclusion of their profiles establishes a foundation for the subsequent analysis.

Business Strategies: The report delves into the business strategies adopted by these major players. It explores their approaches to market penetration, product development, marketing, distribution, and customer engagement. This insight offers readers an understanding of the distinct paths these companies take to secure their positions and expand their market shares.

Product Portfolios: Understanding the range of products offered by these major companies is essential in comprehending their market presence. The report delves into their product portfolios, highlighting the diversity and uniqueness of their offerings. This analysis provides a glimpse into the variety of options available to consumers and underscores how companies differentiate themselves.

Recent Trends and Innovations: The competitive landscape analysis is not static; it also captures the dynamism of the market. The report explores the recent trends and innovations introduced by these major players. It sheds light on how these companies continually adapt to changing consumer preferences, technological advancements, and emerging market demands.

Financial Performance: The financial aspect of these companies is a vital indicator of their market strength and sustainability. The report offers insights into the financial performance of major players, including revenue figures, profit margins, and growth trajectories. This information provides a quantitative perspective on the players' market impact and resilience.

Some of the major companies in the Low Smoke Halogen Free Flame Retardant Agent market are as follows: Albemarle, Clariant, DSM, Evatane(Arkema), Israel Chemicals Ltd, Lanxess, Pinfa, Pluss Advanced Technologies, RTP

Strategies for Sustaining Position:

By presenting a holistic view of the competitive landscape, this section allows readers to glean insights into the strategies employed by major companies to maintain their positions:

Differentiation: Companies strive to differentiate themselves from their competitors. The report reveals how major players leverage unique product features, quality, branding, and customer experiences to set themselves apart in the market.

Innovation: Innovation is a cornerstone of success. By exploring recent trends and innovations, the report illustrates how companies continuously invest in research and development to stay ahead of the curve and meet evolving customer needs.

Market Penetration: Understanding the strategies for expanding market presence is crucial. The report discusses how companies approach entering new markets, expanding their customer base, and increasing their market share.

Adaptability: The competitive landscape is subject to change. Companies that exhibit adaptability in the face of shifting trends and challenges are more likely to sustain their positions. The report highlights how major players adjust their strategies in response to market dynamics.

Customer-Centric Approaches: Successful companies prioritize their customers. The report showcases how major players tailor their products and services to align with customer preferences, creating lasting relationships and fostering brand loyalty.

Request a Glimpse of Our Sample Report:

In-Depth Market Segmentation Analysis:

The report dedicates a section to delve into the market segmentation of the low smoke halogen free flame retardant agent market, focusing on two specific segments named "Type" and "Application." This segmentation analysis serves as a critical framework for understanding the intricacies of the market's composition and potential. The following details are likely explored in this section:

Segment Characteristics: The report initiates the analysis by outlining the unique characteristics that define each segment. Whether these segments are categorized based on product types, customer demographics, use cases, or other distinguishing factors, the report provides a clear picture of how these segments are defined and differentiated.

Market Size: Understanding the size of each market segment is crucial for gauging its significance within the overall market landscape. The report likely provides quantitative data to illustrate the market share and contribution of "Type" and "Application" segments to the entire low smoke halogen free flame retardant agent market. This information helps stakeholders appreciate the relative importance of each segment.

Growth Potential: Beyond current market size, the report delves into the growth potential of these segments. It explores factors such as emerging trends, consumer behaviors, technological advancements, and regulatory influences that could drive the future expansion of these segments. This forward-looking perspective aids stakeholders in identifying where the market's growth opportunities lie.

Key Trends: The analysis likely captures the key trends specific to each segment. Whether it's changing consumer preferences, evolving technology adoption, or shifting regulatory landscapes, the report provides insights into the forces shaping the behavior of "Type" and "Application." These trends inform stakeholders about the directions these segments might take in the coming years.

Strategic Insights: The segment analysis extends beyond descriptive data to offer strategic insights. By understanding the characteristics, potential, and trends of "Type" and "Application," industry participants can make informed decisions. Manufacturers can tailor their product development strategies to meet the demands of these segments, and marketers can create targeted campaigns to reach specific customer groups.

Resource Allocation: Effective resource allocation is a cornerstone of successful business strategies. Armed with knowledge about the characteristics and growth potential of each segment, stakeholders can allocate their resources – whether it's budget, manpower, or marketing efforts – in a more focused and efficient manner. This optimization is crucial for maximizing returns on investments.

Competitive Dynamics: The segment analysis also influences the competitive landscape discussion. Understanding the major players operating within each segment and their strategies provides insights into how companies compete within specific niches. This knowledge helps stakeholders identify where there might be gaps in the market or opportunities for differentiation.

Market Segmentation:

Type: Phosphorus Flame Retardant, Nitrogen Flame Retardant, Silicon Flame Retardant, Aluminum-magnesium Flame Retardant

Application: Electrical Appliances, Automotive, Others

Strategic Decision-Making:

The comprehensive analysis of the "Type" and "Application" segments equips industry stakeholders with actionable insights:

Niche Strategies: Armed with a deep understanding of each segment's characteristics, stakeholders can craft specialized strategies to cater to the unique needs of "Type" and "Application" customers. This can involve tailored product offerings, marketing campaigns, and distribution approaches.

Growth Opportunities: The growth potential assessment informs strategic decisions. Stakeholders can identify which segment holds the most promise for expansion and investment, helping them prioritize their efforts and resources.

Mitigating Risks: Knowledge of key trends within each segment enables stakeholders to anticipate potential challenges and mitigate risks. They can proactively adapt to changing customer preferences, technological shifts, or regulatory changes.

Targeted Resource Allocation: With a clear picture of the market size and potential for each segment, stakeholders can allocate resources more effectively. This optimization enhances efficiency and increases the likelihood of achieving desired outcomes.

In sum, the segmentation analysis provides a roadmap for industry participants to navigate the diverse landscape of the low smoke halogen free flame retardant agent market. By examining "Type" and "Application" segments in detail, the report empowers stakeholders with the insights needed to make informed decisions, seize growth opportunities, and tailor their strategies for success.

Sample Report Available at Your Request:

Exploring Regional Dynamics:

The section dedicated to the regional analysis of the low smoke halogen free flame retardant agent market provides a comprehensive exploration of how the market fares across different geographical areas. This analysis recognizes that markets are not homogenous and that regional variations can significantly impact market dynamics. The report delves into the intricacies of each region – North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa – to provide stakeholders with valuable insights. The analysis includes the following components:

Geographical Coverage: The report begins by outlining the regions under consideration: North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Each of these regions represents a unique landscape with distinct economic, cultural, and regulatory characteristics that influence market behavior.

Sub-Regional Breakdown: Within each major region, the analysis likely provides a sub-regional breakdown. For instance, in Europe, the report might focus on countries like Germany, the U.K., France, Italy, and Spain. This detailed approach recognizes that even within larger regions, markets can differ significantly due to factors like language, culture, and consumer behavior.

Market Size and Growth Potential: The report quantifies the market size for each region and sub-region. This information provides a benchmark for understanding the relative significance of each market in the global context. Moreover, the analysis explores the growth potential of each region, considering factors such as economic growth, population trends, and market maturity.

Trends and Drivers: Regional trends and drivers play a pivotal role in shaping market behavior. The analysis delves into trends specific to each region, highlighting factors such as technological adoption rates, consumer preferences, and regulatory changes. These insights offer stakeholders a nuanced understanding of what is currently driving market dynamics.

Market Challenges: Recognizing that challenges vary by region, the report likely addresses obstacles specific to each geographical area. Regulatory complexities, economic constraints, and cultural nuances can all pose challenges that impact market entry and expansion strategies.

Competitive Landscape: Understanding the competitive dynamics within each region is crucial. The report may highlight major players operating in each region and their strategies. This insight helps stakeholders gauge the intensity of competition and assess the potential barriers to entry.

Culmination of Insights:

The conclusion of the report serves as the final crescendo in the symphony of insights, encapsulating the significance and value that the report brings to industry stakeholders. This section distills the entire report into a concise yet powerful message, reinforcing the key takeaways and underscoring the importance of the information presented.

Comprehensive and Practical Information: The conclusion reiterates the core objective of the report: to provide a comprehensive and practical resource for industry stakeholders. It emphasizes that the report goes beyond mere data collection and presents information in a way that is actionable and applicable to real-world business scenarios.

Insights into Market Dynamics: The report's value is highlighted by its ability to offer insights into the dynamic nature of the low smoke halogen free flame retardant agent market. From dissecting market trends to uncovering growth opportunities and potential risks, the report equips stakeholders with the understanding needed to navigate this ever-evolving landscape.

Informed Decision-Making: One of the central themes of the conclusion is how the report empowers stakeholders to make informed decisions. By offering a deep understanding of market trends, competitive dynamics, and potential challenges, the report serves as a guiding light in an environment often characterized by uncertainty.

Strategic Guidance: The conclusion underscores that the report isn't just a collection of facts; it's a strategic tool. It aids manufacturers in refining their product offerings, guides suppliers in optimizing their supply chain, assists distributors in capitalizing on market trends, and helps investors in evaluating potential opportunities.

Holistic Perspective: The conclusion highlights that the report provides a holistic perspective on the low smoke halogen free flame retardant agent market. It covers a range of critical aspects – from market dynamics to regional variations – ensuring that stakeholders have a comprehensive view that informs their decision-making.

Final Call to Action: The conclusion not only encapsulates the report's essence but also provides a call to action:

Informed Business Decisions: It urges readers to recognize the report's potential to transform their approach to business decisions. By absorbing the insights within, stakeholders are better equipped to navigate challenges, seize opportunities, and strategically position themselves in the market.

Continuous Adaptation: The conclusion suggests that success in the low smoke halogen free flame retardant agent market requires a commitment to continuous adaptation. The insights offered in the report are not static; they reflect the ever-changing landscape. The report encourages stakeholders to view it as a guide for ongoing adaptation and evolution.

A Blueprint for Success: Ultimately, the conclusion presents the report as a blueprint for success. By leveraging the knowledge and insights presented within its pages, industry stakeholders can chart a course that capitalizes on market trends, mitigates risks, and embraces growth opportunities.

Closing Thoughts:

In essence, the conclusion encapsulates the report's journey. It emphasizes the report's role as a strategic tool, a navigator, and a decision-making companion in the complex world of the low smoke halogen free flame retardant agent market. The provided text not only outlines the structural elements of a market report but also captures its essence – to inform, guide, and empower stakeholders as they navigate the dynamic and ever-evolving low smoke halogen free flame retardant agent market.

0 notes

Text

Diverse Benefits Of Collaborating With An Indian Wire Company

Wires and cables are essential parts, used in various places. For the right electrical solutions, you should partner with the right Indian Wire Company. They can bring various benefits to the table.

Let’s Talk About Diverse Benefits Of Collaborating With An Indian Wire Company-

High-Quality Manufacturing- Reputed wire companies in India meet strict manufacturing standards thus ensuring their products meet international quality benchmarks. They manufacture and produce premium quality wires and cables that are reliable, durable and withstand harsh environments.

Technological Advancements- Reputed wire companies in India involveinnovation and technological progress. It ensures that you can easily access the latest advancements in wire manufacturing and buy high-tech products, made of premium materials and design methods.

Customized Solutions- Experienced wire companies in Indian offer customized solutions to meet your exact requirements, be it an industrial application or a residential wiring project. It ensures optimal performance and efficiency.

Competitive Pricing- Reliable wire companies offer competitive pricing to meet your budget range. Because of the cost-effectiveness, wire companies offer high-quality products at the best pricing. You can expect an excellent value for your investment.

Extensive Product Range- Reputable Indian wire companies offer a comprehensive variety, including home automation in India. An extensive product range can cater to different industries and applications. From automotive wiring to power transmission cables, you will get everything. The best part is professional wire manufacturers and suppliers use eco-friendly practices. They have the right industrial infrastructure and access to the resources and capabilities to create first-class wires and cables in large quantities. It ensures on-time delivery and consistent supply for your projects.

Skilled Workforce- These companies have the best team of skilled and dedicated experts; including engineers, technicians and professionals. Rest assured that you will receive superior technical support and assistance. They also meet international safety standards and certifications. You can trust them for quality and safe products that meet industry regulations and are tested.

The Final Thought-

When it comes to premium quality wires and cables, you should always choose a professional and reputed wire company. They can empower you with the right electrical solutions at competitive pricing.

Looking for the best Indian Wire Company? Elleys’ is your right stop. we offer a wide range of wires for different applications including Flame Retardant (FR) grade wires, Flame Retardant Low Smoke (FRLS) wires, Zero Halogen Low Smoke (ZHLS) wires, Heat Resistant Fire Resistant Lead-Free (HRFRLR) wires and so on. Visit https://www.elleys.group/ today for more information.

0 notes

Text

Global Flame-Retardant Market Analysis by 2023-2032: AMR

0 notes

Text

The Rise of Sustainable Circuitry: Exploring Eco-Friendly Practices in PCB Manufacturing

In recent years, there has been a growing global concern regarding the environmental impact of various industries. One sector that has gained significant attention is the electronics industry, particularly in the manufacturing of printed circuit boards (PCBs). PCBs are integral components of electronic devices, ranging from smartphones and laptops to industrial machinery and medical equipment. As the demand for electronics continues to rise, it becomes crucial to explore eco-friendly practices in PCB manufacturing. This article delves into the emerging trend of sustainable circuitry and highlights the importance of adopting environmentally conscious approaches in the production of PCBs.

I. The Environmental Impact of Traditional PCB Manufacturing:

The conventional methods of PCB manufacturing have significant environmental consequences. The production processes involve the use of hazardous chemicals, such as lead, mercury, and brominated flame retardants (BFRs), which pose risks to human health and the ecosystem. Additionally, the energy consumption and carbon emissions associated with PCB manufacturing contribute to climate change. These factors have spurred the need for alternative practices that prioritize sustainability.

II. The Principles of Sustainable Circuitry:

Sustainable circuitry aims to minimize the environmental impact of PCB manufacturing through various principles:

a) Material Selection: One of the fundamental aspects of sustainable circuitry is choosing eco-friendly materials for PCB production. Opting for lead-free solder, recyclable substrates, and non-toxic coatings reduces the ecological footprint of the manufacturing process.

b) Waste Reduction: Sustainable circuitry emphasizes the reduction of waste generated during PCB manufacturing. Implementing efficient production techniques, recycling solder and unused materials, and proper disposal of hazardous waste are crucial steps in achieving this objective.

c) Energy Efficiency: Energy consumption plays a significant role in the environmental impact of PCB manufacturing. Sustainable practices focus on optimizing energy efficiency through process improvements, equipment upgrades, and the utilization of renewable energy sources.

d) Lifecycle Considerations: Sustainable circuitry takes into account the entire lifecycle of PCBs, including their disposal. Designing for disassembly and recyclability ensures that the materials used in PCBs can be recovered and reused, reducing the need for virgin resources.

III. Innovations in Sustainable Circuitry:

The pursuit of sustainable circuitry has driven innovations in PCB manufacturing. These advancements not only reduce environmental impact but also enhance the performance and longevity of electronic devices.

a) Green Chemistry: Green chemistry principles are being applied to develop eco-friendly alternatives to traditional PCB manufacturing chemicals. This includes the use of water-based fluxes and solder masks, as well as the development of halogen-free flame retardants.

b) Renewable Materials: Researchers are exploring the use of renewable materials, such as bioplastics and bio-based resins, as substitutes for conventional PCB substrates. These materials offer reduced environmental impact and can be derived from renewable resources.

c) Closed-Loop Manufacturing: Closed-loop manufacturing systems aim to minimize waste and resource consumption by recycling materials within the production process. This approach reduces the reliance on virgin materials and contributes to a more circular economy.

d) Life Cycle Assessment (LCA): LCA is a methodology used to evaluate the environmental impact of a product throughout its entire lifecycle. Applying LCA to PCB manufacturing allows for the identification of areas with the highest environmental impact, enabling targeted improvements and informed decision-making.

IV. The Role of Vishal International in Sustainable Circuitry:

Vishal International is at the forefront of promoting sustainable circuitry in PCB manufacturing. The company recognizes the importance of minimizing environmental impact and has implemented several eco-friendly practices.

a) Lead-Free Manufacturing: Vishal International utilizes lead-free solder in its PCB manufacturing processes. This eliminates the use of toxic materials and reduces the potential harm to both human health and the environment.

b) Energy Efficiency Measures: The company has invested in energy-efficient machinery and production techniques, reducing energy consumption and greenhouse gas emissions.

c) Waste Management: Vishal International emphasizes proper waste management, ensuring that hazardous materials are disposed of in compliance with environmental regulations. Additionally, the company actively promotes recycling and reuse of materials whenever possible.

d) Sustainable Material Choices: Vishal International prioritizes the use of eco-friendly materials in PCB manufacturing, such as recyclable substrates and non-toxic coatings. These choices contribute to the overall sustainability of their products.

Conclusion

As the demand for eco-friendly electronics grows, Vishal International's dedication to sustainable practices positions it as largest multilayer pcb manufcturers in India. By supporting companies like Vishal International, we can drive the transition toward a more sustainable and greener future in the electronics industry.

#multilayer pcb manufacturers in India#double sided pcb manufacturers in india#pcb suppliers in India

0 notes

Text

Insulated Wire & Cable Market Challenges, Analysis and Forecast to 2023-2032

The insulated wire and cable market is a significant sector within the electrical and electronics industry. Insulated wires and cables are used for various applications, including power transmission and distribution, telecommunications, automotive, aerospace, construction, and industrial machinery.

The insulated wire and cable market has been experiencing steady growth due to several factors:

Increasing Power Infrastructure: The need for efficient and reliable power transmission and distribution systems has driven the demand for insulated wires and cables. Infrastructure development projects, expanding renewable energy installations, and the modernization of existing power grids are contributing to market growth.

Growing Construction and Infrastructure Projects: The construction industry's expansion, including residential, commercial, and infrastructure projects, has increased the demand for electrical wiring systems, further fueling the insulated wire and cable market.

Advancements in Technology: Technological advancements have led to the development of improved insulation materials, such as XLPE, PVC, and halogen-free materials. These materials offer better electrical performance, higher temperature resistance, improved flame retardancy, and environmental sustainability, driving the market growth.

Automotive Electrification: The global shift towards electric vehicles (EVs) and hybrid electric vehicles (HEVs) has significantly impacted the insulated wire and cable market. EVs require a complex network of wiring systems for battery management, power electronics, and electric drivetrain components.

Increasing Telecommunication Infrastructure: The rapid expansion of telecommunication networks, data centers, and high-speed internet connectivity has led to a surge in demand for fiber optic cables and other specialty cables used in telecommunications.

I recommend referring to our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into the humidity sensors market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to the humidity sensors market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in the market.

Remember to look for recent reports to ensure you have the most current and relevant information.

Click Here, To Get Free Sample Report : https://stringentdatalytics.com/sample-request/insulated-wire-&-cable-market/843/

Market Segmentations:

Global Insulated Wire & Cable Market: By Company

Southwire

General Cable

LS Corporation

ABL Electronic Supplies, Inc.

AFC Cable Systems, Inc.

Amphenol Corp.

Asia Pacific Wire & Cable Corporation Limited

Belden, Inc.

Cable USA

Prysmian Group

Nexans

Furukawa Electric Co., Ltd.

Sumitomo Electric Industries, Ltd.

LS Cable & System Ltd.