#Halogen Free Flame Retardant

Explore tagged Tumblr posts

Text

Halogen Free Cables | HFFR, LSZH, FR and FRLSH Cable | LAPP India

Discover halogen-free cables for safer, eco-friendly installations only at LAPP India. High-quality solutions for various applications. Explore our range today!

Know more - https://e.lapp.com/in/c/cables-and-wires/power-and-control-cables/halogen-free-cables

#House Wire#Flame Retardant Low Smoke Halogen Free Cable#FR Cable#FRLSH Cable#Halogen Free Cable#Halogen Free Flame Retardant Cable#HFFR Cable#LSZH Cable

0 notes

Text

0 notes

Text

0 notes

Text

Electric Wire and Cable Burning Tester: Efficient Tool for Assessing Cable Non-Propagation of Flames

The electric wire and cable burning tester is a precision instrument specifically designed to determine the non-propagation of flames of cables under fire conditions. This equipment is suitable for various cable types including single plastic wires, control cables, cross-linked cables, elevator cables, ship cables, and mining cables. Additionally, it can conduct vertical burning tests for high self-extinguishing low smoke halogen-free flame-retardant polyolefin insulation materials and 105°C low smoke halogen-free flame-retardant irradiated polyolefin insulation materials. The design of the electric wire and cable burning tester adheres to the following national standards: • GBT 18380.11-2008 “Tests on electric cables and optical cables under fire conditions – Part 11: Test for vertical flame propagation for a single insulated wire or cable – Apparatus” • GBT 18380.12-2008 “Tests on electric cables and optical cables under fire conditions – Part 12: Test for vertical flame propagation for a single insulated wire or cable – 1 kW pre-mixed flame test method” Furthermore, this equipment is effectively compliant with the international standard IEC 60332-1/2, ensuring international applicability and accuracy of test results. RSB-WC Wire Cable Flame Tester Key Features • Automatic Ignition: Utilizes a high-voltage igniter for automatic ignition, ensuring ease of operation. Corrosion Resistance Design: Designed with a structure resistant to smoke corrosion, enhancing longevity. • High-Quality Components: Critical components are imported to ensure stability and reliability of the equipment. • Digital Display and Automatic Control: Equipped with digital display timing functions, the test procedure is fully automated for convenient operation. Operating Principle The electric wire and cable burning tester employs a control circuit to manage the application time of the flame and operational procedures. The device provides a flaming combustion source to ensure the accuracy and repeatability of tests. Applications The vertical burning tester for electric wires and cables finds wide application in the cable manufacturing industry, construction industry, and quality inspection organizations. Through vertical burning tests, it effectively assesses the safety performance of electric wires and cables under emergency conditions, providing essential guidelines for design, production, and usage. Moreover, this equipment is used for researching new flame-retardant materials, developing high-performance electric wire and cable products, and establishing relevant industry standards. Continual optimization and improvement of testing methods by the vertical burning tester contribute to enhancing the safety performance of electric wires and cables, reducing fire risks, and safeguarding life and property. Testing Procedure • Preparation: Ensure a safe test environment free of flammable materials and check the burning tester for integrity. Prepare the cable samples by cutting them to specified lengths and diameters. • Sample Installation: Secure the cable samples on the fixture of the burning tester in a vertical position. Adjust the burner position to a certain height above the cable. • Start the Test: Ignite the burner to initiate the cable burning. Observe and record parameters such as burning time, burning length, smoke density, etc. Maintain a safe distance during the test to avoid injury from sparks. • End the Test: Once the cable has burned completely or reached the predetermined time, turn off the burner and allow the sample to cool. Compile test data for analysis and evaluation of the cable’s burning performance. This systematic approach ensures thorough assessment of electric wire and cable fire safety characteristics, contributing to enhanced product reliability and safety in various applications. Read the full article

0 notes

Text

Flexible Packaging Market by Regions, Type & Applications During 2024-2030

Flexible Packaging Industry Overview

The global flexible packaging market size was estimated at USD 270.96 billion in 2023 and is expected to expand at a CAGR of 4.8% from 2024 to 2030. Increasing consumption of flexible packaging products in medical and pharmaceutical sectors is driving their demand. These products offer various advantages, such as container variety, need for less raw materials, ease of disposal, and lightweight nature, which are expected to fuel their demand over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Flexible Packaging Market

According to the Flexible Packaging Association, nearly 34.7 million tons of all produced food is sent to landfills annually. Food waste generates 27.0 million tons of carbon dioxide. In addition, there are other indirect effects of food production on the environment, which include the greenhouse gases generated from cattle breeding, farm machinery, vehicles that transport food, and nutrient runoff from fertilizers that often lead to water pollution.

Extending food shelf life is necessary to reduce the amount of food waste dumped in landfills. Oxygen and moisture affect the freshness of food products, thereby rendering them unsafe for consumption due to mold formation on food products. The shelf life of food products depends on factors such as storage conditions, packaging material, and exposure to microorganisms, oxygen, light, and moisture.

The flexible packaging consists of plastic films with high barrier properties. The high-barrier properties efficiently block the transmission of moisture, light, and oxygen from contacting sensitive foods. Furthermore, the reseal closure products featured by flexible packaging allow users to securely close the bags or pouches, ensuring the freshness of the packaged food products over several uses.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global phthalic anhydride market size was valued at USD 4.52 billion in 2023 and is projected to grow at a CAGR of 3.8% from 2024 to 2030. This growth is driven by significant industrial chemicals used as starting materials for manufacturing various chemicals and polymers.

• The global low smoke halogen free flame retardant polypropylene market size was valued at USD 637.1 million in 2023 and is projected to grow at a CAGR of 9.5% from 2024 to 2030. The market growth is attributed to the increased adoption of low-smoking halogen-free flame retardant polypropylene due to its low-smoking emission and environment-favoring properties.

Flexible Packaging Market Segmentation

Grand View Research has segmented the global flexible packaging market report based on material, product, application, and region

Flexible Packaging Material Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • Plastics o Polyethylene (PE) o Polypropylene (PP) o Polyamide (PA) o Polyvinyl Chloride (PVC) o Polystyrene (PS) o Others • Paper • Metal • Bioplastics

Flexible Packaging Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • Bags • Pouches o Retort Pouches o Refill Pouches • Rollstock • Films & Wraps • Others

Flexible Packaging Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • Food • Beverages • Pharmaceutical & Healthcare • Personal Care & Cosmetics • Others

Flexible Packaging Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • North America o US o Canada o Mexico • Europe o Germany o UK o France o Italy o Spain • Asia Pacific o China o India o Japan o South Korea o Australia o Indonesia o Malaysia o Philippines o Thailand o Vietnam o Myanmar • Central & South America o Brazil o Argentina • Middle East & Africa o Saudi Arabia o UAE o South Africa

Order a free sample PDF of the Flexible Packaging Market Intelligence Study, published by Grand View Research.

Key Companies profiled: • Amcor plc • Mondi Group • Huhtamaki Flexible Packaging • Sonoco Products Company • Sealed Air • DS Smith • Berry Global • Constantia Flexibles • Bemis Manufacturing Company • UkrMetal • ProAmpac • Wipak Group • FlexPak Services • Transcontinental Inc. • Coveris Holdings • American Packaging Corporation • InterFlex Group • FLEX-PACK ENGINEERING, INC. • Innovia Films • Cosmo Films • Novolex • Sigma Plastics Group • Graphic Packaging International, LLC • Bischof+Klein SE & Co. KG • Südpack

Recent Developments

• In May 2024, Amcor and AVON both combinedly launch the AmPrima Plus refill pouch for the AVON Little Black Dress classic shower gels in China. The recycle-ready packaging will result in an 83% reduction in carbon footprint, and 88% and 79% reduction in water consumption and renewable energy respectively when it's recycled.

• In August 2023, Amcor acquired Phoenix Flexibles, expanding its capacity in Indian market. Phoenix Flexibles is situated in Gujarat, India, and generates revenue of approximately USD 20 Mn per year from the sale of flexible packaging for food, home care and personal care applications. The acquisition also adds advanced film technology, enabling local production of a broader range of more sustainable packaging solutions, and brings capabilities allowing Amcor to expand its product offering in attractive high-value segments.

• In February 2023, Sealed Air acquired Liquibox for a purchase price of USD 1.15 Bn on a cash and debt-free basis. Liquibox is a pioneer, innovator and manufacturer of Bag-in-Box sustainable fluids & liquids packaging and dispensing solutions for fresh food, beverage, consumer goods and industrial end-markets.

0 notes

Text

Electronic Thin Wall Heat Shrink Tubing ,Sizes ranging from 0.5 to 180mm, shrink ratio 2:1 &3:1, Color Black, Red,Brown,Orange,Yellow,Green,Yellow/Green,Blue,Purple,Gray, White,Pink,Clear

A thin wall, flexible, low-smoke emissions, halogen-free, flame-retardant polyolefin heat shrinkable tube.Suitable for insulation protection, parts identification, mechanical protection, bundling of wires, wire harnesses, and electronic components.

0 notes

Text

Electrical Safety Tips For The Workplace

Electrical Safety Tips

The ever-increasing number of electrical appliances and systems in our homes and commercial spaces has substantially increased the risk of electrical fires. However, by following essential electrical safety tips and utilizing advanced technology and high-quality cables, we can effectively manage these risks.

Electrical safety tips often highlight that overloading circuits, faulty connections, and the use of substandard electrical products can lead to overheating, sparks, and disastrous fires. This underscores the importance of using high-quality, modern cables designed to withstand the demands of today’s electrical systems. Compared to their conventional counterparts, these cables feature enhanced insulation materials that reduce heat generation and support higher current loads without degradation. For instance, halogen-free wires not only offer superior flame-retardant properties but also minimize toxic gas emissions during a fire, thus aiding in safer evacuations.

Today, technology plays a crucial role in electrical safety tips. Advanced gadgets like surge protectors safeguard electronic devices from voltage spikes that occur during power surges. Additionally, integrated circuit breakers and isolators automatically cut off power in the event of an overload or short circuit, effectively preventing potential fire hazards.

Adopting best practices is vital in electrical safety tips to alleviate fire risks. Proper installation and maintenance are key aspects. Ensure all electrical connections are secure and free from defects. Periodic inspections by qualified professionals can help detect and prevent potential fire hazards. As part of electrical safety tips, proper circuit management is essential. Ensure electrical loads are evenly distributed by keeping separate circuits for different types of appliances. This approach not only enhances safety but also prolongs the lifespan of your electrical systems.

Electrical safety tips also emphasize the importance of building-specific cable usage. According to relevant standards, retardant low smoke and low halogen power cables are required in buildings over fifteen meters in height. Flame-retardant power cables are mandated for airports, hotels, and hospitals regardless of building height.

Using certified products is another crucial aspect of electrical safety tips. Certified products ensure approved design and testing. Wires and cables meeting REACH and RoHS standards are free from hazardous substances like lead, mercury, and phthalates, making them the safest choice. Avoid using non-standard electrical products that do not meet safety standards.

Finally, educating household members and employees in commercial spaces about electrical safety tips—including the dangers of overloading circuits and proper use of electrical outlets—helps prevent fires. By prioritizing these safety measures, we can significantly reduce the risk of electrical fires in both residential and commercial spaces.

0 notes

Text

HALOGEN-FREE FLAME RETARDANT MASTERBATCH PP MASTER BATCHES

0 notes

Text

Zero Halogen Cables: Ensuring Safety and Reliability

In the world of modern infrastructure and technology, safety and reliability are paramount. One innovation that significantly enhances both is the use of zero halogen cables. These cables are designed to reduce the risks associated with fire hazards and improve environmental safety. In this blog, we will explore the benefits, applications, and features of zero halogen cables, and why they are the preferred choice for many industries.

What are Zero Halogen Cables?

Zero halogen cables are made from materials that do not contain halogens, such as chlorine, fluorine, bromine, iodine, and astatine. When exposed to high temperatures or flames, these cables emit minimal smoke and no toxic or corrosive gases. This makes them an ideal choice for environments where safety is a critical concern.

Benefits of Zero Halogen Cables

Reduced Toxicity:

Traditional cables made with halogens can release harmful gases when burned, posing significant health risks. Zero halogen cables mitigate this danger by emitting low levels of smoke and toxic substances.

Improved Fire Safety:

Zero halogen cables are designed to be flame-retardant, reducing the spread of fire. This feature is crucial in maintaining the integrity of safety systems during emergencies.

Environmental Safety:

Halogens can be harmful to the environment, particularly when cables are disposed of or incinerated. Zero halogen cables are more eco-friendly, contributing to a safer and healthier planet.

Corrosion Resistance:

In the event of a fire, halogen-free cables produce non-corrosive gases, protecting nearby equipment and structures from damage.

Applications of Zero Halogen Cables

Zero halogen cables are used in various industries and settings where safety and reliability are of utmost importance:

Public Buildings:

In places like schools, hospitals, and airports, the use of zero halogen cables ensures the safety of occupants by reducing the risks associated with toxic smoke and fire spread.

Transportation:

Railways, subways, and ships often use zero halogen cables to enhance passenger safety and protect critical infrastructure from fire hazards.

Industrial Facilities:

Factories and plants with sensitive equipment and materials benefit from the use of zero halogen cables due to their low smoke emission and non-corrosive properties.

Data Centers:

Protecting valuable data and ensuring uninterrupted service is vital in data centers. Zero halogen cables provide a safer environment for both equipment and personnel.

Key Features of Zero Halogen Cables

Low Smoke Emission:

In the event of a fire, zero halogen cables produce significantly less smoke, improving visibility and reducing the risk of inhalation injuries.

Flame Retardant:

These cables are designed to resist ignition and prevent the spread of fire, enhancing overall fire safety.

Non-Toxic Gases:

By eliminating halogens, these cables do not emit harmful gases, ensuring the safety of people and equipment in the vicinity.

Durability and Reliability:

Zero halogen cables are built to withstand harsh conditions, making them a reliable choice for critical applications.

Why Choose Qflx Zero Halogen Cables?

At Qflx, we prioritize safety, quality, and performance. Our zero halogen cables are engineered to meet the highest industry standards, ensuring they deliver exceptional safety and reliability. Whether you are looking to upgrade your current infrastructure or planning a new installation, Qflx zero halogen cables provide the peace of mind that comes with superior fire safety and environmental responsibility.

Conclusion

Zero halogen cables are a crucial advancement in ensuring the safety and reliability of electrical systems across various industries. By reducing the risks associated with fire hazards and toxic emissions, these cables offer unparalleled protection for both people and equipment. At Qflx, we are committed to providing top-quality zero halogen cables that meet the diverse needs of our clients. Contact us today to learn more about our products and how they can enhance the safety and performance of your systems.

0 notes

Text

Global Bio-based Polycarbonate Market Assessment, Opportunities and Forecast, 2030

Bio-based Polycarbonate Market size was valued at USD 75.28 million in 2022, expected to reach USD 145.65 million in 2030 with a CAGR of 8.6% for the forecast period between 2023 and 2030. Conventional polycarbonate resins are made from bisphenol A, which raises the concerns of sustainable goals and innovation shifted to derive alternate polycarbonate from bio or natural resources. Polycarbonates have many applications used alone or blended for numerous sectors like electronics, automotive, housewares, etc. Being produced from natural resources, the features of polycarbonates got enhanced, like delivering excellent optical properties, chemical & UV resistance, higher surface resistance, etc.

Sample report- https://www.marketsandata.com/industry-reports/bio-based-polycarbonate-market/sample-request

Electronics Industry is Augmenting the Bio-based Polycarbonate Market While Concerning the Sustainable Goals

Bio-based polycarbonate copolymer drives the electronics industry by providing sustainable materials and achieving net-zero carbon emissions. It is successively used as a smartphone battery cover, which should be certified by prominent certifications. The bio-based polycarbonate is made of a minimum composition of natural polymers and a maximum content of post-consumer products. Such effective polycarbonates assist in thin-wall injection molding for numerous applications, including electrical housings or health care. SABIC has developed high-performance bio-based polycarbonate that comprises around 21% natural polymers (like vegetable oils) and over 50% post-consumer recycled resin, along with pre-consumer recycled carbon fibers. Substantially the product is halogen free and PIN flame retarded and progressively used for electronics packaging.

Data released by the Static PIB states that the global market industry in 2020 is dominantly estimated at around USD 2.9 trillion, which is almost equivalent to India’s economy. India is growing exponentially, creating a huge production potential of around USD 25 billion in the electronics industry, around 12% of global investment. A survey data published by the Japan Electronics and Information Technology Industries Association JEITA states that the global electronics and IT industries are estimated to rise 5% in 2022, total to USD 3,536.6 billion.

Automotive Industry is Propelling Exceptionally using Bio-based Polycarbonates

Bio-based polycarbonate possesses unique features like incredible optical properties, high transparency, and phenomenal scratch resistance. These properties are substantially important in the perspective of automotive vehicles. Plant-derived polycarbonates are contributing to developing enhanced vehicle features and appearance with extended durability. These polymer formulations develop additional sustainable benefits supporting the economy and reducing product carbon footprint. Mitsubishi Chemical has developed excellent plant-based bicarbonate resin extensively used for automotive exterior and interior parts. Plant-based isosorbide polycarbonates have excellent optical properties and retain high surface hardness and transparency characteristics, imparting vivid colors in the transparent panels.

The demand for cars in South America has increased by 1.8%, accounting for 2.8 million units sold in 2022, where Brazil is contributing majorly to such a segment. In 2022, Indian passenger car sales rose by 23.1%, achieving 3.8 million units due to effective measures taken by the Indian government like lower interest rates. Taking account of 2023, the outlook for the European market is convincingly showing positive trends to create huge growth for the automotive industry.

Roofing Solutions has Effectively Improved by Incorporating Bio-based Polycarbonates

Bio-based Polycarbonate have successively enhanced the roofing and sliding solution from huge malls to large stadiums. The selection of high-strength and durable panels that enable varying heat and light intensity can lead to the proper architecture of such massive constructions. Palram Industries Ltd. is successfully manufacturing polycarbonate flat and corrugated panels for a wide range of applications. Its unique roofing and sliding solutions use proprietary SolarSmart technology which effectively facilitates light penetration selectively. From building huge malls to advancing world-class Olympic stadiums, they have numerous accountings of such projects that provide thermal insulation, heat blocking, chemical resistance, light transmission, and diffusion.

Annual report published by Stadiums Queensland (SQ) stated that during 2021-2022, Stadiums Queensland (SQ) hosted more than 3.4 million patrons across entire venues that substantially contributed more than USD 646 million in economic benefit to the Queensland economy and created around 5,717 FTE jobs for various event-related industries including cleaning, catering, and security.

Impact of COVID-19

The outbreak of COVID-19 has severely impacted numerous sectors and human livelihoods, where every person was vulnerable to infectious disease. The fight against COVID-19 was a challenging operation that evolved every sector to contribute their practices and eradicate the impact. Bio-based polycarbonates are important for developing effective solutions in numerous applications, especially automotive and construction. The pandemic impact was extended to these significant sectors, leading to a complete shutdown of manufacturing units and the delivery of new cars. But after the pandemic, companies invested more to recover the loss during a pandemic, and construction practices also resumed. Therefore, the market for bio-based polycarbonates is on the verge of growing exponentially with such enormous applications.

Bio-based Polycarbonate Chemical Market: Report Scope

“Bio-based Polycarbonate Market Assessment, Opportunities and Forecast, 2016-2030F”, is a comprehensive report by Markets and data, providing in-depth analysis and qualitative & quantitative assessment of the current state of the Bio-based Polycarbonate Market, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities and forecast between 2023 and 2030. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/bio-based-polycarbonate-market

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

0 notes

Text

Halogen-Free Cables: Everything You Need to Know

As we prioritize safety and sustainability in electrical installations, halogen-free cables have emerged as a vital component in modern wiring systems. These cables not only improve safety but also comply with stringent environmental standards. In this blog, we’ll explore what halogen-free cables are, their advantages, and why they are essential for the future of wiring.

What Are Halogen-Free Cables?

Halogen-free cables are designed to eliminate the release of harmful halogen gases during combustion. Traditional cables, when exposed to fire, can emit toxic fumes that pose serious health risks. In contrast, halogen-free cables use materials such as thermoplastic elastomers (TPE) and polyolefins, ensuring safer conditions in the event of a fire. This unique feature makes them ideal for various applications, especially in safety-sensitive environments.

Flame Retardant Low Smoke Halogen-Free Cables

One of the most significant advancements in halogen-free cable technology is the creation of flame retardant low smoke halogen-free cables, commonly known as FR cables. These cables are engineered to resist ignition and limit flame spread, significantly reducing smoke production when exposed to fire. This characteristic is crucial in high-occupancy buildings like schools, hospitals, and offices, where smoke inhalation can be even more dangerous than fire itself. By incorporating FR cables, construction projects can enhance safety and meet regulatory requirements.

Growing Demand for Safety and Compliance

The global emphasis on safety and environmental compliance has fueled the adoption of halogen-free cables. Regulatory bodies are tightening fire safety and emission standards, making it essential for industries to adapt. Halogen-free cables are no longer just an option; they are becoming a necessity to ensure the safety of occupants and workers. As we focus more on building safety, integrating halogen-free cables into electrical installations is a proactive step toward a safer future.

Innovations in Cable Design

The future of halogen-free cable technology is marked by ongoing innovation. Manufacturers are continually enhancing the durability and flexibility of these cables, making them suitable for a wide range of applications. Recent advancements in materials science have led to cables that can withstand extreme temperatures and harsh conditions. This versatility is invaluable, allowing for use in industrial machinery, outdoor installations, and complex building systems.

Enhanced Performance Characteristics

Modern halogen-free cables offer improved performance characteristics that expand their usability. These cables now feature enhanced resistance to chemicals, abrasion, and UV light, making them ideal for outdoor and industrial environments. Their resilience ensures they maintain performance over time, even under challenging conditions. This durability makes halogen-free cables a wise investment for any wiring project.

Integration with Smart Technologies

As smart building technologies evolve, the importance of halogen-free cables becomes increasingly evident. Smart buildings require reliable and efficient wiring solutions to support advanced technologies like IoT devices and automation systems. Halogen-free cables provide the necessary safety and performance features to support these innovations, establishing them as a crucial component of future smart infrastructure.

Eco-Friendly Alternatives

Sustainability is now a requirement in the manufacturing landscape. Manufacturers of halogen-free cables are increasingly focused on using recyclable materials and environmentally responsible production methods. This commitment to sustainability aligns with consumer preferences and sets a standard for responsible product development. As demand for greener options grows, the shift towards eco-friendly alternatives in halogen-free cable technology becomes more critical.

Conclusion

Halogen-free cables, particularly flame retardant low smoke options, are leading the way in modern electrical wiring solutions. Their safety benefits, regulatory compliance, and compatibility with advanced technologies make them indispensable in today’s construction and manufacturing environments. As the industry continues to innovate, we can anticipate further advancements that will enhance the performance and sustainability of these cables. For anyone involved in electrical installations, understanding the importance of halogen-free cables is essential for ensuring safety, compliance, and efficiency in projects.

0 notes

Text

TSTCABLES 10 Tips for B-Side Purchasing Demystifying High Temperature Cable Shopping Tips

I. High temperature cable Overview

High temperature cable is a special type of cable that can work normally in a high-temperature environment, and can usually withstand high temperatures above 200°C. Even some types of high-temperature cables can safely and stably transmit power signals and data signals at temperatures as high as 600°C or higher. Such cables have the following characteristics and uses:

Second, high temperature cable product characteristics

High temperature resistance: can operate stably in environments up to hundreds of degrees Celsius.

Anti-corrosion and anti-corrosion: Long-term performance in corrosive environments.

High efficiency and low consumption: special design to reduce energy consumption and enhance energy efficiency.

Strong anti-interference: Super anti-interference (EMI) shielding ability to ensure stable signal transmission in high temperature and electromagnetic interference environment.

High safety: low smoke and halogen-free flame retardant, reducing fire and other safety risks.

Long life: reduce the frequency of replacement, reduce maintenance costs.

Third, high temperature cable product standards

The production and testing of high-temperature cables follow strict standards. For example, according to the national standard GB12666.6-90, the long-term use of high-temperature cables can reach a working temperature of 200 ℃, and the short-term use of the temperature can even reach 1000 ℃. In addition, the products have passed a number of international certifications, such as CE, EN (EN 50264, EN50382, EN50306) certification, etc., to ensure their quality and safety.

Four, High-temperature cable application cases and scenes

Industrial production of High-temperature cable

Iron and steel smelting: high-temperature cables transmit power and data in steel furnaces and high-temperature production lines to ensure continuous production. Glass manufacturing: used in high-temperature furnaces to ensure the stability and safety of the production process.

Petrochemical High-temperature cable

Chemical reactors: connecting high-temperature reaction equipment and control systems to ensure precise control of chemical reactions.

Pipeline Conveying: Used in high temperature fluid conveying and monitoring systems.

Power and Energy High Temperature Cables

Solar power generation: connecting solar panels and inverters for efficient transmission of electricity.

Wind power generation: in wind turbines to ensure stable transmission of power in high temperature and high humidity environments.

Aerospace High Temperature Cables

Aero-engine: Ensure stable transmission of power and signal under extreme high temperature and vibration environment.

Satellite communication: in the space environment, to provide stable power and data transmission support.

Transportation High Temperature Cables

High-speed trains: Ensure stable power and signal in high temperature, high humidity and vibration car environment.

Electric Vehicle Charging: Support high temperature environment power transmission in fast charging station.

Medical Equipment High Temperature Cables

Medical equipment connection: Ensure stable power and signal transmission in high temperature sterilization and surgical equipment.

Military & Defense High Temperature Cables

Missile Systems: Ensure stable operation of missile systems under extreme conditions.

Mobile equipment: provide stable power support for military mobile equipment.

high temperature resistant cables

V. B-end buyers procurement to avoid the pit guide: High Temperature Cables 10 purchase skills

TST CABLES(www.tstcables.com) senior engineers summarized ten tips for you, I hope to help you choose high-quality high-temperature cables, if you want to buy cables do not step on the pit, pay attention to TST CABLES on the line.

Define the temperature range of high-temperature cables: Need to understand the maximum temperature and duration of the required high temperature cable can withstand, to ensure the safe operation of the cable in a high temperature environment.

Select the appropriate high temperature cable material: According to the different needs of the use of the environment, select the appropriate high temperature cable insulation materials and sheath materials, such as silicone rubber, graphitized polyimide, fluoroplastics, etc. These materials can maintain excellent electrical properties and mechanical strength at high temperatures.

Consider high temperature cable structure and size: The structure of high-temperature cables should meet the requirements of specific environments, such as high-temperature resistance and corrosion resistance.

The size and length of the cable should ensure that it can be adapted to the requirements of the equipment, while taking into account the bending radius and installation space.

High-temperature cable core number and cross-sectional area: According to the specific needs of the appropriate number of cores and cross-sectional area to meet the needs of high-power electrical equipment.

Focus on the safety of high-temperature cables: Select high temperature cables that meet the relevant standards and regulations, such as with UL, CE, EN and other certifications to ensure the safety performance of the cable.

Understand the high-temperature cable technical standards: Familiarize yourself with the relevant technical standards at home and abroad, such as IEC or specific national standards, to ensure that the cable purchased meets the specification requirements.

Consider the special environmental conditions of high-temperature cables: Cables used in special environmental conditions (such as high temperature, high humidity, corrosion, etc.) need special attention to their weather resistance and corrosion resistance.

High-temperature cable packaging and transportation: For high temperature cables exported or transported over long distances, the packaging should be tight and in accordance with international transportation standards to reduce the risk of damage during transportation.

High-temperature cable supplier technical information and certification: Ensure that high temperature cable suppliers provide complete technical information and certification documents, so that there is a clear reference and guidance in the process of use.

Consider High Temperature Cables supplier after-sales service: Choose high temperature cable manufacturer with good after-sales service, TST CALBES is a one-on-one engineer to provide full after-sales guidance, so that when problems arise during the use of the cable can be resolved in a timely manner.

TST CALBES engineers suggest that you need to consider many aspects when purchasing high-temperature cables, including the temperature range of the cable, the choice of materials, structure and size, safety, and the supplier’s after-sales service. Through careful comparison and selection, you can ensure that you get the right high temperature cable for your specific working environment, thus guaranteeing the stability and safety of power transmission.

High Temperature Cables Manufacturer TST CABLES

TST CABLES High Temperature Cables, stable transmission, in control! TST CABLES High Temperature Cables are made of high standard military materials, with excellent moisture-proof, anti-corrosion, anti-damage, anti-radiation, low-smoke, halogen-free, flame-retardant characteristics, to ensure stable and error-free signal transmission. The multi-core design meets the needs of complex circuits, making your industrial automation, energy transportation, aviation, nuclear power, wind power, ships and other projects more reliable and efficient. Strictly enforcing several national standards and passing multiple quality tests, it guarantees the stable operation of your project.

TST CABLES–Specializing in high temperature resistant cable applications and solutions.

For more information on railway cables, Silicone Cables, marine cables, low-smoke, halogen-free, flame-retardant, high temperature resistant cables or to customize cables for your machinery or system, visit https://www.tstcables.com/product/ orsend an e-mail to:[email protected]

0 notes

Text

0 notes

Text

CHT at the Techtextil

The CHT Group focuses on tailor-made and modern product and process solutions to optimize the performance and functionality of technical textiles. The CHT Group's product portfolio includes water-based as well as silicone-based (e.g. LSR) finishing and coating systems that enable new innovative functionalities. And all from a single source.

Products from the TUBCOSIL range are LSR coatings that can be applied to almost all textiles and nonwovens. Thanks to their exceptional material properties, they can meet the highest technical requirements in terms of durability, mechanics, feel and appearance. TUBCOSIL products are solvent-free and therefore also interesting from an ecological point of view.

The circular economy is an important part of our corporate strategy. This is also reflected in our product developments.

A single-variety end product (e.g. carpets, filters, luggage nets, etc.) can be easily recycled and can therefore be returned to the material cycle. Our TUBICOAT PET line has been specially developed for single-variety materials based on polyester (PES).

TUBINGAL RISE is CHT Group's first textile softener made from recycled silicones. In keeping with the circular economy, "end-of-life" silicones are recycled and formulated with emulsifiers from renewable raw materials to create a new hydrophilic softener. Its product quality is identical to a silicone softener made from primary raw materials - only more sustainable. TUBINGAL RISE is suitable for all fiber types.

Similarly, the CHT Group has developed the product ARRISTAN rAIR according to the principles of the circular economy. Here, plastic waste is converted into a high-quality textile finishing product, for example to achieve optimum moisture management in sports and activewear. Other areas of application include socks and tights in the clothing sector, filtration media and nonwovens in the technical textiles sector and cushions and curtains in the home textiles sector. As ARRISTAN rAIR is made from recycled PET flakes, it is suitable for finishing recycled yarns and fabrics, which can then be recycled again. In addition to the positive properties already mentioned, the hydrophilizing agent ARRISTAN rAIR is characterized by its quick-drying properties in combination with excellent soil release and thermoregulation. It therefore offers optimum functionality for high-quality and durable sportswear, especially in the area of functional textiles.

POLYAVIN bPEN is CHT’s new plug-in solution to replace fossil feedstock. This takes the use of polyethylene-based products in the textile chain to the next level by using bio-based raw materials that bind carbon dioxide from the atmosphere. POLYAVIN bPEN is the first finishing agent with a carbon uptake. POLYAVIN bPEN is a versatile lubricant. The product can be used as a processing aid to reduce yarn friction, to prevent sewing damage during confection, to achieve uniform raising effects and to support compressive shrinkage during sanforizing/compacting of fabrics. POLYAVIN bPEN is also excellently suited as a performance additive to increase tear and abrasion resistance and to variate haptic effects. In combination with calandering processes, the product acts as a gloss enhancer to create high-quality surface effects.

Products from the APYROL range are flame retardants that delay the spread of flames in the event of a fire, thus giving people at risk more time to rescue or extinguish the fire or to escape. In addition to their effectiveness in the event of fire, modern flame retardants are also subject to increasingly stringent requirements in terms of environmental compatibility. This applies to everything from production and processing all the way to application. The CHT Group mainly offers antimony/halogen-free products, so-called "green" flame retardants.

Highly effective PFC-free water repellents (DWR), some with a high proportion of bio-based components, for a wide range of applications can be found in the ECOPERL product range. The suitability for various standards such as ZDHC, bluesign, GOTS, Oeko-Tex Standard 100 as well as a Material Health Certificate for Cradle to Cradle are a matter of course and underline the CHT Group's commitment to sustainability.

The new PFC-free water-repellent range under the name ECOPERL COAT represents a further development, especially for the requirements of water-based coatings. Here, the experience gained from years of developing classic PFC-free water repellents and many years of experience in the field of water-based coating systems come together.

The TUBICOAT PU ECO range includes bio-based coating solutions made from water-based polyurethane dispersions.

Visit us from 23 to 26 April 2024 at our booth B11 in Hall 11.0 at Techtextil in Frankfurt on the Main and convince yourself of our intelligent auxiliaries for technical textiles.

0 notes

Text

Alumina Trihydrate, Global Market Size Forecast, Top 5 Players Rank and Market Share

Alumina Trihydrate Market Summary

Alumina trihydrate is produced synthetically from bauxite. The outstanding features of aluminium hydroxide are flame retardance (dehydration at 200°C), high whiteness and low hardness. Alumina trihydrate is regarded as being the most important mineral flame retardant in the world and, thanks to its freedom from halogens, it is environmentally friendly and is characterized by its high efficiency as a smoke gas suppressant. This mineral is made from bauxite in accordance with the Bayer process.

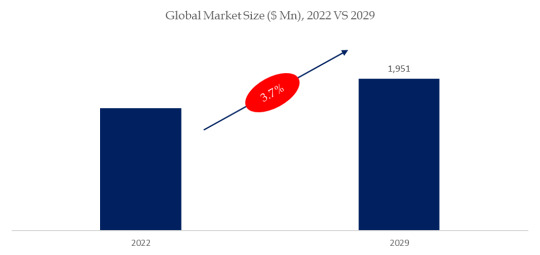

According to the new market research report “Global Alumina Trihydrate Market Report 2023-2029”, published by QYResearch, the global Alumina Trihydrate market size is projected to reach USD 1951.2 million by 2029, at a CAGR of 3.7% during the forecast period.

Figure. Global Alumina Trihydrate Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

Market Drivers:

Growing economies in regions like Asia-Pacific and Latin America are driving increased construction and industrial production, which, in turn, boosts the demand for alumina trihydrate.

There is a growing trend towards using halogen-free flame retardants, including alumina trihydrate, due to concerns about the toxicity and environmental impact of halogenated flame retardants. This shift is driven by regulatory changes and consumer preferences for safer materials.

Restraint:

Alumina trihydrate is typically produced from bauxite ore, and its cost is influenced by fluctuations in the prices of bauxite and other raw materials. Price volatility can affect the profitability of manufacturers and make it difficult to plan for stable production costs.

The alumina trihydrate market is competitive, with several key players operating globally. Intense competition can lead to price wars and reduced profit margins for manufacturers.

Increasing health risks, primarily due to exposure to aluminium trihydrate, are expected to hinder the growth of the market studied.

Opportunity:

Alumina trihydrate is widely used as a flame retardant in plastics, textiles, and other materials. With increasing awareness of fire safety and stricter regulations, the demand for flame retardant materials has been on the rise. This trend is expected to continue as safety standards become more stringent.

Environmental regulations and consumer preferences for eco-friendly products have put pressure on manufacturers to develop more sustainable processes for producing alumina trihydrate. This includes reducing emissions, minimizing waste, and sourcing raw materials responsibly.

Innovations in production technologies have led to more efficient and cost-effective methods of producing alumina trihydrate. These advancements can impact the industry by improving product quality and reducing production costs.

Figure. Alumina Trihydrate, Global Market Size, The Top Five Players Hold 57% of Overall Market

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

This report profiles key players of Alumina Trihydrate such as Huber, CHALCO, Nabaltec, Luoyang Zhongchao, KC Corp.

In 2022, the global top five Alumina Trihydrate players account for 57% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Alumina Trihydrate.

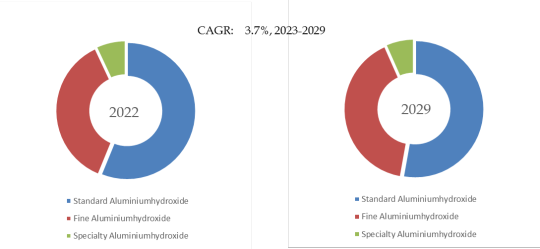

Figure. Alumina Trihydrate, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

In terms of product type, Standard Aluminiumhydroxide is the largest segment, hold a share of 56.2%.

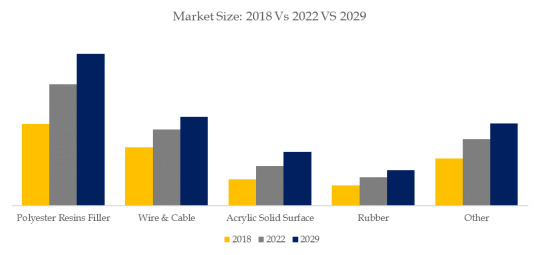

Figure. Alumina Trihydrate, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

In terms of product application, Polyester Resins Filler is the largest application, hold a share of 36.5%.

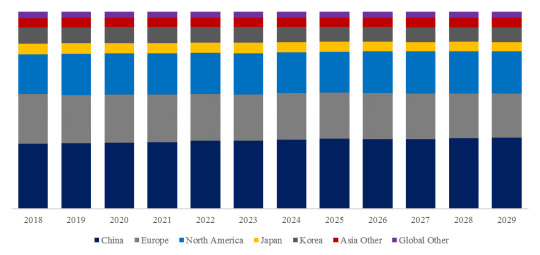

Figure. Alumina Trihydrate, Global Market Size, Split by Region (Production)

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

About The Authors

Lu Jing - Lead Author

Email: [email protected]

Lu Jing is a technology & market senior analyst specializing in chemical, advanced material, and component. Lu has 9 years’ experience in chemical and focuses on catalyst and additive, metal and plastic materials, waste recycling, daily chemicals. She is engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

GJYXCH FTTH Fiber Drop Cable

FTTH Fiber Drop Cable places optical fiber in the center. Two parallel reinforcements (FRP, steel wire) are placed on both sides, and finally, a black or colored low-smoke halogen-free flame retardant sheath is extruded into a cable.

0 notes