#Global Rust Preventive Oil Market

Explore tagged Tumblr posts

Text

Buy SS 304 Blind Flange | Lowest Price in India

SS 304 Blind Flanges are a vital component for industrial piping systems, known for their durability, corrosion resistance, and strength. These flanges, made from stainless steel grade 304, are designed to seal the ends of pipes or valves, making them ideal for industries such as oil and gas, chemical processing, water treatment, and more. For businesses in India, finding SS 304 Blind Flanges at the lowest price is essential for minimizing operational costs while ensuring high-quality performance. With a wide range of suppliers offering competitive pricing, it's easier than ever to source these flanges at the best rates.

What is SS 304 Blind Flange?

SS 304 Blind Flanges are flat, circular components used to close off the ends of pipelines, valves, or pressure vessels. Unlike other flanges, the blind flange does not have a central bore, meaning it completely blocks the flow of liquid or gas through the pipe. This makes it useful for isolating sections of a piping system for maintenance, testing, or system shutdowns.

The material used in these flanges—stainless steel grade 304—is an austenitic alloy with high chromium (18%) and nickel (8%) content. This composition gives SS 304 its excellent corrosion resistance, making it a perfect choice for harsh industrial environments where chemicals, moisture, and high temperatures are present.

Benefits of SS 304 Blind Flange

1. Outstanding Corrosion Resistance: The SS 304 Blind Flange’s high chromium content allows it to form a passive layer of chromium oxide on its surface, which prevents rust and corrosion. This makes it ideal for use in chemical processing, oil refineries, water treatment plants, and other industries that deal with corrosive environments.

2. High Strength and Durability: SS 304 Blind Flanges are designed to withstand extreme pressures and temperatures. This makes them suitable for high-pressure applications, including oil and gas pipelines, steam systems, and heavy-duty processing plants. Their durability ensures long-term performance without frequent replacements, reducing maintenance costs.

3. Low Maintenance: Due to its superior resistance to corrosion and wear, SS 304 Blind Flanges require minimal maintenance compared to other materials. This makes them a cost-effective choice for industries where reliable performance and low upkeep are critical.

4. Versatile Applications: SS 304 Blind Flanges are used across a wide range of industries. They are suitable for temporarily sealing off pipelines during repairs or permanently closing off systems. Their versatility makes them valuable in oil and gas, petrochemical, marine, pharmaceutical, food processing, and water treatment industries.

Why Buy SS 304 Blind Flanges in India?

India is home to a vast array of suppliers and manufacturers offering SS 304 Blind Flanges at competitive prices. Buying locally ensures that you have access to high-quality products that meet Indian and international standards, such as ASTM or ASME certifications. Here are a few reasons why purchasing SS 304 Blind Flanges in India makes sense:

1. Cost-Effective Pricing: Indian suppliers offer some of the most competitive prices in the global market for SS 304 Blind Flanges. Whether you're looking to buy in small quantities or bulk, Indian manufacturers provide quality products at reasonable rates, often with the option to negotiate prices for large orders.

2. Fast Delivery and Local Availability: When you buy from Indian suppliers, you benefit from faster delivery times and lower shipping costs, especially for domestic orders. Many suppliers have stock readily available, ensuring that you can meet your project deadlines without delays.

3. Industry-Standard Certifications: SS 304 Blind Flanges manufactured in India often adhere to industry standards such as ASTM, ASME, or DIN. These certifications guarantee that the flanges meet the required quality and performance specifications, ensuring safety and reliability in industrial applications.

4. Bulk Discounts: Many suppliers in India offer discounts on bulk orders, making it more affordable for businesses that need large quantities of SS 304 Blind Flanges. Bulk purchasing not only reduces the unit price but can also lead to savings on transportation and logistics.

Applications of SS 304 Blind Flange

SS 304 Blind Flanges are used in various industrial settings due to their robust and corrosion-resistant properties. Common applications include:

Oil and Gas Industry: SS 304 Blind Flanges are used to close off pipeline sections during repairs or testing, especially in environments where corrosion is a concern.

Chemical Processing: In chemical plants, these flanges are used to block pipes that carry corrosive fluids, ensuring the system remains secure and sealed.

Water Treatment Plants: SS 304 Blind Flanges help in sealing off sections of water pipelines, providing a rust-resistant solution for water treatment facilities.

Marine Applications: Due to their resistance to seawater corrosion, SS 304 Blind Flanges are used in marine environments, including shipbuilding and offshore drilling operations.

Pharmaceutical and Food Industry: The non-reactive and hygienic properties of SS 304 make it an excellent choice for industries that require clean and sterile processing, such as pharmaceuticals and food manufacturing.

Tips for Finding SS 304 Blind Flanges at the Lowest Price in India

1. Compare Multiple Suppliers: When purchasing SS 304 Blind Flanges in India, it’s important to compare prices from several suppliers. This will allow you to find the most competitive pricing while ensuring the quality of the product.

2. Look for Bulk Discounts: If your project requires a large quantity of flanges, ask suppliers about bulk pricing. Many manufacturers offer substantial discounts for large orders, helping you reduce the cost per unit.

3. Check for Certifications: Make sure the supplier offers SS 304 Blind Flanges that meet industry standards like ASTM, ASME, or DIN. Certified products provide assurance that the flange will perform under the required conditions.

4. Negotiate for Better Pricing: Negotiation is common in the industrial supply market. If you’re placing a large order or planning a long-term partnership, don’t hesitate to ask for better terms or discounts.

5. Look for Seasonal or Promotional Offers: Some suppliers may offer seasonal discounts or promotional deals on SS 304 Blind Flanges. Stay on the lookout for such opportunities to get the best value for your money.

#SS304BlindFlange#BuySS304Flange#StainlessSteelFlange#IndustrialFlange#CorrosionResistantFlange#LowestPriceInIndia#PipelineSolutions#OilAndGasFlange#MarineFlange#WaterTreatmentFlange#BuyNow#IndiaFlangeDeals

5 notes

·

View notes

Video

youtube

Top 5 Materials for Patio Furniture Sets

When it comes to furnishing your outdoor space, selecting the right material for your patio furniture is crucial for both aesthetics and longevity. From the classic charm of wrought iron to the modern appeal of aluminum, each material offers unique benefits click here and styles. In this article, we'll explore the top five materials for patio furniture sets, providing insights into their durability, maintenance, and design potential, to help you create the perfect outdoor retreat.

Aluminum: Lightweight and Rust-Resistant

Aluminum patio furniture is a popular choice for its lightweight, durable, and rust-resistant properties. It's ideal for those who frequently rearrange their outdoor spaces due to its ease of mobility. Aluminum sets are available in a variety of styles, ranging from traditional to contemporary, ensuring they can complement any outdoor décor. These sets often come with powder-coated finishes in a spectrum of colors, enhancing their resistance to the elements and aligning with your color scheme.

According to a report by Grand View Research, the global aluminum outdoor furniture market size was valued at USD 4.09 billion in 2018 and is expected to grow, indicating a strong consumer preference for this material. The maintenance of aluminum furniture is straightforward, typically requiring just soap and water for cleaning.

Wicker: Classic Comfort with a Twist

Wicker furniture, available in natural rattan or synthetic resins, exudes a timeless, casual elegance perfect for laid-back outdoor settings. Synthetic wicker, in particular, is designed to be mildew resistant and can withstand various weather conditions. It's also easy to maintain, often needing just a simple wipe-down with a hose or damp cloth.

The versatility of wicker allows it to be painted to match any outdoor palette, with a primer coat recommended before spray painting to ensure even coverage. The market for wicker furniture has seen a resurgence, with consumers appreciating its blend of traditional craftsmanship and modern materials.

Plastic: Affordable and Weather-Resistant

Plastic furniture is the go-to option for budget-conscious consumers looking for weather-resistant outdoor furnishings. Its lightweight nature and ease of cleaning make it a practical choice for many. However, plastic furniture may lack the longevity of other materials, often requiring replacement every few years due to wear and tear or aesthetic degradation.

Despite its lower cost, the demand for high-quality, eco-friendly plastic furniture is on the rise, as consumers become more environmentally conscious and seek out recycled or recyclable options.

Wrought Iron: Sturdy Elegance

Wrought iron furniture is synonymous with durability and timeless style. Its substantial weight makes it ideal for areas prone to high winds or rough weather. Wrought iron pieces are typically coated with a protective powder finish to prevent rust, ensuring they maintain their beauty for many seasons.

To keep wrought iron furniture in top condition, a simple cleaning with a scrub brush and soapy water is usually sufficient. Adding cushions can enhance the comfort of these sturdy sets, making them a favorite for those who value both resilience and elegance in their outdoor spaces.

Teak: The Premier Choice for Wooden Furniture

Teak is renowned for its exceptional durability and resistance to weather elements, including sun, snow, frost, and rain. This hardwood can be left outside year-round without cover, thanks to its natural oils that prevent rotting. Teak furniture is available in various grades, from more affordable options to luxury collections.

2 notes

·

View notes

Text

Fibreglass Electrical Enclosure Market Landscape: Trends, Drivers, and Forecast (2023-2032)

The global demand for Fiberglass Electrical Enclosure was valued at USD 305.9 Million in 2022 and is expected to reach USD 506.2 Million in 2030, growing at a CAGR of 6.50% between 2023 and 2030.

Fiberglass electrical enclosures are protective housings made from reinforced fiberglass material designed to safeguard electrical components from environmental hazards such as dust, moisture, chemicals, and extreme temperatures. These enclosures are lightweight, highly durable, and corrosion-resistant, making them ideal for use in harsh outdoor and industrial environments. Compared to metal enclosures, fiberglass options offer excellent insulation properties, preventing electrical conductivity and ensuring safety. They are commonly used in industries like telecommunications, utilities, and manufacturing, where exposure to corrosive substances or extreme weather is frequent. Additionally, fiberglass electrical enclosures require minimal maintenance, providing a long-lasting solution for protecting sensitive equipment in both indoor and outdoor settings

The fiberglass electrical enclosure market presents several opportunities for growth, driven by a combination of industrial demands, technological advancements, and regulatory requirements. Here are key opportunities shaping the market:

1. Increased Adoption in Harsh and Corrosive Environments

Fiberglass electrical enclosures are ideal for environments with high exposure to moisture, chemicals, and extreme temperatures, making them highly sought after in industries like oil and gas, chemical processing, and water treatment. As industries continue to operate in these harsh environments, the demand for fiberglass enclosures is expected to rise, particularly where corrosion resistance and durability are crucial.

2. Growth in Renewable Energy Sector

The growing emphasis on renewable energy infrastructure, including solar, wind, and geothermal power, creates significant opportunities for fiberglass electrical enclosures. These industries often operate in outdoor, rugged environments, where enclosures need to withstand the elements. Fiberglass enclosures are favored for their resistance to corrosion and UV degradation, making them suitable for protecting electrical components in renewable energy projects.

3. Expanding Use in Telecommunications and 5G Networks

With the rapid expansion of telecommunications infrastructure, including the rollout of 5G networks, there is increasing demand for durable and non-conductive enclosures to house sensitive electronic equipment. Fiberglass enclosures offer excellent insulation and weather resistance, making them ideal for protecting network components, such as antennas and electrical circuits, in outdoor installations.

4. Urbanization and Smart City Development

As urban areas expand and the development of smart cities accelerates, there is a growing need for reliable electrical infrastructure. Fiberglass enclosures provide a durable, low-maintenance solution for housing electrical and communication systems in urban environments, including smart grids, traffic management systems, and public transportation networks. This urbanization trend creates opportunities for the deployment of fiberglass enclosures in both utility and communication sectors.

5. Increasing Demand for Lightweight and Low-Maintenance Solutions

Compared to metal enclosures, fiberglass enclosures are lightweight, which reduces transportation costs and makes them easier to install. Additionally, they are resistant to rust and require less maintenance over time, which appeals to industries looking for cost-effective, long-lasting solutions. The ease of customization and minimal maintenance required for fiberglass enclosures open opportunities in sectors such as construction and infrastructure development.

6. Rising Safety Standards and Regulatory Compliance

There is an increasing emphasis on meeting stringent safety standards for electrical systems in industrial and public settings. Fiberglass enclosures provide excellent insulation and non-conductive properties, enhancing safety for both workers and equipment. As regulatory bodies enforce higher safety and performance standards for electrical installations, fiberglass enclosures are expected to be a preferred choice due to their compliance with these regulations.

7. Demand for Enclosures in Industrial IoT (IIoT) Applications

As the Industrial Internet of Things (IIoT) continues to grow, more industries are deploying smart sensors, control systems, and connected devices. These components require robust enclosures that can protect against environmental damage while ensuring reliable data transmission and connectivity. Fiberglass enclosures offer the necessary protection for IIoT installations, especially in outdoor and industrial settings, creating new opportunities for manufacturers to serve this expanding market.

8. Customization and Modular Design Flexibility

Fiberglass enclosures are easily customizable to meet the specific needs of various industries. The ability to produce enclosures in different sizes, shapes, and with various mounting options presents significant opportunities for manufacturers to offer tailored solutions. Modular designs are also gaining popularity, allowing industries to create scalable electrical systems that can grow or change over time. This flexibility drives demand for fiberglass enclosures in industries where adaptability is essential.

9. Focus on Sustainable and Eco-Friendly Solutions

As industries and governments focus more on sustainability and eco-friendly solutions, fiberglass electrical enclosures offer an attractive option. Fiberglass is a recyclable material and, compared to traditional metal enclosures, produces fewer greenhouse gas emissions during manufacturing. Companies that prioritize sustainability in their operations may turn to fiberglass enclosures as part of their environmental strategies, opening up new market opportunities.

10. Global Expansion in Infrastructure and Energy Sectors

With increasing investments in infrastructure and energy projects across emerging economies, particularly in Asia, Africa, and Latin America, the market for fiberglass electrical enclosures is poised for significant growth. These regions are seeing a rise in demand for reliable and durable electrical infrastructure, especially in utility and energy distribution sectors, making fiberglass enclosures an attractive solution for both cost and performance reasons.

Access Complete Report - https://www.credenceresearch.com/report/fibreglass-electrical-enclosure-market

Key Players

Schneider Electric SE

Legrand S.A.

Eaton Corp.

Hubbell Incorporated

Siemens AG

ABB Limited

Adalet Inc.

Emerson Electric

General Electric Company

Rittal GmbH & Co. KG

ROSE Systemtechnik GmbH

Hammond Manufacturing Ltd.

Elettrocanali S.p.A.

OBO Bettermann Holding GmbH & Co. KG

Spelsberg

Gustav Hensel GmbH & Co. KG

Conextube

NITTO KOGYO CORPORATION

Hager Bocchiotti Spa

Palazzoli S.p.A

The fiberglass electrical enclosure market varies across different regions, with demand influenced by factors such as industrial growth, infrastructure development, regulatory standards, and environmental conditions. Here is an overview of the market's regional insights:

1. North America

Key Drivers: The North American market is driven by strong industrialization, strict regulatory standards, and advancements in the energy, telecommunications, and automotive sectors.

Industrial Growth: The U.S. and Canada have well-established industries such as oil and gas, energy, and telecommunications, where fiberglass enclosures are critical for protecting electrical components from harsh environmental conditions, including chemicals and extreme temperatures.

Regulatory Push: The region’s focus on safety and compliance with regulatory standards from agencies such as the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL) contributes to the demand for high-performance fiberglass enclosures.

Renewable Energy: The growth of renewable energy projects, especially wind and solar, in the U.S. and Canada offers significant opportunities for fiberglass enclosures, which are highly resistant to corrosion and weather conditions.

2. Europe

Key Drivers: In Europe, the fiberglass electrical enclosure market is shaped by stringent environmental regulations, strong industrial growth, and a focus on renewable energy.

Regulatory Environment: The European Union has strict environmental and safety regulations that drive the adoption of non-corrosive and weather-resistant enclosures, particularly for outdoor installations. Fiberglass enclosures are preferred for their insulation properties and ability to meet the EU's high standards.

Infrastructure Modernization: Europe's ongoing efforts to modernize its infrastructure, particularly in energy distribution, smart grids, and telecommunications, are creating a growing demand for durable and low-maintenance electrical enclosures.

Renewables and Sustainability: The European market is also benefiting from the region's strong push for sustainability and the development of renewable energy sources, including offshore wind farms and solar power projects. Fiberglass enclosures are well-suited for use in these applications due to their lightweight, non-corrosive nature.

3. Asia-Pacific

Key Drivers: The Asia-Pacific region is witnessing rapid industrialization, urbanization, and significant investments in infrastructure, making it the fastest-growing market for fiberglass electrical enclosures.

Emerging Economies: Countries such as China, India, and Southeast Asian nations are investing heavily in infrastructure projects, including energy, transportation, and telecommunications, driving demand for fiberglass enclosures.

Telecommunications Boom: The expansion of telecommunications infrastructure, particularly in the rollout of 5G networks, is generating demand for durable and cost-effective enclosures. Fiberglass enclosures are ideal for outdoor and remote installations in these rapidly expanding networks.

Renewable Energy Growth: Asia-Pacific is also seeing strong growth in renewable energy projects, particularly in solar and wind power, where fiberglass enclosures are favored due to their resistance to environmental factors like UV radiation and saltwater corrosion.

4. Middle East & Africa

Key Drivers: In the Middle East and Africa, the demand for fiberglass electrical enclosures is driven by the harsh environmental conditions and the need for robust infrastructure in the oil and gas, water treatment, and power sectors.

Harsh Environmental Conditions: The extreme heat, sand, and corrosive environments typical of many Middle Eastern countries make fiberglass enclosures a popular choice due to their resistance to these conditions. They are widely used in oil refineries, chemical plants, and desalination facilities.

Oil and Gas Sector: The presence of a strong oil and gas industry in the Middle East, including countries like Saudi Arabia, UAE, and Qatar, is a significant driver of fiberglass enclosure demand. These industries require enclosures that can withstand corrosive environments and protect sensitive equipment.

Emerging Infrastructure Development: In Africa, growing investment in infrastructure development, particularly in energy distribution and telecommunications, is creating new opportunities for fiberglass enclosures as the region works to expand its utility networks and modernize its electrical systems.

5. Latin America

Key Drivers: Latin America's fiberglass electrical enclosure market is driven by growth in energy, utilities, and industrial sectors, particularly in Brazil, Mexico, and Chile.

Renewable Energy Projects: Latin America is seeing a surge in renewable energy projects, especially in wind and solar power. Countries like Brazil and Chile are leaders in these sectors, and fiberglass enclosures are essential for protecting electrical systems in these outdoor installations.

Industrial Expansion: The growth of manufacturing, mining, and oil and gas sectors in the region, particularly in Mexico and Argentina, is driving demand for corrosion-resistant, lightweight enclosures that can endure tough industrial conditions.

Telecommunications Infrastructure: As more countries in Latin America work to expand their telecommunications and energy grids, fiberglass enclosures are increasingly being used for housing electrical components in outdoor and remote areas, where protection from environmental elements is essential.

Segmentation

By Type:

Wall-Mounted Enclosures

Floor-Mounted or Free-Standing Enclosures

Modular Enclosures

Junction Boxes

Terminal Boxes

Operator Consoles

Others

By Size:

Small and Medium-Sized Enclosures

Large Enclosures

Custom-Sized Enclosures

By Application:

Industrial Automation

Power Distribution

Telecommunications

Renewable Energy

Water and Wastewater Treatment

Oil and Gas

Transportation

Others

By End-User Industry:

Manufacturing and Industrial

Utilities

Telecommunications

Renewable Energy

Water and Wastewater

Oil and Gas

Transportation

Commercial and Residential

Others

By Protection Rating:

IP65 and Below

IP66 to IP69

NEMA Ratings

By Customization and Accessories:

Standard Enclosures

Custom Enclosures

Accessories

Browse the full report – https://www.credenceresearch.com/report/fibreglass-electrical-enclosure-market

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Corrosion Inhibitors Market Key Companies and Emerging Trends, 2027

The global corrosion inhibitors market size was valued at USD 7.4 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) 3.8% from 2020 to 2027.

The growth in the market can be attributed to the development of biobased and more eco-friendly corrosion inhibitors. A gradual shift toward the development of environment-friendly corrosion inhibitors may potentially lead the market toward sustainable development and increase the acceptance of corrosion inhibitors among sustainable end users. A corrosion inhibitor functions by creating a barrier over the coated surface and preventing it from moisture, which is primarily the primary cause of erosion. The mechanisms of organic products include interfacial activity, anodic activity, cathodic activity, barrier activity, and adsorption activity.

Gather more insights about the market drivers, restrains and growth of the Corrosion Inhibitors Market

Detailed Segmentation:

Product Insights

The organic segment held largest market share of 73.8% in 2019. In recent years, there has been significant development concerning bio-based corrosion inhibitors. These are low in cost, have low toxicity, and are readily available organic compounds, which are obtained from plant extracts such as aromatic herbs, spices, and medicinal plants. Generally, bio-based corrosion inhibitors have aromatic structures with long aliphatic chains and free electron pairs. For instance, Delonix regia and rosemary leaves prevent the deterioration of aluminum metal, while natural honey inhibits corrosion of copper. The factors mentioned above are estimated to drive segment growth over the forecast period.

Type Insights

The water-based segment held the largest market share of 56.2% in 2019. Water-based corrosion inhibitors are readily soluble in water and are usually sold in solid form. They form a protective layer on the metal surface by altering the physical characteristics of the surface to resist oxidation of the metallic surface, thereby offering rust protection. Moreover, they are cost-effective, form transparent coating after drying, and can be easily applied by using spray, immersion, or brush before subsequent operations.

End-use Insights

The oil and gas segment held the largest market share of 33.1% in 2019. This is attributed to the rising number of internal corrosion problems in pipelines, refineries, and petrochemical plants. The corrosion inhibitors market is gaining popularity in the power generation sector in the developing economies of the Asia Pacific region due to rapid urbanization and industrialization. In power plants, erosion has been one of the significant factors that lead to critical downtime. The steam circuits in nuclear, thermal, and hydropower plants are susceptible to deterioration as the metal components are always in contact with water. To ensure effective power generation, most power plants monitor parameters such as pH value, conductivity, and the presence of corroding anions and cations, which indicate the corrosion rate. Also, they ensure the adequate presence of corrosion inhibitors such as phosphonates, phosphate, and zinc (for steel) and triazoles (for copper).

Regional Insights

Asia Pacific held the largest market share of 36.3% in 2019 and is projected to be one of the fastest-growing markets in the near future. The growth in the market can be attributed to rapid industrialization in the region, which has triggered the demand from the power generation and several other end-use industries as well. The growing chemical and metalworking sectors in developing economies of the region, including India and China, are also projected to contribute significantly to the market in the near future.

Browse through Grand View Research's Organic Chemicals Industry Research Reports.

• The global caprolactam market was valued at USD 15.3 billion in 2023 and is projected to grow at a CAGR of 5.1% from 2024 to 2030.

• The global potting compounds market size was estimated at USD 33,275.20 million in 2023 and is projected to grow at a CAGR of 3.2% in terms of revenue from 2024 to 2030.

Key Companies & Market Share Insights

The competitive landscape of the market is highly fragmented in nature, with the presence of a large number of key players coupled with high demand from end-users. Key players are concentrating on customized production by using advanced technology and adopting new strategic initiatives such as long-term agreements and mergers to strengthen their base and generate more revenue in the near future. Manufacturers involved in the market are integrated across the value chain. For instance, Arkema is integrated backward by using renewable raw materials for production. On the contrary, The Lubrizol Corporation is forward integrated. The company manufactures fuel additives by using its corrosion inhibitors in the formulation of the product (PowerZol 9548A). Cortec Corporation manufactures several strength-release components and coating products by using their Migratory Corrosion Inhibitors (MCIs). In addition, SUEZ supplies its corrosion inhibitors for several water treatment projects. Some of the prominent players operating in the corrosion inhibitors market include:

• Nouryon

• Cortec Corporation

• Ashland

• Ecolab

• Henkel Ibérica, S.A.

• The Lubrizol Company

• BASF SE

• Dow

• DuPont de Nemours, Inc.

• Baker Hughes, a GE company LLC

Corrosion Inhibitors Market Segmentation

Grand View Research has segmented the global corrosion inhibitors market on the basis of product, type, end use, and region:

• Product Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• Organic

• Inorganic

• Type Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• Water Based

• Oil Based

• End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• Power Generation

• Oil & Gas

• Paper & Pulp

• Metal Processing

• Chemical Processing

• Water Treatment

• Others

• Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• North America

o The U.S

o Canada

o Mexico

• Europe

o Germany

o The U.K.

o France

o Italy

• Asia Pacific

o China

o India

o Japan

o South Korea

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o South Africa

o Saudi Arabia

o UAE

o Iran

o Iraq

o Kuwait

o Oman

o Bahrain

Order a free sample PDF of the Corrosion Inhibitors Market Intelligence Study, published by Grand View Research.

#Corrosion Inhibitors Market#Corrosion Inhibitors Market size#Corrosion Inhibitors Market share#Corrosion Inhibitors Market analysis#Corrosion Inhibitors Industry

0 notes

Text

Lubricants Market Dynamics, Top Manufacturers Analysis, Trend And Demand, Forecast To 2030

Lubricants Industry Overview

The global lubricants market size was estimated at USD 139.44 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 3.8% from 2024 to 2030.

This is attributed to the growing demand for automotive oils and greases due to the growing trade of vehicles and spare parts. Lubricants are an essential part of rapidly expanding industries. They are used between two relatively moving machinery parts to reduce friction and wear & tear. They can be either petroleum-based or water-based and are essential for proper machinery functioning. Lubricants also decrease operational downtime and eventually increase overall productivity. Lubricants are extensively used in processing industries and automobile parts, especially brakes and engines, which need lubrication for continuous smooth functioning.

Gather more insights about the market drivers, restrains and growth of the Lubricants Market

The increasing imports and exports of piston engine lubricants are contributing to market growth. The product demand is driven by the rising focus of consumers on enhancing vehicle performance coupled with the introduction of innovative & premium product offerings. Future growth will be highly dependent on motor vehicle production and the miles covered by each vehicle. Furthermore, consumers are looking for standard and specialized lubricants for their regular vehicles to ensure the smooth functioning of their vehicles and reduce long-term maintenance costs.

Lubricant manufacturing requires crude oil, tight oil, and other additives to formulate all lubricant types. There are multiple additives incorporated in lubricants to enhance their functionality and properties. These include antioxidants, extreme pressure additives, rust- & corrosion-prevention additives, detergents, viscosity index improvers, anti-wear agents, and dispersants. Lubricants are 90% base oil and 10% additives, wherein base oils include petrochemical fractions, such as fluorocarbons, esters, polyolefin, and silicones. Base oils increase the viscosity of the lubricants and reduce wear & tear. Paraffinic and naphthenic are the two essential base oils used in lubricant formulations.

Browse through Grand View Research's Petrochemicals Industry Research Reports.

• The global naphtha market size was valued at USD 189.5 billion in 2023 and is projected to grow at a CAGR of 4.3% from 2024 to 2030.

• The global diesel exhaust fluid market size was valued at USD 36.66 billion in 2023 and is projected to grow at a CAGR of 7.9% from 2024 to 2030.

Key Lubricants Company Insights

The global lubricants market is competitive with a large number of well diversified regional, and independent small scale and large scale manufacturers and suppliers. The small-scale companies majorly compete on the basis of price, after sales service and delivery timelines. Whereas the large scale companies focus on product development and innovations as well as marketing strategies.

Some of the key players operating in the market include Exxon Mobil Corp, Shell, and TotalEnergies

ExxonMobil Corp. is a global manufacturer & supplier of synthetic lubricants. The company mainly deals in three business segments that include upstream (oil & gas, E&P, shipping and wholesale operations), downstream (refining, marketing and retail operations) and chemicals. ExxonMobil owns 37 oil refineries in 21 countries with refining capacity of 6.3 million barrels per day.

Shell is a global leader as a group of petrochemical and energy companies, with presence across 70 countries and over 90,000 employees. The group provides fuels, car services, oils, and is also engaged in production, exploration, and refining of petroleum products. The group offers lubricants for industrial and transport businesses along with lubrication process and services.

Total Energies. is oil & gas integrated company. The company has its business segments in upstream, refining & specialty chemicals, and marketing & services. Total Oil India Private Ltd. is an entirely owned subsidiary of TOTAL. It has exploration and production activities in more than 50 countries. The company has a broad catalogue of lubricants for various markets such as agriculture, vehicles, aviation, energy, and chemicals, among others.

Key Lubricants Companies:

The following are the leading companies in the lubricants market. These companies collectively hold the largest market share and dictate industry trends. Financials, strategy maps & products of these lubricants companies are analyzed to map the supply network.

ExxonMobil Corp.

Royal Dutch Shell Co.

BP PLC.

Total Energies

Chevron Corp.

Fuchs

Castrol India Ltd.

Amsoil Inc.

JX Nippon Oil & Gas Exploration Corp.

Philips 66 Company

Valvoline LLC

PetroChina Company Ltd.

China Petrochemical Corp.

Idemitsu Kosan Co. Ltd.

Lukoil

Petrobras

Petronas Lubricant International

Quaker Chemical Corp.

PetroFer Chemie

Buhmwoo Chemical Co. Ltd.

Zeller Gmelin Gmbh & Co. KG

Blaser Swisslube Inc

Recent Developments

In January 2024, Shell U.K. Limited acquired MIDEL and MIVOLT from M&I Materials Ltd. The products of the latter two will be produced and distributed as part of Shell’s Lubricants portfolio. The acquisition will help Shell to strengthen its position in Transformer Oils, which finds use in offshore wind parks, utility companies, and power distribution.

From September 2023, TotalEnergies Lubrifiants accelerated the inclusion of recycled plastics (50% PCR high-density polyethylene) in its lubricants bottles, following a pilot project launched in 2021 called Quartz Xtra bottles. This aims at contributing to a circular economy and in decline of usage of virgin plastic.

In March 2023, ExxonMobil announced investing around INR 900 crore (~USD 110 million) for constructing a lubricants production plant in Raigad, Maharashtra, India. Upon completion, plant’s annual production capacity is expected to be 159,000 kl of finished lubricants. This plant will cater to growing demand from industries such as mining, construction, power, steel, and manufacturing, among others.

Order a free sample PDF of the Lubricants Market Intelligence Study, published by Grand View Research.

0 notes

Text

Top Quality Car Engine Oil In Rajasthan

Source of Info: https://www.venolrajasthan.com/blog/top-quality-car-engine-oil-in-rajasthan

Introduction

Selecting premium car engine oil in Rajasthan is important for maximum vehicle performance and longevity in Rajasthan's harsh environment. Being a well-known trustworthy brand, Venol Motor Oil stands out by its dedication to advanced lubrication technology. Venol Motor Oil is designed to deal with the extreme heat and dust of Rajasthan, providing solid protection against damage, heat, and rust. This oil lowers maintenance expenses by extending maintenance intervals and improving engine performance. Venol Motor Oil is a brand that represents innovation and dependability in car lubrication, and it is trusted by drivers all across Rajasthan. For those who want the highest level of quality and performance from their engine oil, Venol Motor Oil continues to be the go-to option, whether driving on city streets or over desert roads.

Understanding Engine Oil's Value

Engine oil performs a number of important functions for an engine in a car. Its main purpose is to lubricate moving components, which lowers friction and damage. Furthermore, it absorbs heat and prevents the formation of rust and corrosion, which helps in cooling the engine. Modern engines need specialized lubricants that can survive these demanding requirements, especially those found in high-performance cars or exposed to harsh weather like that of Rajasthan. That is why Venol Motor Oil provides the premium solution for you with their car engine oil in Rajasthan to protect your vehicle..

Why Choose Venol Motor Oil?

With an attention to both performance and quality, Venol Motor Oil has become a well-known and trustworthy brand in the automotive lubricants market. Venol Motor Oil provides a wide selection of solutions created to fulfill the unique needs of engines functioning in various settings, such as Rajasthan, through using innovative formulations and following global guidelines.

Factors To Consider When Choosing Car Engine Oil In Rajasthan

Viscosity Grade: Car engine oil in Rajasthan have been classified according to their viscosity grades, which control how they flow at certain temperatures. Higher viscosity grades of oils offer enough lubrication and stability in the hot heat of Rajasthan.

Additive Technology: Chemicals to modern engine oils help against wear, oxidation, and dirt buildup while also improving performance. Advanced chemical offers are included into Venol Motor Oil to improve engine durability and cleanliness.

Compatibility with Engine Type: It is very important to choose an oil that fulfills with the requirements set out by the car manufacturer. Venol Motor Oil provides oils that work well with a variety of engines, guaranteeing compatibility and performance.

Benefits Of Using Venol Motor Oil In Rajasthan

Enhanced Engine Protection: Venol Motor Oil offers powerful protection against damage, preserving engine life and lowering maintenance expenses.

Improved Fuel Efficiency: By reducing internal engine friction, the proper engine oil improves engine performance and lowers overall maintenance expenses.

Consistent Performance: Venol Motor Oil keeps its density and performance even in Rajasthan's severe temperatures, guaranteeing dependable engine operation all year long.

Environmental Considerations

Because of Rajasthan's harsh winters and hot summers, car engine oil in Rajasthan needs to be able to adjust to temperature changes without losing performance. Because they have been created to survive these extremes, Venol Motor Oil products provide reliable performance and protection throughout the year.

Customer Testimonials And Reviews

Customers from Rajasthan as well as beyond have complimented Venol Motor Oil for its dependability and performance. Positive feedback highlights considerable improvements in engine smoothness, lower noise levels, and an overall better driving experience after converting to Venol Motor Oil products.

Conclusion

In conclusion, selecting quality car engine oil in Rajasthan must be maintained for the finest vehicle longevity and performance, especially with the difficult conditions of the area. With its advanced lubricating technology that shields engines from Rajasthan's high temperatures and dust, Venol Motor Oil shines out as a reliable option. Venol Motor Oil provides improved engine protection, increased energy savings, and solid performance all year long because of its dedication to quality, performance, and environmentally friendly behavior. Venol Motor Oil is the go-to choice for anyone looking for premium engine lubricant that can withstand the demands of both city driving and desert travel since it is trusted by drivers all across Rajasthan and maintains its reputation for dependability.

0 notes

Text

Anti Corrosion Coatings Market Environmental Regulations

The anti corrosion coatings market comprises liquid and powder coating compounds that act as protective layers in preventing surfaces from rusting and corrosion caused by environmental factors. Technologies such as epoxy, polyurethane, acrylic and alkyd based coatings are extensively used in oil & gas pipelines, chemical tanks, automotive, marine and infrastructure for their anti corrosive properties.

The Global anti corrosion coatings market is estimated to be valued at US$ 46.90 Bn in 2024 and is expected to exhibit a CAGR of 3.8% over the forecast period 2023 to 2030. Key Takeaways Key players operating in the anti corrosion coatings market are BASF, Ashland Inc., Nippon Paint Co. Ltd., AkzoNobel N.V., Jotun A/S, Axalta Coating System Ltd., The Sherwin-Williams Company, Kansai Paints Co. Ltd., PPG Industries Inc. and Hempel A/S. BASF being one of the largest producers offers anti corrosion coatings under the MasterProtect and Peran brands. The growing demand from oil & gas industry and infrastructure expansion in emerging nations of Asia Pacific and Middle East Africa are major factors driving growth of anti corrosion coatings market. Government investments and initiatives towards rapid urbanization has increased the requirements of anti corrosion protected structures and assets. The accelerating industrialization and expansion of manufacturing sector worldwide is also augmenting consumption of anti corrosion coatings. Infrastructure projects in sectors such as water pipelines, bridges and commercial buildings need anti corrosive coatings to increase durability and service life of structures. Market Key Trends Environment regulations regarding volatile organic compound (VOC) emissions from coatings are forcing manufacturers to develop low VOC and water based coating technologies. AkzoNobel launched its International brand in 2021 made from renewable raw materials exhibiting 95% lower carbon footprint and 100% recyclable. Major players are investing in R&D to offer sustainable anti corrosion solutions without compromising on performance. Another trend gaining popularity is the thermal spray coatings technology used majorly in oil & gas industry which involves applying protective layers through wire arc and flame spraying methods. This technology provides 10 times thicker coatings vs conventional liquid/powder techniques thereby increasing protection lifespan substantially.

Porter’s Analysis

Threat of new entrants: New entrants face high initial investment costs to achieve economies of scale and gain brand recognition in this market.

Bargaining power of buyers: Buyers have moderate bargaining power due to the availability of substitutes and standardized nature of anti-corrosion coatings products.

Bargaining power of suppliers: Suppliers have moderate bargaining power due to the availability of raw material substitute options and presence of many suppliers in the market.

Threat of new substitutes: Threat of new substitutes is low as anti-corrosion coatings have well-established application areas and substitutes face high switching costs.

Competitive rivalry: The market is moderately competitive due to presence of many international players. Geographically, North America holds the largest share of the anti-corrosion coatings market in terms of value, supported by growing oil & gas refineries and robust infrastructure development in the region. Asia Pacific is the fastest growing regional market due to rapid industrialization, infrastructure development and growing water treatment sector in major countries like China and India. Geographical regions where the market is concentrated in terms of value include North America and Western Europe due to early adoption of advanced coating technologies in oil & gas, petrochemicals and infrastructure sectors. The anti-corrosion coatings market in Asia Pacific is the fastest growing regional market supported by increasing investments in water treatment plants, pipelines and oil & gas exploration projects in major economies. Countries like China, India and Southeast Asian nations are expected to drive high demand.

0 notes

Text

Superior Corrosion Resistance Enamel Tanks are The Ideal Choice for Agricultural Water Storage

Superior Corrosion Resistance Enamel Tanks are The Ideal Choice for Agricultural Water Storage

In the realm of agricultural water storage, the quality and durability of tanks play a pivotal role in ensuring efficient water management. Among the array of options available, enamel tanks stand out as a testament to superior corrosion resistance, offering a robust solution for farmers and agricultural enterprises.

As a leading storage tank manufacturer in China. Center Enamel can provide GFS Tanks, SS Tanks, Epoxy Coated Bolted Steel Tanks, Galvanized Tank, Aluminum Dome Roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Enamel tanks are assembled on-site from specialized enamel steel plates, hoops, self-locking bolts, sealing glue, and other components. The steel plate raw material utilizes titanium alloy-specialized enamel hot-rolled plates developed in collaboration with leading domestic iron and steel enterprises, and it is shaped using fast and low-consumption on-site assembly technology. After high-temperature enameling at 820°-930°, the enamel glaze fuses with the surface of the steel plate, forming a solid and chemically inert inorganic coating with outstanding corrosion resistance. The enamel process is currently an advanced coating and corrosion protection technology in the steel tank market.

Enamel tanks parameters

Category

Specification

Coating Color

Black blue, Grey olive, Forest green, Cobalt blue, Desert tan etc.

Coating thickness

0.25-0.45mm

Acid and alkalinity proof

Standard PH: 3~11, Special PH:1~14

Adhesion

3450N/cm²

Hardness

6.0 (Mohs)

Service life

≥30 Years

Holiday test

>1500V

Permeability

Gas liquid impermeable

Easy to clean

Smooth, glossy, inert, anti-adhesion

Corrosion resistance

Excellent, suitable for harsh environment

Enamel tanks Advantages

Unmatched Durability

Enamel tanks, also known as Glass-Fused-to-Steel (GFS) tanks, are crafted through a meticulous process that combines glass and steel, resulting in a product renowned for its durability. This fusion creates a non-porous surface that is resistant to corrosion, rust, and chemical reactions, making it ideal for storing various types of agricultural water, including irrigation water, rainwater harvesting, and livestock drinking water.

Longevity and Low Maintenance

One of the key advantages of enamel tanks is their longevity. Unlike traditional metal tanks that may succumb to rust and degradation over time, enamel tanks offer a prolonged lifespan, often exceeding decades with proper maintenance. This longevity translates to cost savings for agricultural operations, reducing the need for frequent replacements and repairs.

Moreover, enamel tanks require minimal maintenance compared to other tank materials. Their smooth, non-porous surface prevents the buildup of algae, bacteria, and other contaminants, reducing the frequency of cleaning and disinfection processes. This low maintenance requirement not only saves time and effort but also ensures the water stored remains clean and safe for agricultural use.

Environmental Sustainability

In today's environmentally conscious landscape, the sustainability of water storage solutions is a crucial consideration. Enamel tanks align with sustainability goals by promoting water conservation and reducing environmental impact. By efficiently storing water, farmers can optimize irrigation practices, minimize water wastage, and contribute to sustainable agriculture practices.

Additionally, the recyclability of steel components in enamel tanks further enhances their eco-friendly profile. At the end of their lifespan, enamel tanks can be recycled, reducing waste and supporting circular economy principles.

Versatility and Customization

Enamel tanks offer versatility in design and customization to meet the specific needs of agricultural applications. They are available in various sizes, capacities, and configurations, allowing farmers to choose the right tank size based on their water storage requirements. Whether for small-scale farming or large agricultural operations, enamel tanks provide a scalable solution.

Furthermore, enamel tanks can be equipped with additional features such as insulation for temperature control, agitators for mixing additives, and monitoring systems for water quality management. This customization ensures that farmers can tailor their water storage infrastructure to optimize agricultural processes.

Center Enamel is a comprehensive high-tech enterprise primarily engaged in the research, development, manufacturing, and sales of enamel-assembled tanks and diversified environmental protection equipment, as well as undertaking environmental protection EPC projects and anaerobic process segments. Throughout its project practices, the company continuously increases research and development efforts, gathers scientific and technical forces, and establishes a service system covering everything from research and development to after-sales, providing tailored solutions to customers quickly and with high quality.

The measurement standards for projects not only need to meet technical and quality requirements but also must shift towards overall standards of sustainability, quality improvement, energy efficiency, and carbon reduction. In response to market and policy changes, Center Enamel actively leverages its rich experience and research and development strength to empower innovative research and development technologies for enamel-assembled tanks, contributing to the smart manufacturing of diversified environmental protection equipment and environmental protection EPC projects. This aims to meet the diverse needs and project requirements of customers.

Currently, Center Enamel's business covers areas such as kitchen waste, leachate, municipal sewage, biogas projects, aquaculture wastewater, industrial wastewater, drinking water, and firefighting water. In the future, the company's research and development achievements will be further promoted and applied in more projects, striving to achieve a win-win situation for economic, environmental, and social benefits, driving the high-quality development of the environmental protection industry.

0 notes

Text

Steam turbine oil analysis practices

Introduction:

The market studies done by the various analyst on “Global market analysis on Turbine oil “forecast that the global turbine oil market to grow at a CAGR of 3.498% during the period 2017-2021 and the market size has a potential to grow by 1500.05 K MT during 2020-2024, and its momentum will accelerate during the forecast period. Turbine oil manufacturers are continuously working with OEMs to provide high-performance turbine oils to meets the rising demands globally. Nowadays the industries are more focused on extending the life of both lubricants and the equipment by implementing a robust Reliability lubrication Program.

In this article, we have tried to cover the maximum information about turbine oil which could help the power generation & manufacturing industries to move further with a cost-effective sustainable solution.

Turbine & it's lubrication system:

The turbine which is the heart of the power plant extracts thermal energy from high-pressure steam and converts it into mechanical energy on a rotating output shaft. This mechanical energy is used to drive rotating equipment like pumps, compressors, fan, blower, and ultimately to drive a generator for the production of electricity.

Let’s understand a brief of oil flow along with major component and its function in the lubrication system of the turbine with the following steps:

Oil system which is composed of an oil tank (with a heater for a start-up)

Oil pumps to provide the necessary level of oil pressure

Oil coolers to dissipate the heat from the oil during operation

Oil filters to remove erosional debris from the circulating oil

Pressure control valve to regulate an exact and constant supply oil pressure to the bearings

In addition, one pressure relief valves to protect the pumps from overpressure (usually rotary type)

An accumulator for minimizing pressure surge when any operational change occurs, like switching-over between main and stand-by equipment.

A Temperature Control Valve (TCV) is provided to by-pass the coolers when the oil temperature is low, to ensure correct oil viscosity and efficient lubrication. Sometimes it is done by controlling water flow through oil coolers.

Importance of turbine oil:

In this growing modern world where electricity has become the most important part of our life and spending a day without it could slow down our lifestyle, productivity and overall impacting the global economy; then the generation of electricity indeed became fundamental to us. To meet this ever-increasing demand, power plants are delicately performing to improve their output and reliability. In the Power plants, Turbine is the most crucial machine which is the prime movers for other rotating equipment and hence the generation of electricity. Its reliability and availability critically depend on the turbine oil, which makes the lubricant selection very important part in the reliability program. However, the OEM of the turbine carefully specifies the characteristic of the lubricants, laboratory test for oil analysis and standard references for the best performance of the turbine.

Turbine oil has to undergo through an adverse condition like large temperature fluctuation, heavy load, ingress of contamination, moisture, entrained air, heat and many physical & chemical changes. Important roles of oil are cooling of bearings & journals, flushing contaminants away from rotating parts, preventing in leakage of gases, providing hydrostatic lift for shafts, actuating valves in the hydraulic circuit, and protecting lube-system internals.

Modern technologies in lubrication science show clearly a great advancement in the formulation of the turbine oil. Almost 90-95% of turbine oil is a base oil with additives making up the remaining per cent which includes antioxidants, rust inhibitors, metal deactivators, antifoam agents, demulsifier, pour depressants and antiwear additives.

To learn more visit: www.minimacsystems.com

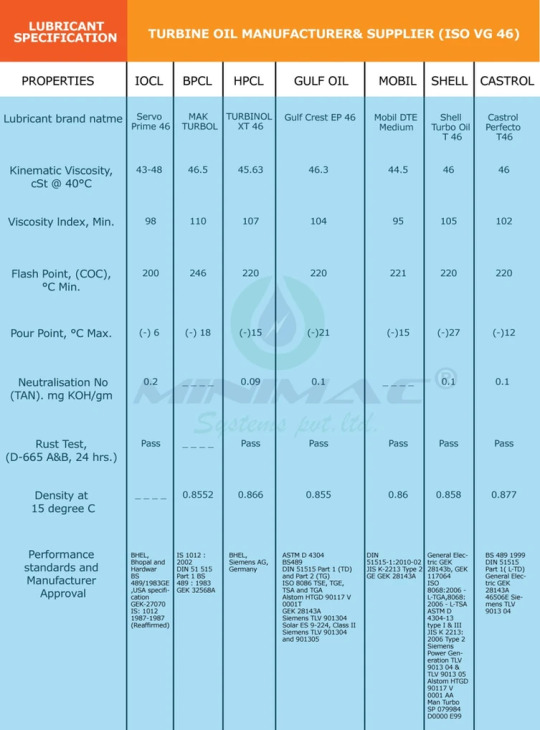

Turbine oil properties, type and brand:

Integral properties of the steam turbine oil are to allow uniform lubricating performance over a wide range of ambient and operating temperatures, to reduce hydrolysis, to reduce the formation of varnish, sludge, emulsion & entrained gas/foam, to prevent rust, minimize acid attack on copper alloy parts, improves lubricity, minimize oxidation, good oil degradation solubility improves filtration, etc. The oil which meets all these mentioned properties is of ISO VG 46.

We at Minimac study your maintenance needs and provide the best solution. We believe in Discern, Design & Deliver.

Lubricant supplier selection and brands:

Selecting a suitable supplier who can meet the performance requirement for the turbine is a vital part of the reliability lubrication program. While finalizing the vendors, many points should be considered like lubricant quality & services, technological advancement, troubleshooting support, emergency preparedness, technical support, laboratory support, price, and delivery capacity.

Turbine oil maintenance (sampling points, testing standards, testing schedule)

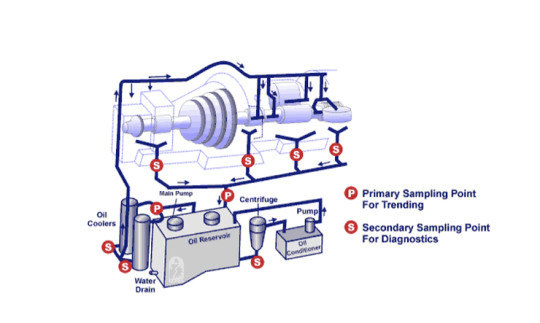

Sampling points:

Maximize data density of oil information

Minimize the distortion of information

Designated sampling location of primary points (return line or drain valve, elbow, turbulent area) and secondary points (anywhere on the system to isolate upstream component)

Proper frequency

Proper sampling hardware

Sample when the machine is running at normal operating temperature

Sample after flushing a small quantity of oil (0.5 - 1.0l) through the sampling point

Use only dedicated clean and dry sampling equipment intended for the sampling of used oils.

Samples should be sent to the lab or processed for on-site analysis before 24 hours from the time the sample was extracted.

To avoid leakage, fill the sample bottle to 90% capacity and ensure it is properly sealed before despatch to the laboratory.

Below images are illustrating both primary sampling points and secondary sampling points of turbine lube oil system:

Primary Sampling Point: Location where regular routine oil samples are taken for monitoring and trending wear metal debris, oil condition, and oil contamination.

Testing Standards:

Power Plant lubrication monitoring is broadly specified under ASTM D4378 and ASTM D6224, and these define almost every test used to qualify lubricants for new and in-service monitoring for power plants. Following are major standards and OEM approval standards

ASTM D4378, "Standard Practice for In-Service Monitoring of Mineral Turbine Oils for Steam, Gas, and Combined Cycle Turbines"

ASTM D6224, "Standard Practice for In-Service Monitoring of Lubricating Oil for Auxiliary Power Plant Equipment", focuses on auxiliary equipment that supports power-generating turbines.

FED-STD-791D (testing method of lubricants, liquid fuels, and related products)

Ahlstom - Gas and Steam - HTGD901117

GE - Gas - GEK 32568f

GE - Steam - GEK 46506D

Solar - ES9-224

MHI - Steam & Gas - MS04-MA- CL001 and CL002

Siemens/ Westinghouse - K-8962-11

Testing schedule with standard reference:

Watch our Low Vacuum Dehydration System video: Click here

Steam turbine breakdown problems:

1. Bearing Failure Bearing & Journal related issues are one of the main causes of turbine generator outages. While faulty design or manufacturing can be occasionally responsible, the most frequent cause of these problems is improper operating conditions. A turbine trip is likely to occur when any bearing/shaft vibration reaches the trip limit. Major operational causes of accelerated wear and failure of turbine generator bearings are:

Improper lubrication (inadequate flow, dirty oil, improper oil temperature)

Excessive load (ie. the force pressing the shaft against the bearing)

Prolonged operation at high vibration levels which can result in fatigue cracking of the bearing lining.

Insufficient oil flow and pressure causes wiping off of babbitt material

Such operating conditions can result in bearing overheating, scoring, or erosion of bearing surfaces by oil contaminants, or fatigue damage.

2. Blade Failure

Turbine blade failure is a nightmare for any power player. It is another major problem and typical operational issues responsible for it are deposits, erosion, corrosion and vibration, fatigue, and manufacturing defect. The most common causes of blade failures are stress corrosion cracking and fatigue cracking due to excessive blade vibration.

Blade failure can cause large scale damage to the turbine. In the worst case, one or more of the long moving blades in an LP turbine may pierce the casing and become turbine missiles. In a less severe case, the broken blade (interfering with the motion of other blades, can shear off or bend some of them. The resultant very high vibration can destroy turbine generator bearings, seals, oil lines, etc. This type of case happened in 2014 at one of the large power generation stations in India where 600 MW LP turbine last stage blade broken at lacing wire area and subsequently damaged 5 more blades. It caused a unit outage of more than 90 days!

The serious consequences of such breakdowns, determination of the causes of bearing failure, and methods of effective repair are of paramount importance. Sublevel maintenance practices or overextending the life of the oil are also important factors for the breakdown of the turbine *A very common myth with lubrication system is that “keeping filters in line with oil circuits will prevent failures due to contamination”. This is the paradox of the situation where emergency oil supply systems bypass all the filters and obstacles in the circuit to fulfill the demand, but contaminants use it as an opportunity to fail the emergency system itself. (Bases on the facts when DC pumps started and failed due to oil contamination).

Turbine bearing failure is not only limited to bearing replacement cost and time but results in rotor damage as well. In 2017, in India, one 300 MW Chinese supplied machine encountered oil starvation during a blackout and resulted in rotor damage which further cost billions of rupee revenue loss to the company.

Consolidated turbine oil care and maintenance points:

Apart from the oil analysis, below lubrication practices should be followed for best performance of Steam Turbine:

Keep oil clean, cool, and dry

Inspect bulk delivery of new oil before acceptance

Maintain proper alignment

Perform regular oil analysis

Install high-capture-efficiency breathers

Inspect for signs of foaming and/or air entrainment

Install primary and secondary sampling points

Routinely inspect sight glasses for level, foam, and water

Keep tank headspace dry using blowers, condensers, or instrument air

Use off-line fluid conditioning for precision contamination control

Regularly inspect for varnish, especially in gas turbines

Analyze the oil periodically

Keep temperature and operation records

Install filter and strainers to retain solid contaminants

Install a multipurpose oil purification unit to prevent solid and liquid contaminants

Check oil filter cartridges or elements periodically

During inspection and overhauls, the turbine oil must be drained from the main oil tank, oil cooler, and the bearing pedestals

Reuse the oil only after ensuring all the parameters within the prescribed limits

Any small change in vibration must be considered on priority

Keep a close view on condition monitoring results and repeat the test in case of any deviation

Call +91 7030901266 for Mechanical Maintenance & Oil Check.

About the Author: Ms. Preeti Prasad associated as Technical Consultant and Business Development Manager with Minimac system Pvt Ltd. She is a chemical engineer with work experience in Oil Refinery and also providing lubrication consultancy services to many companies/sectors. She holds Level I Machine Lubrication Technician(MLT) certification through the International Council for Machinery Lubrication (ICML).

Reference Taken:

Machinery Lubrication India- Noria Corporation Ltd

Monitoring and Optimizing life of Turbine Oil by Analyst, Inc

Troubleshooting bearing and lube oil system problems by Thomas H.McCloseky

BHEL documents on Stem Turbine Maintenance and Turbine oil care maintenance

Turbine Operational Problem (module 234-14)

PDS of mentioned oil manufacturer

#oil flushing#minimac systems#frf#power#minimac#hydraulic oil#oil & gas#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#transformation oil purification#transformers#electrostatics lube cleaner#coalescer separator#metal#mining#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre

1 note

·

View note

Text

Emerging Eco-Friendly Solutions in the Anti-Corrosion Coatings Market

Anti corrosion coatings are protective coatings applied to surfaces to prevent rusting and corrosion. They are primarily used to protect substrates such as metals from degradation. Some key applications of anti corrosion coatings include infrastructure, oil and gas, marine, automotive and construction. In infrastructure, anti corrosion coatings help safeguard infrastructure assets like bridges, pipelines, oil rigs from external corrosion that can compromise structural integrity over time. In the oil and gas industry, anti corrosion coatings play a critical role by protecting offshore and onshore assets exposed to corrosive environments.

The global anti corrosion coatings market is estimated to be valued at US$ 30 Bn in 2023 and is expected to exhibit a CAGR of 3.8% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Dynamics:

The increasing demand from various end-use industries such as infrastructure, oil & gas, marine, automotive etc. is expected to drive the growth of the anti corrosion coatings market over the forecast period. Anti corrosion coatings find widespread application in protecting infrastructure assets exposed to corrosive environments. With growing investments in oil & gas exploration and infrastructure projects globally, the demand for anti corrosion coatings is estimated to increase significantly. Furthermore, stringent government regulations regarding corrosion prevention of offshore oil rigs and pipelines further fuel the market growth. Additionally, ongoing product innovation leading to development of advanced, environment-friendly and cost-effective anti corrosion coating solutions will also contribute to the anti corrosion coatings market expansion during the forecast period. SWOT Analysis Strength: Anti Corrosion Coatings have strong protective properties that help extend the lifespan of assets. They provide a durable barrier between surfaces and corrosive environments. Developing advanced coating materials that are more resistant to wear and chemicals will make corrosion protection stronger. Weakness: Applying Anti Corrosion Coatings requires extensive surface preparation and proper application methods to avoid failures. Improper coating may peel or chip over time exposing the surface. These coatings also add initial costs for materials and labor during application. Opportunity: Growing infrastructure construction in developing countries increases the need for Anti Corrosion Coatings on structures exposed to harsh outdoor conditions. Developing innovative eco-friendly coating solutions without toxic components will unlock new market opportunities. Threats: Stringent environmental regulations around solvent-based coating products poses challenges. Alternatives like powder coatings have higher setup and training costs. Economic slowdowns can negatively impact industries relying on corrosion prevention. Key Takeaways The global Anti Corrosion Coatings market is expected to witness high growth. Driven by investments in oil and gas pipelines, power generation, construction industries the market is projected to grow at a CAGR of 3.8% until 2030. Regional analysis - Asia Pacific currently dominates the market and is expected to remain the fastest growing region due to ongoing infrastructure development projects. China, India and other Southeast Asian countries are major consumers. North America and Europe are established regional markets focusing on upgrades of aging infrastructure. Strict environmental norms drive innovations in these regions. Key players - Key players operating in the Anti Corrosion Coatings market are AkzoNobel N.V., PPG Industries, Inc., The Sherwin-Williams Company, Jotun, Kansai Paint Co., Ltd., Hempel A/S, Chugoku Marine Paints, Ltd. Axalta Coating Systems, NEI Corporation, and Nippon Paint Holdings Co., Ltd. Focus on developing bio-based and powder coating products positions them favorably in the future market.

#Anti Corrosion Coatings Market#Anti Corrosion Coatings Market Trends#Anti Corrosion Coatings Market Growth

0 notes

Text

Anti Corrosion Coatings Market Resilience: Building a Robust Defense Against Oxidation

Anti corrosion coatings are protective coatings applied to surfaces to prevent rusting and corrosion. They are primarily used to protect substrates such as metals from degradation. Some key applications of anti corrosion coatings include infrastructure, oil and gas, marine, automotive and construction. In infrastructure, anti corrosion coatings help safeguard infrastructure assets like bridges, pipelines, oil rigs from external corrosion that can compromise structural integrity over time. In the oil and gas industry, anti corrosion coatings play a critical role by protecting offshore and onshore assets exposed to corrosive environments.

The global anti corrosion coatings market is estimated to be valued at US$ 30 Bn in 2023 and is expected to exhibit a CAGR of 3.8% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Dynamics: The increasing demand from various end-use industries such as infrastructure, oil & gas, marine, automotive etc. is expected to drive the growth of the anti corrosion coatings market over the forecast period. Anti corrosion coatings find widespread application in protecting infrastructure assets exposed to corrosive environments. With growing investments in oil & gas exploration and infrastructure projects globally, the demand for anti corrosion coatings is estimated to increase significantly. Furthermore, stringent government regulations regarding corrosion prevention of offshore oil rigs and pipelines further fuel the market growth. Additionally, ongoing product innovation leading to development of advanced, environment-friendly and cost-effective anti corrosion coating solutions will also contribute to the anti corrosion coatings market expansion during the forecast period. SWOT Analysis Strength: Anti Corrosion Coatings have strong protective properties that help extend the lifespan of assets. They provide a durable barrier between surfaces and corrosive environments. Developing advanced coating materials that are more resistant to wear and chemicals will make corrosion protection stronger. Weakness: Applying Anti Corrosion Coatings requires extensive surface preparation and proper application methods to avoid failures. Improper coating may peel or chip over time exposing the surface. These coatings also add initial costs for materials and labor during application. Opportunity: Growing infrastructure construction in developing countries increases the need for Anti Corrosion Coatings on structures exposed to harsh outdoor conditions. Developing innovative eco-friendly coating solutions without toxic components will unlock new market opportunities. Threats: Stringent environmental regulations around solvent-based coating products poses challenges. Alternatives like powder coatings have higher setup and training costs. Economic slowdowns can negatively impact industries relying on corrosion prevention. Key Takeaways The global Anti Corrosion Coatings market is expected to witness high growth. Driven by investments in oil and gas pipelines, power generation, construction industries the market is projected to grow at a CAGR of 3.8% until 2030. Regional analysis - Asia Pacific currently dominates the market and is expected to remain the fastest growing region due to ongoing infrastructure development projects. China, India and other Southeast Asian countries are major consumers. North America and Europe are established regional markets focusing on upgrades of aging infrastructure. Strict environmental norms drive innovations in these regions. Key players - Key players operating in the Anti Corrosion Coatings market are AkzoNobel N.V., PPG Industries, Inc., The Sherwin-Williams Company, Jotun, Kansai Paint Co., Ltd., Hempel A/S, Chugoku Marine Paints, Ltd. Axalta Coating Systems, NEI Corporation, and Nippon Paint Holdings Co., Ltd. Focus on developing bio-based and powder coating products positions them favorably in the future market.

#Anti Corrosion Coatings Market Share#Anti Corrosion Coatings Market Growth#Anti Corrosion Coatings Market Demand#Anti Corrosion Coatings Market Trend#Anti Corrosion Coatings Market Analysis

0 notes

Text

Sealed for Success: Exploring Growth Avenues in the Bearing Isolators Market

The bearing isolators market is on an upward trajectory driven by the surging demand for isolator solutions. Bearing isolators, characterized by their non-contact, wear-free, and permanent design, serve as essential protective devices for bearings. Operating as a cohesive unit, the rotor and stator remain connected during equipment operation, ensuring the prevention of separation.

Request Sample PDF of this report : https://www.alliedmarketresearch.com/request-toc-and-sample/12448

This ingenious mechanism involves the stator being pressed into the bearing seat, effectively engaging with the rotating shaft. Together, these components collaborate to safeguard bearings from contamination, effectively excluding grease and impurities. Unlike traditional methods, bearing isolators operate without requiring lubrication or a finished shaft. Predominantly crafted from bronze, these isolators leverage a vapor barrier function, facilitating unhindered transmission of vapor contaminants when the system is in motion. This innovation supersedes past measures like lip seals and mechanical seals, which were previously utilized to safeguard bearings in industrial systems but were often temporary and inconsistent in protecting heavy-duty equipment.

Get a Customized Research Report @ https://www.alliedmarketresearch.com/request-for-customization/12448

Exploring Market Dynamics and Structure

The expansion of bearing isolator production is extending beyond projected timelines, driven by the widespread recognition of the product's merits. Its burgeoning popularity spans industries such as oil & gas, manufacturing & processing, mining, pulp & paper, and chemical treatment.

Navigating the COVID-19 Impact