#Global Insulated Glass Market

Explore tagged Tumblr posts

Text

Polycarbonate Composites Market: Lightweight and Durable Innovations Driving Industrial Use up to 2033

The Polycarbonate Composites Market focuses on materials created by combining polycarbonate (PC) resin with reinforcing agents such as glass fibers, carbon fibers, or other fillers. These composites are well-known for their excellent impact resistance, high strength-to-weight ratio, optical clarity, and flame-retardant properties. The versatility of polycarbonate composites makes them widely used in applications across automotive, electronics, aerospace, construction, and healthcare industries.

To Know More @ https://www.globalinsightservices.com/reports/polycarbonate-composites-market

The polycarbonate composites market is anticipated to expand from $2.1 billion in 2023 to $4.3 billion by 2033, achieving a CAGR of 7.4%.

Market Outlook The Polycarbonate Composites Market is experiencing strong growth due to the increasing demand for lightweight yet durable materials in key industries. The automotive sector, in particular, is a significant driver, as manufacturers are seeking materials that reduce vehicle weight to improve fuel efficiency and meet stringent emission standards. Polycarbonate composites are becoming a preferred choice for automotive components such as headlamp lenses, interior parts, and glazing solutions due to their exceptional strength and lightweight characteristics.

In the electronics and electrical industry, the demand for polycarbonate composites is also surging. The materials’ excellent electrical insulation properties and high heat resistance make them suitable for producing enclosures, connectors, and electronic device casings. The growth of the consumer electronics market and the rising adoption of smart devices are contributing to increased usage of polycarbonate composites in this sector.

Aerospace and defense industries are turning to polycarbonate composites for applications that require high performance and safety, such as aircraft interiors, cockpit canopies, and ballistic-grade materials. The aerospace sector’s focus on weight reduction for fuel efficiency and enhanced durability further drives the demand for polycarbonate composites. Additionally, the construction industry is leveraging these materials for glazing applications and structural components where impact resistance and transparency are essential.

The market is witnessing innovations in composite manufacturing processes, such as the development of thermoplastic composites that offer advantages in recyclability and faster production cycles. Advancements in nanotechnology and surface modification techniques are also enhancing the properties of polycarbonate composites, expanding their application range and performance capabilities.

Environmental sustainability is a growing trend in the Polycarbonate Composites Market. Companies are investing in research and development to produce eco-friendly composites using bio-based polycarbonates and recycled materials. The push for sustainable materials aligns with global efforts to reduce plastic waste and promote the circular economy.

Asia-Pacific is expected to dominate the Polycarbonate Composites Market, driven by rapid industrialization, urbanization, and growing automotive and electronics manufacturing. Countries like China, Japan, and South Korea are leading in both production and consumption of polycarbonate composites. North America and Europe are also key markets, with strong demand from the automotive and aerospace sectors.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS32456

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request For Report Customization @ https://www.globalinsightservices.com/request-customization/GIS32456

Market Segmentation

In 2023, the Polycarbonate Composites Market demonstrated robust performance, with a market volume of 600 million metric tons and projections to reach 900 million metric tons by 2033. The automotive sector dominates the market share at 45%, driven by the industry’s demand for lightweight and durable materials. The electronics segment follows with a 30% share, benefiting from the increasing use of polycarbonate composites in consumer electronics. The construction segment holds a 25% share, supported by the material’s strength and versatility. Key players such as Covestro AG, SABIC, and Teijin Limited maintain substantial market presence, influencing sector dynamics.

Competitive pressures and regulatory frameworks significantly impact the Polycarbonate Composites Market. Companies are investing in sustainable production methods to comply with stringent environmental regulations. The EU’s Green Deal and similar policies worldwide are pushing for eco-friendly manufacturing processes. Future projections indicate a 10% annual increase in R&D expenditure, targeting innovations in recycling and material efficiency. The market outlook remains optimistic, with growth driven by advancements in composite technology and expanding applications across various industries. However, challenges such as fluctuating raw material prices and the need for technological advancements persist, necessitating strategic collaborations and investments in cutting-edge technologies.

Major Players

SABIC Innovative Plastics

Covestro

Teijin Limited

Mitsubishi Chemical Corporation

Chi Mei Corporation

LG Chem

Trinseo

Lotte Chemical

Asahi Kasei Corporation

Idemitsu Kosan

RTP Company

Plazit Polygal

PolyOne Corporation

Ensinger

Bayer MaterialScience

A. Schulman

SABIC

Sumitomo Chemical

Toray Industries

Mitsui Chemicals

Request For Discounted Pricing @ https://www.globalinsightservices.com/request-special-pricing/GIS32456

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

For In-Depth Competitive Analysis, Buy Now @ https://www.globalinsightservices.com/checkout/single_user/GIS32456

About Us

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

0 notes

Text

Panel Glass Market: Emerging Trends and Segmentation by Application

Press Release: Panel Glass Market Report – Projected to Reach USD 498.71 Billion by 2032

Company Name: Straits Research

Market Size: The Panel Glass Market was valued at USD 298.53 billion in 2023 and is projected to reach USD 498.71 billion in 2032, growing at a CAGR of 6.1% during the forecast period. This growth reflects the increasing demand for panel glass across multiple industries, including construction, automotive, and solar energy, where innovation and sustainability drive significant market dynamics.

Market Definition:

Panel Glass refers to a type of glass that is used in a variety of applications, particularly in the construction and automotive industries. It encompasses different glass types such as tempered, laminated, float, extra-clear, and coated glass. These products are specifically designed to meet the needs of various sectors, from creating energy-efficient buildings to improving vehicle safety and aesthetics. The use of panel glass is essential in the creation of modern infrastructure, as well as in technologies that reduce energy consumption and enhance safety.

The Panel Glass Market is experiencing rapid growth due to advancements in glass technologies, increasing construction activities, and the rise in automotive manufacturing. Furthermore, the solar energy sector's demand for glass panels is growing steadily, as solar power generation becomes a key source of renewable energy. As global trends favor sustainability and green building practices, panel glass is increasingly seen as a fundamental material that meets both performance and environmental standards.

Growth Factors:

Several key factors are contributing to the growth of the Panel Glass Market:

Advances in Glass Technology: The increasing use of advanced glass technologies such as low-emissivity (Low-E) coatings and the development of stronger, thinner, and more durable glass is driving the market. These innovations not only enhance the aesthetic appeal of buildings and vehicles but also improve their energy efficiency and safety.

Boom in the Construction Industry: With urbanization trends accelerating, especially in developing countries, the demand for construction materials is growing. Panel glass is essential in the development of energy-efficient buildings, offering better insulation and natural lighting solutions.

Increased Focus on Renewable Energy: The growing adoption of solar energy has spurred the demand for high-quality glass used in solar panels. This trend is expected to continue, as solar power becomes a key component in the global push towards sustainable energy solutions.

Safety and Aesthetics in Automotive Manufacturing: The automotive industry's shift towards more sophisticated designs with a focus on safety and comfort has increased the demand for high-strength glass, which is often used for windows, windshields, and sunroofs.

Get Free Request Sample Report @ https://straitsresearch.com/report/panel-glass-market/request-sample

Opportunity:

One of the most significant opportunities in the Panel Glass Market lies in the growing demand for smart glass technologies. Smart glass is capable of adjusting its transparency in response to environmental stimuli, such as temperature and sunlight. This technology offers several advantages, including energy savings, privacy, and enhanced comfort, making it highly attractive for the construction and automotive industries. The expansion of smart glass applications into residential buildings, commercial spaces, and vehicles is expected to fuel future market growth.

Moreover, green building certifications such as LEED (Leadership in Energy and Environmental Design) are increasingly influencing the construction industry's use of materials like energy-efficient glass. As governments and organizations worldwide place greater emphasis on sustainable building practices, the demand for panel glass that meets these standards is expected to rise.

Buy Now @ https://straitsresearch.com/buy-now/panel-glass-market

Key Players in the Panel Glass Market:

The Panel Glass Market is highly competitive, with several global and regional players contributing to its growth. Key players include:

Asahi Glass

Saint-Gobain

Nippon Sheet Glass

Guardian Industries

Taiwan Glass

Central Glass

Sisecam Group

Vitro, S.A.B. de C.V.

CSG Holding Co., Ltd.

Fuyao Glass Industry Group

China Glass Holdings Limited

Xinyi Glass Holdings Limited

Cardinal Glass Industries

Euroglas GmbH

Luoyang Float Glass Group

Trulite Glass & Aluminum Solutions

Schott AG

Scheuten Glass Holding B.V.

Sangalli Group, Emerge Glass India

HNG Float Glass

Tianjin CSG Architectural Glass

Gulf Glass Industries

Qingdao Kangdeli Industrial & Trading Co.

Shandong Jinjing Science and Technology Stock Co., Ltd.

These players are investing heavily in research and development (R&D) to enhance their product portfolios and improve their manufacturing capabilities. Many of these companies are also focusing on strategic collaborations and partnerships to expand their market presence and offer advanced glass solutions.

Market Segmentation:

The Panel Glass Market can be segmented based on product type and applications.

By Product:

Tempered Glass: Used in applications requiring safety and strength, such as windows and automotive windshields.

Laminated Glass: Known for its safety and soundproofing properties, laminated glass is used in a variety of applications, from automotive to architectural designs.

Basic Float Glass: Widely used in construction, this glass is a flat, transparent product with various uses.

Extra Clear Glass: Known for its superior optical clarity, extra-clear glass is used in premium applications, including high-end architectural projects.

Coated Glass: Coatings on glass improve durability, weather resistance, and energy efficiency, making it a top choice in energy-efficient construction.

Others: Includes various specialized glass types for niche markets.

By Applications:

Solar Energy: Glass used in solar panels plays a critical role in the renewable energy sector.

Transportation and Automotive: Glass used in vehicles offers safety, insulation, and aesthetic features.

Infrastructure and Construction: Glass is a major component in modern building designs, used for windows, facades, and interior applications.

Others: Includes other specialized applications in electronics, consumer goods, and more.

Conclusion:

The Panel Glass Market is set for significant growth over the next decade. With its increasing application in sectors such as construction, automotive, and renewable energy, the market is poised to expand. Companies looking to capitalize on this growth will need to focus on innovation, product quality, and sustainability practices to stay ahead in a competitive landscape.

For more information or to request a sample of the Panel Glass Market report, contact Straits Research today.

Contact Us: Email: [email protected] Website: https://straitsresearch.com

0 notes

Text

0 notes

Text

Building and Construction Tapes Market: Regional Growth Trends

The Building and Construction Tapes Market is expanding due to the increasing demand for effective bonding, sealing, and insulation solutions in the construction industry. These tapes play a vital role in enhancing durability, efficiency, and aesthetics across residential, commercial, and industrial projects.

Read Complete Report Details of Building and Construction Tapes Market: https://www.snsinsider.com/reports/building-and-construction-tapes-market-2890

Market Segmentation

By Product

Masking Tapes

Commonly used for temporary protection during painting or finishing.

Features: Easy removal without residue, versatility.

Double-Sided Tapes

Ideal for bonding materials without visible fasteners.

Features: Strong adhesion, aesthetics, durability.

Duct Tapes

Multi-purpose tapes for sealing, repairing, and waterproofing.

Features: High strength, moisture resistance.

Others

Specialty tapes like electrical, reflective, or safety tapes.

By Backing Material

Paper

Lightweight and easy to tear.

Applications: Masking and general-purpose uses.

Foil

Offers high resistance to heat and moisture.

Applications: HVAC and roofing.

Polypropylene (PP)

Flexible, lightweight, and cost-effective.

Applications: Packaging and bonding.

Polyethylene (PE)

High durability and weather resistance.

Applications: Outdoor and heavy-duty tasks.

Foam

Provides cushioning and soundproofing.

Applications: Glazing and insulation.

Polyvinyl Chloride (PVC)

Known for toughness and weather resistance.

Applications: Electrical and plumbing.

PET (Polyethylene Terephthalate)

High tensile strength and thermal stability.

Applications: Specialty bonding.

Others

Includes materials like fabric and rubber-based tapes.

By Application

Building Envelope

Tapes for air sealing and water protection.

Flooring

Used for carpet and tile installation.

Windows and Roofing

Tapes for glazing, sealing, and waterproofing.

Doors, Walls & Ceilings

For bonding, insulation, and soundproofing.

HVAC and Electrical

Tapes used for duct sealing and cable management.

Others

Applications like protection and repair.

By Function

Glazing

Tapes for securing and sealing glass panels.

Bonding

Adhesive tapes replacing mechanical fasteners.

Soundproofing and Insulation

Tapes with acoustic and thermal insulation properties.

Cable Management

Tapes for organizing and securing electrical wiring.

Protection

For surface protection during construction.

By Distribution

Direct Sales

Sales directly to contractors, builders, or end users.

Third-Party

Via distributors, retailers, or e-commerce platforms.

By End Use

Commercial

Office buildings, shopping malls, and institutions.

Industrial

Factories, warehouses, and specialized facilities.

Residential

Houses, apartments, and other living spaces.

By Region

North America

High demand due to renovation and green building trends.

Europe

Focus on energy-efficient and sustainable construction.

Asia-Pacific

Booming construction sector due to urbanization and infrastructure development.

Latin America

Growth driven by increasing investments in housing and commercial projects.

Middle East & Africa

Expansion of commercial and industrial infrastructure.

Market Trends and Opportunities

Sustainability Focus: Growing adoption of eco-friendly tapes using recyclable or biodegradable materials.

Advanced Adhesives: Development of high-strength and weather-resistant adhesive formulations.

Smart Tapes: Incorporation of sensors or functional coatings for advanced applications.

Customization: Tailored tapes to meet specific construction needs.

Market Outlook

The Building and Construction Tapes Market is expected to grow steadily through 2031, driven by urbanization, infrastructure investments, and the push for sustainable construction practices. With innovations in materials and adhesive technologies, the market is poised to offer enhanced performance and versatility across applications.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

Ethylene tetrafluoroethylene (ETFE) Market

Ethylene Tetrafluoroethylene (ETFE) Market Size, Share, Trends: 3M Company Leads

Growing adoption of ETFE in sustainable architecture and green building designs is revolutionizing the construction industry.

Market Overview:

The global Ethylene Tetrafluoroethylene (ETFE) Market is projected to grow at a CAGR of 7.2% from 2024 to 2031. The market value is expected to increase significantly during this period. Asia-Pacific currently dominates the market, followed closely by Europe. Key metrics include the increasing demand for lightweight and durable materials in various industries, growing adoption of ETFE in architectural applications, and rising investments in solar energy projects. The market is experiencing steady growth due to ETFE's unique properties such as high chemical resistance, excellent thermal stability, and superior weatherability.

The growing adoption of ETFE in sustainable architecture and green building designs is a major market trend. Architects and designers are increasingly choosing ETFE over traditional materials like glass for large-scale roofing and façade projects due to its ability to create energy-efficient and aesthetically pleasing structures. ETFE films allow for innovative designs that maximize natural light while minimizing heat gain or loss, resulting in reduced energy consumption in buildings. The expanding use of ETFE in iconic structures worldwide has further popularized its use in sustainable architecture.

The market scope extends beyond construction, with significant applications in the solar energy sector. ETFE films are increasingly being used in photovoltaic modules and solar panels, offering benefits such as high light transmission, durability, and flexibility. This trend aligns with the global push towards renewable energy sources and the need for lightweight, efficient materials in solar technology.

DOWNLOAD FREE SAMPLE

Market Trends:

The ETFE market is experiencing a substantial trend of greater use in sustainable architecture and green building concepts. This trend is being pushed by ETFE's outstanding qualities, which include high light transmission, low weight, and great thermal insulation. ETFE is increasingly preferred by architects and designers over traditional glass for large-scale roofing and façade projects due to its ability to construct energy-efficient, aesthetically beautiful structures. ETFE films enable unique designs that maximize natural light penetration while limiting heat input or loss, resulting in reduced energy usage in buildings. ETFE's widespread use in famous structures, including as the Eden Project in the United Kingdom and the Beijing National Aquatics Centre, has expanded its popularity in sustainable design. As the global emphasis on sustainable construction methods grows, demand for ETFE in green building designs is likely to rise, accelerating market growth.

Market Segmentation:

The Films & Sheets segment dominates the ETFE market due to their versatility and wide-ranging applications in construction and solar energy sectors. The Films & Sheets area has emerged as the most important application category in the ETFE industry, accounting for a significant portion of total sales. This supremacy can be due to the adaptability of ETFE films and sheets, which are used in a variety of industries such as building and solar energy. ETFE films are commonly employed as roofing and facade solutions in large-scale architectural projects, sports stadiums and transportation hubs.

ETFE films and sheets are particularly popular in sustainable building designs due to its outstanding light transmission, thermal insulation, and lightweight nature. These characteristics enable architects to design energy-efficient structures that maximize natural sunshine while retaining thermal comfort.

Recent advances in ETFE film technology have increased its market share. The development of multi-layer ETFE systems with higher insulating properties, as well as the incorporation of photochromic elements for dynamic solar management, have increased the material's usability in building applications.

The solar energy sector has also made a substantial contribution to the expansion of the ETFE films and sheets market. ETFE films are increasingly being utilized as frontsheets in solar modules, providing benefits such as excellent light transmission, durability, and self-cleaning. This application is gaining popularity as the worldwide solar energy market grows, fueled by renewable energy goals and lower solar technology costs.

Market Key Players:

3M Company

Asahi Glass Company Limited

Daikin Industries Ltd.

The Chemours Company

Quadrant AG

Vector Foiltec

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Elastomeric Foam Market Segments and Trends: Size, Share, and Forecast to 2032

The global elastomeric foam market size was USD 2.648 billion in 2019. The market is projected to reach USD 4.462 billion in 2027 at a CAGR of 6.8% during the 2020-2027 period. Increasing demand for HVAC systems for maintaining the internal environment of the commercial and residential buildings which is projected to fuel the market growth. Rising demand for the product in various applications is anticipated to drive the market share. High demand from the construction industry is expected to increase the market size during the forecast period. Popularity for the product is growing as it reduces the need for any vapor barrier. Growing industrialization and miniaturization are expected to boost the demand for the product. Fortune Business Insights™ mentioned this in a report titled, “Elastomeric Foam Market, 2024-2032”.

Segmentation

By Function Analysis, Thermal Insulation Segment Led in 2019

Based on the function, the market is segmented into acoustic insulation and thermal insulation. Thermal insulation segment is anticipated to have a significant growth as it is used in various in industries. It is used in industries such as construction, textiles, automotive, mechanical systems, and general manufacturing. Higher share of this segment is credited to the use of thermal insulation which is done by using processes such as cellulose, glass wools, and others and specially engineered materials. Thermal insulation prevents the buildings from overheating under hot conditions.

By Type Analysis, EPDM Segment to Lead the Type Segment

Based on the type, the market is divided into EPDM, NBR, and others. EPDM segment had majority share in 2019 and is predicted to have a substantial growth during the forecast period. This is due to its advantages such as lower permeability, conformability, and insulation properties. It exhibits for insulating, gasketing, and sealing. It is durable, flexible, cost-effective, and has lower maintenance for insulation. Increasing demand from automotive and industrial sectors.

By Application Analysis, HVAC Segment to Dominate the Application Segment

On the basis of application, the market is divided into automotive & transportation, electrical & electronics, heating, ventilation, cooling, and air conditioning (HVAC), and others. HVAC dominated the segment in 2019 and is expected to dominate in 2027. They are used in residential and industrial for maintaining the heating, airflow, and ventilation.

List of Key Players Present in the Market

Armacell International SA (Germany)

Zotefoams PLC (U.K.)

Kaimann Insulation (Germany)

L'Isolante K-Flex (Italy)

Huamei Energy-Saving Technology Group Co., Ltd. (China)

NMC Insulation (U.K.)

Aeroflex USA, Inc. (U.S.)

Kingswell World Industries (China)

Inc. (U.S.)

Hira Industries (UAE)

Report Coverage

This report covers the overview of this market that provides an analysis of product, impact of COVID-19 pandemic, segmentation, drivers and restraints, regional insights, new developments, and key players present in the market. Dynamic change in the market is subjected to alter the demand in the forecast period.

Drivers & Restraints

Need for Renewable Energy Sources to Display High Growth Trajectory

Increasing demand for HVAC systems from various end-sectors is anticipated to shape of elastomeric foam market growth. HVAC systems is used to maintain the temperature of the internal environment. It involves maintaining air conditioning, ventilation, and heating. Increasing applications in residential facilities, hospitals, and others is projected to drive the market growth. They are used to maintain a healthy temperature according to the weather conditions. Stringent rules and regulations by Occupational Safety and Health Administration (OSHA) for safety and health is expected to fuel the market growth.

On the other hand, disposability and lack of awareness of the product amongst the consumers is expected to hamper market growth for elastomeric foam during the forecast period.

Get More Information: https://www.fortunebusinessinsights.com/elastomeric-foam-market-104004

Regional Insights

High Demand from Industrial Sector in Asia Pacific to Augment Market Growth

Asia Pacific holds the largest part in the global elastomeric foam market share due to ongoing demand for HVAC systems from the industrial sector in the region. The increase in the market size is attributed to high demand from manufacturing industries to boost region’s growth. Thermal insulation is one of the widely techniques that is used to maintain temperature of the environment. The regional market is set to grow owing to easy accessibility of raw materials in countries such as India, China, and Southeastern Asian countries. Low labor costs in the various countries in the region is expected to drive the market growth. The region has established various production facilities and businesses which is anticipated to drive market growth.

Competitive Landscape:

New players entering the market have launched their new product lines making the market more competitive with their advanced solutions. It includes R&D investments, launch of new and advanced products in the market. Companies have been adopting strategies such as partnerships, mergers, and acquisitions to strengthen their market position.

0 notes

Text

Center Enamel: China’s Leading Silo Manufacturer for Efficient Bulk Storage Solutions

As a pioneer in the storage tank industry, Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel) is proud to be recognized as China’s leading silo manufacturer. We specialize in providing advanced silo solutions for bulk storage applications across various industries, including agriculture, chemicals, pharmaceuticals, cement, and more. Our commitment to quality, innovation, and sustainability has established us as a trusted partner in the global market for silo storage systems.

Our Glass-Fused-to-Steel (GFS) silos, Fusion-Bonded Epoxy (FBE) silos, and other custom storage solutions are designed to meet the diverse needs of our customers, ensuring optimal storage conditions, easy maintenance, and long-lasting durability for both dry and liquid bulk materials.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Center Enamel for Your Silo Solutions?

1. Unmatched Durability and Protection

The Glass-Fused-to-Steel (GFS) technology is a standout feature of our silos, providing a corrosion-resistant, robust, and durable solution for long-term bulk storage. The enamel coating is fused to the steel at high temperatures, forming a seamless protective layer that ensures superior resistance to chemicals, environmental conditions, and wear-and-tear.

2. Customizable Storage Solutions

At Center Enamel, we understand that every silo project has unique requirements. Whether you're storing grain, fertilizers, cement, or biomass, we offer customized silo solutions to meet your specific needs. Our team works closely with clients to design silos that meet the required storage volume, capacity, and space constraints, ensuring an efficient and cost-effective solution for your business.

3. Rapid Construction and Installation

Our modular silo systems are designed for rapid construction and easy installation. Using pre-engineered, bolt-together technology, we ensure fast assembly, reducing construction time and labor costs. This makes our silos the perfect solution for projects that need to be completed on tight schedules.

4. Sustainable and Eco-Friendly Design

Sustainability is a priority in all our silo projects. Our Glass-Fused-to-Steel silos are made using eco-friendly materials that are highly durable and energy-efficient. Our silos help reduce material waste, support efficient storage, and are built with environmental protection in mind.

5. High-Standard Engineering and Quality Control

We adhere to stringent quality standards in the design, manufacturing, and testing of our silos. Our engineering team uses the latest technologies to ensure that every silo is built to last, providing maximum strength, stability, and safety in various environmental conditions. Each silo undergoes rigorous testing for performance and structural integrity, ensuring it meets both international and industry-specific standards.

Applications of Center Enamel Silos

Our silos are versatile and serve a wide range of industries and applications, including:

Agriculture: Ideal for storing grains, fertilizers, seeds, and other agricultural products. Our silos protect against moisture, pests, and other environmental factors, ensuring high-quality storage for farm products.

Cement and Concrete: Center Enamel’s cement silos provide a secure, reliable storage solution for bulk cement, lime, and other construction materials, ensuring that your building materials stay dry and free from contaminants.

Food and Feed: For the food and animal feed industries, our silos are designed to safely store flour, sugar, corn, and other ingredients, ensuring that the materials remain uncontaminated and easily accessible.

Chemicals and Pharmaceuticals: Our chemical silos are engineered to safely store raw materials, including powders, granules, and liquids, that require secure and precise storage conditions.

Biomass and Renewable Energy: Our silos are also perfect for storing biomass, wood chips, and other renewable materials, supporting the green energy sector by ensuring safe storage and efficient handling of materials.

Global Reach and Expertise

With over 30 years of experience, Center Enamel has earned a reputation as a leader in the silo manufacturing industry, with successful installations in over 100 countries worldwide. We pride ourselves on providing innovative, high-quality storage solutions that meet the needs of businesses of all sizes and industries.

Our silos have been installed in a wide range of climates, from tropical to arctic regions, proving their durability and versatility in diverse environments. Whether you need a silo for agriculture, cement storage, or chemical storage, our solutions are engineered to withstand the most demanding conditions and provide long-lasting performance.

At Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel), we are committed to providing state-of-the-art silo solutions that meet the unique needs of industries worldwide. Our Glass-Fused-to-Steel silos, Fusion-Bonded Epoxy silos, and Stainless Steel silos offer unmatched durability, rapid construction, and eco-friendly features, making them the ideal choice for bulk material storage.

As China’s leading silo manufacturer, we pride ourselves on delivering high-quality, cost-effective storage solutions that ensure your materials are stored safely, efficiently, and sustainably. With our global reach and expert engineering, we are ready to support your silo needs no matter the size or complexity of your project.

Contact us today to learn more about how Center Enamel can provide the perfect silo solution for your business needs. Let us help you achieve efficient storage and optimize your operations with our high-quality silos.

0 notes

Text

Industrial Furnaces: Backbone of Industrial Processes

Industrial furnaces play a critical role in numerous manufacturing and production processes, providing the controlled heat environments necessary for tasks like metal melting, heat treatment, and material synthesis. From small workshops to large-scale factories, these furnaces are indispensable in industries such as metallurgy, ceramics, glass manufacturing, and chemical processing. In India, the demand for industrial furnaces is growing rapidly, driven by advancements in technology and the expansion of manufacturing sectors. This has also led to the emergence of reliable industrial furnace manufacturers in India, who cater to both domestic and international markets.

What Are Industrial Furnaces?

An industrial furnace is a robust thermal device used to achieve and maintain high temperatures for various processes. These furnaces are engineered to provide precise temperature control, uniform heat distribution, and energy efficiency.

Types of Industrial Furnaces

Blast Furnaces: Used primarily in the steel and iron industries for smelting.

Electric Arc Furnaces: Common in recycling steel, utilizing electric arcs to generate high heat.

Reheating Furnaces: Employed in the rolling of steel to achieve desired shapes and dimensions.

Kilns: Used in ceramics and brick production, operating at lower temperatures compared to other furnaces.

Annealing Furnaces: Essential in heat-treating metals to improve ductility and reduce hardness.

Rotary Furnaces: Designed for melting metals like aluminum and lead.

Each furnace type is tailored for specific applications, with unique designs and fuel sources, such as gas, oil, or electricity.

Importance of Industrial Furnaces

The significance of industrial furnaces extends beyond their functionality. These systems are the linchpins of industrial processes, facilitating:

Material Transformation: Converting raw materials into finished goods.

Process Efficiency: Enhancing production rates while maintaining quality.

Energy Optimization: Leveraging advanced technologies to reduce fuel consumption.

Environmental Compliance: Adopting eco-friendly designs to minimize emissions.

The Role of Industrial Furnace Manufacturers in India

India has emerged as a global hub for manufacturing, with industries continually seeking advanced solutions for their operational needs. Industrial furnace manufacturers in India are addressing these demands by developing cutting-edge furnace designs and technologies. These manufacturers emphasize durability, efficiency, and customization to cater to the diverse needs of industries.

Key Innovations by Indian Manufacturers:

Energy-Efficient Models: Utilizing advanced insulation and heating systems to reduce energy costs.

Automation Integration: Incorporating programmable logic controllers (PLCs) for precise temperature control and monitoring.

Compact Designs: Catering to small-scale industries with space-saving yet powerful furnaces.

Eco-Friendly Furnaces: Focusing on low-emission designs to align with global sustainability standards.

Indian manufacturers also excel in providing after-sales support, including maintenance, spare parts, and operational guidance, ensuring a seamless user experience.

Factors to Consider When Choosing an Industrial Furnace

When selecting an industrial furnace, several factors must be evaluated to ensure optimal performance:

Purpose and Application: Define the specific industrial process for which the furnace will be used.

Capacity: Choose a furnace that matches your production scale.

Fuel Type: Consider availability and cost of fuel or electricity.

Temperature Range: Ensure the furnace can achieve the required temperature levels.

Manufacturer Reputation: Opt for trusted industrial furnace manufacturers in India known for quality and reliability.

Leading Applications of Industrial Furnaces

Metalworking: Forging, casting, and heat-treating metals for automotive and aerospace sectors.

Glass Manufacturing: Melting and shaping glass for consumer and industrial products.

Ceramics Production: Creating durable materials for construction and industrial use.

Chemical Processing: Synthesizing compounds under controlled thermal conditions.

Conclusion

The role of industrial furnaces in driving industrial growth cannot be overstated. From basic material processing to sophisticated manufacturing tasks, these devices form the backbone of various industries. With advancements in technology and a focus on sustainability, the demand for reliable and efficient industrial furnaces is set to grow.

In this context, industrial furnace manufacturers in India are poised to play a pivotal role in meeting both domestic and international demands. Their commitment to innovation, quality, and customer satisfaction ensures that Indian-made furnaces remain at the forefront of the global market, empowering industries worldwide to achieve excellence in their operations.

#indudtrial furnaces#indudtrial furnaces manufacturers in Bangalore#indudtrial furnaces manufacturers in India

0 notes

Text

Structural Insulated Panel Market Grow with a High CAGR- Global Industry Analysis, Key Manufacturers, Trends, Size, and Forecasts

Analysis of Structural Insulated Panel Market Size by Research Nester Reveals the Market to Grow with a CAGR of ~5.3% During 2025-2037 and Attain ~USD 26.69 Billion by 2037

Research Nester assesses the growth and market size of the global structural insulated panel market which is anticipated to be on account of the rising need for structural insulated panels and low labor cost.

Research Nester’s recent market research analysis on “Drug Delivery Systems Market: Global Demand Analysis & Opportunity Outlook 2037” delivers a detailed competitors analysis and a detailed overview of the global structural insulated panel marketin terms of market segmentation by facing material, insulation material, product, application, end-use and by region.

Presence of Favorable Government Regulations and Programs to Promote Global Market Share of Structural Insulated Panel Market

The global structural insulated panel market is estimated to grow majorly on account of the increased surging construction of green buildings. It has been estimated that in the year 2020, there were more than 120,100 green-rated [R1] buildings globally. Also, the demand for rising sustainability would create a requirement for making more green buildings in the future, fueling the global structural insulated panel market in the coming decades. Other than this, there has been an increased demand for the establishment of cold storage due to rising frozen food sales and increased online grocery shopping. For instance, the number of cold storage in California reached almost 263, Texas – 172[R2] , Florida 117, Georgia 65 in the year 2025. The structural insulated panels have string foam of insulation layer placed between 2 surfaces. This makes the cold storage buildings more energy efficient than the traditional buildings. These regulate temperature efficiently and keep the interior cool. Owing to this, the global structural insulated panel market in the forecasted period. Other than this, there is a rise in extreme weather occurrences and increased emphasis on developing disaster-resistant structures. SIPs provide a robust framework that can withstand long-term wear and tear as well force of hurricanes. There is an increased demand for disaster-resilient zones that utilize SIPs, augmenting the global structural insulated panel market growth during the forecasted period.

Some of the major growth factors and challenges that are associated with the growth of the global structural insulated panel market growth are:

Growth Drivers:

Rising Requirement for Structural Insulated Panels in Cold Storage Application

Sustainable and Energy Efficient Construction Practices

Challenges:

Insufficient information related to the structural insulated panels, excessive industry competition, and scarcity of high-quality materials are some of the major factors anticipated to hamper the global market size of global structural insulated panel market growth.

Access our detailed report at: https://www.researchnester.com/reports/structural-insulated-panels-market/5937

By production, the global structural insulated panel market growth is segmented into polystyrene, polyurethane panels, and glass wool panels. Out of these, the polystyrene segment is anticipated to hold a maximum share of almost 45.1% during the forecasted period. The demand for this segment can be attributed to the attributes such as resilience and cost-effectiveness.

By region, the Europe structural insulated panel market growth is to generate the highest revenue by the end of 2037. The growth in the region can be attributed to the rising demand for insulated buildings and helpful government initiatives.

Request Report Sample@ https://www.researchnester.com/sample-request-5937

This report also provides the existing competitive scenario of some of the key players of the global structural insulated panel market growth which includes company profiling of Melt Span, Kingspan Group, Isopan, KPS Global, Owens Corning, PFB Corporation, American Insulated Panel, Structural Panels Inc., All Weather Insulated Panels, Ingreen Systems Corp., TOLI Corporation, DAIKIN Industries Ltd., Panasonic Corporation, NOHARA Co. Ltd., Fukuda Kyoto Co. and others.

Customized report@ https://www.researchnester.com/customized-reports-5937

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

High Temperature Fiber Market Analysis by Growth, Emerging Trends and Future Opportunities Till 2037

Research Nester assesses the growth and market size of the global high temperature fiber market, which is anticipated to be driven by rising demand in the aerospace and defense sector as well as the growth of industrial manufacturing activities.

Research Nester’s recent market research analysis on “High Temperature Fiber Market: Global Demand Analysis & Opportunity Outlook 2037” delivers a detailed competitor’s analysis and overview of the global high temperature fiber market in terms of market segmentation by fiber type, form, application, and region.

Request for customization @

Regulatory Compliance and Safety Standards to Promote Global High Temperature Fiber Market Growth

Governments and regulatory bodies have put in place stringent laws and guidelines that require the use of high-performance materials in a variety of industries, including industrial production, construction, automotive, and aerospace. For instance, the Occupational Safety and Health Administration (OSHA) has set stringent guidelines for the usage of insulation and protective gear in high temperature environments which leads to a rise in the adoption of ceramic and aramid fibers as these are known for their durability and heat resistance. Moreover, the rising emphasis on fire safety in building codes particularly following high-profile incidents in the construction sector has increased the demand for fire-resistant materials such as aramid fibers. These regulatory guidelines and growing safety standards continue to drive modernization and market growth as companies invest in innovative materials to meet the latest compliance requirements.

Growth Drivers

Growth in electronics and automotive industries

Expansion of industrial manufacturing activities

Challenges

Competition from alternative materials plays a significant challenge for the high temperature fiber market as more affordable options are available in the market such as metal composites and certain heat-resistant polymers which progressively offer viable substitutes. For example, Metal Matrix Composites (MMC) developed polymers can deliver adequate thermal resistance for applications in industries such as construction, aerospace, and automotive which are often at a lesser cost than aramid and ceramic fibers. This cost efficiency becomes critical in sectors where the budget is tight, which limits the broader adoption of high temperature fibers.

Access our detailed report at:

Based on fiber type, the ceramicsegment is predicted to capture 52.4% of the global market share by 2037 owing to its remarkable heat resistance, thermal stability, and insulating qualities. These are extensively utilized in parts for aircraft, kiln insulation, and furnace linings that require exposure to high temperatures. In the automotive industry, ceramic fibers are widely used for thermal barriers in catalytic converters and exhaust systems. Their use in industrial operations such as glass manufacture and metal casting stems from their capacity to retain structural integrity at elevated temperatures.

By region, North America is anticipated to account for 35.1% of the revenue share during the forecast period, due to the presence of well-known aerospace and automotive giants such as Ford, General Motors, Boeing, and Airbus. By heavily relying on high-temperature fibers for essential components like exhaust systems, brakes, and aviation engines, these industry leaders highlight the critical role that these fibers play in state-of-the-art manufacturing processes. The nation continues to lead the world in materials science and engineering advancements due to a robust ecosystem composed of esteemed companies, research facilities, and a highly skilled workforce. High-performance material innovation is fueled by the region's sophisticated R&D skills, and its position is further reinforced by the presence of important industry participants and production facilities.

This report also provides the existing competitive scenario of some of the key players of the global high temperature fiber market which includes company profiling of DuPont, 3M Company, Zoltek Companies, Inc., SGL Carbon SE, Kolon Industries, Inc., Yantai Tayho Advanced Materials Co., Ltd., Toray Industries, Inc., Teijin Limited, Toyobo Co., Ltd., Mitsubishi Chemical Corporation, and Asahi Kasei Corporation.

Request Report Sample@

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates, and executives make wise decisions for their future marketing strategy, expansion investment, etc. We believe every business can expand to its new horizon, provided the right guidance at the right time is available through strategic minds. Our out-of-the-box thinking helps our clients to make wise decisions to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

0 notes

Text

https://www.databridgemarketresearch.com/reports/global-insulated-glass-market

0 notes

Text

Glass Fibers & Specialty Synthetic Fibers Market Challenges, Analysis and Forecast to 2034

The Glass Fibers & Specialty Synthetic Fibers Market is a dynamic segment within the materials industry, driven by the increasing demand for lightweight, durable, and high-performance materials across various sectors. These fibers are engineered for applications that require superior mechanical properties, thermal stability, and resistance to environmental factors

The market for glass fiber and specialty synthetic fibers is expected to increase at a compound annual growth rate (CAGR) of 6.4% between 2024 and 2034. According to an average growth trend, the market is expected to reach USD 144.58 billion in 2034. The global market for glass fibers and specialty synthetic fibers is expected to generate USD 85.59 billion by 2024.

Get a Sample Copy of Report, Click Here: https://wemarketresearch.com/reports/request-free-sample-pdf/glass-and-specialty-synthetic-fibers-market/1603

Glass Fibers & Specialty Synthetic Fibers Market Growth Drivers

Urbanization and Infrastructure Growth:

Increasing investments in construction and urban development drive demand for glass fibers.

Rising Defense Budgets:

Governments worldwide are increasing investments in protective equipment using synthetic fibers.

Shift Toward Renewable Energy:

Wind energy projects favor glass fibers for turbine blades.

Advancements in Material Engineering:

Innovations are improving the properties and reducing production costs of synthetic fibers.

Specialty Synthetic Fibers: Types

Aramid Fibers:

Examples: Kevlar, Twaron.

High tensile strength and resistance to impact and heat.

Used in bulletproof vests, fire-resistant clothing, and ropes.

Carbon Fibers:

Lightweight and exceptionally strong.

Applications: Aerospace, sports equipment, automotive (luxury cars).

Ultra-High-Molecular-Weight Polyethylene (UHMWPE):

Examples: Dyneema, Spectra.

Extremely lightweight with high impact resistance.

Used in personal armor, fishing lines, and medical implants.

Polybenzimidazole (PBI):

High thermal and chemical stability.

Used in firefighting gear and aerospace insulation.

Polyimide Fibers:

Heat-resistant fibers ideal for use in high-temperature industrial applications.

Glass Fibers & Specialty Synthetic Fibers Market Challenges

High Costs of Specialty Fibers:

The manufacturing process for carbon and aramid fibers is resource-intensive.

Environmental Impact:

Synthetic fibers contribute to pollution if not recycled properly.

Competition from Emerging Materials:

Natural fibers like hemp and bamboo, as well as metal composites, are gaining attention.

Emerging Trends

Integration with Smart Technologies:

Development of fibers with embedded sensors for structural health monitoring.

Circular Economy Initiatives:

Companies are investing in recycling technologies for glass and synthetic fibers.

Hybrid Materials:

Combining glass and synthetic fibers to create composites with enhanced properties.

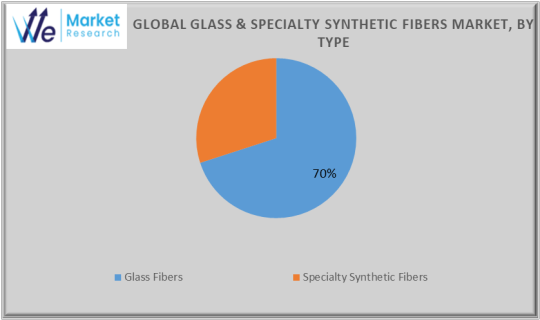

Glass Fibers & Specialty Synthetic Fibers Market Segmentation,

By Type

Glass Fibers

E-Glass

S-Glass

C-Glass

Others

Specialty Synthetic Fibers

Polyester

Nylon

Aramid

Carbon Fibers

Polypropylene (PP)

Others

By Application

Textile

Construction

Automotive

Aerospace & Defense

Marine

Consumer Goods

Packaging

Wind Energy

Others

Key companies profiled in this research study are,

The Global Glass Fibers & Specialty Synthetic Fibers Market is dominated by a few large companies, such as

Owens Corning

Jushi Group

PPG Industries

Saint-Gobain

China National Glass Industrial Group Corporation (CNG)

Nippon Electric Glass Co., Ltd.

Sika AG

DuPont

Solvay

Teijin Limited

Hyosung Corporation

Toray Industries

DSM (Dutch State Mines)

BASF

Asahi Kasei Corporation

Others

Glass Fibers & Specialty Synthetic Fibers Industry: Regional Analysis

Forecast for the North American market

North America will be a significant player in the glass fiber and specialized synthetic fiber industries, accounting for about 40% of the worldwide market in 2023. Due to its technological dominance and strong industrial base in the automotive, aerospace, and defense sectors, North America has a disproportionate amount. North America, particularly the United States, is a major market for glass fibers and specialty synthetic fibers.

Forecast for the European Market

Europe is an essential market for glass and specialty synthetic fibers due to the prevalence of the automobile and aerospace industries there. Countries like Germany, France, and the UK are investing in lightweight materials for cars and airplanes, which directly increases demand for fibers like glass and carbon fibers. The European Union's focus on sustainability and energy efficiency has led to a greater usage of advanced materials, such as carbon fibers for renewable energy applications like wind turbines and glass fibers for construction. Europe is the hub for research and development, particularly in the areas of lightweight composite materials and high-performance fibers for industrial applications.

Forecasts for the Asia Pacific Market

The growth of the Chinese, Japanese, and Indian industries is primarily responsible for the Asia-Pacific region's sharp increase in demand for glass fibers and specialty synthetic fibers. Particularly in countries like China, India, and Japan, the Asia-Pacific region is fast become increasingly urbanized and industrialized. This is driving the demand for glass fibers in the automotive, infrastructure construction, and building industries. The need for lightweight materials is rising in the Asia-Pacific automotive industry as a result of the rising popularity of electric vehicles (EVs) and fuel-efficient cars in countries like China and Japan. The need for glass and carbon fibers rises as a result.

Conclusion

The Glass Fibers & Specialty Synthetic Fibers Market is poised for robust growth, driven by advancements in material science, the increasing demand for lightweight and high-strength materials, and expanding applications across industries like construction, automotive, aerospace, and renewable energy. While challenges such as high production costs and environmental concerns persist, ongoing innovations in recycling and sustainable fiber production are paving the way for a greener future.

As industries worldwide prioritize efficiency, durability, and sustainability, the market for glass and specialty synthetic fibers is set to play a critical role in shaping the future of materials technology. With strong investments in R&D and the rise of eco-friendly initiatives, this market presents vast opportunities for growth and innovation.

0 notes

Text

0 notes

Text

Understanding Pipe Insulation Market: Trends and Growth Drivers

The global pipe insulation market size is expected to reach USD 13.57 billion by 2030, registering a CAGR of 5.5% from 2023 to 2030 according to a new report by Grand View Research, Inc. Increasing infrastructure spending in the emerging markets of Asia Pacific and Central and South America is expected to propel market growth.

The price structure of the product varies with respect to production processes and raw materials used. Fluctuating raw material prices result in variations in the prices of thermal insulating materials, thus affecting the suppliers who have integrated themselves across the value chain, thereby enabling them to gain superior control over product pricing.

The growing adoption of cogeneration or combined cooling, heat, and power (CCHP) technology for electricity generation is expected to drive the product demand. In addition, rising investments in R&D activities to optimize and lower the cost of insulation materials including polyurethane (PU) and polyisocyanurate are expected to benefit the market.

Key industry participants including Saint-Gobain and Rockwool International A/S are expanding their geographic presence and customer base through marketing strategies such as mergers and acquisitions. Furthermore, players such as Knauf Insulation and Armacell LLC are integrated across the value chain to gain a competitive advantage.

Gather more insights about the market drivers, restrains and growth of the Pipe Insulation Market

Pipe Insulation Market Report Highlights

• The polyurethane and polyisocyanurate foam material segment accounted for the largest market share of over 20.0% in 2021 on account of high insulating values with low conductivity and a cellular structure that helps in reducing heat transfer by conduction

• The building and construction application segment is expected to witness lucrative growth over the forecast period owing to the growing number of single-family houses in developing economies and the increasing disposable incomes of consumers, thereby driving the demand for residential construction

• The market in North America is expected to witness considerable growth over the forecast period owing to a positive outlook toward the petrochemical and chemical processing industries in the region

• The market in China is expected to be driven by the wide utilization of pipe insulation in thermal power generation to prevent heat loss while circulating hot water and steam within the power plant

• Key market players are engaged in focused cost leadership strategies, where the players compete based on product prices and target narrow markets. In addition, these companies provide additional services/customization to their customers to gain a competitive advantage

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global automotive heat shield market size was estimated at USD 13.18 billion in 2024 and is projected to grow at a CAGR of 4.9% from 2025 to 2030.

• The global wood and laminate flooring market size was estimated at USD 58.96 billion in 2024 and is projected to grow at a CAGR of 5.5% from 2025 to 2030.

Pipe Insulation Market Segmentation

Grand View Research has segmented the global pipe insulation market based on material, application, and region:

Pipe Insulation Material Outlook (Revenue, USD Million, 2018 - 2030)

• Cellular glass

• Polyurethane & Polyisocyanurate Foam

• Fiberglass

• Elastomeric Foam

• Others

Pipe Insulation Application Outlook (Revenue, USD Million, 2018 - 2030)

• Industrial

• Building & Construction

• District Energy System

Pipe Insulation Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o U.K.

o France

o Italy

o Spain

• Asia Pacific

o China

o India

o Japan

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

Order a free sample PDF of the key Pipe Insulation Market word Intelligence Study, published by Grand View Research.

#Pipe Insulation Market#Pipe Insulation Market Size#Pipe Insulation Market Share#Pipe Insulation Market Analysis#Pipe Insulation Market Report

0 notes

Text

The Future is Nano: Exploring the Growing Global Nano Glass Market

Welcome to my corner of Tumblr, where we explore innovation, sustainability, and the materials shaping our future! Today, we’re diving into one of the most exciting advancements in material science: Nano Glass. 🌟

Download Sample: Click

What is Nano Glass?

Imagine a material that’s stronger, scratch-resistant, self-cleaning, and eco-friendly—welcome to the world of nano glass! Engineered at the nanoscale, this remarkable glass is revolutionizing industries with its superior properties.

From construction to automotive and solar energy, nano glass is more than just a trend—it’s a transformative force. Here are some exciting insights into this growing market!

Key Facts About the Nano Glass Market

📊 Market Value: The global nano glass market was valued at $8.4 billion in 2023 and is projected to nearly double to $17.11 billion by 2030. With a CAGR of 10.7%, the growth trajectory is impressive!

💡 Efficiency Boost: Did you know that using nano glass in solar panels can improve efficiency by up to 30%? It's a game-changer for renewable energy.

🏗️ Construction Boom: Over 60% of new commercial buildings now incorporate nano glass for its energy efficiency and durability.

🚗 Automotive Revolution: In 2023, 25% of newly manufactured vehicles included nano glass, improving safety and reducing fuel costs.

🌍 Regional Dominance: The Asia-Pacific region leads the way with a 35% share of the global market, driven by rapid urbanization.

Why Nano Glass is a Big Deal

Nano glass isn’t just another material—it’s a problem solver for multiple industries:

1️⃣ Construction: Provides sustainable, energy-efficient solutions for modern architecture. 🌇 2️⃣ Electronics: Enhances touchscreens with better transparency and durability. 📱 3️⃣ Solar Energy: Increases solar panel lifespan and efficiency. ☀️ 4️⃣ Automotive: Offers lightweight, durable glass that improves vehicle safety. 🚘

Emerging Trends to Watch

💡 Smart Buildings: Nano glass is integral to the rise of smart cities, thanks to its thermal insulation and UV protection properties.

🧴 Multifunctional Coatings: Self-cleaning, antimicrobial, and anti-reflective coatings are making nano glass even more versatile.

🎨 Customization: Manufacturers are now offering tailored solutions for specific industry needs—how cool is that?

Market Leaders Driving Innovation

Inquire to Buy: Click

The companies leading the charge in nano glass innovation include:

AGC Inc.

Saint-Gobain S.A.

Corning Incorporated

Guardian Industries

Nanogate AG

Final Thoughts

Nano glass is more than a material—it’s a glimpse into the future of innovation and sustainability. With its expanding applications and the push for eco-friendly solutions, nano glass is set to revolutionize industries and make the world a better place.

What do you think about the future of nano glass? Are there any applications you’re most excited about? Let’s discuss in the comments!

🌟Stay tuned for more deep dives into transformative technologies! 🌟

0 notes