#Global Compressor Valve Industry

Explore tagged Tumblr posts

Text

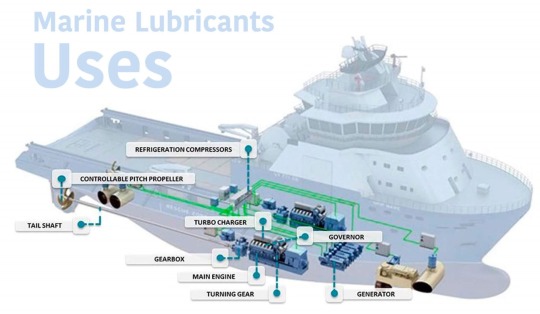

An In-Depth Analysis of the Marine Lubricants Industry : Lubricating the Future of Shipping

The global marine lubricants market size is expected to reach USD 10.27 billion by 2030, registering a CAGR of 4.2% over the forecast period, according to a new report by Grand View Research, Inc. Growing concerns regarding oceanic pollution caused by improper engine function and subsequent demand for fuel-efficient engines are estimated to trigger the growth of the market.

Growth in international trade, removal of trade barriers being the principal reason, is encouraging developing countries to concentrate more on the improvement of their infrastructure, such as roads, airports, and seaports, which play a vital role in the development of the economy. Product storage, along with the capacity to move large shipments, has placed the shipping industry in a very advantageous position.

Gain deeper insights on the market and receive your free copy with TOC now @: Marine Lubricants Market Report

Global shipping majors, just like other segments of the conventional transport industry, are increasingly getting integrated with emerging global logistics and supply chain activities, owing to both external and internal dynamics. These factors have aided industry participants in substantially consolidating their market position and supplementing their ocean freight income, subsequently stoking the demand for marine lubricants.

Engine oils dominated the market over 46.0% volume share in 2022. These products are widely used in high, medium, and slow speed marine engines to extend service life and protect interior components from high temperatures & pressure. Some lubricants even offer additive protection against crankcases, camshaft areas, under-crowns, and ring belts.

Other products such as refrigeration compressor oils are specifically formulated to perform in extreme temperature environments and consist of HFC, CFC, and ozone-friendly refrigerants. These lubricants significantly prevent congealing on valves.

#Marine Lubricants Market Size & Share#Marine Lubricants Market Latest Trends#Marine Lubricants Market Growth Forecast#COVID-19 Impacts On Marine Lubricants Market#Marine Lubricants Market Revenue Value

3 notes

·

View notes

Text

Virtual Pipeline Systems Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Global Virtual Pipeline Systems Market – Industry Trends and Forecast to 2028

Global Virtual Pipeline Systems Market, By Type (Ordinary Type, Special Type), Product (Liquefied Petroleum Gas (LPG), Liquid Natural Gas (LNG), Compressed Natural Gas (CNG), Propane, Diesel and Oils), Container Size (Type I, Type II, Type III, Type IV), Mode of Transportation (Intermodal ISO Tank Containers, Tanker Rail Cars, Pipeline Transport, Reticulated Gas System or Piped Gas System, Road Tankers, Local Bobtail Tankers), Application (Industrial, Transportation, Commercial and Residential), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- **By Component:** The virtual pipeline systems market can be segmented based on components into compressors, trailers, cylinders, valves, fittings, and others. Compressors play a crucial role in the transportation of natural gas, enabling it to be moved efficiently through pipelines. Trailers are used for the physical transportation of compressed natural gas (CNG) or liquefied natural gas (LNG) to areas without access to pipelines. Cylinders are another essential component, providing storage for the transported gas. Valves and fittings ensure smooth operations and safe handling of the gas in the virtual pipeline system.

- **By Application:** In terms of applications, the virtual pipeline systems market can be categorized into industrial, transportation, commercial, and residential sectors. The industrial sector utilizes virtual pipelines for various operations such as heat generation, power generation, and manufacturing processes. The transportation sector relies on virtual pipelines to fuel vehicles, especially in regions where traditional pipelines are not feasible. The commercial and residential sectors use virtual pipeline systems for heating, cooking, and other energy needs.

- **By Mode of Supply:** Virtual pipeline systems can also be segmented by the mode of supply, which includes truck-based transportation, rail-based transportation, and ship-based transportation. Truck-based transportation is the most common mode, offering flexibility and scalability in delivering natural gas to remote locations. Rail-based transportation provides a cost-effective solution for long-distance gas transportation. Ship-based transportation involves the use of tankers for transporting LNG to areas inaccessible by land.

**Market Players**

- **GE Oil & Gas:** GE Oil & Gas is a key player in the virtual pipeline systems market, offering a range of solutions for the compression, transportation, and storage of natural gas. The company's expertise in industrial equipment and services makes it a reliable partner for virtual pipeline projects.

- **Hexagon Composites ASA:** Hexagon Composites ASA specializes in high-pressure composite cylinders for gas storage, making them a significant player in the virtual pipeline systems market. TheirGE Oil & Gas and Hexagon Composites ASA are two key players in the virtual pipeline systems market, each bringing unique strengths and capabilities to the industry. GE Oil & Gas stands out for its comprehensive solutions for compression, transportation, and storage of natural gas. With its expertise in industrial equipment and services, the company offers a broad range of offerings that cater to the diverse needs of virtual pipeline projects. GE's reputation for reliability and innovation positions it as a trusted partner for implementing virtual pipeline systems across various sectors.

On the other hand, Hexagon Composites ASA specializes in high-pressure composite cylinders for gas storage, a critical component in virtual pipeline systems. The use of advanced composite materials in their cylinders enables Hexagon to provide lightweight and durable storage solutions for transporting natural gas efficiently and safely. The company's focus on innovation and sustainability in gas storage technologies has solidified its position as a significant player in the virtual pipeline systems market. Hexagon's expertise in high-pressure cylinders aligns with the increasing demand for reliable and high-performance storage solutions in virtual pipeline applications.

As the virtual pipeline systems market continues to grow, players like GE Oil & Gas and Hexagon Composites ASA are poised to capitalize on the increasing demand for efficient and flexible gas transportation solutions. The market trends indicate a rising adoption of virtual pipelines across various sectors, driven by the need for reliable energy supply in remote locations and areas without access to traditional pipelines. The versatility of virtual pipeline systems in industrial, transportation, commercial, and residential applications further expands the market potential for key players like GE and Hexagon.

In terms of competition within the virtual pipeline systems market, companies like GE Oil & Gas and Hexagon Composites ASA differentiate themselves through technological advancements, product innovation, and strategic partnerships. Establishing strong relationships with customers and industry stakeholders is essential for driving growth and expanding market presence. Furthermore, addressing evolving regulatory requirements and sustainability concerns will be crucial for staying competitive in the dynamic virtual pipeline systems market.

Overall, the market outlook for virtual pipeline systems remains**Global Virtual Pipeline Systems Market Analysis:**

- **Segments:** - **By Component:** Virtual pipeline systems market components include compressors, trailers, cylinders, valves, fittings, and others. Compressors are essential for efficient gas transportation, while trailers are used for physical gas transportation to areas without traditional pipelines. Cylinders provide storage for the transported gas, with valves and fittings ensuring smooth operations and safe handling within the system.

- **By Application:** Market applications cover industrial, transportation, commercial, and residential sectors. Industrial operations utilize virtual pipelines for heat and power generation, transportation for vehicle fueling, and commercial/residential sectors for heating and cooking purposes.

- **By Mode of Supply:** Segmentation by the mode of supply includes truck-based, rail-based, and ship-based transportation. Truck-based transportation offers flexibility and scalability, rail-based is cost-effective for long-distance transportation, and ship-based involves tankers for LNG transportation to remote areas.

**Market Players:** - **GE Oil & Gas:** GE Oil & Gas offers compression, transportation, and storage solutions for natural gas with a focus on industrial expertise, making them a reliable partner for virtual pipeline projects.

- **Hexagon Composites ASA:** Specializing in high-pressure composite cylinders for gas storage, Hexagon Composites ASA provides lightweight and durable storage solutions for efficient and safe gas transportation, aligning with the increasing demand for reliable storage solutions in virtual pipeline applications.

Key players like GE Oil & Gas

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Virtual Pipeline Systems Market

Chapter 3: Regional analysis of the Global Virtual Pipeline Systems Market industry

Chapter 4: Virtual Pipeline Systems Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Key takeaways from the Virtual Pipeline Systems Market report:

Detailed considerate of Virtual Pipeline Systems Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the Virtual Pipeline Systems Market-leading players.

Virtual Pipeline Systems Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of Virtual Pipeline Systems Market for forthcoming years.

Browse Trending Reports:

Air Sports Equipment Market Secondary Macronutrients Market Blood Gas Analyzer Market Methotrexate Injection Market Smart Room Heater Market Battery Market Infrastructure As a Service Iaas Health Cloud Market Peritonitis Treatment Market Yacht Charter Market Next Generation Printing Ink Market Functional Confectionery Market Herbal Ready To Brink Beverages Market Wirewound Resistor Market Gelatin Substitutes Market Soy Based Surfactants Market Trimethlyaminuria Market Secondary Agricultural Nutrients Market Tomatoes Market Electric Kick Scooters Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Air Suspension Market Overview: Growth Factors and Future Trends (2023-2032)

The Air Suspension Market is projected to grow from USD 18,554.78 million in 2024 to USD 25,589.49 million by 2032, reflecting a compound annual growth rate (CAGR) of 4.10%.

Air suspension is an advanced automotive technology designed to replace traditional steel or coil springs in vehicles. This system uses air-filled rubber bladders, also known as air springs, which are controlled by an onboard compressor and valves that regulate the pressure within the bladders. The primary advantage of air suspension lies in its ability to provide a smoother and more adaptable ride compared to traditional suspension systems. By adjusting the air pressure in the bladders, the system can alter the vehicle's ride height and stiffness, enabling it to handle different loads and road conditions more effectively. This adaptability is particularly beneficial for heavy-duty vehicles like trucks, buses, and RVs, where the load can vary significantly. Additionally, air suspension systems enhance the overall driving experience by improving ride comfort, stability, and handling, especially on uneven or rough terrain. They also contribute to better aerodynamics by allowing the vehicle to maintain a consistent ride height, which can improve fuel efficiency.

Here are the key trends in the air suspension market:

Increasing Demand for Ride Comfort: Consumers, particularly in the luxury vehicle segment, are demanding smoother and more comfortable rides, driving the adoption of air suspension systems.

Technological Advancements: Integration of advanced electronic control systems in air suspensions allows for precise adjustments, improving vehicle handling, stability, and overall performance.

Focus on Vehicle Load Management: Air suspension systems are increasingly used in commercial vehicles for their superior load-carrying capabilities, enabling automatic adjustment of ride height based on cargo weight, enhancing safety and efficiency.

Growth in Electric and Hybrid Vehicles: The rise of electric and hybrid vehicles is contributing to the air suspension market, as these vehicles often require sophisticated suspension systems to manage battery weight and ensure ride quality.

Regulatory Push for Emissions Reduction: Air suspension systems can contribute to better aerodynamics and fuel efficiency, aligning with global regulatory efforts to reduce vehicle emissions.

Aftermarket Growth: There is a rising trend in the aftermarket sector for retrofitting vehicles with air suspension systems, driven by the desire to upgrade existing vehicles with modern comfort and performance features.

Expansion in Commercial Vehicle Segment: The commercial vehicle segment, including trucks and buses, is increasingly adopting air suspension systems to improve ride quality, reduce maintenance costs, and enhance vehicle durability.

Customization and Personalization: Air suspension systems offer significant customization options, allowing consumers to tailor ride height and stiffness according to personal preferences, further driving demand.

Rising Popularity in Developing Markets: Growing automotive industries in developing regions are adopting air suspension systems, driven by increasing consumer awareness and demand for premium features in vehicles.

Integration with Autonomous Vehicles: The development of autonomous vehicles is expected to drive further innovations in air suspension technology, as these systems play a crucial role in ensuring smooth and stable rides for driverless cars.

Key Player Analysis

Hitachi Automotive, Ltd.

WABCO

LORD Corporation

ZF Friedrichshafen AG

VB-Air Suspension

Dunlop Systems and Components

Mando Corporation

Magneti Marelli S.p.A.

Hendrickson USA, L.L.C.

ThyssenKrupp AG

Firestone Industrial Products

Beijing West Industries Co., Ltd.

Continental AG

Accuair Suspension

Air Lift Company

More About Report- https://www.credenceresearch.com/report/air-suspension-market

The air suspension market is witnessing varied growth across different regions, driven by regional factors such as automotive industry development, economic conditions, and consumer preferences. Here’s a regional analysis of the air suspension market:

North America: The air suspension market in North America is robust, primarily due to the strong presence of the automotive industry and high demand for luxury vehicles and commercial trucks. The United States and Canada are key markets where the adoption of advanced suspension technologies is driven by consumer demand for comfort and the need for efficient load management in commercial vehicles. The growing trend towards electric vehicles (EVs) is also supporting the adoption of air suspension systems in the region.

Europe: Europe is a significant market for air suspension systems, particularly due to the region's focus on automotive innovation and stringent regulations on vehicle emissions and safety. Countries like Germany, the UK, and France are leading in the adoption of air suspension technologies, driven by the high demand for luxury and performance vehicles. The presence of major automotive manufacturers in the region, coupled with the increasing popularity of electric and hybrid vehicles, is further propelling market growth.

Asia Pacific: The Asia Pacific region is experiencing rapid growth in the air suspension market, driven by the expanding automotive sector, particularly in China, Japan, and India. The rising demand for commercial vehicles and the growing consumer preference for luxury features in passenger cars are key drivers. Additionally, the region's focus on improving road infrastructure and the increasing adoption of electric vehicles are contributing to the growth of air suspension systems. The aftermarket for air suspension systems is also gaining traction in this region, as consumers seek to upgrade their vehicles.

Middle East and Africa: The air suspension market in the Middle East and Africa is growing steadily, particularly in the commercial vehicle segment. The demand for air suspension systems is driven by the need for vehicles that can handle heavy loads and navigate challenging terrains. The region's luxury vehicle market is also contributing to the adoption of air suspension systems, especially in countries like the UAE and Saudi Arabia, where there is a high demand for premium automotive features.

Latin America: In Latin America, the air suspension market is gradually expanding, with increasing adoption in both the commercial and passenger vehicle segments. Brazil and Mexico are the leading markets in the region, driven by the growth of the automotive industry and the increasing demand for vehicles that offer better ride comfort and load management. Economic fluctuations and varying consumer preferences across the region pose challenges, but the market is expected to grow as automotive production and sales improve.

Overall, the air suspension market is expanding globally, with each region experiencing growth driven by local automotive trends, economic conditions, and consumer demands.

Segments:

Based on Control Type:

Electronically Controlled Air Suspension

Non-electronically Controlled Air Suspension

Based on Application Type:

Passenger Cars

Commercial Vehicles

Based on End User:

OEM

Aftermarket

Browse the full report – https://www.credenceresearch.com/report/air-suspension-market

Browse Our Blog: https://www.linkedin.com/pulse/air-suspension-market-analysis-global-industry-trends-z7pjf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Global Reach, Premium Quality, and Economical Price: Gajjar Compressor’s Air Compressor Spare Parts

In today's fast-paced industrial landscape, air compressors play a vital role in ensuring the smooth operation of various industries, from manufacturing to healthcare. A well-maintained air compressor can enhance efficiency and productivity, but this is only possible with high-quality spare parts. Gajjar Compressor, a leading name in the compressor industry, is renowned for its superior air compressor spare parts, offering global reach, premium quality, and economical prices.

Introduction to Gajjar Compressor: A Global Leader

Gajjar Compressor has been a trusted name in the air compressor industry for decades, providing top-tier products and services to industries around the world. Their reputation is built on a foundation of quality, reliability, and customer satisfaction. By focusing on delivering air compressor spare parts that meet international standards, Gajjar Compressor has positioned itself as a leader in both manufacturing and exporting.

The company’s global reach is a testament to its commitment to excellence. Gajjar Compressor not only supplies spare parts to local markets but also exports them to numerous countries across the world. This global presence ensures that businesses everywhere have access to the spare parts they need to maintain optimal operations.

Global Reach: Supporting Industries Worldwide

One of the key factors that set Gajjar Compressor apart from its competitors is its global reach. The company has established strong distribution networks that span continents, ensuring that their products are readily available in major industrial markets.

Expanding to Key Markets

From North America to Europe, Asia, and the Middle East, Gajjar Compressor's spare parts are used by companies in diverse sectors. Whether it’s the automotive industry, food and beverage production, or oil and gas exploration, industries worldwide depend on Gajjar Compressor’s high-quality components to keep their systems running efficiently.

This extensive global network allows Gajjar Compressor to understand the unique needs of different markets. They tailor their spare parts solutions to meet regional standards, ensuring compatibility with various compressor models and brands.

Efficient Logistics for Timely Delivery

Maintaining a global presence also requires efficient logistics. Gajjar Compressor excels in delivering spare parts promptly, no matter where the customer is located. By streamlining their supply chain and working with reliable shipping partners, Gajjar Compressor minimizes downtime for industries that rely on their products.

Premium Quality: Setting a Benchmark in Spare Parts Manufacturing

Quality is the hallmark of Gajjar Compressor’s spare parts. The company understands that even the smallest component can have a significant impact on the performance and longevity of an air compressor. That’s why they go above and beyond to ensure that every part they produce meets the highest standards of quality.

High-Grade Materials for Durability

Gajjar Compressor uses only the finest materials in the manufacturing of their spare parts. From precision-engineered bearings to corrosion-resistant valves and durable seals, every component is built to withstand the rigors of demanding industrial environments.

By focusing on durability, Gajjar Compressor helps businesses reduce the frequency of part replacements, leading to lower maintenance costs and improved operational efficiency. The longevity of their spare parts also minimizes the risk of unexpected breakdowns, which can result in costly downtime.

Advanced Manufacturing Processes

In addition to using high-quality materials, Gajjar Compressor employs advanced manufacturing processes to produce their spare parts. Their state-of-the-art facilities are equipped with cutting-edge machinery and technology, enabling them to achieve the highest levels of precision and consistency.

Every spare part undergoes rigorous quality control checks throughout the production process. This ensures that each component not only meets but exceeds industry standards. By adhering to strict quality protocols, Gajjar Compressor delivers products that customers can rely on, time and time again.

Economical Pricing: Value without Compromise

While Gajjar Compressor is known for its premium quality, the company also understands the importance of affordability. Their spare parts are priced competitively, making them accessible to businesses of all sizes, from small workshops to large multinational corporations.

Balancing Quality with Cost-Effectiveness

Achieving the perfect balance between quality and cost-effectiveness is no easy task, but Gajjar Compressor has mastered the art. By optimizing their production processes and leveraging economies of scale, they are able to keep costs low without compromising on quality.

This approach allows Gajjar Compressor to offer spare parts that provide exceptional value for money. Businesses that invest in Gajjar Compressor’s spare parts not only benefit from superior performance but also enjoy significant cost savings over the long term.

Custom Solutions for Cost-Optimization

In addition to offering affordable prices, Gajjar Compressor provides custom solutions for businesses looking to optimize their spare parts budget. By working closely with their clients, they can identify the most critical components and develop tailored packages that meet both technical requirements and financial constraints.

This personalized approach ensures that customers get exactly what they need, without overspending on unnecessary parts or services. Gajjar Compressor’s commitment to providing cost-effective solutions has made them a trusted partner for industries around the world.

Sustainability: A Responsible Approach to Manufacturing

In today’s world, sustainability is a critical consideration for businesses in every industry. Gajjar Compressor recognizes the importance of environmental responsibility and has incorporated sustainable practices into their manufacturing processes.

Reducing Environmental Impact

Gajjar Compressor is committed to reducing its environmental footprint through various initiatives. These include minimizing waste in production, optimizing energy usage, and using eco-friendly materials wherever possible.

By focusing on sustainability, Gajjar Compressor not only contributes to a greener planet but also helps its customers meet their own environmental goals. Businesses that choose Gajjar Compressor’s spare parts can take pride in knowing that they are supporting a company that values sustainability as much as quality and affordability.

Customer-Centric Support: Ensuring Satisfaction Worldwide

Gajjar Compressor’s success is not only due to the quality of their products but also the exceptional customer support they provide. The company takes a customer-centric approach to ensure that every client receives the assistance they need, whether it’s selecting the right spare part or resolving a technical issue.

Technical Expertise and Guidance

Gajjar Compressor’s team of experts is always available to provide technical guidance and support. They help customers identify the correct spare parts for their specific compressor models and offer advice on installation and maintenance to ensure optimal performance.

After-Sales Support

In addition to technical assistance, Gajjar Compressor offers comprehensive after-sales support. This includes warranty services, replacement parts, and ongoing maintenance solutions. Their commitment to customer satisfaction extends beyond the point of sale, ensuring long-term relationships with their clients.

Conclusion: A Trusted Partner for Industries Worldwide

Gajjar Compressor’s global reach, premium quality, and economical pricing make them the go-to choice for air compressor spare parts. With a commitment to innovation, sustainability, and customer satisfaction, Gajjar Compressor continues to lead the industry, helping businesses around the world maintain efficient, reliable operations. Whether you’re looking for high-grade spare parts for industrial air compressors or custom solutions tailored to your needs, Gajjar Compressor is the trusted partner you can count on.

0 notes

Text

Complete Guide to Air Source Heat Pump Courses

Introduction

Definition of Air Source Heat Pump Course

An air source heat pump course provides training on the installation, maintenance, and repair of air source heat pumps. These courses are designed for professionals looking to specialize in this technology, which is known for its energy efficiency and environmental benefits.

Importance and Relevance

With increasing global emphasis on reducing carbon emissions and improving energy efficiency, air source heat pumps are becoming a popular choice for both residential and commercial heating and cooling. Proper training ensures technicians can install and maintain these systems effectively, meeting industry standards and client expectations.

Overview of Article Content

This guide will explore the fundamentals of air source heat pump courses, including their importance, course structure, and how to choose the right program. We'll also look at future trends in the field and practical applications of the training.

2. What is an Air Source Heat Pump?

Definition and Function

An air source heat pump extracts heat from the outside air and transfers it inside to heat a building. It can also reverse the process to provide cooling during warmer months. This technology operates efficiently even at low outdoor temperatures.

How It Works

Air source heat pumps use a refrigeration cycle involving an evaporator, compressor, condenser, and expansion valve. The refrigerant absorbs heat from the air outside, compresses it to increase the temperature, and releases it indoors.

Types of Air Source Heat Pumps

Air-to-Air Heat Pumps: Transfer heat to the air inside the building.

Air-to-Water Heat Pumps: Transfer heat to water for use in radiators or underfloor heating systems.

3. Importance of Air Source Heat Pump Courses

Benefits for Technicians

Specialized training equips technicians with the skills needed to handle air source heat pump systems efficiently. This includes understanding system design, troubleshooting issues, and performing maintenance tasks.

Environmental and Economic Impact

Air source heat pumps reduce reliance on fossil fuels and lower greenhouse gas emissions. For businesses and homeowners, they offer long-term savings on energy bills through efficient heating and cooling.

Compliance and Certification

Courses often lead to certifications from recognized bodies, validating a technician's competence and adherence to industry standards. This is crucial for regulatory compliance and enhancing professional credibility.

4. Overview of Air Source Heat Pump Courses

Course Structure and Content

Air source heat pump courses cover a range of topics, including system installation, operation, and troubleshooting. The curriculum typically includes both theoretical knowledge and practical hands-on experience.

Duration and Format

Courses can vary in length from a few days to several weeks. They may be offered in-person, online, or in a hybrid format, depending on the provider.

Key Learning Outcomes

Upon completion, participants should be able to install and maintain air source heat pumps, understand system components, and address common issues. Certification often accompanies course completion, enhancing employability.

5. Choosing the Right Course

Factors to Consider

When selecting a course, consider the reputation of the provider, course content, and the qualifications of instructors. Ensure the program covers all relevant topics and meets industry standards.

Evaluating Training Providers

Look for accredited providers with positive reviews and a track record of successful training. Check if they offer post-training support and resources.

Cost vs. Value

While cost is an important factor, consider the overall value of the course, including the quality of instruction, certification offered, and potential career benefits.

6. Course Content and Curriculum

Core Modules and Topics

Typical modules include system design, installation techniques, maintenance practices, and troubleshooting. Hands-on practice with real systems is crucial for gaining practical experience.

Practical vs. Theoretical Training

Effective training balances theoretical knowledge with practical application. Hands-on experience helps solidify understanding and build confidence in managing air source heat pump systems.

Certification and Accreditation

Certifications from recognized industry bodies validate the skills acquired during training. Accredited courses ensure that the training meets established standards and enhances professional credibility.

7. Expert Insights

Quotes from Industry Experts

"Air source heat pumps are a key technology in the transition to a more sustainable energy system. Proper training ensures technicians are equipped to handle these systems effectively." – [Expert Name], HVAC Specialist

Success Stories and Case Studies

Case Study 1: A technician who completed an advanced course significantly improved their service offerings, leading to increased client satisfaction and business growth.

Case Study 2: A company that invested in comprehensive training for its staff saw a reduction in system failures and improved operational efficiency.

8. Future Trends in Air Source Heat Pump Technology

Emerging Technologies

New advancements in air source heat pumps include improved refrigerants and smart controls. These innovations enhance efficiency and user experience.

Evolving Standards and Regulations

As regulations become stricter, training programs must adapt to include updated standards and practices. Keeping current with these changes ensures compliance and relevance in the field.

Training Needs for Future Developments

Future training programs will need to address new technologies and evolving industry requirements. Continuous learning and adaptation will be key for professionals to stay competitive.

9. Practical Applications

Real-World Scenarios

Technicians will encounter various scenarios, from installing new systems to troubleshooting complex issues. Practical training prepares them for these challenges and enhances their problem-solving skills.

Tips for Applying Skills

Practice Regularly: Gain hands-on experience with different systems.

Stay Updated: Follow industry trends and new technologies to remain knowledgeable.

Common Challenges and Solutions

Challenge: Diagnosing issues in complex systems.

Solution: Utilize advanced diagnostic tools and consult with experienced peers.

10. Conclusion

Air source heat pump courses are essential for professionals seeking to excel in this growing field. They provide the knowledge and skills needed to effectively manage air source heat pump systems, ensuring efficiency and compliance. Invest in a high-quality training program to enhance your skills and career prospects. Consider factors such as course content, provider reputation, and certification to make an informed decision.

0 notes

Text

The Vital Role of Spare Parts in Oil & Gas Plant Machinery

The oil and gas industry is a cornerstone of the global economy, providing the energy required to power industries, transport, and households. At the heart of this industry lies a complex network of machinery and equipment, crucial for extraction, refining, and distribution processes. The reliability and efficiency of these machines are paramount, and this is where the importance of spare parts comes into play.

Importance of Spare Parts

Spare parts are essential components that ensure the continuous and efficient operation of machinery in oil and gas plants. They are critical for several reasons:

Minimising Downtime: Unexpected breakdowns can lead to significant operational delays. Having the right spare parts on hand can drastically reduce downtime, ensuring that the plant remains operational and productive.

Enhancing Safety: Oil and gas plants operate under stringent safety standards. Faulty equipment can pose serious safety risks. Regular maintenance and timely replacement of worn-out parts help maintain a safe working environment.

Cost Efficiency: Proactive maintenance using spare parts can prevent larger, more costly repairs. Investing in high-quality spare parts can also extend the lifespan of machinery, leading to long-term cost savings.

Maintaining Efficiency: Over time, parts can wear out and affect the performance of machinery. Regular replacement of these parts helps maintain the efficiency and productivity of the plant.

Types of Spare Parts

The range of spare parts required in an oil and gas plant is extensive and varies depending on the specific machinery and equipment in use. Some of the common categories include:

Mechanical Components:

Bearings

Valves

Pumps

Gaskets and seals

Compressors

Electrical Components:

Sensors and detectors

Switches and circuit breakers

Motors and drives

Control panels

Instrumentation Components:

Pressure gauges

Temperature sensors

Flow meters

Analyzers

Hydraulic and Pneumatic Components:

Actuators

Hoses and fittings

Filters and regulators

Challenges in Spare Parts Management

Managing spare parts inventory in an oil and gas plant comes with its own set of challenges:

Inventory Management: Balancing the availability of spare parts without overstocking is crucial. Overstocking can lead to increased costs and storage issues, while understocking can result in extended downtimes.

Quality Assurance: Ensuring the quality of spare parts is critical. Using substandard parts can lead to frequent breakdowns and safety hazards. It is essential to source parts from reputable suppliers.

Technological Advancements: As technology evolves, older machinery may become obsolete, and finding compatible spare parts can become challenging. Keeping up with technological advancements and upgrading equipment when necessary is essential.

Logistics and Supply Chain: The timely procurement and delivery of spare parts can be complicated, especially for offshore or remote locations. Efficient supply chain management is essential to ensure that parts are available when needed.

Best Practices for Spare Parts Management

To overcome these challenges, oil and gas plants can adopt several best practices:

Predictive Maintenance: Utilizing predictive maintenance techniques and technologies, such as IoT sensors and data analytics, can help predict when parts are likely to fail and schedule replacements proactively.

Vendor Management: Building strong relationships with reliable vendors ensures a steady supply of high-quality spare parts. It also helps in negotiating better terms and faster delivery times.

Inventory Optimization: Implementing inventory management systems that use algorithms to predict the optimal inventory levels can help balance the availability and cost of spare parts.

Training and Skill Development: Ensuring that maintenance personnel are well-trained and knowledgeable about the latest technologies and best practices in spare parts management is crucial for effective maintenance.

Conclusion

Spare parts are the lifeline of oil and gas plant machinery. Their timely and efficient management ensures the smooth and safe operation of the plant, enhancing productivity and reducing costs. By adopting best practices and leveraging technological advancements, oil and gas plants can optimize their spare parts inventory and maintain a competitive edge in the industry..

Email: [email protected]

Call: (+971)45776444

Website: https://www.rushmore.ae/

#Rushmore#Rushmore group#Rushmore group Fze#Earth Moving Spare Parts Manufacturers dubai#Heavy Equipment and Plant Machinery Suppliers#Heavy Machinery Parts suppliers in Dubai#Truck & Trailer Spare Parts Dealer Dubai#Truck & Trailer Spare Parts Dealer in Dubai#trailer spare parts dealer in Dubai#construction equipment suppliers in Dubai#Best Machinery Spare Parts Suppliers in Dubai#Best Machinery Spare Parts Suppliers Dubai#Oil and Gas Field Equipment Suppliers#oil & gas plant machinery spare parts

0 notes

Text

Key Insights on Ball Valves: What You Need to Know

Introduction

Ball valves are essential components in controlling the flow of gases and liquids. They are versatile and used in various applications, including food and pharmaceutical industries, as well as in broader industrial settings. This blog will provide an in-depth look at ball valves, their types, uses, and maintenance.

Ball Valves: A Global Choice for Controlling Fluid Power Systems

Ball valves are widely used across the globe in plumbing and fluid systems to regulate the flow of fluids such as air, water, oil, and fuel. Common systems where ball valves are found include:

– Plumbing systems

– Air compressors

– Oil pumps

– Air conditioning units

The ball valve functions as a one-way valve with an internal ball that rotates to control flow. It operates with a simple turn of the handle to open or close the valve, ensuring efficient control of fluid flow.

Different Types of Ball Valves and Their Uses

Ball valves are employed in numerous applications due to their simple yet effective mechanism. They consist of a valve body with a hollow cylinder (the ball seat) and a circular metal ball with a hole in the center. This design allows the valve to regulate the flow of liquids and gases, making them suitable for various environments, including:

– Chemical facilities

– Water treatment plants

– Power plants

– Gas stations

– Breweries

– Water or fuel pipes

How to Choose a Ball Valve

Selecting the right ball valve depends on several factors:

– Application requirements: Determine the specific needs of the system, such as fluid type and pressure.

– Material: Ball valves come in various materials like brass, chrome, stainless steel, and plastic. Choose based on the fluid’s properties and the environment.

How to Maintain a Ball Valve

Proper maintenance of ball valves ensures their longevity and optimal performance:

– Regular Inspection: Periodically check for leaks and wear.

– Cleaning: Keep the valve and surrounding area clean to prevent contamination.

– Lubrication: Apply appropriate lubricants to moving parts to ensure smooth operation.

– Replacement: Replace worn-out parts promptly to avoid system failures.

Conclusion

Ball valves are crucial for controlling fluid flow in both residential and industrial applications. Their efficiency, reliability, and versatility make them indispensable in various industries, including food, pharmaceutical, and broader industrial sectors. Understanding the different types of ball valves and their maintenance requirements can significantly enhance their performance and lifespan, ensuring smooth operation in any setting.

By choosing the right ball valve and maintaining it properly, you can ensure efficient and reliable fluid control in your systems.

1 note

·

View note

Text

What's the difference between an air compressor and a screw compressor in Abu Dhabi?

When considering the intricacies of air compressor and screw compressor overhauling in Abu Dhabi, it’s crucial to grasp the fundamental distinctions between these two essential systems. Sea Global UAE offers comprehensive services tailored to each type, ensuring optimal performance and longevity.

Air Compressor Overhauling:

Functionality: Air compressors utilize pistons or rotors to compress air.

Components: Includes cylinders, valves, pistons, and connecting rods.

Maintenance Focus: Emphasizes lubrication, cleaning of filters, and inspection of valves.

Benefits: Cost-effective for smaller-scale operations, and simpler maintenance procedures.

Screw Compressor Overhauling:

Functionality: Screw compressors use twin screws to compress air within a sealed chamber.

Components: Rotors, bearings, seals, and cooling systems are critical.

Maintenance Focus: Requires precision alignment of rotors, thorough inspection of seals, and monitoring of cooling systems.

Benefits: Ideal for continuous operation, higher efficiency, suited for larger industrial applications.

Why Choose Sea Global UAE?

Sea Global UAE distinguishes itself through:

Expertise: Specialized knowledge in both air and screw compressor technologies.

Comprehensive Service: From diagnostics to complete overhauling services.

Quality Assurance: Ensures adherence to manufacturer standards and best practices.

Customer Satisfaction: Prioritizes uptime and operational efficiency for all clients.

Whether your requirement involves air compressors or screw compressors, Sea Global UAE stands ready to deliver tailored solutions that optimize performance and extend equipment lifespan in Abu Dhabi’s demanding industrial landscape also consider Generator Annual Maintenance Contract Abu Dhabi.

0 notes

Text

Reynold India One Of The Best Chillers Manufacturer and Suppliers Company In India

Reynold India One Of The Best Chillers Manufacturer and Suppliers Company In India. Reynold India Private Limited Company 28 Years OLD Sucessfull Company 12000 Happy Customers Like International and Domestic. We are 24*7 Avalable Engineers and Services Engineers Like Experence 5 years to 20 years. Fast Service and Good Chillers Products, Like: Products Name is- Screw Chillers Air-cooled Screw Chillers Water-cooled Screw Chillers Industrial Screw Chillers

Customized Chillers Gas Liquefaction Chillers Medical Equipment Chillers Dual Temperature Chillers Milk & Beverage Chillers Cascade Low Temperature Chillers Chillers for Hydrogen Filling Stations Atex Certified Hazardous Area Chillers & Air Conditioners Methanol Chillers Chillers for Multi Layers Brine Chiller Scroll Chillers Air-cooled Scroll Chillers Water-cooled Scroll Chillers Water Chiller Water Cooled Chillers Air Cooled Chillers

Heating Systems Oil MTC & Water MTC Plastic Auxiliaries Hot Air Dryer & Dehumidifier,s Auto Loaders Conveying System Centralized Conveying System Proportional Valve Regrind Homogenise Global Presence Industrial Chillers South Africa Screw Chillers in South Africa Best Chiller Manufacturer in South Africa Industrial Chillers In UAE Industrial Water Chillers In UAE Reciprocating Chillers Air-cooled Reciprocating Chillers Water-cooled Reciprocating Chillers Industrial Reciprocating Chillers

Others Variable Speed Chillers Ammonia Chillers Batching Plant Chillers Oil Chillers Air Chillers Covid Disinfection Tunnel CO2 Based Chillers Industrial Refrigeration System Cold Storage VRU Vapor Recovery Unit Plastics Industry Chillers Chiller for Injection Moulding Hdpe Cpvc Upvc Pipe Chillers Oil Pouch Packing Chillers Bag Chiller Manufacturer Rubber Moulding Chiller Air Cooled Screw Chiller Air Cooled Inverter Screw Chiller Water Cooled Screw Chiller Water Cooled Inverter Screw Chiller Water Cooled Scroll Chiller Chillers for Lamination Plant Auxiliary for Chillers Auxiliary Equipment

Compressor Spare Parts Compressor Filter Core Compressor Filter Dryer Compressor Zr 72

If you are looking for best Chiller Manufacturer Company in Delhi Noida Haridwar India. Then this is the right place. Call now +91–9971396904 or mail us: [email protected] / Our sales team will call you personally or contact you by email within next two working days.

Reynoldindia

Chiller

Chillers India

Chiller Manufacturers

Chiller Suppliers

0 notes

Text

Innovations Driving the High Pressure Seal Market to Reach US$ 11.5 Billion by 2034

The global high pressure seal market is poised for significant growth between 2024 and 2034, driven by various factors such as increasing industrialization, technological advancements, and the growing demand for high-performance sealing solutions across multiple industries. This article explores the market landscape, key trends, challenges, and future outlook of the high pressure seal market.

The global High Pressure Seal industry, valued at US$ 5.7 billion in 2023, is projected to experience significant growth over the next decade. With an estimated compound annual growth rate (CAGR) of 6.7% from 2024 to 2034, the industry is expected to reach a value of US$ 11.5 billion by the end of 2034. This substantial increase reflects the dynamic expansion and evolving opportunities within the sector, highlighting its robust potential for future development and investment.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=37535

Market Segmentation

By Service Type:

Gasket Seals

Mechanical Seals

O-rings

Others

By Sourcing Type:

OEM (Original Equipment Manufacturer)

Aftermarket

By Application:

Pumps

Valves

Compressors

Others

By Industry Vertical:

Oil & Gas

Chemical

Pharmaceutical

Manufacturing

Others

By Region:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Regional Analysis

North America and Europe are expected to hold significant market shares, owing to the presence of established industries and stringent regulations regarding leakage prevention and environmental protection.

The Asia Pacific region is projected to witness the highest growth rate, driven by rapid industrialization in countries like China, India, and Southeast Asian nations.

Market Drivers and Challenges

Drivers:

Increasing demand for high pressure seals in various industries to prevent leaks and ensure operational efficiency.

Technological advancements leading to the development of innovative sealing solutions.

Growing awareness about the importance of maintaining a safe working environment and reducing environmental impact.

Challenges:

High initial investment required for implementing high pressure sealing solutions.

Concerns regarding the compatibility of seals with different operating conditions and fluids.

Intense competition among market players leading to pricing pressures.

Market Trends

Adoption of advanced materials such as fluoropolymers and thermoplastics for manufacturing high pressure seals, enhancing their performance and durability.

Integration of IoT (Internet of Things) technology for real-time monitoring and predictive maintenance of sealing systems.

Shift towards customized sealing solutions to meet specific application requirements and regulatory standards.

Future Outlook

The high pressure seal market is expected to witness continued growth in the coming years, driven by ongoing industrialization, globalization, and the need for efficient sealing solutions across various sectors. Market players are likely to focus on innovation, product diversification, and strategic partnerships to gain a competitive edge in the market.

Key Market Study Points

Market dynamics including drivers, restraints, opportunities, and challenges.

Competitive landscape analysis highlighting key players, their market share, and strategies.

Market segmentation based on service type, sourcing type, application, industry vertical, and region.

Technological advancements and their impact on market growth.

Regulatory landscape and its influence on market trends and developments.

Competitive Landscape

The high pressure seal market is highly competitive, with several global and regional players vying for market share. Key players include:

John Crane

Flowserve Corporation

AESSEAL plc

EagleBurgmann

Parker Hannifin Corporation

Recent Developments:

Launch of new sealing solutions catering to specific industry requirements.

Strategic acquisitions and partnerships to expand product portfolio and geographic presence.

Investments in research and development to enhance product performance and reliability.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Unlocking Efficient Oil and Gas Maintenance Services with Get Global Group

The oil and gas industry is a complex and dynamic sector, requiring precision and reliability to ensure seamless operations. One of the most critical aspects of this industry is maintenance, which plays a vital role in preventing downtime, reducing costs, and ensuring safety. Get Global Group, a leading provider of oil and gas maintenance services, is dedicated to delivering top-notch solutions to optimize operations and maximize efficiency.

Importance of Oil and Gas Maintenance Services

In the oil and gas industry, maintenance is not just a necessity but a crucial aspect of ensuring the smooth operation of equipment and facilities. A well-maintained facility is essential for:

Reducing Downtime: Regular maintenance helps prevent unexpected breakdowns, reducing downtime and minimizing the impact on production.

Cost Savings: Proper maintenance can reduce energy consumption, minimize waste, and extend equipment lifespan, resulting in significant cost savings.

Enhanced Safety: Regular maintenance ensures that equipment is functioning properly, reducing the risk of accidents and ensuring a safe working environment.

Improved Efficiency: Optimized maintenance schedules can improve production efficiency, enabling operators to respond quickly to changes in market conditions.

Get Global Group: A Leader in Oil and Gas Maintenance Services

Get Global Group is a trusted partner for oil and gas companies worldwide, offering comprehensive maintenance services designed to meet the unique needs of each client. With a team of experienced professionals, Get Global Group provides customized solutions that cater to various aspects of oil and gas maintenance, including:

Equipment Maintenance: Regular maintenance and repair services for equipment such as pumps, compressors, generators, and valves.

Facility Maintenance: Comprehensive maintenance services for oil and gas facilities, including inspection, repair, and replacement of mechanical equipment.

Turnaround Maintenance: Planned maintenance services for shutdowns and turnarounds, ensuring that facilities are returned to service quickly and efficiently.

Predictive Maintenance: Advanced analytics and condition monitoring services to predict equipment failures and optimize maintenance schedules.

Benefits of Partnering with Get Global Group

By partnering with Get Global Group, oil and gas companies can expect numerous benefits, including:

Increased Efficiency: Optimized maintenance schedules enable operators to respond quickly to changes in market conditions.

Cost Savings: Reduced energy consumption, minimized waste, and extended equipment lifespan result in significant cost savings.

Improved Safety: Regular maintenance ensures that equipment is functioning properly, reducing the risk of accidents and ensuring a safe working environment.

Enhanced Compliance: Compliance with industry regulations and standards is ensured through regular audits and reporting.

Expertise: Get Global Group's team of experienced professionals provides expert advice and guidance on all aspects of oil and gas maintenance.

Conclusion

In today's competitive oil and gas industry, efficient maintenance services are crucial for optimizing operations and maximizing efficiency. Get Global Group is a trusted partner for oil and gas companies worldwide, offering customized maintenance services designed to meet the unique needs of each client. By partnering with Get Global Group, oil and gas companies can expect numerous benefits, including increased efficiency, cost savings, improved safety, enhanced compliance, and expert guidance. If you're looking for a reliable partner to help you optimize your oil and gas operations, look no further than Get Global Group.

0 notes

Text

Exporter of Multi Effect Evaporator in Ghana

Drytech Engineering Systems is an Exporter of Multi Effect Evaporator in Ghana. Drytech Engineering System is a Manufacturer, Supplier, and Exporter of Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, and Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, and Dust Collector Systems. We are an ISO 9001:2015-certified company since 2017, based in Ahmedabad, Gujarat, India. These plants are produced using top-quality raw materials, adhering to global quality standards. Industries widely seek our evaporator plants for their simple installation, robust design, and extended operational lifespan. Multi-effect evaporator is a system that includes multiple evaporation stages arranged in a series. Each stage operates at a lower pressure than the preceding one, facilitating the efficient evaporation of liquids. Utilizing steam supplies the required heat for evaporation, offering a cost-effective method for concentrating liquids and reclaiming valuable substances. Features: Oily emulsions, coolant fluids, and mold release agents Purging compressors and removing water from floor-washing processes Disposing of water from cleaning tanks and reactors Baths used in galvanic processes and surface treatments for work and cleansing Liquids with penetration properties Rejection of water from treatment plants Application: Textile Pharmaceutical Automobile Chemical Dyeing industries Drytech Engineering Systems is Exporter of Multi Effect Evaporator in Ghana and including locations like Accra, Kumasi, Tamale, Sekondi-Takoradi, Ashaiman, Sunyani, Cape Coast, Obuasi, Teshie, Tema, Madina, Koforidua, Wa, Techiman, Ho, Nungua, Lashibi, Dome, Tema New Town, Gbawe, Oduponkpehe, Ejura, Taifa, Bawku, Aflao, Agona Swedru, Bolgatanga, Tafo, Berekum, Nkawkaw, Akim Oda, Winneba, Hohoe, Yendi, Suhum, Kintampo, Adenta East, Nsawam, Mampong, Konongo, Asamankese, Wenchi, Savelugu, Agogo, Anloga, Prestea, Effiakuma, Tarkwa, Elmina, Dunkwa-on-Offin, Begoro, Kpandu, Kintampo, Navrongo, Axim, Apam, Salaga, Saltpond, Akwatia, Shama, Keta, Nyakrom, Bibiani, Somanya, Foso, Nyankpala, Aburi, Mumford, Bechem, Duayaw Nkwanta, Kade, Anomabu, Akropong, Kete-Krachi, Kibi, Kpandae, Mpraeso, Akim Swedru, Aboso, Bekwai, Drobo, Banda Ahenkro, Dodowa, Larteh Akuapim. For detailed information and inquiries, please feel free to contact us. Read the full article

0 notes

Text

Automotive Scroll e-Compressor, Global Market Size Forecast, Top 23 Players Rank and Market Share

Automotive Scroll e-Compressor Definition

The Automotive Scroll e-Compressor is the heart of the automobile air-conditioning refrigeration system, which plays a role in compressing and transporting refrigerant vapor. The scroll compressor is composed of an end plate and involute scroll teeth extending from the end plate. It has many advantages. For example, the compressor is small in size and light in weight, and the eccentric shaft driving the moving turbine can rotate at a high speed. Because the scroll compressor can operates reliably without the suction valve and the exhaust valve, and it is easy to realize variable speed movement and variable displacement technology. Multiple compression chambers work simultaneously and the gas pressure difference between adjacent compression chambers is small so that the gas leakage is small.

Automotive Scroll e-Compressor Picture

Automotive Scroll e-Compressor Market Summary

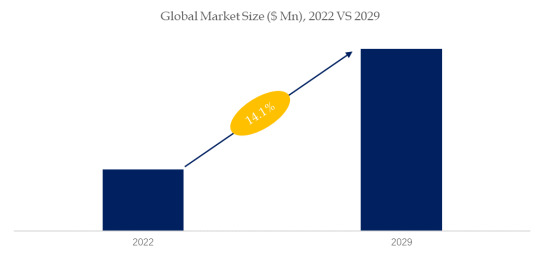

According to the new market research report “Global Automotive Scroll e-Compressor Market Report 2023-2029”, published by QYResearch, the global Automotive Scroll e-Compressor market size is projected to reach USD 9.33 billion by 2029, at a CAGR of 14.1% during the forecast period.

Figure. Global Automotive Scroll e-Compressor Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Automotive Scroll e-Compressor Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

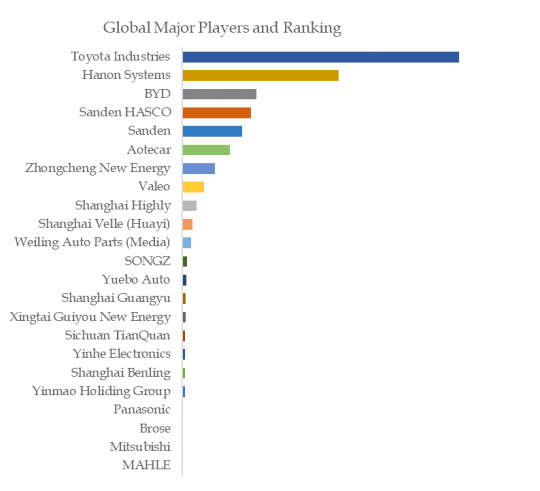

Figure. Global Automotive Scroll e-Compressor Top 23 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Automotive Scroll e-Compressor Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

The global key manufacturers of Automotive Scroll e-Compressor include Toyota Industries, Hanon Systems, BYD, Sanden HASCO, Sanden, Aotecar, Zhongcheng New Energy, Valeo, Shanghai Highly, Shanghai Velle (Huayi), etc. In 2022, the global top five players had a share approximately 70.0% in terms of revenue.

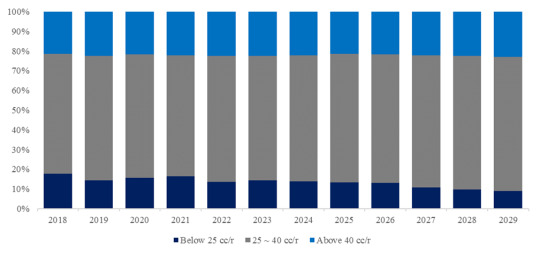

Figure. Automotive Scroll e-Compressor, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Automotive Scroll e-Compressor Market Report 2023-2029.

In terms of product type, currently 25 ~ 40 cc/r is the largest segment, hold a share of 63.9%.

Figure. Automotive Scroll e-Compressor, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Automotive Scroll e-Compressor Market Report 2023-2029.

In terms of product application, currently Passenger Vehicle is the largest segment, hold a share of 73.7%.

Figure. Automotive Scroll e-Compressor, Global Market Size, Split by Region (Production)

Based on or includes research from QYResearch: Global Automotive Scroll e-Compressor Market Report 2023-2029.

Figure. Automotive Scroll e-Compressor, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Automotive Scroll e-Compressor Market Report 2023-2029.

Market Trends:

Downstream demand drives the growth of the automotive air-conditioning scroll compressor market: The global electric vehicle market will continue to show strong growth in 2021. Traditional car companies and new car manufacturers continue to improve their products and industrial chain layout, and consumers' acceptance of new energy products is also constantly improving.

The electric scroll compressor itself has superior performance: In the field of automotive air conditioning, scroll compressors are called the third-generation compressors, and are gradually replacing traditional swash plate compressors and rotary compressors with their unique performance advantages, especially in the field of new energy vehicles.

Policy Support: Due to the tightening of global environmental protection standards and the increase in consumer demand, many countries have introduced industrial support policies to support the research and development of electric vehicle technology, and further promote the entire industry chain and ecological construction of electric vehicles.

Continuous technological innovation: Technological innovation plays an important role in promoting market growth. In order to survive in a highly competitive market, suppliers should develop new ideas and technologies and keep pace with advanced technologies.

Challenges:

Technical difficulties: The R&D and production of scroll compressors for electric vehicle air conditioners require high technical content, including key technologies such as electric compressors, frequency conversion control, and high-efficiency refrigeration, as well as product reliability and stability. These technical problems require continuous technological innovation and research and development to achieve product upgrades and optimization.

Market competition: The market for scroll compressors for electric vehicle air conditioners is fiercely competitive, with both domestic and international companies competing on product prices and with small profit margins. Therefore, it is necessary to continuously improve product quality and reduce costs to improve market competitiveness.

Policy environment: The government has given strong support to the development of new energy vehicles, but changes in the policy environment will also have an impact on the electric vehicle air conditioning scroll compressor market. For example, the government's subsidy policy for new energy vehicles may change, leading to uncertainty in market demand.

Supply chain issues: The production of electric vehicle air conditioning scroll compressors requires a large number of parts and raw materials, such as motors, compressors, electronic control components, etc. Supply chain instability and shortages can impact production and even lead to delivery delays and other issues.

Diversified customer demands: Different brands and models of electric vehicles have diversified demands for air-conditioning systems, requiring customized production according to different customer needs. This places higher demands on the R&D and production capabilities of manufacturing companies.

About The Authors

Liu Wang- Lead Author

Email: [email protected]

Tel: +86 15755356372

Ms. Wang has 5 years of industry research experience. She focuses on research related to the industry chain of automotive, consumer goods, software, and services, including auto parts, advanced automotive materials, various popular software, etc. Some research topics include Automotive Air Conditioning Electric Scroll Compressors, Lithium Battery Aluminum Plastic Film, Model-based Development (MBD), Predictive Maintenance Solutions, Webtoons, 3D models, Cloud Gaming Backend Service, Visual Content, DHA from Algae, etc. As an analyst with many years of experience in the consulting industry, she has a keen insight into the industry's market trends and developments and uses data analysis to discover potential market opportunities and threats, providing data support for corporate strategic decisions.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

youtube

ELGi | EG SERIES | OIL-LUBRICATED SCREW AIR COMPRESSORS | 11-250 kW / 18 – 1515 cfm | ALWAYS BETTER

Across the globe, energy systems are going through rapid transitions that are changing the way we power industries. Industries need to reduce energy consumption and develop efficient energy technologies to create viable and long-lasting solutions for the future.

For over 60 years, ELGi has helped companies across the world achieve their production goals while lowering operational costs, aimed at addressing this increasing need for energy efficiency and high productivity. ELGi has expanded its range of oil lubricated screw air compressors.

EG Series, built for energy efficiency and performance, offers low total cost of ownership and best in class reliability. The EG series, with its proprietary airend design and unique eta V profile, engages large rotors operating at slow speeds for improved efficiency. Cast in ELGi's world-class foundry and finished in ELGi's Locus Machine Centers, the airends have the highest quality.

The ingeniously optimized split cooling system powers it to perform efficiently even in the hottest conditions. The intake valves offer suction modulation that saves 20% of energy during the load and unload cycles. The compressor subsystems are designed to minimize pressure losses and ensure high energy efficiency. The four pole motors have been designed to be more efficient than two pole motors. The pressure versions enable customers to select the optimum variant for their application.

The integrated variable frequency drive offers significant energy savings by varying the flow with the actual demand of the application. The EG series of compressors are equipped with advanced yet easy to use, Neuron 3 controllers. The controller ensures safe compressor operation providing protection against major failures and ensuring safety for critical components. Additionally, the controller allows remote operation through Modbus.

The EG Series compressors contribute up to 10 % reduction in power consumption, translating into annual lifecycle cost savings for the customer. Reliability and uptime are ensured by leak-free, corrosion-free connections. All major components are designed for an ambient temperature, 45 degrees centigrade or 113 degrees Fahrenheit, ensuring operation in extremely hot environments. A multistage inlet air filtration system that filters up to 99.9%. The oil separator efficiency with oil carry-over of less than 1 ppm. Top quality components backed by industry's best warranty programs across the globe. Low maintenance costs and superior service.

ELGi has over the years developed world-class products with best-in-class lifecycle costs resulting in higher uptime for the customer. ELGI's screw air compressors are tested for performance by Compressed Air and Gas Institute in the US.

ELGi is the first globally established industrial air compressor manufacturer to be awarded the Deming Prize for Excellence in total quality management in over six decades. Customers around the world have invested in ELGi's energy-efficient products that have time and again proved to be reliable and backed by the best service.

Today, global brands from over 120 countries trust ELGi, with many more customers choosing ELGi to power their industries.

ELGi has become a forerunner for energy efficiency and increased productivity in the world.

The EG Series, built for energy efficiency and performance. ELGi - Always Better.

0 notes

Text

Forecasting the Future: Heat Pump Market Trends and Predictions (2019-2026)

A heat pump is a cost-effective modern heating method that replaces fuel-based conventional methods. As a result, an increase in awareness regarding modern heating methods and their benefits is not only a way to move toward a smart heating solution but also a sustainable way to reduce CO2 emissions. This shift from conventional to modern heating methods is shaping the growth trajectory of this market. The global heat pump market size was valued at $55.2 billion in 2018 and is projected to reach $99.6 billion by 2026, growing at a CAGR of 7.74% from 2019 to 2026.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞: https://www.alliedmarketresearch.com/request-sample/5341

A heat pump is a mechanical compression cycle refrigeration system that can be reversed to either heat or cool the desired space. It has main components, which include a condenser, expansion valve, evaporator, and compressor. When heat is transferred through these four components it is known as refrigerant. Heat pumps are mainly used in heating, ventilation, and air conditioning (HVAC) applications, but are different from furnace and air conditioners.

The global heat pump market is registering extensive growth across the globe as the heat pump is gaining popularity as a substitute for traditional combustion-based heating methods. Heat pump offers space heating and cooling operations at a relatively lower price and also emits relatively lower CO2 gas as compared to traditional methods. As a result, an increase in efforts to reduce CO2 emissions and decarbonization is mainly driving the growth of the heat pump market. For geographies with moderate heating and cooling needs, heat pumps offer an energy-efficient alternative to furnaces and air-conditioners. This is possible because of less electricity consumption by heat pumps that have a proven track record of being cost-competitive. Therefore, growth in demand for refrigerant in household applications fuels the scope of utilization to a heat pump that ultimately contributes to the global market growth. The high cost of installation associated with heat pumps is anticipated to hamper the global market growth.

𝐆𝐞𝐭 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬 𝐰𝐢𝐭𝐡 𝐲𝐨𝐮’𝐫𝐞 𝐑𝐞𝐪𝐮𝐢𝐫𝐞𝐦𝐞𝐧𝐭𝐬: https://www.alliedmarketresearch.com/request-for-customization/5341

𝐂𝐨𝐦𝐩𝐞𝐭𝐢𝐭𝐢𝐯𝐞 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬:

The Heat Pump industry's key market players adopt various strategies such as product launches, product development, collaboration, and agreements to influence the market. It includes details about the key players in the market's strengths, product portfolio, market size and share analysis, operational results, and market positioning.

𝐒𝐨𝐦𝐞 𝐨𝐟 𝐭𝐡𝐞 𝐦𝐚𝐣𝐨𝐫 𝐤𝐞𝐲 𝐩𝐥𝐚𝐲𝐞𝐫𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐇𝐞𝐚𝐭 𝐏𝐮𝐦𝐩 𝐌𝐚𝐫𝐤𝐞𝐭 𝐢𝐧𝐜𝐥𝐮𝐝𝐞,

• Viessmann Werke GmbH & Co. KG • Ingersoll Rand, Plc. • Vaillant Group • Stiebel Eltron • Glen Dimplex Group • Panasonic Corporation • NIBE Industrier AB • Daikin Industries, Ltd. • Melrose Industries PLC. • Mitsubishi Electric Corporation

𝐏𝐫𝐞𝐬𝐬 𝐑𝐞𝐥𝐞𝐚𝐬𝐞: https://www.alliedmarketresearch.com/press-release/heat-pump-market.html

Asia-Pacific is the prominent consumer of the heat pump market where demand for heat pumps has seen a sudden rise in 2009 as Energy Conservation Law (ECL) was amended and residential & commercial sectors were added as targets in 2009.

Based on type, the air-to-air segment accounted for the largest heat pump market share of around 75% in 2018 and is anticipated to be the largest market during the forecast period. As compared to electric resistance heating, i.e., furnaces and baseboard heaters, air-to-air heat pumps save 50% energy and that is why they are known to be energy efficient.

Based on application, the residential application segment dominated the global market in 2018. Residential buildings and housing spaces represent the need for space heating and cooling due to climate changes. This provides a scope of utilization for heat pumps in the residential sector and make it a prominent application segment over others.

𝐈𝐧𝐪𝐮𝐢𝐫𝐲 𝐛𝐞𝐟𝐨𝐫𝐞 𝐁𝐮𝐲𝐢𝐧𝐠: https://www.alliedmarketresearch.com/purchase-enquiry/5341

𝐊𝐞𝐲 𝐅𝐢𝐧𝐝𝐢𝐧𝐠𝐬 𝐎𝐟 𝐓𝐡𝐞 𝐒𝐭𝐮𝐝𝐲:

- Based on type, the air-to-air segment emerged as the global leader by acquiring a 78% market share in 2018. Superior energy efficiency, its use as a legitimate space heating alternative in colder regions, and cost-competitive use are the factors that drive their use across the globe. - Based on application, the residential segment acquired more than 75% market share in 2018 in response to an increase in the need for economical and energy-efficient space heating, cooling, and sanitary hot water. - Asia-Pacific emerged as the global leader in the global heat pump market with around 40% market share in 2018. This is attributed to the high adoption of a heat pump as an alternative to fuel-based heating methods, growth in residential spaces and resulting demand for heating products, and favorable government regulation. - Stringent regulatory outlook to reduce CO2 emissions as well as efforts to monitor these reduced emission activities is expected to offer promising growth opportunities to heat pump technology during the forecast period. - Although heat pump is cost-competitive in nature, high installation costs associated with them significantly increase their cost and is expected to restrain the growth of this market.

𝐋𝐚𝐭𝐞𝐬𝐭 𝐓𝐫𝐞𝐧𝐝𝐢𝐧𝐠 𝐑𝐞𝐩𝐨𝐫𝐭𝐬 𝐛𝐲 𝐀𝐥𝐥𝐢𝐞𝐝 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡: