#Global Ceramic Balls Market

Explore tagged Tumblr posts

Text

Drinkware Market Dynamics, Share, Scope and Analysis Forecast 2025 - 2032

The Latest Trending Drinkware Market sector is on the brink of remarkable evolution, with projections indicating robust growth and groundbreaking technological advancements by 2032. A recent comprehensive market research report highlights the sector's promising trajectory, fueled by key drivers including expanding market size, increasing market share, and the emergence of innovative trends.

This comprehensive report provides key insights into the Drinkware market, exploring critical market segmentation and definitions. It highlights the essential components driving growth, offering a clear picture of the industry's trajectory. Utilizing SWOT and PESTEL analyses, the report evaluates the market's strengths, weaknesses, opportunities, and threats, while also considering political, economic, social, technological, environmental, and legal factors that impact the market landscape.

The study offers valuable insights into the competitive landscape, highlighting recent developments and geographical distribution across key regions. Expert competitor analysis provides a detailed understanding of market dynamics, offering strategic guidance for businesses and investors.

With robust analysis and future projections, this report serves as a vital resource for stakeholders looking to capitalize on emerging opportunities and navigate challenges in the Drinkware market.

What is the projected market size & growth rate of the Drinkware Market?

Market Analysis and Insights

Drinkware Market

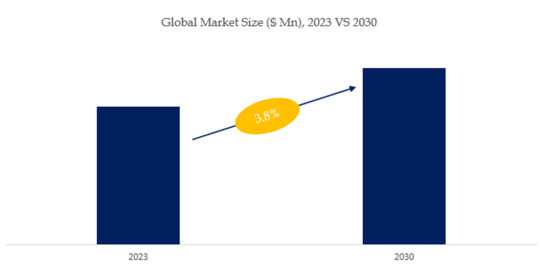

The drinkware market is expected to be growing at a growth rate of 3.80% in the forecast period of 2022 to 2029. Drinkware market report analyses the growth, which is currently being growing due to the significant demand of the product from food service and hospitality industry.

Drinkware refers to containers used to consume water, beverages, juices, or any other liquid product. Metal drinkware was popular in the ancient world; however, the trend has shifted to glass, ceramic, clay, and polymer. Glass drinkware is available in a variety of styles, including goblet, champagne saucer, champagne flute, red wine glass, cordial, high ball, finger bowl, decanter, and pitcher. Metal drinkware was popular in the ancient world; however, the trend has now shifted to glass. The drinkware is available in a variety of finishes and textures, and it can be personalised by etching.

Growing demands for products from the hospitality and foodservice sectors, as well as an increase in beverage consumption, are driving the global drinkware market. Furthermore, corporate initiatives to introduce innovative, designer products made from eco-friendly materials will drive the growth of the drinkware market. The availability of beverage products in a variety of designs and types, increasing number of pubs, restaurants, hotels, and home bars, access to online distribution channels and increasing online sales of beverage products, are driving the drinkware market growth.

The prevalence of favourable government policies regarding the growth of the tourism sector, as well as rising water consumption, will address health issues, bringing various opportunities that will lead to the growth of the drinkware market during the forecast period.

On the flip side, the availability of flexible food and beverage packaging will impede the growth of the drinkware market during the forecast period. Also, large number of local players will further challenge the drinkware market.

This drinkware market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on drinkware market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Browse Detailed TOC, Tables and Figures with Charts which is spread across 350 Pages that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

This research report is the result of an extensive primary and secondary research effort into the Drinkware market. It provides a thorough overview of the market's current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Drinkware Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-drinkware-market

Which are the driving factors of the Drinkware market?

The driving factors of the Drinkware market include technological advancements that enhance product efficiency and user experience, increasing consumer demand driven by changing lifestyle preferences, and favorable government regulations and policies that support market growth. Additionally, rising investment in research and development and the expanding application scope of Drinkware across various industries further propel market expansion.

Drinkware Market - Competitive and Segmentation Analysis:

Global Drinkware Market, By Product (Bottles, Wine Glass, Beer Glass, Coffee Mugs and Tea Cups, Everyday Glass, Cocktail Glass, Spirit Glass, Others), Material (Polymer, Metal, Glass, Silicone, Ceramic, Plastic, Bone China, Porcelain/Stoneware), Application (Domestic, Commercial), Distribution Channel (Supermarket, Independent Stores, E-commerce), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2032.

How do you determine the list of the key players included in the report?

With the aim of clearly revealing the competitive situation of the industry, we concretely analyze not only the leading enterprises that have a voice on a global scale, but also the regional small and medium-sized companies that play key roles and have plenty of potential growth.

Which are the top companies operating in the Drinkware market?

Some of the major players operating in the drinkware market are Newell Brands, Amcor plc, Mizu Life, PMI Worldwide., Thermos L.L.C., Bormioli Rocco S.p.A., Hydro Flask LLC., Klean Kanteen, CAMELBAK, Vapur., Thermo Fisher Scientific Inc., Arc International, soulproducts GmbH, Libbey Inc., Pasabahçe Cam, The Oneida Group Inc., Steelite International., Ocean Glass Public Company Limited, Toyo Seikan Group Holdings, Ltd., O-I Glass, Inc., Silgan Holdings Inc., Mondi, Alcoa Corporation, Stora Enso, among others.

Short Description About Drinkware Market:

The Global Drinkware market is anticipated to rise at a considerable rate during the forecast period, between 2025 and 2032. In 2024, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

North America, especially The United States, will still play an important role which can not be ignored. Any changes from United States might affect the development trend of Drinkware. The market in North America is expected to grow considerably during the forecast period. The high adoption of advanced technology and the presence of large players in this region are likely to create ample growth opportunities for the market.

Europe also play important roles in global market, with a magnificent growth in CAGR During the Forecast period 2025-2032.

Drinkware Market size is projected to reach Multimillion USD by 2032, In comparison to 2025, at unexpected CAGR during 2025-2032.

Despite the presence of intense competition, due to the global recovery trend is clear, investors are still optimistic about this area, and it will still be more new investments entering the field in the future.

This report focuses on the Drinkware in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Get a Sample Copy of the Drinkware Report 2025

What are your main data sources?

Both Primary and Secondary data sources are being used while compiling the report. Primary sources include extensive interviews of key opinion leaders and industry experts (such as experienced front-line staff, directors, CEOs, and marketing executives), downstream distributors, as well as end-users. Secondary sources include the research of the annual and financial reports of the top companies, public files, new journals, etc. We also cooperate with some third-party databases.

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2025-2032) of the following regions are covered in Chapters

What are the key regions in the global Drinkware market?

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

This Drinkware Market Research/Analysis Report Contains Answers to your following Questions

What are the global trends in the Drinkware market?

Would the market witness an increase or decline in the demand in the coming years?

What is the estimated demand for different types of products in Drinkware?

What are the upcoming industry applications and trends for Drinkware market?

What Are Projections of Global Drinkware Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

Where will the strategic developments take the industry in the mid to long-term?

What are the factors contributing to the final price of Drinkware?

What are the raw materials used for Drinkware manufacturing?

How big is the opportunity for the Drinkware market?

How will the increasing adoption of Drinkware for mining impact the growth rate of the overall market?

How much is the global Drinkware market worth? What was the value of the market In 2024?

Who are the major players operating in the Drinkware market? Which companies are the front runners?

Which are the recent industry trends that can be implemented to generate additional revenue streams?

What Should Be Entry Strategies, Countermeasures to Economic Impact, and Marketing Channels for Drinkware Industry?

Customization of the Report

Can I modify the scope of the report and customize it to suit my requirements? Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

Inquire more and share questions if any before the purchase on this report at - https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-drinkware-market

Detailed TOC of Global Drinkware Market Insights and Forecast to 2032

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Drinkware Market By Type

Drinkware Market By Function

Drinkware Market By Material

Drinkware Market By End User

Drinkware Market By Region

Drinkware Market: Company Landscape

SWOT Analysis

Company Profiles

Continued...

Purchase this report – https://www.databridgemarketresearch.com/checkout/buy/singleuser/global-drinkware-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]

Browse More Reports:

Hallermann-Streiff Syndrome Market

Inkjet Printers Market

Carpets and Rugs Market

Drinkware Market

Processed Milk Processing Equipment Market

#Drinkware Market#Drinkware Market Size#Drinkware Market Share#Drinkware Market Trends#Drinkware Market Growth#Drinkware Market Analysis#Drinkware Market Scope & Opportunity#Drinkware Market Challenges#Drinkware Market Dynamics & Opportunities#Drinkware Market Competitor's Analysis

0 notes

Text

Inside the Ball Mill: A Look at Leading Manufacturers

The ball mill. A seemingly simple piece of equipment, yet a cornerstone of countless industries. From ceramics to pharmaceuticals, cement to mining, these powerful grinding machines are essential for reducing materials to the required fineness. But have you ever stopped to consider what goes on inside a ball mill, or who the leading ball mill manufacturers are that drive innovation in this field? Let's delve deeper.

The Inner Workings of a Ball Mill

At its core, a ball mill is a type of grinder consisting of a rotating cylindrical vessel filled with grinding media, typically balls made of steel, ceramic, or flint. As the cylinder rotates, the balls cascade and impact the material being processed, reducing it in size through a combination of impact and attrition.

The efficiency of a ball mill depends on several factors, including:

The type and size of the grinding media: Different materials and sizes are suited for different applications.

The speed of rotation: Optimal speed ensures efficient grinding without excessive wear and tear.

The mill's lining: Linings protect the mill from wear and can be customized to suit specific materials.

The material feed size and consistency: Proper preparation of the feed material is crucial for optimal grinding.

Leading Ball Mill Manufacturers

The market for ball mills is competitive, with a range of manufacturers offering diverse solutions to meet various industrial needs. Some of the leading ball mill manufacturers include:

FLSmidth: A global leader in cement and mining equipment, FLSmidth offers a wide range of ball mills known for their robustness and reliability.

Metso Outotec: This Finnish company provides comprehensive solutions for mineral processing and aggregates production, including high-performance ball mills.

Fives: With a focus on innovation and sustainability, Fives designs and manufactures ball mills for various industries, including mining, cement, and energy.

ThyssenKrupp: This German multinational conglomerate offers a diverse range of industrial solutions, including ball mills for mineral processing and other applications.

These manufacturers, along with many others, continually invest in research and development to improve the efficiency, durability, and environmental performance of their ball mills.

Ball Mills and Related Equipment

While ball mills are powerful grinding tools, they often work in conjunction with other equipment to achieve desired results in various industries. For instance, in the pharmaceutical industry, a ball mill might be used to grind active pharmaceutical ingredients before they are processed in a coating tablet machine. This ensures the API is the correct particle size for optimal drug delivery.

Similarly, in the food processing industry, a cone blender might be used to homogenize a mixture after it has been ground in a ball mill. This ensures even distribution of ingredients and consistent product quality.

Choosing the Right Ball Mill Manufacturer

Selecting the right ball mill manufacturer is crucial for any business. Factors to consider include:

Experience and expertise: Look for manufacturers with a proven track record in your industry.

Product quality and reliability: Choose mills built to last and perform consistently.

Customization options: Ensure the manufacturer can tailor solutions to your specific needs.

After-sales service and support: Reliable support is essential for minimizing downtime and maximizing productivity.

By carefully considering these factors, you can find a ball mill manufacturer that will be a valuable partner in your success.

The Future of Ball Milling

As industries evolve and environmental regulations become stricter, the demand for more efficient and sustainable ball milling solutions is growing. Manufacturers are responding with innovations such as:

Energy-efficient drives and motors: Reducing energy consumption and operating costs.

Advanced process control systems: Optimizing mill performance and minimizing waste.

Wear-resistant materials and linings: Extending mill lifespan and reducing maintenance needs.

The future of ball milling is bright, with ongoing advancements promising to further enhance the efficiency, productivity, and sustainability of this essential industrial process.

0 notes

Link

0 notes

Text

Bearing the Load: Top Bearings for High-Demand Industries

The report on the global bearings market provides a comprehensive analysis of the market segments and sub-segments, offering insights into both global and regional market trends from 2015 to 2023. According to the report, the global bearings market is expected to grow at a compound annual growth rate (CAGR) of 5.5% over the forecast period of 2023 to 2030, with the market projected to reach an estimated value of USD 55 billion by 2030.

What are Bearings?

Bearings are mechanical components used to reduce friction between moving parts and support the load, ensuring smooth and efficient movement. Bearings are widely used in a variety of industries, including automotive, aerospace, manufacturing, and industrial machinery. They come in various types, including ball bearings, roller bearings, and fluid bearings, each suited for specific applications requiring load support and motion control.

Get Sample pages of Report: https://www.infiniumglobalresearch.com/reports/sample-request/876

Market Drivers and Growth Factors

Several factors are contributing to the growth of the bearings market:

Rising Demand in Automotive Industry: Bearings are essential components in vehicles, ensuring smooth operation of various moving parts such as wheels, engines, and transmissions. As the automotive sector continues to grow, the demand for high-performance bearings rises, particularly in electric vehicles (EVs) and autonomous vehicles.

Growth in Industrial Manufacturing: Industrial machinery and manufacturing applications require reliable bearings for efficient operation. The expansion of the manufacturing industry, especially in emerging markets, boosts the demand for bearings in machinery, robotics, and production lines.

Technological Advancements: Continuous innovations in bearing materials and designs, such as ceramic and hybrid bearings, offer higher performance, durability, and resistance to wear and tear, driving their adoption across industries.

Demand from Renewable Energy Sector: Bearings are increasingly used in renewable energy systems such as wind turbines and solar tracking systems, where reliability and low maintenance are critical to system performance.

Regional Analysis

North America: North America is a key market for bearings, driven by the demand from the automotive, aerospace, and industrial machinery sectors. The U.S. is the largest contributor, with major manufacturers and strong industrial bases.

Europe: Europe remains a significant market due to the presence of key automotive manufacturers and a robust manufacturing industry. Germany, France, and the UK are the leading countries in the region, driving the demand for advanced bearing solutions.

Asia-Pacific: The Asia-Pacific region is expected to see the highest growth in the bearings market. This is mainly driven by the rapid industrialization in countries like China, India, and Japan, as well as the increasing demand for bearings in automotive and machinery sectors.

Rest of the World: The Middle East, Latin America, and Africa are gradually increasing their adoption of bearings, mainly driven by infrastructure development and expanding industrial sectors in these regions.

Competitive Landscape

The global bearings market is competitive, with key players focusing on product innovation, technological advancements, and expanding their market presence:

SKF Group: SKF is a leading global player known for its extensive portfolio of high-quality bearings used across various industries, including automotive, aerospace, and energy.

Schaeffler Group: Schaeffler is a prominent player providing a wide range of bearings, with a strong focus on high-precision and energy-efficient bearing solutions.

NSK Ltd.: NSK specializes in automotive, industrial, and aerospace bearings, focusing on advanced technologies to improve product performance and reliability.

Timken Company: Timken manufactures bearings for multiple applications, with a focus on high-performance bearings for demanding environments, including heavy machinery and energy sectors.

JTEKT Corporation: JTEKT offers bearings for diverse industries, including automotive and industrial applications, with a strong emphasis on product innovation and sustainability.

Report Overview : https://www.infiniumglobalresearch.com/reports/global-bearings-market

Challenges and Opportunities

Challenges:

Price Volatility of Raw Materials: Bearings are often made from high-quality steel and other materials whose prices can fluctuate, impacting the production costs and pricing of bearings.

Competition from Low-Cost Manufacturers: Low-cost manufacturers, especially from emerging economies, pose a challenge for premium bearing manufacturers due to the price sensitivity of certain markets.

Environmental Concerns: Increased focus on sustainability and energy efficiency may push manufacturers to develop eco-friendly and recyclable bearing solutions, which requires additional investment in R&D.

Opportunities:

Electric Vehicles (EVs): The rapid growth of the EV market presents significant opportunities for bearings, especially in areas like motor assemblies, transmissions, and wheel hubs.

Emerging Markets: Rapid industrialization in countries like China, India, and Brazil is creating new opportunities for bearings in manufacturing, construction, and automotive sectors.

Smart Bearings: The development of smart bearings, which include sensors for real-time monitoring and predictive maintenance, presents an exciting opportunity to enhance performance and efficiency.

Conclusion

The global bearings market is expected to continue its growth trajectory, driven by the expanding automotive, industrial manufacturing, and renewable energy sectors. With a projected CAGR of 5.5%, the market is poised to reach USD 55 billion by 2030. Technological advancements, particularly in the automotive and energy industries, and the increasing demand for high-performance bearings, will continue to shape the market's future. As industries grow and evolve, bearings will remain crucial components for ensuring operational efficiency and reliability.

0 notes

Text

Ceramic Packing Solutions for Modern Industries: The SKJ Overseas Advantage

In the realm of industrial ceramics and packing solutions, few names stand out as prominently as SKJ Overseas. With decades of expertise and an unwavering commitment to quality, SKJ Overseas has established itself as a trusted name in the global market, particularly in the Middle East and Asia. Specializing in inert ceramic balls, high alumina ceramic balls, and an array of ceramic saddles, rings, and other specialized products, SKJ Overseas caters to various industries, including petrochemical, oil and gas, and environmental engineering.

A Focus on Quality: Inert Ceramic Balls Exporters

One of the flagship products of SKJ Overseas is inert ceramic balls. These ceramic balls are widely used in industries for their high resistance to corrosion, abrasion, and chemical attack, making them ideal for use in applications like catalyst bed support, chemical reactors, and heat exchangers. As leading inert ceramic balls exporters, SKJ Overseas ensures that their products meet international standards for both quality and performance.

Inert ceramic balls serve a crucial role in providing mechanical strength, minimizing reactor fouling, and improving the overall efficiency of chemical processes. Their primary role is to act as support material, ensuring that catalysts remain in place during operation. As industrial demands continue to evolve, the need for reliable inert ceramic ball exporters like SKJ Overseas becomes even more critical. The company prides itself on not only meeting but exceeding customer expectations with timely deliveries and custom solutions tailored to specific operational needs.

High Alumina Ceramic Balls: Versatility and Strength

Another highly sought-after product from SKJ Overseas is high alumina ceramic balls. These balls are known for their exceptional mechanical strength, thermal stability, and high resistance to wear and tear. Manufactured from top-grade alumina, these ceramic balls are widely used in applications such as grinding media in ball mills, catalyst bed supports, and fillers in various chemical processes.

As high alumina ceramic balls exporters, SKJ Overseas provides high-quality products that adhere to the strictest industrial standards. Their ceramic balls have gained a reputation for being durable and reliable, even in harsh operational environments. This makes SKJ Overseas a preferred choice for industries such as petrochemical, chemical, and mining, where durability and longevity are paramount.

The company’s position as a leading high alumina ceramic balls manufacturer is underpinned by their state-of-the-art manufacturing facilities, which are equipped with cutting-edge technology to ensure precision in production. From the selection of raw materials to the final inspection of the finished products, every stage of the manufacturing process is closely monitored to guarantee that each batch meets the desired specifications.

Furthermore, SKJ Overseas has a well-established supply chain, making them reliable high alumina ceramic balls suppliers to industries across the globe. Their commitment to timely deliveries and the consistency of their product quality has earned them the trust of countless businesses, particularly in regions like the Middle East, Europe, and Southeast Asia.

The Dubai Connection: Pall Rings, Ceramic Saddles, and More

Dubai, with its rapidly expanding industrial base, has become a key market for SKJ Overseas. The city’s strategic location as a global hub for trade and commerce makes it an ideal gateway for exporters like SKJ Overseas to supply their products to industries across the Middle East, Africa, and beyond.

One of the standout products that SKJ Overseas offers in Dubai is the Pall Ring. These rings are a type of random packing material used in various separation and absorption processes, such as gas scrubbing, distillation, and heat recovery. The Pall Ring in Dubai market is highly competitive, but SKJ Overseas has managed to carve out a niche for itself by offering high-quality Pall Rings that offer superior surface area, low-pressure drop, and high efficiency in mass transfer operations.

In addition to Pall Rings, SKJ Overseas is also a leading supplier of Ceramic Saddles in Dubai. Ceramic saddles are commonly used in mass transfer operations in industries like petrochemical, chemical, and environmental engineering. SKJ Overseas offers a range of ceramic saddles, including standard types as well as specialized designs like the Ceramic Super Intalox Saddle in Dubai, which is known for its enhanced mass transfer efficiency and durability in challenging environments.

The ceramic ring partitioned in Dubai is another critical product that SKJ Overseas supplies to the region. These partitioned rings are used in packed beds and reactors to provide support for catalysts and to enhance mass transfer efficiency. As industries in Dubai continue to expand, particularly in the areas of oil refining and chemical processing, the demand for high-quality ceramic rings has also grown. SKJ Overseas has successfully positioned itself as a key supplier to meet this growing demand.

Specialty Products: Cecebe HP Porcelain Saddles

For industries requiring specialized solutions, SKJ Overseas offers Cecebe HP Porcelain Saddles in Dubai. These saddles are designed for high-performance applications where conventional packing materials may not provide the required level of resistance to chemical attack or temperature fluctuations. Cecebe HP Porcelain Saddles are commonly used in highly corrosive environments, such as sulfuric acid plants and alkylation units, where their superior chemical resistance and mechanical strength ensure long service life and consistent performance.

SKJ Overseas has been quick to recognize the unique challenges faced by industries in Dubai and the surrounding regions. The extreme temperatures, combined with the high levels of corrosive chemicals used in various industrial processes, mean that only the highest-quality materials will suffice. By offering products like Cecebe HP Porcelain Saddles, SKJ Overseas has proven itself to be a valuable partner to companies that need reliable, high-performance packing materials.

Global Reach, Local Expertise

One of the reasons behind SKJ Overseas’ success is their ability to combine global reach with local expertise. While the company exports its products to over 50 countries around the world, including major markets like the United States, Europe, and Southeast Asia, they also take great care to understand the specific needs of local markets.

In Dubai, for example, SKJ Overseas has built strong relationships with key players in industries like petrochemical, oil and gas, and environmental engineering. By working closely with their clients and understanding the unique challenges posed by the local environment, the company has been able to provide tailored solutions that deliver exceptional performance.

Moreover, SKJ Overseas maintains a strong focus on customer service. Whether it’s providing technical support, offering customized product solutions, or ensuring timely deliveries, the company goes above and beyond to meet the needs of its customers. This customer-centric approach has been one of the key drivers of their continued success and growth in both established and emerging markets.

Innovation and Sustainability

In today’s competitive industrial landscape, staying ahead of the curve requires a commitment to innovation and sustainability. SKJ Overseas has made significant investments in research and development to ensure that their products not only meet current market demands but also anticipate future challenges.

For instance, the company has been exploring new ways to improve the energy efficiency of their manufacturing processes, reduce waste, and minimize the environmental impact of their operations. By adopting more sustainable practices, SKJ Overseas is not only helping to protect the environment but also positioning itself as a forward-thinking leader in the industry.

Conclusion

As one of the leading inert ceramic balls exporters and high alumina ceramic balls manufacturers, SKJ Overseas has cemented its place as a global leader in industrial ceramics and packing solutions. With a broad product portfolio that includes Pall Rings, Ceramic Saddles, and Cecebe HP Porcelain Saddles, the company serves industries in diverse markets, including Dubai and beyond.

The company’s commitment to quality, innovation, and customer satisfaction has enabled them to build a strong reputation in the industry. Whether it’s providing standard products or developing customized solutions to meet specific client needs, SKJ Overseas continues to set the standard for excellence in the field of industrial ceramics and packing solutions.

Contact Us

+97155 849 6348

IFZA Business Park - Premises Number 44631-001 - DDP - Dubai Silicon Oasis - Dubai - United Arab Emirates

0 notes

Text

Global Babbitt Bearings Market Trends and Future Analysis Report 2024 - 2031

The global Babbitt bearings market plays a crucial role in the machinery and manufacturing industries, providing reliable support and reducing friction in various mechanical systems. This article delves into the market dynamics, key trends, challenges, and future prospects of Babbitt bearings.

Overview of the Babbitt Bearings Market

Babbitt bearings, named after their inventor, Isaac Babbitt, are antifriction bearings made from a soft metal alloy. They are primarily used in applications that require low friction and high load capacity, making them essential in various industries, including automotive, aerospace, and industrial machinery.

The global Babbitt bearings market is poised for growth, driven by industrial expansion, technological advancements, and increasing demand in various sectors. By addressing challenges and leveraging emerging opportunities

Key Features of Babbitt Bearings

Low Friction: The soft metal alloy used in Babbitt bearings provides excellent anti-friction properties, reducing wear and tear.

Load Capacity: Designed to handle heavy loads, Babbitt bearings are ideal for high-stress applications.

Self-Lubricating: Many Babbitt bearings have self-lubricating properties, which enhance their performance and longevity.

Market Dynamics

Drivers of Market Growth

Industrial Growth: The expanding industrial sector, particularly in emerging economies, is driving the demand for reliable bearing solutions.

Automotive Sector Demand: The increasing production of vehicles and machinery requiring high-performance bearings is boosting market growth.

Technological Advancements: Innovations in bearing materials and designs are enhancing the performance of Babbitt bearings, making them more appealing to manufacturers.

Challenges Facing the Market

Competition from Alternative Bearings: The rise of alternative bearing materials, such as ceramic and composite bearings, poses a challenge to the traditional Babbitt bearings market.

Raw Material Costs: Fluctuations in the prices of raw materials used in Babbitt bearings can affect overall production costs.

Environmental Regulations: Stricter environmental regulations regarding the manufacturing processes may impact production methods and costs.

Regional Analysis

North America

North America is a significant market for Babbitt bearings, driven by the presence of a robust industrial base and automotive sector. The United States is the largest consumer, with numerous manufacturers and suppliers catering to various applications.

Europe

Europe is experiencing steady growth in the Babbitt bearings market, particularly in Germany, France, and the UK. The region’s emphasis on advanced engineering and manufacturing practices supports the demand for high-quality bearing solutions.

Asia-Pacific

The Asia-Pacific region is anticipated to witness the highest growth in the Babbitt bearings market due to rapid industrialization, urbanization, and increasing demand for automotive components. Countries like China and India are leading this growth, fueled by expanding manufacturing sectors.

Competitive Landscape

Key Players

Timken Company: A global leader in bearings, Timken offers a range of Babbitt bearings for various industrial applications.

New Hampshire Ball Bearings, Inc.: Specializes in precision bearings, including Babbitt bearings, catering to aerospace and industrial markets.

RBC Bearings Incorporated: Known for manufacturing high-performance bearings, including Babbitt bearings, for various industries.

Market Strategies

Product Innovation: Companies are focusing on R&D to enhance the properties and performance of Babbitt bearings, making them suitable for advanced applications.

Sustainability Initiatives: Emphasizing eco-friendly manufacturing processes and materials to attract environmentally conscious customers.

Geographic Expansion: Targeting emerging markets in Asia and Africa to capitalize on growing industrial demand.

Future Outlook

The global Babbitt bearings market is projected to grow steadily over the next decade. As industries increasingly rely on high-performance bearing solutions, the demand for Babbitt bearings is likely to rise.

Trends to Watch

Smart Manufacturing: The integration of smart technologies in manufacturing processes may influence the development and application of Babbitt bearings.

Growth in Renewable Energy: The expansion of renewable energy projects, such as wind and solar, will drive demand for reliable bearing solutions in these sectors.

Customization: Increasing demand for tailored bearing solutions that meet specific application requirements will shape product development in the market.

Conclusion

The global Babbitt bearings market is poised for growth, driven by industrial expansion, technological advancements, and increasing demand in various sectors. By addressing challenges and leveraging emerging opportunities, stakeholders can thrive in this dynamic market. The future of Babbitt bearings will be characterized by innovation, sustainability, and a commitment to meeting the evolving needs of industries worldwide.

#Global Babbitt Bearings Market Size#Global Babbitt Bearings Market Trend#Global Babbitt Bearings Market Growth

0 notes

Text

Kaolin Market Intelligence Report Offers Growth Prospects

Kaolin Industry Overview

The global kaolin market size was valued at USD 3.98 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 4.0% from 2024 to 2030.Increasing investment in construction and infrastructure industry is propelling demand for paints & coatings, ceramic-based products, and cement, which is driving market growth.

Global construction industry is expected to witness lucrative growth over shifting inclination towards green construction, which in turn is expected to provide a significant growth opportunity for kaolin market. For instance, according to the World Bank’s new IFC report, green construction is anticipated to make investment opportunities worth USD 1.5 trillion for emerging markets.

Gather more insights about the market drivers, restrains and growth of theKaolin Market

Investments in construction, infrastructure development, and automotive production are expected to contribute to market growth over the forecast period. Growth of construction industry in the U.S. is a key factor contributing to demand for kaolin in the country. According to U.S. Census Bureau, total construction spending (residential and non-residential) grew by 3.5% in June 2023 on a y-o-y basis. The spending on single-family housing increased by 2.1% and multi-family housing by 1.5%.

Growing demand for painting due to rising investments in construction is leading companies to engage in strategic measures such as mergers & acquisitions, which are expected to influence the market demand positively. For instance, in November 2021, GDB International, Inc., a producer of paints & coatings, acquired a paint manufacturing plant in Illinois, U.S. This plant has a production capacity of 5 million gallons per year and can produce both water and solvent-based paints.

Further investments in medical industry are another driving factor for the market. For instance, in December 2021, Pfizer announced that it would acquire Arena Pharmaceuticals for about USD 6.70 billion. This deal was completed in March 2022 and is expected to help advance its presence in treatment of several immuno-deficiency diseases. Such developments indicate healthy growth for country’s pharmaceutical and medical industries. This is anticipated to have a positive impact on demand for kaolin in pharmaceuticals and medical application segment.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The India kaolin market size was estimated at USD 349.6 million in 2023 and is expected to grow at a CAGR of 5.2% from 2024 to 2030. The increasing construction and infrastructural developments, paper manufacturing, and growing paints and coating industries are driving growth for kaolin.

The global HDPE and LLDPE geomembrane market size was estimated at USD 1.36 billion in 2023 and is expected to grow at a CAGR of 5.6% from 2024 to 2030.

Key Companies profiled:

BASF SE

EICL Ltd.

Imerys S.A.

I-Minerals Inc.

KaMin LLC

LB Minerals Ltd.

Maoming Xingli Kaolin Co. Ltd.

Quazwerke GmbH

Sibelco

Thiele Kaolin Company

Key Kaolin Company Insights

Some of the key players operating in the market include KaMin LLC, Imerys S.A. and Sibelco.

KaMin LLC acquired the kaolin business from BASF SE in September 2022. The divestiture consists of the production hub with sites Toddvile, Edgar, Deweyville, and Gordon mines, mills, and reserves in the U.S.

Imerys S.A. specializes in the production & processing of minerals. It sells its products through three business segments: Performance Minerals Americas, Performance Minerals Asia Pacific, and Performance Minerals Europe, Middle East, and Africa.

Sibelco’s product portfolio includes dry sand, wet sands, kaolin, silica flour, frac sand, ball clay, cristobalite, feldspar, filtration sand, olivine sand, spherical silica, high-purity quartz, quicklime, coated sands, red clay, prepared bodies, hydrated lime, diatomite, nepheline Semite, olivine flour, and lithium minerals. The company manufactures kaolin for producing fine ceramics. The company’s kaolin reserves are in UK, Czech Republic, France, Germany, Spain, Portugal, and Ukraine.

WA Kaolin Limited and Maoming Xingli Kaolin Co., Ltd. are some of the emerging market participants.

WA kaolin is a mineral exploration, mining, and processing company. In November 2020, the company completed its definitive feasibility study of Wickepin Kaolin Project and in 2022 the company commissioned stage 1 of the Wickepin Processing plant

Maoming Xingli Kaolin Co., Ltd. has a high-quality mine named acicular kaolin mine that spreads across 800 acres. The company offers several products such as bone china clay, clay for porcelain, kaolin clay, porcelain clay, and others. Its key focus is on washed kaolin (without acid), 90-degree ball clay, and 90- degree kaolin.

Recent Developments

In November 2023, KaMin LLC and CADAM announced a price increase of their kaolin products by up to 9% starting from January 2024. This is to offset cost increase due to inflation, increase in mining cost, stringent environmental and regulatory requirements, and increase in electricity rates in the U.S. and Brazil, and labor cost.

In January 2024, the Federal Government of Nigeria announced that it has started to explore the possibility of production of salt and kaolin in Abuja. This is expected to increase global supply, hence providing price favorability to end users at a regional level.

Order a free sample PDF of the Kaolin Market Intelligence Study, published by Grand View Research.

0 notes

Text

Discover the Best Ceramic Solutions in Mandsaur: A Comprehensive Guide

Mandsaur, a notable hub for industrial materials, has become a significant player in the ceramic industry. With an increasing demand for advanced ceramic products across various sectors, Mandsaur stands out due to its exceptional ceramic ultra suppliers and manufacturers. This article explores the leading ceramic ultra suppliers, High Alumina Ceramic Balls exporters, ceramic grid block suppliers, PP Saddles manufacturers, Ceramic Saddles suppliers, and Ceramic Super Intalox Saddle providers in Mandsaur. We will delve into each category to provide a comprehensive overview of what you can expect from these leading ceramic suppliers and manufacturers.

Ceramic Ultra Suppliers: Leading the Industry

Ceramic Ultra materials are known for their exceptional durability, resistance to high temperatures, and excellent mechanical properties. In Mandsaur, ceramic ultra suppliers offer a range of high-quality products designed for demanding applications. These materials are ideal for use in aerospace, automotive, and heavy machinery industries due to their superior performance and longevity.

Ceramic Ultra suppliers in Mandsaur pride themselves on delivering products that meet stringent international standards. Their commitment to quality is evident in their state-of-the-art manufacturing processes and rigorous quality control measures. By leveraging advanced technology and innovative techniques, these suppliers ensure that their ceramic ultra products provide exceptional reliability and efficiency.

High Alumina Ceramic Balls Exporters: Quality and Precision

High Alumina Ceramic Balls are crucial in various industrial applications, particularly in grinding and milling processes. Known for their high density and wear resistance, these balls are essential in enhancing the efficiency of machinery and extending the lifespan of equipment.

Mandsaur is home to several renowned High Alumina Ceramic Balls exporters who specialize in providing these high-performance materials to global markets. These exporters are known for their adherence to international quality standards, ensuring that their ceramic balls deliver outstanding performance and reliability. Their expertise in sourcing, manufacturing, and exporting ensures that customers receive top-quality products tailored to their specific needs.

Ceramic Grid Block Suppliers: Essential for Efficient Filtration

Ceramic Grid Blocks are integral components used in various industrial processes, particularly in filtration and separation applications. They are designed to support catalyst beds and facilitate efficient fluid distribution in chemical reactors and other processing units.

In Mandsaur, ceramic grid block suppliers offer a diverse range of products designed to meet the specific requirements of different industries. These suppliers utilize advanced manufacturing techniques to produce grid blocks with precise dimensions and superior structural integrity. Their commitment to quality ensures that their products contribute to improved operational efficiency and reduced maintenance costs.

PP Saddles Manufacturers: Robust and Reliable

PP Saddles, or polypropylene saddles, are essential components used in various industrial processes, including chemical processing and water treatment. These saddles provide support for catalyst beds and improve fluid distribution, making them a critical part of many industrial systems.

Mandsaur boasts a number of reputable PP Saddles manufacturers who excel in producing high-quality saddles that meet the demands of modern industry. These manufacturers utilize advanced materials and cutting-edge technology to ensure that their PP Saddles are robust, reliable, and resistant to chemical degradation. Their expertise in manufacturing ensures that their products deliver optimal performance and longevity.

Ceramic Saddles Suppliers: Enhancing Process Efficiency

Ceramic Saddles are widely used in industrial applications for their excellent chemical resistance and high-temperature stability. They are commonly employed in processes such as catalytic reactions and fluidized bed operations, where they contribute to efficient fluid distribution and improved process performance.

Ceramic Saddles suppliers in Mandsaur offer a broad selection of saddles designed to meet the specific needs of various industrial applications. Their products are known for their durability, precision, and ability to withstand harsh operating conditions. By focusing on quality and innovation, these suppliers ensure that their ceramic saddles provide reliable performance and contribute to overall process efficiency.

Ceramic Super Intalox Saddle Providers: Advanced Solutions

Ceramic Super Intalox Saddles are advanced packing materials used in chemical processing and distillation columns. They are designed to provide enhanced mass transfer efficiency and improved process performance. Their unique design allows for optimal fluid distribution and minimizes pressure drop, making them a preferred choice for many industrial applications.

In Mandsaur, Ceramic Super Intalox Saddle providers offer high-quality saddles that meet the rigorous demands of modern industrial processes. These providers utilize advanced manufacturing techniques and materials to produce saddles that deliver exceptional performance and durability. Their commitment to innovation ensures that their products contribute to improved process efficiency and reduced operational costs.

Ceramic Ultra Manufacturers: Excellence in Production

Ceramic Ultra Manufacturers in Mandsaur are at the forefront of producing high-performance ceramic materials designed for a wide range of applications. These manufacturers leverage advanced technologies and strict quality control measures to ensure that their products meet the highest standards of performance and reliability.

From raw material selection to final product testing, Mandsaur’s ceramic ultra manufacturers maintain a strong focus on quality throughout the production process. Their expertise in ceramic manufacturing enables them to produce materials that offer exceptional durability, high-temperature resistance, and superior mechanical properties. Whether for industrial, aerospace, or other demanding applications, these manufacturers provide solutions that meet the needs of their clients.

Conclusion

Mandsaur has emerged as a key player in the ceramic industry, offering a wide range of high-quality products and services. From ceramic ultra suppliers to High Alumina Ceramic Balls exporters, ceramic grid block suppliers, PP Saddles manufacturers, Ceramic Saddles suppliers, and Ceramic Super Intalox Saddle providers, the city is home to a wealth of expertise and innovation.

Whether you are looking for advanced ceramic materials for high-performance applications or reliable components for industrial processes, Mandsaur’s ceramic industry offers the solutions you need. By choosing products from these leading suppliers and manufacturers, you can ensure that your operations benefit from the best materials and technologies available in the market.

Visit- https://mbctower.in/

Address-

Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India

Phone:

088276 97111

0 notes

Text

0 notes

Text

Bearings, Global Market Size Forecast, Top 18 Players Rank and Market Share

Bearings Market Summary

Bearings are used as a mechanical component to transfer the power and to move a certain part, and this is done by utilizing the small frictional force of the bearings, which makes them rotate easily (or move in one direction easily), all the while withstanding the force and weight load acting against them.

According to the new market research report “Global Bearings Market Report 2024-2030”, published by QYResearch, the global Bearings market size is projected to reach USD 70.11 billion by 2030, at a CAGR of 3.8% during the forecast period.

Figure. Global Bearings Market Size (US$ Million), 2019-2030

Figure. Global Bearings Top 18 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

In terms of product application, currently Automotive Industry is the largest segment, hold a share of 62%.

Market Drivers:

Industrial policy support

The development of downstream in Automotive Industry, Industrial Machine, etc. will further promote the development of the industry

The steady development of upstream industries is conducive to promoting the healthy development of the industry

Restraint:

Competition from Low-end Ball Bearings manufacturers is bad for industrial upgrading

Fluctuations in upstream raw material prices have a greater impact on product prices.

Lack of support from upstream/downstream partners as a new entry to the market

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Expanding the Market: Carbon Steel Ball Bearings in Kenya

As the global demand for robust and reliable industrial components continues to rise, the spotlight increasingly turns to emerging markets where infrastructure development is accelerating at an unprecedented pace.

Among these, Kenya stands out as a burgeoning hub of industrial growth. Abbott Ball Company, a renowned leader in the manufacturing of precision balls, is proud to present our range of carbon steel ball bearings, engineered to meet the demands of Kenya’s dynamic industries.

The Backbone of Industrial Precision

Ball bearings are essential components in countless applications, from automotive and aerospace to manufacturing and robotics. Their primary function is to reduce rotational friction and support radial and axial loads. Among the various types of ball bearings, those made from carbon steel are particularly valued for their durability, cost-effectiveness, and versatility.

Why Carbon Steel Ball Bearings?

Carbon steel ball bearings are made from high-quality carbon steel, which provides several distinct advantages:

Durability: Carbon steel is known for its high tensile strength and wear resistance, making these bearings suitable for high-load applications and extending their lifespan even under strenuous conditions.

Cost-Effectiveness: Compared to other materials like stainless steel or ceramics, carbon steel offers a more economical solution without compromising on performance. This makes it ideal for industries looking to optimize cost without sacrificing quality.

Versatility: These bearings are suitable for a wide range of applications, including agricultural machinery, conveyors, electric motors, and household appliances. Their adaptability makes them a versatile choice for Kenya’s diverse industrial needs.

Applications in Kenya’s Growing Industries

Kenya’s industrial landscape is rapidly evolving, driven by sectors such as manufacturing, automotive, agriculture, and construction. Here’s how carbon steel ball bearings can play a pivotal role in each:

Manufacturing: In an industry where precision and efficiency are paramount, carbon steel ball bearings ensure smooth operation of machinery and production lines. Their robustness reduces downtime and maintenance costs, boosting overall productivity.

Automotive: The automotive sector relies heavily on reliable bearings to enhance vehicle performance and safety. Carbon steel bearings are used in various automotive components, from wheel hubs to transmissions, ensuring longevity and reliability.

Agriculture: Kenya’s agricultural sector, a cornerstone of its economy, benefits significantly from durable machinery. Carbon steel ball bearings in tractors, plows, and harvesters contribute to better performance and longer equipment life, supporting the agricultural output.

Construction: With infrastructure development on the rise, construction machinery demands components that can withstand harsh conditions. Carbon steel ball bearings are ideal for this purpose, offering resilience and strength in demanding environments.

Why Abbott Ball Company?

Abbott Ball Company brings over a century of expertise in precision ball manufacturing. Our commitment to quality and innovation ensures that every carbon steel ball bearing meets the highest standards. Here’s what sets us apart:

Precision Manufacturing: Our state-of-the-art manufacturing processes guarantee the highest level of precision and consistency, essential for the optimal performance of ball bearings.

Quality Assurance: Rigorous quality control measures are in place to ensure that every bearing meets industry standards and customer specifications.

Global Reach, Local Support: While we operate on a global scale, we understand the importance of local support. Our presence in Kenya is backed by a dedicated team ready to provide technical assistance and customer service.

Conclusion

As Kenya’s industries continue to grow and evolve, the demand for high-quality, reliable components will only increase. Abbott Ball Company’s carbon steel ball bearings are well-positioned to meet this demand, providing the durability, cost-effectiveness, and versatility needed to support the nation’s industrial ambitions. With our commitment to excellence and customer satisfaction, we are proud to be a part of Kenya’s journey towards a robust industrial future. For more information on our products and services, visit https://abbottball.com/materials/carbon-steel-balls/.

Contact Us

Abbott Ball Co Inc

📍Business Address : 19 Railroad Pl West Hartford CT 06110 United States

📞 Phone: 18602365901

🌐 Website: https://abbottball.com

🕘 Hours of Operation: MON - FRI 8AM - 5PM

1 note

·

View note

Text

Ball Bearing Market Growth, Share, Trends and Opportunity 2024-2032

IMARC Group's report titled "Ball Bearing Market Report by Application (Automobile, General Engineering, Mining and Construction, Railways, Aerospace and Shipping, Agriculture, and Others), and Region 2024-2032", offers a comprehensive analysis of the industry, which comprises insights on the global ball bearing market trends. The global ball bearing market size reached US$ 43.7 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 62.0 Billion by 2032, exhibiting a growth rate (CAGR) of 3.8% during 2024-2032.

For an in-depth analysis, you can refer sample copy of the report: https://www.imarcgroup.com/ball-bearing-market/requestsample

Factors Affecting the Growth of the Ball Bearing Industry:

Demand in the Wind Energy Sector:

The increasing shift towards renewable energy sources is leading to investments in wind power, which relies heavily on ball bearings for turbine operation. These bearings are critical in wind turbines for blade pitch and yaw mechanism control and in gearbox and generator applications. Additionally, the growing commitment of various countries to reduce carbon emissions and increase renewable energy capacities is catalyzing the demand for high-quality and durable ball bearings. Moreover, technological advancements in turbine design, aiming for higher efficiency and longer service life, are driving the need for specialized ball bearings in this sector.

Advancements in Bearing Technologies:

Technological advancements in bearing design and materials are supporting the market growth. The development of bearings with enhanced performance capabilities, such as higher load-bearing capacity, reduced noise levels, and increased energy efficiency, caters to a wide range of industrial applications. Innovations like sensor-equipped bearings, which provide real-time monitoring of performance and maintenance needs, are becoming popular in predictive maintenance regimes. Additionally, advancements in materials science are resulting in the creation of bearings with superior properties, including ceramic ball bearings, which offer reduced friction, higher temperature resistance, and longer service life compared to traditional steel bearings. These technological developments not only extend the application range of ball bearings but also improve their operational efficiency.

Demand in the Automotive Industry:

Automotive manufacturers are focusing on enhancing vehicle performance, lifespan, and energy efficiency, which is catalyzing the demand for high-quality ball bearings. These components are essential in various automotive applications, including engines, transmissions, and wheel hubs. Additionally, the rising popularity of electric vehicles (EVs) that require specially designed bearings for electric motors and other components, distinct from those used in traditional internal combustion engine vehicles is supporting the market growth. Furthermore, the focus on reducing carbon emissions is leading to higher production of EVs, thereby catalyzing the demand for ball bearings.

Leading Companies Operating in the Global Ball Bearing Industry:

NTN Corporation

Timken

JTEKT

SKF

Schaeffler Group

Ball Bearing Market Report Segmentation:

By Application:

Automobile

General Engineering

Mining and Construction

Railways, Aerospace and Shipping

Agriculture

Others

The automobile holds the biggest market share as ball bearings play an essential role in various vehicle components, such as wheels, transmissions, and engines.

Regional Insights:

North America (United States, Canada)

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Asia Pacific dominates the market, driven by the extensive manufacturing activities and the presence of major automotive and industrial sectors in the region.

Global Ball Bearing Market Trends:

The growing trend of miniaturization and the development of lightweight ball bearings is offering a favorable market outlook. This trend is driven by industries, such as aerospace, medical devices, and robotics, where space constraints and weight reduction are critical factors. Miniature bearings are employed in applications like small electric motors, dental drills, and precision robotics. Manufacturers are innovating in materials and design, utilizing advanced alloys and engineering plastics to produce bearings that meet these stringent requirements without compromising on durability or load-bearing capacity.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARCs information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the companys expertise.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

`

SKJ Overseas: Leading Manufacturer of Ceramic Saddles, Rings, Grid Blocks, and More

SKJ Overseas is a renowned name in the manufacturing and export sector of high-quality industrial ceramic products such as Ceramic Saddles, Rings, Grid Blocks, PP Pall Rings, Ceramic Ultra, and more. With a commitment to superior quality and innovation, SKJ Overseas has earned a reputation as a reliable supplier in both domestic and international markets. This article will explore SKJ Overseas' product range, manufacturing processes, and its growing presence in key global markets, including Pall Ring in Dubai, Ceramic Super Intalox Saddle in Dubai, and Grid Block in Mandsaur. Additionally, we'll discuss their prominence as inert ceramic balls manufacturers, inert ceramic balls exporters, and High Alumina Ceramic Balls exporters.

SKJ Overseas: Excellence in Ceramic and Industrial Products Manufacturing

SKJ Overseas has established itself as a leader in the manufacturing of ceramic and industrial products that are widely used in various industrial processes, including chemical engineering, gas treatment, and distillation processes. Their product portfolio includes Ceramic Saddles, PP Pall Rings, Grid Blocks, and High Alumina Ceramic Balls, among others, which are known for their high durability, strength, and heat resistance.

The company’s manufacturing capabilities are backed by advanced technology and stringent quality control processes, ensuring that each product meets international standards. Moreover, SKJ Overseas is not just a domestic supplier; it has a strong export portfolio, serving clients across several countries.

Product Range at SKJ Overseas

Ceramic Saddles

Ceramic Saddles are used in various industries for gas scrubbing, distillation, and filtration processes. SKJ Overseas manufactures Ceramic Saddles that are designed to provide maximum surface area, ensuring efficient mass transfer and gas-liquid interaction. Their products are highly durable, resistant to thermal shock, and offer excellent chemical resistance.

PP Pall Rings

PP Pall Rings are a crucial element in packed bed columns, offering high surface area and low-pressure drop, which improves the efficiency of various industrial processes such as gas absorption, distillation, and stripping. SKJ Overseas manufactures high-quality PP Pall Rings with precise dimensions that ensure optimal performance in diverse chemical and petrochemical industries. With a growing demand for Pall Rings in Dubai, SKJ Overseas has become a key supplier for companies in the region that require reliable and efficient mass transfer solutions.

Ceramic Super Intalox Saddle

The Ceramic Super Intalox Saddle in Dubai is another product SKJ Overseas is well-known for. These saddles provide excellent packing performance due to their unique design, which offers a large surface area, making them ideal for gas and liquid distribution applications. Industries in Dubai and other parts of the Middle East prefer SKJ Overseas' Ceramic Super Intalox Saddles due to their high mechanical strength, resistance to high temperatures, and superior chemical stability.

Grid Blocks

Grid Blocks in Mandsaur and other regions play a crucial role in catalyst support in various industries. These blocks are used in applications requiring high surface area, excellent mechanical strength, and long operational life. SKJ Overseas produces high-quality Grid Blocks designed for uniform gas flow and temperature distribution, essential for efficient catalytic reactions.

Inert Ceramic Balls

As an inert ceramic balls manufacturer, SKJ Overseas has gained significant recognition for producing ceramic balls that are used as catalyst bed support media in chemical reactors. These balls are designed to provide excellent chemical stability, resistance to high temperatures, and mechanical strength, making them essential in various industrial applications.

SKJ Overseas is also an established inert ceramic balls exporter, supplying these critical industrial components to clients worldwide. The company ensures that its inert ceramic balls meet international standards, offering durability and performance that cater to the needs of industries such as oil refining, gas processing, and petrochemical manufacturing.

High Alumina Ceramic Balls

High Alumina Ceramic Balls are another significant product offered by SKJ Overseas. These balls are known for their high density, low porosity, and superior resistance to corrosion, making them ideal for use in various demanding industrial environments. As a prominent High Alumina Ceramic Balls exporter, SKJ Overseas ensures that these balls provide excellent wear resistance and longer service life, contributing to enhanced operational efficiency for industries worldwide.

Global Market Presence: Exporting High-Quality Ceramic Products

Pall Rings in Dubai: Meeting Industrial Demands

Dubai's booming industrial sector has created a significant demand for high-performance industrial packing solutions, and SKJ Overseas has been a crucial player in meeting this demand. Pall Rings in Dubai are widely used in industries such as petrochemicals, gas treatment, and chemical processing, and SKJ Overseas has emerged as a preferred supplier for these products. Their PP Pall Rings, known for their durability and low-pressure drop, have become a staple in many industrial plants in the region.

Dubai's strategic location as a global trade hub further enhances SKJ Overseas' ability to serve clients in the Middle East, Africa, and beyond. The company’s commitment to timely delivery and consistent product quality has strengthened its position in this competitive market.

Ceramic Super Intalox Saddle in Dubai: A Key Product for Gas and Liquid Distribution

In addition to Pall Rings, the demand for Ceramic Super Intalox Saddles in Dubai has also seen significant growth. These saddles are critical for gas and liquid distribution applications, offering excellent mechanical strength and chemical resistance. SKJ Overseas' Ceramic Super Intalox Saddles are preferred by industries in Dubai due to their superior performance in high-temperature and corrosive environments.

By offering customized solutions tailored to the needs of clients in Dubai, SKJ Overseas has solidified its presence in the region’s industrial market, becoming a key player in supplying advanced ceramic products.

Grid Blocks: Supporting Catalyst Processes

In the Indian market, particularly in regions like Mandsaur, Grid Blocks play a critical role in industrial processes. SKJ Overseas has been a major supplier of high-quality Grid Blocks to industries requiring efficient catalyst support systems. These blocks are designed for durability and optimal gas flow distribution, ensuring the efficient operation of reactors and other industrial equipment.

The company's strong manufacturing capabilities and strict adherence to quality standards have made it a trusted supplier in the Indian market, providing solutions that enhance the operational efficiency of chemical, petrochemical, and refining industries.

Commitment to Quality and Innovation

SKJ Overseas has earned a reputation for delivering products that adhere to the highest quality standards. The company’s production facilities are equipped with cutting-edge technology, allowing for precise manufacturing processes that ensure consistent product quality. From inert ceramic balls manufacturers to High Alumina Ceramic Balls exporters, SKJ Overseas adheres to rigorous quality control protocols at every stage of production.

Moreover, SKJ Overseas places a strong emphasis on research and development (R&D), constantly innovating to meet the evolving needs of their clients. This dedication to innovation allows them to stay ahead of market trends and offer products that meet the increasing demands of modern industrial applications.

Export Excellence: A Global Reach

With a strong export portfolio, SKJ Overseas is recognized as one of the leading inert ceramic balls exporters and High Alumina Ceramic Balls exporters. Their products are shipped to clients across Europe, the Middle East, Asia, and Africa, ensuring that industries worldwide have access to high-quality ceramic products that enhance their operational efficiency.

SKJ Overseas’ commitment to timely delivery, competitive pricing, and superior product quality has earned the company a loyal customer base across the globe. Their ability to cater to both large-scale industrial projects and smaller specialized requirements demonstrates their versatility and dedication to customer satisfaction.

Conclusion: SKJ Overseas – A Trusted Partner for Industrial Ceramic Solutions

SKJ Overseas has established itself as a leader in the manufacturing and export of high-quality ceramic products, including Ceramic Saddles, Rings, Grid Blocks, PP Pall Rings, and Ceramic Ultra. Their products are trusted by industries worldwide, from Pall Ring in Dubai to Grid Block in Mandsaur. As a company that places a high emphasis on quality, innovation, and customer satisfaction, SKJ Overseas continues to be a reliable partner for businesses seeking durable and efficient ceramic solutions.

Whether you are looking for inert ceramic balls manufacturers or High Alumina Ceramic Balls exporters, SKJ Overseas offers comprehensive solutions tailored to meet your specific industrial needs. Their dedication to quality and excellence ensures that their products continue to play a vital role in global industrial processes.

Contact Us

+97155 849 6348

IFZA Business Park - Premises Number 44631-001 - DDP - Dubai Silicon Oasis - Dubai - United Arab Emirates

0 notes

Text

https://www.databridgemarketresearch.com/reports/global-ceramic-balls-market

0 notes

Text

Biofilter Market May See a Big Move 2024-2030

Biofilter Market May See a Big Move 2024-2030

Global Biofilter Market, Biofilter Market Demand, Biofilter Market Trends, Biofilter Market Analysis, Biofilter Market Growth, Biofilter Market Share, Biofilter Market Forecast, Biofilter Market Challenges, Biofilter Market Opportunity

At Intellect Markets, published a new research publication on "Biofilter Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting Market associated stakeholders. The growth of the Biofilter Market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample Copy of This Research @ https://intellectmarkets.com/report/biofilter-market/request-sample

Some of the key players profiled in the study are:

Veolia Water Solutions & Technologies, SUEZ - Water Technologies & Solutions, Evoqua Water Technologies Corp., CMI Europe Environnement SA, OdaTech, Bohn Biofilter Corporation, Pentair Aquatic Eco-Systems, Inc., Anua International LLC, Pure Air Solutions, PPC Air, Waterloo Biofilter Systems Inc., AZU Water Gmbh, Velda B.V., Ambio Biofiltration Ltd., Biorem Inc.