#Germany Composite Insulators Market

Explore tagged Tumblr posts

Text

The Cladding Market Boom: What’s Driving Demand and Innovation?

The global cladding market size is expected to reach USD 386.04 billion by 2030, as per a new report by Grand View Research Inc. The market is expected to register a CAGR of 7.3% from 2024 to 2030. Increasing construction spending, particularly for non-residential applications such as office and commercial sectors, is expected to drive the adoption of claddings, thereby driving market growth.

Rising consumer demand for aesthetically attractive residences, along with significant growth in single and multi-family building units due to population growth is expected to drive industry growth. Furthermore, the increasing use of lightweight materials to promote energy savings in households and workplaces is expected to drive market expansion throughout the forecast period.

The market has struggled due to the underperformance of its end-use sectors such as industrial, residential, and commercial construction due to trade restrictions caused by the COVID-19 pandemic. However, high consumer awareness, positive government outlook, and rising product penetration had resulted in the high demand for claddings.

The industry has witnessed extensive competition owing to the growing demand and increasing innovations for cladding products. The entry of major brands with substantial manufacturing capabilities and unique product attributes has fostered market innovation, prompting existing companies to collaborate with each other or engage in extensive R&D.

Cladding Market Report Highlights

The terracotta segment led the market and accounted for more than 35% share of the global revenue in 2023

The office application segment accounted for the revenue share of 33.9% in 2023 and is expected to witness significant growth on account of growing employment rates, combined with regional growth of established industries. These factors are propelling the need for new office spaces which use various types of claddings for aesthetics and energy-saving purposes.

Asia Pacific is projected to witness substantial market growth of 8.0% from 2024 to 2030. The region is generally characterized by high temperature and extreme climatic conditions, which is anticipated to propel the product demand for the exterior protection of structures.

New generation claddings do not allow organic substances to settle on the surface while anti-bacterial tiles with light-activated antibacterial surface coatings kill bacteria. These tiles are increasingly being used in household and hospital applications.

Cladding Market Segmentation

Grand View Research has segmented the global cladding market report based on product, application, and region

Cladding Product Outlook (Volume, Million Sq. Meters; Revenue, USD Million, 2018 - 2030)

Steel

Aluminum

Composite Materials

Fiber Cement

Terracotta

Ceramic

Others

Cladding Application Outlook (Volume, Million Sq. Meters; Revenue, USD Million, 2018 - 2030)

Residential

Industrial

Commercial

Offices

Institutional

Cladding Regional Outlook (Volume, Million Sq. Meters; Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Europe

Germany

UK

France

Italy

Asia Pacific

China

India

Japan

Central & South America

Brazil

Mexico

Middle East & Africa

Bahrain

Kuwait

Qatar

Oman

Saudi Arabia

UAE

Jordan

Iraq

Iran

Egypt

Turkey

Libya

Sudan

List of Key Players

Kingspan Group

Carea Group

GB Architectural Cladding Products Ltd

Rieger Architectural Products

OmniMax International, Inc.

CGL Systems Ltd.

SFS Group

Cladding Corp

Centria

Trespa International B.V.

Middle East Insulation LLC

Shildan, Inc.

Avenere Cladding LLC

Order a free sample PDF of the Cladding Market Intelligence Study, published by Grand View Research.

0 notes

Text

VAE Redispersible Powder Prices: Trend, Pricing and Forecast

The VAE Redispersible Powder market has gained significant traction in recent years, driven by the growing demand for high-performance building materials and sustainable construction practices. VAE, or vinyl acetate ethylene, is a key component in redispersible powders, offering superior adhesive properties, flexibility, and durability. These powders are extensively used in a wide range of applications, including tile adhesives, external thermal insulation composite systems (ETICS), self-leveling compounds, and repair mortars. The rising construction activities worldwide, coupled with the increasing adoption of energy-efficient building solutions, have fueled the demand for VAE redispersible powders, making them an indispensable material in modern construction practices.

One of the primary factors driving the growth of the VAE redispersible powder market is the booming construction industry, especially in developing economies. Rapid urbanization and industrialization have created a surge in infrastructure development, leading to an increased need for versatile construction materials. VAE redispersible powders play a crucial role in enhancing the performance of dry-mix mortars, making them a preferred choice among builders and contractors. Their ability to improve adhesion strength, water retention, and workability ensures high-quality construction outcomes, even in challenging environments. Additionally, the push towards green building materials has further boosted the adoption of VAE-based solutions, as they align with sustainable construction practices.

Get Real time Prices for VAE Redispersible Powder: https://www.chemanalyst.com/Pricing-data/vae-redispersible-powder-1282

The increasing focus on renovation and repair activities in developed regions has also contributed to the expansion of the VAE redispersible powder market. Aging infrastructure in countries like the United States, Germany, and Japan has necessitated the use of advanced materials that can withstand harsh conditions while ensuring long-term durability. VAE redispersible powders have emerged as a reliable solution in repair mortars, offering superior bonding strength and crack resistance. Furthermore, the growing awareness of the environmental benefits associated with these powders, such as reduced carbon emissions and minimal waste generation, has made them an attractive choice for eco-conscious consumers and regulatory bodies alike.

Technological advancements in the production of VAE redispersible powders have further accelerated market growth. Manufacturers are investing heavily in research and development to enhance the performance characteristics of these powders, catering to the evolving needs of the construction industry. Innovations such as improved particle size distribution, enhanced hydrophobicity, and superior freeze-thaw stability have widened the scope of applications for VAE redispersible powders. These advancements not only improve the overall efficiency of construction processes but also contribute to cost savings, making them a cost-effective alternative to traditional construction materials.

The global VAE redispersible powder market is also benefiting from the growing trend of energy-efficient buildings. Governments and organizations across the globe are emphasizing the importance of reducing energy consumption in buildings to combat climate change. VAE redispersible powders are integral to the production of ETICS, which provide excellent thermal insulation properties and reduce energy consumption for heating and cooling. This has led to a surge in demand for VAE-based solutions, particularly in regions with extreme climatic conditions. Moreover, the increasing adoption of green certification programs, such as LEED and BREEAM, has further incentivized the use of VAE redispersible powders in construction projects.

Asia-Pacific has emerged as a dominant player in the VAE redispersible powder market, owing to the rapid economic growth and infrastructural development in countries like China, India, and Southeast Asian nations. The region's burgeoning population and urban migration have created a massive demand for residential and commercial buildings, driving the consumption of advanced construction materials. Additionally, the availability of low-cost raw materials and labor in Asia-Pacific has attracted global manufacturers to establish their production facilities in the region, further strengthening its position in the market. The increasing government initiatives to promote affordable housing and smart city projects are also expected to fuel the demand for VAE redispersible powders in the coming years.

Europe and North America are also significant markets for VAE redispersible powders, driven by the growing emphasis on sustainability and energy efficiency in construction practices. The stringent regulations imposed by governments and environmental agencies in these regions have encouraged the use of eco-friendly building materials, creating a favorable environment for the adoption of VAE-based solutions. In addition, the high disposable incomes and increasing awareness of advanced construction technologies among consumers in these regions have further propelled market growth. The presence of well-established construction companies and a robust distribution network also play a pivotal role in the expansion of the VAE redispersible powder market in these regions.

Despite its promising growth prospects, the VAE redispersible powder market faces certain challenges, such as fluctuating raw material prices and the availability of substitutes. The volatility in the prices of vinyl acetate monomer, a key raw material for VAE production, can impact the profit margins of manufacturers and hinder market growth. Additionally, the presence of alternative redispersible powders, such as acrylic-based and styrene-butadiene-based powders, poses a competitive threat to the VAE market. However, the superior performance characteristics and environmental benefits of VAE redispersible powders provide a competitive edge, ensuring their sustained demand in the global market.

The future of the VAE redispersible powder market looks promising, with significant opportunities for growth in emerging economies and untapped regions. The increasing investments in infrastructure development, coupled with the rising awareness of sustainable construction practices, are expected to drive the demand for VAE-based solutions in the years to come. Moreover, the ongoing innovations in product formulations and production technologies will further enhance the market's growth potential, making VAE redispersible powders an indispensable component in the construction industry. As the world moves towards a more sustainable and energy-efficient future, the role of VAE redispersible powders in shaping modern construction practices will undoubtedly continue to expand.

Get Real time Prices for VAE Redispersible Powder: https://www.chemanalyst.com/Pricing-data/vae-redispersible-powder-1282

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#VAE Redispersible Powder Price#VAE Redispersible Powder Prices#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Specialty Chemicals Market is poised to reach $364.8 billion by 2028

The report "Specialty Chemicals Market by Type (Plasticizers, Water-Based, Coagulants and Flocculants, Scale Inhibitors), Application (Paper and Packaging, Automotive, Consumer Goods, Construction), and Region– Global Forecast to 2028", size was USD 272.6 billion in 2022 and is projected to reach USD 364.8 billion by 2028, at a CAGR of 5.0%, between 2023 and 2028.

Specialty chemicals are used in various industries including construction, packaging, consumer goods, automotive, industrial, medical and others. One of the biggest consumers of specialty chemicals is the automotive sector. These chemicals are employed in the manufacture of a few automobile parts, including tires, coatings, and adhesives. New specialty chemicals that can enhance the performance of these components have been developed in response to the rising need for lightweight and fuel-efficient automobiles. To make automobiles lighter and more fuel-efficient, for instance, specialty chemicals like high-performance polymers and composites are used.

Download PDF Brochure: https://www.marketsandmarkets.com/Market-Reports/global-specialty-chemicals-165.html

Water-based adhesive technology accounted for the largest market share, in terms of volume, in 2022.

Water-based technology is expected to dominate the adhesives type of specialty chemicals, in terms of volume, during the forecast period. Factors such as environmental regulations, health and safety considerations, performance and versatility, and industrial requirements and preferences drive the demand for water-based adhesive technology across the globe. Stringent environmental regulations and increasing consumer awareness have prompted the industry to adopt more environmentally friendly adhesive technologies, such as water-based adhesives.

Medical is estimated to be the fastest-growing application of adhesives, in terms of value, during the forecast period.

With improvements in surgical methods, medical equipment, and wearable technologies, the medical sector is always developing. To ensure appropriate assembly, bonding, and performance, many of these advancements need trustworthy adhesives. For example, in minimally invasive surgeries, adhesives are used to secure medical devices and seal incisions. The development in medical sector is expected to drive the market for adhesives globally.

Asia Pacific is estimated to be the largest market for adhesives, in terms of value, during the forecast period.

Asia Pacific is the largest and fastest-growing adhesives market. Asia uses plastic packaging extensively, with nations like China and India making significant contributions through their food and beverage industries. The use of adhesives in green building initiatives is becoming more and more popular due to increasing focus on sustainability and energy efficiency. Insulation materials, building exterior systems, and energy-efficient windows are all installed using adhesives. The promotion of eco-friendly and energy-saving practices by governments and organizations in Asia Pacific drives the demand for such adhesive solutions.

Note: For illustration, fastest-growing application, largest type, region is provided for adhesives market similar information is provided for all the ten chemicals in the report.

The key players profiled in the report include BASF SE (Germany), DOW Inc. (US), Nouryon (The Netherlands), LANXESS AG (Germany), Evonik Industries AG (Germany), Huntsman Corporation (US), Covestro AG (Germany), Clariant AG (Switzerland), Solvay S.A. (Belgium), and Arkema (France).

1 note

·

View note

Text

Global Nanocomposites Market Analysis, Trends, Development and Growth Opportunities by Forecast 2034

Nanocomposites Market Research, 2034

The Nanocomposites market is predicted to develop at a compound annual growth rate (CAGR) of 16.5% from 2024 to 2034, when it is projected to reach USD 18,493.53 Million in 2034, based on an average growth pattern. The market is estimated to reach a value of USD 5,638.47 Million in 2024.

A ductile alloy or metal matrix makes up metal matrix nanocomposites (MMNC). These materials combine the toughness and ductility of ceramics with the strength and modulus of metals. Therefore, MMNCs can be used to produce materials that need to have high strength in procedures involving shear or compression as well as high service temperature capabilities.

To learn more about this report, request a free sample copy

Nanocomposites Market Trends:

The development of transparent conductive films (TCF) using carbon nanotubes (CNT) is one of the well-known uses of these composites. Currently, indium tin oxide is utilized in the production of TCFs. The improved, inexpensive, and superior CNT-based transparent films will take the place of the conventional TCF thanks to recent technological advancements in CNT manufacturing. Arc discharge, chemical vapor deposition, and laser vaporization are three significant and improved commercial production techniques that are chosen over traditional synthesis techniques. These are less complicated and more straightforward ways to get premium CNT. Advanced techniques such as Combustion Chemical Vapor Deposition (CCVD) and Plasma Enhanced Chemical Vapor Deposition (PECVD) are frequently employed in the production of Single-Walled Carbon Nanotubes.

Nanocomposites market Segments

By Nanoparticles Type

Nanofiber

Carbon Nanotube

Graphene

Metal Oxide

Nanoclay

Others

By Matrix Material

Polymer

Metal

Ceramic

By Application

Automotive

Aerospace & Defense

Electronics & Semiconductor

Packaging

Energy

Medical & Healthcare

Others

Key Market Players

Arkema SA

BASF SE

Cabot Corporation

Elementis plc

Evonik Industries AG

Inframat Corporation

Nanocor Inc.

Showa Denko K.K.

3M Company

Zyvex Technologies

Other

Challenges and Opportunities in the Nanocomposites Market:

High Production Costs: The production of nanocomposites can be expensive, limiting their widespread adoption.

Regulatory Concerns: Ensuring the safe and responsible use of nanocomposites requires stringent regulations and standards.

Market Penetration: Expanding market penetration in emerging industries and regions presents opportunities for growth.

Applications of Nanocomposites Across Industries:

Automotive: Lightweight components, improved fuel efficiency, enhanced safety features

Aerospace: High-strength, heat-resistant materials for aircraft component

Electronics: Conductive materials for printed circuit boards, energy storage devices, and sensors

Construction: Durable, lightweight building materials with improved insulation properties

Healthcare: Medical devices, drug delivery systems, and tissue engineering

Nanocomposites Industry: Regional Analysis

North America Market Forecast

With over 38% of the global market share in 2023, North America is the market leader for nanocomposites. In terms of nanocomposites' invention, uptake, and research and development, the US and Canada are leaders in a number of areas, including aerospace, automotive, electronics, and healthcare. robust technological foundation, R&D expenditures, and the need for materials that are lightweight and highly effective.

Europe Market Statistics

Europe is a significant market for nanocomposites, driven by developments in industrial applications, strict environmental restrictions, and sustainability programs. Important contributors are the UK, France, and Germany. Pay attention to the development of the building and packaging industries, automobile lightweighting, and energy efficiency.

Frequently Asked Questions

What is the market size of Nanocomposites Market in 2024?

What is the growth rate for the Nanocomposites Market?

Which are the top companies operating within the market?

Which region dominates the Nanocomposites Market?

Nanocomposites Market Highlights:

Report Features

This is the most thorough study available for market intelligence. In order to maximize commercial value, the report structure has been maintained. Strategic decision making for both current and prospective market participants will be made possible by the crucial insights it offers into the dynamics of the industry. Here are the report's salient characteristics

Market structure: Overview, industry life cycle analysis, supply chain analysis

Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis

Market trend and forecast analysis

Market segment trend and forecast

Competitive landscape and dynamics: Market share, application portfolio, application launches, etc.

Attractive market segments and associated growth opportunities

Emerging trends

Strategic growth opportunities for the existing and new players

Key success factors

Future Outlook for the Nanocomposites Market:

Technology breakthroughs, rising demand for high-performance materials, and rising awareness of the advantages of nanocomposites are expected to propel the market's significant rise globally. Nanocomposites are anticipated to have a significant impact on a number of industries as production prices decline and regulatory frameworks develop.

Conclusion:

Materials science could undergo a revolution thanks to nanocomposites, a game-changing breakthrough. Nanocomposites present a promising future because of their remarkable qualities and ability to tackle urgent issues. Keeping up with the current advancements in the industry and investigating the immense possibilities of this novel substance are crucial as it undergoes continuous changes.

0 notes

Text

Medical Composites Market is expected to display a steady growth by 2028

According to a new report published by UnivDatos Markets Insights the Medical Composites Market is expected to grow at a CAGR of around 10% from 2022-2028. The analysis has been segmented into Material Type (Foamed Plastic, Paper & Paperboard, Plastic, Others); Product Type (Foam, Flexible, Rigid); Function (Cushioning, Blocking & Bracing, Void Fill, Insulation, Wrapping); End-User (Food & Beverage, Automotive, Industrial Goods, Household Appliances, Healthcare, Consumer Electronics); Region/Country.

The medical composites market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the medical composites market. The medical composites market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the medical composites market at the global and regional levels.

Market Overview

The demand for medical composites has been increasing rapidly all over the globe owing to the growth in the number of instruments used by people to measure their suffering from sudden health issues or keep regular track of their health. Also, the rise in expenditure on diagnostic instruments by consumers as well the healthcare sector in various countries across the globe. For instance, the average annual household expenditure on health in the United States amounted to almost 1100 US dollars in 2019, as per OECD Library.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted the healthcare industry and has transformed the way healthcare is delivered. The COVID-19 pandemic has a neutral effect on the medical composites market as there has been a continuous making of decline in the healthcare industries operations which directly or indirectly affected the market of medical composites increases in the usage of medical composites is increasing as diagnostic instruments to lower the weight of an instrument. In addition, the production of diagnostic instruments requires the use of medical composites, by which the growth of the market will be seen increasing during the forecasted period.

Based on fiber type, the market is fragmented into carbon fiber, glass fiber, and others. During the forecast period, the carbon fiber segment is likely to have significant growth in the global medical composites market. As carbon fiber medical composites offer enhanced load-bearing capability, which makes them suitable to be used in artificial limbs. In addition, load-carrying links are of utmost importance in joint mechanism and carbon fiber medical composites are used for this application, owing to their stiffness and biocompatibility. Furthermore, the factors justify its use in the market which will drive its growth during the forecasted period

Medical composites Market Geographical Segmentation Includes:

North America (U.S. Canada, and Rest of North America)

Europe (Germany, United Kingdom, Italy, France, Spain, and the Rest of Europe)

Asia-Pacific (China, India, Australia, Japan, and the Rest of Asia-Pacific)

Rest of the World

For a better understanding of the market dynamics of the medical composites market, a detailed analysis was conducted for different regions across the globe including North America (U.S, Canada, and the Rest of North America), Europe (Germany, France, Spain, United Kingdom, Italy, and Rest of Europe), Asia-Pacific (China, India, Australia, Japan, and Rest of APAC), Rest of World has been conducted. Geographically, the North America region dominated the medical composites market owing to the growing prevalence of extensive healthcare industries in the region.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=29637

The major players targeting the market include

CeramTec GmbH

The 3M Company

Toray Industries Inc.

Dentsply Sirona

Royal DSM N.V.

SGL Carbon SE

Kulzer GmbH

IDI Composites International

Zeus Industrial Products Inc.

Composiflex Inc.

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the medical composites market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the medical composites market?

• Which factors are influencing the medical composites market over the forecast period?

• What are the global challenges, threats, and risks in the medical composites market?

• Which factors are propelling and restraining the medical composites market?

• What are the demanding global regions of the medical composites market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Green Methanol Market: SWOT Analysis [2023-2028]

Glycerol Market: SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

EV Composites Market worth $5.1 billion by 2029

The report "EV Composites Market by Fiber Type (Glass Fiber, Carbon Fiber), Resin Type (Thermoplastics, Thermoset), Type (Ultra-Premium, Premium and Non-Premium), Manufacturing Process, Application, and Region - Global Forecast to 2029", is estimated at USD 2.3 billion in 2024 and is projected to reach USD 5.1 billion by 2029, at a CAGR of 17.1% from 2024 to 2029.

Download pdf -https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=153929333

The growth of electric vehicle (EV) composites is driven by several key factors, including the ability of lightweight materials like carbon fibre reinforced polymers and glass fibre reinforced plastics to reduce the weight of EV components by up to 50% compared to traditional materials, improving performance, energy efficiency, and driving range, providing moderate strength suitable for various applications like body panels, hoods, doors, and interior components, offering high strength-to-weight ratios that can absorb and dissipate energy during collisions to enhance passenger safety and provide corrosion resistance and fire protection for critical components. Specific thermal properties used for battery enclosures and insulation to maintain optimal operating temperatures, improving efficiency and lifespan, moldability enabling more aerodynamic shapes and complex designs that reduce air resistance and improve efficiency.

Carbon fiber type segment is expected to grow with highest CAGR in EV composites market during the forecasted period.

The EV composites market is segmented based on the fiber types into carbon fiber, glass fiber and other fiber. Carbon fibers are twice as strong and 30% lighter compared to glass fibers and has been used in electric vehicles for the major purpose of weight reduction. carbon fiber composites can be moulded into complex shapes, simplifying the assembly process and reducing part counts, and the lightweight nature of carbon fiber composites reduces the carbon footprint and emissions of EVs, making them a more environmentally friendly option compared to traditional gasoline-powered vehicles.

In Feb 2023, Toray Industries Inc. developed a rapid integration molding technique for CRFP (Carbon Reinforced Fiber Plastic) mobility components. This innovation will aid in molding CFRP mobility components in a better and faster way than traditional molding setups. The versatility and superior characteristics of carbon fiber composites make it an attractive option for EV industry, driving its adoption and growth in the market.

Thermoplastic resin type segment is expected to grow with highest CAGR in EV composites market during the forecasted period.

The EV composites market is segmented based on the resin types into thermoset and thermoplastic. In recent years, the use of thermoplastic resins as a matrix material in fiber-reinforced composites has surged. These resins, combined with continuous fibers, create structural composite products with several key advantages. Unlike thermoset resins, thermoplastic composites can be reshaped and reformed, making them easily recyclable. This recyclability has contributed to their growing popularity over the past decade. Additionally, thermoplastic resins allow for faster molding cycles since no chemical reaction is required for curing, and they offer superior impact resistance compared to thermosets.

When used with long fibers, thermoplastic resins provide high stiffness and lightweight properties, which are particularly beneficial for EV applications. In June 2016, LANXESS AG from Germany developed multiaxial Tepex, a product designed to enhance the mechanical performance of automotive components. This innovation has helped the company address the increasing demand for lightweight electric automotive parts.

Ultra-premium segment type is expected to have third largest share during forecasting period in terms of value

In this segment, The electric vehicles which costs more than 100,000 USD are considered to be ultra-premium. In ultra-premium segment, composites offer not only performance benefits but also exclusivity, allowing manufacturers to create bespoke vehicles with unique designs and advanced features, attracting discerning customers seeking unparalleled sophistication. The use of composites in ultra-premium electric vehicles is set to grow as manufacturers seek to enhance performance, range, and sustainability. Innovations in materials and manufacturing processes will likely continue to drive this trend, making composites an integral part of the future of high-end electric mobility.

Battery enclosure segment is expected to have third largest share during forecasting period, both in terms of value and volume during the forecast period

The demand for EV composites in battery enclosure applications within the electric vehicle (EV) composites market varies across premium, ultra-premium, and non-premium segments, driven by distinct factors tailored to each segment's requirements and priorities. In the premium segment, renowned for luxury and cutting-edge technology, automakers prioritize advanced materials like composites to enhance the performance, safety, and longevity of EV battery systems. Similarly, in the ultra-premium segment, the demand for automotive composites in battery enclosures is driven by the desire to offer state-of-the-art solutions that uphold the brand's reputation for excellence and sophistication. Composites offer advantages such as lightweight construction, corrosion resistance, and thermal insulation, contributing to the overall reliability and durability of electric vehicle battery systems. This factors are expected to boost EV composites in battery enclosure application.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=153929333

Asia Pacific region is expected to registered highest CAGR both in terms of value and volume during forecasted period

The EV composites market has been studied in North America, Europe, Asia Pacific, Latin America and Middle East and Africa.

The Asia Pacific EV composites market is experiencing explosive growth, fueled by a potent mix of factors. The Asia Pacific electric vehicle (EV) market is experiencing rapid growth, driven by supportive government policies and incentives, environmental awareness and sustainability, technological advancements, affordability and cost savings, increasing urbanization, and the development of charging infrastructure. Governments are providing significant subsidies and tax rebates for EVs, such as China's subsidies based on battery size, and the Indian government's Production-Linked Incentive Scheme for ACC Battery Storage Manufacturing. The region's growing concerns about air pollution and the need for cleaner mobility solutions are also driving demand for EVs. Technological advancements and sustainability goals aligns perfectly with the advantages of EV composites, ensuring continued demand in the years to come.

Key players

Prominent companies include Toray Industries, Inc. (Japan), Teijin Limited (Japan), Syensqo (Belgium), Piran Advanced Composites (UK), HRC (Hengrui Corporation) (China), Envalior (Germany), Exel Composites (Finland), Kautex Textron GmbH & Co. KG (Germany), SGL Carbon (Germany), POLYTEC HOLDING AG (Austria), Plastic Omnium (France), Röchling SE & Co. KG (Germany), Mar-Bal, Inc. (US), ElringKlinger AG (Germany), and Faurecia (France), The Gund Company (US), IDI Composites International (US), TRB Lightweight Structures (US), CIE Automotive India (India), ZhongAo Carbon (China), Atlas Fibre (US), Jiangsu Kangde Xin Composite Material (China), Euro Advanced Carbon Fiber Composites GmbH (US), Owens Corning (US) and among others.

#EVComposites#ElectricVehicles#SustainableMaterials#LightweightTechnology#AdvancedMaterials#EVMarket#AutomotiveInnovation#GreenTechnology#EVIndustry#CarbonFiber#CompositesTechnology#FutureOfMobility#SustainableMobility#AutomotiveComposites#EVManufacturing

0 notes

Text

Industrial Insulation Market Anticipated To Accelerate The Growth By 2030

Industrial Insulation Market Overview

The global industrial insulation market size is expected to reach USD 12.10 billion by 2030, expanding at a compound annual growth rate (CAGR) of 5.0%, according to a new report by Grand View Research, Inc. The increasing demand for adequate thermal insulation for industrial equipment for energy-efficient operations, and economical design, is expected to drive the market during the forecast period.

The raw materials used for the production of various industrial insulation products are available in abundance, which benefits the industry. However, some of the feedstock used for insulation production is derived from petrochemicals, so fluctuations in the price of crude oil result in changes in the procurement cost of the feedstock, limiting the bargaining power of insulation manufacturers.

Gather more insights about the market drivers, restrains and growth of the Industrial Insulation Market

The industry is under high scrutiny from government environmental agencies, including EPA, REACH, and NGT. These agencies have imposed stringent regulations on the production, storage, and transportation of insulation materials. Government support to develop sustainable manufacturing practices is expected to hamper the market growth.

Major players, such as Rockwool Technical Insulation, Paroc Group, and Knauf Gips KG, hold most market share due to their vast product portfolio and wider geographical reach. These companies develop a powerful business model to adapt to the market volatility and any technological & geographical change.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The global green steel market size was estimated at USD 718.30 billion in 2024 and is projected to grow at a CAGR of 6.0% from 2025 to 2030.

The global flooring adhesive market size was estimated at USD 5.64 billion in 2024 and is projected to grow at a CAGR of 9.3% from 2025 to 2030.

Industrial Insulation Market Segmentation

Grand View Research has segmented the global industrial insulation market based on material, product, application and region:

Industrial Insulation Material Outlook (Volume, Kilotons; Revenue, USD Billion; 2018 - 2030)

Stone Wool

Elastomeric Foam

Micro Silica

Glass Wool

Composites

CMS Fibers

Calcium Silicate

Cellular Glass

Foamed Plastic

Perlite

Aerogel

Cellulose

Others

Industrial Insulation Product Outlook (Volume, Kilotons; Revenue, USD Billion; 2018 - 2030)

Pipe

Board

Blanket

Others

Industrial Insulation Application Type Outlook (Volume, Kilotons; Revenue, USD Billion; 2018 - 2030)

Power Generation

Petrochemical & Refineries

EIP Industries

LNG/LPG

Others

Industrial Insulation Regional Outlook (Volume, Kilotons; Revenue; USD Billion; 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Poland

Spain

Italy

Benelux

Nordic

CIS

Asia Pacific

China

India

Japan

South Korea

Indonesia

Malaysia

Thailand

Vietnam

Central & South America

Brazil

Argentina

Colombia

Middle East & Africa

GCC

Turkey

Key Companies profiled:

Rockwool Insulation A/S

Poroc Group Oy

Knauf Insulation

TechnoNICOL Corporation

Anco Products, Inc.

Aspen Aerogels, Inc.

Cabot Corporation

Morgan Advanced Materials plc

Unifrax LLC

RATH Group

IBIDEN Co., Ltd.

Armacell International

Order a free sample PDF of the Industrial Insulation Market Intelligence Study, published by Grand View Research.

0 notes

Text

Glass Fiber Prices Trend | Pricing | Database | Index | News | Chart

Glass Fiber Prices also known as fiberglass, is a versatile material used in a wide range of industries, including construction, automotive, aerospace, and electronics. It is made by combining fine strands of glass into a woven fabric, providing strength, durability, and flexibility. Glass fiber prices are influenced by various factors, including supply and demand dynamics, raw material costs, and market trends.

One of the key drivers of glass fiber prices is the availability of raw materials. The main ingredient in glass fiber production is silica sand, which is abundant in nature. However, fluctuations in the cost of silica sand and other raw materials, such as chemicals and additives, can impact the overall production cost of glass fiber. This, in turn, affects the final price of the product.

Another factor that influences glass fiber prices is the demand for the material. As mentioned earlier, glass fiber finds applications in multiple industries. The construction sector, for instance, utilizes glass fiber in the production of insulation materials, pipes, and panels. The automotive industry uses it to manufacture lightweight and strong parts. Increased demand from these industries can result in higher prices due to supply constraints.

Get Real Time Prices for Glass Fiber: https://www.chemanalyst.com/Pricing-data/glass-fiber-1558

Market trends and technological advancements also play a significant role in determining glass fiber prices. Innovations in manufacturing processes, such as the development of advanced fibers and composites, can impact the cost of production. Additionally, changes in consumer preferences, environmental regulations, and government policies can influence the demand for glass fiber and, consequently, its price.

It is important to note that the global glass fiber market is highly competitive, with several key players operating in the industry. These companies compete based on factors such as product quality, price, and customer service. The presence of multiple manufacturers and suppliers helps maintain a healthy level of competition, which can moderate price fluctuations.

To ensure SEO friendliness, it is essential to include relevant keywords related to glass fiber prices throughout the content. Keywords such as "glass fiber prices," "fiberglass cost," and "price trends" can help improve the visibility of the content in search engine results. However, it is important to use these keywords naturally and avoid overstuffing the content, as it may negatively impact readability and user experience.

In conclusion, glass fiber prices are influenced by various factors, including raw material costs, supply and demand dynamics, market trends, and technological advancements. The availability and cost of raw materials, as well as the demand from industries like construction and automotive, play a significant role in determining the price of glass fiber. Additionally, market competition and consumer preferences contribute to price fluctuations. By understanding these factors, stakeholders in the glass fiber industry can make informed decisions and adapt to market dynamics.

Get Real Time Prices for Glass Fiber: https://www.chemanalyst.com/Pricing-data/glass-fiber-1558

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Industrial Insulation Market Emerging Trends And Forecast, 2030

The global industrial insulation market size was valued at USD 8.21 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.0% from 2023 to 2030.

Increasing product demand for boosting process efficiency, condensation control, noise reduction, freeze protection, and for reducing environmental pollution is expected to drive market growth over the forecast period. In addition, the rising awareness regarding the benefits of insulation in the industrial application and its related costs is expected to drive the market for industrial insulation in North America.

The market witnessed a severe downfall in the investments in the industrial sector owing to the pandemic, thereby impacting the market. In addition, dramatic fall in crude oil prices led to a drop in fiscal resources for oil-producing countries, which affected the product demand from oil & gas sector.

The market in the U.S. is expected to witness increased demand for insulation for industrial applications, such as, machinery, boilers, pipes, and storage tanks, and in linings of heat exchangers, cooling towers, and ventilation & air conditioning systems, among others. The demand outlook for the U.S. is favorable, with private investments in the industrial sector reaching the highest levels in 2018. The industrial sector is predicted to witness significant expansion owing to the rising GDP.

Gather more insights about the market drivers, restrains and growth of the Industrial Insulation Market

Industrial Insulation Market Highlights

• Stone wool accounted for the largest market share of 21.6% in 2022, owing to its high-temperature tolerance, flame resistance, and its ability to offer thermal and acoustic insulation

• Pipe insulation led the market and accounted for about 47.76% share of the revenue in 2022. The market is projected to witness notable demand, expanding at a CAGR 5.5% from 2023 to 2030, due to its superior performance and ability to stabilize the process temperatures.

• Power generation industry is expected to witness a heightened demand for these products, owing to its ability to minimize power losses. Growing concerns regarding the energy management among the power generation industry across the globe is expected to drive the market growth over the forecast period.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global air deflector market size was estimated at USD 11.51 billion in 2023 and is projected to grow at a CAGR of 3.4% from 2024 to 2030.

• The global district heating market size was valued at USD 190.5 billion in 2023 and is anticipated to grow at a CAGR of 5.2% from 2024 to 2030.

Industrial Insulation Market Segmentation

Grand View Research has segmented the global industrial insulation market based on material, product, application and region:

Industrial Insulation Material Outlook (Volume, Kilotons; Revenue, USD Billion; 2018 - 2030)

• Stone Wool

• Elastomeric Foam

• Micro Silica

• Glass Wool

• Composites

• CMS Fibers

• Calcium Silicate

• Cellular Glass

• Foamed Plastic

• Perlite

• Aerogel

• Cellulose

• Others

Industrial Insulation Product Outlook (Volume, Kilotons; Revenue, USD Billion; 2018 - 2030)

• Pipe

• Board

• Blanket

• Others

Industrial Insulation Application Type Outlook (Volume, Kilotons; Revenue, USD Billion; 2018 - 2030)

• Power Generation

• Petrochemical & Refineries

• EIP Industries

• LNG/LPG

• Others

Industrial Insulation Regional Outlook (Volume, Kilotons; Revenue; USD Billion; 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o U.K.

o France

o Poland

o Spain

o Italy

o Benelux

o Nordic

o CIS

• Asia Pacific

o China

o India

o Japan

o South Korea

o Indonesia

o Malaysia

o Thailand

o Vietnam

• Central & South America

o Brazil

o Argentina

o Colombia

• Middle East & Africa

o GCC

o Turkey

Order a free sample PDF of the Industrial Insulation Market Intelligence Study, published by Grand View Research.

#Industrial Insulation Market#Industrial Insulation Market size#Industrial Insulation Market share#Industrial Insulation Market analysis#Industrial Insulation Industry

0 notes

Text

Europe Aluminium Magnesium Spinel Market Industry Trends, Competition Strategies, Revenue Analysis and Forecast to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Europe Aluminium Magnesium Spinel Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the Europe Aluminium Magnesium Spinel Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Europe Aluminium Magnesium Spinel Market?

Europe aluminium magnesium spinel market was valued at US$ 166.4 Million in 2023 and is expected to register a CAGR of 4.1% over the forecast period and reach US$ 238.3 Mn in 2032.

What are Europe Aluminium Magnesium Spinel?

Aluminium Magnesium Spinel in Europe is a high-performance ceramic known for its outstanding thermal and mechanical properties. Made from aluminum oxide (Al₂O₃) and magnesium oxide (MgO), it offers excellent resistance to thermal shock, corrosion, and mechanical wear. This material is widely used in industrial applications including refractory linings in furnaces and reactors, as well as in aerospace components and advanced ceramic products. Its exceptional combination of high melting point, hardness, and chemical stability makes it ideal for demanding environments where durability and reliability are essential.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2351

What are the growth prospects and trends in the Europe Aluminium Magnesium Spinel industry?

The Europe aluminium magnesium spinel market growth is driven by various factors and trends. The Aluminium Magnesium Spinel market in Europe is experiencing growth, fueled by its widespread adoption in multiple industries due to its strong thermal and mechanical properties. This high-performance ceramic, comprised of aluminum oxide (Al₂O₃) and magnesium oxide (MgO), is prized for its resilience against thermal shock, corrosion, and mechanical wear. It is utilized extensively in industrial refractories, aerospace components, and advanced ceramics, leveraging its high melting point, hardness, and chemical stability. Market expansion is driven by rising demand for durable materials in industrial applications and continuous advancements in technology to enhance its effectiveness across various uses. Hence, all these factors contribute to Europe aluminium magnesium spinel market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Fused Spinel

Reaction Bonded Spinel

Sintered Spinel

Others

By Composition

Al2O3 (76/78%)

MgO (24/22%)

By Form

Powder

Granules

Bricks

Others

By Production Method

Sol-Gel Process

Conventional Solid-State-Reaction

Spray Drying (Atomization)

Chemical Vapor Deposition (CVD)

Electrical Fusion Process

Wet Synthesis Techniques

Mechano-Chemical Alloying

Molten Salt Synthesis

Others

By Purity

99%

Above 99%

By Packaging

Steel Drum

Container

By Application

Refractory Materials

Metal Casting

Electrical Insulators

Iron And Steel Smelting

Glass Furnace

Calcined Lime Furnace Lining

Cement Rotary Kiln

Steel Ladles

Alumina-Magnesia Brick

Sliding Nozzle

Ceramics Manufacturing

HumiditySensors

Others

By End-Use Industry

Automotive

Electronics

Refractories

Cement

Iron and Steel

Glass

Water Treatment

Others

Europe

Germany

Austria

Switzerland

Italy

Spain

Portugal

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Ukraine

Moldova

Balkan Countries

Rest of Europe

Who are the key players operating in the industry?

The report covers the major market players including:

Almatis

Refratechnik Group

Keralit LLC

Surmet Corporation

CeraNova Corporation

Washington Mills

Baikowski

MFE Magnesium

View Full Report: https://www.reportsandinsights.com/report/Europe Aluminium Magnesium Spinel-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Europe Aluminium Magnesium Spinel Market share#Europe Aluminium Magnesium Spinel Market size#Europe Aluminium Magnesium Spinel Market trends

0 notes

Text

Owens Corning: Global Locations and Facilities

Owens Corning, a leader in building materials and composite solutions, operates a vast network of facilities worldwide. This article provides an extensive overview of Owens Corning's global locations, highlighting key manufacturing sites, regional offices, and research centers that drive the company's innovation and market reach.

North America

United States

Owens Corning's presence in the United States is extensive, with numerous facilities dedicated to manufacturing, research, and corporate operations.

Key Locations:

Toledo, Ohio: Headquarters and central hub for Owens Corning's corporate operations, housing executive management and key administrative functions.

Granville, Ohio: Science and Technology Center, a cornerstone for research and development activities focused on advancing insulation and composite materials.

Kansas City, Missouri: Major manufacturing site for roofing materials, serving both residential and commercial markets.

Fort Smith, Arkansas: Production facility specializing in insulation products, pivotal for energy efficiency solutions.

Canada

Owens Corning maintains a significant footprint in Canada, with facilities supporting the production of insulation and roofing materials.

Key Locations:

Toronto, Ontario: Regional office and distribution center, coordinating operations across Canada.

Candiac, Quebec: Manufacturing plant for insulation products, catering to the Canadian market's demand for energy-efficient building materials.

Europe

France

Owens Corning operates several key facilities in France, central to its European operations.

Key Locations:

Chambery: Manufacturing site for composite materials, supplying advanced solutions for various industrial applications.

Laval: Insulation production facility, crucial for meeting the energy efficiency needs of the European market.

Germany

Germany hosts important Owens Corning facilities that contribute to its European market leadership.

Key Locations:

Apeldoorn: Production plant for insulation materials, supporting the regional demand for sustainable building solutions.

Birkenfeld: Manufacturing site specializing in composite materials, serving automotive and industrial sectors.

Asia-Pacific

China

Owens Corning has established a robust presence in China, with facilities that bolster its market penetration in the Asia-Pacific region.

Key Locations:

Shanghai: Regional headquarters and innovation center, focusing on strategic growth and technological advancements.

Jiangsu: Major manufacturing site for composite materials, supporting the construction and automotive industries.

India

India is a growing market for Owens Corning, with facilities aimed at expanding its footprint in the region.

Key Locations:

Taloja, Maharashtra: Production plant for insulation and roofing materials, addressing the needs of the Indian construction market.

Latin America

Brazil

Owens Corning's operations in Brazil are essential for serving the Latin American market.

Key Locations:

Rio Claro: Manufacturing facility for insulation products, catering to regional demand for energy-efficient building solutions.

São Paulo: Regional office, coordinating operations and strategic initiatives across Latin America.

Middle East and Africa

Saudi Arabia

In the Middle East, Owens Corning focuses on addressing the region's unique building and industrial requirements.

Key Locations:

Dammam: Manufacturing site for composite materials, crucial for infrastructure projects and industrial applications in the region.

South Africa

Owens Corning's presence in Africa is marked by key facilities supporting regional growth.

Key Locations:

Johannesburg: Regional office and distribution center, managing operations and logistics across the African continent.

Research and Innovation Centers

Owens Corning places a strong emphasis on research and innovation, with dedicated centers worldwide.

Granville, Ohio, USA

The Science and Technology Center in Granville is a pivotal site for Owens Corning's research and development efforts. It focuses on advancing materials science and developing innovative solutions for insulation, roofing, and composites.

Shanghai, China

The Innovation Center in Shanghai is instrumental in driving technological advancements and product development tailored to the Asia-Pacific market. It fosters collaboration with local industries and academic institutions.

Conclusion

Owens Corning's extensive network of global locations underscores its commitment to innovation, sustainability, and market leadership. By strategically positioning its facilities worldwide, the company ensures efficient production, distribution, and customer service, meeting the diverse needs of its global clientele.

0 notes

Text

Commercial Space Ventures Fuel Demand in Aerospace Tapes Market

The surge in commercial space activities, including satellite launches and mega-constellations are the factors driving market in the forecast period 2025-2029.

According to TechSci Research report, “Aerospace Tapes Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2029”, The Global Aerospace Tapes Market stood at USD 5.48 Billion in 2023 and is anticipated to grow with a CAGR of 7.44% in the forecast period, 2025-2029.

The Global Aerospace Tapes Market is experiencing robust growth, driven by the dynamic landscape of the aerospace industry. The increasing demand for air travel, coupled with the expansion of commercial and military aviation fleets, has fueled the need for advanced materials and technologies, including aerospace tapes. These tapes are instrumental in providing critical functionalities such as bonding, sealing, and protection of surfaces in diverse aerospace applications.

A significant factor propelling the market is the relentless pursuit of lightweight solutions within the aerospace sector. As the industry strives to enhance fuel efficiency and overall performance, aerospace tapes play a pivotal role in achieving these objectives. Manufacturers are continually exploring innovative materials and adhesive technologies to develop tapes that are not only lightweight but also offer exceptional strength and resilience under the demanding conditions experienced during flight.

Material advancements are a key highlight of the aerospace tapes market. The transition towards high-performance materials, including advanced polymers and composites, has been notable. These materials contribute to the tapes' ability to withstand extreme temperatures, resist corrosion, and ensure longevity in the aerospace environment. The adaptability of aerospace tapes to diverse surfaces and their compatibility with other aerospace materials make them indispensable components in the manufacturing and maintenance processes of aircraft and spacecraft.

The application areas of aerospace tapes are diverse and critical. They are extensively used in structural bonding, interior installations, electrical insulation, and protection against environmental elements. The aerospace industry's commitment to stringent regulatory standards further accentuates the importance of high-quality tapes to ensure the safety and reliability of aerospace components.

In conclusion, the Global Aerospace Tapes Market is characterized by a confluence of factors, including the industry's drive for lightweight solutions, continuous material advancements, and the essential role these tapes play in critical aerospace applications. As the aerospace sector continues to evolve, the market for aerospace tapes is expected to witness sustained growth, with ongoing innovations shaping the future of this integral segment within the aerospace industry.

Browse over market data Figures spread through 180 Pages and an in-depth TOC on " Global Aerospace Tapes Market.” https://www.techsciresearch.com/report/aerospace-tapes-market/22649.html

North America holds a prominent position in the Global Aerospace Tapes Market, with the United States at the forefront. The region boasts a robust aerospace industry, home to major manufacturers and suppliers. North America's dominance is driven by a strong focus on research and development, technological innovation, and a high rate of aircraft production. The aerospace tapes market in North America benefits from a well-established infrastructure and a constant drive for efficiency and safety in aviation.

Europe plays a significant role in the aerospace industry, with countries like the United Kingdom, Germany, and France leading the way. The European aerospace sector emphasizes innovation and sustainability, influencing trends in aerospace tapes. The region is characterized by stringent environmental standards and a commitment to adopting advanced materials. Europe's aerospace tapes market reflects these priorities, with a focus on efficiency, safety, and reducing the industry's environmental footprint.

The Asia-Pacific region, particularly China and India, has become a key player in the aerospace industry. The growing demand for air travel, rising disposable incomes, and the establishment of new airlines contribute to the region's influence on the aerospace tapes market. Asia-Pacific experiences trends such as the adoption of lightweight materials, technology transfer agreements, and collaborations with global aerospace companies. The region's rapid growth in aviation infrastructure and manufacturing capabilities positions it as a vital contributor to the global aerospace tapes market.

The Middle East, notably the Gulf countries, has been making significant investments in aerospace and aviation infrastructure. This region is home to major airlines and hosts important events like airshows. The aerospace tapes market in the Middle East and Africa experiences growth driven by expanding aviation fleets, construction of new airports, and the need for tapes designed to withstand the unique challenges posed by hot and arid climates.

Major companies operating in Global Aerospace Tapes Market are:

3M Company

Advance Tapes International

Avery Dennison Corporation

Berry Global Group, Inc.

Compagnie De Saint-Gobain

DeWAL Industries, Inc.

Intertape Polymer Group

Nitto Denko Corporation

Download Free Sample Report https://www.techsciresearch.com/sample-report.aspx?cid=22649

Customers can also request 10% free customization in this report.

“The Global Aerospace Tapes Market, driven by a persistent demand for lightweight, high-performance materials in aviation. The emphasis on technological advancements, especially in adhesive formulations, aligns with the industry's pursuit of enhanced safety and efficiency. Regional variations in market dynamics underscore the importance of adapting aerospace tapes to diverse environmental conditions and regulatory standards worldwide,” said Mr. Karan Chichi, Research Director with TechSci Research, a research-based management consulting firm.

“Aerospace Tapes Market – Global Industry Size, Share, Trends Opportunity, and Forecast, Segmented By Category (Specialty, Masking), By Resin Type (Acrylic, Rubber, Silicone, Others), By Backing Material (Paper Tissue, Film, Foam, Others), By Region, Competition, 2019-2029”, has evaluated the future growth potential of Global Aerospace Tapes Market and provides statistics & information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides, the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in Global Aerospace Tapes Market.

Browse Related Research

Aircraft Empennage Market https://www.techsciresearch.com/report/aircraft-empennage-market/12912.html Military Truck Market https://www.techsciresearch.com/report/military-truck-market/12880.html Global Aircraft Evacuation Slide Market https://www.techsciresearch.com/report/aircraft-evacuation-slide-market/8020.html

Contact

Techsci Research LLC

420 Lexington Avenue, Suite 300,

New York, United States- 10170

M: +13322586602

Email: [email protected]

Website: www.techsciresearch.com

#Aerospace Tapes Market#Aerospace Tapes Market Size#Aerospace Tapes Market Share#Aerospace Tapes Market Trends#Aerospace Tapes Market Growth

0 notes

Text

Specialty Chemicals Market is Estimated to Hit $364.8 billion by 2028

The report "Specialty Chemicals Market by Type (Plasticizers, Water-Based, Coagulants and Flocculants, Scale Inhibitors), Application (Paper and Packaging, Automotive, Consumer Goods, Construction), and Region– Global Forecast to 2028", size was USD 272.6 billion in 2022 and is projected to reach USD 364.8 billion by 2028, at a CAGR of 5.0%, between 2023 and 2028.

Specialty chemicals are used in various industries including construction, packaging, consumer goods, automotive, industrial, medical and others. One of the biggest consumers of specialty chemicals is the automotive sector. These chemicals are employed in the manufacture of a few automobile parts, including tires, coatings, and adhesives. New specialty chemicals that can enhance the performance of these components have been developed in response to the rising need for lightweight and fuel-efficient automobiles. To make automobiles lighter and more fuel-efficient, for instance, specialty chemicals like high-performance polymers and composites are used.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=165

Water-based adhesive technology accounted for the largest market share, in terms of volume, in 2022.

Water-based technology is expected to dominate the adhesives type of specialty chemicals, in terms of volume, during the forecast period. Factors such as environmental regulations, health and safety considerations, performance and versatility, and industrial requirements and preferences drive the demand for water-based adhesive technology across the globe. Stringent environmental regulations and increasing consumer awareness have prompted the industry to adopt more environmentally friendly adhesive technologies, such as water-based adhesives.

Medical is estimated to be the fastest-growing application of adhesives, in terms of value, during the forecast period.

With improvements in surgical methods, medical equipment, and wearable technologies, the medical sector is always developing. To ensure appropriate assembly, bonding, and performance, many of these advancements need trustworthy adhesives. For example, in minimally invasive surgeries, adhesives are used to secure medical devices and seal incisions. The development in medical sector is expected to drive the market for adhesives globally.

Asia Pacific is estimated to be the largest market for adhesives, in terms of value, during the forecast period.

Asia Pacific is the largest and fastest-growing adhesives market. Asia uses plastic packaging extensively, with nations like China and India making significant contributions through their food and beverage industries. The use of adhesives in green building initiatives is becoming more and more popular due to increasing focus on sustainability and energy efficiency. Insulation materials, building exterior systems, and energy-efficient windows are all installed using adhesives. The promotion of eco-friendly and energy-saving practices by governments and organizations in Asia Pacific drives the demand for such adhesive solutions.

Note: For illustration, fastest-growing application, largest type, region is provided for adhesives market similar information is provided for all the ten chemicals in the report.

Key Players:

The key players profiled in the report include BASF SE (Germany), DOW Inc. (US), Nouryon (The Netherlands), LANXESS AG (Germany), Evonik Industries AG (Germany), Huntsman Corporation (US), Covestro AG (Germany), Clariant AG (Switzerland), Solvay S.A. (Belgium), and Arkema (France).

Content Source: https://www.marketsandmarkets.com/PressReleases/specialty-chemicals-market.asp

#Specialty chemicals market#specialty chemicals industry#specialty chemicals market size#specialty chemicals#chemical industry#chemicals

1 note

·

View note

Text

Resin Market: Long-Term Value & Growth Seen Ahead

Market Research Forecast added research publication document on Worldwide Resin Market breaking major business segments and highlighting wider level geographies to get deep dive analysis on market data. The study is a perfect balance bridging both qualitative and quantitative information of Worldwide Resin Market. The study provides valuable market size data for historical (Volume** & Value) from 2019 to 2023 which is estimated and forecasted till 2032*. Some are the key & emerging players that are part of coverage and have being profiled are DuPont (U.S.),Arkema (France),BASF SE (Germany),INEOS Holdings Ltd. (U.K.),Hexion (U.S.),Invista (U.S.),LyondellBasell (Netherlands),Mitsubishi Engineering-Plastics Corporation (Japan),Mitsui Chemicals (Japan),Nova Chemicals (Canada),Qenos (Australia),Radici Group (Italy),SABIC (Saudi Arabia),Repsol (Spain),Sumitomo Chemical Co. Ltd. (Japan),Teijin Limited (Japan),Tosoh Corporation (Japan),Toray Group (Japan). Get free access to Sample Report in PDF Version along with Graphs and Figures @ https://marketresearchforecast.com/report/reports/resin-market-1341/sample-report

The Resin Marketsize was valued at USD 533.55 USD Billion in 2023 and is projected to reach USD 750.76 USD Billion by 2032, exhibiting a CAGR of 5.0 % during the forecast period.resins can be formulated from either organic or synthetic compounds that convert from the liquid state to a solid, homogeneous structure. Resin is a very tough material which can be used even in such harshest conditions as impact of the water and other environmental factors. Annealing makes wire unbreakable when it is restored to its original properties by cooling. This feature enhances its multi-purpose characteristics for use indoors in settings like bathrooms, kitchens, and living rooms. They might be the products of natural materials or be manufactured using other chemicals. Resins are remarkably resistant to all types of chemicals and therefore a perfect choice for application in a large pool of industrial and commercial utilities. The resins are heat-resistant, therefore, they will not melt nor get stuck to the hot wheels of cars when a garage is being entered. Tackifiers samples are unlike any other clear resins, the fact if they are of a good quality and professional makes them ideal for decorative and aesthetic use.

Keep yourself up-to-date with latest market trends and changing dynamics due to COVID Impact and Economic Slowdown globally. Maintain a competitive edge by sizing up with available business opportunity in Resin Market various segments and emerging territory. Influencing Market Trend

Rising demand for flexible packaging in the food & beverage industry

Increased adoption of lightweight materials in transportation sectors

Growing use of resins in construction for insulation and reinforcement

Challenges:

Volatile Raw Material Costs: Price fluctuations of crude oil and natural gas impact resin production costs.

Competition from Alternative Materials: Growing adoption of metals, ceramics, and composites in various applications.

Environmental Concerns: Conce

Have Any Questions Regarding Global Resin Market Report, Ask Our Experts@ https://marketresearchforecast.com/report/reports/resin-market-1341/enquiry-before-buy Analysis by Type (Polyethylene, Polypropylene, Polyethylene Terephthalate, Polyvinyl Chloride, Acrylonitrile Butadiene Styrene, Polyamide, Polycarbonate, Polyurethane, Polystyrene, and Others), by End-use Industry (Packaging, Automotive & Transportation, Building & Construction, Consumer Goods/Lifestyle, Electrical & Electronics, Agriculture, and Others), by North America (U.S., Canada), by Europe (Germany, U.K., France, Italy, Spain, Rest of Europe), by Asia Pacific (China, Japan, India, South Korea, Rest of Asia Pacific), by Latin America (Brazil, Argentina, Mexico, Rest of Latin America), by Middle East & Africa (Saudi Arabia, South Africa, Rest of Middle East & Africa) Forecast 2024-2032

Competitive landscape highlighting important parameters that players are gaining along with the Market Development/evolution

• % Market Share, Segment Revenue, Swot Analysis for each profiled company [DuPont (U.S.),Arkema (France),BASF SE (Germany),INEOS Holdings Ltd. (U.K.),Hexion (U.S.),Invista (U.S.),LyondellBasell (Netherlands),Mitsubishi Engineering-Plastics Corporation (Japan),Mitsui Chemicals (Japan),Nova Chemicals (Canada),Qenos (Australia),Radici Group (Italy),SABIC (Saudi Arabia),Repsol (Spain),Sumitomo Chemical Co. Ltd. (Japan),Teijin Limited (Japan),Tosoh Corporation (Japan),Toray Group (Japan)]

• Business overview and Product/Service classification

• Product/Service Matrix [Players by Product/Service comparative analysis]

• Recent Developments (Technology advancement, Product Launch or Expansion plan, Manufacturing and R&D etc)

• Consumption, Capacity & Production by Players The regional analysis of Global Resin Market is considered for the key regions such as Asia Pacific, North America, Europe, Latin America and Rest of the World. North America is the leading region across the world. Whereas, owing to rising no. of research activities in countries such as China, India, and Japan, Asia Pacific region is also expected to exhibit higher growth rate the forecast period 2023-2028. Table of Content Chapter One: Industry Overview Chapter Two: Major Segmentation (Classification, Application and etc.) Analysis Chapter Three: Production Market Analysis Chapter Four: Sales Market Analysis Chapter Five: Consumption Market Analysis Chapter Six: Production, Sales and Consumption Market Comparison Analysis Chapter Seven: Major Manufacturers Production and Sales Market Comparison Analysis Chapter Eight: Competition Analysis by Players Chapter Nine: Marketing Channel Analysis Chapter Ten: New Project Investment Feasibility Analysis Chapter Eleven: Manufacturing Cost Analysis Chapter Twelve: Industrial Chain, Sourcing Strategy and Downstream Buyers Read Executive Summary and Detailed Index of full Research Study @ https://marketresearchforecast.com/reports/reports/resin-market-1341 Highlights of the Report • The future prospects of the global Resin Market during the forecast period 2023-2028 are given in the report. • The major developmental strategies integrated by the leading players to sustain a competitive market position in the market are included in the report. • The emerging technologies that are driving the growth of the market are highlighted in the report. • The market value of the segments that are leading the market and the sub-segments are mentioned in the report. • The report studies the leading manufacturers and other players entering the global Resin Market. Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia. Contact US : Craig Francis (PR & Marketing Manager) Market Research Forecast Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837 Phone: +1 201 565 3262, +44 161 818 8166 [email protected]

#Global Resin Market#Resin Market Demand#Resin Market Trends#Resin Market Analysis#Resin Market Growth#Resin Market Share#Resin Market Forecast#Resin Market Challenges

0 notes

Text

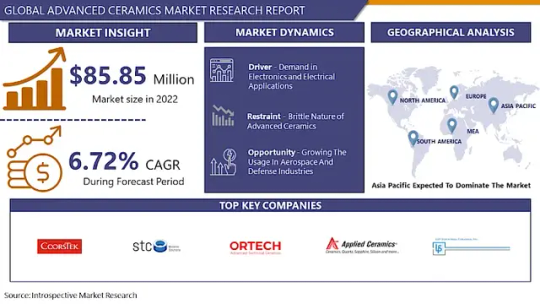

Advanced Ceramics Market: Global Industry Analysis and Forecast 2023 – 2030

Advanced Ceramics Market Size Was Valued at USD 85.85 Billion in 2022, and is Projected to Reach USD 144.44Billion by 2030, Growing at a CAGR of 6.72% From 2023-2030.