#Gas Leak At Chemical Plant

Explore tagged Tumblr posts

Text

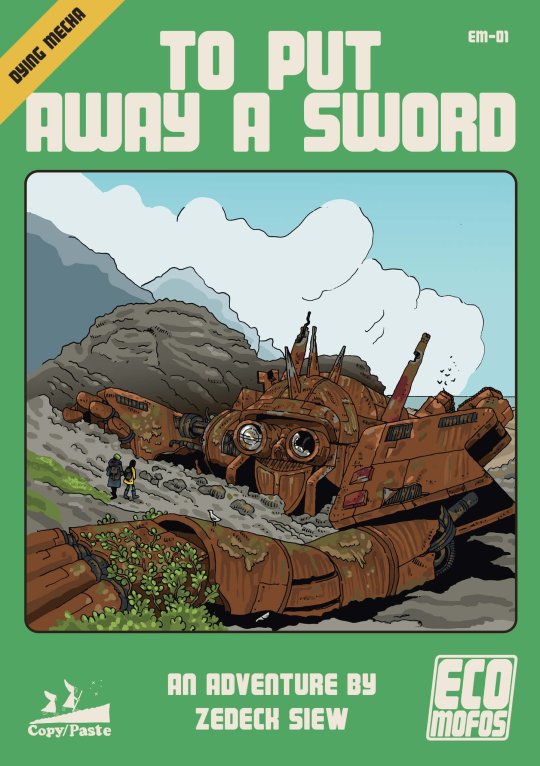

TO PUT AWAY A SWORD

David Blandy + Daniel Locke's post-apocalyptic hopepunk TTRPG ECO MOFOS is back from the printers. Meaning it will soon be in our hands.

Am fairly hyped for it, because I wrote an adventure!

To Put Away A Sword is about the woes of building a home on poisoned earth. The terrible powers that hurtled us to the end of the world continue to bear bitter fruit in your garden.

You are villagers living under the shadow of a fallen giant mecha. Its reactors and warheads leak into your groundwater, poison your goats. What will you do about it? What can you do?

+

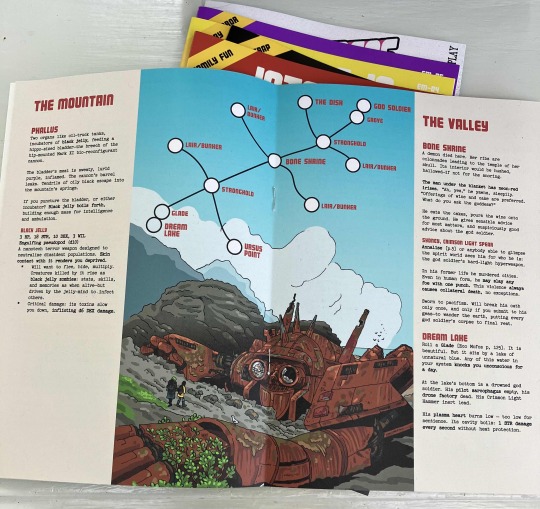

Mechanically it is a pointcrawl around your local valley. Not super complex, design-wise; but I was pleased with my gimmick solution for mapping both the adventure's dungeons:

Grab a mecha figure, pose it, place it on the game table; each part of the figure corresponds to a location in the dungeon key. Solves for stuff like relative orientation.

Easy!

+

To Put Away A Sword is me making a mecha adventure.

Disclaimer: I am not a mecha nerd. I am unfamiliar with most of the genre. Anything I know about Gundam I've absorbed by osmosis.

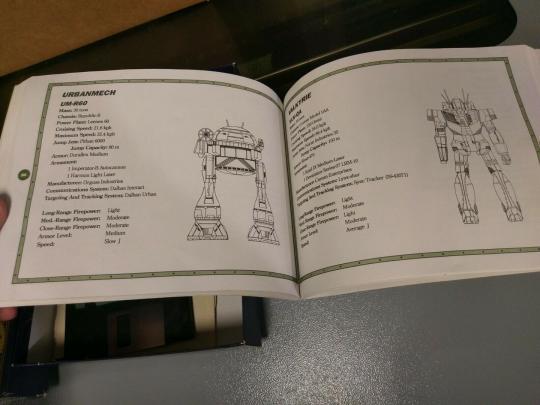

I was mainly into giant robots in childhood. Receiving a Macross figure for my birthday. Pouring over the manual for The Crescent Hawks' Revenge, which my brother left behind:

While I was not much a fan of mecha, I was very much a fan of Evangelion. I spent my middle teens obsessed with it. The biomechanical, pseudo-mystical stuff; the teen angst. I wanted to be Shinji. I thought trauma was so cool.

So cringe. Anyway:

One of the inspirations for To Put Away A Sword is the survivors-rebuilding-a-town-and-planting-rice sequence in Thrice Upon A Time; probably my favourite part of the whole franchise, now.

The joy and difficulties of trying to build your paradise in the weird ruins of the old world:

Yeah, the adventure has a lot of Evangelion in it. There's a Nerv HQ analogue to explore. There's a content warning for child soldiers.

+

The other inspiration for To Put Away A Sword is this piece of box art, an accessory set for Macross's iconic Stonewell Bellcom VF-1 Variable Fighter:

I don't know what this kind of arrange-your-missiles-in-front-of-your-fighter-jet photo is technically called. Hardware porn parade?

You see it often enough. Here's a real-life photo of the Lockheed Martin F35 Joint Strike Fighter:

Fairly or not, in my head I associate mecha with seeing copies of Jane's Defence in airport magazine racks. The genre feels like such a natural way to riff on the hyper-charged corpo-military-industrial complex.

After the brush war ends, and the natural resources extracted, and the ethnic cleansing concluded, and the profits announced, who gets to clean up after a Raytheon missile?

In To Put Away A Sword---you do.

+

Ultimately, as always, I am writing and designing from my lived experiences.

See that? The gas flare from the Hengyuan Refining Company? It is about 200 metres from my living room.

That gas flare surfaces constantly in the stuff I make. As I write this post I am breathing its acrid chemical smell. My nose itches. I was asthmatic as a child; I seriously worry about cancer, nowadays.

At night it lights up the sky like Barad-dur.

The plant obviously and continuously flaunts regulations. We've tried lodging complaints: with its corporate management; with the Department of Environment. Nothing has worked so far.

"A home on poisoned earth" is a visceral fact of my life.

+

To Put Away A Sword is wish-fulfilment, I guess? In the world of the adventure, at least, the forces that are poisoning your home are post-peak oil.

It is nice to imagine a reality where a kind of survival and flourishing is still possible. My partner Sharon and I talk a lot about imagining hope.

Last month she bought this small mecha-looking thing. A wireless camera! She built a little hut for it on our garden wall. It is trained, 24-7, at the gas flare.

Environmental activists we've met say video evidence of emissions is important. We'll see. We imagine it helping.

+

Anyway. David just sent me this photo of my adventure, in print:

Looking good. I hope folks play it and enjoy it.

Preorder ECO MOFOS and its adventure bundle >>>HERE<<<

107 notes

·

View notes

Text

Today's request is 'You've got one minute' for @ralndown ^_^

Every time Cal thinks he’s settling into a routine on Bracca, something awful happens. Maybe the Ibis Maw gets hungry for flesh and grabs a tentacleful of unsuspecting scrappers. Maybe a ship that’s been in the same place for two years suddenly decides to collapse under its own weight. Maybe someone breaks something aboard an old terraforming lab and suddenly there’s a bunch of people turned into trees.

Today, Cal’s crew makes it halfway through their shift before the worst, most terrifying siren goes off. Bracca doesn’t have a lot of warnings for incoming disaster, but this one? This is the one they’re all trained to react to in one way, and one way only.

Get out. Get out now or die.

Maybe that’s why the Force left Cal feeling nauseous all day. It’s so useful like that.

Dropping the wires he’d started stripping, Cal follows the others. Prauf’s leading them and he’s already on the comms, listening intently to whatever’s being said. When he stops still and holds up a hand to make everyone else do the same, Cal shivers under the weight of the collective fear around him.

It only gets worse when Prauf starts issuing orders in a sharp tone of voice Cal’s never heard before.

“It’s a chemical leak. A bad one. We’re too deep in the ship to get out in time. Get into your emergency teams, find a room, and seal yourselves in. If we’re lucky, we’ll see each other on the other side of this thing.”

People break off into their groups. There’s no time for goodbyes or good lucks. Cal sticks close to Prauf and Tabbers. He takes a breath and immediately coughs it out, a sharp bite scraping the back of his throat. Prauf grabs him, throws him into a room, and Tabbers seals the door.

It’s not enough. The room, a tiny refresher, has an air conditioning vent high on the ceiling. Even Prauf can’t reach it to close it off. Gas seeps in. Cal hears people coughing and choking from all around, senses their fear and pain.

“We gotta seal it, now!” Tabbers shouts. His eyes stream, coughing hard. “We’ve got one minute before we’re all spitting out chunks of our lungs.” He pulls a wall panel down. “Weld this over that vent!”

“Lift me up,” Cal says. He puts his filter mask on, hoping it will help. “I can do it.”

Putting his own mask on, Prauf grabs Cal, lifting him. Cal plants his feet on Prauf’s shoulders. His eyes burn, so full of tears he can hardly keep them open. Tabbers hands him a sheet of metal and Cal presses it to the vent, welding torch in hand as he covers it up. He can’t keep his eyes open, so he trusts Prauf to guide him, molten metal sealing the panel in place.

“Good job,” Prauf says, lowing Cal down. “Sit, both of you. That gas is light, so we should be safer down here.”

Cal’s feet touch the ground. He drops to the deck moments later, eyes squeezed shut, lungs still rebelling. His mask isn’t doing much to help, but it’s better than nothing.

“Is this shit what I think it is?” Tabbers’ voice is muffled by his mask.

“Yeah,” Prauf replies. Cal hears him sit beside him. “Someone messed up big time.”

“I’d threaten to beat the idiots myself, but I cannae imagine they’re alive now,” Tabbers says.

“What is it?” Cal asks when he can talk again.

“A chemical weapon designed to rot battle droids,” Prauf says.

“Aye, not that it worked,” Tabbers adds. “It’s far better at killing us organics.”

Cal never heard about anything like that. Not that he tells the others. The idea that the Republic would create something like that leaves him nauseous.

“Looks like no one thought to remove the canisters before we started pulling this thing apart,” Prauf says. “Foreman said someone cut off the wrong thing and boom – we’re all breathing in poison.”

Cal doesn’t join the conversation. He pulls his knees to his chest, keeps his eyes firmly closed, and tries not to suffocate in the feelings of so many people dying around him. He pushes the Force away, begs it to leave him alone like it usually does.

“Cal?”

Prauf’s big, warm hand lands on his back. Cal startles, eyes flying open. His vision is fractured by the tears still running, but the burn is easier to manage now.

“You okay?” Prauf asks.

“Yeah,” he says, knowing he doesn’t have to worry about how rough his voice sounds. And then, because he needs a distraction, he keeps talking. “Can’t believe we’re stuck in a ‘fresher.”

Tabbers chuckles. “Get comfy, brat. We might be here a while.”

It’s two days before the foreman gives them the all-clear. The survivors are given a half-shift break to clean up, get something to eat and drink, and then sent back to work to make up for the two days of sitting around doing nothing. Cal notes that their crew is down several people when they meet up to be assigned duties, but no one says anything.

Back to the Bracca routine.

#fic requests 2023#star wars jedi: fallen order#jfo headcanon#jfo minific#back to bracca!!#cal kestis#prauf#tabbers

109 notes

·

View notes

Text

Detours to You - 20

Hello all,

Here I am with another chapter. This is a bit angsty but I swear it's the only one. There is a big disaster that I hope it make sense. Since I finished ALB I am not used anymore to write these epic scenes with big disasters. So yeah, I hope it makes sense.

Enjoy.

MASTERLIST

Rowan jumped in the car and started driving to the destination, sirens and blue lights blazing.

He heard the address over the radio and his heart sank. It was a factory fire. A place that he had been inspecting on a regular basis recently because on his first visit he had spotted so many health and safety infractions that it was a miracle the place was still open. He had pushed for changes and improvements but there had been so many red tapes from the big bosses that it was frustrating. All his connections had not been enough to help prevent what he had labelled in his reports as a disaster waiting to happen. And now, while rushing to that site he had a feeling that the worst case scenario had happened and that once again money and politics had placed the lives of his firefighters in danger.

Instead of spending time with his girls, Rowan was driving towards a five alarm fire.

*

As the address grew closer, black plumes began to appear at the horizon and his heart sank. His mind started making possible plans. The smoke was very dark which meant a volatile fire. He pressed on the gas and pushed to the extreme the privileges that the sirens gave him in an emergency.

The location in question was a textile factory where the tanks containing highly flammable liquids were kept at the right storing temperature by a generator. In all his inspections Rowan had noticed signs of old age in the tanks and the generator had three system failures in a short time span. Rowan just tried to guess which one had failed.

He arrived at the site and quickly wore his bunker gear and walked to Lorcan who was acting as Incident Commander for a report.

“Chief.

“Lor, what is the situation?”

The dark-haired captain looked at the fire in front of him “we are evacuating the workers. The generator is failing and one of the tanks with treating chemicals has a leak that started a fire in a section with stored acrylic clothes. They caught fire and as you can imagine it spread quickly. We are working on containing it.”

Rowan looked at the inferno in front of him and rage surged in him.

“Triage is ready, mass casualty plan has been activated and we have four stations on duty.” Lorcan added to finish his report.

Rowan nodded “That is perfect, Lorcan. I take it from here, now.”

Lorcan nodded and ran to grab his gear and joined his team inside.

He took over the scene and started directing the rescue and gathered more information every time more firefighters came out. There were still workers trapped near the centre of the plant, the core that was likely minutes away from breaking down. If the generator failed, the tank would stop working properly and from there the whole site would just blow up.

“Chief to all units, what is the situation near the generator?”

Static was his answer.

“Chief to captain Salvaterre, do we have the fire contained near the generator?”

“One of the storage tanks is leaking heavily, we will need hazmat.”

“Copy that, asking dispatch now.”

“Chief,” Ilias voice came through the radio “We have found a group of four workers, taking them out now.”

“Copy that Ilias, paramedics are ready.”

Not long after he saw two firefighters take out a group of wounded workers. The paramedics ran to them and carried the victims to triage to be assessed.

Lorcan ran out of the building with a firefighter that had to be rescued after he got separated from his buddy.

“Lor, what happened?”

The man ripped his mask from his face and took a deep breath of air “It’s impossible to get to the centre. We can’t get any deeper. The smoke is very thick and dark.”

“Hazmat is on another call.”

Lorcan swore.

Rowan looked up and watched the smoke change “Lor, you take back command, I am going in.”

“Fuck no, Rowan.”

Rowan started to wear his SCBA “I have visited this factory more times in the past few months than any other industrial site. I know where everything is and I know how to get safely to the generator and where the failsafe panel is.”

“Rowan, that place is a time bomb.”

“I am aware, but there are four of my men inside and probably more workers. I am not going to another firefighter’s funeral, Lorcan.”

Rowan finished getting ready and ran inside “Keep the water going Lorcan, and tell hazmat to get their arses here ASAP.”

Lorcan shouted orders to the four teams “Let’s attack this fire and kill it,” he ordered another team inside to attack the centre of the factory and keep the generator cool to allow Rowan some time.

*

Rowan made his way inside the building and all he saw was thick smoke, but with the help of some burnt landmarks he found his way around. Progress was slow and time was a luxury he did not have. The fire around him was still raging and he only had his memory to guide him through the inferno. Deeper in the venue he heard a PASS alarm and his heart sank. One of his men was down and he rushed towards the sound.

“Chief, Lorcan, I have a firefighter down on the south east quadrant near the central room.”

“Copy that, Chief I am sending in rescue.”

Rowan waited for the two firefighters and then continued on his mission. He was so close but the smoke started changing badly and he knew that he was close to the epicentre. What made things worse was the very distinctive smell of electrical fire “Lor, keep water away from the centre of the structure. Electrical fire.”

He did not wait for his friend’s reply and with his axe he just smashed his way through the door and found four of his men and then two workers on the floor. The PASS alarms haunting his dreams. He grabbed the two workers and dragged them outside in a safe location, alerted Lorcan and then he stormed back inside and took out two of his men at a time. They had a pulse, faint but they were okay. He kept dragging the people as far as possible until he was exhausted. Rowan radioed his teams to rescue a few more people and then got ready for the last mission.

The generator had a failsafe switch that he hoped was still working and not being destroyed by the fire. He knew he had minutes to stop the plant from blowing up and flatten the building. He stood, gathering all the strength he had left, looked at the oxygen meter on his wrist and realised he had less than ten minutes of air left. It was enough, he kept telling himself. Enough to do his job and hopefully make it out alive. He wanted to get back to Maya and finish celebrating her birthday. He wanted to have a moment alone with Aelin and finally tell her that he was in love with her. That he was tired of pushing his feelings aside and overthink it. She was the love of his life and if he made it out alive he was going to tell her.

With a mighty roar he burst inside the plant room and crawled to the bottom where the smoke and the toxic air was less thick. The air was thick with electricity and one of the panel was clearly shorted. Slowly he elbowed his way to the centre and found the core computer that was barely working. Blindly he found his way to where he knew the failsafe panel was. Or was meant to be. He froze when he realised that it was not there anymore. The computer that would allow him to safely shut down all the tanks was gone.

“Lorcan, Chief,” he coughed “Mission has failed. Push back, the building is lost.”

Slowly he made his way back, his oxygen was starting to run low and Rowan went through all of his old training routines to keep oxygen consumption low.

He was dragging his sorry arse out of that hellish place when he saw all the signs. He tried to run, his body screaming for oxygen, his legs failing him. And when he noticed the fire pattern change he threw himself on the ground as a series of flashovers spread through the building.

Aelin and Maya’s laughter the last images in his mind before the darkness engulfed him.

*

Lorcan hated that he was outside. Rowan should be there and he should be inside, that was his job. But Rowan knew the place inside out. He had been conducting regular inspection and Lorcan knew that place was a ticking bomb, Rowan had told him the fights he had been having to change things but it looked that no one listened to him.

Pushing aside his rage he listened to the teams for what was happening. More workers kept being found alive and he counted that as a success. Rowan’s voice came through the radio alerting him that he had found the firefighter that had gone missing after he lost track of his partner.

“Come on, Rowan…”

The fire started to change and Lorcan called for more water to be pumped on the building, the water cannons moving to concentrate on where the tanks were.

Hazmat was still busy and he needed the team there immediately. He called dispatch for another update and he got the same answer. Time was ticking and he was growing worried. Surely Rowan’s oxygen was about to run out soon. Why the fuck he was not out yet?

The radio became alive once more and Rowan’s voice came through alerting him that he had more survivors. He sent Fenrys, Brullo and two more firefighters in to recover the people Rowan had saved.

Long minutes passed and silence stretched. He called Rowan but no answer came through.

“Lor, it has been too long. We need to get in to get Rowan.” Fenrys walked to him and shouted “He is inside that inferno on his own. That’s not how we do things.”

“Rowan, come through.”

More silence.

And then his strained voice finally reached him “Lorcan, Chief,” he coughed “Mission has failed. Push back, the building is lost.”

Lorcan’s heart sank at the words.

“Push back everyone. Move the perimeter back.” His voice thick with panic for his friend.

His men got into action and started to retreat to safety and then the explosion hit. Lorcan waited for the flashovers to die down and then grabbed his gear “Ilias, you have command, I need to save the Chief.” He shouted like a desperate man.

“Fen, Brullo and Ansel, with me.”

The three firefighters exchanged their bottles and grabbed a jump bag and a stretcher from the paramedics.

From the outside, Ilias restarted the water attack to allow them further progress inside.

Lorcan had an idea of where to go because had listened to Rowan when had talked abut the building but had never been inside. He followed his instincts and walked towards the centre of the structure until in the distance he heard the unmistakable sound of the PASS alarm. One of the sounds he hated the most, especially when it meant his best friend was in peril.

“Rowan,” screamed Fenrys at spotting Rowan’s body on the floor.

“Slowly, Fen.”

The young man walked quickly among the debris, pushing aside beams and part of structures “Fen, be careful.”

He did not listen and Brullo and Lorcan followed with Ansel in tow. When they finally arrived Rowan’s body was sprawled on the ground “Ilias, we got the Chief, we are assessing him just now.”

“Copy, I have paramedics on standby.”

Ansel crouched to his side, removed his broken mask and started assessing him “he is breathing but it’s very shallow.” The woman placed an oxygen mask on his face to help him breath better. The mask was cracked and he likely had inhaled toxic fumes. She checked his sats and she had her answers when the number turned out to be too low.

Brullo opened the jump bag. All firefighters had some sort of first aid training, but Brullo and Ansel were also certified paramedics so Lorcan let them work.

Fenrys helped them remove his bunker jacket and that’s when he saw a piece of metal sticking out of his left flank.

“Don’t pull it,” said Brullo “The spike just now it’s preventing him to bleed to death.”

Lorcan helped remove some of the debris covering his body “Possible fractures in the lower body,”

Ansel inspected his side and saw some burnt marks along his right arms down his chest “Second degree burn on his right side.”

“Is he stable enough for transport?” Asked Lorcan.

Ansel passed the stretch-board they had carried and with Brullo’s help they slid it under Rowan’s back.

“Yes, we are good to go. Alert the paramedics we have him and we are coming out. We need immediate transport to the hospital.”

Once outside, Lorcan stared at his team carry Rowan to the paramedics, watched them gave him initial treatment and then load him on the ambulance and disappear at the horizon.

He took command back from Ilias and guided the team until the fire was extinguished. Hazmat eventually arrived and took over the scene and Lorcan sent his teams inside for overhaul.

The sun had started to set once the scene was clear. Lorcan ordered engine back to quarters but he took the truck to a side mission.

The vehicle slithered through the traffic of Orynth and he prepared how he could tell Aelin about what happened. It was Maya’s birthday and he was about to destroy that day.

*

Aelin, Lys, Aedion, Elide and her parents had remained at the bookshop to continue the celebrations. Maya was sitting on her plastic table with her uncle and grampa and they were all reading some stories.

Aelin was about to start cleaning up when she saw a big fire truck park in front of the shop.

Her book tumbled off her hands when Lorcan stepped in, blackened by smoke and a dark stare.

Aelin’s hand shook and she felt sick.

Elide stepped at her side and placed a hand on her shoulder.

“Aelin,” he paused “I need you to come to the hospital with me.”

taglist

@rowaelinismyotp @swankii-art-teacher @whimsicallyreading @elentiyawhitethorn @aelin-bitch-queen @bruiseonthefaceofhumanity @mis-lil-red @thegreyj @sailorsassley @leiawritesstories @clairec79 @morganofthewildfire @sv0430 @heartless--aromantic @autumnbabylon @rowanaelinn @backtobl4ck @susumaus98 @gracie-rosee @mybloodrunsblue @tanvee1231 @avenrebekah @whoever-you-choose-to-love @theywillnotsingforme @universallytreepost @black-daisy-water @goddess-aelin @whispers-in-the-darkest-heart @lovely-dove-zee @athena127

#rowaelin#rowan whitethorn#rowan x aelin#rowaelin fanfiction#rowaelin fanfic#aelin x rowan#rowanwhitethorn#throne of glass fanfiction#aelin galathynius

38 notes

·

View notes

Text

Alt National Park Service

People often ask, “What exactly are we resisting?” So, we decided to keep a detailed list. From 2017 to 2021, the Trump administration reversed over 100 environmental regulations, affecting climate policy, air, water, wildlife, and chemical safety. Additionally, more than a dozen other rollbacks were in progress but not finalized by the end of the term, prompting questions about the potential impact of another four years. You might wonder what another four years could look like. Here's a summary of Trumps last four years in office:

- Weakened fuel economy and greenhouse gas standards.

- Revoked California's stricter emissions standards.

- Withdrawn legal basis for limiting mercury from coal plants.

- Exited the Paris climate agreement.

- Altered Clean Air Act cost-benefit analysis methods.

- Canceled methane emissions reporting for oil and gas companies.

- Revised rules on methane emissions from drilling on public lands.

- Eliminated methane standards for oil and gas facilities.

- Withdrew rule limiting toxic emissions from industrial polluters.

- Eased pollution safeguards for new power plants.

- Changed refinery pollution monitoring rules.

- Reversed emissions reduction during power plant malfunctions.

- Weakened air pollution rules for national parks and wilderness areas.

- Loosened state air pollution plan oversight.

- Established minimum threshold for regulating greenhouse gases.

- Relaxed pollution regulations for waste coal plants.

- Repealed hydrofluorocarbon leak and venting rules.

- Ended use of social cost of carbon in rulemaking.

- Allowed increased ozone pollution from upwind states.

- Stopped including greenhouse gas emissions in environmental reviews.

- Revoked federal greenhouse gas reduction goal.

- Repealed tailpipe emissions tracking on federal highways.

- Lifted ban on higher ethanol gasoline blends in summer.

- Extended deadlines for methane emissions plans for landfills.

- Withdrew rule reducing pollutants at sewage plants.

- Dropped tighter pollution standards for offshore oil and gas.

- Amended emissions standards for ceramics manufacturers.

- Relaxed leak monitoring at oil and gas facilities.

- Cut two national monuments in Utah.

- Ended freeze on new coal leases on public lands.

- Permitted oil and gas development in Arctic Refuge.

- Opened land for drilling in National Petroleum Reserve, Alaska.

- Lifted ban on logging in Tongass National Forest.

- Approved Dakota Access pipeline near Sioux reservation.

- Rescinded water pollution rules for fracking.

- Withdrawn rig decommissioning cost proof requirement.

- Moved cross-border project permits to presidential office.

- Altered FERC's greenhouse gas considerations in pipelines.

- Revised ocean and coastal water policy.

- Loosened offshore drilling safety regulations post-Deepwater Horizon.

- Weakened National Environmental Policy Act.

- Revoked flood standards for federal projects.

- Eased federal infrastructure project environmental reviews.

- Ended financing for overseas coal plants.

- Revoked directive to minimize natural resource impacts.

- Revoked climate resilience order for Bering Sea.

- Reversed public land-use planning update.

- Withdrawn climate change consideration in national park management.

- Limited environmental study length and page count.

- Dropped Obama-era climate change and conservation policies.

- Eliminated planning system to minimize oil and gas harm on sensitive lands.

- Withdrawn policies for improving resources affected by federal projects.

- Revised Forest Service project review process.

- Ended natural gas project environmental impact reviews.

- Rolled back migratory bird protections.

- Reduced habitat for northern spotted owl.

- Altered Endangered Species Act application.

- Weakened habitat protections under the Endangered Species Act.

- Ended automatic protections for threatened species.

- Reduced environmental protections for California salmon and smelt.

- Removed gray wolf from endangered list.

- Overturned bans on lead ammo and fishing tackle on federal lands.

- Reversed ban on predator hunting in Alaskan refuges.

- Reversed rule against baiting grizzly bears for hunting.

- Amended fishing regulations.

- Removed commercial fishing restrictions in marine preserve.

- Proposed changes to endangered marine mammal injury limits.

- Loosened fishing restrictions for Atlantic Bluefin Tuna.

- Overturned migratory bird handicrafts ban.

- Reduced Clean Water Act protections for tributaries and wetlands.

- Revoked stream debris dumping rule for coal companies.

- Weakened toxic discharge limits for power plants.

- Extended lead pipe removal time in water systems.

- Eased Clean Water Act for federal project permits over state objections.

- Allowed unlined coal ash ponds to continue operating.

- Withdrawn groundwater protections for uranium mines.

- Rejected chlorpyrifos pesticide ban.

- Declined financial responsibility rules for spills and accidents.

- Opted against requiring mining industry pollution cleanup proof.

- Narrowed toxic chemical safety assessment scope.

- Reversed braking system upgrades for hazardous material trains.

- Allowed liquefied natural gas rail transport.

- Rolled back hazardous chemical site safety rules.

- Narrowed pesticide application buffer zones.

- Removed copper filter cake from hazardous waste list.

- Limited use of scientific studies in public health regulations.

- Reduced corporate settlement funding for environmental projects.

- Repealed light bulb energy-efficiency regulation.

- Weakened dishwasher efficiency standards.

- Loosened efficiency standards for showerheads and appliances.

- Altered energy efficiency standard-setting process.

- Blocked efficiency standards for furnaces and water heaters.

- Simplified appliance efficiency test exemption process.

- Limited environmentally focused investments in 401(k) plans.

- Changed policy on using sand from protected ecosystems.

- Halted contributions to the Green Climate Fund.

- Reversed national park plastic bottle sale restrictions.

5 notes

·

View notes

Text

𝙎𝙏𝘼𝙂𝙀𝙎 𝙊𝙁 𝘿𝙀𝘾𝙊𝙈𝙋𝙊𝙎𝙄𝙏𝙄𝙊𝙉 𝙁𝙍𝙊𝙈 𝘼 𝙁𝙊𝙍𝙀𝙉𝙎𝙄𝘾𝙎 𝙎𝙏𝙐𝘿𝙀𝙉𝙏 𝙊𝙁 5 𝙔𝙀𝘼𝙍𝙎

Disclaimer! Decomposition is not only time-dependent, hence why the stages do not have time scales. Decomposition can be delayed by cold temperatures, dry atmosphere, burial/underwater/hanging above ground, embalming etc, and can be promoted by warmth, humidity, unrestricted oxygen, visible wounds on the body, surface burning, being on top of soil etc...

— 1: FRESH STAGE

immediately after death

no discolouration or insect activity

paling of the skin (pallor mortis) and

cooling of the body (algor mortis)

skin loses elasticity

muscles become flaccid - body may release stool, urine, saliva, etc

(within 3-6 hours) muscles become rigid due to chemical reaction (rigor mortis) - face affected first, can take up to 24 hours to reach max rigor and can last for up to 3 days

(within 6-12 hours) blood pools to the inferior-most parts of the body following gravity (livor mortis) - looks like big bruises, but doesn't affect body parts which make direct contact with a surface because the capillaries are crushed

autolysis/deconstruction of cells/tissues by their own enzymes may cause blisters to appear on the skin

— 2: BLOAT STAGE

body bloats due to the production of vapours

cells are rupturing and breaking apart

tissues are broken down by bacteria

intestines push out and are subjected to distension

eyes, lips and tongue swell

blisters form on the skin filled with putrid gas (1-20cm)

skin becomes green with brown/purple veins (marbling) - because of an excess of sulphur due to bacteria/enzyme activity, primarily seen in the abdomen

skin slippage (degloving on hands)

adipocere!!! is the process of anaerobic bacterial hydrolysis creating a wax-like substance over the body - this only happens when exposed to alkaline, warm and damp water/soil - this STOPS further decomposition!!! looks soft, greasy and grey and then hardens and becomes brittle

fluids and gases seep through any orifices (purging)

— 3: ACTIVE DECAY

the body deflates

decomposition fluids leak into the surrounding environment

skin perforates/punctures exposing organs

MASSIVE maggot feeding

presence of diptera and coleoptera - invertebrae detritivores

blowflies are of the first colonising insects

— 4: ADVANCED DECAY

insect activity lessens

any plant life surrounding the corpse will die

— 5: DRY STAGE

dry skin and bone

no tissues, organs or liquid remaining

in very hot and dry atmospheres, soft tissues dry out and mummification can occur - begins in areas with little fluid such as fingers and toes - and takes at least 3 months

#writers on tumblr#writerscommunity#whump prompt#sick!fic#sickfic prompts#so many people give wrong information about this#i'm qualified i promise#taphonomy

31 notes

·

View notes

Text

The Basis of the Environmental Crisis

There is a fundamental problem here: The dynamics of capitalism have an inherent tendency towards ecological devastation. To understand why this is so, we need to look at how firms are constantly searching for ways to minimize their expenses. This is how they ensure the firm can make the maximum in profits. Because capitalism is made up of relatively autonomous firms, they are in competition. If a firm doesn’t continuously seek ways to make profits, they won’t be able to expand their business, move into new markets, invest in new technology. Other firms will out-compete them. And minimizing expenses is central to the pursuit of profits. Thus minimizing expenses is central to survival for the capitalist firms. And to do this, firms do cost-shifting at the expense of both workers and the environment.

First, companies try to keep compensation to workers as low as they can get away with. They may look to cut taxes that support services working class people rely on. They try to find new forms of technology or new ways to organize the work that reduces the number of worker hours it takes to produce a unit of output. They might automate a production operation with robots, or they will seek ways to intensify work through “lean production” methods. For example, they’ll use computer tracking of a warehouse worker picking items for an order so that they have no rest time after finishing an order but are pushed to a new task through computer control. Work intensification and computer monitoring puts workers under more stress which can have damaging health effects over time. This means the employers are imposing a human cost on workers. If workers in a furniture factory are constantly breathing in finishes or paints being sprayed on furniture in the open, or electronics assemblers are breathing in solder fumes, these are also cases where capital is shifting costs onto workers. And these are cases where the costs could be avoided. For example, there are soldering tools that have a vacuum to suck off solder fumes so workers don’t breath it, but a firm may not want to pay the expense of installing that equipment. These are examples of how the capitalist mode of production tends to shift costs onto workers.

Second, emissions into the air and water are another form of cost-shifting. A utility firm may burn coal to generate electricity. This creates emissions that damage the respiratory systems of people in the region and also contributes to global warming. But the power firm is not required to pay anything for these damages. These costs to others from emissions are “external” to the market transaction between the power firm and its customers who pay for electricity. This is an example of a “negative externality.” Externalities are a pervasive feature of the capitalist mode of production. The fossil fuel industry generates many “negative externalities.” Fracking operations insert chemicals underground which can pollute the underground water sources. A large gas field or leaky oil refinery will generate large amounts of volatile organic compounds — including carcinogens and endocrine disruptors. Studies of gas fields show effects in the surrounding area such as goat herds and barn cats losing the ability to have viable offspring, due to the endocrine disruptors. Gas fields also contribute to global warming by leaking large amounts of methane. Contrary to gas industry claims, gas power plants contribute as much as coal-fired power plants to global warming due to all the methane leaks.

You’ll notice here that I’m focusing on how environmental devastation is rooted in production — not consumption. Some environmentalists try to suggest that we should understand the global warming problem by looking at consumption practices, and they use ideas like a person’s “carbon footprint” to focus on personal consumption. But consumers of electric power don’t have control over the decisions of power firms on the methods of electricity generation, or what technology firms rely on to move cargo around in the global supply chains.

Another useful concept here is throughput. The throughput of production consists of two things: (1) All the material extracted from nature for the production process, and (2) all the damaging emissions (“negative externalities”) from the production process. In addition to the damaging emissions into the air and water, capitalism is an extractivist regime with a long history of land-grabbing to minimize expenses — as in the US government handing over mineral wealth to mining companies, lands for commercial ranching and extraction of logs and wood debris from forests for the lumber and paper industries. The search for short-term profits can lead to unsustainable practices such as clear-cutting of forests or use of huge nets to scarf up all the fish in a coastal region without regard to the future of that fishery.

With the concept of throughput, we can define a concept of ecological efficiency. If a production process is changed in ways that reduce the amount of damage from emissions (or amount of extracted resource) per unit of human benefit, then that change improves ecological efficiency. And here is a basic structural problem of capitalism: It has no inherent tendency towards ecological efficiency. If nature is treated as a free dumping ground for wastes, there will be no tendency to minimize damaging emissions per unit of human benefit from production. Also, there will be no tendency to minimize materials extracted from nature except to the extent firms have pay for these resources.

A production system that could generate increasing ecological efficiency would tend towards reductions in pollution and resource extraction. This would require a non-profit, non-market type of eco-socialist economy where production organizations are held socially accountable — required to systematically internalize their ecological costs. Capitalism’s tendency to ever greater environmental devastation happens because firms have an incentive to not internalize their costs, but dump them on others.

The devastation wrought by the cost-shifting dynamic of capitalism is not limited to global warming. Capitalism has favored the evolution of agricultural practices that aim at highest output at lowest financial cost to the firm. Intense competition has led to ever-greater concentration in ownership of farm land. The capitalist setup allows the growers to rely on labor contractors to pay laborers as little as possible and get rid of workers who try to organize. Growers often own lands in various locations and pursue different crops to minimize their risks. With encouragement from the chemical industry, growers have adopted industrial production of a single crop in a large field with increasing usage of pesticides and inorganic fertilizer over time. Inorganic fertilizers typically provide some mix of nitrogen, phosphorus and calcium. Over-use of these fertilizers has led to excessive runoff, polluting water courses and leading to ocean “dead spots” around the mouths of rivers. Destructive effects on fisheries is thus one of the negative externalities from capitalist agriculture.

Since World War 2 chemical pesticide production world-wide grew from 0.1 ton to 52 million tons in 1976 and 300 million tons in 2015. Pesticides produced by the chemical industry are damaging to the health of farm workers, and pollutes water courses, and leaves residues on food. Pesticide overuse also destroys the natural predators of insects and breeds pesticide-resistant pests. This leads a kind of agricultural arms race as more and more pesticide is needed. As Fred Magdoff and Chris Williams report in Creating an Ecological Society, pesticides also reduce “presence in the soil of organisms that stimulate plants to produce chemicals to defend themselves.”

As with pesticides the chemical industry has also vastly pumped up the production of petroleum-based plastics which do not biodegrade but end up as vast scourge of pollution in the oceans. Plastic bags have grown in use because they take a lot less energy to produce than paper bags, and thus cost less. Production has increased from less than 5 tons in 1950 to over 340 million tons by 2014, according to the Plastics Europe trade association. At least a third of all plastic produced is not recaptured, but mostly ends up in the ocean where it is destructive to living organisms. The plastics industry does not have to pay for the negative effects on living things in the oceans.

If we bring in our definition of throughput, pollution and dumping of wastes are one aspect, but we need to also look at the destructive extractivist tendencies in capitalism, such as clear-cutting of forests or over-fishing. According to a 2003 study, “90 percent of all large fishes have disappeared from the world’s oceans in the past half century,” since the onset of industrial fishing with huge nets in the 1950s. “”Whether it is yellowfin tuna in the tropics, bluefin in cold waters, or albacore tuna in between, the pattern is always the same. There is a rapid decline of fish numbers,” according to Ransom Myers, a fisheries biologist at Dalhousie University in Halifax. To address the problem, many countries have banned long drift nets and untended longlines, and have instituted elaborate systems of licensing, and have instituted quotas and third party observers working on boats. Nonetheless, capitalist fishing outfits frequently ignore or evade these rules.

#climate crisis#Working Class#autonomous zones#autonomy#anarchism#revolution#ecology#climate change#resistance#community building#practical anarchy#practical anarchism#anarchist society#practical#daily posts#communism#anti capitalist#anti capitalism#late stage capitalism#organization#grassroots#grass roots#anarchists#libraries#leftism#social issues#economy#economics#anarchy works#environmentalism

6 notes

·

View notes

Text

SS 304 Blind Flange | Best Deals at Lowest Price

SS 304 Blind Flanges are an essential component for sealing off pipelines and preventing the flow of liquids or gases in various industrial systems. Known for their exceptional corrosion resistance, strength, and durability, SS 304 Blind Flanges are widely used in industries like oil and gas, chemical processing, water treatment, and more. Finding the best deals at the lowest price for SS 304 Blind Flanges is key to optimizing your operational costs while maintaining the quality and performance you need.

In this article, we'll explore the benefits of SS 304 Blind Flanges, their industrial applications, and how you can find the best deals online.

Why Choose SS 304 Blind Flange?

SS 304, a grade of stainless steel, is one of the most popular and versatile alloys used in various industrial components, including flanges. It contains 18% chromium and 8% nickel, which makes it highly resistant to corrosion, even in harsh environments where moisture, chemicals, and high temperatures are present. Here’s why SS 304 Blind Flanges stand out as a top choice for industrial use:

1. Exceptional Corrosion Resistance: One of the main reasons why SS 304 Blind Flanges are favored across multiple industries is their corrosion resistance. The chromium content in the stainless steel creates a passive oxide layer on the surface of the flange, preventing it from rusting. This makes it ideal for use in environments exposed to moisture, chemicals, or high humidity.

2. High Durability and Strength: SS 304 Blind Flanges are known for their strength and ability to withstand high pressures and temperatures. Whether you're dealing with high-pressure pipelines or industrial systems that operate in extreme temperatures, SS 304 Blind Flanges provide the durability needed to keep your systems running smoothly.

3. Low Maintenance: Because of their corrosion resistance and strength, SS 304 Blind Flanges require minimal maintenance, which reduces the need for frequent replacements or repairs. This makes them a cost-effective solution for industrial applications where reliability and long-term performance are essential.

4. Easy Installation: SS 304 Blind Flanges are designed for easy installation, making them a convenient option for industrial systems that need to be sealed off temporarily or permanently. They can be quickly bolted into place, ensuring a tight seal that prevents leakage or contamination.

5. Versatile Use Across Industries: SS 304 Blind Flanges are used in a wide range of industries, from oil and gas to food processing and water treatment. Their versatility makes them a reliable choice for various applications, ensuring that they meet the needs of different industrial environments.

Applications of SS 304 Blind Flanges

SS 304 Blind Flanges are used in several industries for their ability to seal off piping systems. Common applications include:

Oil and Gas Pipelines: SS 304 Blind Flanges are used to close off pipeline sections during repairs, testing, or maintenance. Their corrosion resistance makes them suitable for handling hydrocarbons and other chemicals typically found in the oil and gas industry.

Chemical Processing Plants: In chemical plants, where pipelines carry corrosive fluids, SS 304 Blind Flanges are a reliable option for sealing pipes during system shutoffs or maintenance periods. They prevent leaks and ensure the integrity of the system.

Water Treatment Facilities: In water treatment plants, SS 304 Blind Flanges are used to block off sections of water pipelines, ensuring that the water remains uncontaminated and the system remains functional during maintenance.

Marine Industry: The saltwater environment can be particularly corrosive, but SS 304 Blind Flanges are resistant to seawater corrosion. This makes them ideal for use in shipbuilding, offshore platforms, and other marine-related industries.

Food and Beverage Industry: The non-reactive properties of SS 304 make it a preferred material in industries that require high hygiene standards, such as food processing and beverage production. SS 304 Blind Flanges ensure a safe, clean, and durable seal in these environments.

Tips for Finding the Best Deals on SS 304 Blind Flanges

Finding SS 304 Blind Flanges at the lowest price doesn't mean compromising on quality. With a bit of research and strategy, you can secure the best deals on high-quality flanges. Here are a few tips to help you get the most value for your money:

1. Compare Prices from Multiple Suppliers: To find the best deals, it's important to compare prices from several suppliers. With the availability of online platforms, you can easily compare pricing, shipping options, and customer reviews. Be sure to check if the supplier offers any promotions or discounts that could further lower the price.

2. Look for Bulk Purchase Discounts: If your project requires a large number of SS 304 Blind Flanges, buying in bulk can significantly reduce the cost per unit. Many suppliers offer discounts on bulk purchases, which can help you save money in the long run, especially for large-scale projects.

3. Check for Seasonal Promotions: Some suppliers offer seasonal discounts, promotional offers, or clearance sales. These can be a great opportunity to buy SS 304 Blind Flanges at reduced prices. Keep an eye on major online marketplaces and industrial suppliers for these kinds of offers.

4. Verify Product Quality and Certifications: While getting a good deal is important, ensuring product quality is equally crucial. Make sure the SS 304 Blind Flanges you’re purchasing meet international standards such as ASTM, ASME, or DIN certifications. This ensures that the product has been manufactured to meet rigorous quality control and safety standards.

5. Negotiate with Suppliers: Don't hesitate to negotiate with suppliers, especially if you’re placing a large order or planning a long-term partnership. Many suppliers are willing to offer discounts or better pricing for repeat business, so it’s worth asking for a better deal.

Advantages of Buying SS 304 Blind Flanges Online

Purchasing SS 304 Blind Flanges online offers several benefits:

Convenience: Online platforms make it easy to browse, compare, and purchase products from the comfort of your office or home. You can explore a wide range of suppliers, products, and prices in just a few clicks.

Wide Selection: Online suppliers often offer a greater variety of SS 304 Blind Flanges in different sizes and specifications, ensuring that you find the exact product to meet your requirements.

Fast Shipping: Many online suppliers provide fast delivery options, ensuring that you receive your SS 304 Blind Flanges when you need them, helping to keep your project on schedule.

Customer Reviews: Reading reviews from other customers can give you insight into the quality of the product and the reliability of the supplier, helping you make an informed decision before making a purchase.

#SS304BlindFlange#BestDealsFlanges#LowestPriceFlange#StainlessSteelFlange#IndustrialFlanges#BuyNow#CorrosionResistantFlange#OilAndGasFlange#WaterTreatmentFlange#PipelineSolutions#BulkOrderFlanges#ChemicalProcessingFlange

6 notes

·

View notes

Text

Union Carbide's Value

The images of this article are ads. They’re ads for a company called Union Carbide, which proudly promoted themselves through the 50s and 60s for the way their chemical plants and development projects were capable of transforming the world. They could bring pesticides to your community, kill the bugs and help you be self-sustaining as a culture, a promise they started in South America, and then made a big, active push to start doing in India.

These ads are now, absolutely unhinged to look at, not just in the 1960s put-your-whole-butt-into-the-project industrial futurism represented by the hands of a vast white man reshaping the world to his wants, but they become even more messed up when you understand what this company wound up doing, and who it wound up hurting, because of its choices.

Content Warning: I’m going to talk about the Union Carbide gas leak disaster in Bhopal, India. It is an incident in which a lot of people were exposed to a dangerous chemical that killed and injured a lot of them (a lot). I’m not going to go into grisly detail and I don’t intend to go in-depth on the process of the accident.

Spoiler Warning: The bad guy is capitalism, again.

In 1984, a pesticide plant built and maintained by a company called Union Carbide India Limited, which was, coincidentally, 50.9% owned by the American company Union Carbide and Carbon Corporation, suffered a catastrophic gas leak that released a chemical agent known as methyl isocyanate (MIC) over the towns around the plant.

This chemical is colourless but has a sharp, pungent odour, which is useful for detecting it as it creeps into your system. One of the things this chemical does that I didn’t know there was a term for was that it’s a lachrymatory agent, which if you recognise that word, you know it because it’s a thing cops throw at you. MIC is not the agent in tear gas, but it’s the same kind of thing that aggravates the eyes and tear ducts. This stuff is safe only up to a volume of .004 ppm, or ‘parts per million’ – a very small amount. You can’t smell it until it hits 5 ppm, at which point it’s gotten real dangerous in how it messes with your body, particularly your nerves.

Notably, MIC is heavier than air, meaning that it crept along the ground as it leaked from the plant, which just so happens to have made it really dangerous to anyone who was low down to the ground compared to standing up, such as children or people sleeping on or near the ground.

Union Carbide’s leak happened at night.

Bonus: It’s flammable.

Arranged around the Bhopal plant were a variety of towns that were made up of people who were there to work for the plant or serve the people who were working for the plant, and of course, their families, which included elders and children. The population around Bhopal was hard to precisely quantify (the central government not being one with a ton of perfect information), but the estimates put it at around 500,000 people living in these spaces who were exposed to the MIC.

Note: That’s not ‘how many people, total, were there.’ That’s how many people the estimates are confident were exposed.

This is one of the reasons why the Union Carbide gas leak in Bhopal is regarded as the worst industrial accident in history.

This is one of those stories that I feel are well-known if you know anything about it at all; you’re either a very normal person whose experience of massive national industrial disasters is about the things you’ve seen in the news or mentioned in other media, or you’re like me and you pay attention to podcasts or Youtube channels or books about how some things went catastrophically wrong somewhere or other, in a sequence of texts that seems to present the idea that maybe capitalism is just bad at taking care of people, weird, I’m sure there’s no particular reason for that.

When it comes to large-scale disasters, especially given its potential environmental impact and recent TV series bringing it back into focus, the general vibe is that Chernobyl was ‘one of the worst disasters in history.’ Which, make no mistake, Chernobyl is and remains one of the worst disasters in history, but it’s in a way we have a hard time measuring, because we tend to look at disasters in terms of their immediate deadly outcomes.

Wikipedia picks a range between 95 deaths and 4,000 deaths for Chernobyl, which is again, a simplification of its values. But in raw dead, we can point to Chernobyl killing about 4,000 people based on whatever pixies Wikipedia gets its information from. To contrast with that, the estimated dead from the Union Carbide leak in Bhopal starts at 3,787 dead, near the height of estimates for Chernobyl. When you look at the people individually impacted, Pripyat, the city by Chernobyl had a population of 49,000 people exposed to the potential harm of the reactor. The Bhopal gas leak impacted again, half a million people.

One really easy thing to point to is that Chernobyl happened in a Soviet state and the victims were white, while Bhopal is a very clear example of an American, capitalist company that messed up in a way that killed a lot of brown people. Make no mistake, the racism is part of it, and the normalcy of it too – after all, companies have accidents sometimes, oops, guess that’s just part of it.

When I wrote about Chernobyl I talked about how hard it was to properly consider the scale of the disaster because of the way actual immediate deaths were rare while an enormous number of people were heavily impacted by the disaster in ways that shortened their lives. Bhopal is kind of so much worse because also, yeah, a lot of people died, and also the land around the place was really permanently damaged, and the harm was so vast there was no way to really address it, and also because the harm was so vast, well what are you going to do about it, not like Union Carbide could fix the problem they caused with their negligence.

The system of systems in which we live is one where half a million people injured is an acceptable problem because once it’s happened, it can’t be addressed. Causing problems on such a vast scale is acceptable, because you can’t do the one thing that makes it right (which is give them money). It’s a vision of justice that is purchased, that all things in life can be measured and weighted in terms of their relationship to money. If they hurt enough people enough, then there’s no way they can reasonably make good on that, they can’t afford to pay it back, and so…

That’s just gotta be okay.

Maybe the government will help you.

This kind of externality is pretty normal under capitalism. In 1952, a weather event meant that the pollution that the city of London was generating settled down on the city for a few days, creating a severe weather event that killed somewhere between 10,000 to 12,000 people. Turns out that was just enough people dying that the government could make a good case for starting a set of laws to address that and make it so the air in London was livable, and it only took four more years to get that done.

Union Carbide is still around, you know. The company was acquired by Dow, because its stock price was hurt a lot by the disaster they caused in Bhopal (and the disaster they caused in West Virginia, and disaster they caused here in Australia over land damage). After the Union Carbide Gas Leak Disaster in Bhopal, they sold off brands they had to try and generate money, which includes Glad trash bags (which we use) and Eveready Batteries (which I’m sure I have some of in the house). They were bought out by Dow, for stock.

They were worth 11 billion dollars when they were bought, and now they exist as just a part of Dow. They made about 4 billion dollars in 2019, which is down overall. Turns out you just can’t make the same kind of profits as you could when you were able to cut enough corners that half a million people were exposed to your flammable tear gas leaks.

It’s enough to make you wonder how these systems can be captured, can be punished, can be made to address the violence they do. Is it right to murder a company? Is it right for the state to execute them? If the company isn’t responsible, what about the person in that company who made the choice? If they did so, knowingly, how many people is the threshold for your personal willingness to kill in the name of maximising profits?

About 5 million people a year die thanks to abnormal temperatures.

Check it out on PRESS.exe to see it with images and links!

3 notes

·

View notes

Text

Preserving Assets: The Role of Corrosion Inhibitors in Industrial Maintenance

Corrosion is a persistent threat to industrial assets, causing billions of dollars in damages annually across various sectors. From oil and gas facilities to manufacturing plants, the impact of corrosion can be devastating, leading to equipment failures, production downtime, and costly repairs. However, with the right preventive measures in place, such as corrosion inhibitors, industrial facilities can effectively mitigate the risk of corrosion and prolong the lifespan of their assets. As a leading chemical company in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) understands the critical role of corrosion inhibitors in industrial maintenance. In this blog post, we'll explore the importance of corrosion inhibitors, their applications, and the expertise of ICPL as a corrosion inhibitor manufacturer and exporter in India.

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemical compounds designed to protect metal surfaces from the damaging effects of corrosion. By forming a protective barrier on the metal surface or altering the corrosion process, inhibitors prevent or slow down the oxidation and deterioration of metals in corrosive environments. Corrosion inhibitors are widely used in various industries, including oil and gas, petrochemicals, power generation, water treatment, and manufacturing, to safeguard critical assets and infrastructure from corrosion-related failures.

The Importance of Corrosion Inhibitors in Industrial Maintenance

1. Asset Protection: Industrial facilities rely heavily on equipment and infrastructure made of metal, such as pipelines, tanks, vessels, and machinery. Corrosion inhibitors play a crucial role in protecting these assets from corrosion, extending their service life and reducing the need for frequent repairs or replacements.

2. Cost Savings: Corrosion-related failures can result in significant financial losses due to equipment downtime, production disruptions, and repair expenses. By incorporating corrosion inhibitors into maintenance programs, industries can minimize the risk of corrosion-related failures and realize substantial cost savings in the long run.

3. Safety and Reliability: Corrosion compromises the structural integrity of industrial assets, posing safety hazards to personnel and the surrounding environment. Corrosion inhibitors help maintain the reliability and safety of critical infrastructure, reducing the likelihood of accidents, spills, and environmental contamination.

4. Environmental Protection: Corrosion-related leaks and spills can have detrimental environmental consequences, polluting soil, water bodies, and ecosystems. By preventing corrosion and minimizing the risk of leaks and spills, corrosion inhibitors contribute to environmental protection and sustainability efforts.

Applications of Corrosion Inhibitors

Corrosion inhibitors find applications across various industrial sectors, where metal components are exposed to corrosive environments. Some common applications of corrosion inhibitors include:

Oil and Gas Production: In the oil and gas industry, corrosion inhibitors are used to protect pipelines, well casings, and production equipment from corrosion caused by corrosive fluids, gases, and environmental conditions.

Water Treatment: Corrosion inhibitors are added to cooling water systems, boilers, and wastewater treatment facilities to prevent metal corrosion caused by dissolved oxygen, scale formation, and aggressive ions.

Manufacturing: In manufacturing processes involving metal components, such as automotive, aerospace, and electronics manufacturing, corrosion inhibitors are used to protect parts, components, and machinery from corrosion during production, storage, and transportation.

Marine and Offshore Structures: Corrosion inhibitors are applied to marine vessels, offshore platforms, and coastal structures to protect against corrosion in seawater environments.

ICPL: Your Trusted Corrosion Inhibitor Manufacturer and Exporter in India

As the best chemical company in Vadodara, ICPL is dedicated to delivering high-quality corrosion inhibitors tailored to the specific needs of industrial clients. Here's why ICPL is the preferred choice for corrosion inhibitors in India:

Expertise and Experience: With decades of experience in the chemical industry, ICPL possesses the expertise and technical know-how to develop and manufacture corrosion inhibitors that meet the highest quality standards and regulatory requirements.

State-of-the-Art Facilities: ICPL operates state-of-the-art manufacturing facilities equipped with advanced technologies and production processes to ensure the consistent quality and performance of its corrosion inhibitors.

Customized Solutions: ICPL offers customized corrosion inhibitor formulations tailored to the unique requirements and operating conditions of industrial applications. Our team of experts works closely with clients to develop solutions that address specific corrosion challenges and performance objectives.

Global Reach: As a corrosion inhibitor exporter in India, ICPL serves clients worldwide, exporting its products to diverse markets across Asia, Africa, the Middle East, and beyond. With a strong global presence and distribution network, ICPL delivers reliable corrosion protection solutions to industries around the globe.

Conclusion

In conclusion, corrosion inhibitors play a crucial role in industrial maintenance by protecting metal assets from the damaging effects of corrosion. As a leading corrosion inhibitor manufacturer and exporter in India, ICPL is committed to providing high-quality corrosion inhibitors that safeguard critical infrastructure, ensure operational reliability, and promote cost-effective maintenance practices. With ICPL's expertise, customized solutions, and global reach, industries can effectively mitigate the risk of corrosion and preserve the integrity of their assets for years to come. Contact ICPL today to learn more about our corrosion inhibitor products and solutions.

#Corrosion inhibitor Vadodara#Best chemical company in Vadodara#Corrosion Inhibitor exporter in India#Corrosion inhibitors manufacturer in India#Oxygen scavenger Chemical in Vadodara#Oxygen scavenger Chemical supplier in Gujarat#Oxygen scavenger Chemical Manufacture India#Oxygen scavenger Chemical exporter in Gujarat#Oil and gas industry#Oil and gas companies#Oil and gas pipelines#leading Oilfield Chemicals manufacturer and exporter in India

7 notes

·

View notes

Text

Excerpt from this story from Inside Climate News:

Inside a cinder block office building perhaps best known for the Hindu temple and table tennis club next door, a startup company is testing what may be one of the hottest new developments in clean energy technology.

At the back of a small warehouse laboratory buzzing with fans and motors, an MIT spinoff company called Electrified Thermal Solutions is operating something its founders call the Joule Hive, a thermal battery the size of an elevator.

The Hive is a large, insulated metal box loaded with dozens of white-hot ceramic bricks that convert electricity to heat at temperatures up to 1800 degrees Celsius—well beyond the melting point of steel—and with enough thermal mass to hold the heat for days.

As the price of renewable energy continues to plummet, one of the biggest challenges for the clean energy transition is finding a way to convert electricity to high temperature heat so societies don’t have to continue burning coal or natural gas to power heavy industries. Another thorny issue is finding a way to store energy—in this case heat—for when the sun doesn’t shine and the wind doesn’t blow.

“If you are running an industrial plant where you’re making cement or steel or glass or ceramics or chemicals or even food or beverage products, you burn a lot of fossil fuels,” Daniel Stack, chief executive of Electrified Thermal Solutions, said. “Our mission is to decarbonize industry with electrified heat.”

The industrial sector accounts for nearly one-fourth of all direct greenhouse gas emissions in the U.S., which drive climate change, according to the EPA. Thermal batteries powered by renewable energy could reduce roughly half of industry’s emissions, according to a 2023 report by the Center for Climate and Energy Solutions, a nonprofit, and its affiliated Renewable Thermal Collaborative.

Additional emissions come from chemical reactions, such as carbon dioxide that is formed as an unwanted byproduct during cement production, and from methane that leaks or is intentionally vented from natural gas pipes and other equipment.

The challenge to replacing fossil fuel combustion as the go to source for heat, is that there aren’t a lot of good options available to produce high temperature heat from electricity, Stack said. Electric heaters, like the wires that turn red hot in a toaster, work well at low temperatures but quickly burn out at higher temperatures. Other, less common materials like molybdenum and silicon carbide heaters can withstand higher temperatures, but are prohibitively expensive.

As a grad student at MIT, Stack wondered if firebricks, the bricks commonly used in residential fireplaces and industrial kilns, could be a less expensive, more durable solution. Bricks do not typically conduct electricity, but by slightly altering the recipe of the metal oxides used to make them, he and ETS co-founder Joey Kabel were able to create bricks that could essentially take the place of wires to conduct electricity and generate heat.

“There’s no exotic metals in here, there’s nothing that’ll burn out,” Stack said standing next to shelves lined with small samples, or “coupons,” of brick that he and his team have tested to find the ones with the best heating properties.

5 notes

·

View notes

Text

MS ERW B/Weld Reducer Eccentric at Best Price in India

In the dynamic world of industrial piping, efficiency and reliability are paramount. The MS ERW (Electric Resistance Welded) Butt Weld Eccentric Reducer plays a crucial role in connecting pipes of different diameters while ensuring optimal fluid flow. If you're in search of the best prices for MS ERW B/Weld Eccentric Reducers in India, look no further than Udhhyog, your trusted supplier.

What is an MS ERW B/Weld Eccentric Reducer?

An MS ERW B/Weld Eccentric Reducer is a specialized fitting designed to connect pipes of varying sizes. Unlike concentric reducers, which maintain a circular profile, eccentric reducers feature a flat edge on one side. This design is essential for preventing sedimentation in applications where solids may accumulate, making them ideal for use in wastewater systems and other similar setups. The robust construction and butt-welded design provide a secure, leak-proof connection suitable for high-pressure environments.

Key Features of MS ERW B/Weld Eccentric Reducers

Efficient Fluid Flow: The eccentric design minimizes turbulence and ensures a smooth transition between pipe sizes, facilitating better flow rates.

Durable Material: Crafted from high-quality mild steel, these reducers are built to withstand harsh operating conditions, including high pressures and temperatures.

Leak-Proof Connections: The butt weld design ensures a secure joint that significantly reduces the likelihood of leaks.

Versatile Applications: Suitable for a range of industries, including oil and gas, water treatment, and chemical processing.

Cost-Effective Solution: Offering exceptional quality at competitive prices, these reducers are an economical choice for industrial applications.

Applications of MS ERW B/Weld Eccentric Reducers

Wastewater Management: Eccentric reducers are particularly useful in wastewater applications, where preventing sediment buildup is crucial for maintaining system efficiency.

Oil and Gas Pipelines: These fittings provide seamless transitions in pipelines, ensuring pressure integrity and fluid management.

Chemical Processing: In chemical plants, they help maintain efficient fluid transitions, facilitating various processes with minimal disruption.

HVAC Systems: Eccentric reducers are often used in HVAC systems to ensure balanced airflow and effective pressure control.

Why Choose Udhhyog for MS ERW B/Weld Eccentric Reducers?

At Udhhyog, we pride ourselves on being a leading supplier of MS ERW B/Weld Eccentric Reducers at the best prices in India. Here’s why you should partner with us:

Quality Manufacturing: Our reducers are produced under strict quality control measures to meet industry standards, ensuring you receive top-tier products.

Affordable Pricing: We are committed to providing high-quality products without breaking your budget, making us the go-to supplier for industrial fittings.

Prompt Delivery: Located in Delhi, we offer timely delivery services across India, ensuring your projects remain on schedule.

Extensive Product Range: Beyond eccentric reducers, we offer a wide selection of industrial fittings, flanges, and valves to cater to all your piping needs.

Dedicated Customer Support: Our team is focused on understanding your specific requirements and delivering tailored solutions to enhance your operational efficiency.

Order Your MS ERW B/Weld Eccentric Reducers Today

Choosing Udhhyog as your supplier for MS ERW B/Weld Eccentric Reducers means gaining access to high-quality products at the best prices in India. Whether you're involved in large-scale industrial projects or specific applications, we are here to support your needs with reliable and effective solutions.

#MSErwEccentricReducer#PipeFittings#IndustrialPiping#Udhhyog#EccentricReducerIndia#BestPriceIndia#DelhiSupplier#SteelPipeFittings#CostEffectiveSolutions#MSPipeFittings

2 notes

·

View notes

Text

MS Eccentric Reducer-Trusted Supplier in India

An MS Eccentric Reducer is a crucial pipe fitting used to connect pipes of different diameters, with an offset centerline, commonly used in industries such as oil & gas, water treatment, and chemical processing. The eccentric design ensures that the reducer prevents air pockets, making it ideal for horizontal piping systems. This fitting is essential for maintaining fluid flow efficiency while preventing the accumulation of gases in the pipeline.

Features of MS Eccentric Reducers

Material: Made from high-quality mild steel (MS), known for its strength, durability, and corrosion resistance.

Eccentric Design: The offset centerline design helps in the smooth transition of fluids and prevents air pockets in horizontal pipelines.

Butt Weld Connection: Ensures a strong, leak-proof, and seamless connection between pipes.

Versatility: Suitable for use in various industrial applications such as fluid transfer, oil and gas pipelines, and chemical processing plants.

Benefits of Using MS Eccentric Reducers

Durability: Mild steel construction ensures long-lasting performance, even in challenging industrial environments.

Leak-Proof Design: The butt weld connection ensures a secure and leak-free joint, essential for safety and efficiency.

Smooth Flow: The eccentric design maintains a smooth fluid flow, reducing the risk of turbulence and air blockages.

Cost-Effective: MS eccentric reducers offer a cost-effective solution for connecting pipes of different diameters, providing excellent value for money.

Choosing a Trusted Supplier for MS Eccentric Reducers in India

When selecting a reliable supplier of MS Eccentric Reducers in India, you should consider the following factors:

Product Quality: Ensure that the supplier provides products that meet industry standards and are manufactured using high-quality materials.

Competitive Pricing: Look for suppliers offering cost-effective solutions without compromising on product quality.

Timely Delivery: Fast and reliable delivery is crucial to ensure that your project timelines are met.

Customer Support: A supplier with excellent after-sales support can help you address any concerns promptly.

Udhhyog – Trusted Supplier of MS Eccentric Reducers in India

Udhhyog is a leading B2B platform for industrial steel products, specializing in the supply of MS Eccentric Reducers at competitive prices. With a strong reputation for quality and reliability, Udhhyog is the go-to choice for businesses across India. Here’s why:

Top-Quality Products: We provide MS eccentric reducers that meet industry standards and are built to last.

Competitive Prices: Udhhyog offers some of the best prices in India, ensuring affordability without compromising on quality.

Reliable Delivery: We ensure timely and efficient delivery, so your project deadlines are never compromised.

Excellent Customer Service: Our team is dedicated to providing exceptional customer support and after-sales assistance, ensuring a smooth purchasing experience.

For more information or to buy MS Eccentric Reducers, visit Udhhyog's website and explore our extensive range of industrial fittings at competitive prices.

2 notes

·

View notes

Text

Ensuring Safety: The Importance of Gas Detectors in Malaysia's Industrial Sector

As Malaysia continues its rapid industrialization, workplace safety has become an increasingly important priority for industries and regulatory authorities alike. Among the most critical tools in ensuring workplace safety are gas detectors—devices that monitor and alert workers to the presence of hazardous gases. These detectors are indispensable in industries where toxic or flammable gases are produced or used, including oil and gas, chemical manufacturing, mining, and construction.

Malaysia's industrial sector has witnessed significant growth, making it crucial to address occupational safety issues more robustly. Gas detectors can save lives, protect infrastructure, and prevent environmental damage. This article explores the importance of gas detectors in Malaysia's industrial sector, emphasizing their role in enhancing safety, complying with regulations, and protecting workers.

Understanding the Risks in Malaysia's Industrial Sector

Industries across Malaysia operate in environments where hazardous gases are common. Whether it's the risk of explosions in refineries or toxic gas leaks in manufacturing plants, these gases pose serious risks to workers, machinery, and the surrounding environment. In many cases, hazardous gases like carbon monoxide (CO), methane (CH4), hydrogen sulphide (H2S), and volatile organic compounds (VOCs) are colourless, odourless, and difficult to detect without the aid of specialized equipment.

For example, hydrogen sulphide, commonly found in the oil and gas industry, can be lethal in small concentrations. Prolonged exposure to low levels can cause eye irritation, headaches, and respiratory issues, while high-level exposure can result in unconsciousness or even death. Similarly, methane, often encountered in mining and waste management, is highly flammable and can cause catastrophic explosions if not detected in time.