#Fluke Calibration

Explore tagged Tumblr posts

Text

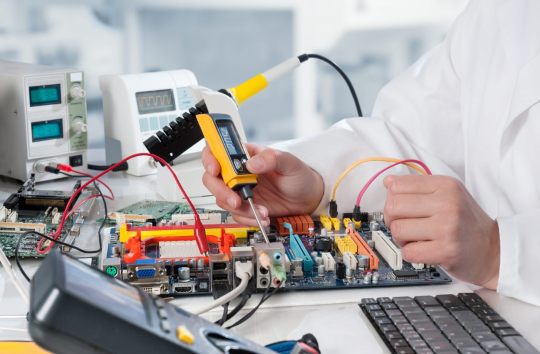

A Fluke Battery Analyser is a diagnostic tool used to evaluate and test the performance of batteries, particularly in large-scale industrial and critical backup systems. Fluke, a well-known brand in the field of electrical testing and measurement tools, designs these analysers to provide accurate and reliable assessments of battery health, which is vital for ensuring the proper functioning of devices that depend on battery power.

Key features of a Fluke Battery Analyser typically include:

Battery Testing: It evaluates the condition of individual battery cells or entire battery banks by testing parameters such as voltage, internal resistance, and capacity. This helps identify weak or failing cells that could affect the performance of the system.

Monitoring and Analysis: The tool allows for continuous or periodic monitoring of battery performance, generating reports and data trends over time. This can help in predictive maintenance by detecting potential issues before they cause system failures.

Measurement of Key Parameters:

Voltage: The analyser measures the voltage of the battery or battery bank, which is an essential indicator of charge level and health.

Internal Resistance: This is a critical factor that indicates the battery’s ability to deliver current. High resistance can point to degradation or aging.

Capacity Test: The analyser may also assess the remaining capacity of the battery, helping to estimate how long it will last under load.

Data Logging and Reporting: The analyser often includes a feature for storing and exporting test results for further analysis or record-keeping. This helps technicians track the performance of battery banks over time.

Application: Fluke Battery Analysers are primarily used in uninterruptible power supply (UPS) systems, telecom equipment, energy storage systems, and other critical infrastructure that rely on batteries for backup power.

By providing an in-depth analysis of battery performance, the Fluke Battery Analyser helps prevent unplanned outages, extend battery life, and ensure the safety and reliability of electrical systems that depend on battery power.https://sapphire-tech.com/product-category/fluke-battery-analyser/

0 notes

Text

Why Instrument Certification Matters for Your Business

Instrument is a crucial aspect of ensuring the quality, safety, and reliability of the tools and equipment used in your business operations. Whether you're in the manufacturing, construction, healthcare, or any other industry, having certified instruments can make a significant difference in the efficiency and accuracy of your processes.

In this blog, let's delve into the reasons why certification matters for your business, and how it can impact your overall operations and reputation. Whether you're a small business owner or a large corporation, understanding the importance of certified Instrument calibration services is essential for maintaining standards and meeting regulatory requirements.

Ensuring Accuracy

The certification ensures that your business meets industry standards and regulations, minimising the risk of non-compliance. Certified instruments provide accurate and reliable results, helping you make informed decisions for your business operations. Having certified instruments can enhance the credibility of your business, showing clients and partners that precision is a top priority.

The certification contributes to maintaining consistent quality in your products and services, building trust with your customers. This certification is not just a box to tick; it's a valuable investment in the long-term success and reputation of your business.

Compliance with Standards

Compliance with standards through instrument is crucial for your business. It guarantees that your equipment meets legal requirements, safeguarding your business from potential fines or penalties. Certified instruments also help demonstrate to regulatory authorities that your business adheres to necessary industry standards and guidelines, creating a solid foundation for sustainable growth.

Moreover, ensuring compliance through certification reflects positively on your brand's reputation, signalling reliability to both customers and stakeholders. This not only enhances your credibility but also builds trust with your customers, contributing to the long-term success and reputation of your business.

Precision and Reliability

Instrument assures the precision and reliability of measurements, fostering confidence in the accuracy of your processes and products. With certified instruments, you can avoid costly errors or rework by maintaining high levels of precision in all aspects of your operations. The precision guaranteed by certification can result in improved efficiency and cost savings for your business over time.

Reliable measurements achieved through instrument are essential for delivering consistent quality to meet customer expectations. Having certified instruments can enhance the credibility of your business, showing clients and partners that precision is a top priority and contributing to the long-term success and reputation of your business.

Legal Requirements

Instrument ensures compliance with legal standards and regulations, reducing the risk of penalties or legal issues. Certification provides a level of assurance to customers and stakeholders that your business operates within the bounds of the law. By obtaining certification for your instruments, you demonstrate a commitment to upholding industry-specific legal requirements and standards.

Having certified instruments can contribute to building a trustworthy and reputable brand image, which is essential for long-term success in business. This commitment to compliance not only safeguards your business from potential fines and penalties but also enhances your credibility and builds trust with your customers and partners, laying a strong foundation for sustainable growth and success.

Liability Protection

Instrument can mitigate potential liability risks by ensuring that your equipment meets safety and quality standards. In the event of an incident, certified instruments may provide a layer of protection by demonstrating adherence to established safety protocols. Certification helps establish a clear record of due diligence, which can be invaluable in liability cases or insurance claims.

When instruments are certified, it indicates that they have undergone thorough testing, reducing the likelihood of malfunctions that could lead to liability issues. This level of certification offers peace of mind and a solid defence against potential liabilities for your business operations.

Regulatory Compliance

Instrument is crucial for meeting industry-specific regulatory requirements, preventing non-compliance fines and repercussions. Maintaining certified instruments streamlines the process of fulfilling regulatory obligations, saving time and resources in the long run. Certification demonstrates proactive efforts to comply with evolving regulations, contributing to a positive relationship with regulatory authorities.

Failure to adhere to regulatory compliance can tarnish your business's reputation and result in severe consequences, making certification imperative. Having certified instruments not only ensures compliance but also reinforces your commitment to upholding the highest standards in your industry.

Quality Assurance

Instrument plays a crucial role in ensuring that your business meets industry standards and regulations for quality assurance. Certified instruments provide accurate and reliable data, contributing to the overall quality of your products or services.

With instrument certification, you can build trust with your customers by demonstrating a commitment to delivering high-quality and reliable results. Additionally, compliance with certification requirements helps to mitigate potential risks and liabilities, safeguarding your business reputation and providing peace of mind to your customers.

Customer Trust

Instrument plays a vital role in assuring your customers that the measurements and tests conducted by your business are precise and trustworthy, increasing their confidence in your offerings. By investing in certification, you demonstrate a steadfast commitment to upholding integrity and transparency in all facets of your business operations.

Customers are inclined to choose a certified business over non-certified competitors, perceiving it as a symbol of reliability and professionalism. Prioritising instrument not only leads to increased customer satisfaction and loyalty but also fosters long-term relationships with your client base, ultimately contributing to the sustained success of your business.

Consistent Performance

Consistent performance is a key advantage of instrument. Certified instruments contribute to consistent performance by providing accurate results time after time, minimising variability and errors.

Through regular certification maintenance, you can ensure that your instruments continue to perform optimally, supporting consistent quality outputs. This reliability achieved through certification translates into improved operational efficiency and reduced rework or product failures, giving you a competitive edge in the market and setting you apart as a dependable choice for clients.

Final Thoughts

Certification is not just about meeting legal requirements; it is about building a trustworthy brand image and ensuring precision, reliability, and compliance with industry standards. By prioritising Fluke Meter Calibration Services, businesses can mitigate liability risks, maintain regulatory compliance, and assure customers of the quality and consistency of their products and services.

Investing in instrument not only safeguards businesses from potential fines and penalties but also enhances credibility, builds trust, and fosters long-term relationships with clients. Ultimately, certification is a crucial investment for sustainable growth and long-term success in the business world.

0 notes

Text

Thank you for leaving these tags @pharawee! Without getting into any speculation about how Dead Friend Forever will actually end, I do want to address your question and talk about why most of us want to see severe consequences for these boys. The short answer: it's about genre expectations and the psychological catharsis of a good revenge narrative.

To get down to the really basic point: people who love revenge thrillers love them because they are a fantasy construct in which good people survive and bad people get what they deserve. In a world where bad things happen and we rarely have any control, a good revenge story can be exhilarating, giving you the feeling that justice prevailed, villains received appropriate comeuppance for their wrongs, and the protagonist seized control back and experienced much needed catharsis for their suffering. Real life is very much not like this, which is why it's such an appealing genre of fiction.

So how do we calibrate what "appropriate comeuppance" means? This is where genre expectations become really important, because the genre the revenge narrative plays out in sets the terms for where that bar sits. In The Glory, a recent world class revenge drama, we were in the psychological thriller genre, so revenge came in the form of Dong Eun playing mind games with her bullies until they destroyed their own lives. No murder necessary. Dead Friend Forever, however, is in the horror genre, and specifically began its story by planting itself in the slasher subgenre, giving us a masked killer and setting up expectations that these boys are being hunted. When you watch a slasher, you come in with the mindset that most of the characters are going to die and begin rooting for it and looking for reasons why they "deserve" it. And typically, in a slasher, it takes very little for a character to "deserve" a death--you often see people die for the tiniest infractions, like making a rude comment, telling a bad joke, or having sex. But DFF went much farther than that and gave us a multi episode flashback in which we got a detailed accounting of every wrong this group of boys committed against Non, increasing the audience's bloodlust and conviction that these boys needed to pay.

So why do so many of us want the bullies to die? Because the genre demands it, and the story set the audience up to expect it from the outset. I have seen some discussion of the way the show is blending different horror subgenres and not sticking strictly to typical slasher conventions, and that's true, and expected. Slashers are usually two hours max, and this show needed to fill 10+ hours of content, so it's doing a really interesting blend of slasher, mystery, psychological thriller, and other horror subgenres. But the bones of the story still hold, and despite the storytelling choice to give the villains some nuance and fleshed out motivations for their behavior, they are still villains who destroyed Non's life. If you're feeling overly sympathetic to any of these boys at present, I encourage you to go back and remind yourself how they behaved in the early episodes of this story, which took place after the events of the flashbacks. These are not genuinely remorseful kids who made minor mistakes and then got their acts together and became upstanding citizens; they just want to move on and avoid blame and accountability for what they did, while Non's entire family was irrevocably destroyed by their actions.

If this story ends without Por, Tee, Top, Fluke, Jin, and Phee suffering genre appropriate consequences for their choices that harmed and betrayed Non, it will be a letdown and many will feel unsatisfied. In real life, we may believe that forgiveness is the right path, and we know that Buddhism teaches unconditional forgiveness. But this is not real life. This is a fantasy genre that is specifically meant to provide an escape from the constraints of real life morality and obligations. No one wants to show up to a fantasy party only to receive a moral scolding. The most disappointing thing a revenge narrative can do is wimp out on delivering the actual revenge.

#hope this helps!#i think folks coming to this show mostly from a bl lens and not grounded in horror genre might have a harder time with this#dead friend forever#dff the series#shan shouts into the void#thai bl

159 notes

·

View notes

Text

Thought Dump about YM and being heir, and some other stuff.

The circumstances in which YM got declared heir is a whole nother long-ass post in itself, but I do think the starting trouble of his heir-dom is both that he represents a Lot™ as far as the von Valancius dynasty goes and the choice to foist that on him was mostly a rash decision Casimira made before he was born and now they're both stuck with it because by the time she started to reconsider it was far too late.

Like, being a regular Rogue Trader's heir is a lot of pressure, but he is also the first von Valancius born in the Expanse for at least the last 3-400 years (Theodora being from Scarus and Casimira being Calixian), the first heir born after his dynasty became the most powerful one in the region, and (quietly) a living result of his mom's particular policies regarding Aeldari.

Which is a lot even without even without factoring in parental issues! And no doubt the above became a factor that contributed to Cas deciding not only to publicly make him heir presumptive but also go out of her way to have the "Royal Baby Legitimacy Experience" (with plenty of bribes and negotiations under the table) on Dargonus. Which, barring some quarrels about not having him be born in the capitol world, worked very well in signifying the continuation of the dynasty etc etc.

But at the same time being an only child and heir presumptive kinda did mess him up in a way that definitely isn't helpful to making him want to be heir. Because Cas is very disdainful of hereditary nobility without merit, and inasmuch as Cas' protective shield of exceptionalism extends to her son, YM does on some level recognize he is the very type of person his mom would usually be bitching about after a long day at court. And so, like both his parents, he tends to draw on his origins as a form of self-justification but unlike his parents he doesn't yet have any big deeds to back up that self-belief and therefore deepens his own anxiety around failure because if he's not careful he rationalizes himself into being the thing he's scared of being.

Another "not helping" thing is that Cas learned how to be Rogue Trader by trial and error but doesn't really want YM to have to do that yet. So she gets big on him having a formal Noble Education so that he'll have a good base to work with, despite that fact that he is her and Marazhai in all the ways most calibrated to frustrate her and so doesn't take to hardly any of them. Not because he's not smart enough to grasp the material, but because neither of his parents had to sit in school like this and they turned out fine, so why should he care about Administratum procedures when he could be out in the Heathen Stars adventuring or something? The underside of this is also avoidance, in that failing these things are also a reflection on him so to get out of being "the Heir who tried and failed Administratum Procedures 101" its best to blow it off entirely. Which irritates his mom, because while she understands his wanting to go out and learn the hard way, the tedious shit is important too and its not boding well that it doesn't seem that he sees that. And thus the eternal war of "Im too good for this" and "I'm failing" continues eternal.

Having parents with very different timescales also doesn't help, nor does the fact that his mom and direct comparison point is kind of a fluke. Like on the one hand his young adult years mean nothing to Aeldari in total lifespan so he has time, on the other hand his mother was ruling a large chunk of the Independent Expanse by her early-to-mid thirties, Realspace Time. So being in his twenties and still not even having command of his own ship stings.

Making Marazhai more explicitly a Corsair Prince in my canon does offer a lot more when it comes to "what could've been" for YM. Because by the mere fact of his existence he was never going to be a bastard with nothing. There is a potential future (and one he'd probably like more) where he was just Cas' bastard and was Marazhai's heir presumptive. He wouldn't have the same cushy future job security for sure but the role might have fit his temperament better. Or he would just inherit a different flavor of parental issues and long to be a Rogue Trader's heir. Who knows.

Heir blues aside, YM also does have a perfectly calibrated "fucking with my parents" gene and makes it his business to cultivate a circle of "not necessarily harmful but personally irritating" set of friends and acquaintances to be on hand for social occasions where annoying either parent is the goal.

One of his "learning how the Administratum works" lessons was absolutely getting Jae the renewal of her Mercatum Tabular Rasa. It was a success....ignoring suspicious blood stains and the disappearance of a particularly annoying clerk.

During his eventual Gap Decade with Marazhai he probably gets some training from a Void Dreamer, a type of Aeldari Corsair Psyker that helps ships navigate both Warp and Webway. This solves one of the bigger problems in his life, being that he can't totally atrophy his abilities to the same extent as a Drukhari but following a Path like an Asuryani would send Marazhai into a fit. Void Dreamers, being adept at Warp travel, would be able to help him manage his senses during longer Warp Jumps without necessarily having to resort to violence.

#its been a big week for Trashcan Baby thoughts so#YM#beloved godparent Kate Poetikat wants him out the toddler gate so#ezhan von valancius

6 notes

·

View notes

Note

hey ma'am, i just finished the last evaluation of the last project/course of my bachelor's degree. from what i'm hearing, i should pass.

i went from utterly fucking up my grades when my college started during covid to slowly clawing it back to something semi respectable (not good enough though, i fucked up too hard during 2020-2021). i also did it my way. i am proud of that.

i'll now have to take the next steps to try to get further education, and it's honestly terrifying. i am scared. heart feels hollow. eyes want to water. i still don't know if all of this wasn't just a fluke. too many things in my head.

it's not something i need to work on right this second (this is a problem for me a week in the future probably, hurrah!), and i am about to drown my fear in a bunch of lewd skyrim, but still.

may i please have some praise?

That's wonderful news! You were in school at the absolute worst possible time in decades, and now you're on the other side of it with your degree. You should be proud to be where you are. It's not a fluke; it's overcoming a tsunami of adversity. If you told me your grades hadn't suffered during Covid I would have called you a liar.

My own journey to a BA was belabored and marred by circumstances as well, so I understand how you're feeling right now. It takes a minute to break out of that marathon mindset even after you've crossed the finish line. You've done a wonderful job and there are good things ahead of you. Take some time to rest, re-calibrate, and enjoy this because you deserve it 💜

4 notes

·

View notes

Text

DEWALT Power Tools and Fluke Testing Equipment Distributor in Dubai, UAE — AABTools

In the ever-evolving industrial landscape of the UAE, having access to reliable tools and testing equipment is essential for ensuring efficiency, safety, and quality across various sectors. Whether you’re in construction, manufacturing, or maintenance, AABTools stands out as a trusted distributor of DEWALT power tools and Fluke testing equipment in Dubai and the UAE. With a reputation for delivering top-tier products and comprehensive support, AABTools has become the go-to choice for professionals and businesses alike.

Why Choose AABTools for DEWALT Power Tools?

DEWALT is a global leader in power tools, known for its innovation, durability, and precision. From heavy-duty drills and saws to high-performance grinders and sanders, DEWALT’s product line is designed to meet the demands of professionals in industries such as construction, woodworking, and metalworking. AABTools, as an authorized distributor, ensures that you have access to the latest DEWALT tools, accompanied by warranties and after-sales services.

Here’s why you should consider AABTools for your DEWALT tool needs:

Wide Range of Products: AABTools offers a full range of DEWALT tools, from cordless drills to impact drivers and cutting-edge saws.

Genuine Products: As an authorized distributor, you are guaranteed genuine DEWALT products, providing long-term durability and performance.

Expert Advice and Support: AABTools’ experienced staff can guide you in selecting the right tools for your project, ensuring optimal results.

After-Sales Service: AABTools not only sells DEWALT tools but also provides maintenance and repair services to keep your tools running at peak performance.

Fluke Testing Equipment — Precision for Professionals

When it comes to testing and measurement equipment, Fluke is an industry leader, trusted by electricians, technicians, and engineers worldwide. From digital multimeters and thermal imaging cameras to calibration tools and electrical testers, Fluke equipment ensures accuracy and safety in critical industrial processes. AABTools brings these advanced tools to the UAE market, ensuring professionals have the precision tools they need for reliable diagnostics and testing.

Here’s why AABTools is your best choice for Fluke testing equipment in Dubai:

Comprehensive Range: AABTools offers a wide selection of Fluke products, covering everything from basic multimeters to advanced calibration and thermal imaging tools.

Enhanced Accuracy: Fluke’s equipment is designed for professionals who need precise measurements to ensure safety and compliance.

Robust Support: With AABTools, you’re not just purchasing equipment; you’re gaining access to technical support, product training, and calibration services that ensure your tools are used effectively.

AABTools — Your Partner for Industrial Success

AABTools is more than just a distributor — it’s a partner in helping you achieve industrial excellence. By offering both DEWALT power tools and Fluke testing equipment, AABTools supports businesses in the UAE with comprehensive tool and equipment solutions.

Convenient Locations: AABTools has multiple outlets in Dubai and across the UAE, making it easy for customers to access products and services.

Competitive Pricing: AABTools ensures you get the best value with competitive pricing on all DEWALT and Fluke products.

Customer-Centric Approach: Whether you’re a large corporation or an individual contractor, AABTools delivers personalized service to meet your specific needs.

Conclusion

Choosing AABTools as your supplier of DEWALT power tools and Fluke testing equipment in Dubai guarantees reliability, precision, and excellent service. As a leader in the industrial tools market, AABTools provides top-tier products, professional advice, and unbeatable after-sales support. Whether you’re looking to upgrade your tools or ensure accuracy in your testing equipment, AABTools has the expertise and inventory to meet your requirements.

For more information on DEWALT tools and Fluke equipment in Dubai, visit AABTools or reach out to their customer service team today!

0 notes

Text

Fluke Temperature Calibration: Precision Tools for Accurate Results

The Fluke Temperature Calibration tools offer industry-leading accuracy and reliability for all your temperature calibration needs. Designed to meet the rigorous demands of industrial environments, these calibration instruments ensure precise measurements and optimal performance. Whether you're working in laboratories, manufacturing, or process industries, Fluke’s advanced calibration solutions help maintain consistency and compliance in temperature-sensitive applications.

0 notes

Text

Blackbody Calibrator Market Overview and Growth Dynamics 2024 - 2032

The blackbody calibrator market plays a crucial role in ensuring accurate temperature measurement and calibration across various industries. This article delves into the market dynamics, key players, applications, and future trends of blackbody calibrators.

Introduction to Blackbody Calibrators

A blackbody calibrator market is a device used to provide a stable and reproducible source of thermal radiation. It simulates an ideal black body by emitting radiation in a manner that is predictable and consistent. These devices are essential in calibrating infrared thermometers and thermal cameras, making them vital in various sectors including aerospace, automotive, and medical imaging.

Definition and Functionality

Blackbody calibrators operate on the principle of Planck’s law of black-body radiation. They are designed to reach specific temperatures and maintain thermal stability, allowing for accurate calibration of temperature-sensing instruments. By providing known radiation levels, they facilitate the comparison of measurements from various devices.

Market Overview

Current Market Landscape

The blackbody calibrator market has experienced steady growth due to increasing demand for precise temperature measurement in numerous applications. The rise of automation and the growing importance of quality control in manufacturing have further propelled the market.

Key Drivers

Technological Advancements: Innovations in calibration technologies have enhanced the performance and accuracy of blackbody calibrators.

Industrial Growth: Expansion in sectors such as aerospace, automotive, and healthcare is driving the need for accurate temperature measurement.

Regulatory Standards: Stricter regulations regarding quality assurance and safety in manufacturing processes necessitate the use of reliable calibration devices.

Challenges

Despite its growth, the market faces challenges such as high initial costs and the need for specialized training to operate advanced calibrators. Additionally, the availability of alternative calibration methods can impact market growth.

Key Players in the Blackbody Calibrator Market

Leading Companies

Fluke Corporation

Offers a range of high-quality blackbody calibrators known for their precision and reliability.

Calorimetry

Specializes in advanced calibration solutions, including portable blackbody calibrators for field applications.

Omega Engineering

Provides a variety of calibration equipment, including infrared blackbody sources.

Competitive Landscape

The blackbody calibrator market is characterized by a mix of established players and new entrants. Companies are focusing on product innovation, strategic partnerships, and expansions to enhance their market presence.

Applications of Blackbody Calibrators

Aerospace and Defense

In the aerospace sector, blackbody calibrators are essential for testing and calibrating thermal imaging systems used in aircraft and satellite technologies. Accurate temperature measurement is critical for ensuring safety and operational efficiency.

Automotive Industry

Automakers use blackbody calibrators to validate thermal sensors in vehicles, ensuring that engine and cabin temperature measurements are accurate. This contributes to improved vehicle performance and passenger comfort.

Medical Imaging

In the healthcare industry, blackbody calibrators are used in thermal imaging systems for diagnostic purposes. Accurate temperature measurements are vital for detecting anomalies and ensuring patient safety.

Future Trends in the Blackbody Calibrator Market

Growth Opportunities

The market for blackbody calibrators is expected to grow as industries continue to emphasize precision measurement and automation. The integration of IoT and AI technologies into calibration processes could lead to smarter and more efficient calibrators.

Regional Analysis

North America: Dominates the market due to advanced industrial infrastructure and high demand for precise calibration.

Asia-Pacific: Anticipated to witness significant growth due to rapid industrialization and increasing investments in manufacturing technology.

Conclusion

The blackbody calibrator market is poised for substantial growth driven by technological advancements and increasing demand for accurate temperature measurement across various industries. As regulations tighten and industries evolve, the importance of reliable calibration solutions will continue to rise, shaping the future of the blackbody calibrator market.

#Blackbody Calibrator Market Size#Blackbody Calibrator Market Trend#Blackbody Calibrator Market Growth

0 notes

Text

Learning More About Fluke Process Calibration Tools

http://dlvr.it/TB1KBQ

0 notes

Text

Reference Thermometers Market Analysis 2023 Dynamics, Players, Type, Applications, Trends, Regional Segmented, Outlook & Forecast till 2033

Reference Thermometer Market is projected to surpass value of USD 12.9 Billion by the end of 2028, Expected To reach at USD 15.92 Billion in 2032, grow at a CAGR of 5.4% from 2022 to 2032.

The competitive analysis of the Reference Thermometers Market offers a comprehensive examination of key market players. It encompasses detailed company profiles, insights into revenue distribution, innovations within their product portfolios, regional market presence, strategic development plans, pricing strategies, identified target markets, and immediate future initiatives of industry leaders. This section serves as a valuable resource for readers to understand the driving forces behind competition and what strategies can set them apart in capturing new target markets.

Market projections and forecasts are underpinned by extensive primary research, further validated through precise secondary research specific to the Reference Thermometers Market. Our research analysts have dedicated substantial time and effort to curate essential industry insights from key industry participants, including Original Equipment Manufacturers (OEMs), top-tier suppliers, distributors, and relevant government entities.

Receive the FREE Sample Report of Reference Thermometers Market Research Insights @ https://stringentdatalytics.com/sample-request/reference-thermometers-market/10746/

Market Segmentations:

Global Reference Thermometers Market: By Company • WIKA • Peak Sensors • Fluke Calibration • Electronic Temperature Instruments • Thermco Products • ThermoProbe • ThermoWorks • Dostmann Electronic

Global Reference Thermometers Market: By Type • PRTs • Thermocouples • Precision thermistors Global Reference Thermometers Market: By Application • Laboratory • Industrial • Others

Regional Analysis of Global Reference Thermometers Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Reference Thermometers market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Reference Thermometers Market Research Report @ https://stringentdatalytics.com/purchase/reference-thermometers-market/10746/

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country ➋ Key winning strategies followed by the competitors ➌ Who are the key competitors in this industry? ➍ What shall be the potential of this industry over the forecast tenure? ➎ What are the factors propelling the demand for the Reference Thermometers? ➏ What are the opportunities that shall aid in significant proliferation of the market growth? ➐ What are the regional and country wise regulations that shall either hamper or boost the demand for Reference Thermometers? ➑ How has the covid-19 impacted the growth of the market? ➒ Has the supply chain disruption caused changes in the entire value chain? Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

Unlocking Efficiency: Optimizing Instrument Configuration for Success

Instrument configuration plays a crucial role in the success and efficiency of various industries. Whether it's the setup of machinery in a manufacturing plant or the configuration of software for data analysis, the way instruments are configured can significantly impact productivity and output.

In this comprehensive guide, we will delve into the intricacies of instrument configuration, its role in unlocking efficiency, and how optimising configuration can enhance overall performance for individuals and businesses alike.

Section 1: Understanding Instrument Configuration

Instrument configuration refers to the arrangement and setup of tools, equipment, or software to perform specific tasks. In various industries such as manufacturing, healthcare, engineering, and information technology, the configuration of instruments is pivotal in ensuring smooth operations and achieving desired outcomes. Optimal configuration directly impacts productivity, output quality, and resource utilisation.

The impact of optimal configuration on productivity and output is substantial. When instruments are configured efficiently, tasks are executed seamlessly, leading to streamlined processes and enhanced productivity. Moreover, a well-optimized configuration minimises errors and rework, thereby improving output quality. In essence, understanding instrument configuration is fundamental to maximising efficiency and overall performance.

Section 2: Assessing Current Configuration

Evaluating the current instrument setup is the first step towards identifying opportunities for improvement. It's essential to assess whether the existing configuration aligns with the operational requirements and goals of the organization. Key indicators of inefficiency or suboptimal performance may include bottlenecks in processes, frequent errors, or underutilization of resources.

To assess the current configuration effectively, it's important to consider factors such as compatibility, scalability, and alignment with industry standards. Additionally, gathering feedback from end-users and stakeholders can provide valuable insights into the practical aspects of the current configuration and its impact on operations.

Section 3: Identifying Improvement Opportunities

Identifying areas where configuration improvements can be made is a proactive approach towards enhancing efficiency. Tips for identifying improvement opportunities may include conducting thorough performance analyses, seeking input from subject matter experts, and staying informed about technological advancements that can optimise instrument configuration.

Proactive identification and addressing of potential issues can lead to substantial benefits. By staying ahead of operational challenges through continuous assessment and improvement, organisations can mitigate risks, enhance reliability, and maintain a competitive edge in their respective industries.

Section 4: Implementing Changes

Implementing changes to instrument configuration requires a strategic approach. Best practices include conducting a comprehensive impact analysis to assess the implications of proposed changes on various aspects of operations. Moreover, thorough documentation of the configuration adjustments and their rationale is essential for transparency and future reference.

Thorough testing and validation post-adjustments are critical to ensuring the stability and effectiveness of the new configuration. Rigorous testing protocols, user training, and contingency plans in case of unforeseen issues contribute to the successful implementation of changes.

Section 5: Monitoring and Maintaining Efficiency

Ongoing monitoring and maintenance of optimised configurations are vital for sustaining efficiency gains. Strategies for monitoring may involve automated performance tracking, periodic audits, and real-time analytics to identify deviations or performance trends. Regular reviews and updates to the configuration based on changing requirements or technological advancements are imperative for maintaining optimal efficiency.

Addressing the significance of regular reviews and updates to sustain efficiency gains is crucial. By staying proactive in monitoring and maintaining configurations, organisations can adapt to evolving needs, prevent performance degradation, and capitalise on opportunities for continuous improvement.

Conclusion

Optimising Fluke Meter Calibration services is a catalyst for success and efficiency across diverse industries. By understanding the role of configuration, assessing current setups, identifying improvement opportunities, implementing changes, and maintaining efficiency, individuals and businesses can unlock substantial benefits.

It's imperative to take proactive steps towards enhancing efficiency through configuration optimisation to stay competitive and achieve sustained success in a dynamic business landscape.

0 notes

Text

Fabi Lok Measuring and Control Equipment LLC, a premier provider of cutting-edge measuring and control solutions has now joined TradersFind! They offer a range of top-notch products, including Wika Pressure Gauges, Calibration Services, Fluke Calibrator, and Biohall GlassWare. Their commitment to quality and precision ensures each product meets the highest industry standards, empowering businesses with the best-in-class instruments. Click here to explore their superior-quality products and specialized services- https://www.tradersfind.com/seller/fabi-lok-measuring-and-control-equipment-llc

#fabilokllc#measuringequipment#controlsolutions#industrialsupplies#qualityinstruments#precisiontools#wikapressuregauges#calibrationservices#flukecalibrator#biohallglassware#industrialautomation#processcontrol#engineeringtools#manufacturingsupplies#qualityassurance#precisionmeasuring#uaebusiness#uaemanufacturing#uaetrade#uaesuppliers#uaeindustry#uaebrands#tradersfind#b2bportal

1 note

·

View note

Text

Sapphire Technologies is an authorized Fluke distributor in Bangalore. We are also authorized dealer of Honeywell Salisbury, Fluke Networks, Fluke Calibration, Amprobe & Kyoritsu in Bangalore & Hosur, Karnataka, India.

0 notes

Text

Guadalajara jalisco laboratorio de calibración

¿Cómo se mide la temperatura?

Los modelos de termopares se clasifican según el hilo metálico empleado en todos y cada pata del termopar. Termopares de metales nobles, incluidos los termopares de tipo S, tipo R, tipo Au/Pt y tipo Pt/Pd, en los termopares de metales nobles un hilo es siempre de platino. La clase de termopares de metales nobles incluye el tipo B, el tipo Y también , el tipo J, el tipo K, el tipo N y el tipo T. Estos termómetros se clasifican en dos clases de precisión distintas , con límites de error estándar y límites de fallo especiales. Los termómetros de la clase con límites de error especiales tienen una alta precisión de medición. La tabla de informaciones de los termopares llamados con símbolos de letras está en el sitio web del NIST o en la monografía 175 del NIST.

Lo que todo técnico debe saber sobre medición y medición de temperatura

Termopares - Termopares (TC)

Solución completa: La organización que elija debe tener una gama completa de artículos para agradar sus necesidades y opciones, de modo que pueda elegir el equipo que verdaderamente satisfaga sus requisitos, en vez de seleccionar entre la limitada gama de productos de que dispone. Si, en el futuro , quiere emplear un programa de programa de automatización para aumentar la productividad , recuerde que sólo va a estar vinculado a una organización, puesto que los programas de programa de automatización solo son correctos para los equipos de la organización a la que pertenecen.

En la Tabla 2 se equiparan las especificaciones propias de rango de medición, precisión y coste de los sensores de temperatura. Los costes de los sensores de medición precisa de la temperatura son superiores. Por norma general , la precisión de la medición puede verse comprometida en rangos de temperatura amplios.

La división Fluke Calibration fabrica los patrones de temperatura primarios que necesita para calibrar los sensores de temperatura, empezando por los baños de temperatura incesante y continuando con los baños de temperatura seca, que son extraordinariamente equilibrados y usados por los institutos nacionales de metrología. Para apps de termómetros de precisión, los termómetros y calibradores de Fluke Calibration son muy precisos y fáciles de usar. Los registradores de datos de humedad y temperatura de Fluke Calibration ponen fin al registro en papel.

¿Cuál es la precisión de medición necesaria?

Experiencia: Nadie puede esperar que se convierta en un especialista en medición de temperatura por sí solo. Posiblemente deba recurrir de manera directa a la experiencia de la organización de la que obtuvo el aparato , por lo que necesitará trabajar con una organización experta en medición de temperatura.

Precisión, repetibilidad y resolución de los termómetros

Lo que todo técnico ha de saber sobre medición y calibración de la temperatura

Lo que todo técnico ha de saber sobre medición y calibración de la temperatura

Determinar la precisión de los valores medidos por el instrumento de medida.

En la figura 2, los cables del termopar están conectados a conductores de cobre en la entrada de unión del termómetro, formando una unión de referencia (J). La temperatura del bloque de unión (TJ) suele medirse con un termistor y compensarse numéricamente. La precisión de medición de la unión de referencia es un factor que frecuenta perjudicar a la precisión de medición de la temperatura.

Las especificaciones de los termómetros para la medición y el control de la temperatura las determinan los ingenieros de diseño. Dentro de estas informaciones , asimismo debe especificarse la precisión del termómetro. El ingeniero de diseño, el ingeniero de calidad o el especialista en medición especifican los requisitos de calibración del termómetro. Se estima que la medición sea llevada a cabo por un técnico en instrumentación, y que este tenga suficientes conocimientos sobre los requisitos de calibración.

De este modo , se proporciona la suficiente profundidad de inmersión que se requiere para las sondas. En ciertos casos , ya que el diámetro de la tubería es limitante para una inmersión suficiente , si las vainas de los termómetros se montan en la tubería, la sonda de temperatura se sumergirá en paralelo a la dirección del fluido y se garantizará una profundidad de inmersión bastante.

Hay tres causas principales para calibrar un instrumento:

Los gadgets de medición y visualización de la temperatura suelen calibrarse por comparación con termómetros de referencia. La precisión de la medición mejora conforme disminuye la distancia entre los dos termómetros. El más destacable método para lograrlo es alinear los centros de los elementos sensores del termómetro de referencia y del termómetro que se está calibrando. Tenga presente que los puntos centrales de los sensores tienen la posibilidad de variar en función del tipo y modelo de sensor (como PRT, TC o sensores bimetálicos).

La unión formada por la soldadura de los extremos de 2 metales de aleaciones diferentes produce una pequeña señal de tensión proporcional a la temperatura, y semejantes sensores de temperatura se nombran Termopares-Termopares. Los termopares tienen dos uniones, una unión, llamada unión de medida, está situada en el punto final de la sonda del sensor, y la segunda unión, la unión de referencia, está conectada al instrumento de medida. El instrumento de medida mide 2 cosas el signo de tensión en el punto final del termopar y la temperatura en la unión de referencia. Calculando estos dos valores medidos, se calcula la temperatura en el punto final de la sonda. Hay que tener en cuenta que la señal de tensión producida por la sonda no es el valor absoluto de la temperatura del punto de medición, sino más bien la diferencia de temperatura entre el punto de medición y el de referencia.

Figura 1. Modelización del circuito del termopar: Los hilos A y B son de 2 metales distintas. T1 es la temperatura en la unión de medición y T2 es la temperatura en la unión de referencia. En este modelo, el valor de la tensión medida no es la tensión en el punto T1, sino la diferencia entre las tensiones en los puntos de medición y de referencia.

Acompañamiento : Aparte de la experiencia, es importante que tenga acceso a especialistas. Si puede conseguir respuesta a todas sus cuestiones por teléfono, es señal de que está tratando con una aceptable organización. Intente saber el tiempo medio de reparación, ya que es probable que se encuentre con retrasos esenciales si el equipo se envía a diferentes países para su reparación.

Hay muchos causantes que buscar en las organizaciones que dan soluciones para gadgets de medición. Ahora se hablan de algunos de ellos:

La existencia de una unión de referencia tiene un efecto positivo en la precisión de la medición de la temperatura del termopar, como se especifica en la monografía NIST 175, Tabla de termopares, la temperatura del punto de referencia es 0 ° C. Si se dispone de una unión de referencia externa, para ello se utiliza un baño de hielo, comunmente los termopares se conectan de manera directa a los plataformas de entrada del termómetro calibre, que están a temperatura ámbito. Así , el indicador de medición proporciona una compensación automática de la desviación del valor de referencia de unión 0°C a la temperatura ambiente.

La temperatura es quizás el factor físico más extensamente medido. Actualmente , la temperatura puede medirse de diversas formas. La disponibilidad de distintas opciones de medición plantea naturalmente una serie de cuestiones.¿De qué forma puedo medir la temperatura? ¿Qué precisión tienen mis mediciones? ¿Cuál es el mejor instrumento para medir la temperatura?¿Es necesario calibrar el aparato de medición?

Termistores

Aparte de la trazabilidad, en algunos casos , las organizaciones similares con la medición precisan acreditación. La acreditación garantiza que se cumplen los requisitos especialistas del servicio de calibración prestado mediante la app de programas y procedimientos correctos de calidad y capacitación. El certificado de calibración emitido por un laboratorio de medición acreditado lleva el logo del organismo de acreditación.

Los factores empleados con estas ecuaciones se determinan a lo largo del desarrollo de medición , y estos coeficientes se indican en las tablas de relación resistencia-temperatura de los informes de calibración. Ciertos PRT industriales económicos tienen la posibilidad de usarse sin calibración. Estos PRT deben ajustarse a reglas como IEC80751 o ASTM1137. Estas reglas especifican los coeficientes CVD y las tolerancias dependientes de la temperatura. Sin embargo , la precisión de las sondas puede mejorarse relevantemente a través de calibración.

Después de que el sensor de temperatura entre en contacto con la área cuya temperatura se quiere medir, es requisito esperar un tiempo a fin de que la temperatura se estabilice. A fin de que el termómetro se estabilice en la temperatura medida, la sonda debe sumergirse a una hondura suficiente. Ciertos termómetros requieren una mayor profundidad de inmersión. Por norma general , los termómetros de precisión tienen que sumergirse en un baño líquido o seco hasta una hondura de unos 15 cm (6 pulgadas); la profundidad de inmersión especificada varía en proporción al diámetro de la sonda. Para obtener una aceptable precisión y estabilidad en la medición, es necesario agitar el líquido cuya temperatura se desea medir. Gracias a las burbujas de aire que se forman entre la sonda y las superficies sólidas, el tiempo de equilibrio se prolonga , en un caso así es necesario sumergir la sonda a mayor hondura. Ciertos termómetros destacables realizan la medición desde la superficie , en ocasiones es imposible sumergir el cable de la sonda a mayor hondura pues no es compatible altas temperaturas.

La temperatura es quizás el factor físico más ampliamente medido. Actualmente , la temperatura puede medirse de distintas formas. La disponibilidad de distintas opciones de medición expone naturalmente una secuencia de preguntas.¿Cómo puedo medir la temperatura? ¿Qué precisión tienen mis mediciones? ¿Cuál es el más destacable instrumento para medir la temperatura?¿Es requisito calibrar el aparato de medición?

El NIST es el Centro Nacional de Metrología responsable de los patrones nacionales en Estados Unidos. La metrología es la ciencia de la medición y, además de la investigación básica en la materia, candela por la utilización conveniente de los instrumentos de medida en las mediciones similares con las actividades industriales, económicas, la salud pública y la seguridad laboral. La trazabilidad al NIST o a otro Centro Nacional de Metrología se consigue a través de la medición.

Si los termómetros miden frecuentemente valores fuera de tolerancia, deben aumentarse los intervalos de calibración o reemplazarse los termómetros. Para comprobar el desempeño de los termómetros en el periodo de calibración en curso y registrar su desempeño , se usa un baño de hielo o un punto triple de agua (TIP). De este modo , se evitan o limitan las lecturas fuera de tolerancia de los termómetros certificados de precisión y medición.

Según el enfoque general de medición , las incertidumbres de los patrones empleados en la calibración han de ser muy buenas con relación a la precisión del termómetro sometido a prueba. De esta manera , se evitan probables errores durante la comparación. Si en la práctica militar y otras prácticas industriales se especifica la Relación de Indecisión de Prueba (TUR) 4: 1, se entiende que la incertidumbre total de los patrones de medición es 4 veces mejor que la precisión especificada del termómetro sometido a prueba, la indecisión total del patrón usado es el 25% de la exactitud del termómetro sometido a prueba, si la Relación de Incertidumbre de Prueba (TUR) 2: 1, la indecisión total de los patrones de calibración es 4 ocasiones mejor que la precisión detallada del termómetro sometido a prueba: 1, la incertidumbre total de los estándares de medición es 2 ocasiones mejor que la precisión del termómetro bajo prueba que se está calibrando, la indecisión total del estándar usado es el 50% de la precisión del termómetro bajo prueba. Si el termómetro de referencia utilizado en la medición tiene la misma indecisión que el termómetro sometido a prueba que se va a calibrar, la relación de incertidumbre de la prueba (TUR) se expresa como 1:1 y no se recomienda pues se obtendrán desenlaces poco fiables.

La unión formada por la soldadura de los extremos de dos metales de aleaciones distintas genera una pequeña señal de tensión proporcional a la temperatura, y tales sensores de temperatura se denominan Termopares-Termopares. Los termopares tienen 2 uniones, una unión, llamada unión de medida, está ubicada en el punto y final de la sonda del sensor, la otra unión está situada en el bloque conector de entrada del indicio para proporcionar esta compensación, el termistor detecta la temperatura ámbito de hoy y proporciona la corrección necesaria para la medida de temperatura del termopar.

NIST y calibración

Termómetros de resistencia de platino

Acreditación: Si bien no tenga una solicitud de acreditación, trabajar con un desarrollador cuyo laboratorio de calibración esté acreditado le dará garantías. Como es sabido , un laboratorio con acreditación ISO 17025 es auditado técnica y organizativamente por especialistas en acreditación.

Para comprobar el desempeño energético de sistemas de vapor, torres de refrigeración, intercambiadores de temperatura, sistemas de refrigeración, turbinas, máquinas de combustión externa o interna, es requisito medir la diferencia entre las temperaturas de entrada y salida. Estas mediciones se realizan a veces con termopares, sensores de película fina o gadgets de medición de temperatura por infrarrojos por medio de tuberías. Para obtener desenlaces muy precisos, es requisito utilizar vainas termométricas en sitios correctos de la entrada y la salida.

Para la verificación y el ajuste de la temperatura de ultracongeladores, hornos, armarios de aire acondicionado, el termómetro se pone de forma directa en el interior de estos aparatos, es necesario registrar los datos de temperatura durante varias horas para verificar el desempeño. Al tiempo , se registran valores estadísticos como la media, el máximo, el mínimo y la desviación estándar cuando es requisito.

Fluke - Medición

El término de precisión tiene 2 componentes importantes , la repetibilidad y la resolución. Estos dos componentes esenciales tienen que tenerse presente adjuntado con otros causantes que afectan a la precisión. La estabilidad en los desenlaces de las mediciones repetidas se define como repetibilidad. La repetibilidad del instrumento de medida se garantiza a través de una medición periódica. La repetibilidad del termómetro se garantiza registrando los desenlaces de las mediciones periódicas en el punto triple del agua en todo el tiempo.

El procedimiento más frecuente para calibrar los sensores de temperatura consiste en extraerlos de su localización y sumergirlos en baños secos o microbaños. Con estos calibradores puede proveer un ambiente de temperatura permanente en un amplio rango y comparar las temperaturas medidas por el sensor calibrado y un termómetro de referencia para asegurar una alta precisión.

Asegurar la confiabilidad de medición del instrumento de medida.

Lo que todo técnico ha de saber sobre medición y calibración de temperatura

Puede transformar la unidad base resistencia o tensión en temperatura. La conversión es dependiente de la sensibilidad del sensor de temperatura. Por servirnos de un ejemplo , un cambio de temperatura de 1 °C provoca un cambio de resistencia de 0,4 Ω en un PRT de cien Ω, un cambio de resistencia de 0,1 Ω en un SPRT de 25 Ω y un cambio de resistencia de 1000 Ω en un termistor. Esto quiere decir que el efecto de un cambio de temperatura de un grado en la resistencia puede ser muy pequeño o muy grande. Por poner un ejemplo , los medidores con una precisión de ± 1 Ω, sensores con la mayor sensibilidad a la temperatura, deben utilizarse con termistores.

Tabla 3. Vista general de las pantallas de los termómetros electrónicos

Figura 2. La compensación de la unión de referencia es el factor más importante en las mediciones de temperatura con termopares, que optimización significativamente la precisión. Advertencia : Algunos fabricantes no detallan el papel de este esencial aspecto en la precisión.

Garantía La calibración es garantía. Primeramente , se establece que se proporcionan los valores de precisión del desarrollador y, ahora , se garantiza la validez de estos valores de precisión del fabricante en todo el tiempo. Lo último en lo que debería meditar es en tener instrumentos que no hacen más que ocupar espacio innecesariamente.

La precisión de medición necesaria debe determinarse cuidadosamente. Las precisiones bajas provocan errores y suponen una carga económica. Los errores en la precisión de medición provocan tiempos de inactividad , consumo insignificante de energía, elevados errores de producción, accidentes laborales y problemas de salud pública.

Cuando aparece la necesidad de medir la temperatura, estamos con las cuestiones generales antes citadas. Para medir la temperatura se usan diferentes instrumentos de medición: Termómetros de vidrio líquido (LIG), termopares (TC), termistores, detectores de temperatura por resistencia (RTD), termómetros de resistencia de platino (PRT), termómetros de resistencia de platino estándar (SPRT). En este artículo , vamos a encontrar respuestas a los inconvenientes con los que nos encontraremos centrándonos en los gadgets electrónicos de medida empleados en la medición de la temperatura.

Para medir la temperatura con PRT, la correlación del cambio de temperatura con la resistencia del elemento sensor se consigue a través de ecuaciones y coeficientes lineales. Generalmente , la mayor parte de los indicadores termométricos aceptan estas ecuaciones tal es así que el cálculo del valor de temperatura desde el valor de resistencia se realiza de manera automática , como las ecuaciones ITS-90, las ecuaciones Calender Van Dusen (CVD), las ecuaciones polinómicas. Los mejores resultados con los PRT se calculan con las ecuaciones ITS-90. Los modelos mucho más antiguos de medidores de temperatura y los PRT no calibrados pueden utilizar las ecuaciones CVD.

Termistores

El termistor es un material semiconductor y su resistencia eléctrica varía con la temperatura en una relación no lineal. Los termistores son preferibles por su sensibilidad, pequeño tamaño, robustez y bajo coste. La precisión del termistor es dependiente de su diseño y construcción. Termistores de bajo coste Los valores numéricos se consiguen como resultado de un cálculo. Por poner un ejemplo , los valores de precisión variable se manifiestan en partes por millón (PPM). Los valores de precisión fijos se aplican a todo el rango de medición. Por ejemplo , se expresan en porcentaje del campo de medida.

La relación resistencia-temperatura de los termistores se describe mediante varias ecuaciones polinómicas diferentes. En una forma de la ecuación, la temperatura T(R) se calcula basándose en el valor de la resistencia; en la otra forma de la ecuación, la resistencia se calcula basándose en la temperatura R(T). En la versión estándar de estas ecuaciones hay 4 factores , pero en la ecuación Steinart-Hart bastan tres factores.

En la Tabla 2 se equiparan las peculiaridades propias de rango de medición, precisión y coste de los sensores de temperatura. Los costes de los sensores de medición precisa de la temperatura son superiores. En general , la precisión de la medición puede verse comprometida en rangos de temperatura extensos.

¿Qué buscar en las organizaciones que fabrican equipos de medición de temperatura?

Mantener la validez de los equipos calibrados es una parte esencial de la garantía de calidad. No hay garantía de que un termómetro calibrado continúe calibrado de manera continua a lo largo del tiempo. Los cambios en la relación de temperatura de los termómetros utilizados a lo largo del tiempo se corrigen repitiendo el desarrollo de medición a intervalos regulares.

La escala de temperatura ITS-90 definida por el BIPM (Bureau International Poids et Measure) (Oficina Internacional de Pesas y Medidas) es utilizada por países de todo el mundo para asegurar la coherencia en las mediciones de temperatura. La precisión de las mediciones de los instrumentos viene determinada por el patrón de alta precisión con el que se equiparan. Estas mediciones forman una cadena de comparación, que comienza con las mediciones de referencia del usuario final sobre el terreno , pasa por los laboratorios de medición en el nivel secundario y llega hasta los patrones de todo el mundo en el Instituto Nacional de Metrología.

La extensa selección de productos de Fluke Calibration incluye calibradores, patrones, programas de programa y resoluciones de servicio, capacitación y asistencia. Nuestros clientes del servicio son laboratorios de todo el planeta que realizan calibraciones eléctricas, de temperatura, presión y fluidos, y nuestros artículos también se utilizan en pruebas de producción, I+D y servicio técnico.

Para garantizar la congruencia de los valores medidos tomados por el instrumento de medida con otros valores medidos.

En el momento en que surge la necesidad de medir la temperatura, estamos con las preguntas generales antes mencionadas. Para medir la temperatura se usan distintos instrumentos de medición: Termómetros de vidrio líquido (LIG), termopares (TC), termistores, detectores de temperatura por resistencia (RTD), Como opción alternativa , puede calibrar los sensores de temperatura sin precisar retirarlos de su localización. En un caso así , se aplica un termómetro de referencia al entorno en el que se encuentra el sensor que debe calibrarse o a la caja del termómetro próxima.

Termopares - Termopares (TC)

Los termómetros que figuran en la tabla 2 deben usarse con un indicio numérico. Los más adecuados son los diseñados para la medición directa de la temperatura. La Tabla 3 enumera los requisitos que debe cumplir un buen indicador de termómetro.

Usando un patrón de calibración de alta precisión, puede identificar de forma más verdadera los dispositivos de campo fuera de tolerancia que deben calibrarse. En la tabla siguiente puede ver las frecuencias de fallo que se producen en las calibraciones efectuadas con distintas relaciones de indecisión de prueba. En este caso de ejemplo de tabla, 950 de 1000 gadgets calibrados están verdaderamente en la tolerancia detallada. Si se calibran 1000 gadgets con una relación de incertidumbre de prueba de 2:1, 925 de ellos van a estar dentro de la tolerancia (aceptados ), 12 de los aceptables (incorrectamente admitidos ) están de todos modos fuera de la tolerancia. Además de esto , 41 de los 75 gadgets fuera de tolerancia (rechazados incorrectamente) deberían aceptarse realmente en tolerancia. El coste de calibración de cada dispositivo rechazado incorrectamente es desde 50.- USD, y en la industria de procesos químicos, parar el desarrollo gracias a este dispositivo deficiente puede ocasionar un coste mínimo de 10 .000.- USD.

En guadalajara jalisco laboratorio de calibración, la resolución suele ser seleccionable por el usuario. Es requisito seleccionar un termómetro con una resolución que responda a la precisión deseada, sin embargo , resolución no es exactamente lo mismo que precisión, la resolución es un aspecto limitante de la precisión. En los termómetros de vidrio líquido y de aguja, la resolución es el aspecto más importante que perjudica a la precisión, aparte de la medición.

Los coeficientes usados con estas ecuaciones se determinan a lo largo del desarrollo de medición , y estos coeficientes se indican en las tablas de relación resistencia-temperatura de los informes de medición. Ciertos PRT industriales económicos tienen la posibilidad de utilizarse sin calibración. Estos PRT deben ajustarse a normas como IEC80751 o ASTM1137. Estas reglas detallan los factores CVD y las tolerancias dependientes de la temperatura. No obstante , la precisión de las sondas puede mejorarse relevantemente a través de medición.

Las tablas de precisión del desarrollador (especificación) tienen la posibilidad de presentarse de distintas formas. Generalmente , los valores de precisión del desarrollador se dividen en pasos de temperatura y se manifiestan como temperatura, resistencia o tensión como unidad básica de medida. Los valores de precisión sencillos son valores fijos o variables ; los valores de precisión complejos son una combinación de valores fijos y cambiantes. En el momento en que se utilizan valores de precisión variables , el valor de error admisible incrementa con el incremento de la temperatura medida.

El termistor es un material semiconductor y su resistencia eléctrica cambia con la temperatura en una relación no lineal. Los termistores son preferibles por su sensibilidad, pequeño tamaño, solidez y bajo coste. La precisión del termistor es dependiente de su diseño y construcción. Los termistores de bajo coste acostumbran a utilizarse en apps eléctricas. Por otro lado , los termistores de precisión tienen la posibilidad de desafiar a los SPRT por su enorme exactitud y también se usan como patrones de calibración.

Cuidado de la validez de las reglas

En las mediciones de temperatura con termopares, la compensación de la unión de referencia es un factor importante para la precisión de la medición. Las tablas de termopares se fundamentan en el valor de la unión de referencia a 0 °C. No obstante , con las uniones de referencia ajenas , la unión de referencia puede medirse utilizando un baño de hielo, los plataformas del termopar suelen estar conectados de manera directa al indicio de temperatura, en tal caso las desviaciones sobre 0 °C debidas a la temperatura ámbito se compensan de forma automática. Para medir la temperatura de la unión se emplea un termistor, el indicio mide la resistencia del termistor y calcula la corrección que se requiere para el termopar.

El termómetro de resistencia de platino (PRT) contiene un bobinado de alambre de platino de alta pureza. La resistencia del elemento PRT exhibe el cambio más lineal con la temperatura en comparación con otros géneros de sensores. El termómetro de resistencia de platino estándar (SPRT) se usa en los laboratorios nacionales de normalización y en la industria para realizar mediciones de temperatura de alta precisión trazables a la escala de temperatura de 1990 (ITS-90). El artículo terminado de la ITS-90 puede consultarse en:

1 note

·

View note

Text

AABTools: The Premier Fluke Distributor in UAE

Introduction: Navigating the vast landscape of industrial and electronic test tools in the UAE can be daunting. AABTools stands out as a beacon for professionals looking for reliable Fluke instruments. As the authorized distributor for Fluke in the UAE, AABTools offers an extensive array of high-quality, precision tools essential for a wide range of industries. This blog explores why AABTools is the go-to source for Fluke products in the region.

Why Choose AABTools for Fluke Products?

Extensive Product Range: AABTools offers a comprehensive catalog of Fluke products, including digital multimeters, electrical power analyzers, thermal imagers, and more. These tools are indispensable for tasks requiring accuracy, from routine maintenance to complex diagnostics and troubleshooting.

Ready Stock Availability: Efficiency is key in business, and AABTools supports this by maintaining a large inventory that promises one business day delivery for all in-stock items. This swift service ensures that projects continue without unnecessary delays due to tool shortages.

Accredited Calibration Services: Precision is at the heart of Fluke’s ethos, and AABTools upholds this by providing ISO 17025:2017 accredited calibration services. This not only ensures compliance with stringent quality standards but also means that the equipment is ready to perform right out of the box.

Expert Support and On-site Demonstrations: AABTools isn’t just about selling products; they enhance the customer experience by offering expert advice and on-site product demonstrations. Their Fluke-trained specialists are equipped to answer technical queries and assist in selecting the right tools for specific needs.

Strategic Locations and Accessibility: With multiple locations across the UAE, accessing AABTools’ services is convenient. Whether you visit one of their stores or schedule a demo at your site, they are ready to meet your Fluke tool needs.

Customer-Centric Services: AABTools understands the importance of customer service. They offer various customer-friendly services like the option to request quotes online, easy access to their sales team via WhatsApp, and regular updates through their newsletters.

Concluding Thoughts: For professionals across the UAE, AABTools is more than just a supplier; it’s a valuable partner offering reliable Fluke instruments and exceptional service. Whether you are in electrical, HVAC, or any other field requiring precise measurement and testing tools, AABTools can equip you with the best to ensure your tasks are completed to the highest standards.

For more information on their product range and services, visit the AABTools website to discover how they can facilitate your instrumentation needs with unmatched professionalism and expertise.

Call to Action: Ready to enhance your toolset with the industry’s best? Contact AABTools today to find the perfect Fluke instruments for your projects, and experience service that goes beyond just sales.

0 notes