#Flue Gas Temperature

Explore tagged Tumblr posts

Text

#ducting expansion joints#flue gas expansion joints#flue ducting expansion joints#flue duct expansion joints#high temperature expansion joint

0 notes

Text

Writing Notes: Carbon Monoxide Poisoning

Carbon monoxide (CO) poisoning - occurs when carbon monoxide gas is inhaled.

CO - a colorless, odorless, highly poisonous gas.

Produced by incomplete combustion.

Interferes with the ability of the blood to carry oxygen.

Found in: automobile exhaust fumes, faulty stoves and heating systems, fires, and cigarette smoke.

Other sources: woodburning stoves, kerosene heaters, improperly ventilated water heaters and gas stoves, and blocked or poorly maintained chimney flues.

The result is headache, nausea, convulsions, and finally death by asphyxiation.

Symptoms

The symptoms of CO poisoning in order of increasing severity include:

headache

shortness of breath

dizziness

fatigue

mental confusion and difficulty thinking

loss of fine hand-eye coordination

nausea and vomiting

rapid heart rate

hallucinations

inability to execute voluntary movements accurately

collapse

lowered body temperature (hypothermia)

coma

convulsions

seriously low blood pressure

cardiac and respiratory failure

death

In some cases, the skin, mucous membranes, and nails of a person with CO poisoning are cherry red or bright pink. Because the color change doesn’t always occur, it is an unreliable symptom to rely on for diagnosis.

Although most CO poisoning is acute, or sudden, it is possible to suffer from chronic CO poisoning. This condition exists when a person is exposed to low levels of the gas over a period of days to months.

Symptoms are often vague and include (in order of frequency) fatigue, headache, dizziness, sleep disturbances, cardiac symptoms, apathy, nausea, and memory disturbances.

Little is known about chronic CO poisoning, and it is often misdiagnosed.

Treatment

Immediate treatment: Remove the victim from the source of carbon monoxide gas and get him or her into fresh air.

If the victim is not breathing and has no pulse, cardiopulmonary resuscitation (CPR) should be started.

Depending on the severity of the poisoning, 100% oxygen may be given with a tight fitting mask as soon as it is available.

Taken with other symptoms of CO poisoning, COHb levels of over 25% in healthy individuals, over 15% in patients with a history of heart or lung disease, and over 10% in pregnant women usually indicate the need for hospitalization.

In the hospital, fluids and electrolytes are given to correct any imbalances that have arisen from the breakdown of cellular metabolism.

In severe cases of CO poisoning, patients are given hyperbaric oxygen therapy. This treatment involves placing the patient in a chamber breathing 100% oxygen at a pressure of more than one atmosphere (the normal pressure the atmosphere exerts at sea level). The increased pressure forces more oxygen into the blood.

Prevention

Carbon monoxide poisoning is preventable.

Particular care should be paid to situations where fuel is burned in a confined area. Portable and permanently installed carbon monoxide detectors that sound a warning similar to smoke detectors are available for less than $50.

Specific actions that will prevent CO poisoning include:

Stopping smoking. Smokers have less tolerance to environmental CO.

Having heating systems and appliances installed by a qualified contractor to assure that they are properly vented and meet local building codes

Inspecting and properly maintaining heating systems, chimneys, and appliances

Not using a gas oven or stove to heat the home

Not burning charcoal indoors

Making sure there is good ventilation if using a kerosene heater indoors

Not leaving cars or trucks running inside the garage

Keeping car windows rolled up when stuck in heavy traffic, especially if inside a tunnel.

Source ⚜ More: Writing Notes & References ⚜ Poison ⚜ Fictional Poisons

#writing notes#poison#fiction#writeblr#dark academia#writing reference#spilled ink#writing inspiration#creative writing#writers on tumblr#literature#poets on tumblr#writing prompt#poetry#light academia#writing ideas#michael sowa#writing resources

67 notes

·

View notes

Text

What is Alloy 825 Material Grade? Understanding its Properties and Applications

High-performance nickel-based alloy Alloy 825, also known as Incoloy 825, is renowned for its exceptional resistance to a wide range of corrosive conditions. The characteristics, makeup, and uses of Inconel 825 ASTM grade will be covered in this weblog. Vardhman Ferro Alloys plays a significant role in providing super substances like Incoloy 825 Scrap and steel metal scrap.

Composition and Essential Properties of Alloy 825

Nickel, iron, chromium, and molybdenum make up Incoloy 825, collectively with key quantities of copper, niobium, and titanium. Strength, corrosion resistance, and normal performance at high temperatures are all balanced with the aid of the alloy's precise composition. Key additives encompass:

Nickel (38-46%): Provides remarkable corrosion resistance.

Iron (22-26%): Enhances electricity.

Chromium (19-23%): Increases resistance to oxidation and corrosion.

Molybdenum (2.5-3.5%): Contributes resistance to chloride-brought about pressure corrosion cracking.

Alloy 825 is known for its terrific resistance to sulfuric and phosphoric acids, in addition to lowering conditions like the ones determined in a few chemical processing environments.

Key Properties of Alloy 825

Corrosion Resistance: The alloy excels in environments in which it’s exposed to sulfuric acid, phosphoric acid, and other corrosive substances.

High-Temperature Strength: Incoloy 825 maintains energy at improved temperatures, making it appropriate for industrial applications with high temperatures.

Weldability and Formability: Alloy 825 is straightforward to manufacture and weld, this is critical for various production methods.

Versatility: It is used in many industries because of its exceptional mechanical houses and corrosion resistance.

Applications of Incoloy 825

Alloy 825 is frequently applied in industries that face harsh working situations, inclusive of chemical processing, nuclear strength, and pollutant control. Some key applications consist of:

Chemical Processing: Used in heating exchangers, piping structures, and reactors in industries like oil and gas and medicinal drugs.

Nuclear Power: The alloy’s resistance to corrosive environments makes it exceptional for coping with radioactive materials.

Pollution Control: Used in flue gasoline desulfurization structures and certainly one of type pollution manipulation technology.

Marine and Offshore: Its resistance to chloride pressure corrosion makes it great for marine programs together with seawater desalination plant life and offshore oil rigs.

Scrap and Recycling in Incoloy 825

The potential to be recycled is one of Incoloy 825's benefits. Reusing Incoloy alloy 825 scraps can result in quite incredible alloy products, reducing waste and promoting sustainability. Recycling this material lowers production costs and reduces the environmental footprint of manufacturing strategies. We offer splendid Incoloy alloy 825 Scrap, ensuring that it meets corporation requirements to be used in generating alloys for lots of applications.

Comparison with Other Materials: 13 Mo Stainless Steel and Steel Metal Scrap

While Incoloy 825 is often evaluated of large alloys like 13 Mo stainless steel grade and steel scrap, it stands proud for its advanced corrosion resistance, especially in sulfuric and phosphoric acid environments.

13 Mo Stainless Steel Grade: Known for its power at excessive temperatures, this grade is frequently used within the oil and gasoline organization but doesn’t offer equal corrosion resistance as Alloy 825.

Steel Metal Scrap: Steel scrap is normally recycled but generally lacks the specialized houses of Incoloy 825, which incorporates superior corrosion resistance.

We are Your Trusted Alloy Supplier

We are the number one provider of superb alloys, inclusive of Incoloy alloy 825 Scrap. We make sure that all materials meet the very superb industry necessities, offering reliable and cost-effective solutions for various commercial applications. Whether you want to scrap for recycling or custom alloys for manufacturing, we can offer top-rated products for your goals.

Conclusion

Alloy 825, or Incoloy 825, is a flexible and high-performing alloy, valued for its resistance to corrosion, high-temperature balance, and ease of production. It is broadly used at some unspecified time in the future of industries including chemical processing, nuclear strength, and marine applications. By sourcing substances from trusted providers like Vardhman Ferro Alloys, companies can ensure they may be the usage of splendid, dependable materials that meet the annoying wishes of present-day industries. Whether you are searching out Incoloy 825 Scrap for recycling or specialized alloys on your subsequent challenge, we are your trusted associate.

0 notes

Text

Understanding FRP Pipes: A Comprehensive Guide to Benefits and Applications

D Chel Oil & Gas is a recognised FRP pipe manufacturer in India. FRP pipes are well-known for their exceptional durability, corrosion resistance, and lightweight construction. These pipes are utilised in a variety of sectors, including chemical processing, water treatment, and oil and gas, where they must withstand high pressures and extreme environmental conditions. FRP pipes' non-corrosive nature makes them perfect for long-term applications, lowering maintenance costs and assuring consistent performance.

What Are FRP Pipes?

FRP pipes are composite structures composed of thermosetting resins, such as polyester, vinyl ester, or epoxy, reinforced with fiberglass. These materials are layered to form a robust yet lightweight structure, creating pipes with superior mechanical and chemical properties. The use of advanced manufacturing techniques, such as filament winding and centrifugal casting, ensures consistent quality and performance.

Key Features and Advantages of FRP Pipes

Corrosion Resistance One of the standout properties of FRP pipes is their excellent resistance to corrosion. Unlike steel, which is prone to rusting, or concrete, which degrades over time when exposed to harsh chemicals, FRP pipes maintain their integrity in aggressive environments. They are ideal for transporting corrosive fluids in chemical plants, wastewater treatment facilities, and marine applications.

Lightweight and High Strength Despite their lightweight nature, FRP pipes are incredibly strong. Their high strength-to-weight ratio makes them easier to handle, transport, and install compared to heavier materials like steel or concrete. This reduces labor costs and minimizes the need for heavy equipment during installation.

Longevity and Low Maintenance FRP pipes have an impressive lifespan, often exceeding 50 years when properly maintained. Their resistance to wear and tear, combined with their immunity to chemical attacks, means they require minimal maintenance, saving costs over time.

Thermal and Electrical Insulation FRP pipes are excellent insulators, both thermally and electrically. This makes them suitable for applications where temperature fluctuations or electrical conductivity pose challenges.

Customization and Versatility FRP pipes can be customized in terms of size, shape, and resin composition to suit specific industrial needs. Their adaptability ensures they can be tailored to meet the exact requirements of various applications.

We Supply In Various Countries Llike :

FRP Supplier in Qatar

FRP Supplier in Saudi Arabia

FRP Supplier in Bangladesh

FRP Supplier in Oman

FRP Supplier in Malaysia

Applications of FRP Pipes

FRP pipes have found applications in diverse industries, thanks to their unique properties. Some of the key sectors where they are widely used include:

Chemical and Petrochemical Industries FRP pipes are extensively used for transporting corrosive chemicals, acids, and alkalis in chemical and petrochemical plants. Their ability to withstand extreme pH levels and high temperatures makes them a preferred choice.

Water and Wastewater Management Municipalities and industries use FRP pipes for sewage systems, desalination plants, and water treatment facilities. Their corrosion resistance ensures long-term performance in handling potable and non-potable water.

Oil and Gas Industry In oil and gas operations, FRP pipes are used for offshore platforms, pipelines, and storage tanks. Their lightweight nature and resistance to saltwater and hydrocarbons make them indispensable in this sector.

Power Plants FRP pipes are commonly employed in cooling water systems, flue gas desulfurization (FGD) units, and other power plant infrastructure due to their durability and thermal insulation properties.

Marine and Offshore Applications FRP pipes are well-suited for marine environments, where exposure to salt water can corrode traditional materials. They are used in shipbuilding, docks, and offshore platforms.

FRP Pipe Manufacturers in India

India is home to numerous famous FRP pipe manufacturers who provide high-quality goods that match international specifications.FRP Pipe Suppliers in India provide a wide range of solutions tailored to specific industrial requirements, ensuring that clients receive long-lasting and efficient pipe systems. These producers are well-known across the world for their long-lasting and cost-effective FRP pipe solutions, which are the result of modern manufacturing procedures and strict quality control. We are also one of the leading FRP grating manufacturers in India.

0 notes

Text

Preparing Your Gas Pipeline for Winter: Tips and Tricks

As temperatures drop, it's important to ensure that your gas pipeline is ready to handle the challenges of winter. Cold weather can affect the performance and safety of gas systems, making proactive maintenance essential. Follow these tips to keep your gas pipeline functioning efficiently throughout the winter season:

1. Inspect for Leaks

Check for any signs of gas leaks, such as an unusual smell (rotten eggs) or hissing sounds.

Use a soap-and-water solution to test connections for leaks. Bubbles will form if there’s a problem.

Address leaks immediately with professional assistance.

2. Schedule a Professional Maintenance Check

Hire a certified technician to inspect the pipeline for wear and tear, blockages, or weak connections.

Ensure all valves, regulators, and seals are in good condition.

Professional maintenance reduces the risk of unexpected issues during winter.

3. Insulate Exposed Pipes

Use weatherproof insulation to protect exposed gas pipes from freezing temperatures.

Insulation prevents condensation buildup, which could lead to freezing or corrosion.

4. Check Gas Pressure Levels

Ensure the gas pressure is adequate for your appliances to function efficiently.

Low pressure may indicate blockages or other issues in the pipeline that need immediate attention.

5. Protect Outdoor Pipelines and Appliances

Clear debris, snow, or ice from around outdoor gas lines and meters.

Avoid piling snow or using de-icing chemicals near pipelines, as they may cause damage.

Use protective covers designed for outdoor gas equipment to shield them from harsh weather.

6. Test Emergency Shutoff Valves

Confirm that the emergency shutoff valves are operational and accessible.

Educate your household members on how to use the shutoff valve in case of an emergency.

7. Maintain Proper Ventilation

Ensure vents and flues connected to gas appliances are clear of blockages, such as snow or ice.

Proper ventilation prevents gas buildup and ensures efficient combustion.

8. Monitor Gas Appliances

Inspect gas-powered heaters, stoves, and water heaters for any signs of malfunction.

Clean appliance burners and vents to ensure optimal performance.

Consider upgrading older appliances to energy-efficient models for better winter performance.

9. Prevent Pipeline Freezing

Keep a steady flow of gas through the pipeline by using appliances regularly.

If you're away for an extended period, do not shut off the gas completely—maintain a minimal flow to prevent freezing.

10. Prepare for Emergencies

Save the contact information of your gas service provider for quick access in case of issues.

Install a carbon monoxide detector to identify any dangerous gas buildup indoors.

Keep an emergency kit with flashlights, batteries, and a portable heater ready for use.

Benefits of Winter Preparation

Prevents costly repairs and interruptions during the cold season.

Ensures the safety of your household by reducing the risk of gas leaks or appliance failure.

Enhances the efficiency of your gas appliances, saving energy and money.

By taking these proactive measures, you can ensure a safe and warm winter for your family while keeping your gas pipeline in top condition.

#GasPipelineInstallation#HyderabadGasServices#SafeGasInstallation#HomeSafetyFirst#GasPipelineExperts#HyderabadHomes#LPGPipelineInstallation#ApartmentGasSafety#VillaGasSolutions#HyderabadLiving#HomeSafetyHyderabad#EfficientGasSolutions#GasPipelineForHomes#HyderabadApartments#TrustedGasInstallers#SmartHomeSafety#ResidentialGasPipeline#HyderabadRealEstate#ExpertGasTechnicians#SafeLivingHyderabad#LPGSafety#HomeGasSolutions#PipelineExpert#GasTech#DomesticGasServices#EnergyEfficiency#SmartHomeGas#SustainableEnergy#ProfessionalInstallers#GasPipelinePros

0 notes

Text

Hydrated Lime Explained: Production, Properties, and Uses

Hydrated lime, also known as calcium hydroxide, is a versatile compound widely used in various industries. With applications spanning construction, agriculture, water treatment, and more, hydrated lime has become an essential material due to its unique properties. This blog will delve into the production process, properties, and diverse uses of hydrated lime and hydrated lime powder, along with a look at its relation to quick lime powder.

What is Hydrated Lime?

Hydrated lime, chemically known as calcium hydroxide (Ca(OH)₂), is a fine, white powder created when quick lime (calcium oxide or CaO) reacts with water. This reaction, called slaking, produces a substance with versatile applications due to its high pH and reactive nature.

Hydrated lime is often referred to as hydrated lime powder because of its finely powdered form, which makes it easy to handle and apply in different processes. Its ability to neutralize acids, purify, and stabilize materials makes it a key ingredient in many industries.

How is Hydrated Lime Produced?

The production of hydrated lime involves two main steps:

Production of Quick Lime Powder Quick lime powder, or calcium oxide, is produced by heating limestone (CaCO₃) in a kiln at high temperatures. This calcination process removes carbon dioxide, leaving behind calcium oxide.

Slaking of Quick Lime The calcium oxide (quick lime powder) is then mixed with water in a controlled reaction. This exothermic reaction produces hydrated lime (calcium hydroxide). The process must be carefully managed to prevent over-slaking or under-slaking, which can impact the quality of the final product.

Properties of Hydrated Lime

Hydrated lime is known for its distinctive properties that make it valuable across industries:

Chemical Stability: It is highly alkaline with a pH of about 12, making it an excellent neutralizing agent.

Fine Powder Form: As hydrated lime powder, it is easy to mix and spread, offering excellent solubility in water.

Non-Toxic Nature: While it is alkaline, hydrated lime is non-toxic, making it safer for certain agricultural and water purification applications.

Reactivity: It reacts readily with carbon dioxide in the air to form calcium carbonate, contributing to its ability to bind materials.

Applications of Hydrated Lime 1. Construction Industry

Hydrated lime is a key material in construction. Its primary applications include:

Mortar and Plaster: Hydrated lime improves workability, water retention, and durability of lime-based mortars and plasters.

Soil Stabilization: Used to stabilize clay-rich soils, hydrated lime enhances the load-bearing capacity of roadbeds and foundations.

2. Agriculture

Farmers often rely on hydrated lime to improve soil health:

pH Adjustment: Hydrated lime neutralizes acidic soils, creating a more suitable environment for crops.

Pest Control: It acts as a mild pesticide, controlling harmful insects and pathogens in the soil.

3. Water and Wastewater Treatment

One of the most common uses of hydrated lime is in water purification:

Neutralization of Acids: Its alkaline nature helps neutralize acidic water.

Flocculation Agent: Hydrated lime is used to remove impurities from water, improving clarity and safety.

4. Environmental Applications

Hydrated lime plays a role in reducing environmental pollution:

Flue Gas Treatment: It removes sulfur dioxide and other harmful emissions from industrial flue gases.

Waste Treatment: Hydrated lime is effective in treating industrial and municipal waste, reducing odors and neutralizing acidic waste streams.

How Hydrated Lime Differs from Quick Lime Powder

Although both are derived from limestone, hydrated lime and quick lime powder differ significantly:

Quick Lime Powder (Calcium Oxide):

Highly reactive and caustic

Requires careful handling due to its exothermic reaction with water

Typically used in steel manufacturing, chemical production, and high-temperature processes

Hydrated Lime (Calcium Hydroxide):

Safer and easier to handle

Ready for use in applications requiring water-reacted lime

Versatile in agriculture, construction, and environmental sectors

Quick lime powder serves as the precursor to hydrated lime. Its transformation into calcium hydroxide makes it more user-friendly and suitable for broader applications.

Advantages of Using Lime Hydrated

Hydrated lime and hydrated lime powder offer several benefits, such as:

Cost-Effectiveness: Widely available and affordable compared to other alkaline agents.

Eco-Friendliness: Helps in pollution control and is derived from natural materials.

Versatility: Applicable across a wide range of industries, from agriculture to industrial manufacturing.

Challenges and Precautions

While hydrated lime is safer to handle than quick lime powder, precautions are still necessary:

Dust Control: The fine powder form can become airborne, requiring masks and ventilation during handling.

Storage: It must be stored in dry conditions to prevent premature reactions with moisture.

Application Knowledge: Proper dosing is essential for optimal results, whether in soil treatment or water purification.

Conclusion

Hydrated lime, or calcium hydroxide, is a vital compound with diverse applications. Its production from quick lime powder transforms it into a safe and effective material for use in construction, agriculture, environmental management, and more. Whether in its finely powdered form or as a pH-balancing agent, hydrated lime continues to prove its value in various industries. By understanding its production, properties, and applications, businesses and individuals can make the most of this versatile material, leveraging its unique characteristics to address challenges efficiently and sustainably.

0 notes

Text

Incinerators in Kerala: A Sustainable Solution for Waste Management Challenges

Introduction

Kerala, with its growing population and bustling urban centers, faces significant waste management challenges. With limited space for landfills and the need to manage waste responsibly, incinerators in Kerala have become an essential solution to reduce landfill dependency and provide cleaner waste disposal options. In this article, we’ll explore how waste incinerators work, their benefits, potential environmental impacts, and how Kerala is incorporating incineration to manage waste sustainably.

How Incinerators Work

Incinerators are advanced facilities designed to burn waste materials at high temperatures, converting them into ash, flue gas, and heat. The heat generated can be used for energy production, making waste incineration a dual-purpose solution. This process is especially effective for reducing waste volume by up to 90%, making it ideal for Kerala’s limited waste disposal space.

The Need for Incinerators in Kerala

Increasing Waste Generation: As urban areas expand, Kerala has seen a rise in waste generation. Traditional waste disposal methods like landfilling are unsustainable due to space constraints.

Environmental Concerns: Improper waste disposal can lead to severe environmental pollution, impacting soil and water quality. Incinerators offer a cleaner way to handle waste.

Energy Recovery Potential: Waste-to-energy incinerators can contribute to Kerala’s renewable energy goals, turning waste into a valuable resource.

Benefits of Waste Incineration in Kerala

Space Savings: By significantly reducing waste volume, incinerators help conserve valuable land in Kerala.

Cleaner Disposal: Incineration can destroy harmful pathogens and hazardous materials in medical and industrial waste, making it a safer disposal option.

Energy Production: The heat generated during incineration can be used to produce electricity, contributing to sustainable energy goals.

Environmental Impact of Incinerators in Kerala

While incinerators offer numerous benefits, they must be operated with proper emissions control to minimize environmental impact. Advanced filtration systems and adherence to environmental regulations are crucial for reducing pollutants and maintaining air quality.

Future of Waste Incineration in Kerala

With the government and local authorities supporting sustainable waste management, incinerators in Kerala are likely to play a more prominent role. The state is already implementing pilot programs to incorporate modern incineration technology with minimal environmental impact.

Conclusion

Incinerators in Kerala offer a promising solution to address the state’s waste management challenges while reducing landfill use and contributing to energy production. Through ongoing advancements and responsible operation, incineration can provide Kerala with a sustainable path toward effective waste management.

#biogas in kerala#biogas plant for home#incinerator manufacturers in kerala#portable biogas plant for home#incinerators in kerala#biogas#kerala

0 notes

Text

Baystate Pool 420020024S Stack Flue SCV Kit for Pool & Spa Heaters

The Baystate Pool 420020024S Stack Flue SCV Kit is a specialty component intended for use in pool and spa heating systems. This equipment is required for proper ventilation of gas-fired heaters, resulting in safe and efficient operation. The stack flue SCV regulates the flow of exhaust gases from the heater to the outside environment, reducing the possibility of backdrafts and increasing overall safety. The package comprises a stack flue and a control valve to manage exhaust flow, ensuring peak performance and extending the life of the heating system. It is critical for preventing overheating and keeping the heater operating within acceptable temperature ranges. The Baystate Pool 420020024S Stack Flue SCV Kit improves pool and spa heating system performance by allowing for appropriate ventilation.

#BaystatePool#420020024S#StackFlueSCVKit#Pool&SpaHeaters#usapoolshop#poolequipmentparts#poolparts#poolmaintenance#swimmingpoolparts

0 notes

Text

Industrial Chimney Supplier in Rajasthan

Amma En-fab Is a leading Manufacturer and Supplier of Industrial Chimney in Rajasthan, India. Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India. Industries design industrial chimneys as vertical structures to reduce the adverse environmental impacts of greenhouse gases and other emissions. Constructed from materials like steel, concrete, or masonry, these chimneys release gases generated during industrial processes. The primary goal is to mitigate the harmful effects of these emissions on human health and the environment. Some chimneys help reduce contaminants, while others focus on lowering gas temperatures. Types of Industrial Chimney: Industrial Mild Steel Chimney Industrial Steel Chimney MS Boiler Chimney Benefits of Industrial Chimneys Industrial chimneys are built to reduce harm from greenhouse gases and pollutants. Companies use materials like masonry, concrete, or steel to release gases after production. The goal is to limit emissions' negative effects on people and the environment. For boiler use, consider surface area, efficiency, and draft requirements. Flue gas temperature and its variations are key factors. Also consider specific weight, dust content, and flue gas aggressiveness. How do industrial chimneys work? Industrial chimneys work by creating an updraft that allows hot gases, smoke, and pollutants to rise and exit the facility. The chimney design ensures that industries expel these emissions at high altitudes, where they can disperse safely into the atmosphere. What materials are used in the construction of industrial chimneys? Common materials used in industrial chimney construction include brick, concrete, steel, and fiberglass. The material choice depends on factors such as the type of emissions, temperature, and environmental conditions. Amma En-fab Is a leading Turnkey Projects Solutions in Rajasthan, India Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur. Feel free to contact us for more information and inquiries. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alwar#Anupgarh#Balotra#Banswara#Baran#Barmer#Beaware#Bharatpur#Bhilwara#Bikaner#Bundi#Chittorgarh#Churu#Dausa#Deeg#Dholpur#Didwalna-Kuchaman#Dudu#Dungarpur#Exporter#Ganganagar#GangapurCity#Gujarat#Hanumangarh#India#IndustrialChimneySupplier#IndustrialChimneySupplierinAhmedabad#IndustrialChimneySupplierinIndia

0 notes

Video

youtube

Low-temperature flue gas denitrification catalyst research: This study explored flue gas denitrification catalysts under low-temperature conditions, focusing on the design and preparation of catalysts, as well as their performance in NOx and CO removal. This study highlights the potential for the application of new catalysts at low temperatures, especially in the context of urgent environmental protection requirements. 🌍✨ #scrcatalyst #catalyst #Filtration #PelletizingPlant #Metallurgicalindustry #AirPollutionControl #CleanAir #Innovation #decarbonisation #fluegastreatment

0 notes

Text

Good news | One more project added, Snowwave Environment continues to expand overseas markets

Good news | Plus one more project, the snow wave environment continues to layout overseas markets+++The snow wave environment closely revolves around the "the Belt and Road" policy, responds to the country's development call to "go global", and many overseas projects have been implemented in Singapore, Japan, Thailand, Vietnam, Ethiopia and other countries. Recently, the snow wave environment overseas project has become another country, and successfully signed the contract for flue gas purification system of Bishkek waste technology disposal power generation project in the Kyrgyz Republic. The garbage technology disposal and power generation project in Bishkek, Kyrgyz Republic, is located on the north side of the capital city of Bishkek. The total area of the project is sixty-five thousand seven hundred and twenty square meters (approximately ninety-eight.fifty-eight acres), with a daily processing capacity of one thousand tons of household waste; Configure one set of one thousand tons/day incineration line, using medium temperature and medium pressure (four.zeroMPa, four hundred ℃) main steam parameters, and equip one set of thirtyMW condensing steam turbine generator set with corresponding flue gas treatment and sewage treatment equipment and facilities. The flue gas purification system of this project adopts the process of "SNCR furnace denitrification+semi dry deacidification+dry powder injection+activated carbon adsorption+bag dust removal", which is supplied by our company. (Snow and Waves Environment)

0 notes

Text

Carbon Capture and Storage: A Key to Achieve Net-Zero Targets

Amidst rising CO2 emissions, renewable energy sources and improving energy efficiency are critical components of climate change solutions. One of the most promising technologies to mitigate industrial carbon emissions is Carbon Capture and Storage (CCS). This innovative technology provides a pathway to capture CO2 emissions before they enter the atmosphere, significantly reducing their impact on the environment. According to the International Energy Agency’s (IEA) Sustainable Development Scenario, Carbon Capture, Utilization, and Storage (CCUS) technology could account for nearly 15% of the total emissions reduction needed to achieve global net-zero targets by 2070. This highlights CCUS as a key component in addressing climate change and meeting long-term sustainability goals.

Carbon Capture and Storage (CCS) is no longer a far-off vision of the future but a practical solution to today’s climate crisis. CCS is also recognized as an essential tool to meet the Paris Agreement’s target of limiting global temperature rise to below 2°C. According to the Global CCS Institute, to meet these goals, the world would need to increase CCS capacity from the current 40 million tons annually to around 5.6 billion tons per year by 2050.

What is Carbon Capture and Storage?

Carbon Capture and Storage (CCS) is a carbon emissions reduction technology designed to capture and securely store CO2 produced by industries. It is utilized in industries like steel, cement, and power generation, where emissions are difficult to decarbonize. The CCS process can be broken down as follows:

Capture: CO2 is separated from other gases in industrial processes using advanced carbon capture technology.

Transport: Captured CO2 is then transported via pipelines, ships, or other means to a designated storage site.

Storage: CO2 is stored deep underground in geological formations, such as depleted oil and gas reservoirs or saline aquifers, preventing its release into the atmosphere.

The Technologies behind Carbon Capture and Storage

The most common CO2 storage methods involve geological formations. These include depleted oil and gas reservoirs, saline aquifers, and unmineable coal seams. A successful example of geological CO2 storage is Norway’s Sleipner project, which has been storing approximately 1 million tons of CO2 annually in a saline aquifer beneath the North Sea since 1996. Other carbon capture methods are generally classified into three primary approaches:

Pre-Combustion Carbon Capture: This method captures CO2 before the fuel is burned, making it particularly suitable for industries that convert coal, oil, or gas into fuel gas. Pre-combustion capture typically involves gasifying the fuel to produce a mixture of hydrogen and CO2. The CO2 is then separated and captured for storage.

Post-Combustion Carbon Capture: The method involves capturing CO2 from the flue gases emitted after fossil fuels are burned. This approach is widely applicable to power plants and various industrial facilities. A notable example is the Boundary Dam power station in Canada, which captures approximately 1 million tons of CO2 annually through post-combustion capture.

Oxyfuel Combustion Technology: This process involves burning fuels in oxygen rather than air, resulting in a concentrated stream of CO2, which makes it easier to capture. This method is still being developed and tested but holds promise for future CCS projects.

Once captured, CO2 must be transported to storage sites. Pipelines are the most common mode of CO2 transportation, particularly for large-scale carbon capture and storage systems. Currently, more than 6,500 kilometers of CO2 pipelines are in operation globally, especially in regions like the US and Canada, which have well-established infrastructure for CCS and carbon capture utilization and storage (CCUS).

Real-World Applications of Carbon Capture and Storage

Around the world, CCS projects are already in action as power generation is a major source of CO2 emissions. Implementing CCS in power plants has proven effective in reducing their environmental impact. For instance, the Petra Nova power station in Texas employed a CCS system that captured over 1.6 million tons of CO2 annually during its operation from 2017 to 2020.

The Gorgon Project in Australia is one of the largest CCS initiatives in the world, aiming to store 4 million tons of CO2 annually in an offshore gas field. Such large-scale projects demonstrate the feasibility of CCS in combating industrial emissions.

Similarly, the Drax Group in the UK, which operates the country’s largest power station, plans to capture 8 million tons of CO2 annually as part of its bioenergy with carbon capture and storage (BECCS) project. In January 2024, the UK government approved Drax’s plan to convert two of its biomass units into carbon capture and storage stations for bioenergy.

Challenges and Opportunities in Carbon Capture and Storage

While the potential of Carbon Capture and Storage (CCS) is promising, several challenges remain. The cost of implementing CCS technology remains high. Estimates suggest that capturing CO2 can cost between $60 to $100 per ton, depending on the technology and source. The IEA forecasts that the cost of carbon capture and storage (CCS) could decrease significantly in the coming years, primarily due to increased deployment and technological advancements. In addition to the costs, developing the infrastructure required for CCS, such as pipelines and storage facilities, demands substantial investment. Countries without established pipelines or suitable geological storage sites face logistical challenges. Most importantly, public concern about the safety of storing CO2 underground and a lack of clear government policies have slowed the widespread adoption of CCS.

However, despite these financial and regulatory hurdles, varied opportunities are paving the way for stakeholders to explore the full potential of CCS. Active R&D efforts are leading to more efficient and cost-effective CCS technologies. Innovations in materials for CO2 capture, such as advanced solvents and membranes, are expected to further drive down costs. Governments are increasingly recognizing the role of CCS in meeting climate goals. For instance, the US Infrastructure Investment and Jobs Act passed in 2021 allocated $3.5 billion for CCS projects, and similar investments are being made worldwide.

Future Prospects in Carbon Capture and Storage

Looking ahead, CCS will play a pivotal role in managing CO2 and keeping our planet’s climate in balance. As we strive toward a net-zero future, industries and governments are expected to invest heavily in CCS infrastructure. Countries like China and India, with their heavy reliance on coal, could be key players in adopting CCS to reduce their emissions while maintaining economic growth. From power generation to heavy industry, CCS is proving its ability to significantly curb CO2 emissions. However, realizing its full potential will require overcoming economic and infrastructural challenges, supported by continued innovation, government policy, and investment.

#carboncapture#carbonstorage#netzerocarbon#carbonemissions#renewableenergy#bioenergy#ccstechnology#marketresearch#tritonmarketresearch

0 notes

Text

Nickel Alloys in Extreme Conditions: What You Need to Know

Nickel alloys play an important role in industries subjected to harsh environments such as extreme heat, pressure, and corrosive chemicals. Their great performance in these conditions makes them the backbone of industries like aerospace, chemical processing, and oil and gas. Understanding the technical nuances of nickel alloys will help businesses choose the right material for specific operational needs, making sure long-lasting and cost-effective solutions.

Why Nickel Alloys?

Nickel’s atomic structure, combined with other elements like chromium, molybdenum, and iron, gives rise to unique properties such as:

1. High Melting Point: Nickel alloys remain stable at temperatures reaching 1455°C (2651°F), maintaining their structural integrity even in severe heat.

2. Corrosion Resistance: These alloys resist oxidation, pitting, and stress corrosion cracking, making them ideal for both acidic and alkaline environments.

3. Toughness at Low Temperatures: Nickel alloys do not become brittle in cryogenic conditions, unlike most metals, which makes them ideal for extreme cold applications like LNG (Liquefied Natural Gas) systems.

Key Nickel Alloy Grades and Their Performance:

The following table highlights popular nickel alloy grades, their composition, and their applications, making it easier to identify the right alloy for your industry:

Nickel Alloy Grade, Composition (Key Elements),

Properties, Applications

Nickel 200/201 (UNS N02200/N02201),

Nearly pure nickel (99% Ni),

Excellent resistance to alkalis, good mechanical properties at subzero temperatures,

Chemical processing, caustic soda production, electrical components

Inconel 625 (UNS N06625)

Nickel-Chromium-Molybdenum (58% Ni, 21.5% Cr, 9% Mo),

High strength, excellent weldability, oxidation and corrosion resistance,

Aerospace, offshore platforms, gas turbines,

Monel 400 (UNS N04400)

Nickel-Copper (63% Ni, 28–34% Cu),

Best seawater and chemical resistance, good mechanical strength,

Marine environments, hydrocarbon processing, valves and pumps,

Hastelloy C276 (UNS N10276)

Nickel-Molybdenum-Chromium (57% Ni, 16% Mo, 15.5% Cr),

Excellent corrosion resistance in harsh environments, particularly against acids,

Chemical reactors, pollution control equipment, flue gas desulfurization.

Some Least Known Mechanical Properties of Nickel Alloys

1. Superplasticity in Manufacturing: Certain nickel alloys, such as Nimonic 90, show superplasticity, meaning they can tolerate extreme deformation without failure at high temperatures. This property allows for easier shaping of complex geometries, like turbine blades, without sacrificing material strength.

2. Creep Resistance: Creep refers to the gradual deformation of a material under constant stress at rising temperatures. Nickel alloys, particularly Inconel 718 and Hastelloy X, are designed to resist creep deformation, maintaining their shape over long periods, even in heater components and jet engines where constant thermal cycling occurs.

3. Fatigue Strength: Nickel alloys also excel in fatigue resistance, which is the ability to withstand repeated stress cycles without cracking. This is critical for industries such as aerospace and automotive, where components like engine valves and turbine discs are subjected to constant cyclic loads at high temperatures.

Nickel Alloy Innovations in Modern Applications

1. 3D Printing with Nickel Alloys: Recent advances in additive manufacturing have enabled the use of nickel alloys like Inconel 718 and Hastelloy X in 3D printing. These alloys, in powder form, are used to create complex, high-performance components for aerospace and defence, offering reduced material waste and increased design flexibility.

2. Nickel-Aluminide Alloys for High-Temperature Industrial Equipment: Nickel-aluminides, a class of nickel alloys, have gained attention for their exceptional strength and oxidation resistance at temperatures exceeding 1200°C. These alloys are now being deployed in combustion chambers for power plants due to their combination of low density and high durability.

3. Nickel-Titanium Shape Memory Alloys: Nickel alloys also have niche applications in shape memory technology. Nickel-titanium (Nitinol) is widely used in the medical field. When damaged, Nitinol can return to its original shape when exposed to heat, offering high fatigue resistance and durability in high-performance environments.

Nickel alloys are essential for industries where extreme conditions are the norm. Selecting the right alloy is crucial for ensuring durability and performance. For instance, understanding the differences between fasteners made from Inconel 600 or Monel can significantly influence your application’s success. By making informed choices, businesses can reduce maintenance costs and guarantee the longevity of their components.

Do not leave your operations to chance, choose the best with Online Fittings! Explore our extensive range of premium nickel alloys today and elevate your industrial performance to new heights!

0 notes

Text

Capturing carbon from the air just got easier

A new type of porous material called a covalent organic framework quickly sucks up CO2 from ambient air

Date:October 23, 2024Source:University of California - BerkeleySummary:In the face of rising CO2 levels, scientists are searching for sustainable ways of pulling carbon dioxide out of the air, so-called direct air capture. A new type of porous material, a covalent organic framework (COF) with attached amines, stands out because of its durability and efficient adsorption and desorption of CO2 at relatively low temperatures. The material would fit into carbon capture systems currently used for point source capture.Share:

FULL STORY

Capturing and storing the carbon dioxide humans produce is key to lowering atmospheric greenhouse gases and slowing global warming, but today's carbon capture technologies work well only for concentrated sources of carbon, such as power plant exhaust. The same methods cannot efficiently capture carbon dioxide from ambient air, where concentrations are hundreds of times lower than in flue gases.

Yet direct air capture, or DAC, is being counted on to reverse the rise of CO2 levels, which have reached 426 parts per million (ppm), 50% higher than levels before the Industrial Revolution. Without it, according to the Intergovernmental Panel on Climate Change, we won't reach humanity's goal of limiting warming to 1.5 °C (2.7 °F) above preexisting global averages.

A new type of absorbing material developed by chemists at the University of California, Berkeley, could help get the world to negative emissions. The porous material -- a covalent organic framework (COF) -- captures CO2 from ambient air without degradation by water or other contaminants, one of the limitations of existing DAC technologies.

"We took a powder of this material, put it in a tube, and we passed Berkeley air -- just outdoor air -- into the material to see how it would perform, and it was beautiful. It cleaned the air entirely of CO2. Everything," said Omar Yaghi, the James and Neeltje Tretter Professor of Chemistry at UC Berkeley and senior author of a paper that will appear online Oct. 23 in the journal Nature.

"I am excited about it because there's nothing like it out there in terms of performance. It breaks new ground in our efforts to address the climate problem," he added.

According to Yaghi, the new material could be substituted easily into carbon capture systems already deployed or being piloted to remove CO2 from refinery emissions and capture atmospheric CO2 for storage underground.

UC Berkeley graduate student Zihui Zhou, the paper's first author, said that a mere 200 grams of the material, a bit less than half a pound, can take up as much CO2 in a year -- 20 kilograms (44 pounds) -- as a tree.

"Flue gas capture is a way to slow down climate change because you are trying not to release CO2 to the air. Direct air capture is a method to take us back to like it was 100 or more years ago," Zhou said. "Currently, the CO2 concentration in the atmosphere is more than 420 ppm, but that will increase to maybe 500 or 550 before we fully develop and employ flue gas capture. So if we want to decrease the concentration and go back to maybe 400 or 300 ppm, we have to use direct air capture."

COF vs MOF

Yaghi is the inventor of COFs and MOFs (metal-organic frameworks), both of which are rigid crystalline structures with regularly spaced internal pores that provide a large surface area for gases to stick or adsorb. Some MOFs that he and his lab have developed can adsorb water from the air, even in arid conditions, and when heated, release the water for drinking. He has been working on MOFs to capture carbon since the 1990s, long before DAC was on most people's radar screens, he said.

Two years ago, his lab created a very promising material, MOF-808, that adsorbs CO2, but the researchers found that after hundreds of cycles of adsorption and desorption, the MOFs broke down. These MOFs were decorated inside with amines (NH2 groups), which efficiently bind CO2 and are a common component of carbon capture materials. In fact, the dominant carbon capture method involves bubbling exhaust gases through liquid amines that capture the carbon dioxide. Yaghi noted, however, that the energy intensive regeneration and volatility of liquid amines hinders their further industrialization.

Working with colleagues, Yaghi discovered why some MOFs degrade for DAC applications -- they are unstable under basic, as opposed to acidic, conditions, and amines are bases. He and Zhou worked with colleagues in Germany and Chicago to design a stronger material, which they call COF-999. Whereas MOFs are held together by metal atoms, COFs are held together by covalent carbon-carbon and carbon-nitrogen double bonds, among the strongest chemical bonds in nature.

As with MOF-808, the pores of COF-999 are decorated inside with amines, allowing uptake of more CO2 molecules.

"Trapping CO2 from air is a very challenging problem," Yaghi said. "It's energetically demanding, you need a material that has high carbon dioxide capacity, that's highly selective, that's water stable, oxidatively stable, recyclable. It needs to have a low regeneration temperature and needs to be scalable. It's a tall order for a material. And in general, what has been deployed as of today are amine solutions, which are energy intensive because they're based on having amines in water, and water requires a lot of energy to heat up, or solid materials that ultimately degrade with time."

Yaghi and his team have spent the last 20 years developing COFs that have a strong enough backbone to withstand contaminants, ranging from acids and bases to water, sulfur and nitrogen, that degrade other porous solid materials. The COF-999 is assembled from a backbone of olefin polymers with an amine group attached. Once the porous material has formed, it is flushed with more amines that attach to NH2 and form short amine polymers inside the pores. Each amine can capture about one CO2 molecule.

When 400 ppm CO2 air is pumped through the COF at room temperature (25 °C) and 50% humidity, it reaches half capacity in about 18 minutes and is filled in about two hours. However, this depends on the sample form and could be speeded up to a fraction a minute when optimized. Heating to a relatively low temperature -- 60 °C, or 140 °F -- releases the CO2, and the COF is ready to adsorb CO2 again. It can hold up to 2 millimoles of CO2 per gram, standing out from other solid sorbents.

Yaghi noted that not all the amines in the internal polyamine chains currently capture CO2, so it may be possible to enlarge the pores to bind more than twice as much.

"This COF has a strong chemically and thermally stable backbone, it requires less energy, and we have shown it can withstand 100 cycles with no loss of capacity. No other material has been shown to perform like that," Yaghi said. "It's basically the best material out there for direct air capture."

Yaghi is optimistic that artificial intelligence can help speed up the design of even better COFs and MOFs for carbon capture or other purposes, specifically by identifying the chemical conditions required to synthesize their crystalline structures. He is scientific director of a research center at UC Berkeley, the Bakar Institute of Digital Materials for the Planet (BIDMaP), which employs AI to develop cost-efficient, easily deployable versions of MOFs and COFs to help limit and address the impacts of climate change.

"We're very, very excited about blending AI with the chemistry that we've been doing," he said.

The work was funded by King Abdulaziz City for Science and Technology in Saudi Arabia, Yaghi's carbon capture startup, Atoco Inc., Fifth Generation's Love, Tito's, and BIDMaP. Yaghi's collaborators include Joachim Sauer, a visiting scholar from Humboldt University in Berlin, Germany, and computational scientist Laura Gagliardi from the University of Chicago.

Materials provided by University of California - Berkeley. Note: Content may be edited for style and length.

Journal Reference:

Zihui Zhou, Tianqiong Ma, Heyang Zhang, Saumil Chheda, Haozhe Li, Kaiyu Wang, Sebastian Ehrling, Raynald Giovine, Chuanshuai Li, Ali H. Alawadhi, Marwan M. Abduljawad, Majed O. Alawad, Laura Gagliardi, Joachim Sauer, Omar M. Yaghi. Carbon dioxide capture from open air using covalent organic frameworks. Nature, 2024; DOI: 10.1038/s41586-024-08080-x

0 notes

Text

Knowledge Sharing Series#2

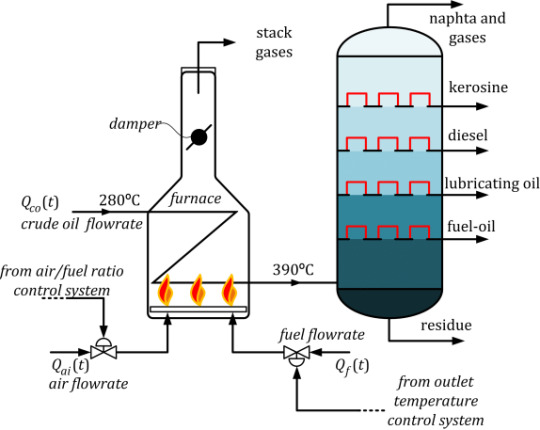

What is the Process that undergoes in Oil Preheating Furnace?

Crude Oil Entry: The desalted crude oil, which has already been heated and mixed with water to remove salt, enters the preheating furnace.

Heat Exchange: The furnace is typically designed with a series of tubes through which the crude oil flows. Hot flue gases, generated by burning fuel (such as natural gas or fuel oil), pass over these tubes, transferring heat to the crude oil.

Temperature Increase: As the crude oil flows through the tubes, it absorbs heat from the flue gases, gradually increasing in temperature.

Desired Temperature: The furnace is carefully controlled to ensure that the crude oil reaches the desired temperature, typically around 350°C to 360°C. This temperature is essential for effective vaporization of the lighter components in the crude oil.

Exit to Distillation Column: Once the crude oil has reached the target temperature, it exits the preheating furnace and enters the atmospheric distillation column, where the separation process begins.

#OilAndGas#Refinery#ChemicalEngineering#ProcessEngineering#Petrochemical#DownstreamProcessing#Distillation#UnitOperations#EnergyIndustry#Fuels#FossilFuels#PreheatingFurnace#CrudeOilPreheating#AtmosphericDistillation#DistillationColumn#HydrocarbonSeparation#RefiningProcess#OilAndGasEquipment#ProcessControl#HeatTransfer#Decontamination

0 notes

Text

Seasonal Furnace Maintenance: Preventative Measures to Avoid Costly Repairs

As winter approaches, ensuring your furnace operates efficiently is crucial for keeping your home warm and cozy. Regular furnace maintenance can prevent costly repairs, extend the lifespan of your unit, and improve energy efficiency. This article outlines essential seasonal maintenance tasks and preventative measures that homeowners can take to ensure their furnace runs smoothly throughout the cold months.

The Importance of Seasonal Maintenance

Regular maintenance of your furnace is vital for several reasons:

Preventing Breakdowns: Just like any appliance, furnaces can break down without warning. Seasonal maintenance helps identify and address potential issues before they become major problems.

Improving Efficiency: A well-maintained furnace operates more efficiently, reducing energy consumption and lowering heating bills.

Extending Lifespan: Regular check-ups can prolong the lifespan of your furnace, saving you money on premature replacements.

Enhancing Safety: A neglected furnace can pose safety hazards, such as gas leaks or carbon monoxide buildup. Regular maintenance ensures your system operates safely.

Seasonal Furnace Maintenance Checklist

1. Change or Clean Air Filters

Dirty air filters restrict airflow, forcing your furnace to work harder and consume more energy. Replace or clean your air filter every 1-3 months during the heating season. Opt for high-efficiency filters to enhance indoor air quality and system performance.

2. Inspect the Thermostat

Ensure your thermostat is functioning correctly and accurately reflects the temperature in your home. If you have an older thermostat, consider upgrading to a programmable or smart thermostat for better control over your heating schedule.

3. Check the Ductwork

Inspect your ductwork for leaks, gaps, or blockages. Proper sealing and insulation of ducts can prevent heat loss and improve overall efficiency. If you notice any issues, consult a professional to perform duct sealing or cleaning.

4. Clean the Furnace and Surrounding Area

Dust and debris can accumulate around your furnace, impacting its performance. Clean the furnace exterior and the surrounding area to ensure adequate airflow. Keep combustible materials away from the furnace to reduce fire hazards.

5. Inspect the Blower Motor and Fan

The blower motor circulates heated air throughout your home. Ensure it is clean and functioning properly. Listen for unusual noises during operation, which may indicate wear and tear. Lubricate any moving parts as needed to reduce friction and wear.

6. Test Safety Controls and Components

Check safety controls such as the limit switch and flame sensor to ensure they are functioning correctly. A malfunctioning safety feature can lead to dangerous situations. If you’re unsure how to test these components, contact a professional technician.

7. Schedule a Professional Tune-Up

While many maintenance tasks can be performed by homeowners, a professional tune-up is essential for thorough inspection and servicing. A qualified technician can:

Inspect and clean critical components

Check gas lines and connections

Adjust the burner for optimal combustion

Test the efficiency and output of the furnace

8. Inspect the Exhaust System

Check the flue and vent pipes for any signs of blockage or corrosion. Proper ventilation is crucial for safe operation, as it prevents carbon monoxide buildup. Ensure that the exhaust system is clear and in good condition.

Additional Preventative Measures

Consider a Maintenance Plan: Many HVAC companies offer maintenance plans that include seasonal inspections and priority service. This can save you money on repairs and ensure your system is regularly serviced.

Monitor Performance: Keep an eye on your furnace's performance throughout the heating season. If you notice inconsistent temperatures or unusual sounds, contact a professional for assistance.

Know When to Replace: If your furnace is over 15-20 years old, it may be time to consider replacement. Newer models are typically more energy-efficient and can save you money in the long run.

Conclusion

Seasonal furnace replacement is essential for ensuring your heating system operates efficiently and safely throughout the winter months. By following this checklist and implementing preventative measures, you can avoid costly repairs and enjoy a warm, comfortable home. Don’t wait until the first cold snap to address your furnace—schedule your maintenance today to ensure peace of mind all season long.

0 notes