#Flue Gas Desulfurization Systems Market Size

Explore tagged Tumblr posts

Text

https://www.vevioz.com/read-blog/345403_fgd-systems-market-analysis-growth-drivers-amp-forecast.html

#Flue Gas Desulfurization Systems Market size#Flue Gas Desulfurization Systems Market share#Flue Gas Desulfurization Systems Market scope

0 notes

Text

Flue Gas Desulfurization Systems Market - Forecast(2024 - 2030)

FGD systems is utilizing in the industry to extract to remove Sulphur dioxide (SO2) from the flue gases, it assist in lowering the amount of SO2 in flue gas and assist greenhouse gas emission. Dry, wet and semi dry FGD systems is the key technology to the market. wet FGD is mostly use in the market that is high priced as compare to the dry FGD system and it have low maintenance and operating cost feature also. Dry FGD system perform efficiently in power plant with the capacity of 300MW while wet FGD system efficiency is more than 300MW. Some of the country is growing the flue gas desulfurization market for thermal power generation, the control of SO2 emission from thermal power plant is examined in developing commercial process.

Request Sample

The worldwide Flue Gas Desulfurization Systems Market has been analyzed on the basis its types and the process and different absorbers of flue gas desulfurization and their applications. FGD process are segmented as throwaway product, saleable product process. It has many applications in different industry such as to produce the power, to provide energy to metal smelters, and for cement kilns.

What is Flue Gas Desulfurization Systems Market?

Term flue gas desulfurization referred to wet scrubbers which remove Sulphur dioxide (SO2) from emissions of coal combustion. Flue gas desulfurization is commonly named as FGD, this technology is generally used in power plants to extract the Sulphur dioxide (SO2) from the exhaust combustion gases, this combust gases comes when they burn coal or oil to produce steam for turbines that drive electricity generators. In FGD we use acid rain or acid control system interchangeably to segment a wide range of control system design. FGD system can be categorized as dry FGD, semi-dry FGD, and wet FGD system.

Inquiry Before Buying

What are the applications of Flue Gas Desulfurization Systems Market?

Flue gas desulfurization system has various role to the environment, their sub process such as lime plays a key role to air pollution control. It has many typical industrial application such as pollution control in utility combustion in industry like stationary coal and oil fired, other combustion unit such as medical and municipal waste incinerators, petroleum refineries, glass furnaces, metal smelters, and cement and lime kilns manufacturing facilities.

Market Research and Market Trends of Flue Gas Desulfurization Systems Market:

Many of the country with high pollution rate are working for new advanced feature of FGD system, which is one of the outcomes to their continuous innovation over years. This new AFGD system is more efficient as compare to FGD system efficiency.

FGD scrubbers system creates a wastewater stream which contains high suspended solids, metals and chloride content that is very difficult to handle and recycling for reuse in power plant. So without disposing that waste water they take it into the Zero-liquid discharge (ZLD) water treatment process which completely recycle water under certain limitations.

Schedule a Call

Who are the Major Players of Flue Gas Desulfurization Systems Market?

The major players in this market are Siemens, Chinaboqi, Babcock & Wilcox Company and XX other companies.

What is our report scope?

The report incorporates in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2018-2023.

All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Buy Now

Key Takeaways from this Report

Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

Analyze the sales and distribution channels across key geographies to improve top-line revenues.

Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

#flue gas desulfurization systems market#flue gas desulfurization systems market price#flue gas desulfurization systems market size#flue gas desulfurization systems market shape#flue gas desulfurization systems market report#flue gas desulfurization systems market research#flue gas desulfurization systems market forecast#Sulphur dioxide (SO2)#flue gases#exhaust combustion gases

0 notes

Text

Flue Gas Desulfurization System Market Analysis: Key Players and Competitive Landscape

Stringent Emission Regulations and Rising Industrialization Drive Growth in the Flue Gas Desulfurization System Market.

The Flue Gas Desulfurization System Market Size was USD 21.6 Billion in 2023 and is expected to reach USD 34.1 Billion by 2032 and grow at a CAGR of 5.2% over the forecast period of 2024-2032.

The Flue Gas Desulfurization (FGD) System Market is experiencing significant growth due to the rising need for air pollution control and regulatory compliance in industries such as power generation, cement, iron & steel, and chemical manufacturing. FGD systems play a critical role in reducing sulfur dioxide (SO₂) emissions, which contribute to acid rain and respiratory diseases. Governments and environmental agencies worldwide are enforcing stringent emission norms, driving industries to adopt advanced FGD technologies such as wet, dry, and semi-dry desulfurization systems. The growing transition toward clean energy and sustainable industrial practices is further propelling market expansion.

Key Players

Koch-Glitsch (Tower Packing and Scrubber Systems)

HAMON (Wet and Dry Scrubbing Solutions)

Babcock & Wilcox Enterprises, Inc. (Spray Dryer Absorbers and Wet FGD Systems)

GE Power (Advanced FGD Systems and Limestone-based Solutions)

Mitsubishi Hitachi Power Systems, Ltd. (Twin Tower FGD and Wet-Limestone Scrubbers)

GEA Group Aktiengesellschaft (Dry Scrubbing Technologies and Filter Systems)

KraftPowercon (Power Supplies for FGD and Electrostatic Precipitators)

Carmeuse (Limestone and Lime Products for Desulfurization)

ANDRITZ AG (FGD Gypsum Dewatering Systems and Scrubbing Units)

Thermax Ltd. (FGD Retrofit and Custom Solutions)

Future Scope

The FGD System Market is expected to expand significantly, driven by global efforts to combat industrial air pollution and meet stringent emission standards set by organizations like the EPA, EU, and CPCB. The increasing shift toward renewable energy sources may reduce demand for FGD systems in the long term, but in the short term, coal-based power plants and industrial facilities will continue to require efficient sulfur removal technologies. The adoption of hybrid and multi-pollutant control systems, integrating FGD with carbon capture and NOx reduction technologies, is expected to shape the market's future.

Emerging Trends

The FGD market is witnessing a shift toward high-efficiency, low-energy-consuming technologies, with a focus on reducing operating costs and improving SO₂ removal efficiency. Wet FGD systems remain dominant due to their high efficiency (95%-99% SO₂ removal), but dry and semi-dry technologies are gaining traction in regions with water scarcity and smaller industrial facilities. Additionally, the development of sorbent-based and ammonia-based FGD processes is opening new opportunities for byproduct recovery and enhanced sustainability. The integration of AI-based monitoring and predictive maintenance systems is also improving operational efficiency and reducing downtime in power plants and industrial units.

Key Points

Growing need for emission control solutions due to stringent environmental regulations.

High adoption of wet FGD technology due to superior SO₂ removal efficiency.

Increasing use of dry and semi-dry systems in water-scarce regions.

Development of sorbent-based and ammonia-based FGD technologies for improved efficiency.

Integration of AI and IoT for real-time monitoring and predictive maintenance in FGD systems.

Conclusion

The Flue Gas Desulfurization (FGD) System Market is poised for steady growth, driven by environmental policies, industrial expansion, and advancements in pollution control technologies. As industries seek cost-effective and energy-efficient FGD solutions, innovations such as hybrid desulfurization systems, AI-powered monitoring, and byproduct recovery technologies will shape the future of the market. With global efforts focused on reducing industrial emissions and improving air quality, the demand for effective SO₂ removal systems will remain strong, ensuring a sustainable and cleaner environment.

Read Full Report: https://www.snsinsider.com/reports/flue-gas-desulfurization-system-market-1976

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Flue Gas Desulfurization System Market#Flue Gas Desulfurization System Market Size#Flue Gas Desulfurization System Market Share#Flue Gas Desulfurization System Market Report#Flue Gas Desulfurization System Market Forecast

0 notes

Text

Industrial Flue Gas Treatment Market Analysis: Trends, Drivers, and Outlook

The industrial flue gas treatment market is experiencing significant growth, driven by stringent environmental regulations, technological advancements, and the increasing need for industries to comply with emission standards. This article provides an in-depth analysis of the current state of the FGT market, examining key trends, drivers, challenges, and regional dynamics.

Market Overview

The global Industrial Flue Gas Treatment Systems & Services Market was valued at approximately USD 73.09 billion in 2023 and is projected to reach USD 120.99 billion by 2032, growing at a compound annual growth rate (CAGR) of 5.76% during the forecast period from 2024 to 2032 . This growth reflects the increasing emphasis on reducing industrial emissions and improving air quality.

Key Market Drivers

1. Stringent Environmental Regulations

Governments worldwide are implementing stricter emission standards to combat air pollution and mitigate climate change. For instance, the European Union's Industrial Emissions Directive and the U.S. Environmental Protection Agency's regulations mandate industries to install advanced flue gas treatment systems to limit pollutants such as sulfur dioxide (SO₂), nitrogen oxides (NOₓ), and particulate matter. These regulations are compelling industries to invest in FGT technologies to comply with legal requirements and avoid penalties.

2. Technological Advancements

Innovations in flue gas treatment technologies, such as Selective Catalytic Reduction (SCR) for NOₓ removal, Wet Flue Gas Desulfurization (FGD) systems for SO₂ control, and Electrostatic Precipitators (ESPs) for particulate matter collection, are enhancing the efficiency and effectiveness of emission control. These advancements enable industries to achieve higher compliance levels with lower operational costs.

3. Growing Industrialization in Emerging Economies

Rapid industrialization in regions like Asia-Pacific, Latin America, and Africa is driving the demand for flue gas treatment systems. Countries such as China and India are investing heavily in infrastructure development, leading to increased emissions and a subsequent need for effective emission control solutions .

Market Segmentation

The Industrial Flue Gas Treatment market can be segmented based on pollutant control systems, end-user industries, and regions:

Pollutant Control Systems

DeNOₓ Systems: Utilize catalysts to reduce nitrogen oxides emissions.

Flue Gas Desulfurization (FGD): Remove sulfur dioxide from exhaust gases.

Particulate Control Systems: Capture solid particles from flue gases.

Mercury Control Systems: Reduce mercury emissions.

End-User Industries

Power Generation: The largest consumer of FGT systems due to high emissions from coal-fired plants.

Cement Manufacturing: Significant emitter of particulate matter and CO₂.

Chemical & Petrochemical: Require advanced emission control due to complex processes.

Iron & Steel: High NOₓ and CO₂ emissions necessitate effective treatment solutions.

Regional Insights

Asia-Pacific: Dominates the market due to rapid industrialization and stringent emission norms in countries like China and India.

North America: Strong regulatory frameworks drive the adoption of advanced FGT systems.

Europe: Established emission standards and a focus on sustainability propel market growth.

Challenges in the Market

1. High Capital and Operational Costs

The installation and maintenance of advanced flue gas treatment systems require significant investment. Small and medium-sized enterprises (SMEs) may find it challenging to afford these costs, potentially hindering market penetration.

2. Technological Complexity

The operation of sophisticated emission control systems demands specialized knowledge and skilled personnel. Lack of expertise can lead to inefficiencies and increased downtime.

3. Regulatory Compliance

Adhering to evolving environmental regulations can be complex, especially for industries operating in multiple jurisdictions with varying standards. Non-compliance can result in legal repercussions and damage to reputation.

Future Outlook

The Industrial Flue Gas Treatment market is poised for continued growth, driven by technological advancements and increasing regulatory pressures. Key trends shaping the future include:

Integration of Artificial Intelligence (AI) and Internet of Things (IoT): Enabling real-time monitoring and predictive maintenance of flue gas treatment systems.

Development of Sustainable and Cost-Effective Technologies: Focus on creating solutions that are both environmentally friendly and economically viable.

Expansion in Emerging Markets: Increased adoption of FGT systems in developing regions to meet industrial growth and environmental goals.

Conclusion

The Industrial Flue Gas Treatment market is integral to achieving global environmental objectives. While challenges such as high costs and technological complexities exist, the ongoing advancements and regulatory support are paving the way for a cleaner industrial future. Stakeholders across industries must continue to invest in innovative solutions to meet emission standards and contribute to sustainable development.

0 notes

Text

Why Rajasthan Tops as the Best Hydrated Lime Manufacturer in India

Introduction

Rajasthan, often referred to as the land of minerals, has carved a unique identity in India's lime industry. As demand grows for quality hydrated lime in infrastructure, metallurgy, and chemical sectors, Rajasthan emerges as the frontrunner, thanks to its abundant natural resources and advanced manufacturing capabilities. This blog delves into the reasons why Rajasthan dominates as the hub of hydrated lime manufacturers in India, with a special focus on industries seeking premium lime for asphalt and the role of the best limestone manufacturers in powering this growth.

1. Geographical Advantage and Rich Mineral Deposits

One of the primary reasons Rajasthan is a leader in hydrated lime production is its vast natural limestone reserves. Districts such as Nagaur, Jodhpur, and Udaipur are known for their high-purity limestone, which forms the foundation for producing top-grade hydrated lime.

The availability of raw material in close proximity not only reduces transportation costs but also allows manufacturers to maintain consistent quality—a critical requirement for industries relying on premium lime for asphalt or chemical processing.

2. Advanced Manufacturing Infrastructure

Over the years, Rajasthan has witnessed rapid industrial development, especially in the lime sector. Many of the best limestone manufacturers in the country have set up cutting-edge production facilities here. These plants are equipped with modern kilns, automated hydration systems, and quality control labs that ensure superior product consistency.

Companies in Rajasthan adopt environmentally friendly practices and energy-efficient technologies, helping them stay compliant with both Indian and international standards. This focus on quality makes Rajasthan a go-to destination for hydrated lime manufacturers in India blog searches.

3. Skilled Workforce and Industrial Experience

With decades of experience in lime production, Rajasthan's workforce has become highly skilled in the processes of calcination and hydration. From quarry management to final packaging, every step is handled by professionals trained to meet the stringent demands of industries like asphalt mixing, construction, and metallurgy.

This experience adds another layer of reliability, particularly when supplying premium lime for asphalt, where precision in chemical composition and particle size is vital for road durability and strength.

4. Quality That Meets Global Standards

Hydrated lime from Rajasthan is well-regarded for its high calcium content, low impurities, and fine texture. This makes it suitable for a wide range of industrial applications including water treatment, flue gas desulfurization, steel manufacturing, and road construction.

Many hydrated lime manufacturers in India, particularly from Rajasthan, now export to markets in the Middle East, Southeast Asia, and Africa. The reputation for high-quality products has been a game-changer for buyers seeking consistent and reliable supply.

5. Strategic Location and Excellent Logistics

Rajasthan’s location provides easy access to both northern and western parts of India. The robust road and rail connectivity ensure faster delivery times and reduced transit damage. For industries relying on bulk supplies of hydrated lime—such as cement, steel, or asphalt contractors—this logistical convenience adds immense value.

Leading hydrated lime manufacturers in India from Rajasthan also offer customized packaging and bulk delivery services, further cementing their reputation among national and international clients.

6. Application of Premium Lime in Asphalt

One of the fastest-growing applications of hydrated lime is in asphalt road construction. Premium lime for asphalt is used to enhance adhesion, reduce stripping, and improve durability of pavements. Rajasthan-based manufacturers offer hydrated lime with ideal moisture content and chemical purity tailored for this specific application.

Their lime acts as an anti-stripping agent, binding the bitumen to the aggregate more effectively and significantly extending the life of roads—especially in India’s extreme weather conditions.

7. Supportive Government Policies

Rajasthan’s state government has long supported the growth of the lime industry by offering incentives like subsidies on equipment, access to mineral leases, and streamlined licensing processes. These policies have helped local businesses scale their operations and invest in research and development.

As a result, manufacturers in the state continue to innovate and diversify their offerings to cater to evolving industry needs—from construction-grade lime to high-end applications such as food processing and pharmaceuticals.

8. Rising Export Opportunities

With India being a cost-effective manufacturing destination, Rajasthan-based hydrated lime companies are increasingly looking beyond domestic markets. Thanks to their scale, quality, and pricing, these companies are becoming preferred partners for international buyers looking for large volumes of premium lime for asphalt and other industrial applications.

Customs-friendly policies at ports like Kandla and Mundra—both easily accessible from Rajasthan—further facilitate smooth exports.

9. Sustainability and Eco-Friendly Practices

Environmental sustainability is a growing concern across industries. Many best limestone manufacturers in Rajasthan are now adopting sustainable mining techniques and carbon capture technologies in their lime kilns.

They also invest in water recycling, dust management, and tree plantation efforts around mining sites. These steps not only make the production eco-friendly but also align with global buyers’ expectations on sustainable sourcing.

10. Rajasthan's Reputation and Industry Leadership

The sheer number of lime manufacturers in Rajasthan, coupled with decades of consistent supply and product excellence, has given the state a near-monopoly in India’s hydrated lime market. It has become the first name that comes to mind when one thinks of hydrated lime manufacturers in India blog topics, thanks to the state's comprehensive ecosystem.

Buyers across industries—from road construction to water purification—prefer Rajasthan for its trustworthiness, volume capabilities, and innovation-driven mindset.

Conclusion

Rajasthan’s dominance in hydrated lime manufacturing isn’t a coincidence—it’s the result of geological blessings, industrial foresight, and a commitment to quality. From being home to the best limestone manufacturers to becoming the preferred source of premium lime for asphalt, the state offers unmatched advantages for industries across India and abroad.

Whether you're sourcing lime for a government road project or a high-precision industrial process, Rajasthan remains the top choice. As the market grows and evolves, Rajasthan is poised to lead from the front, maintaining its stature as the heart of India’s lime industry.

#limestone suppliers in india#hydrated lime manufacturers in jodhpur#quick lime manufacturers in india

0 notes

Text

Flue Gas Desulfurization Systems Market - Forecast(2025 - 2031)

The Flue Gas Desulfurization Systems Market size is estimated to reach $33,611.30 Million by 2030, growing at a CAGR of 5.10% during the forecast period 2024-2030.

FGD systems is utilizing in the industry to extract to remove Sulphur dioxide (SO2) from the flue gases, it assist in lowering the amount of SO2 in flue gas and assist greenhouse gas emission. Dry, wet and semi dry FGD systems is the key technology to the market. wet FGD is mostly use in the market that is high priced as compare to the dry FGD system and it have low maintenance and operating cost feature also. Dry FGD system perform efficiently in power plant with the capacity of 300MW while wet FGD system efficiency is more than 300MW.

0 notes

Text

Saudi Arabia Air Quality Control Systems Market

Saudi Arabia Air Quality Control Systems Market Size, Share, Trends: General Electric Leads

Rising Adoption of Hybrid and Multi-Pollutant Control Systems

Market Overview:

The Saudi Arabia Air Quality Control Systems Market is projected to grow at a CAGR of 6.5% from 2024 to 2031, reaching a value of SAR YY billion by 2031. The Central region currently dominates the market, accounting for a significant share. Key metrics include installation volume, emission reduction efficiency, and adoption rates across different industrial sectors. The industry is expanding rapidly, owing to strict environmental regulations, increased industrialisation, and growing awareness of the health risks of air pollution. Government measures encouraging renewable energy and sustainable development are accelerating market growth.

DOWNLOAD FREE SAMPLE

Market Trends:

The Saudi Arabia Air Quality Control Systems market is seeing a substantial transition towards hybrid and multi-pollutant control technologies, driven by the need for more efficient and cost-effective emission reduction solutions. Leading environmental technology companies are responding to this trend by developing integrated systems capable of addressing multiple pollutants simultaneously, such as particulate matter, sulfur dioxide, and nitrogen oxides. For instance, a leading global air quality control system manufacturer reported a 60% year-on-year growth in sales of advanced multi-pollutant control solutions in Saudi Arabia in 2023.

Market Segmentation:

Flue Gas Desulfurization (FGD) systems dominate the market, driven by stringent sulfur emission regulations. The FGD sector now commands the greatest market share in Saudi Arabia's Air Quality Control Systems market. According to recent data from the Saudi General Authority of Meteorology and Environmental Protection, FGD systems helped reduce sulfur dioxide emissions from large industrial sites by 60% in 2023 compared to 2018. Technological advancements in FGD systems, such as the development of seawater FGD for coastal facilities and dry sorbent injection for smaller applications, have increased their usefulness across various industries.

Market Key Players:

General Electric (GE)

Siemens

Babcock & Wilcox

Mitsubishi Hitachi Power Systems

Saudi Environmental Projects Ltd.

Advanced Pollution Control Company

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

0 notes

Text

Synthetic Gypsum Market: A Growing Alternative with Sustainable Potential

In recent years, the synthetic gypsum market has witnessed a substantial rise, largely propelled by industries that value sustainable, cost-effective alternatives to natural resources. Synthetic gypsum, produced as a byproduct from various industrial processes, has carved out a vital role across sectors like cement production, building materials, gypsum board manufacturing, soil amendments, and even dentistry. This market trend is not just about substituting natural gypsum but also about supporting industries with a more environmentally friendly and accessible option.

Synthetic gypsum market size is projected to grow from USD 1.4 billion in 2024 and is projected to reach USD 1.8 billion by 2030, at a CAGR of 4.3%.

Let’s delve into the unique dynamics and potential of synthetic gypsum, highlighting its applications, challenges, and emerging opportunities for industries that are increasingly focused on sustainable growth.

What is Synthetic Gypsum?

Synthetic gypsum is chemically identical to natural gypsum—both composed of calcium sulfate dihydrate. However, unlike natural gypsum that is mined, synthetic gypsum is a byproduct, often generated from industrial processes like flue gas desulfurization (FGD) in coal-fired power plants. When these plants capture sulfur dioxide emissions to reduce air pollution, the process yields synthetic gypsum as a usable byproduct. This environmentally beneficial cycle transforms waste into a resource, aligning with broader sustainability goals.

This "upcycled" form of gypsum can be used almost interchangeably with natural gypsum in many applications, thus reducing the demand for mining activities and conserving natural resources.

Key Factors Driving Market Growth

Sustainable Construction and Building Materials: In today’s world, there’s a growing demand for greener building solutions. Since synthetic gypsum comes from recycled industrial byproducts, it’s an attractive option in the construction industry. It conserves natural gypsum reserves, reduces waste, and helps minimize environmental damage, making it an ideal choice for eco-conscious builders and contractors.

Increasing Regulatory Focus on Environmental Protection: Environmental regulations around air quality have driven more facilities to adopt FGD systems, inadvertently boosting synthetic gypsum supply. Governments worldwide have implemented strict environmental policies to reduce industrial emissions, further encouraging the use of synthetic gypsum. The fact that this byproduct can be reused in critical industries only strengthens its appeal.

Surge in Demand for Gypsum Board: The construction boom, particularly in urbanized and rapidly developing regions, has led to an increased demand for drywall. Synthetic gypsum plays a critical role in gypsum board production, offering a fire-resistant, durable, and easy-to-install building material that is highly valued in the construction industry. With this demand on the rise, synthetic gypsum is increasingly essential to meet production needs.

Growing Agricultural Applications: Agriculture is an emerging avenue for synthetic gypsum, where it acts as a soil conditioner. Gypsum helps improve soil structure, enhance water absorption, and prevent erosion. This application has gained attention worldwide, especially in arid and semi-arid regions where synthetic gypsum can provide essential nutrients like calcium and sulfur, improving crop yield and soil health.

Dental and Medical Fields: While perhaps less known, synthetic gypsum is also used in dentistry to create molds and impressions. Its uniformity and purity make it a great choice for this precision-driven field. This niche application is opening up new avenues for synthetic gypsum, as dental professionals recognize its benefits over traditional materials.

Key Applications of Synthetic Gypsum

Cement Production: In cement production, synthetic gypsum is added to clinker to control the setting time. This not only helps improve the consistency of cement but also enhances its structural properties. With synthetic gypsum as an alternative, cement producers can opt for a sustainable and cost-efficient material, supporting their production processes without compromising quality.

Gypsum Board (Drywall) Manufacturing: Synthetic gypsum has a pivotal role in gypsum board manufacturing, particularly in regions like North America and Europe. Gypsum board, made of a gypsum core sandwiched between paper liners, is essential for interior construction. It offers fire resistance, ease of use, and cost-effectiveness. As construction activities increase globally, especially with new housing and commercial projects, synthetic gypsum's demand is set to grow significantly in this segment.

Soil Conditioner in Agriculture: For agricultural use, synthetic gypsum has shown promise as an effective soil amendment. It can improve soil quality by adding calcium and sulfur, enhancing root growth, and aiding in water absorption. This is particularly beneficial in saline or sodic soils, where gypsum helps to balance the soil structure, allowing for better crop growth and soil health.

Dental and Medical Uses: In the dental industry, synthetic gypsum is highly valued for its use in creating dental molds, impressions, and casts. Due to its chemical consistency and purity, synthetic gypsum is a preferred choice in this field, meeting the precision requirements necessary for high-quality dental applications.

Challenges and Future Opportunities

While synthetic gypsum holds numerous advantages, the market does face a few challenges. Transportation costs can be high due to the weight and bulk of gypsum, which may limit its usage in areas far from production facilities. Quality control is another consideration, as synthetic gypsum derived from different sources can vary, making consistent standards necessary, especially for high-end uses in industries like construction and healthcare.

However, the future looks bright for synthetic gypsum. As sustainable materials gain popularity and industries continue to prioritize recycled content, synthetic gypsum is well-positioned to meet the growing demand. Emerging markets, in particular, offer significant potential as they expand infrastructure and prioritize environmentally friendly resources. Additionally, advancements in synthetic gypsum production processes could further enhance its quality, expanding its application potential across new sectors.

To know more Download PDF Brochure :

The synthetic gypsum market is more than just a substitute for natural gypsum—it’s a sustainable alternative that holds unique value across multiple industries. By repurposing industrial waste, synthetic gypsum helps conserve natural resources, supports sustainable manufacturing practices, and meets the needs of diverse applications. From construction and agriculture to healthcare, synthetic gypsum is making a positive environmental impact, helping industries reduce their carbon footprint and promote greener practices. As industries continue to move towards sustainability, synthetic gypsum’s role is only set to grow, carving a more substantial presence in the global marketplace and contributing to a greener future.

#Synthetic Gypsum Market#Sustainability#Cement Industry#Building Materials#Gypsum Board#Soil Amendments#Eco-Friendly Solutions

0 notes

Text

Flue Gas Desulfurization System Market 2024 : Size, Growth Rate, Business Module, Product Scope, Regional Analysis And Expansions 2033

The flue gas desulfurization system global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Flue Gas Desulfurization System Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The flue gas desulfurization system market size has grown strongly in recent years. It will grow from $19.59 billion in 2023 to $20.77 billion in 2024 at a compound annual growth rate (CAGR) of 6.1%.The growth in the historic period can be attributed to stringent environmental regulations, rising global focus on air quality, increased coal-fired power generation, public awareness and environmental activism, expansion of industrial manufacturing.

The flue gas desulfurization system market size is expected to see strong growth in the next few years. It will grow to $26.25 billion in 2028 at a compound annual growth rate (CAGR) of 6.0%.The growth in the forecast period can be attributed to transition to renewable energy, market expansion for fgd by-products, government support for clean energy, increasing use of natural gas, focus on circular economy practices. Major trends in the forecast period include integration of digital technologies, shift towards dry fgd technologies, byproduct utilization, collaborations and partnerships, technological advancements in fgd systems.

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/flue-gas-desulfurization-system-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers - The increasing number of coal-fired power plants is expected to propel the flue gas desulfurization system market. Coal-fired power plants refer to power stations that generate electricity by burning coal. The increasing number of coal-fired power plants requires flue gas desulfurization systems to reduce the emission of harmful gases. For instance, in August 2022, according to the U.S. Energy Information Administration, a US-based principal agency for collecting, analyzing, and disseminating energy information, published an article according to which in the US the coal-fired generation of power has increased by 16% to reach 898,679 GWh in 2021 . Therefore, the increasing number of coal-fired power plants is driving the growth of the flue gas desulfurization system market.

Market Trends - Collaboration is a key trend in the flue gas desulfurization system market. Major players are associating themselves with various companies to sustain in the market. For instance, in January 2022, General Electric (GE), a US-based conglomerate, associated with Apollo International Limited for MB Power Madhya Pradesh Ltd to design the whole Wet Flue Gas Desulfurization (WFGD) system. The project entails the design, engineering, and supply of vital WFGD system components. Once completed, it will help the client clean 7.4 million cubic meters of flue gas per hour and eliminate 51,000 tons of SO2 annually.

The flue gas desulfurization system market covered in this report is segmented –

1) By Type: Wet FGD Systems, Spray Dry FGD System, Dry and Semi-dry FGD Systems 2) By Installation: Greenfield, Brownfield 3) By End-Use: Power Generation, Chemical, Iron and Steel, Metal Processing and Mining, Cement Manufacturing, Paper and Pulp, Other End Uses

Get an inside scoop of the flue gas desulfurization system market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=8889&type=smp

Regional Insights - Asia-Pacific was the largest region in the flue gas desulfurization system market share in 2023. The regions covered in the flue gas desulfurization system market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - Major companies operating in the flue gas desulfurization system market report are Mitsubishi Heavy Industries Ltd., General Electric Company, Doosan Lentjes GmbH, Babcock & Wilcox Enterprises Inc., Rafako S.A, Siemens AG, FLSmidth & Co. A/S, Hamon Corporation, Marsulex Environmental Technologies Corporation, Thermax Limited, Ducon Technologies Inc., Clyde Bergemann Power Group, Andritz AG, Valmet Corporation, Hitachi Power Systems America Ltd., Chiyoda Corporation, China Energy Engineering Group Co. Ltd., Tri-Mer Corporation, Umicore, Veolia Water Technologies, Wärtsilä Corp., Wheelabrator Technologies Inc., Xcel Energy Inc., Yokogawa Electric Corporation, Zhejiang Feida Environmental Science & Technology, Zhejiang DunAn Artificial Environment, Zhejiang Shuanghuan Environmental Protection, Dürr AG, GEA Group AG

Table of Contents 1. Executive Summary 2. Flue Gas Desulfurization System Market Report Structure 3. Flue Gas Desulfurization System Market Trends And Strategies 4. Flue Gas Desulfurization System Market – Macro Economic Scenario 5. Flue Gas Desulfurization System Market Size And Growth ….. 27. Flue Gas Desulfurization System Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Flue Gas Desulfurization (FGD) Market Analysis 2023 Dynamics, Players, Type, Applications, Trends, Regional Segmented, Outlook & Forecast till 2033

The global flue gas desulfurization (FGD) system market is expected to have a compound annual growth rate (CAGR) of 5.1% from 2023 to 2033. In 2023, the market is expected to be worth USD 22,252.3 million and to reaching a value of USD 36,593.3 million by 2033.

The Flue Gas Desulfurization (FGD) market pertains to the industry involved in the reduction of sulfur dioxide emissions from industrial processes, particularly those related to power generation and combustion of fossil fuels. FGD systems are designed to remove sulfur dioxide (SO2) from flue gases before they are released into the atmosphere, thereby mitigating air pollution and environmental damage associated with acid rain, smog, and respiratory illnesses.

Driven by stringent environmental regulations, growing public awareness of air quality issues, and the need for cleaner energy production, the FGD market has experienced significant growth in recent years. Power plants, refineries, chemical plants, and other industrial facilities are increasingly adopting FGD technologies to comply with emissions standards and reduce their environmental footprint.

FGD systems typically employ various methods, including wet scrubbing, dry scrubbing, and semi-dry scrubbing, to remove sulfur dioxide from flue gases. Wet scrubbing involves the use of alkaline solutions such as limestone or lime to react with sulfur dioxide and produce calcium sulfite or sulfate, which can be disposed of or recycled. Dry scrubbing utilizes sorbent materials such as activated carbon or sodium bicarbonate to absorb sulfur dioxide from flue gases, while semi-dry scrubbing combines elements of both wet and dry processes for sulfur removal.

The FGD market is characterized by technological advancements aimed at improving efficiency, reliability, and cost-effectiveness of FGD systems. Innovations such as advanced scrubber designs, optimized reagent utilization, and integration with other pollution control technologies enhance the performance and competitiveness of FGD solutions.

Furthermore, the FGD market is influenced by factors such as fuel type, plant size, regulatory requirements, and economic considerations. Coal-fired power plants, in particular, represent a significant market segment for FGD systems due to the high sulfur content of coal and the stringent emissions limits imposed by environmental regulations. However, the market is also expanding to include other industries such as oil and gas, cement production, and metal smelting, where FGD technologies can help mitigate air pollution and comply with emissions standards.

Trends: Identify and analyze trends relevant to the market you're researching. This could include shifts in consumer behavior, industry regulations, technological advancements, or changes in market demand. Look at both short-term and long-term trends to provide a comprehensive view.

Technological Developments: Highlight the latest technological innovations impacting the market. This might involve advancements in automation, artificial intelligence, IoT (Internet of Things), blockchain, or any other relevant technologies. Discuss how these developments are shaping the industry landscape and driving change.

Analysis: Conduct a thorough analysis of the market, including SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis, Porter's Five Forces analysis, and any other relevant analytical frameworks. Assess market dynamics, competitive landscape, and barriers to entry. Provide insights into market segmentation, customer demographics, and buying behavior.

Growth Drivers: Identify the primary drivers fueling market growth. This could include factors such as increasing demand for certain products or services, expansion into new geographic regions, rising disposable income levels, technological advancements driving innovation, or favorable regulatory policies. Quantify the impact of these drivers on market growth wherever possible.

Receive the FREE Sample Report of Flue Gas Desulfurization (FGD) Market Research Insights @ https://stringentdatalytics.com/sample-request/flue-gas-desulfurization-(fgd)-market/14961/

Market Segmentations:

Global Flue Gas Desulfurization (FGD) Market: By Company Mitsubishi Heavy Industries General Electric Doosan Lentjes Babcock & Wilcox Enterprises Rafako Siemens Flsmidth Hamon Corporation Clyde Bergemann Power Group Marsulex Environmental Technologies Thermax andritz

Global Flue Gas Desulfurization (FGD) Market: By Type Wet FGD System Limestone Seawater Dry & Semi-dry FGD System Others

Global Flue Gas Desulfurization (FGD) Market: By Application Iron & Steel Industry Cement Manufacturing Industry Power Generation Chemical Industry Others

Regional Analysis of Global Flue Gas Desulfurization (FGD) Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Flue Gas Desulfurization (FGD) market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Flue Gas Desulfurization (FGD) Market Research Report @ https://stringentdatalytics.com/purchase/flue-gas-desulfurization-(fgd)-market/14961/?license=single

Challenges: Identify and discuss the challenges that the market is currently facing. These challenges could include regulatory hurdles, economic instability, supply chain disruptions, intense competition, changing consumer preferences, or technological limitations. Provide insights into how these challenges are impacting the industry and potentially hindering growth or innovation.

Future Outlook: Offer a forward-looking perspective on the market's trajectory. Based on the analysis conducted earlier, forecast the future direction of the market. Consider factors such as emerging technologies, shifting consumer behaviors, regulatory changes, and global economic trends. Discuss potential opportunities that may arise in the future and how stakeholders can capitalize on them. Additionally, highlight potential threats or disruptions that could impact the market landscape.

Mitigation Strategies: Suggest mitigation strategies to address the challenges identified and capitalize on future opportunities. This could involve recommendations for businesses to adapt their strategies, invest in R&D, forge strategic partnerships, or diversify their product/service offerings. Provide actionable insights that stakeholders can use to navigate uncertainties and position themselves for success in the evolving market environment.

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected] ), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

0 notes

Text

Global Top 5 Companies Accounted for 77% of total Flue Gas Desulfurizer (FGD) market (QYResearch, 2021)

Flue gas desulfurizer (FGD) is equipment which can remove sulfur dioxide (SO2) from flue gas emissions, often chemically. Sulfur dioxide in gases is produced by the combustion of fossil fuels and many industrial processes such as gasoline refining as well as cement, paper, glass, steel, iron and copper production. Sulfur dioxide emissions are a primary contributor to acid rain and have been regulated by every industrialized nation in the world.

FGD processes vary depending on the amount of SO2 involved, the solution being used to absorb the SO2, and the particular equipment used in the absorption tower.

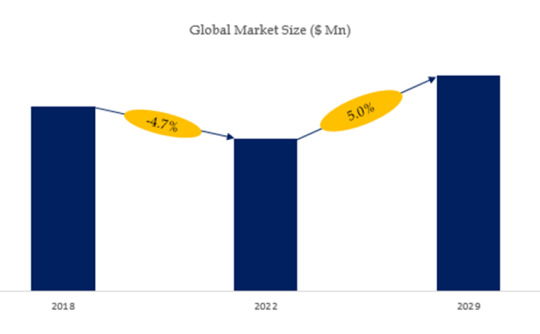

According to the new market research report “Global Flue Gas Desulfurizer (FGD) Market Report 2023-2029”, published by QYResearch, the global Flue Gas Desulfurizer (FGD) market size is projected to reach USD 6.29 billion by 2029, at a CAGR of 5.0% during the forecast period.

Figure. Global Flue Gas Desulfurizer (FGD) Market Size (US$ Million), 2018-2029

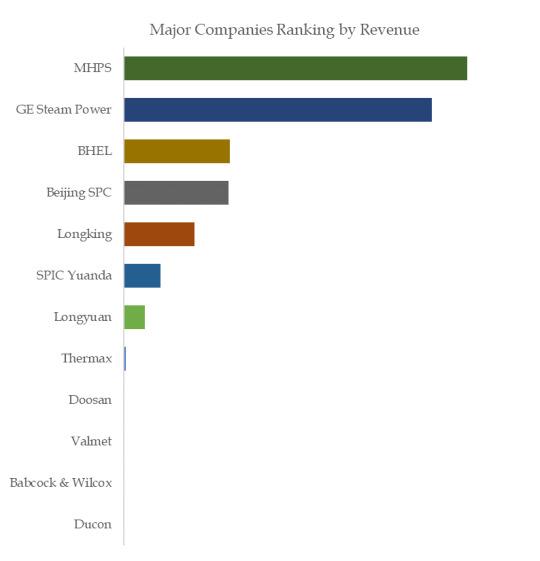

Figure. Global Flue Gas Desulfurizer (FGD) Top 12 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Flue Gas Desulfurizer (FGD) include MHPS, GE Steam Power, BHEL, Beijing SPC, Longking, SPIC Yuanda, Longyuan, Thermax, Ducon, Babcock & Wilcox, etc. In 2020, the global top five players had a share approximately 77.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Understanding the Competitive Landscape of the Sulfur Dioxide Market through 2030

The global sulfur dioxide market is poised for substantial growth, with an anticipated size of US$ 9.15 Billion in 2024, projected to reach US$ 10.01 Billion by 2030. This surge is attributed to a robust revenue compound annual growth rate (CAGR) of 5% from 2024 to 2030. The market's momentum is propelled by the escalating demand for sulfur dioxide (SO2) across various applications, encompassing the production of sulfuric acid, bleaching of paper and pulp, refrigeration of food and beverages, and food preservation.

SO2, a colorless gas with a distinctive pungent odor reminiscent of burnt matches, plays a pivotal role in numerous industries. It is a byproduct of the combustion of sulfur-containing fuels like coal, oil, and diesel. Additionally, natural sources such as volcanoes can also contribute to the presence of SO2 in the atmosphere.

Get your Sample Report with Latest Market Information! https://absolutemarketresearch.com/Global-Sulfur-Dioxide-Market/1793/request-sample

Despite its industrial significance, exposure to elevated levels of SO2 poses health risks. The inhalation of SO2 can lead to various respiratory problems, including coughing, wheezing, and breathing difficulties. Individuals with pre-existing respiratory conditions, such as asthma, may experience exacerbated symptoms. In higher concentrations, SO2 exposure may result in eye irritation, nausea, and vomiting.

This market expansion underscores the critical need for sustainable practices and technologies in SO2 emissions control. As the demand for SO2 continues to rise across industries, it becomes imperative to address the associated environmental and health concerns. Industry stakeholders are encouraged to prioritize and invest in technologies that mitigate SO2 emissions, ensuring responsible and sustainable growth.

Key Market Trends:

The sulfur dioxide market is witnessing several key trends, including:

Increasing demand for sulfuric acid: Sulfuric acid is the most widely used industrial chemical, and its production is the primary driver of demand for SO2. The increasing demand for sulfuric acid in industries such as fertilizers, pharmaceuticals, and electronics is expected to drive the growth of the SO2 market.

Growing adoption of SO2 emission control technologies: Stringent environmental regulations aimed at reducing SO2 emissions are driving the adoption of SO2 emission control technologies. These technologies, such as flue gas desulfurization (FGD) systems, are used to remove SO2 from industrial emissions.

Increasing demand for SO2 in the food and beverage industry: SO2 is used as a preservative and antioxidant in the food and beverage industry. The growing demand for processed foods and beverages is expected to increase the demand for SO2.

Key Takeaways:

The global Sulfur Dioxide market size is likely to reach US$ 9.15 Billion in 2024 and is expected to reach US$ 10.01 Billion by 2030, and register a rapid revenue CAGR of 5% from 2024 to 2030.

The increasing demand for sulfuric acid, a key derivative of sulfur dioxide, is driving the growth of the market.

The growing adoption of sulfur dioxide in the food and beverage industry as a preservative and bleaching agent is also contributing to the market growth.

The stringent environmental regulations on sulfur dioxide emissions are posing a challenge to the market growth.

Asia Pacific is expected to be the fastest-growing region in the sulfur dioxide market, followed by North America and Europe.

Regional Analysis:

North America is the largest market for sulfur dioxide, followed by Asia Pacific and Europe.

The growth of the sulfur dioxide market in North America is being driven by the increasing demand for sulfuric acid in the region.

The growth of the sulfur dioxide market in Asia Pacific is being driven by the growing population and the increasing demand for food and beverages in the region.

The growth of the sulfur dioxide market in Europe is being driven by the growing demand for sulfuric acid in the chemical industry.

Key Players:

BASF SE

The Chemours Company

Huntsman Corporation

Lanxess AG

Olin Corporation

The Mosaic Company

Sinochem Corporation

Sumitomo Chemical Co., Ltd.

Taiyo Nippon Sanso Corporation

Tokuyama Corporation

Segmentation:

The global sulfur dioxide market is segmented by application, end-use, and region.

By Application:

Sulfuric acid

Bleaching agent

Refrigerating agent

Food preservative

Textiles

Food and beverages

Others

By End-Use:

Chemical

Textiles

Food and beverages

Others

By Region:

North America

Europe

Asia Pacific

South and Central America

0 notes

Text

0 notes

Text

Global Flue Gas Desulfurization Market Trends for 2023-2030

As per Triton Market Research, the Global Flue Gas Desulfurization Market report is segmented by Technology (Wet FGD Systems, Spray Dry FGD Systems, Dry FGD Systems), Application (Power Generation, Chemicals, Iron and Steel, Cement Manufacturing, Other Applications), and Regional Outlook (North America, Middle East and Africa, Asia-Pacific, Europe, Latin America).

The report highlights the Market Summary, Industry Outlook, Impact Analysis, Porter’s Five Forces Analysis, Market Maturity Analysis, Regulatory Framework, Key Market Strategies, Market Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology & Scope, Global Market Size, Forecasts & Analysis (2023-2030).

As per Triton’s research report, the global market for flue gas desulphurization is anticipated to progress with a CAGR of 4.93% over the forecasting years 2023-2030.

Flue gas desulfurization is a process to extract sulfur dioxide from the fossil fuel emissions of power plants. It has multiple applications across the coal, chemical, iron, and steel industries.

In order to curb the hazardous effects of sulfur dioxide on the environment and human health, industries are focused on reducing the sulfur content from emissions by adopting flue gas desulfurization systems. Additionally, the strict emission norms by the regulatory authorities to maintain clean air, improve air quality, and reduce degradation have the potential to drive demand for FGD systems. Industries also have an alternative to adopt tailored FGD solutions to cater to their specific needs.

However, slowdown in industrial activities, a reduction in industrial operations, a decline in investments, and slow production are some impacts during economic slowdown. Along with this, an inclination towards renewable energy hinders the growth of flue gas desulfurization market.

Asia-Pacific is anticipated to witness the fastest growth in the flue gas desulfurization market. Surrounded by developing countries, this region has tremendous scope to expand its industrial landscape to cater to economic needs. An increasing number of industries pose a threat to the environment. In this regard, installing FGD systems will become a top priority for the new industries. Thus, it will create a huge demand for the studied market in the coming years. However, the rise of renewable energy has a significant scope to challenge the market as countries slowly move towards achieving a green economy.

The major competitive companies in the flue gas desulfurization market are Babcock & Amp, Chiyoda Corporation Doosan Lentjes GmbH, Fujian Longking Co Ltd, Andritz AG, Hamon Group, Thermax Ltd, Rafako SA, Mitsubishi Hitachi Power Systems Ltd, Harsulex Environmental Technologies, Flsmidth AS, John Wood Group Plc, Ducon Technologies Inc, Kawasaki Heavy Industries Ltd, Willcox Enterprises Inc, and Ducon Technologies Inc.

The technical complexity and lack of specialized knowledge to design and manufacture FGD systems are potential barriers to the new market players. Companies are encouraged to go for Zero Liquid Discharge (ZLD) using other alternatives to mitigate sulfur dioxide emissions, which pose a significant threat to the FGD market. Technological advancements and new solutions prompt companies to have a competitive edge and stay ahead in terms of environmental compliance.

#fluegasdesulfurizationmarket#fluegas#desulfurization#ENVIRONMENT#ENVIRONMENTSERVICES#tritonmarketresearch#marketresearchreports

0 notes