#Flexo Printing Press Manufacturers

Explore tagged Tumblr posts

Text

Used Labels and Forms Machine for SALE

MPS - EE 330

Buy Directly from SELLER -

Manufacturer: MPS

Year: 2006

Machine Availability: Immediately

Price: On Request

Location: United Kingdom

#print #press #Machinedalal

0 notes

Text

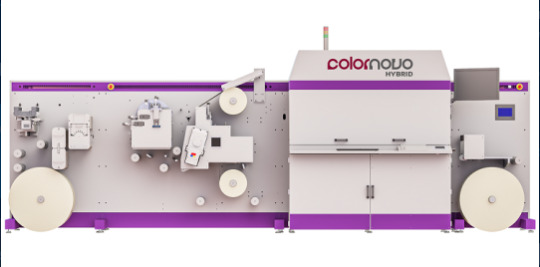

Flexible packaging at Labelexpo Americas 2024

FlexPack@Labelexpo, co-located with Labelexpo Americas 2024, will focus on the complete production chain from materials selection to print, laminating and pouch-making. Andy Thomas-Emans reports.

Flexible packaging will be a key focus at Labelexpo Americas 2024 next month as label converters continue to diversify their product offering and wide web converters seek solutions for the increasing amount of short run work coming their way.

This is a trend we are now seeing across Labelexpo shows around the world. Labelexpo Asia 2023 was the first Labelexpo show to feature a dedicated flexible packaging hall, being effectively a ‘show within a show’. This takes nothing away from Labelexpo’s core focus on label technologies. Rather, these two sectors of the package print industry are entirely complementary.

Why this growing interest from label converters in flexible packaging?

The last decade has seen a quiet revolution in packaging formats as brands have moved more of their premium products into high-value, small-format laminated stand-up pouches as an alternative to labeled containers.

At the same time, label press technology has been evolving towards wider web widths and the ability to handle extensible films. Mid-web presses – defined as in the range 26-30 ins - will be a standout machine category at Labelexpo Americas 2024, and for many label converters these are becoming the main gateway into flexible package printing and converting. These presses can be configured with both UV and extended hot air drier units for water-based inks and coatings.

At Labelexpo Americas 2024, Mark Andy stages the global launch of its 26in-wide P Series S9 press for label and flexible packaging markets. Show attendees can also see the US debut of Nilpeter’s 26in-wide FA-26 following its highly successful launch at Labelexpo Europe 2023 when multiple presses were sold off the show floor. Lombardi shows a print unit from its mid-web Invicta press.

Digital printing of flexible packaging has been dominated by HP since the launch of its 30in-wide HP Indigo 20000-series presses at Labelexpo ten years ago. At Labelexpo Americas 2024, HP marks the US launch of the latest press in this series, the HP Indigo 200k, which greatly increases productivity over previous generation machines.

Flexpack Ecosystem

Entering the flexible packaging market requires much more from a label converter than simply installing a press, either digital or flexo. It requires acquiring a wide range of knowledge about the flexible packaging ecosystem, which is a different world from labels. Put shortly, labels are secondary packaging, not in direct contact with the product, while flexible packaging is the primary container of the product.

This means it is essential to come to grips with the required properties of flexible packaging: burst resistance, moisture and light resistance, structural properties, and, increasingly, sustainability profile. Flexible packaging requires an understanding of lamination, multi-layer structures, barrier properties and surface and reverse printing. The finished pack needs to be tested for a range of properties including leakage and pack integrity.

Following printing and laminating, the pouch needs to be formed ready for filling. And depending on the end use, a filling/dispensing spout may need to be incorporated.

To help converters understand all aspects of the flexpack workflow, Labelexpo Americas 2024 has introduced a dedicated ‘exhibition within an exhibition’ called FlexPack@Labelexpo. This will allow show visitors to focus on materials, lamination technology and pouch manufacturing machinery, supported by a half day deep dive flexible packaging masterclass organized by the Label Academy.

FlexPack@Labelexpo will be located in Hall F of the Donald E Stephens Convention Center. Exhibitors will be present to talk about everything from materials - films, zippers, thermal laminates, overprint varnishes for example - to curing technology, laminating technology, slitting machinery, pouch-making and spouting equipment.

Companies currently confirmed in the FlexPack@Labelexpo zone include Karlville, Gonderflex, S-One LP, ABG, Mamata, Protect-All, Novaflex, Bonset American Corporation, Sanzip re-closable zipper and Nobelus. In addition, three times a day, visitors will have the chance to attend a short introduction to flexible packaging presented by HP.

Flexpack equipment

Focusing on the equipment on show, Gonderflex will demonstrate its P-8009 GFXW single pass thermal laminator-coater-embellishment-slitting machine. The Labelexpo machine configuration includes lamination, a single flexo unit for either surface or reverse print and textured cold foil application with an integrated JetFX print bar system, followed by slitting and rewinding.

Karlville Converting and Karlville Swiss partner to demonstrate post-print flexible packaging machinery for pouch making, lamination and slitting in partnership with HP Indigo. The company will showcase its compact thermal laminator for surface print application running a Protect-all MET PET with Nobelus Soft Touch thermal laminate.

Alongside is the Karlville Swiss Compact D, a quick change pouch making machine running Charter MDO PE Mono Material.

S-OneLP demonstrates the Cellcoat Systems T-14 thermal laminator, for which the company is the exclusive US and European distributor. S-OneLP also displays its range of flexible packaging films and related primers, including Michelman in-line and off-line primers and water-based varnishes.

Attendees can also see a range of overprint varnishes and coatings helping to achieve bespoke surface effects and protection for printed materials. Available OPVs include water-based, UV, LED, and eBeam varnishes and topcoats.

Companies providing information on different aspects of the flexpack supply chain include, Protect-All, which demonstrates printable barrier films and laminations; Novaflex promoting its laminating systems; and Mamata promoting its pouching machines and Form, Fill, Seal (FFS) equipment.

FlexPack@Labelexpo is also set to attract conventional wide-web flexible packaging converters interested both in meeting existing suppliers and deciding how they will tackle the challenge presented by increasing requests for short run packaging.

It is worth noting that the wide web converting industry generally regards shrink sleeves as flexible packaging – as one more unsupported film application. FlexPack@Labelexpo will follow this categorization, so shrink sleeve materials and converting equipment will be included in the exhibition zone going forward.

At Labelexpo Americas 2024, ABG will demonstrate new and shrink sleeve systems in the FlexPack@Labelexpo zone. The Turret Seaming Rewinder (TSR750) ensures a weld that conforms to any container shape. Alongside this will be ABG’s Doctoring machine (DR450).

Karlville Converting shows its Plus series shrink sleeve seamer running a Bonset CPET as well as a film printed with Siegwerk inks demonstrating a de-inking application.

0 notes

Text

Understanding the Flexographic Flat Printer

Understanding the Flexographic Flat Printer Flexographic printing, often referred to as flexo, is a versatile and widely used technique for creating high-quality printed materials. Particularly popular in the packaging and label sector due to its efficiency and ability to produce vibrant, detailed prints, flexographic printing delivers consistent and reliable results.Get more news about Flexographic Flat Printer,you can vist our website!

The basis for effective flexo printing is the printing plates, which are usually manufactured from soft and resilient rubber or flexible photopolymer. During the process of flexo printing, images are separated into a minimum of four process colours - cyan, magenta, yellow, and black - with the option to include spot colours and over varnishes if needed.

Once the plates are prepared, they are mounted onto the printing press cylinders, with each colour in the design requiring a separate plate. The mounting process must be meticulously completed to ensure that the colours are precisely aligned, as this will produce accurate and vibrant prints.

The ink is supplied to the printing press through ink chambers or rubber rollers. To control the ink application, anilox rollers are used which have a pattern of tiny cells that carry and deliver a precise amount of ink to the plate surface. By carefully controlling the application of ink, consistent and sharp prints can be achieved.

Next, the substrate, which is usually in the form of rolls of paper or plastic film, is fed into the printing press, passing through various rollers and tension controls to ensure smooth and consistent movement through the press. Controlled feeding is vital to prevent misalignment and ensure the exceptional quality of the final print.

As the substrate moves through the press, the inked plates transfer the desired image or text onto it. The pressure applied between the plate and the substrate enables the ink to transfer effectively, creating the final print. This is a highly precise process which makes flexo printing ideal for detailed and high-quality work on a variety of different substrates.

Finally, after the ink is transferred to the substrate, it must undergo a drying or curing process to become permanent. Depending on the specific application, drying can be achieved through air drying or by utilising drying systems such as hot air, infrared, ultraviolet (UV), or LED UV technologies. The choice of drying method depends on the type of ink used and the requirements of the final product.

In conclusion, flexographic printing is a versatile and efficient method for producing high-quality prints on a variety of substrates. Its ability to deliver consistent and vibrant prints makes it a popular choice in many industries, particularly in the packaging and label sector.

0 notes

Text

Lug Caps Manufacturers Suppliers In India

We have our units located in Site IV Sahibabad Industrial Area, Ghaziabad, UP (Delhi NCR) with a consolidated covered working space of more than 30 thousand square feet. We are well equipped and with all the amenities rendered by UPSIDC. Our units are very well connected to all type of transportations lug caps manufacturers suppliers in india .

We manufacture : .

LUG CAPS in various sizes and colours.

RO CAPS in all sizes & gauges.

SELF ADHESIVE LABELS upto eight colour printing in roll or sheet form.

WETGLUE LABELS of various sizes and colour to cater all types of packaging modes.

ROPP CAPS in different sizes for pharma, distilleries, or all bottle packaging.

PARMESHTHI Enterprises manufactures self-adhesive labels and wet glue labels for variety of bottled or canned products. It also manufactures pp caps for glass or plastic bottles.

In unit 2 plant, the lug caps and dop Caps are also manufactured of various sizes to cater the needs of the customer.

The plant is situated at a very good location and easy approachable by road at Site IV in the Sahibabad industrial area with all amenities provided by lug caps exporters in india.

It is a team of high skilled technical experts, designers and professionals, continuously pouring the essence of their talent and endeavours, delivering the fine quality in large quantity of multi -colour labels.

The processing and production is operational under a 15000sft covered area, equipped with electric generator for an uninterrupted productivity. The sensitive areas are dust proof and air-conditioned.

Added to other machines, it has a fully loaded multicolor LED flexo printing press, first of its kind in India, delivering cost effective and high-quality labels. It drives out 40 thousand meters per day, of printed rolls. The company has its own brand of paper/stock for its labels to challenge the quality, durability, colour stability, gloss and finish of its labels.

The automatic electronic cutters are tuned to recognize and slice the contiguous borders in simple straight line or designer cut finish.

A team of experts equipped with scanners shuffle the production for its continuous integration to table it for packing and dispatch metal caps manufacturer delhi ncr .

P.ent remains its brand of stock, labels, caps.

Company has its own fleet of vehicles to manage the logistics and schedules of deliveries directly to the esteemed clients.Mr. Anuj Jain, the young and dynamic entrepreneur is behind the wheels, steering the organization to build its reputation in shape of reliability and product confidence.

0 notes

Text

Bengaluru to host the premiere edition of Bharat Print Expo!

The Total Print and Package Converting exhibition will be held from 24-26 April 2025 at Bangalore International Exhibition Centre, Bengaluru.

"This is not just another printing exhibition," declares Anil Arora, President of ReEnvision Events Private Limited. "India is poised to become the world's third-largest economy within the next five years, and we acknowledge that specific sectors as well as regions of the country have played a crucial role in driving this growth. It is essential that we feature them prominently on our event calendar."

Bharat Print Expo is inspired by the county’s adoption of new Print and Converting technologies, coupled with the surge in e-commerce, evolving lifestyles, urbanization, and heightened awareness about personal health, that has significantly fuelled the expansion of the Print and Packaging sectors. Bengaluru is a city that mirrors its diversity, combining a rich cultural tapestry with advanced technologies. According to the Bengaluru Innovation Report, among the 780 major cities globally, 17 of the 20 fastest growing cities will be in India. Among them, Bengaluru is projected to have the world's fastest GDP growth at 8.5%, maintaining this pace until 2035. The vibrant city will hold the first edition of Bharat Print Expo, driving participation from all across the country along with a global brand presence. The venue selection was made based on a survey conducted among the exhibitors of our current show.

Exhibitor Profile

Bharat Print Expo 2025 will delve into the growing demand and prospects within South India and its surrounding areas. Exhibitors hailing from various parts of the nation will showcase cutting-edge products and solutions spanning the print and related industries, including- Printing Equipment: Offset/ Screen/ Digital/ Flexo/ Gravure; Prepress Equipment; Post-press & Packaging Converting Equipment; Label Converting & Printing Press; Paper Converting Machines; Adhesives & Consumables; Binding & Lamination; Paper, Films, Foils; Ink & Chemicals; Dies, Cutters, Rollers; Corrugated Box Making Machinery; Carton Folding Equipment; Testing Equipment, Inspection Systems & Accessories; Textile Printing Machines; 3D Printers; Wide Format Signage Printers; Plant Automation; Infrastructure, Trade Associations & Financial Organisations and Services & Software.

Visitor Profile

The exhibition will attract visitors from the entire Southern region, with extensive promotional activities planned to reach a wide audience. Targeted visitors from all over Bharat and Sri Lanka will also attend the Show. The profile will broadly include: Commercial Printers, Package Printers & Label Printers; Brand Owners & Print Buyers; Package Converters & Corrugated Box Manufacturers; Textile Printers & Professionals; Signage & Graphic Arts Specialists; Retailers, Manufacturers & Industry Suppliers; Packaging Professionals, Design Houses, Art Directors & Consultants; Trade publications, Advertising, Marketing, Media & PR Agencies; Government Bodies and Trade Associations.

Venue

The Bangalore International Exhibition Centre (BIEC) enhances its 77,000 square meters of covered space with aesthetically and functionally designed exhibition halls, along with vast open areas ideal for showcasing large and heavy machinery. The venue is conveniently linked via the Green Metro Line and is just a 45-minute drive from the airport and a 30-minute drive from the city centre.

Organizer

ReEnvision carries forward the legacy of its group companies that have launched or co-organized India’s most successful events in the printing and packaging sector including India Label Show, Pack Plus and PAMEX. ReEnvision Events Private Limited is a sister organization of Print-Packaging.com Private Limited.

"We are preparing to open bookings for the Show and anticipate a tremendous response from the industry,” concludes Anil Arora.

0 notes

Text

Flexographic Printing

Flexographic printing sleeves manufactured in the round ITR allow for a seamless, continuous print on various substrates. You need both efficiency and quality. In most industries, those two production results don’t often come in the same combination. However, ITR sleeves, especially those composed of elastomer blends, bring both speed and accuracy needed for perfect, repeatable prints. While we’re looking forward to educational sessions on flexo printing processes and networking, take the time to educate yourself on a choice you’ll have to make - gravure cylinders.

Consider the variables in your printing project. Do you have a job requiring shorter runs and frequently changing images for instance, product labels with special promotions? Then a photopolymer sleeve may be best. Do you have a job requiring laying an adhesive on a continuous foil substrate? Then an elastomer blend sleeve may work better. Engravings range from security print cylinders with engraved text thats so small its not visible to the naked eye to large embossing rollers with bold designs and deep engravings. Industry demand has led to the development of many processes in design and origination.

With our new laser technology we are now able to manufacture flexographic sleeves and cylinders on numerous types of compounds with a range of screen counts, text and line weights that were unachievable few years ago. Our laser engraved (In The Round) sleeves and cylinders provide you with trouble free cost-effective print runs without the inconvenience of plate lift and press downtime. The laser will traverse across the cylinder vaporising unwanted areas of rubber, leaving an engraved high definition replication of the artwork sent - gravure printing cylinder.

The flexographic industry is evolving, and across the industry, Our firm specializes in automatic flexographic plate mounting technology, as well as overall automation in prepress. The latest innovation by our company is the featuring complete robotization of the prepress department from automatic taping to mounting flexographic plates onto sleeves with no operator interference and zero waste. For more information, please visit our site https://packadvance.com/

0 notes

Text

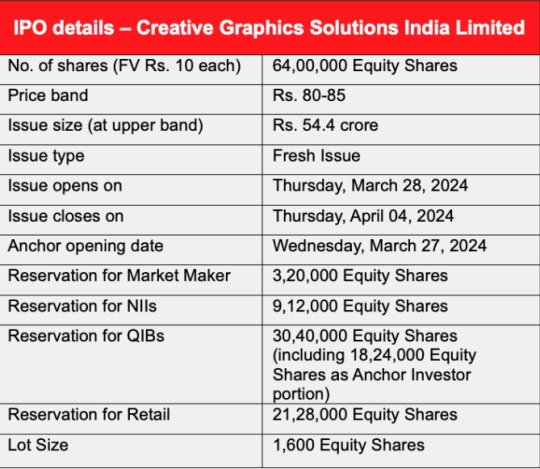

Creative Graphics Solutions India Limited IPO opens for retail investors today – 28 March 2024

Today, 28 March, the retail portion of the Creative Graphics Solutions IPO opens for subscription. The anchor portion of the public issue that opened yesterday has apparently received a good response from investors, including financial institutions.

On 22 March 2024, Noida-headquartered Creative Graphics Solutions India Limited, one of India’s leading organized and integrated packaging ecosystem players, announced that its initial public offering (IPO) will open on Thursday, 28 March 2024. The anchor portion opened on Wednesday, 27 March 2024, and the issue will conclude on Thursday, 4 April 2024. The company intends to raise approximately Rs 54.4 crore (at the upper band) from the offering and aims to be listed on the NSE Emerge platform. The price band for the issue has been fixed at Rs 80 to Rs. 85 per share, and the lot size will be 1,600 equity shares.

Corporate Capital Ventures is the Book Running Lead Manager, and Bigshare Services Private Limited is the Registrar for the issue. According to the press release from Creative Graphics, Corporate Capital Ventures Private Limited has completed a string of successful SME IPOs in recent months, including Alpex Solar, Esconet Technologies, Rockingdeals, Accent Microcell, Oriana Power, Droneacharya and Crayons Advertising.

Creative Graphics is a product of the MSMEx SME IPO Cohort program, mentored by Amit Kumar, founder and CEO at MSMEx.

The Noida-based company’s IPO comprises a fresh issue of 64,00,000 Equity Shares with a face value of Rs 10 through the book-building route. As many as 3.2 lakh equity shares are reserved for the Market Maker, 9.12 lakh equity shares allocated for NIIs, 30.4 lakh equity shares for QIBs (including 18.24 lakh equity shares as the Anchor investor portion), and the Retail (RII) portion accounts for 21.28 lakh equity shares.

According to the Red Herring Prospectus document, the company intends to utilise the net proceeds from the IPO to meet the working capital requirements of the company, repay/prepay, in part or full of certain of the company’s borrowings, meet the capital expenditure of the company, fund inorganic growth through unidentified acquisition for the company, and general corporate expenses.

Creative Graphics specializes in manufacturing flexographic printing plates, including digital flexo plates, conventional flexo printing plates, letter press plates, metal back plates, and coating plates. The company serves its customer base in India, Thailand, Qatar, Kuwait, Nepal, and Africa. It operates seven manufacturing facilities in various states – Noida (Uttar Pradesh), Vasai, Pune (Maharashtra), Chennai (Tamil Nadu), Baddi (Himachal Pradesh), Hyderabad (Telangana), and Ahmedabad (Gujarat).

Founded by Deepanshu Goel, a first-generation entrepreneur and incorporated in 2014, Creative Graphics has expanded its business through its wholly owned subsidiaries – Creative Graphics Premedia Private Limited (CG Premedia) and Wahren India Private Limited. While CG Premedia offers end-to-end premedia services, from design adaptation to print production, Wahren India supplies high-quality packaging solutions for the pharmaceutical industry. It produces Alu-Alu Foil, Blister Foil, Tropical Alu-Alu Foil, CR Foil, and Pharmaceutical Sachets.

The company clocked a revenue of Rs 48.07 crore and earned a profit (PAT) of Rs. 7.24 crore during the first half (H1) of the current FY 2023-24 financial year, which ended 30 September 2023. It registered revenue of Rs. 90.14 crore and a profit (PAT) of Rs. 8.64 crore in FY2022-23.

Our take

We have known Creative Graphics for the past decade and have also admired its fast growth in establishing new plants across the country. We appreciate the need for companies in the printing and packaging industry to expand and raise capital for scaling up their operations. Creative Graphics' team has always been enthusiastic about vertical integration and diversification to new areas of packaging. The company’s IPO will hopefully open a path for other companies in the industry needing to raise capital for scaling up.

For more information, please visit: https://creativegraphics.group/

Disclaimer: CREATIVE GRAPHICS SOLUTIONS LIMITED is proposing, subject to applicable statutory and regulatory requirements, receipt of requisite approvals, market conditions and other considerations, to make an initial public offer of its Equity Shares and has filed the RHP with the NSE Emerge. The RHP is available on the website of BRLM and the website of NSE. Any potential investors should note that investment in equity shares involves a high degree of risk, and for details relating to the same, please refer to the RHP, including the section titled “Risk Factors”, beginning on page 28.

The Equity Shares have not been and will not be registered under the U.S. Securities Act of 1933, as amended (the "Securities Act) or any state securities laws in the United States, and unless so registered, and may not be issued or sold within the United States, except pursuant to an exemption from, or in a transaction not subject to, the registration requirements of the Securities Act and in accordance with any applicable U.S. state securities laws. The Equity Shares are being issued and sold outside the United States in 'offshore transactions in reliance on Regulation "S* under the Securities Act and the applicable laws of each jurisdiction where such issues and sales are made. There will be no public offering in the United States.

First published on 23 March 2024, this article has been updated on the morning of 28 March 2024 – editor.

0 notes

Text

Revolutionize your Label Printing : The Superiority of Narrow Web Flexographic Printing and WEBTECH'S Cutting-Edge Solution!

In the ever-evolving landscape of label printing, choosing the right technology is paramount for ensuring not just efficiency but also excellence in your end products. Today, we unravel the distinctive advantages of Narrow Web Flexographic Printing Machines over Offset and Gravure alternatives, and how Webtech's latest generation Flexo Label Press stands as a game-changer in this domain.

### 1. Precision in Flexibility : Narrow Web Flexo Printing Machines offer unmatched flexibility when it comes to substrate selection. Whether you're dealing with paper, film, or other specialty materials, the precision in handling diverse substrates provides label printers with a competitive edge. Webtech's Flexo Label Press takes this flexibility to the next level, accommodating a wide range of materials, ensuring you have the versatility needed for your varied label applications.

### 2. Cost-Effective Advantage : In the realm of label printing, cost-effectiveness is a critical factor. The setup costs of Narrow Web Flexo Printing are notably lower compared to Offset and Gravure alternatives, making it a financially savvy choice, especially for short to medium print runs. Webtech's latest Flexo Label Press optimizes this advantage, offering a seamless and cost-effective setup process for enhanced operational efficiency.

### 3. Speed, Productivity, and Precision : Webtech's advanced Flexo Label Press brings speed, productivity, and precision together. The press is engineered for high-speed label production, ensuring not only rapid turnaround times but also maintaining precision in every print. This competitive advantage over Offset and Gravure printing is a game-changer in meeting tight deadlines and delivering labels of superior quality.

### 4. Sustainable Printing Practices : The latest generation of Narrow Web Flexo Printing is aligned with growing environmental concerns. Webtech's Flexo Label Press integrates eco-friendly features, minimizing resource usage and waste generation. This commitment to sustainability resonates with the increasing demand for environmentally responsible printing practices.

### 5. Unparalleled Print Quality and Customization : Webtech's Flexo Label Press leverages cutting-edge technology to deliver unparalleled print quality. The servo-driven presses, advanced drying systems, and precise registration mechanisms ensure sharp and vibrant labels. This level of print quality, coupled with the press's capability for intricate customization, surpasses the limitations often encountered in Gravure and Offset printing.

### 6. Technological Innovation with Webtech's Flexo Label Press : Webtech's latest generation Flexo Label Press introduces innovative features that redefine label printing standards. From enhanced automation for streamlined workflows to intuitive controls for user-friendly operation, this press is designed to elevate your label printing experience. The incorporation of the latest technology ensures that you stay ahead in the competitive landscape of label manufacturing.

In conclusion, the decision to embrace Narrow Web Flexographic Printing, particularly with Webtech's cutting-edge Flexo Label Press, is a strategic move toward operational efficiency, cost-effectiveness, sustainability, and superior print quality. Stay ahead in the label printing game with technology that evolves with your needs.

Thank you for entrusting us with your time and attention and for joining us on this exploration of the world of label printing technology. Stay tuned for more insights and innovations in the dynamic field of printing machinery.

For further inquiries or a closer look at Webtech's Flexo Label Press, please feel free to contact our dedicated team.

Best Regards,

WEBTECH GROUP

www.webtechengg.com

#label printing#flexo innovation#packaging industry#PrintCraft Chronicles by Webtech#Packaging Labels

0 notes

Text

Flexo Printing Doctor Blade Steel

Doctor blade steel refers to the type of steel used to manufacture doctor blades. Doctor blades are thin, flat strips of metal typically made from stainless steel, used in various industrial applications, including printing presses, paper machines, and other equipment.

The choice of steel for doctor blades is crucial because they need specific properties to perform their function effectively. Some common characteristics desired in doctor blade steel include:

1. Hardness: Doctor blades should be hard enough to effectively scrape or clean surfaces without wearing down quickly. The high hardness allows the blade to maintain its edge and provide consistent performance over time.

2. Wear resistance: Rotogravure printing doctor blades Steel are subjected to repeated sliding and scraping motions, so they need to resist wear and retain their shape. Wear-resistant steel helps prolong the blade’s lifespan and reduces the frequency of blade replacements.

3. Corrosion resistance: Flexo printing doctor blades Steel often come into contact with various liquids, chemicals, or inks during their operation. Stainless steel, which contains a minimum of 10.5% chromium, is commonly used for doctor blades due to its excellent corrosion resistance.

4. Smoothness: The surface finish of the doctor’s blade is crucial to prevent streaking or damage to the surface being cleaned or scraped. Smooth steel with minimal imperfections helps maintain consistency and even contact with the surface.

The specific grade of steel used for Solventless Machine Doctor Blade may vary depending on the application and industry requirements. Some commonly used stainless steel grades for doctor blades include AISI 300 series stainless sheets of steel such as 304 and 316, which offer a good balance of hardness, wear resistance, and corrosion resistance.

Overall, doctor blade steel is selected based on the specific performance requirements of the application, considering factors such as hardness, wear resistance, corrosion resistance, and surface finish.

#doctor blade#doctor blade coating machine#doctor blade for printing machine#doctor blade price#doctor blade printing#Doctor Blade Stainless Steel#Doctor Blade Steel#Flexo printing doctor blades#Flexo printing doctor blades Steel#plastic doctor blade#polymer doctor blade#polymer doctor bla

0 notes

Text

Top Three Differences Between Flexographic and Offset Printing

To keep up with the fast paced demand for products, UFlex has adopted printing techniques that guarantee quality at rapid speeds. That is why flexographic and offset printing have become two of the most popular printing processes in the industry.

Although both are popular, they perform differently. So while picking the right printing technology, manufacturers have to consider a lot of factors like set-up time, additional costs, printing process and so on.

Let’s take a closer look at how flexographic and offset printing differ!

Difference #1 - Printing Quality

Flexographic printing at UFlex uses a controlled rotary process with Flexographic Printing Plates that can be wrapped around the printing cylinders. The stable and straightforward process ensures all images are printed clearly and cleanly with high quality output.

Offset printing can also provide high quality imaging but the quality tends to vary depending on the manpower hired to handle the complex printing units.

Difference #2 - Cost

Flexo plates are much more durable and can be re-used several times, in comparison to offset printing plates. The press automates the additional tasks like lamination and die-cutting, reducing the set-up time and minimizing waste to cut costs.

Since offset printing involves a lot of different and separate processes, the set up time and waste is higher, leading to an expensive printing process. Offset printing technology can only be handled by highly skilled professionals who have had the training to handle the equipment, which will also contribute to the high operational costs.

Difference #3 - Material

The flexible printing process of flexographic printing allows a lot of flexibility with the printing material. It is used for a variety of substrates like PET, BOPP Films, paper, metal and so on. Flexography is mostly used for packaging materials like food and Beverage Packaging, retail bags, sweet wrappers, newspaper, and envelopes.

Offset printing provides quality printing only on flat and smooth surfaces, making it excellent for printing out books, newspapers, stationery, and brochures.

Flexographic Printing is The Future!

Until recently, Label Packaging within the industry depended on offset printing technology. Flexography offers an evolutionised version of this technology, giving manufacturers the best of offset printing, baked in convenience, affordability and versatility.

As brands take note of this, the flexographic printing market continues to grow and is expected to reach USD 124.61 billion by 2026. The current trends have allowed UFlex to embrace flexography as a sound long-term investment that is ready to integrate a wide range of in-line processes to outperform the traditional offset printing presses.

Invest in Powerful Printing Technology with UFlex

To keep your place in the competitive and fast-changing market, take the viability of your printing process to the next level with UFlex.

As a leader in Flexible Packaging, UFlex offers Flexo printing technology that simplifies operations for excellent transfer of printing inks with high-speed production. The seamless printing aids in the beautification of your packaging design, thereby improving the consumer experience!

UFlex continues to strengthen its commitment to sustainability by providing your business with Flexible Packaging solutions that preserve both the quality of your product and the environment. Visit our website to know more about our product range which includes a variety of Flexo Plates, Gravure Printing Cylinders and Flexo Printing Sleeves.

#Flexible Packaging#Flexo Plates#flexo printing sleeves#uflex#Label Packaging#Beverage Packaging#bopp films#flexographic printing plates

0 notes

Text

The Different Types Of Commercial Printing, and Choosing The Right Type for Your Business

Printing is a very important part of any business. It helps to create a brand and provide a sense of trust for your customers. Commercial printing is one of the most widespread types of printing in commercial markets. It includes various printing processes such as offset lithography, digital printing, and letterpress.

What are the different types of commercial printing?

With a wide range of printing options, it may be difficult to decide which type of commercial printing to choose. There are many factors that go into this decision, including the size of the project and the materials used.

There are 4 main types of commercial printing: digital, offset, flexo and letterpress.

Digital printing is usually done with a computer printer or an inkjet printer. This process is not limited by size or materials because it uses digital technology to produce high-quality prints on various substrates such as paper, cardstock, or fabric. The downside is that digital prints cannot be touched up after they have been made so it’s important for digital print jobs to be accurate in the first place.

Offset printing is done using an offset lithography press where the image is transferred onto a plate before being printed onto paper using an inkjet printer. Offset presses are used in a wide variety of industries including printing, packaging, and garment manufacturing. They can print on a variety of substrates including paper, metal, plastic, and fabric. Offset presses are limited by the type of substrate they can print on. They cannot print on some substrates such as glass or ceramics due to the quality of the printing process.

Flexo printing is a type of printing that uses a flexographic plate, which is a plate with an inked rubber surface and an electrostatic image-bearing layer, instead of ink. It also uses direct imaging rather than using offset lithography. The process of flexo printing is different from conventional screen-printing because the inked rubber surface is directly exposed to the electrostatic image bearing layer, which makes it possible to achieve much finer registration lines and sharper images.

Letterpress printing uses metal plates to print text or images on paper or other materials. This method provides high-quality prints with sharp details but can be difficult to produce in large quantities at one time because it requires manual labour such as pressing ink into the metal plates by hand.

How to Choose the Correct Type of Commercial Printing for Your Business?

A lot of businesses, especially those in the service industry, choose to print their own materials for marketing purposes. The benefits of doing so are many. For one, it allows them to create unique material that is not found anywhere else. It also allows them to keep costs low while ensuring that they have a high-quality product.

There are many types of commercial printing that you can choose from. There are different types of materials and finishing options available with each type of commercial printing. In order to choose an appropriate type of printing for your business and avoid potential pitfalls, you should research and understand what types of printing services are available in your area and how much they cost as well as what their turnaround time is like before choosing which type would be best for you.

For any commercial printing needs, contact Go!Brand here. For more information: Signage

Signage Brisbane

Source URL: https://medium.com/@gobrand1/the-different-types-of-commercial-printing-and-choosing-the-right-type-for-your-business-352445cbeaff

0 notes

Text

Used Flexo Machine for SALE

Edale - Beta 250

Buy Directly from SELLER -

Manufacturer: Edale

Year: 2008

Machine Availability: Immediately from stock

Price: On Request

Location: United Kingdom

#print #press #Machinedalal

0 notes

Text

Vinsak Group completes acquisition of Rotatek

Vinsak Group, a manufacturer and supplier of printing and packaging machines, has completed the acquisition of Rotatek, an European printing machinery manufacturer for labels, packaging, folding cartons, security printing, commercial printing, and pharmaceutical inserts headquartered in Barcelona, Spain.

The Vinsak group has been associated with Rotatek from 1996 to 2013 and then again from 2020 onward, having sold more than 100 Rotatek presses. In July 2023, the Vinsak Group acquired the productive unit, the patents, technical knowledge, and the team of Rotatek. In 2023, it was owned by a PE firm from Spain, which was able to run it commercially but could not invest in R&D, new software, and production methods.

The complete business transformation activity is being led by Gita Bajaj, group director of HR and business transformation, Vinsak. Post the acquisition, which was publicly announced at drupa, Rotatek is known as Rotatek Printing and Packaging Technologies SL.

Ranesh Bajaj, director, Vinsak, says, “We are proud that we absorbed all the employees and did not make even one person redundant. We are delighted that the core technical team of Rotatek is intact, offering their experience and technical knowledge to the world. They are successfully supporting more than 1,800 machines around the world, including some that are up to 30 years old.”

Speaking on sales, Bajaj said they have sold more than 100 Rotatek presses, including some with very complicated configurations. “For instance, we sold a machine with 17 units, which included offset, flexo, digital, screen printing, die cutting, and sheeting units all in one line to produce high-security products. This press was 120 feet long and improved productivity by five times. It reduced production costs of the end product by 40%.”

Rotatek CEO Mario Gamez continues to lead the company by managing all the functions of the organization. He is also a shareholder in the new entity, thus confirming his confidence in the company as well as the future.

Vinsak's group CFO, who works out of the UK, is working on the financial aspects of the turnaround including European compliances.

“On the sales front, the global sales structure has been revived. Our close association with Rotatek Brazil will ensure a new thrust in the Brazilian markets. Our existing distributors in Germany, Italy, Portugal, France, and the UK have been retrained on the portfolio and they are generating new leads every week. We have new distributors in Thailand, Vietnam, and Japan to grow the market in the Far East. With the Vinsak group active in the Middle East, India, and Africa, we have the globe more or less covered. North America is the territory under development now and we are looking to appoint a distributor for the US and Canada,” Vinsak said.

On the technical front, Vinsak has a host of new developments planned. In 2024, the company will launch the Universal 850, claimed to be a game-changer in pharma and carton markets. The other universal models continue to offer excellent solutions for flexible packaging as well. In 2025 it plans to launch the new Brava Semi rotary press for labels, which will be fully revamped. Ths press will be displayed at LabelExpo Barcelona.”

The group will continue to listen to feedback from converters and label printers around the world and build bespoke solutions to enable converters to create the highest quality labels and packaging around the world.

Two important focus areas for Rotatek are sustainability and security. The company is developing machines that produce excellent print quality while leaving behind minimal carbon footprint. Its security printing solutions provide governments and brand owners the ability to print sophisticated documents with security features. “Rotatek R&D is geared to enhance these printing features to address concerns of counterfeiting, imitation, and environmental degradation.”

0 notes

Text

Flexo Printing Machine

Flexo Printing Machine

UV Graphic Technologies Manufactures state of the art Flexographic Film, Label and Carton Presses with the highest accuracy standards known to the label and flexible packaging industry. Our presses are designed to achieve 100% register in less than 3 meters of waste. All our presses are capable of printing multiple substrates from 8µ unsupported films to 450µ Carton Board with fully automated settings.Get more news about Flexographic Flat Printer,you can vist our website! UV Graphic manufactures an array of multi capability presses which are designed for Hot Foil, Cold Foil, Cast n Cure, Roto Gravure, Silk Screen, Peel n Seal, Crossover, Hanger and Booklet Labels all in one Pass. All units can be mounted on a rail for free and easy movement between print units.

The Quick-Change Die Cutting units on all presses can be incorporated with Semi Rotary, Full Rotary, Wet Glue and In-Mold (IML) Label Punching in line with ease. The Sheeting Units are designed for sheeting at 150 Meters / minute. Ultraflex UFO Presses are also Ultra Compact and occupy the smallest floor space and the shortest web path in the label industry. The Design makes it possible to fit an 8-color press in less than 20 Sq. Meters of Floor Space. All Ultraflex presses come with Combo UV Dryers which are LED Ready.These LED ready UV Systems are standard on all presses manufactured by UV Graphic which makes all presses Future Ready for LED Curing. In addition, all presses can be equipped with Hot Air and Infra-Red Dryers and special dryers for specific applications.

0 notes

Text

Major Milestones For Kwality Offset

Going Strong - Today We are standing tall as one of the leading label converters of India. With our vision of continuously innovating and expanding to international boundaries by keeping focus on our core principles of quality and service, we are honoured to be a part of this industry.

Digital Printing Machine - 2016 After watching this breakthrough technology in label printing at various exhibitions, we were confident that this is the future of our industry. An all- new digital machine was installed to meet the growing demand of short runs.

Eight Colour Flexo Machine - 2014-15 After receiving much success with this new technology, we were convinced that this is the future of printing industry. We decided to install an eight colour servo flexo press.

In house Pre-Press System - 2011-12 In order to bring everything in house, we decided to become a Kodak certified partner and use their latest Flexcel NX System to maximize the capability of digital flexo and offset plates in the press room.

Eight Colour Flexo Machine - 2009-10 Due to changing market trends and more demand for labels in roll form, we installed a premium eight colour flexo machine with online UV coating.

Five Colour Offset Machine - 2005-06 In order to expand our operations and create a mark in the industry, another five colour offset machine with online UV coating was installed.

Six Colour Offset Machine - 2001-02 Continued our investment in Offset technology which requires high level of skill and expertise. We installed an all-new six colour offset printing machine with online coating.

Six Colour Flexo Machine - 1993-94 We planned to revolutionise our business by installing our first six colour, narrow web, flexo printing machine.

Four Colour Offset Machine - 1983-86 After achieving much success, our first four colour offset machine was installed for printing labels.

Single Colour Offset Machine - 1971-72 After seeing high potential and opportunity in printing industry, we Installed one of the first single colour offset printing machine of North India.

Pioneered as a Paper Cup Manufacturer - 1965-70 We started our operations in 60’s as a leading paper cup manufacturer for various industries.

0 notes

Text

Digital Label Press –Jetsci

What are the benefits of digital label press?

Printing technology has advanced rapidly over the course of a few years, and digital label printing has enabled manufacturers to take out prints easily and in a cost-efficient manner. The label printing industry has also advanced over a few years, and today, several upgrades are available that are reforming traditional label printers. Digital label press is a one-stop solution that provides numerous benefits to users.

If you are a local producer or a small business owner, locating a label supplier can be daunting. High set-up time, huge fees, high order minimums, and storing additional label inventory can increase inefficiencies and costs for your business. Jetsci digital label press offers suitable digital printing solutions to business organizations looking for the best alternative to other printing forms. Digital printing press comes with benefits like low order minimums, increased substrate variety, low production time, etc. Digital printing machines have a great advantage for big firms and large companies since they can track inventory with the help of variable data, print several labeled versions, and bring the necessary products to the market quickly. Following are the top benefits of investing in a digital printing machine for your business operation, irrespective of whether you are a startup company or an established firm.

1. Low printing minimums

The best advantage of digital label machines for startups or small businesses is that they can print low-quantity orders and remain cost-effective at the same time. Flexo printing is an ideal solution for large orders; however, long production times and plate creation can be expensive in small runs. Digital label press enables companies to create high-end and professional-looking products even in small batches.

2. Quick Turnaround Time

Pre-press steps such as making plates can be eliminated in the case of digital label press; therefore, designs can be finalized and printed quickly. You can introduce new designs or products on a short timeline and stay ahead in the competitive market.

3. Easy Updates

Digital label press helps you to make changes or updates to your label without hassle. Growing companies who want to update their information related to ingredients, branding, or any process can use digital printing press best. This way, you can keep your customers engaged with modern and new versions like seasonal flavors and special editions.

4. Top print quality

Low order minimums and quick turnaround times will not help your company unless you have stunning looking labels. Jetsci digital printing machine prints consistent and high-quality images, including a variety of colors, fonts, and details. Barcodes, SKUs, and serial numbers can be read or scanned easily and remain sharp even in small sizes. Clear images can be printed on a diverse substrate.

5. Environmentally Friendly

Digital printing is environmentally friendly in nature. With the help of digital printing machines, companies can minimize waste during production and setup. There is no requirement to store old labels or bulk stock that becomes obsolete. You can create environmentally friendly, beautiful labels to showcase your brand as well as your product.

6. Durable UV link

UV inject printer is durable as UV inks completely highlight the fastness degree and resist fading even if they are exposed to light for a prolonged time. UV inject printers are amazing for applications in places where moisture is a great factor, like beer labels. You must test the digital label drafts on the specific products to see if they are the right choice for you. Digitally printed labels result in saving costs for business owners.

0 notes