#Filtration system

Explore tagged Tumblr posts

Text

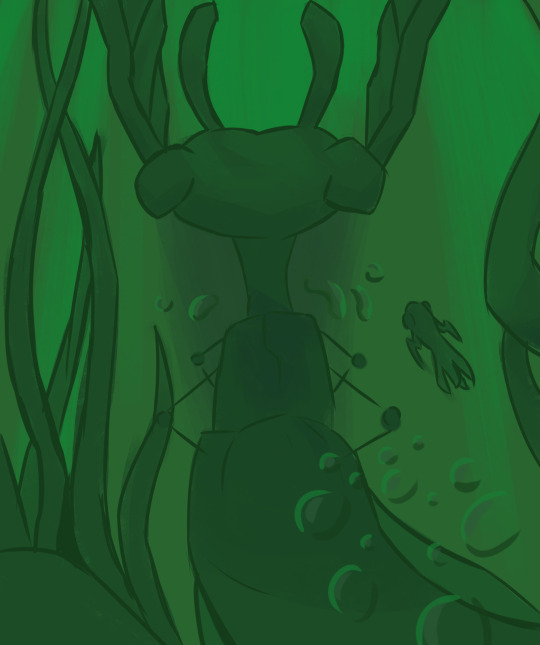

filtration system

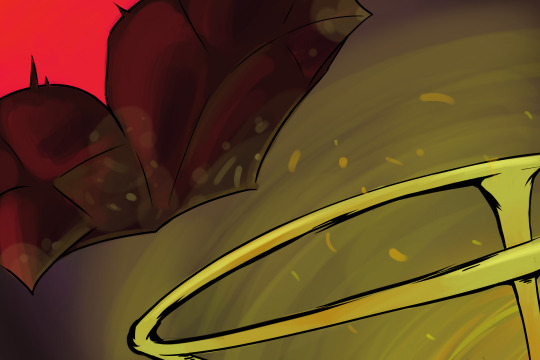

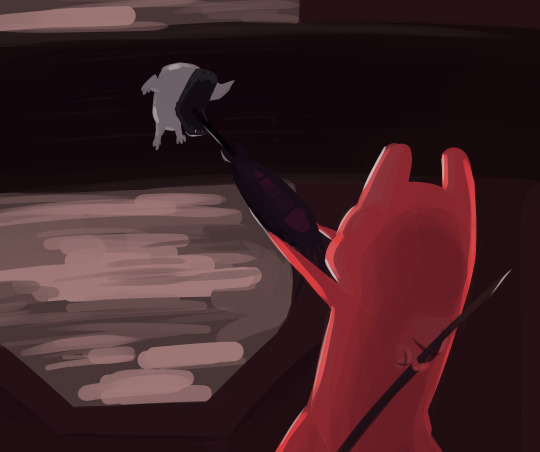

based on a tense moment in my second survivor playthrough where i went from outskirts -> drainage -> filtration -> sub -> outer expanse

#rain world#rain world downpour#slugcat#slugpup#filtration system#rain world art#rw art#art#my art#black lizard#subterranean

108 notes

·

View notes

Text

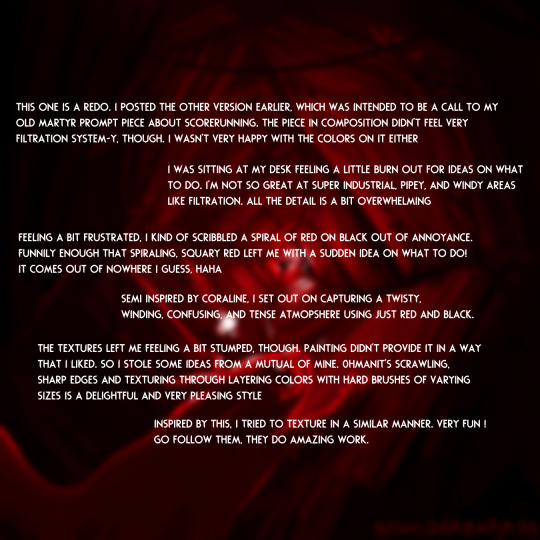

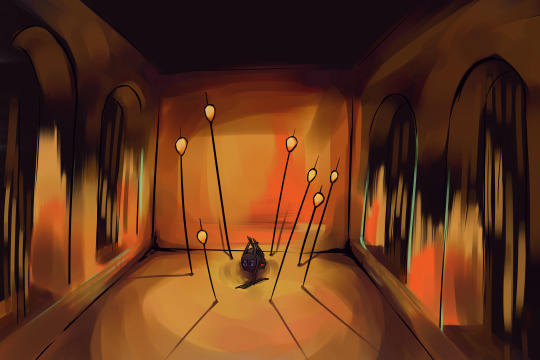

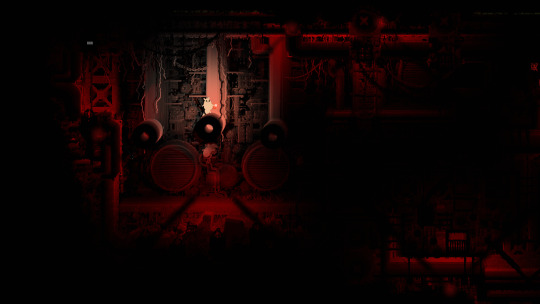

day 9 - filtration system

the final stretch. shoutout to @0hmanit for inspiring the :fish out of this piece (go follow them ) more insight below the cut

#rwartmonth#rwartmonth 2024#rain world art month#rain world#rain world art#rain world fanart#filtration system#black lizard#slugcat#pipes#industrial#wild draws#wild draws rain world

80 notes

·

View notes

Text

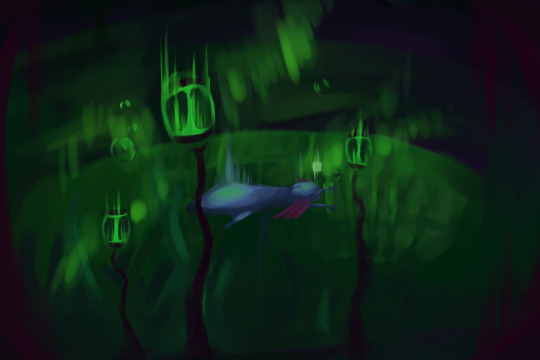

"The Final Stretch"

RW Art Month Days 9 and 10 - Filtration System and Worm Grass

I know this is more depths-focused but it was hard mixing these two prompts. bear with me

#rain world#rw art#rw art month#rain world art month#rain deer#farm arrays#filtration system#rw void#zenalaart#black lizard#mole lizard

43 notes

·

View notes

Text

Day 8, 9 and 10

oops almost forgot to post these

#rain world#rain world downpour#rainworld#slugcat#rw saint#rw art month#rw slugcat#rw#rw raindeer#rw artificer#rw scavenger#rw vinki#the vinki#modcat#farm arrays#filtration system

27 notes

·

View notes

Text

First batch of art month art

Second Half

#Art Month#RW Art Month 2024#Rain World#Rivulet#Submerged Superstructure#Chimney Canopy#Fire Spear#Fire Egg#Taming#Crafting#Saint#Filtration System#Worm Grass#Lantern#Glow Weed#Five Pebbles#Leviathan#Spiders#Hunter#Monk#Gourmand#Survivor#Scavenger#Slugcat#Vulture#vulture grub

30 notes

·

View notes

Text

8 notes

·

View notes

Text

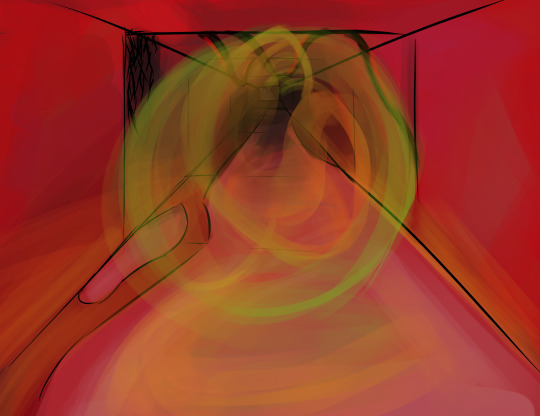

day 9: filtration system

i despise filtration system. did you wanna see?? well that's too damn bad, vision rights revoked. had fun with this tho nonetheless

i think this is the debut of my surv design as well, so here ya go, eat your meal. i made them feathery like my monk design, which.. also hasn't been posted. whoops. i'll get on that eventually lol

i really hate filtration system. don't get me wrong, it is beautifully designed and the concept is executed amazingly, i just hate dark and enclosed spaces, and filtration system is both of those. sigh

#✨alias does art#art#rain world art month#rw art month#rain world#rain world art#rw survivor#rain world survivor#filtration system#rw filtration system#rain world filtration system

5 notes

·

View notes

Text

Purewell Water Purifier Pump Review

Have you ever found yourself in the wilderness, surrounded by the serene whispers of nature, only to be distracted by the whisper of your thirst? Or perhaps, faced an unexpected situation where accessing clean water proved to be a challenge? The Purewell Water Purifier Pump with Replaceable Carbon 0.01 Micron Water Filter might be the companion you never knew you needed. Understanding the Water…

0 notes

Text

Swimming Pool Filtration System: Essential for Clean, Clear, and Safe Water

#Swimming Pool Filtration System#Pool Filtration System#Filtration System#Swimming Pool Filtration System in Delhi#high-quality filtration systems

0 notes

Text

Why Every Natural Gas Plant Needs a Reliable Filter Separator System

When you are looking to maintain the purity and quality of gas in a natural gas plant for safe and efficient operations, you will need the help of a filter separator. A vital component of a filtration system, a filter separator works to effectively remove contaminants like liquids and other particles that can hinder processes or even damage equipment if left unchecked. But what exactly is a filter separator, and how does it play a crucial role in the natural gas industry? In this write-up we will dive into the workings of filter separator systems, look at why they are indispensable in every natural gas plant, and how they help keep operations running smoothly and safely.

How Filter Separator Systems Prevent Contamination in Gas Processing

When using filter separators, it is important to understand that the separators address the issue of contamination with the help of a two-stage separation process. In the first stage, a centrifugal or cyclonic mechanism forces heavier droplets to separate from the gas stream. A drain chamber then effectively collects these contaminants and prevents them from moving further down the pipeline. The second stage of filtration employs a fine mesh or coalescing filter. This captures smaller particles and fine aerosols, which ensure that only clean, purified gas continues onward. This layered approach not only enhances the effectiveness of the filtration system but also extends the life of downstream equipment, reducing maintenance costs and preventing unexpected downtime.

By efficiently removing impurities, filter separator systems help natural gas plants maintain a higher standard of gas purity. As mentioned, this process protects downstream equipment, reduces the frequency of maintenance, and minimizes the risk of costly operational disruptions. Reliable filter separator systems are indispensable for any natural gas plant that seeks safe, efficient, and contamination-free gas processing.

Key Benefits of Reliable Filter Separator Systems

As we all know, the stakes at a natural gas plant are high and this makes having a reliable filter separator not just an addition to the works but an absolute necessity. Imagine a steady flow of gas traveling through the plant’s network of pipes, valves, and compressors. Now, imagine that same flow loaded with contaminants like moisture, and hydrocarbon aerosols. When there is no effective filtration system, these impurities can quickly wreak havoc, corrode equipment, clog components, and ultimately cause costly downtime. This is where a dependable filter separator steps in, ensuring clean gas, smooth operations, and reduced maintenance costs.

The key benefits of a reliable filter separator system go far beyond basic filtration. To begin with, it preserves equipment health by removing harmful particles before they reach vital machinery. They are also responsible for reducing wear and extending the lifespan of costly plant components. By consistently purifying the gas stream, the filter separator protects against rust, scaling, and corrosive buildup, helping maintain an efficient, safe work environment.

Another standout benefit is the cost efficiency. When your filtration system operates effectively, you will face fewer maintenance demands, less frequent part replacements, and a much lower risk of unscheduled shutdowns. Reliable filter separators help plants avoid sudden expenses while improving operational uptime—a win win in any situation.

The most important benefit, however, is the filter separator’s role in safety. Filter separator systems support the plant’s broader safety goals by preventing potential hazards associated with contaminant buildup, such as blockages or corrosion-induced leaks. In an industry where safety is paramount, a quality filter separator provides peace of mind, helping ensure that operations are as secure as they are smooth.

Choosing the Right Filter Separator System for Your Plant

For maximizing efficiency and for equipment protection, it is vital that you choose the right filter separator system for the natural gas plant. While it must be understood that not all filtration systems are created equal, there are certain critical factors that will determine the perfect fit for your processes and needs. Having the right filter separator not only enhances the gas purity, but it also reduces operational costs and improves safety and extends the life of your equipment.

To begin with, consider the specific contaminants present in your gas stream. Some plants may deal with high levels of liquid hydrocarbons or water vapor. Identifying the primary impurities will help determine whether you need a high-efficiency coalescing filter, a dual-stage separator, or a system customized for multi-phase separation. The filtration efficiency of your filter separator system will largely depend on matching the equipment to these requirements.

Further you will need to know that flow rate and pressure can play a very important role in selecting the optimal system. Your filter separator must handle the plant’s peak gas flow without causing a drop in pressure. A drop in pressure can lead to inefficiencies or equipment stress. By considering the capacity and pressure specifications, you can ensure a smooth, uninterrupted flow of clean gas through the entire system.

Going further, we will look at material durability and maintenance requirements. Systems made from corrosion-resistant materials such as stainless steel can better withstand harsh environments, requiring less frequent replacement and upkeep. Maintenance intervals and ease of filter replacement are factors that can save significant costs over time. A reliable filter separator system will strike the right balance between filtration efficiency and ease of maintenance, reducing unexpected downtime and keeping operational costs in check.

When you carefully evaluate these aspects, you will be well-equipped to choose a filter separator system that meets the demands of your plant and supports long-term operational success.

0 notes

Text

A pond isn’t just a hole filled with water; it’s a complete system. You’ll need a pump to circulate the water, a filtration system to keep it clean, and potentially lighting if you want your pond to glow in the evening. You might also want an aerator or a UV clarifier to keep the water clear and algae-free.

0 notes

Text

Understanding the Product: PP Disc Filter T Shape SUPER 3” or 90MM

A PP Disc Filter T Shape SUPER 3” or 90MM is a high-performance filtration system designed for various industrial applications. This product is particularly effective in filtering particles from liquids, making it an essential component in water treatment, agricultural irrigation, and other fluid management systems. Here's a detailed look at this innovative filtration solution.

Key Features of PP Disc Filter T Shape SUPER 3” or 90MM

Material Composition:

Polypropylene (PP): Known for its chemical resistance and durability, PP is the primary material used in the construction of this disc filter. It ensures longevity and reliability even under harsh operating conditions.

Design and Structure:

T Shape: The T-shaped design facilitates easy integration into existing piping systems. It allows for efficient flow distribution and minimal pressure drop.

3” or 90MM Size: This size specification indicates the diameter of the filter, suitable for medium to large-scale filtration applications.

Filtration Mechanism:

Disc Filtration: The filter uses a stack of grooved discs to trap particles. When water flows through the discs, particles are trapped within the grooves, providing high filtration efficiency.

High Dirt Holding Capacity: The disc design ensures a large surface area for filtration, which translates to longer intervals between cleanings and maintenance.

Ease of Maintenance:

Quick Cleaning: The disc filter can be easily disassembled for cleaning. The discs can be washed and reassembled without specialized tools, reducing downtime.

Low Maintenance Cost: The robust design and durable materials result in lower maintenance costs over the product's lifespan.

Applications of PP Disc Filter T Shape SUPER 3” or 90MM

Agricultural Irrigation:

Ensures clean water supply for irrigation systems, protecting crops from clogging and ensuring even water distribution.

Water Treatment:

Essential in pre-filtration stages to remove large particulates before water undergoes further purification processes.

Industrial Processes:

Used in various industrial applications where fluid cleanliness is crucial, such as cooling systems, chemical processing, and manufacturing.

Aquaculture:

Provides clean water for fish farming, reducing the risk of disease and promoting healthier aquatic environments.

Benefits of Using PP Disc Filter T Shape SUPER 3” or 90MM

Improved Efficiency:

The high filtration efficiency ensures that only clean water passes through, protecting downstream equipment and processes.

Cost-Effective:

The durable construction and low maintenance requirements make this filter a cost-effective solution over time.

Versatility:

Suitable for a wide range of applications, making it a versatile choice for various industries.

Environmental Impact:

By ensuring clean water supply and reducing the need for chemical treatments, this filter contributes to more sustainable and environmentally friendly operations.

Conclusion

The PP Disc Filter T Shape SUPER 3” or 90MM stands out as a reliable, efficient, and versatile filtration solution for various industries. Its innovative design, combined with the robustness of polypropylene, ensures that it can meet the demanding requirements of modern fluid management systems. Whether for agricultural, industrial, or aquaculture applications, this disc filter provides a cost-effective and environmentally friendly solution for maintaining clean water supply.

For More products Visit Manan Water Tech .

#water management solutions#water filtration systems#tap water filters#water purifiers#PP screen filter#irrigation filter#water filtration#polypropylene filter#agricultural irrigation#industrial filtration#filtration system

0 notes

Text

Air Relief Valve Irrigation - DFShou

Automatic Filtration System - Air Relief Valve Irrigation

Exhaust the air in the irrigation system to avoid negative pressure downstream of the pump and the water along the pipeline and up-down slope of the pipeline.

Discharge air to prevent negative pressure at the filter and fertilizer tank.

0 notes

Text

The Vital Role of Water Treatment Plant Manufacturers in Urban Water Systems

Water treatment plant manufacturers play a crucial role in ensuring the availability of clean and safe water in urban areas. As populations grow and urbanization accelerates, the demand for clean water continues to rise. In this article, we will explore the vital role that water treatment plant manufacturers play in urban water systems.

Understanding Urban Water Systems

Urban water systems encompass the infrastructure and processes involved in supplying water to urban areas and managing wastewater. These systems include water treatment plants, distribution networks, sewage treatment facilities, and stormwater management systems. The goal of urban water systems is to provide safe drinking water to residents and to manage wastewater in an environmentally sustainable manner.

The Importance of Water Treatment Plants

Water treatment plants are essential components of urban water systems. These facilities are responsible for treating raw water from natural sources such as rivers, lakes, and groundwater to make it safe for consumption. Water treatment involves several processes, including coagulation, sedimentation, filtration, disinfection, and desalination, depending on the source and quality of the water.

Role of Water Treatment Plant Manufacturers

Water treatment plant manufacturers play a vital role in designing, building, and maintaining water treatment plants. These manufacturers leverage engineering expertise, advanced technology, and innovation to develop state-of-the-art treatment systems that meet the unique needs of urban environments.

Design and Engineering

Leading water treatment plant manufacturers employ teams of engineers and experts who specialize in designing treatment systems tailored to specific requirements. These designs take into account factors such as water quality, source characteristics, treatment goals, and regulatory requirements.

Manufacturing and Construction

Once the design phase is complete, water treatment plant manufacturers oversee the manufacturing and construction of treatment facilities. They work closely with construction firms and subcontractors to ensure that the plant is built according to specifications and in compliance with safety and environmental regulations.

Technology and Innovation

Water treatment is an evolving field, and manufacturers are constantly innovating to improve treatment processes and efficiency. Advanced technologies such as membrane filtration, nanotechnology, and remote monitoring systems are revolutionizing the way water is treated and managed in urban areas.

Benefits of Working with Leading Manufacturers

Partnering with leading water treatment plant manufacturers offers several benefits for urban water systems:

Quality and Reliability

Water treatment plants built by reputable manufacturers are known for their quality, reliability, and performance. These plants adhere to stringent quality standards and undergo rigorous testing to ensure that they meet or exceed regulatory requirements.

Efficiency and Cost-Effectiveness

State-of-the-art treatment technologies developed by leading manufacturers improve efficiency and reduce operating costs. Advanced filtration systems, energy-efficient processes, and optimized treatment algorithms help minimize water wastage and energy consumption, leading to cost savings for water utilities and consumers.

Environmental Sustainability

Leading manufacturers prioritize environmental sustainability in their designs and operations. By incorporating green technologies, minimizing waste generation, and optimizing resource utilization, these manufacturers help urban water systems minimize their environmental footprint and promote sustainable water management practices.

Conclusion

In conclusion, water treatment plant manufacturers play a vital role in urban water systems by designing, building, and maintaining treatment facilities that provide clean and safe water to urban populations. Through their expertise, technology, and innovation, these manufacturers contribute to the efficiency, reliability, and sustainability of urban water infrastructure. By partnering with leading manufacturers, cities and municipalities can ensure the availability of clean water for their residents while minimizing environmental impact and maximizing cost-effectiveness.

If You Want to Discover More About Water Treatment Plant Manufacturers then Visit the Site: Jasmino

#manufacturing#manufacturing industry#water management#watermanagement#safe drinking water#water treatment plant#water treatment technology#plant manufacturers#filtration system#manufacturer

0 notes

Text

0 notes

Text

4 notes

·

View notes