#Electromechanical level measurement

Explore tagged Tumblr posts

Text

Pressure Switch Guide: Types, Uses & Maintenance Tips

Pressure switches are vital components in various industrial, commercial, and even residential applications. These devices monitor and regulate pressure levels, ensuring systems operate safely and efficiently. In this comprehensive guide, we’ll explore the types, uses, and maintenance tips for pressure switches, providing you with the knowledge to choose and maintain the right pressure switch for your needs.

What Is a Pressure Switch?

A pressure switch is an electromechanical device designed to activate or deactivate a circuit when a certain pressure level is reached. These devices are commonly used to control equipment like pumps, compressors, and alarms, playing a crucial role in systems that require precise pressure management.

Types of Pressure Switches

1. Mechanical Pressure Switches

Mechanical pressure switches rely on mechanical components, such as diaphragms, pistons, or bellows, to sense pressure changes. These components trigger a micro-switch to open or close the circuit.

Pros:

Durable and reliable

Cost-effective

Simple to use

Cons:

Limited sensitivity

May require frequent calibration

2. Electronic Pressure Switches

Electronic pressure switches utilize sensors and electronic circuits to monitor and respond to pressure changes. They often include digital displays and programmable settings.

Pros:

High precision and sensitivity

Customizable settings

Data logging capabilities

Cons:

Higher initial cost

More complex to install

3. Differential Pressure Switches

These switches measure the difference between two pressure points and activate when a specified differential is reached. They are essential in systems like HVAC and filtration processes.

Pros:

Ideal for monitoring flow and filter conditions

Versatile applications

Cons:

More complex than standard switches

Can be more expensive

4. Vacuum Pressure Switches

Vacuum pressure switches activate when a system's pressure drops below atmospheric pressure. They’re often used in vacuum systems and packaging machinery.

Pros:

Perfect for low-pressure applications

Reliable in vacuum systems

Cons:

Limited to specific uses

Common Uses of Pressure Switches

1. Industrial Applications

Pressure switches are widely used in industries such as manufacturing, oil and gas, and chemical processing to control pumps, compressors, and safety alarms. For instance, in a hydraulic system, they ensure pressure stays within safe operating limits.

2. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, pressure switches monitor airflow and refrigerant pressure to maintain efficient operation.

3. Automotive Applications

Pressure switches play a critical role in automotive systems, including brake systems, transmission controls, and air conditioning systems.

4. Water Systems

In residential and commercial water systems, pressure switches regulate water pressure to prevent pump overuse and ensure consistent water supply.

5. Safety Systems

Pressure switches are integral in safety mechanisms, such as fire suppression systems, where they detect pressure changes and trigger alarms or automated responses.

Maintenance Tips for Pressure Switches

Proper maintenance of pressure switches is essential to ensure their longevity and reliability. Here are some tips:

1. Regular Inspection

Inspect pressure switches periodically for signs of wear, corrosion, or damage. Check electrical connections and ensure no loose or frayed wires.

2. Calibration

Calibrate your pressure switches regularly to maintain accuracy. Over time, mechanical components can drift, leading to inaccurate pressure readings.

3. Cleanliness

Keep pressure switches clean and free from debris. Dirt or residue can obstruct mechanical components, affecting performance.

4. Monitor for Leaks

Inspect the system for pressure leaks that could cause the switch to malfunction. Repair any leaks promptly.

5. Replace Worn Components

Replace diaphragms, pistons, or other components that show signs of wear. Regular replacement prevents unexpected failures.

6. Environmental Protection

Ensure pressure switches are protected from extreme environmental conditions, such as excessive moisture, heat, or vibration. Use enclosures or protective covers if necessary.

Choosing the Right Pressure Switch

When selecting a pressure switch, consider the following factors:

1. Pressure Range

Choose a switch with a pressure range suitable for your application. Operating outside the specified range can lead to failure or reduced lifespan.

2. Type of Media

Ensure the pressure switch is compatible with the medium it will monitor, such as air, water, oil, or corrosive fluids.

3. Accuracy Requirements

For applications requiring high precision, opt for an electronic pressure switch with customizable settings and digital displays.

4. Environmental Conditions

Consider the operating environment. For harsh conditions, select a rugged switch with appropriate protection ratings, such as IP67 or NEMA-rated enclosures.

5. Cost and Maintenance

Balance initial cost with maintenance needs. Mechanical switches are cost-effective but may require frequent calibration, while electronic switches have higher upfront costs but lower maintenance needs.

0 notes

Text

T-3630L DIGITAL INSULATION RESISTANCE TESTER

T-3630L Digital insulation resistance meter also known as megohmmeter, high voltage insulation resistance tester, etc., for the insulation resistance test. The instrument has a large LCD screen gray backlight display, data storage, data access, alarm, automatic shutdown and other functions. At the same time, it also has the function of measuring AC voltage absorption ratio and polarization index of DC voltage. The machine is beautiful and upscale, has a wide range, high resolution, convenient operation, easy to carry, accurate, reliable, stable performance, strong anti-interference ability. Moreover, it has a shockproof, dust-proof, moisture-proof structure and is a commonly used and indispensable instrument for telecommunications, electricity, meteorology, computer rooms, oil fields, electromechanical installation and maintenance, and industrial enterprises that use electricity as industrial power or energy. T-3630L insulation resistance meter is suitable for measuring the resistance value of various insulating materials and the insulation resistance of transformers, motors, cables and electrical equipment. T-3630L Digital insulation resistance meter consists of medium and large scale integrated circuits. The output power of T-3630L is large, and its output voltage level is 5 voltage levels. Rated insulation test voltage range 100-2500V, insulation resistance measurement range 0.01MΩ - 200GΩ. DC voltage measurement range 0-1000V, AC voltage measurement range 0-750V.

FUNCTION & FEATURES ■ 0-200GΩ; ■ Accuracy 3%; ■ DC Voltage test; ■ AC Voltage test; ■ AC voltage 0-750V; ■ With gray backlight; ■ DC voltage 0-1000V; ■ Recorder 500 sets data; ■ With replacement battery; ■ 100V, 250V, 500V, 1KV, 2.5KV; ■ Digital insulation resistance test; ■ User friendly menu guided operation;

APPLICATION ■ Universities; ■ Power plant; ■ Oil gas company; ■ Research institutes; ■ Electrical laboratory; ■ Electrical testing center; ■ Communication company; ■ Railway electrical department; ■ Electrical equipment manufacturers; ■ Electricity power bureau & power company; ■ Power engineering commissioning company; ■ Electrical department of industrial and mining enterprises;

0 notes

Text

Automatic Bollards in Bangladesh: A Modern Approach to Traffic Management and Security

In recent years, Bangladesh has experienced rapid urbanization and infrastructural development. With these advancements, managing the growing traffic and ensuring public safety has become critical. Traditional security measures, such as gates, barriers, and speed bumps, often prove inadequate in busy urban areas. This is where automatic bollards come into play.

Automatic bollards are advanced, retractable posts that can be used for controlling vehicle access, managing traffic flow, and enhancing security. These bollards can be raised or lowered with the help of an automated system, offering a seamless and efficient solution for areas where security and traffic management are a priority.

What are Automatic Bollards?

Automatic bollards are cylindrical barriers made of robust materials such as steel or stainless steel. They are usually installed in the ground and can be raised or lowered depending on the need. When raised, these bollards act as physical barriers, preventing unauthorized vehicles from entering restricted zones. When lowered, they allow smooth access to vehicles with proper clearance or permission.

The primary feature that sets automatic bollards apart from traditional ones is the automation aspect. These bollards are controlled electronically, usually through a remote control, sensors, or an access control system. They can be integrated with other security measures like cameras, alarms, or even traffic lights for an enhanced security network.

Types of Automatic Bollards

There are several types of automatic bollards available in the market, each designed to serve specific needs. Some common types include:

Hydraulic Bollards: These bollards are powered by a hydraulic system, which ensures a smooth and efficient operation. They are commonly used in areas where heavy-duty security is required, such as government buildings, airports, and high-security corporate offices.

Pneumatic Bollards: These bollards function using air pressure, making them more energy-efficient. They are best suited for locations where there is a moderate level of security required, like shopping malls, office complexes, and public parking lots.

Electromechanical Bollards: Powered by electric motors, these bollards are popular for their reliability and low maintenance needs. They are ideal for residential areas, private parking spaces, and gated communities.

Solar-Powered Bollards: A more eco-friendly option, these bollards are powered by solar panels, making them sustainable and cost-effective. Solar-powered bollards are best for areas where energy conservation is a priority, such as parks, walkways, and eco-friendly business complexes.

The Importance of Automatic Bollards in Bangladesh

As Bangladesh continues to develop, especially in urban centers like Dhaka, Chittagong, and Sylhet, managing traffic congestion and ensuring public safety have become increasingly challenging. The adoption of automatic bollards offers a modern, efficient solution to these issues.

Traffic Management: One of the most pressing issues in major Bangladeshi cities is traffic congestion. With the growing number of vehicles on the road, traditional methods like manual barriers and roadblocks are becoming obsolete. Automatic bollards provide a flexible solution for managing traffic flow, especially in areas prone to congestion. They can be used to control vehicle entry in restricted zones, pedestrian crossings, and commercial parking spaces, ensuring a smoother flow of traffic.

Enhanced Security: In a world where security threats are on the rise, automatic bollards serve as a robust defense mechanism. These bollards can be installed at the entrances of sensitive areas like government offices, embassies, airports, and military bases, where unauthorized vehicle access needs to be prevented. They are also a great solution for private properties and business complexes that require an additional layer of security.

Protection Against Vehicle-Borne Attacks: Automatic bollards are effective in preventing vehicle-borne threats, such as car bombings or unauthorized vehicle ramming attacks. By acting as physical barriers, they ensure that only authorized vehicles can pass through, significantly reducing the risk of such incidents.

Pedestrian Safety: In crowded urban areas, the safety of pedestrians is a priority. Automatic bollards can be used in zones with high pedestrian activity, such as shopping districts, marketplaces, and tourist spots. By controlling vehicle access, these bollards ensure that pedestrians can move freely and safely without the risk of vehicle interference.

Aesthetic Appeal: Apart from their functional benefits, automatic bollards can also enhance the aesthetic appeal of public spaces. With sleek designs and customizable options, they can blend seamlessly with the urban landscape, making them ideal for city centers, public parks, and business districts.

Use Cases of Automatic Bollards in Bangladesh

Automatic bollards can be utilized in various sectors to address specific security and traffic management needs. Some of the key areas where automatic bollards can play a crucial role in Bangladesh include:

Government and Diplomatic Buildings: High-security zones, such as government offices, embassies, and military installations, require stringent security measures. Automatic bollards can be installed at entry points to prevent unauthorized vehicle access and protect these sensitive areas from potential threats.

Commercial Complexes: Shopping malls, office buildings, and business parks can benefit from automatic bollards to manage vehicle entry and parking access. These bollards can be integrated with access control systems, allowing only authorized vehicles to enter, enhancing both security and traffic flow.

Residential Areas: Gated communities and residential complexes can use automatic bollards to restrict vehicle entry, ensuring that only residents and authorized visitors have access. This enhances the safety and security of the neighborhood.

Airports and Transportation Hubs: Airports, bus terminals, and railway stations are high-traffic areas where efficient traffic management and security are essential. Automatic bollards can be installed at strategic points to control vehicle access, preventing unauthorized vehicles from entering restricted zones.

Public Spaces and Events: Public spaces like parks, pedestrian zones, and event venues can utilize automatic bollards to restrict vehicle access during specific times or events. This ensures the safety of pedestrians and helps in managing traffic during large gatherings or public events.

Challenges in Implementing Automatic Bollards in Bangladesh

While automatic bollards offer numerous benefits, there are also some challenges to their implementation in Bangladesh. These include:

Cost: The initial installation of automatic bollards can be expensive, especially for large-scale projects. Hydraulic and electromechanical bollards, in particular, come with a higher price tag due to their advanced technology and robust materials.

Maintenance: Regular maintenance is essential to ensure the smooth functioning of automatic bollards. In Bangladesh’s tropical climate, dust, rain, and humidity can affect the performance of the bollards, requiring frequent servicing and repairs.

Power Supply: Automatic bollards, especially electromechanical and hydraulic ones, require a reliable power supply to function. In areas where power outages are frequent, solar-powered bollards may be a more sustainable option.

Public Awareness: Many people in Bangladesh are not yet familiar with automatic bollards and their benefits. Public awareness campaigns and education are necessary to promote the use of these systems for better traffic management and security.

Conclusion

As Bangladesh moves forward in its journey of urbanization and modernization, the need for advanced traffic management and security solutions becomes more apparent. Automatic bollards offer a reliable, efficient, and aesthetically pleasing solution to these challenges. From managing traffic congestion in busy city centers to enhancing security at high-risk areas, these bollards play a crucial role in shaping a safer and more organized urban environment.

Investing in automatic bollards not only addresses current traffic and security issues but also lays the foundation for future-proofing Bangladesh’s cities. While there are challenges in terms of cost and maintenance, the long-term benefits far outweigh these initial hurdles. As awareness grows and technology becomes more accessible, automatic bollards are likely to become a common feature in Bangladesh’s urban landscape, ensuring the safety and security of its citizens.

0 notes

Text

Industrial Control PCB Assembly Manufacturer

Industrial Control PCB Assembly Manufacturer – One-stop service

Industrial Control PCB Assembly – PCBA Manufacturers, Suppliers, Factory From China

Since the establishment of our company, the primary goal has been to maintain the superior quality, excellent durability and high cost performance of PCB Assembly. We are an enterprise specialized in manufacturing Industrial Control PCB Assembly integrating development, scientific research, manufacturing, technical services and marketing. Network interaction can enhance the value of our product brand, increase market share, and spread our brand image more effectively. Enterprises spare no effort to meet the needs of customers and serve customers unconditionally is the basic principle to achieve the first-class service level. With the in-depth understanding of product manufacturing process and market, our company collects high-quality brands and technical services targeted to meet the needs of customers with rapid response and high-quality service.

Because of robots and comparable technologies, many different remote control devices are being employed in numerous sectors. Assemblies of printed circuit boards are critical to the smooth movement and robust electrical connections between controllers and industrial machinery.

Rapid Assemblies was well aware of the potential influence remote-controlled machines would have on several sectors as soon as they entered the market. We’ve taken significant initiatives to ensure that our circuit board assemblies fulfill this industry’s rigorous criteria.

Electronics must be rock-solid, long-lasting, and capable of withstanding the most punishing environments for industrial usage. Additionally, industrial control PCB must adhere to tight industrial SIL and IEC requirements and offer unique design features and form factors for any industrial environment.

Advanced Electronic Manufacturing

• PCB Manufacturing

• PCB Assembly

• Integrated Manufacturing

• Cable Wire Harness Assembly

• Electromechanical Assembly

Application of PCBs for Industrial Use

Here are few examples of our industrial application:

Units that provide power

Robotics

Electronically controlled gearboxes

Drives and inverters for industrial applications

Instrumentation for electronic testing and measurements

Systems for regulating energy consumption

The use of smart meters in industrial settings

Smart labels for computers and other electronic devices

Lighting Systems

How to make industrial PCB?

Printed circuit boards (PCBs) are constructed from insulating panels onto which copper layers and signal lines are etched or printed. As the intricacy of the circuit increases, the number of layers on an industrial PCB may range from a single to eight or more. PCB Manufacturing Process includes the following steps:

PCB Layout

Design and layout come first when thinking about the industrial control PCB manufacturing process.

You need to know what you want and select a designer that will bring your vision to life (virtually) (virtually). Understand that PCB design and layout is the most critical step of producing an industrial circuit board.

PCB Design

The design will determine how the product will look and operate. A successful PCB design supports the operation of the device within which it is housed. Not all gadgets have the exact pricing, and hence the PCB design might differ on numerous parameters. The kind of users and their access to resources also determine the style of PCB.

Designing nowadays is done with specialized tools that may be used online and offline; they can be free or expensive.

PCB Prototyping

Once the design and layout have been authorized for production, you may prototype and test the product to confirm its functions and features as intended. It’s possible that prototyping will take longer than usual if the industrial PCB is very complicated.

Once a PCB prototype is complete, third parties often put through further testing before being released into production. So, the final product’s function and other features rely entirely on this one component.

Industrial Control PCB Assembly Characteristics:

According to the characteristics and technical particularities of industrial control products, it is not difficult to find that it has a high dependence on PCBA. The demand for information and intelligence is higher than that of general computers in some places. Industrial computers are computers, but they are different from personal computers.

Industrial computer configuration is not very high, as long as it meets the needs of the project. However, the motherboard has relatively rich slots, which can be used for various expansion functions. So it is not difficult to see that in practical work, the demand for PCBA is more diverse and the quality requirement is higher.

The application of industrial control board in industrial control board can adapt to the harsh industrial application environment and has good stability and reliability. Customers can also customize motherboards, core boards, module boards, and support specific specifications such as TG180, hot-roll boards, etc.

In order to meet the production demand of high-layer and high-precision industrial control products, Hitech Circuits has mature circuit board manufacturing technology and advanced imported production equipment, such as Korea OPE punch, Germany Burkle press, Japan Mitsubishi laser drill, Germany Schmoll drill, and vacuum resin plug machine; meanwhile, it has mastered the advanced production of the industry.

Conclusion

Industrial automation control is mainly used in industrial control units, high-power transformers for advanced integration and testing electric vehicle charging stations, smart metering and other fields. Printed circuit board assemblies are important for smooth movement and robust electrical connections between controllers and industrial machinery. Crucially, in the field of industrial control, PCBA can help companies save costs and reduce human errors, while PCB assembly for industrial control needs to involve large-scale component procurement and PCB production.

Industrial electronics assemblies are an integral part of modern industrial automation, playing an important role in improving the productivity, precision, and safety of industrial operations. Since industrial electronic equipment needs to run for a long time and the operating environment is complex, their quality must be strictly guaranteed. Hitechpcba is an expert in electronics assembly manufacturing, we provide a full range of industrial electronics manufacturing services from design to production and testing. With professional equipment, skilled technicians, and a strong quality management system, we are capable of consistently producing reliable and high-quality electronic equipment for industrial applications.

0 notes

Text

Demystifying the Control Panel: Your Electrical System's Unsung Hero

When you flip a switch or turn on a device, countless processes are set in motion behind the scenes to ensure everything functions seamlessly. At the heart of these operations lies the control panel, an essential component that often goes unnoticed. This unsung hero of electrical systems plays a crucial role in managing and protecting various processes across numerous industries. In this blog, we'll demystify the control panel, exploring its components, functions, and significance.

What is a Control Panel?

A control panel is an assembly of electrical devices that regulate, monitor, and control various systems and machinery. It acts as a centralized hub for managing electrical power and ensuring the safe and efficient operation of equipment. Control panels are used in a wide range of applications, from industrial machinery to power generation and distribution systems.

Key Components of a Control Panel

Control panels are composed of several key components, each serving a specific function:

Circuit Breakers and Fuses: These protective devices prevent overloads and short circuits by interrupting the flow of electricity when abnormal conditions are detected.

Relays and Contactors: Relays and contactors are electromechanical switches that control the flow of electricity to various parts of the system, enabling the automation of processes.

Meters and Gauges: These instruments measure and display electrical parameters such as voltage, current, and power, providing real-time data for monitoring and control.

Programmable Logic Controllers (PLCs): PLCs are digital computers used for automation of industrial processes. They receive input signals, process the data, and send output signals to control machinery and systems.

Human-Machine Interfaces (HMIs): HMIs are user interfaces that allow operators to interact with the control panel, view system status, and adjust settings as needed.

Transformers and Power Supplies: These components convert electrical power to the required voltage and current levels for various devices within the control panel.

Wiring and Terminals: Wiring and terminals connect all the components within the control panel, ensuring proper electrical connectivity and signal transmission.

Functions of a Control Panel

Control panels perform several critical functions that are essential for the operation of electrical systems:

Power Distribution: Control panels distribute electrical power to various devices and systems, ensuring that each component receives the appropriate voltage and current.

Protection: By monitoring electrical parameters and detecting abnormal conditions, control panels protect equipment from damage caused by overloads, short circuits, and other faults.

Control and Automation: Control panels enable the automation of processes by using relays, contactors, and PLCs to control the operation of machinery and systems.

Monitoring and Data Collection: Control panels provide real-time data on electrical parameters, allowing operators to monitor system performance and make informed decisions.

System Integration: Control panels integrate various components and systems, ensuring coordinated operation and efficient management of electrical power.

The Significance of Control Panels in Various Industries

Control panels are indispensable across numerous industries, playing a vital role in ensuring the smooth and efficient operation of electrical systems:

Manufacturing: Control panels automate production processes, monitor machinery, and ensure the safe and efficient operation of industrial equipment.

Power Generation and Distribution: Control panels manage the distribution of electrical power, monitor system performance, and protect critical infrastructure from faults.

Water and Wastewater Management: Control panels regulate pumps, valves, and treatment processes, ensuring the safe and efficient management of water resources.

Oil and Gas: Control panels monitor and control drilling operations, pipeline systems, and processing equipment, enhancing safety and efficiency.

Transportation: Control panels manage electrical systems in railways, airports, and seaports, ensuring the reliable operation of transportation infrastructure.

Conclusion

Control panels are the unsung heroes of electrical systems, playing a crucial role in managing, protecting, and automating various processes across industries. By understanding the components and functions of control panels, we can appreciate their significance in ensuring the smooth and efficient operation of our modern world. As technology continues to evolve, control panels will become even more sophisticated, further enhancing their ability to keep our electrical systems running seamlessly. Stay tuned for more insights into the vital technologies that power our everyday lives.

0 notes

Text

Bonanza Wealth Management Research Recommends Apollo Micro Systems Ltd. as a 'Buy'

In a detailed research report, Bonanza Wealth Management has identified Apollo Micro Systems Ltd. (AMSL) as a strong 'Buy' candidate. The report highlights AMSL’s significant experience, robust financial performance, and strategic growth initiatives, positioning it favorably within the defense and electronic manufacturing sectors.

Company Overview - Apollo Micro Systems Ltd. (AMSL) brings over 38 years of expertise in designing, developing, and assembling custom-built electronic and electromechanical solutions. The company’s extensive portfolio includes electronic manufacturing services, PCB fabrication, embedded software design and development, circuit board assembly, hardware design services, and custom-built electronic systems. AMSL serves critical sectors such as defense, space, and homeland security, providing high-performance and mission-critical solutions to both public and private sectors.

AMSL initially focused on offering design services to the Indian Space Research Organisation (ISRO). Over time, it expanded to develop systems and subsystems for electronic hardware and software, serving esteemed clients like the Defence Research and Development Organisation (DRDO) and various Defence Public Sector Undertakings (DPSUs). The company’s vision is to evolve into a platform-level development and supply provider, offering end-to-end solutions from concept to production.

Financial Performance and Projections - AMSL has demonstrated impressive financial growth, with revenue and profit after tax (PAT) growing at a compound annual growth rate (CAGR) of 22.3% and 44.8%, respectively, during the fiscal years 2021 to 2024. Key financial highlights from Bonanza Wealth Management’s report include:

Revenue: Increased from INR 1,354 million in Q4 FY23 to INR 1,354 million in Q4 FY24, marking a year-over-year growth of 26.8%.

EBITDA: Grew by 25.6% year-over-year to INR 287 million in Q4 FY24, driven by increased scale of operations and cost-efficient execution. The EBITDA margin slightly declined by 19 basis points to 21.2% in Q4 FY24.

PAT: Experienced a substantial year-over-year growth of 79.3% in Q4 FY24, reaching INR 129 million compared to INR 72 million in Q4 FY23.

Strategic Expansion Plans

AMSL is expanding its manufacturing capabilities significantly. The company operates a 55,000 square feet facility in Hyderabad and plans to add two new facilities measuring 40,000 and 350,000 square feet. This expansion, involving a capital expenditure of INR 1,500 million, is expected to be operational within the next 12 months, enhancing AMSL’s production capacity and enabling it to meet the growing demand.

The company’s strategic expansion aligns with its participation in over 150 indigenous programs and 60 Development cum Production Partner (DcPP) programs as a sub-system partner, boasting more than 700 onboard technologies.

Market Position and Opportunities - AMSL is a key player in India’s electronic, electromechanical, and engineering design sector, specializing in critical mission and time-sensitive solutions. Its products serve various industries, including aerospace systems, ground defense, space, avionics systems, homeland security, and transportation.

The company’s involvement in significant defense projects, including missiles, naval torpedoes, and underwater mines, underscores its strong market position. AMSL’s participation in indigenous missile programs like AGNI, PINAKA, AKASH-NG, VLSRSAM, VARUNASTRA, TAL, NIRBHAY, and ATAGS further solidifies its role as a major supplier in the defense sector.

Valuation and Recommendations - Bonanza Wealth Management values AMSL at 84.0 times the FY26 estimated earnings per share (EPS) of INR 1.53, resulting in a target price of INR 129.00, indicating an upside potential of approximately 20.0%. This valuation reflects AMSL’s strong order execution visibility, capacity expansion plans, and growth opportunities in the defense sector.

Risks and Concerns - While AMSL’s expansion plans are promising, any delays in adding new facilities could impact future growth prospects. Additionally, changes in defense manufacturing policies by the Ministry of Defence could negatively affect the company.

Analyst Insight - Rajesh Sinha, Senior Research Analyst at Bonanza Wealth Management, emphasizes AMSL’s robust financial performance, strategic expansion plans, and strong market position as key drivers for its recommendation. The report assures investors of the research's objectivity and independence, with no conflicts of interest.

Conclusion - With a proven track record and strategic growth initiatives, Apollo Micro Systems Ltd. is well-positioned to capitalize on emerging opportunities in the defense and electronic manufacturing sectors. Bonanza Wealth Management’s 'Buy' recommendation highlights the company’s potential for long-term growth and value creation for investors.

0 notes

Text

The Elements of Your PCBs: A Comprehensive Guide to 10 Most Popular Electronic Components

With the increasing demand for electronic gadgets, automation, and the Internet of Things (IoT), the electronic sector has tremendous growth potential. According to reports, by 2025, the worldwide electronic market will observe an exponential revenue growth of CAGR 8,92% till 2029, resulting in $712.30 billion.

The small components often constitute the foundation of everything the electrical gadgets we use daily, from life-saving medical equipment to cell phones. Navigating this small segment of electronic component sourcing, though, can be intimidating, given the thousands of available component sources.

This blog will go into the top 10 most important and regularly used electronic components, outlining their roles and how they work to create the magic inside your PCBs (Printed Circuit Boards).

Top 10 Essential Electronic Components for PCB Manufacturers

Out of numerous electronic components used in PCB manufacturing, here are the 10 essential components.

1. Resistors:

The backbone of every circuit, resistors regulate the current flow. It is recognised as “R” in the diagram. Picture them as small barriers that control the flow of electricity. The amount of current flowing through them is determined by their resistance value, measured in ohms (Ω). Selecting the correct one for your design among the many available options is essential, as they come in different sizes and power levels.

2. Capacitors:

A capacitor is essentially a small energy storage device. Capacitors (C) are measured in F (farad). They serve as a temporary power source for your circuit by storing electrical charge and reducing voltage fluctuations. Ceramic and electrolytic varieties exist, and each has advantages in certain contexts.

3. Diode:

The third type of electrical device is the diode, which allows current to flow in just one direction. They protect delicate components and make sure the current flows properly, like security guards. Diodes are versatile and can regulate voltage, route signals, and rectify alternating current (AC). In PCBs the most commonly used diode is Zener diode that offers various voltage stabilization options.

4. Transistors:

In the electronic industry, transistors are everywhere. These microscopic technological wonders are the building blocks of integrated circuits (ICs) and other intricate parts, used to control and can amplify the current. Its function is to amplify weak signals into electrical signals with larger amplitudes making it an essential component in PCB.

5. Crystals and Oscillators:

These are the beating heart of many electronics. Oscillators create a steady clock signal by applying a specific frequency to the vibrations of crystals. From regulating microprocessors to facilitating radio transmission, this timing signal is crucial for a multitude of tasks.

6. Light-Emitting Diodes (LEDs):

Incredibly flexible, LEDs aren't limited to glitzy gadgets. They are perfect for indicator lights, displays, and backlighting since they transform electrical energy into light. They have a long lifespan and consume very little power.

7. Integrated Circuits (ICs):

Integrated circuits (ICs), sometimes called chips, are considered the most important invention in the electronic field. They incorporate millions of transistors and other components on a single silicon chip to create complicated functionality. Integral circuits (ICs) are the central processing units (CPUs) and memory chips (MCUs) of contemporary electronics.

8. Electromechanical Components (Switches and Relays):

Components connect electrical and physical parts, known as electromechanical components (such as switches and relays). Relays enable high-power applications as electrically controlled switches, while switches allow you to manually control the current flow.

9. Connectors:

Connectors, the essential component of PCB construction, guarantee secure connections between various on-board components and any external devices you may be using. The correct connector, whether a basic header or a complicated socket, is critical for the operation and integrity of the signal.

10. Transformers:

An electrical device that alters the alternating current voltage. It has a magnetic iron core and two or more primary and secondary coils that wind around it. A transformer can maintain the electrical power balance while converting the input voltage into the needed output voltage using the electromagnetic induction principle. Power systems, electronic devices, communication networks, and manufacturing all use transformers heavily.

Choosing the Right Components for Your PCB

Now that you know what these BoM components are, you can choose them for your PCB design and BoM data creation with care, but there are a few things to keep in mind:

Function: The purpose of each part of your circuit must be defined.

Detailed Specifications: Read the technical specs and BoM data carefully, especially those dealing with voltage ratings and current constraints.

Fitment and Size: Get the dimensions and virtual footprint of your components right so they'll fit snugly on your printed circuit board design.

Availability and Cost: Consider how easy it is to get your hands on the parts you need through dependable electronic component sourcing and how much they will cost.

In summary:

Gaining familiarity with these ten electronic parts and component sourcing will put you in a strong position to succeed in the thrilling field of printed circuit board design and production. The success of a project depends on dependable component sourcing. To make sure your PCBs work perfectly, team up with a reliable provider with a large selection of high-quality components.

Click here to get the instant quotation.

Contact us at [email protected] or +1(818) 886 8900 if you have any more questions about our PCB service.

This Blog Originally Posted Here: The Elements of Your PCBs: A Comprehensive Guide to 10 Most Popular Electronic Components

0 notes

Text

Linear Variable Differential Transformer (LVDT) Sensors, Global Key Players Rank and Market Share, Top Twelve Companies Hold 39.18% (2022)

Linear Variable Differential Transformer (LVDT) Sensors Market Summary

LVDT is an acronym for Linear Variable Differential Transformer. It is a common type of electromechanical transducer that can convert the rectilinear motion of an object to which it is coupled mechanically into a corresponding electrical signal.

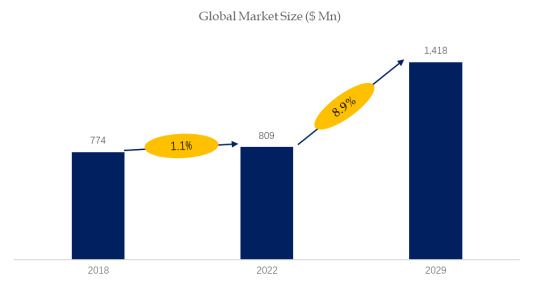

According to the new market research report “Global Linear Variable Differential Transformer (LVDT) Sensors Market Report 2023-2029”, published by QYResearch, the global Linear Variable Differential Transformer (LVDT) Sensors market size is projected to reach USD 1.42 billion by 2029, at a CAGR of 8.9% during the forecast period.

Figure. Global Linear Variable Differential Transformer (LVDT) Sensors Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Linear Variable Differential Transformer (LVDT) Sensors Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

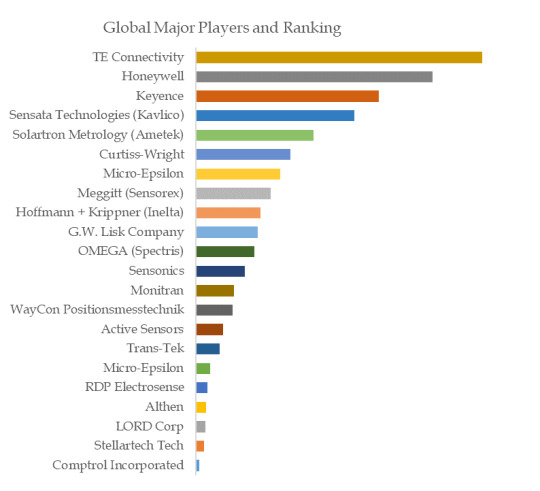

Figure. Global Linear Variable Differential Transformer (LVDT) Sensors Top Twelve Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Linear Variable Differential Transformer (LVDT) Sensors Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Linear Variable Differential Transformer (LVDT) Sensors include Comptrol Incorporated, Stellartech Tech, LORD Corp, Althen, RDP Electrosense, Micro-Epsilon, Trans-Tek, Active Sensors, WayCon Positionsmesstechnik, Monitran, etc.

In 2022, the global top 12 players had a share approximately 39.18% in terms of revenue.

Market Drivers:

1. The product has its own advantages: the LVDT sensor is a non-contact displacement sensor. There is no frictional contact between the coil and the iron core, and no wear will occur. Regardless of the level conversion and conditioning modules, the sensor body is a mechanical structure, which has the advantages of extremely high reliability, high precision, impact resistance and good dynamic performance, and is widely used in industrial and military fields.

2. Demand for industrial automation and smart manufacturing: With the advancement of Industry 4.0 and smart manufacturing, the demand for accurate, stable and reliable displacement measurement increases. LVDT sensors are widely used in automated production lines, due to their high accuracy, durability and wide operating temperature range. It is widely used in robotics, heavy machinery and precision manufacturing.

3. Aerospace and defense industry: In the aerospace and defense industry, precise displacement measurement of key parts of mechanical systems such as engines, flight control systems, missile guidance systems, etc. is crucial. LVDT sensors are used due to their high stability and harsh conditions. It is widely used due to its ability to adapt to the environment.

4. Technological innovation and product upgrades: With the continuous development of LVDT sensor technology, smaller, more efficient, and higher-precision products have emerged, meeting the market's demand for miniaturization and integration, and promoting further expansion of the market.

About The Authors

Analyst: Ran xinrong

Email: [email protected]

Website: www.qyresearch.com Hot Line:4006068865

QYResearch focus on Market Survey and Research

US: +1-888-365-4458(US) +1-202-499-1434(Int'L)

EU: +44-808-111-0143(UK) +44-203-734-8135(EU)

Asia: +86-10-8294-5717(CN) +852-30628839(HK)

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

MEMS Sensor Market Worth US$ 41.1 Million in 2022: FMI Report

The global MEMS Sensor Market is on an impressive trajectory, set to reach an estimated value of US$ 82.6 million by 2032. This substantial growth marks a moderate Compound Annual Growth Rate (CAGR) of 7.2% from 2022 to 2032. In 2022, the market had already crossed the milestone of US$ 41.1 million.

To Get Sample Copy of Report Visit: https://www.futuremarketinsights.com/reports/sample/rep-gb-17182

Key Takeaways:

The MEMS sensor market is projected to reach US$ 82.6 million by 2032, growing at a CAGR of 7.2%.

Accelerometers, gyroscopes, pressure sensors, temperature sensors, and humidity sensors are key MEMS sensor categories.

Accelerometers are expected to witness increased demand due to their ability to measure acceleration.

Gyroscopes are poised for high demand for their capacity to measure angular velocity.

Pressure sensors find extensive use in the automotive industry, while temperature sensors are crucial for measuring temperature changes.

MEMS sensors are integral to the expanding Internet of Things (IoT) and smart device ecosystem.

Smart home devices, smart meters, and other IoT-based devices will leverage MEMS sensors for data collection and automation.

MEMS sensors are favored for IoT due to their compact size, ideal for portable and small-scale devices.

Drivers and Opportunities: The escalating popularity of miniature mechanical and electrical devices, particularly micro-electromechanical systems (MEMS) sensors, is driving the global MEMS sensor market. MEMS sensors have the unique ability to detect and measure a range of physical phenomena, including motion, temperature, pressure, and humidity.

Accelerometers, a subcategory of MEMS sensors, are expected to experience a surge in demand as they play a pivotal role in measuring acceleration and changes in velocity. Likewise, gyroscopes are estimated to witness high demand owing to their capacity to measure angular velocity and changes in orientation. Pressure sensors, commonly employed in the automotive sector to gauge pressure fluctuations, and temperature sensors for monitoring temperature changes, are integral components of the MEMS sensor ecosystem.

The proliferation of the Internet of Things (IoT) and the surging demand for smart devices are set to propel the use of MEMS sensors. These sensors will feature prominently in smart home devices, smart meters, and various other IoT-driven gadgets, enabling seamless data collection and automation. The compact size of MEMS sensors makes them particularly well-suited for IoT devices, which are designed for portability and space-efficiency.

Request Report Methodology: https://www.futuremarketinsights.com/request-report-methodology/rep-gb-17182

Competitive Landscape – Regional Trends: The MEMS sensor market is highly competitive, with several key players vying for market share. Regional trends indicate varying levels of market penetration and adoption of MEMS sensors. In North America, for instance, robust investments in IoT infrastructure and the presence of major tech giants are fueling the demand for MEMS sensors. Meanwhile, the Asia-Pacific region is witnessing a surge in manufacturing activities, further driving the need for these sensors in various applications.

Restraints: Despite their significant growth prospects, the MEMS sensor market faces certain challenges. These include the need for continuous technological advancements to keep pace with evolving IoT and smart device requirements. Additionally, concerns related to data security and privacy in the IoT ecosystem may pose hurdles to widespread MEMS sensor adoption.

Region-wise Insights:

North America and Asia-Pacific are key growth regions, driven by IoT and manufacturing, respectively.

Europe also shows promise, with increasing applications in automotive and industrial sectors.

Latin America and the Middle East are emerging markets with potential for MEMS sensor growth.

Category-wise Insights:

Accelerometers and gyroscopes are expected to dominate the MEMS sensor market.

Pressure and temperature sensors will continue to find significant application in automotive and industrial sectors.

Humidity sensors are gaining importance in environmental monitoring and agriculture.

In conclusion, the MEMS sensor market is poised for substantial growth, driven by the proliferation of IoT and smart devices. Key categories like accelerometers and gyroscopes are set for increased demand, while regional trends vary based on the market maturity and technological adoption. Overcoming challenges related to data security and privacy will be crucial in ensuring the market’s continued expansion.

MEMS Sensor Market Outlook by Category

By Type:

Inertial Sensor

Pressure Sensor

Optical Sensor

Environmental Sensor

Ultrasonic Sensor

By Application:

Consumer Electronics

Automotive

Industrial

Aerospace & Defense

Healthcare

Telecommunication

Others

By Region:

North America

Latin America

Europe

Asia Pacific

Middle East and Africa

0 notes

Text

Generators will Grow Fastest in Piezoelectric Devices Market

The total revenue generated by the piezoelectric devices market was USD 30.9 billion in 2022, and it will power at a CAGR of 5.80% in the years to come, to reach USD 48.5 billion by 2030.

Sensors will grow significantly by the end of this decade, as per the report by P&S Intelligence. The demand for Piezoelectric sensors is increasing due to the acceptance in a number of industries, like autonomous vehicles, electronics and manufacturing for detecting the slightest changes of energy, which are converted to electrical signals.

Furthermore, piezoelectric sensors are put to use for measuring the force of touch, vibrations and shocks in aviation, healthcare, and electronics. These offer high-frequency responses, for sensing sudden parameter differences, detecting events in microseconds, and provide a linear output. These sensors are able to transform acceleration, pressure, physical, and other inputs into an electrical signal.

Energy harvesting is a procedure through which the energy collected from solar power, wind and heat, is directly transformed to electricity and transported to a different equipment.

Furthermore, for later use, the energy can be accrued in batteries or ultracapacitors. For example, piezoelectric generators allow the alteration of the energy contained in vibrations into electrical power, that can be used.

The key benefit of piezoelectric energy harvesters is MEMS incorporation and miniaturization, which the reason they are deployed for powering IoT uses and low-power wireless sensor systems.

Moreover, the technology offers affordable power solutions, supporting boost the energy proficiency by providing a simple design with a number of moving parts at a low cost. Energy harvesters are extensively installed on roads for generating power when automobiles pass over them.

Generators will grow at the fastest rate of 6.4%, in the years to come. The requirement for these generators is growing due to their capability for converting mechanical power into electricity and their use in energy harvesting devices.

The development would also be as a result of a number of tech improvements, for example nano-scaling and vibration energy harvesting.

Aerospace & defense will grow considerably in the future, because of the extensive use of these devices in the aviation, defense, and aerospace sector, where piezoelectric actuators reduce vibrations, thus plummeting noise and energy expenditure and improving the fuel efficacy of aircraft.

In the past, the lowering levels of noise in helicopters has expanded substantial focus. The aerospace sector will also increase the use of electromechanical piezoelectric-based systems for building a compactable system with a fast reaction and a high-power density.

Europe piezoelectric devices market will grow significantly, credited to the presence of numerous medical device, industrial and automotive manufacturing companies.

It is because of the growing trend of energy harvesting that the demand for piezoelectric devices will grow considerably in the future.

0 notes

Text

Airborne LiDAR Market Size, Global Key Players, Types, Applications, Countries & Forecast 2023 to 2032

The latest research report by Emergen Research, named ‘Global Airborne LiDAR Market - Forecast to 2032’, entails a comprehensive review of the global Airborne LiDAR market’s present and future trends The report gathers viable information on the most established industry players, sales and distribution channels, regional spectrum, estimated market share and size, and revenue estimations over the forecast timeframe. The study is inclusive of a profound analysis of this business sphere focuses on the overall remuneration of the market over the projected period.

The global Airborne LiDAR Market is forecasted to be worth USD 1,291.2 Million by 2027, according to a current analysis by Emergen Research.Due to the increasing demand for remote scouting and geo exploration operations, the airborne LiDAR market is expected to grow significantly over the forecast timeframe. In different fields, such as geographic measurements and corridor mapping, the growing demand for 3D imaging is expected to further fuel market growth.

Get a sample of the report @ https://www.emergenresearch.com/request-sample/239

The global Airborne LiDAR market report employs an extremely extensive and perceptive process that analyzes statistical data relating to services and products offered in the market. The research study is a pivotal document in understanding the needs and wants of the clients. The report is comprised of significant data about the leading companies and their marketing strategies. The Airborne LiDAR industry is witnessing an expansion and change of dynamics owing to the entry of several new players.

The Emergen Research report takes a closer view of the global market share, estimated growth rate, future market trends, entry-level barriers, fundamental market drivers, restraints, challenges, and opportunities. The report clearly defines the Airborne LiDAR market position on a global level. The detailed insights into the market’s geographical spectrum offered by the report make it an excellent source of knowledge about the Airborne LiDAR industry.

Key Companies Profiled in the Report are

Leica Geosystems, Saab AB, FLIR Systems, Inc., Teledyne Technologies International Corp, Faro Technologies, Inc.,, Lasermap Inc., Merrick & Company, Inc., Xactsense Inc., RIEGL Laser Measurement Systems GmbH, Firmatek, L.L.C.

Product Type Segmentation & Application Segmentation:

Type Outlook (Revenue, USD Million; 2017-2027)

Bathymetric

Topographic

Platform Outlook (Revenue, USD Million; 2017-2027)

UAVs

Fixed Wing Aircraft

Rotary Wing Aircraft

Component Outlook (Revenue, USD Million; 2017-2027)

Cameras

Lasers

Micro-electromechanical Systems

Inertial Navigation Systems

GPS/GNSS

Request a discount on the report @ https://www.emergenresearch.com/request-discount/239

The research report offers a comprehensive regional analysis of the market with regards to production and consumption patterns, import/export, market size and share in terms of volume and value, supply and demand dynamics, and presence of prominent players in each market.

Regional Analysis Covers:

North America (U.S., Canada)

Europe (U.K., Italy, Germany, France, Rest of EU)

Asia Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

Latin America (Chile, Brazil, Argentina, Rest of Latin America)

Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

To know more about the report, visit @ https://www.emergenresearch.com/industry-report/airborne-lidar-market

Furthermore, the report provides the analytical data in an organized format segmented into charts, tables, graphs, figures, and diagrams. This enables readers to understand the market scenario in an easy and beneficial manner. Moreover, the report aims to impart a prospective outlook and draw an informative conclusion to assist the reader in making lucrative business decisions. The report, in conclusion, provides a detailed analysis of the segments expected to dominate the market, the regional bifurcation, the estimated market size and share, and comprehensive SWOT analysis and Porter’s Five Forces Analysis.

Unfolding the prime factors prompting global market growth:

The study offers an in-depth analysis of the product outlook, which depicts the latest production growth trends and profit valuation. It further fragments the global Airborne LiDAR market into a broad product spectrum.

The study covers essential data related to these products’ application landscape, the demand for and market share held by each application type, and their growth rate analysis over the estimated period.

A detailed description of the distribution channels, including distributors, producers, and buyers, is one of the report’s key market highlights.

Request customization of the report @https://www.emergenresearch.com/request-for-customization/239

You need to discover how this will impact the Airborne LiDAR market today, and over the next 10 years:

Our 250-page report provides 194 tables and 189 charts/graphs exclusively to you.

The report highlights key lucrative areas in the industry so you can target them – Now.

It contains in-depth analysis of global, regional and national sales and growth.

It highlights for you the key successful trends, changes and revenue projections made by your competitors.

Related Reports:

Irrigation automation market https://www.emergenresearch.com/industry-report/irrigation-automation-market

Single use/disposable endoscopy market https://www.emergenresearch.com/industry-report/single-use-disposable-endoscopy-market

Smart water management market https://www.emergenresearch.com/industry-report/smart-water-management-market

Smart speaker market https://www.emergenresearch.com/industry-report/smart-speaker-market

Battery pack market https://www.emergenresearch.com/industry-report/battery-pack-market

Thank you for reading our report. For further queries, please connect with us, and our team will provide you the report best suited to your requirements.

About Emergen Research Emergen Research is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target, and analyze consumer behavior shifts across demographics, across industries, and help clients make smarter business decisions. We offer market intelligence studies ensuring relevant and fact-based research across multiple industries, including Healthcare, Touch Points, Chemicals, Types, and Energy

Contact Us: Eric Lee Corporate Sales Specialist Emergen Research | Web: https://www.emergenresearch.com/ Direct Line: +1 (604) 757-9756 E-mail: [email protected] Explore Our Blogs and Insights Section: https://www.emergenresearch.com/insights

0 notes

Text

Flame Retardant Film

As the base film of flame retardant film, the flame retardant film can exert its flame retardant performance after downstream coating, compounding and other processing procedures, and is widely used in the electromechanical industry as an insulating material.The flame retardant film can be used as the packaging of lithium batteries and insulating material in large capacitors after being coated with flame-retardant adhesive downstream.

Uses of Flame Retardant Film

1. The flame retardant film is mainly used in electrical machinery, building decoration materials and heating engineering in cold weather areas with requirements for product safety.

2. It is used for labels and labels of batteries and electronic products, as well as insulating clapboard with high flame retardant requirements. The flame retardant grade can reach the VTM-0 standard of UL94 (yellow card number: E516097)

3. Thickness range from 25-100 μ m with various colors, including transparent flame retardant film, black flame retardant film, white flame retardant film and golden flame retardant film.

Advantages of Flame Retardant Film

Fire Protection

flame retardant pet film

Fire protection - Creates a barrier that slows the spread of fires and prevents property damage and loss of life.

Health And Safety

fire retardant plastic film

Health and safety - Non-toxic, environmentally safe, and protects occupants from inhalation of toxic fumes.

Cost-effective

flame retardant film

Cost-effective - Economical compared to replacing or repairing fire-damaged properties, making them a viable solution for businesses and individuals.

Flame Retardant Film Tests and Standards

Fire Resistance Tests

Flame retardant films must be able to resist the ignition and spread of fire. Fire resistance tests measure the film's capacity to extinguish flames, prevent or delay the spread of fire, and release low levels of heat and smoke. Among the most common standards for fire resistance tests are the ASTM E84, NFPA 701, and UL 723.

Smoke and Toxicity Tests

During a fire, smoke and toxic fumes can cause asphyxiation, which can be very dangerous for occupants. Smoke and toxicity tests for flame retardant films evaluate the level of smoke that the film emits, the impact of the smoke on the environment, and the level of toxicity that the emitted gases have. Test standards such as ASTM E662, SAE J369, and NF F 16-101 regulate smoke and toxicity evaluations.

Thermal Stability Tests

Flame retardant films must have the capacity to maintain their fire-resistant properties at extended high temperatures. Thermal stability tests measure the film's capacity to withstand high temperatures, which is critical to preventing fires from spreading or igniting. Testing standards relating to thermal stability include ASTM D4804, ASTM D3014, and NF X 70-100.

1 note

·

View note

Text

Precision and Reliability: Custom Solenoid Coils by QualityCoils.com

In the world of electromechanical engineering, solenoid coils hold a pivotal role, providing the essential force required to power a vast array of devices and applications. While standard solenoid coils can serve many purposes, certain industries demand precise and tailored solutions to meet their unique requirements. QualityCoils.com, a leading manufacturer in the field, offers an extensive range of custom solenoid coils designed with precision engineering and unwavering reliability to ensure optimal performance in diverse applications. In this article, we delve into the significance and advantages of QualityCoils.com's custom solenoid coils, setting the standard for high-quality electromagnetic solutions.

Understanding Custom Solenoid Coils:

Solenoid coils are electromechanical devices comprising insulated copper wire wound around a magnetic core. When an electric current passes through the coil, a magnetic field is generated, creating linear or rotational motion in the application's associated components. While standard solenoid coils serve many purposes, they might not always meet the specific demands of certain projects. Custom solenoid coils are designed to cater to unique applications, offering tailored solutions that optimize performance and efficiency.

The Need for Customization:

Different industries and applications have distinct requirements, such as specific force outputs, response times, voltage levels, and environmental conditions. Standard solenoid coils might not provide the precision and reliability necessary for such specialized tasks. Customization allows engineers to design coils with exact specifications, ensuring a perfect fit for each project and enhancing the overall performance of the application.

Precision Engineering for Superior Performance:

QualityCoils.com takes pride in its precision engineering approach. Their team of skilled engineers collaborates closely with clients to understand the intricacies of their projects. By incorporating cutting-edge materials, Custom Coil Winding techniques, and adhering to stringent quality control measures, they create custom solenoid coils with superior performance and durability. These coils are designed to withstand harsh environments, high-cycle operations, and demanding conditions, ensuring long-lasting and reliable operation.

Versatility Across Industries:

QualityCoils.com's custom solenoid coils cater to a wide range of industries and applications. From medical devices, aerospace, and automotive systems to industrial machinery and consumer electronics, their coils find applications in diverse sectors. The versatility of their custom solutions ensures that clients receive coils that meet their specific needs, enabling seamless integration and efficient functionality.

Streamlined Production Process:

QualityCoils.com is equipped with state-of-the-art facilities and advanced manufacturing capabilities, allowing them to streamline the production process for custom solenoid coils. From rapid prototyping to efficient mass production, they deliver high-quality coils with short lead times. Their agile approach ensures that clients can bring their projects to market faster and maintain a competitive edge.

Commitment to Customer Satisfaction:

At QualityCoils.com, customer satisfaction is paramount. Their dedicated team of professionals works closely with clients throughout the design and manufacturing process, ensuring that all requirements and expectations are met. Moreover, they provide excellent post-sales support, offering technical assistance and guidance to ensure seamless integration and optimal performance of their custom solenoid coils.

QualityCoils.com stands as a leader in the world of electromagnetic solutions, with their custom solenoid coils delivering precision, reliability, and versatility across industries. By leveraging their expertise in precision engineering and commitment to customer satisfaction, they provide tailored solutions that enhance the performance of various applications. With QualityCoils.com as a trusted partner, businesses can be confident in receiving custom solenoid coils that exceed expectations, driving efficiency and innovation in their projects.

0 notes

Text

Choosing the Right 3 Phase Meter for Your Business: Key Considerations

Managing energy consumption efficiently is crucial for businesses, and selecting the right 3 phase meter plays a pivotal role in accurate energy monitoring. As businesses have diverse energy needs, understanding the key considerations is essential to make an informed choice.

Reliable single phase energy meter connection for Residential Usage ensures accurate energy readings and efficient billing. Trust our advanced technology to monitor and manage your energy consumption effectively, promoting sustainability and cost savings for your home.

Factors to consider -

Capacity and Load Requirements:

Evaluate your business's energy demand and load requirements to determine the appropriate 3-phase meter capacity. Consider factors like peak power demands, load fluctuations, and any potential future expansions that may impact energy usage.

2. Accuracy and Precision:

Accurate meter readings are essential for precise billing and effective energy management. Look for 3-phase meters with high accuracy levels and adherence to relevant industry standards to ensure dependable measurements.

3. Meter Type and Communication:

Choose between traditional electromechanical meters and modern digital meters with advanced communication capabilities. Digital meters provide real-time data, facilitating remote monitoring and enabling businesses to analyze energy consumption patterns conveniently.

4. Tariff and Billing Options:

Consider your specific tariff requirements and billing preferences. Some 3-phase meters support time-of-use tariffs, enabling businesses to capitalize on off-peak rates and optimize energy usage.

5. Compatibility and Integration:

Ensure that the selected 3-phase meter is compatible with your existing power distribution system and energy management software. Seamless integration simplifies data collection, streamlines energy analysis, and enhances overall energy efficiency.

While 3-phase meters are widely used in commercial and industrial settings, businesses with smaller energy needs may opt for single-phase energy meter connections. It is crucial to distinguish between the two meter types to ensure a suitable fit for your business's energy requirements.

Conclusion

Choosing the right 3-phase meter for your business is critical to optimize energy consumption, control costs, and ensure accurate billing. Consider factors like capacity, accuracy, meter type, communication, tariff options, compatibility, load profiling, safety, and maintenance to make an informed decision. By carefully evaluating these key considerations, businesses can select the ideal 3-phase meter that aligns with their energy management goals and needs. Additionally, businesses with smaller energy requirements can explore the benefits of single-phase energy meter connections for efficient energy monitoring and management.

0 notes

Text

What are the Main Applications of the Piezoelectric Ceramic Tube?

Introduction of piezoelectric ceramic tube

Piezoelectric ceramic tubes are the most commonly used type of ceramic tubes due to the versatility anc efficiency of their design. They have a variety of uses in electronics, micro-electromechanical systems, and sensors. Piezoelectric ceramics are valuable in these fields because they excel at transmitting power easily and making power voltages with low levels of distortion and noise.

This allows for more efficient transmissions such as those required for wireless communication. Piezoelectric ceramic tubes are built with a variety of piezoceramics including aluminium nitride and lead zirconate titanate.

Advantages of piezoelectric ceramic tube

The main advantages of piezoelectric ceramic tubes are their ability to have continuous duty cycles, their quick response times, and their ability to withstand high temperatures. These tubes have a very large range of frequencies that they can use. Unlike other types of ceramic tubes, piezoelectric tubes are not limited to the frequency range that they were built for.

This is because they are piezoelectric, which means that they have the property of generating an electric charge when they are deformed, especially under a strong mechanical force. In this way, the property allows them to be used in many different situations as well as to cover large ranges of frequencies.

Piezoelectric tubes can protect more than just themselves. They can also be used to protect other devices placed in close proximity to them, such as those in the use of semiconductor chips. This is because piezoelectric ceramic tubes are the type of materials that are able to withstand the high temperatures of semiconductor chips. Although this has not been studied thoroughly, it is likely that piezoelectric ceramic tubes may have the ability to easily respond to electronic signals at much higher frequencies than other types of ceramic tubes. This is because of the high levels of mechanical forces that can be applied to them.

Piezoelectric ceramic tubes are not limited to just producing power and transmitting it; they can also work in the other direction, to generate a voltage after being mechanically deformed. This allows for easy device designs that are able to act as sensors as well. This property is mainly used in pressure sensors and accelerometers.

The main applications of piezoelectric ceramic tubes are in the field of electronics, micro-electromechanical systems, and sensors. This is because they are able to efficiently transmit power such as those required to power semiconductor chips without any loss in communication or quality of the signal. This allows for them to be used in many different situations such as being used as a sensor to accurately measure pressure and other mechanical forces.

Another field where they are commonly used is microfluidics. This type of technology requires piezoelectric ceramics because they can efficiently transmit and receive information in such liquids as opposed to other types of tubes.

Disadvantages of piezoelectric ceramic tube

The main disadvantages of piezoelectric ceramic tubes include the fact that their lifespan is low,coupled with the fact that their costs are relatively higher than those of comparable materials. These disadvantages are due to the difficulty in producing such tubes as well as their need for high levels of processing steps.

Most commonly, piezoelectric ceramic tubes are made from aluminium nitride and lead zirconate titanate. This is because these materials are able to easily withstand the high mechanical forces that their role requires without losing any of their properties. However, other materials have been used for this purpose as well, for example, quartz crystals and silicon piezoceramic ceramics.

Conclusion

Piezoelectric ceramic tubes have a variety of applications in electronics, micro- electromechanical systems, and sensors. Because of their piezoelectric property and ability to transmit power at high frequencies with little loss or distortion, they are able to be used in these fields with relative ease.

Piezoelectric ceramic tubes are relatively easy to design and can be built using a variety of materials for their construction. They are able to easily withstand the high mechanical forces that are required for their applications without losing any of their properties.

About Us

Weifang Jude Electronic Co. Ltd is a manufacturer and supplier of high-quality piezoelectric ceramics for a multitude of electrical functions. As a piezo material supplier, we provide piezoelectric components, piezoelectric ceramic sensors, ultrasonic piezo, and other piezo products.

1 note

·

View note

Text

Linear Variable Displacement Transducers Market Consumption Analysis, Business Overview and Upcoming Trends|TE Commectivity, Honeywell, Sensata Technologies (Kavlico), AMETEK, etc

The linear variable displacement transducers (LVDT) market refers to the market for devices that are used to measure linear displacement or position changes. LVDTs are electromechanical devices that convert linear motion into an electrical signal for measurement and control purposes.

LVDTs are widely used in various industries and applications where precise and accurate measurements of linear displacement are required. They consist of a coil assembly and a core that moves within the coil. As the core moves, it induces changes in the output voltage of the coil, which can be measured and converted into a displacement value.

Free Download Link:-https://www.marketinforeports.com/Market-Reports/Request-Sample/342102

The LVDT market is driven by the increasing demand for high-precision measurement and control systems in industries such as automotive, aerospace, manufacturing, healthcare, and robotics. LVDTs offer several advantages over other displacement sensing technologies, including high resolution, excellent linearity, wide measurement range, and long-term stability.

The market for LVDTs is competitive, with several manufacturers offering a wide range of products tailored to different application requirements. LVDTs are available in various sizes, measurement ranges, and mounting options to accommodate different installation and integration needs. Major players in the market include sensor manufacturers, automation solution providers, and specialized LVDT manufacturers.

The LVDT market is influenced by factors such as technological advancements, industry regulations, and the need for accurate position feedback in critical applications. With advancements in LVDT design and manufacturing processes, newer models offer improved performance, higher accuracy, and increased durability.

The market is also driven by the growing trend towards automation and the need for precise positioning and motion control in various industries. LVDTs play a crucial role in automation systems, ensuring accurate feedback for positioning, leveling, and control applications.