#Electrical Capacitor Market

Explore tagged Tumblr posts

Text

youtube

At Kineto, our mission is to revolutionise lives by unleashing electricity's power. Our mission is to effect good change by providing dependable and robust solutions. Our products are designed to integrate into your daily life easily. By investing in our own tooling, designing, and testing teams, we distinguish ourselves in the industry. Our high-performance solutions provide outstanding efficiency and user-friendliness whether it comes to illuminating your areas or managing electrical systems.

#LED Light Manufacturers in kolkata#LED Lights in kolkata#led light dealers in kolkata#led light wholesale market in kolkata#led bulb manufacturer in kolkata#led bulb in kolkata#led bulb Suppliers In Kolkata#led lighting solutions#energy saving light bulbs#wholesale led lights#wholesale light bulbs#led ceiling fan#industrial led lighting#plug in led lights#electrical wire for led lights#led wire in kolkata#Wires & Cables in kolkata#Capacitors in kolkata#fans in kolkata#Switchgears in kolkata#Pipes & Casings in kolkata#Wires & Cables Manufacturers in kolkata#Capacitors Manufacturers in kolkata#fans Manufacturers in kolkata#Switchgears Manufacturers in kolkata#Pipes & Casings Manufacturers in kolkata#Youtube

0 notes

Text

https://www.htfmarketintelligence.com/report/global-electric-double-layer-capacitor-edlc-market

1 note

·

View note

Text

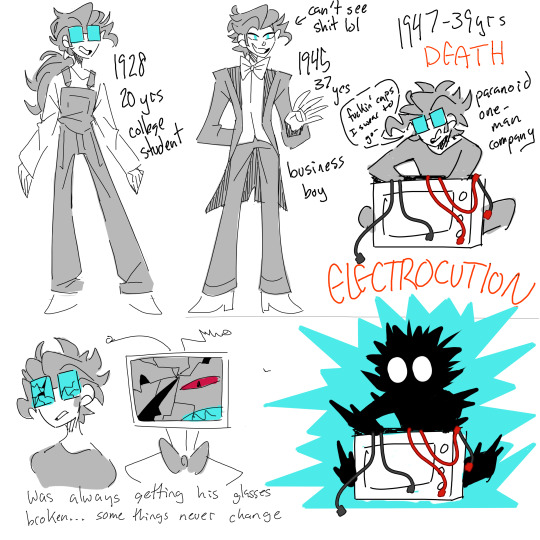

vox's life: headcannons

im an electrical engineer and i have opinions on this character. moral of the story: don't fuck with CRT capacitors, shits scary

i have a lot of Vox thoughts, or Voughts, and i will be rambling about them at legnth under the cut.

TLDR: he invented zuckerberging. also i see his "canon" death date of 1950s and respectfully disagree. its way funnier if he died the year widespread television became a thing. the fruits of his labor were all for naught etc etc

1928: Vox was in college as an electrical engineer when the first ever live TV Demo happened, and I think he was immediately obsessed with it. Decided he'd do anything to work with TV. He and his friend/roommate at the time went full tilt into learning about TVs and working on them, and by the time they graduated, they had the beginnings of what would be a very profitable company.. together.

1930s: Out of the two of them, Vox has the better social skills(relative), so he's the one who talks to investors and handles that part of the business, though he still works on some tech. He decides he likes talking to people, marketing, manipulating, being a little showman. I like to think this ties into that one trivia fact that he likes watching commercials.

early 1940s: He starts wondering why he's splitting half of this company(HIS company) with some guy who can't even bother to attend business meetings. Tensions start rising, he starts using some of that handy manipulation skill he honed in business on his friends

1945: Tensions break. Through less than legitimate means, he steals the company out from under his partner. His partner threatens to go start his own, since he did the majority of the tech work. We can't have that. Vox doesn't kill him himself, imo, because he is kind of allergic to getting his hands dirty. He revs up that media training and uses it to create a smear campaign so brutal and widespread that his former partner offs himself. Problem solved

Late 1940s: Vox starts getting paranoid about people trying to steal his empire from him, funny that. He starts trying to do everything himself, because he doesn't trust anyone. Starts losing a lot of sleep, getting a little insane but its fine man. Don't worry about it.

1947: Sleep deprived, paranoid, and working on a final prototype model due soon, he electrocutes himself because you shouldn't fuck with CRT capacitors. Wakes up in hell with electricity powers and a CRT head because it's hilarious.

Alastor: Yeah we all know what we're here for. I don't think they ever met in life, but I definitely think Vox knew of him. Alastor was actively broadcasting during the 20s up until his death in 1933, and college student Vox I think listened to a lot of radio while studying and working. I also think in the later years, Alastor was never technically caught as a serial killer, but "hey I think that radio guy was that one killer, cuz he stopped broadcasting right after he stopped killing" was like one of those insane conspiracy statements you'd say to get a laugh at parties, but Vox always secretly kind of believed it, and was VERY vindicated in hell.

I am fully prepared for actual canon to contradict all of this but that's fine because it means they finally had to get season 2 out.

#hazbin hotel#hellaverse#vox#vox hazbin hotel#hazbin hotel vox#hazbin hotel vees#fanart#hazbin hotel fanart#hazbin hotel art#art

212 notes

·

View notes

Text

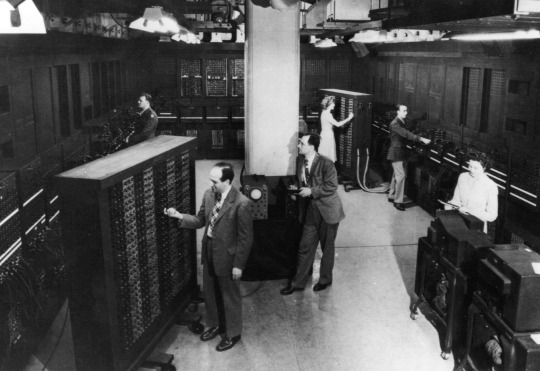

Today in Computer History (02/14/2024):

Today is Valentine’s Day, which means we say a very special happy birthday to the ENIAC! Today, February 14th 2024, the first ever electric, programmable, general purpose digital computer turns 79 years old!

(Picture via University of Pennsylvania)

Completed in 1945, the ENIAC (Electronic Numerical Integrator and Computer) was the first computer to integrate all its features into one unit. The ENIAC took up more than 1,800 square feet and weighed over 27 ton, and was made up of 40 panels, 17,000 vacuum tubes, 7,200 crystal diodes, 1,500 relays, 70,000 resistors, 10,000 capacitors, and over 5,000,000 hand-soldered joints. These numbers have gotten bigger over time, of course. Today, a single stick of 4gb RAM has somewhere in the ballpark of 32 billion capacitors.

The ENIAC could perform up to 5,000 additions or 50 multiplications per second, with a clock speed of around 100 kilohertz. It calculated trajectories 40 times faster than humans could. For additional context by modeling calculators, the classic Ti-84 plus (2004), one of the most used calculators to this day, has a clock speed of 15 megahertz, 150 times faster than the ENIAC.

The ENIAC was the first dive into digital calculators in the modern age, retired in 1955 at ten years old. And nearly eight decades later, we now carry devices with calculators in our pockets. The ENIAC was thousands of times bigger than the largest smartphones on the modern market, and part of it is on display at the University of Engineering and Applied Science at the University of Pennsylvania.

(Picture via Wikipedia)

#computers#today in computer history#February 14th#ENIAC#calculators#isn’t this shit CRAZY#queueputer!

12 notes

·

View notes

Text

What is Circuit Card Assembly and Why is it Crucial for PCB Board Production?

A Circuit Card Assembly (CCA), too known as PCB Board Assembly or PCBA Circuit Board, speaks to a vital breakthrough in electronic manufacturing where components are mounted onto a printed circuit board (PCB) to make a useful electronic gadget. This prepare changes a uncovered PCB into a working electronic assembly that powers everything from smart phones to mechanical machinery.

The travel of circuit card assembly starts with a uncovered PCB, which serves as the establishment for all electronic components. Amid the Assembly handle, different electronic components counting resistors, capacitors, coordinates circuits, and chip are carefully put and patched onto the board concurring to the plan details. This change from a straightforward PCB to a completely useful PCBA circuit board includes a few advanced steps and technologies.

Surface Mount Technology (SMT) plays a significant part in advanced circuit card Assembly. This strategy permits components to be specifically mounted onto the surface of the PCB, empowering higher component thickness and more compact plans. The SMT handle ordinarily starts with applying patch glue to particular areas on the board through a stencil, taken after by exact arrangement of components utilizing robotized pick-and-place machines. These machines can position thousands of components per hour with surprising accuracy.

Through-hole Technology, in spite of the fact that more seasoned than SMT, remains crucial in PCB board assembly, particularly for components that require more grounded mechanical associations or require to handle higher control loads. This strategy includes embeddings component leads through pre-drilled gaps in the PCB and fastening them on the inverse side, making vigorous associations that can withstand mechanical stress.

Quality control speaks to a basic viewpoint of circuit card Assembly. Each PCBA circuit board experiences thorough testing methods, counting automated optical inspection (AOI), X-ray assessment for covered up patch joints, and utilitarian testing to guarantee all components work as expecting. These quality measures are basic since indeed minor surrenders can lead to gadget failure.

The significance of exact circuit card assembly in PCB board generation cannot be exaggerated. To begin with, it straightforwardly impacts the unwavering quality and execution of the last electronic item. A well-assembled board guarantees legitimate electrical associations, warm administration, and flag judgment, all pivotal for gadget functionality.

Additionally, proficient circuit card Assembly makes a difference minimize electromagnetic impedances between components, which is basic in today's thickly stuffed electronic gadgets. Appropriate component arrangement and steering amid PCBA Circuit Board Assembly offer assistance keep up flag keenness and decrease commotion, guaranteeing ideal performance.

The financial suggestions of quality circuit card assembly are noteworthy. Appropriate Assembly diminishes the hazard of field disappointments, guarantee claims, and item returns, eventually sparing producers significant costs. Besides, effective assembly forms offer assistance optimize generation throughput and diminish time-to-market for modern electronic products.

As gadgets proceed to advance with expanding complexity and miniaturization, the part of circuit card assembly gets to be indeed more basic. Present day PCB board assembly must suit progressed components like ball grid arrays (BGAs), quad flat no-leads (QFN) bundles, and other complex coordinates circuits whereas keeping up tall unwavering quality and abdicate rates.

Looking ahead, circuit card Assembly proceeds to progress with unused technologies and strategies. Automated assembly lines, manufactured intelligence-driven quality control, and progressed materials are pushing the boundaries of what's conceivable in PCBA circuit board manufacturing, empowering the generation of progressively modern electronic gadgets that control our cutting edge world.

0 notes

Text

Power Capacitors Market Competitor Analysis: Key Players, Strategies, and Future Growth Trends

The power capacitors market has witnessed significant growth due to the rising demand for energy-efficient solutions and the increasing use of power electronics in industries such as automotive, renewable energy, and consumer electronics. As companies strive to gain a competitive edge, understanding the competitive landscape becomes crucial. This article explores key players, market strategies, and industry trends that shape the power capacitors market.

Market Overview

Power capacitors are vital components used in energy storage, power factor correction, and voltage regulation in electrical circuits. The demand for these capacitors is driven by advancements in electric vehicles (EVs), smart grids, and industrial automation. The market is highly competitive, with major global players focusing on product innovation, mergers, and strategic partnerships to strengthen their positions.

Key Competitors in the Power Capacitors Market

1. ABB Ltd.

ABB is a global leader in power and automation technologies, providing high-quality capacitors for industrial and energy applications. The company focuses on R&D and innovative solutions to enhance energy efficiency and sustainability.

2. General Electric (GE)

GE offers a diverse range of power capacitors used in power transmission and distribution systems. The company leverages its strong market presence and technological expertise to stay ahead in the competition.

3. Siemens AG

Siemens provides power capacitors for industrial applications, emphasizing reliability and energy efficiency. The company integrates digital technologies to optimize power management and reduce energy losses.

4. Schneider Electric

Schneider Electric specializes in energy management and automation solutions. Its capacitors are widely used in power factor correction and harmonic filtering, contributing to energy savings and improved system performance.

5. Eaton Corporation

Eaton delivers advanced capacitor solutions for power quality and electrical distribution applications. The company focuses on sustainability and efficiency, offering innovative products to meet evolving industry needs.

6. TDK Corporation

TDK is known for its high-performance capacitors used in industrial and consumer electronics. The company invests heavily in R&D to develop cutting-edge capacitor technologies.

7. Vishay Intertechnology, Inc.

Vishay manufactures capacitors for various applications, including automotive, industrial, and medical devices. Its strong portfolio and technological advancements position it as a key market player.

Competitive Strategies in the Power Capacitors Market

1. Innovation & Technological Advancements

Companies invest in R&D to develop high-efficiency capacitors with improved performance and longevity. The integration of smart capacitor technology and IoT-enabled power management systems is gaining traction.

2. Mergers & Acquisitions (M&A)

Leading players engage in strategic mergers and acquisitions to expand their product portfolio and strengthen market reach. For instance, acquisitions of niche capacitor manufacturers help companies enhance their technological capabilities.

3. Regional Expansion & Market Penetration

To capitalize on growing demand, companies are expanding their presence in emerging markets such as Asia-Pacific, where industrialization and renewable energy adoption are rising.

4. Sustainability & Energy Efficiency

With increasing environmental concerns, manufacturers focus on developing eco-friendly capacitors that contribute to energy conservation and carbon footprint reduction.

5. Strategic Partnerships & Collaborations

Industry leaders collaborate with technology firms, research institutions, and government bodies to develop advanced capacitor solutions that meet future energy demands.

Future Outlook

The power capacitors market is expected to witness sustained growth driven by the expansion of renewable energy infrastructure, the rise of electric mobility, and increasing industrial automation. Market players will continue investing in innovation and strategic collaborations to maintain their competitive advantage.

Conclusion

The power capacitors market is highly competitive, with key players leveraging innovation, strategic partnerships, and global expansion to gain an edge. As industries increasingly adopt energy-efficient technologies, companies must continuously evolve to meet market demands and technological advancements.

0 notes

Text

MLCC Market Trends 2034: How 5G, IoT, and ADAS Are Reshaping the Industry

The global Multilayer Ceramic Capacitor (MLCC) market is witnessing significant growth, driven by advancements in consumer electronics, 5G technology, electric vehicles (EVs), and renewable energy. MLCCs, known for their high capacitance and compact size, are widely used in various applications, making them an essential component in modern electronic devices.

In 2023, the MLCC market was valued at US$ 13.0 billion and is projected to reach US$ 28.7 billion by 2034, growing at a CAGR of 7.5%. Leading manufacturers such as Murata, Samsung Electro-Mechanics, and Taiyo Yuden dominate the market, with China, South Korea, and Japan being key production hubs.

Key Market Drivers

1. Expanding Consumer Electronics Industry

The demand for MLCCs is surging due to the rising popularity of portable consumer electronics like smartphones, laptops, and wearable devices. The miniaturization trend in electronics has further propelled the need for compact yet high-performance capacitors.

For instance, Taiyo Yuden launched new low-profile MLCCs (AWK105 BJ474MN and PWK105 C6474MN) in April 2021, specifically designed for smartphones and wearables to improve power supply efficiency.

2. Growth of Electric Vehicles (EVs)

As the world transitions to sustainable transportation, MLCCs play a vital role in electric vehicles. They are used to smooth voltage fluctuations, filter noise, and protect semiconductors in EV drive systems.

According to the International Energy Agency (IEA), global EV sales reached 14 million units in 2023, marking a 35% YoY growth. With this surge, MLCC manufacturers are focusing on developing high-performance capacitors to meet the demands of the EV sector.

3. 5G Infrastructure Expansion

The rollout of 5G technology has significantly boosted MLCC demand. These capacitors are crucial for 5G base stations, smartphones, and network infrastructure due to their ability to handle high frequencies and temperature variations efficiently.

4. Rise in IoT and Industrial Automation

With the expansion of IoT devices and smart industrial applications, MLCCs are in high demand for embedded systems, sensors, and control circuits. Their reliability and efficiency make them indispensable for industrial automation and AI-driven applications.

Read More: https://www.transparencymarketresearch.com/multi-layer-ceramic-capacitor-market.html

Market Segmentation Analysis

1. By Dielectric Type

X7R (29.9% market share in 2023): Preferred for automotive and industrial applications due to its balanced capacitance stability and temperature resistance (-55°C to +125°C).

Other types: C0G (NP0), X8G, U2J, X5R, Y5V, X7S, and others.

2. By Voltage

Low Voltage (Up to 75V) - 45.5% share in 2023: Used in consumer electronics, IoT, and telecommunications.

Medium Voltage (100-630V): Suitable for industrial and medical applications.

High Voltage (Above 1kV): Essential for power grids, automotive, and defense applications.

Regional Market Insights

Asia-Pacific: The Leading MLCC Hub

Asia-Pacific accounted for 44.3% of the MLCC market in 2023, with China, Japan, South Korea, and Taiwan dominating the production landscape. The region benefits from a robust electronics manufacturing ecosystem, strong supply chains, and increasing consumer electronics consumption.

North America: Technological Innovation Hub

North America holds a 21.1% share, driven by its advanced semiconductor industry, strong automotive sector, and increasing automation. The U.S. leads the region in MLCC innovation and production, particularly for high-performance capacitors used in aerospace and defense.

Europe: Growth in EV and Industrial Sectors

Europe is witnessing steady MLCC market growth, fueled by the rising adoption of electric vehicles and industrial automation. The region’s stringent environmental regulations are also pushing manufacturers to develop eco-friendly capacitor solutions.

Competitive Landscape & Key Players

The MLCC market is highly competitive, with major companies focusing on R&D, strategic collaborations, and capacity expansion to maintain market dominance.

Key Players:

Murata Manufacturing Co., Ltd.

Samsung Electro-Mechanics

Taiyo Yuden Co., Ltd.

Kyocera Corporation

Yageo Corporation

TDK Corporation

These companies are investing in next-generation MLCCs with enhanced temperature stability, high capacitance, and improved reliability for critical applications.

Future Outlook (2024-2034)

The MLCC market is expected to witness robust growth, driven by:

The increasing integration of AI and IoT technologies

Expansion of 5G networks and telecommunications infrastructure

Rising demand from electric vehicles and industrial automation

Continuous advancements in miniaturization and high-capacitance MLCCs

Manufacturers are expected to focus on expanding production capabilities, diversifying supply chains, and investing in R&D to stay ahead in this competitive market.

Contact Us: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Get the Best Deals on 220uF 16V Aluminum Electrolytic Capacitors and More

When it comes to building or repairing electronic circuits, capacitors play an essential role in regulating voltage, filtering signals, and smoothing power supplies. Among the many types of capacitors available, the 220uF 16V 20% 6.3X7.7mm Chip Type Aluminum Electrolytic Capacitor SMT is one of the most commonly used for various applications. Whether you're designing power supplies, audio equipment, or LED lighting systems, this component is vital for ensuring smooth and reliable circuit performance. In this article, we will explore the features of this capacitor and how you can easily find and buy it, along with other electronic components, from online stores in India.

What is a 220uF 16V 20% 6.3X7.7mm Chip Type Aluminum Electrolytic Capacitor?

The 220uF 16V 20% 6.3X7.7mm Chip Type Aluminum Electrolytic Capacitor is a high-quality, surface-mount (SMT) component used in electronic circuits to store and release electrical energy. Here's a breakdown of its key specifications:

220uF Capacitance: This indicates the capacitor's ability to store charge. With a capacitance of 220 microfarads (uF), this component can handle significant energy storage, making it ideal for filtering applications in power supplies.

16V Voltage Rating: The capacitor can handle a maximum operating voltage of 16 volts, which is ideal for low to medium-voltage circuits. It ensures that the capacitor can work efficiently without the risk of breakdown under normal operating conditions.

20% Tolerance: This specification tells you how much the actual capacitance could vary from the stated 220uF. With a 20% tolerance, the capacitor will perform within a range of ±20% of its nominal value, which is typical for many aluminum electrolytic capacitors.

6.3X7.7mm Size: The size (6.3mm x 7.7mm) makes this capacitor perfect for compact circuit boards, especially where space is limited. The chip-type design ensures that it can be surface-mounted (SMT), making it compatible with modern assembly techniques like pick-and-place machines.

Aluminum Electrolytic Construction: Aluminum electrolytic capacitors are known for their high capacitance values and relatively small size, making them an excellent choice for power supply filters, decoupling, and energy storage.

Why is This Capacitor Important?

The 220uF 16V Aluminum Electrolytic Capacitor is widely used in power supply circuits, audio equipment, lighting systems, and voltage regulation applications. Its primary role is to smooth out fluctuations in the supply voltage, ensuring stable and reliable operation of electronic devices. For example, in a power supply circuit, it helps filter out noise from the incoming AC voltage, converting it into a clean DC voltage.

It is also often used for decoupling and bypassing high-frequency noise in sensitive circuits, allowing other components to operate without interference. This versatility makes it indispensable in both commercial and DIY electronics projects.

Buy Electronic Components Online in India

Buying electronic components like the 220uF 16V Chip Type Aluminum Electrolytic Capacitor online is easier than ever, thanks to several trusted electronic components online store India catering to the growing electronics market in India. Choose some of the best online electronic stores in India where you can find this capacitor and other components without compromising on quality and your budget.

Why Shop Online for Electronic Components?

Shopping for electronic components online has several benefits, including:

Convenience: You can shop at any time of day, from the comfort of your home, and have components delivered right to your doorstep.

Access to a Wide Range of Products: Whether you're looking for a specific part like the 220uF 16V Capacitor or something more niche, online stores offer an extensive selection to suit all your needs.

Competitive Pricing: Online stores often have competitive prices and offer regular discounts and deals, allowing you to get the best value for your money.

Conclusion

The 220uF 16V 20% 6.3X7.7mm Chip Type Aluminum Electrolytic Capacitor is a vital component for numerous electronic applications, and finding it online is easy and efficient. Whether you're a seasoned engineer or a hobbyist, online platforms like Robu.in, Element14, and RS Components make sourcing these components quick, simple, and affordable. By shopping online, you gain access to a vast array of electronic components, ensuring that you always have the right parts for your projects. So, take advantage of the convenience of online shopping and elevate your electronics work to new heights today!

1 note

·

View note

Text

0 notes

Text

0 notes

Text

At Kineto, our mission is to revolutionise lives by unleashing electricity's power. Our mission is to effect good change by providing dependable and robust solutions. Our products are designed to integrate into your daily life easily. By investing in our own tooling, designing, and testing teams, we distinguish ourselves in the industry. Our high-performance solutions provide outstanding efficiency and user-friendliness whether it comes to illuminating your areas or managing electrical systems.

#LED Light Manufacturers in kolkata#LED Lights in kolkata#led light dealers in kolkata#led light wholesale market in kolkata#led bulb manufacturer in kolkata#led bulb in kolkata#led bulb Suppliers In Kolkata#led lighting solutions#energy saving light bulbs#wholesale led lights#wholesale light bulbs#led ceiling fan#industrial led lighting#plug in led lights#electrical wire for led lights#led wire in kolkata#Wires & Cables in kolkata#Capacitors in kolkata#fans in kolkata#Switchgears in kolkata#Pipes & Casings in kolkata#Wires & Cables Manufacturers in kolkata#Capacitors Manufacturers in kolkata#fans Manufacturers in kolkata#Switchgears Manufacturers in kolkata#Pipes & Casings Manufacturers in kolkata

0 notes

Text

"High-Quality Trickle Impregnation Machines Manufacturer & Supplier in Pune, India"

Revolutionizing Manufacturing with the Trickle Impregnation Technique

The trickle impregnation technique is a crucial process in enhancing the quality and durability of various electrical and mechanical components. Whether you're working in the transformer, motor, or capacitor industries, the trickle impregnating machine plays a vital role in improving the performance and longevity of your products.

At Transformer Oil Filter Machines, we specialize in manufacturing and supplying trickle impregnating machines that are designed to meet the highest industry standards. Our machines ensure precise and efficient impregnation of components with the right resin, making them more durable and efficient.

What is Trickle Impregnation?

Trickle impregnation is a method used for filling the pores of porous materials with resin, which is often used in electrical and mechanical industries. The process involves the gradual trickling of resin into the components, ensuring complete saturation and optimal protection. This technique is widely used for insulating electrical motors, transformers, and various other industrial components.

The trickle impregnation technique guarantees better adhesion, moisture resistance, and insulation, which are essential for increasing the performance and lifespan of electrical components.

Why Choose Our Trickle Impregnating Machines?

State-of-the-Art Technology Our trickle impregnating machines are built with the latest technology, ensuring efficient and precise impregnation. We provide machines that are user-friendly, energy-efficient, and require minimal maintenance.

Tailored Solutions We offer customized trickle impregnating machines that can be tailored to meet your specific industry requirements. Whether you're in Pune, Satara, or anywhere in Maharashtra or India, we provide machines that suit your needs for resin impregnation in a variety of applications.

Global Export Reach Our trickle impregnating machines are not limited to the Indian market. We proudly export our machines to several countries, including Saudi Arabia, Jordan, Qatar, Iraq, Nepal, Bangladesh, Zambia, Egypt, Turkey, and beyond. Our machines are known for their reliability and high performance across various international markets.

Durability & Efficiency Our machines are engineered for durability, ensuring long-lasting performance even in the most demanding conditions. With efficient resin consumption and optimal impregnation quality, our machines deliver exceptional results while reducing operational costs.

Comprehensive Support We offer full support, from consultation and installation to after-sales service. Our team of experts ensures that your trickle impregnating machine operates efficiently throughout its lifecycle.

Key Features of Our Trickle Impregnating Machines

Precise Impregnation Process: Our machines guarantee consistent and uniform resin impregnation for optimal results.

Energy Efficient: Designed to minimize energy consumption while maximizing output.

User-Friendly: Easy to operate with simple controls for hassle-free production.

Versatile Applications: Ideal for a wide range of industrial components such as motors, transformers, capacitors, and more.

High Durability: Built with high-quality materials to withstand heavy usage and last for years.

Industries We Serve with Trickle Impregnating Machines

Our trickle impregnating machines cater to various industries, including:

Transformer Manufacturing: For impregnation of transformer windings and components, enhancing insulation and preventing moisture ingress.

Motor Industry: To ensure the impregnation of electric motors, improving their durability and electrical performance.

Capacitor Industry: Used to impregnate capacitors, improving their dielectric properties and operational lifespan.

Electrical Component Manufacturers: For impregnation of coils, insulators, and other critical electrical parts.

Advantages of Trickle Impregnation

Improved Component Performance: The impregnation process enhances the electrical and mechanical properties of components, making them more resilient to wear, tear, and environmental damage.

Moisture Resistance: Trickle impregnation significantly improves moisture resistance, reducing the risk of corrosion and damage from environmental factors.

Better Adhesion: Resin impregnation ensures stronger adhesion to materials, improving the overall structure and strength of components.

Cost-Effective: The technique reduces the need for frequent maintenance and repair, lowering long-term operational costs.

Why Choose Transformer Oil Filter Machines?

As a leading manufacturer and supplier of trickle impregnating machines in Pune and Maharashtra, we pride ourselves on providing high-quality, durable, and efficient machines. Our custom-made solutions cater to diverse industries, and our global export reach ensures that our products are trusted worldwide.

We are committed to delivering machines that provide the best trickle impregnation results for a variety of industrial applications. Whether you're located in India or international markets such as Saudi Arabia, Jordan, Qatar, or Turkey, we are here to provide the most reliable trickle impregnating machines for your business.

Conclusion

If you're in search of the best trickle impregnating machines for your business, look no further than Transformer Oil Filter Machines. With years of experience in manufacturing and supplying top-quality machines, we guarantee you the best solutions for your resin impregnation needs. Our machines provide high-performance, durability, and efficiency, ensuring that your components are insulated and protected to the highest standards.

Contact us today for more information and to discuss your specific requirements for trickle impregnating machines. We look forward to helping you enhance your manufacturing process and improve the quality of your products!

#trickle impregnation technique#Trickle Impregnating Machines manufacturer#trickle Impregnating Machines supplier#Trickle Impregnating Machines dealer#Trickle Impregnating Machines exporter#Trickle Impregnating Machines manufacturer in Pune#Trickle Impregnating Machines manufacturer in Satara#Trickle Impregnating Machines manufacturer in Maharashtra#Trickle Impregnating Machines manufacturer in India#trickle Impregnating Machines supplier in Pune#trickle Impregnating Machines supplier in Satara#trickle Impregnating Machines supplier in Maharashtra#trickle Impregnating Machines supplier in India#Trickle Impregnating Machines dealer in Pune#Trickle Impregnating Machines dealer in Satara#Trickle Impregnating Machines dealer in Maharashtra#Trickle Impregnating Machines dealer in India#Saudi Arabia#Jordan#Qatar#Iraq#Nepal#Bangladesh#Zambia#Equator#Egypt#Turkey

0 notes

Text

Supercapacitor Market

𝐒𝐮𝐩𝐞𝐫𝐜𝐚𝐩𝐚𝐜𝐢𝐭𝐨𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐆𝐫𝐨𝐰𝐭𝐡: 𝐊𝐞𝐲 𝐃𝐫𝐢𝐯𝐞𝐫𝐬 𝐚𝐧𝐝 𝐎𝐩𝐩𝐨𝐫𝐭𝐮𝐧𝐢𝐭𝐢𝐞𝐬 | IndustryARC™

Supercapacitor Market Size is forecast to reach $ 64,330 Million by 2030, at a CAGR of 35.40% during forecast period 2024–2030.

👉𝑫𝒐𝒘𝒏𝒍𝒐𝒂𝒅 𝑺𝒂𝒎𝒑𝒍𝒆 𝑹𝒆𝒑𝒐𝒓𝒕

The Supercapacitor Market is growing due to rising demand in #electric #vehicles (#EVs) for energy efficiency and quick power bursts. Hybrid energy storage systems combining #supercapacitors and #batteries are gaining traction, offering optimized performance. Supercapacitors are also increasingly used in #renewable #energy applications like #solar and #wind_power to store energy and stabilize output. Innovations in materials are improving their energy density and lifespan, further driving market growth.

👉𝑭𝒐𝒓 𝑴𝒐𝒓𝒆 𝑰𝒏𝒇𝒐𝒓𝒎𝒂𝒕𝒊𝒐𝒏

Supercapacitors offer key benefits including fast charging and discharging, ideal for applications requiring rapid energy bursts. They have a long lifespan, enduring millions of charge cycles, and provide high power density for short, intense power needs. They are energy-efficient, operate in a wide temperature range, and are more environmentally friendly than traditional batteries. These advantages make supercapacitors valuable in sectors like renewable energy, electric vehicles, and consumer electronics.

By Now

➡️ 𝐤𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬 : CAP-XX Limited | Nippon Chemi-Con | Panasonic | Maxwell Technologies | Eaton | Cornell Dubilier — Manufacturer of Power Capacitors | Illinois Capacitor (Cornell Dubilier) | Ioxus | LS Mtron | Murata | Skeleton Technologies |

#Supercapacitors#EnergyStorage#ElectricVehicles#RenewableEnergy#PowerDensity#SustainableEnergy#BatteryTechnology#GreenEnergy#EnergyEfficiency#CleanTech#SupercapacitorInnovation#FastCharging#EnergyStorageSolutions#FutureOfEnergy#SupercapacitorTech#RenewableStorage#SmartEnergy#HybridEnergySystems#PowerManagement#EnergyRevolution#TechInnovation

0 notes

Text

0 notes

Text

Automotive Regenerative Braking System Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Regenerative Braking System Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Regenerative Braking System Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Regenerative Braking System Market is experiencing robust growth driven by the expanding globally. The Automotive Regenerative Braking System Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Regenerative Braking System Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive Regenerative Braking System Market Size, Share & Industry Analysis, By System type (Flywheel, Battery, Ultra-Capacitors, Hydraulics), By Electric Vehicle (BEV, HEV, PHEV), By Vehicle Type (Passenger Cars, Commercial Vehicles) Others and Regional Forecast, 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/102236

Key Strategies

Key strategies in the Automotive Regenerative Braking System Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Regenerative Braking System Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Regenerative Braking System Market.

Major Automotive Regenerative Braking System Market Manufacturers covered in the market report include:

Some of the major companies that are present in the automotive regenerative braking system market include Robert Bosch GmbH, Continental AG, ZF Friedrichshafen AG, among others.

The vacuum-independent regenerative braking system reduces almost all of the brake dust of the electric vehicles. Therefore, this regenerative braking system is an emission-free generator braking with also allowing recovery of the kinetic energy. The increasing demand for electric vehicles, even in public transport, is likely to generate numerous opportunities for market players over the forecast period.

Trends Analysis

The Automotive Regenerative Braking System Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Regenerative Braking System Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Regenerative Braking System Market Solutions.

Regions Included in this Automotive Regenerative Braking System Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Regenerative Braking System Market.

- Changing the Automotive Regenerative Braking System Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Regenerative Braking System Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Regenerative Braking System Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive Regenerative Braking System Market?

► Who are the prominent players in the Global Automotive Regenerative Braking System Market?

► What is the consumer perspective in the Global Automotive Regenerative Braking System Market?

► What are the key demand-side and supply-side trends in the Global Automotive Regenerative Braking System Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Regenerative Braking System Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Regenerative Braking System Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Automotive Regenerative Braking System Market#Automotive Regenerative Braking System Market Share#Automotive Regenerative Braking System Market Size#Automotive Regenerative Braking System Market Trends#Automotive Regenerative Braking System Market Growth#Automotive Regenerative Braking System Market Insights

0 notes