#Drill Machine Screwdriver Set

Explore tagged Tumblr posts

Text

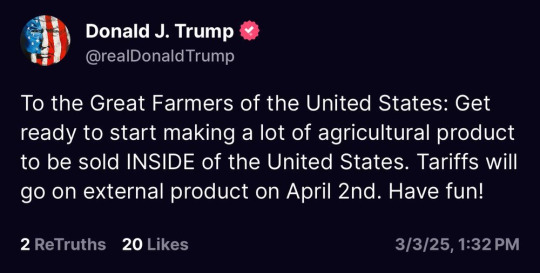

Donald fucked around, we get to find out

Via Narcity: "Starting Tuesday, Canada is slapping new counter-tariffs on U.S. products, targeting $30 billion worth of American goods. And that's just the beginning — Trudeau says an additional $125 billion in tariffs will roll out in the next three weeks if things don't de-escalate."

What follows is the full list of affected American products:

Food & drink

Poultry & eggs — chicken, turkey, goose, duck and their byproducts (fresh, frozen, preserved)

Dairy products — milk, cream, butter, ice cream, yogurt, cheese

Fruits & vegetables — tomatoes, beans, snap peas, citrus fruits, melons, peaches, nectarines, berries

Coffee & tea

Spices & flavourings — pepper, vanilla, dried spices (cinnamon, turmeric, curry, etc.)

Sauces & condiments — soy sauce, ketchup, mustard, mayonnaise, salad dressing, peanut and nut butters

Grains & baking essentials — wheat, rye, rice, barley, oats, flour, mixes and doughs

Oils & fats — canola, sunflower, safflower, palm, peanut and nut oils; margarine and butter substitutes

Sugars & sweeteners — honey, cane sugar, beet sugar, maple sugar and syrup, sugar syrups, molasses

Packaged foods — pasta, pizza, bread, cakes, biscuits, cereal-based foods, soup and broth, pickles, gum, candies, chocolate

Supplements — whey powder, casein, fish oil

Beverages & alcohol — orange juice, soda beer, wine, cider, spirits, liqueurs, coolers, bitters

Tobacco products

Raw & processed tobacco — unmanufactured tobacco, tobacco extracts, chewing tobacco, pipe tobacco

Cigarettes & cigars — cigars, cheroots, cigarillos and cigarettes

Nicotine products — vapes, e-cigarettes, nicotine patches and other smokeless tobacco products

Personal care products

Cosmetics & skincare — makeup, nail polish and manicure tools, hair care, deodorants, soaps and cleansers, razors, shaving products, bath products

Electronic tools — electric razors and clippers, hair dryers, curling irons, flatirons

Fragrances — perfumes, room deodorizers

Oral care — toothpaste, dental floss

Paper products — toilet paper, tissues, napkins

Home & office items

Kitchenware — paper and plastic tableware, storage containers, glassware, cutlery and utensils, kitchen knives, scissors

Furniture & home goods — metal, wooden and plastic furniture; chairs; mattresses and bedding; lighting; storage racks

Home textiles — carpets, rugs, blankets, bed linens, table and kitchen linens, curtains, cleaning cloths

Paper & books — stationery, notebooks, memo pads, binders, file folders, carbon sets, albums, printed materials

Office supplies — letter openers, pencil sharpeners

Artwork — paintings, drawings, pastels

Clothing & accessories

Clothing — shirts, pants, dresses, suits, underwear, hosiery, pyjamas, sweaters, activewear, swimwear, outerwear, baby clothes

Activity-specific attire — diving suits, ski suits, protective gear, life jackets, climbing harnesses, work belts, safety headgear, animal saddlery

Accessories — footwear, hats, gloves, scarves, belts, neckties, jewelry

Bags & luggage — handbags, wallets, suitcases, briefcases, backpacks

Electronics & appliances

Household appliances — refrigerators, freezers, dishwashers, washing machines and dryers, stoves, barbecues, fans, humidifiers, vacuum cleaners, fabric steamers

Countertop appliances & kitchen gadgets — blenders, food mixers, juicers, microwaves, grills, rice cookers, coffee makers, toasters

Gaming & entertainment — video game consoles, board games, card games

Vehicles & machinery

Motorcycles & recreational vehicles — motorbikes, sidecars, recreational boats, drones

Yard equipment — snowblowers, lawnmowers

Tools — saws, pliers, wrenches, spanners, hammers, drills, cutting tools, screwdrivers, staple guns, vices, lighters, pneumatic tools, padlocks

Rubber tires

Building materials

Silica & quartz sands

Plastic wall, floor & ceiling coverings

Window and door fixtures — window and door components and frames, shutters, blinds

Bathroom fixtures — plastic and ceramic baths, showers, sinks and wash basins, toilets, bidets, urinals

Plastic packaging

Wood products — planks, chips, veneer sheets, particle board, MDF, fibreboard, laminated wood, posts, beams, floor panels, wood pulp

Cardboard & paper — cartons, boxes, cases, paper bags

Textiles — tarps, tents, canopies, sails, woven fabric

Precious metals & gemstones — diamonds, silver, palladium

Weapons & ammunition

Firearms — pistols, revolvers, rifles, shotguns, air guns

Ammunition — bullets, cartridges, pellets

"Have fun!"

9 notes

·

View notes

Text

Hold on I'm gonna use some of my hardware store employee powers to advise you guys

- If you're just using it at home, get the cheap drill. You don't need the Dewalt. Drill is used for making holes, driver is used for putting stuff in those holes.

- That being said please please please don't use power tools you aren't familiar with without tutorials or having someone show you. Yes use PPE even if you think it is stupid. I have had customers who are highly experienced come in with missing fingers because a chop saw kicked back on them. Be. Careful. Use. Protective. Equipment. Unplug them or remove the battery when you are done or lock them or something OK.

- A small screwdriver set is extremely useful. SAE + Metric together is the best. Having a socket set at home will also save you so much headache. Try to use the proper sized driver and socket the first time because a stripped screw or bolt will be way worse than just finding the right tool.

- If you need a nut or a bolt or machine screw or whatever please bring in an example of what you want or the thing it's going to be screwed into or something. Bolts and machine screws have different thread patterns and so having it with you will make it way easier for you And the employee. Eyeballing it will not work if it has to thread into the hole or nut or whatever.

- When screwing in a nylon lock nut you will probably need a socket wrench and you need to put the part that lays flat on first. The bump faces outwards. Like a normal nut. Thread it on with your hands first then use the wrench and if you can't get it on with your hands then you are doing it the wrong way turn it around.

- If you have a snowblower yes get a sheer pin or butter bolt. Yes it's annoying when they break. But a 2$ pin is a lot less expensive than a new 200$ snowblower.

- Bolts and machine screws are not the same they have different uses. Try to stick with whatever your project calls for ok.

- Be yourself and have fun

8 notes

·

View notes

Text

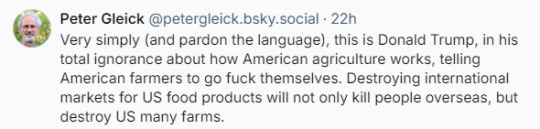

What I Watched This Week – 5/12 – 5/25

King of Braves GaoGaiGar – I’ve been trying to watch more super robot mecha lately, and this has been sitting on my watchlist ever since Discotek licensed it and posted the memorable opening song on Twitter, so I decided it was time to watch it. Strange sentient machines invade the planet, turning people into mechanical kaiju aligned with whatever was stressing them, and it falls to a mysterious 8 year old boy to stop them, helped by a secret government agency of mecha and cyborg fighters. I’m not really sure why it took me so long to start seeking this stuff out, because it’s a ton of fun to watch. The lion mecha combines with the cyborg to become GaiGar, then that robot combines with a pair of drills, a jet, and a fucking shinkansen to become GaoGaiGar, and then that robot combines with either a giant screwdriver that splits dimensional space or a massive squeaky hammer that turns everything to light particles. If that’s not enough for you, the fights also include a green fairy who sets the transformed humans free. The entire thing is so absurd and over the top, yet played so completely straight that I have to marvel at the voice actors’ ability to deliver the dialog. I didn’t love the overuse of strobe effects, and the plot was getting a little repetitive by the end of the 49 episodes, but I had a smile on my face the whole time. 7/10

Kurayukaba – I’m not really sure how I felt about this short little movie, to be honest. I enjoyed watching a down-on-his-luck private detective exploring the shady underworld built in the old tunnels under a coal mining city as he attempted to investigate a rash of missing person cases. The characters were engaging, with intriguing backgrounds and distinct personalities, and the antagonists were somewhat more complex than making trouble for trouble’s sake. On the other hand, though, the animation was kinda puppet-show, and the ending felt super rushed through and inconclusive, making the whole story feel a little aimless. 6/10

Kuramerukagari – This movie takes place in the same setting as Kurayakuba, but it shares none of the characters or events in it, so it stands completely alone. The story follows a young woman who travels around the ever shifting gangways and underground tunnels of the city and draws maps of them that she sells to a local book lender and information broker. It shares the same iffy visuals as the other movie, but I ended up enjoying this one a little bit more. The uprising she accidentally uncovers unfolded in a way that was pretty fun to watch, with a good collection of colorful characters and steampunk-style contraptions joining the fight, and the ending felt conclusive. Both movies definitely could’ve used more space to use all the characters they introduced, and I would’ve liked to spend more time seeing their world, but they weren’t a bad watch. 7/10

4 notes

·

View notes

Text

How to Identify Genuine Drywall Screw in Indian Markets?

Identifying genuine drywall screw in India requires careful attention to quality, material, and brand reliability. When purchasing drywall screw, ensure they are made from high-quality steel for durability and corrosion resistance. Raj Industries, a trusted name in the market, recommends checking the screw’s threading, sharpness, and head design to ensure it is suitable for drywall installation. Genuine drywall screw in India should have precise threading that grips well into drywall without stripping. Additionally, verify the packaging and certification to avoid counterfeit products. Always buy from reputable suppliers like Raj Industries, which guarantees high-quality, reliable drywall screw that meet industry standards. By considering these factors, you can ensure your drywall projects are done with durable and secure fasteners.

The Importance of Choosing the Right Drywall Screw for Your Project

When working with drywall, selecting the right screw is crucial for ensuring durability and proper installation. In India, the market for drywall screw is vast, but not all options offer the same level of quality. A genuine drywall screw is designed specifically to hold drywall to studs securely and prevent issues like stripping or loosening over time. Raj Industries, a leading manufacturer of screw, nuts, bolts, and allied fasteners, emphasizes the importance of choosing the right screw for the job to avoid complications during installation. The key lies in the screw’s material, design, and quality, which significantly impact both performance and longevity.

Recognizing the Right Material for Drywall screw

A genuine drywall screw in India should be made from high-quality steel, often coated with a corrosion-resistant layer like black phosphate or zinc. The material of the screw determines its strength, resistance to rust, and overall performance over time. Drywall screw that are made from subpar materials may corrode quickly, compromising the integrity of your project. Raj Industries advises customers to look for screw made from hardened steel, as they are less likely to break under pressure and offer long-term durability, making them ideal for drywall installation in both residential and commercial settings.

Identifying the Correct Threading and Length for Drywall screw

Threading is one of the most important features of a genuine drywall screw. The screw’s threads should be sharp and consistent, ensuring they can grip the drywall and studs effectively without slipping or stripping. The length of the screw also matters: too short, and it won’t properly anchor the drywall; too long, and it may protrude through the other side. When shopping for drywall screw in India, ensure that the screw’s threading and length match the specifications required for your project. Raj Industries recommends checking product details carefully to confirm you are purchasing the right size and thread type for your needs.

Inspecting the Screw’s Head and Design Features

The design of the screw’s head plays an important role in the ease of installation and the final result. A genuine drywall screw typically features a bugle-shaped head, which allows the screw to sit flush with the surface of the drywall without damaging it. The head should also be designed for compatibility with standard screwdrivers or drills, allowing for efficient installation. Drywall screw from Raj Industries are designed with precision, ensuring a perfect fit for common drywall applications. When purchasing screw in India, look for heads that are properly shaped and sized for the type of installation you are performing, whether manual or machine-driven.

How to Spot Counterfeit Drywall screw in India?

Unfortunately, the market for drywall screw in India is rife with counterfeit or substandard products. These low-quality screw may look similar to genuine products but can result in poor performance or even damage to your drywall. One key indicator of counterfeit screw is irregular threading, which can cause the screw to slip or break during installation. Additionally, cheap screw may have poorly coated surfaces that rust quickly, compromising the integrity of your project. Raj Industries advises customers to only purchase drywall screw from reputable sources, as this ensures the product is genuine and meets industry standards for strength and durability.

The Role of Certifications and Packaging in Verifying Authenticity

One of the best ways to verify the authenticity of a drywall screw in India is to check the packaging and certifications. Genuine drywall screw are typically packaged in well-branded, secure packaging that includes clear product information, such as material specifications, manufacturer details, and certifications. Look for any industry-specific certifications or quality assurance marks that indicate the screw meets established standards. Raj Industries ensures all of its products come with detailed packaging and certifications, making it easier for customers to verify the quality of their purchases. Always avoid buying from unverified or unbranded sources, as this increases the risk of receiving counterfeit screw.

Understanding the Price Difference Between Genuine and Substandard screw

Price is often a major deciding factor when purchasing drywall screw, but it’s important to be cautious about unusually low prices. While genuine drywall screw may come at a slightly higher cost due to their superior materials and design, excessively cheap screw are often a red flag for poor quality. Substandard screw may seem like a bargain, but they are likely to compromise the safety and durability of your drywall installation. Raj Industries encourages buyers to compare prices and consider the long-term value of high-quality drywall screw. In most cases, investing in genuine products will save money in the long run by avoiding costly repairs and replacements.

Conclusion

Identifying genuine drywall screw in India may seem challenging, but with attention to detail, it’s possible to ensure you’re purchasing quality products. Focus on key factors such as material, threading, head design, and packaging. Genuine drywall screw are built to withstand the demands of drywall installation, offering a secure and durable solution for your projects. Raj Industries, as a leading manufacturer of screw, nuts, bolts, and allied fasteners, provides high-quality products that meet industry standards. By choosing reliable brands and verifying authenticity through proper channels, you can ensure your drywall projects are completed successfully, with no compromises on safety or performance.

0 notes

Text

Power and Hand Tools in Saudi Arabia at Nassguard

When it comes to precision, performance, and durability, nothing beats the importance of power and hand tools in industrial, construction, and repair jobs. In Saudi Arabia, Nassguard is a trusted name that supplies top-quality tools to professionals across Riyadh, Jeddah, Dammam, and Jubail. Whether you're a contractor, technician, or workshop owner, Nassguard has the tools you need to get the job done right.

Wide Range of Power Tools

Nassguard offers a broad selection of high-performance power tools suitable for every type of task. From heavy-duty machines to portable electric tools, the range includes:

Electric Drills & Cordless Drills Perfect for fast drilling into metal, wood, or concrete.

Angle Grinders & Bench Grinders Used for grinding, polishing, or cutting through tough materials.

Circular Saws, Jigsaws, and Reciprocating Saws Ideal for cutting wood, metal, and composite materials.

Impact Drivers and Rotary Hammers Designed for construction and demolition tasks with precision.

Reliable Hand Tools for Professionals

In addition to power tools, Nassguard stocks a wide variety of durable hand tools for daily use. These include:

Wrenches and Ratchets Available in adjustable, combination, and socket sets.

Screwdrivers and Pliers Including insulated models for electrical applications.

Hammers and Measuring Tools From claw hammers to digital calipers and tape measures.

Files, Chisels, and Allen Keys Suitable for fine-tuning, fitting, and tightening.

These tools are sourced from globally recognized brands, ensuring professional results every time.

Why Choose Nassguard for Power and Hand Tools in Saudi Arabia?

Trusted Supplier Across Industries Nassguard serves oil & gas, construction, logistics, and manufacturing sectors with tool solutions that fit specific needs.

Availability Across All Major Cities With logistics and warehousing in Riyadh, Jeddah, Dammam, and Jubail, tool deliveries are fast and reliable.

Expert Assistance Get advice from professionals on selecting the right tool for the job and proper usage tips.

Affordable Pricing Competitive rates and financing options make it easy for both small workshops and large contractors to access top-quality tools.

Certified Products Every tool is certified for quality, safety, and reliability under international standards.

Upgrade Your Toolbox with Nassguard

Using the right tools improves productivity, reduces error, and enhances safety. Nassguard makes sure your toolbox is packed with only the best. Whether you’re equipping a new workshop or upgrading your old tools, Nassguard is your one-stop shop for power and hand tools in Saudi Arabia.

1 note

·

View note

Text

Best Electrical Hand Tools

Best Electrical hand tools

Introduction:

Electrical hand tools are not limited to just electronic work; they play a crucial role in everyday hobby projects, repairs, and small-scale production industries. With the integration of modern technology, the efficiency and accuracy of these tools have improved, helping to ensure high-quality work.

As the demand for electronic devices continues to grow, hand tools are being upgraded and developed with new technologies to enhance their capabilities. These tools are not only becoming more advanced but also smarter. Using the right hand tool for a specific task allows for faster and more precise completion of work. The addition of modern sensors, automatic calibration, and digital displays has significantly increased the performance and functionality of these tools.

Electrical hand tools list:

Electric drill and drill bits: Electric drills and drill bits in the range of 0.31 cm to 1.27 cm will come in handy when you need to drill holes on the printed circuit board (PCB) that has been etched. Drilling of plastic or metal enclosures that house the PCB is sometimes necessary. A suitable PCB high speed drill can be easily obtained from any electronics shop.

Soldering iron: A 20-watt to 30-watt soldering iron with tips of 0.31 cm to 1.27 cm can be used for soldering through-hole components. Soldering surface mount components may require smaller tips, depending on their size. Soldering irons normally last a long time if taken care of properly by keeping the tips clean and well tinned.

Wire stripper: This is used to strip off the wire insulator from its conductor before it is used to connect t another wire or soldered into the PCB. Some wire strippers or cutters have a measurement engraved on them to indicate the length that will be stripped.

Long nose pliers: Nose pliers of 10 cm length will come in handy when you have to hold components that have short leads and need to be soldered onto the PCB but it will be too hot to handle with bare hands. It can also be used to hold the component that needs to be de-soldered from the board.

Side-cutting pliers: A pair of 10 cm side cutting pliers is handy to trim off excess component leads on the PCB and cut wires into shorter lengths before being used.

Tweezers: Small tweezers are used to hold small components, especially when soldering and de-soldering surface mount components.

Flat head screwdrivers: These tools come in various sizes since there are many different screw sizes.

Socket wrench sets: These include nut drivers, hex drivers and starters in assorted sizes which are handy during the assembly work of electronics projects.

Pocket knives: These are useful to cut PCBs, wires or remove some coper from the board.

Electrical hand tools can be divided into several groups:

Laying out tools – used for measuring and marking.

Impact or striking tools – hammers, mallets and sledges

Twisting tools or fastening tools – wrenches and screwdrivers

Metal-cutting tools – dies, drills, files, punches, reamers, taps

Holding tools – clamps, pliers, vices

ESD safe equipment – goggles, gloves

Grinding and sharpening tools

Finishing tools and abrasives

Tool storage and accessory containers

Advantages of electrical hand tools:

Hand tools are faster than machines. Of course, if many identical parts need to be cut, hand tools are definitely slower. But if you work on a unique project, it will surely be easier to perform some operations with hand tools, rather than waste time in setting up and configuring a machine.

One advantage of hand tools is that they are cheaper than power tools. Another benefit is that they are much safer than power tools, which is important for both beginners and amateurs, who use hand tools for quick repairs.

Important things to look in electrical hand tools:

Safety in work:

Though it is difficult to make improvements to tools such as hammers, wrenches, pliers and screwdrivers, but there have been some products which have to be come improvements so that electric work can be done with much safety way. The utility of knife is a great example of a hand tool that has been given a lot of attention, and there have been some great safety enhancements made to it recently.

Testing process:

A lot of communication and electronic systems are deployed on the field, and this requires live testing in active conditions. With the advent of new technology, nearly 80 per cent of the actual testing can today be caried out with handheld tools.

Easy to handle:

Small changes to hand tools go a long way making them safer as well easy to handle. One major safety feature of most hand tools is insulation with rubber or plastic materials. This not only protects those working with live electricity but also gives them an extra grip, making the tool easier to handle and reducing the chance of it slipping from their hands.

Multi-functional uses:

Tool manufacturers are working hard to design electrical hand tools that not only work better, but are multi-functional as well. One of the most common multi-functional tools used today is a multi-bit screwdriver. It works in one of two ways – by either storing multiple bits in its base which can be snapped on magnetically when needed, or by using a slide system by which you can simply slide the bits up from a track on the inside of the screwdriver’s base.

Read: Maintenance of Electrical Hand Tools

0 notes

Text

best garage tools suppliers in Jaipur

If you are searching for the best garage tools suppliers in Jaipur, look no further than the reputed shops in Murlipura, a hub for high-quality tools and equipment. Whether you are a professional mechanic, a DIY enthusiast, or a workshop owner, having the right set of tools is essential for efficiency and precision.

Wide Range of Hand Tools and Power Tools

Murlipura is known for its well-established tool shops that provide a wide range of hand tools and power tools. A reliable tool shop ensures that you get genuine, high-quality tools from top brands, which can significantly enhance your work efficiency. From simple wrenches and pliers to advanced electric drills and grinders, you can find every tool you need under one roof.

Hand Tools

Hand tools are the backbone of any workshop or garage. Some of the most commonly used hand tools include:

Wrenches

Screwdrivers

Hammers

Pliers

Spanners

Socket sets

Power Tools

For heavy-duty tasks, power tools play a crucial role. Some of the widely used power tools include:

Drilling machines

Angle grinders

Impact wrenches

Electric saws

Cordless screwdrivers

Welding machines

Conclusion

When searching for high-quality garage tools, it is essential to consider factors such as product variety, brand availability, pricing, and after-sales support. Investing in premium tools ensures that your work is efficient, safe, and precise. Choose wisely and enhance your productivity with the right tools for your garage or workshop!

0 notes

Text

Best Replacement Plugs for Every Appliance

Why Choosing the Right Plug Matters

Appliances play an essential role in daily life, and their efficiency depends on a reliable power connection. A damaged or outdated plug can pose safety risks, including electrical hazards. Whether for kitchen appliances, workshop tools, or entertainment devices, selecting a Replacement Plug ensures safety and optimal performance. Additionally, exploring Acupuncture for back pain can provide natural relief for those experiencing discomfort.

Types of Replacement Plugs for Different Appliances

1. Heavy-Duty Plugs for Power Tools

Power tools require robust plugs designed to handle high electrical loads. These plugs feature reinforced prongs and durable casings, making them ideal for drills, saws, and other workshop equipment.

2. Polarized Plugs for Home Electronics

For household items like lamps, fans, and televisions, polarized plugs help maintain proper electrical flow. The design ensures safe connections and reduces the risk of electrical shorts.

3. Three-Prong Plugs for Large Appliances

Large appliances such as refrigerators, washing machines, and ovens require three-prong plugs. These grounded options enhance safety by preventing electrical shocks and system failures.

4. Right-Angle Plugs for Compact Spaces

If an appliance is placed against a wall or in a tight space, a right-angle plug can be a practical solution. These designs reduce cord strain while keeping furniture and appliances flush with the surface.

5. Weather-Resistant Plugs for Outdoor Use

Outdoor appliances and equipment, such as garden tools and holiday lights, need weather-resistant plugs. These plugs withstand extreme temperatures, moisture, and UV exposure for long-lasting performance. For more info Click here.

Key Factors to Consider When Choosing a Replacement Plug

1. Amperage and Voltage Ratings

It is crucial to check the amperage and voltage rating to ensure the plug matches the appliance's power requirements. Using an incorrect rating can cause overheating or electrical failures.

2. Material and Durability

High-quality plugs are made from durable plastic or rubber, with brass prongs that improve conductivity and reduce wear over time.

3. Safety Certifications

Look for UL or ETL certification when selecting a plug. These certifications indicate that the plug meets strict safety and quality standards.

4. Ease of Installation

Some plugs are designed for easy installation, while others require more advanced wiring. Choose one that aligns with your comfort level and skill set.

How to Replace a Plug Safely

1. Gather Tools and Materials

Before starting, ensure you have a screwdriver, wire cutters, and electrical tape for a secure installation.

2. Disconnect the Appliance

Always unplug the appliance before working on the wiring to avoid any risk of electric shock.

3. Remove the Old Plug

Cut off the damaged plug, strip the wire insulation, and prepare the wires for connection.

4. Attach the New Plug

Connect the wires to their respective terminals—black (hot) to brass, white (neutral) to silver, and green (ground) to green.

5. Secure and Test

After tightening the connections, test the plug by reconnecting the appliance to ensure proper functionality.

Choosing the right plug enhances appliance performance and ensures long-term safety. By considering factors like durability, amperage, and proper installation techniques, you can make an informed decision for every appliance in your home or workspace.

0 notes

Text

Pop Frame Manufacturer in India Recommends This Step-by-Step GI Channel Installation Guide – Allied Ispat India

Introduction: Allied Ispat India’s GI Channel Installation Guide: A Step-by-Step Approach to Perfect POP Ceilings

Looking for a trusted and professional GI channel installation guide that makes POP ceiling work seamless and efficient? You’ve landed on the right page. At Allied Ispat India, a leading POP Parts Manufacturer in Mumbai, we’ve helped thousands of contractors and architects streamline their ceiling installation process with our ISO 9001 certified, moisture-proof GI channels for false ceilings. In this blog, we walk you through a detailed step-by-step process to install GI channels correctly ensuring durability, safety, and a flawless finish.

Our expert-backed advice is based on decades of experience, and our GI channels are designed to perform in India’s varied climate conditions, making Allied Ispat India a go-to POP Parts Manufacturer in India for B2B clients seeking quality and trust.

1. Understanding GI Channels in POP Ceilings

GI (Galvanized Iron) channels form the skeletal structure of POP (Plaster of Paris) false ceilings. They play a crucial role in the ceiling's overall strength, design alignment, and durability.

Key Points:

What are GI channels and why are they used in false ceilings?

Difference between GI channels and traditional ceiling frameworks

Types of GI channels: Ceiling section, Perimeter channel, Intermediate channel

Role of GI channels in POP ceiling strength and durability

Importance of choosing branded, ISO-certified GI channels

2. Tools & Materials You’ll Need for GI Channel Installation

Before beginning installation, gathering the right tools and materials ensures safety and smooth execution.

Checklist:

Measuring Tape, Spirit Level, Laser Level

Drill Machine, Screwdrivers, Screws, Wall Plugs

Suspension Rods/Wires, Hangers

Plumb Bob & Chalk Line

Safety Gear and PPE Kits

Materials:

Main Ceiling Channel (Ceiling Section)

Intermediate Channels (Cross Sections)

Perimeter/Wall Angle Channels

POP Sheets or Boards

Allied Ispat Installation Kits

Pro Tip: Purchase your complete installation set from Allied Ispat India to ensure quality and uniform compatibility between materials.

3. Planning the Layout for a False Ceiling

A successful GI channel installation begins with a well-designed layout. This ensures the frame is balanced, functional, and aesthetically pleasing.

Step-by-Step Layout Planning:

Marking the Ceiling Level using Laser or Spirit Level

Checking Load-Bearing Limits

Spacing Between Channels: 3 to 4 feet between main channels and 2 feet for intermediate ones

Grid Layout Planning: Ensure symmetry and balance

Technical Layout Support by Allied Ispat Experts

4. Step-by-Step GI Channel Installation Guide

This is the core section the most detailed and critical for contractors following our GI channel installation guide.

Step 1: Install the Wall Angle (Perimeter Channel)

Fix it around the marked ceiling level using wall plugs and screws

Ensure it’s perfectly horizontal using a spirit level

Step 2: Hang the Main Ceiling Channels

Suspend the main GI channels using suspension rods or adjustable hangers

Maintain equal distances and use a laser level to ensure alignment

Step 3: Fix Intermediate Channels

Place intermediate channels between main channels to complete the grid

Fasten cross-sections with screws to ensure firmness

Step 4: Secure and Level the Grid

Double-check levels and make necessary adjustments

All connections should be tight but not overtightened to avoid material bending

Step 5: Final POP Application

Once the frame is ready, fix the POP boards or sheets

Finish with screwing, joint taping, and coating for a smooth ceiling

Need visuals? Contact Allied Ispat for a downloadable PDF with diagrams of each step.

5. Common Mistakes to Avoid in GI Channel Installation

Even skilled contractors can face issues. Here’s how to avoid them.

Mistakes:

Using Low-Quality Channels

Improper Spacing or Poor Alignment

Overloading Frames or Skipping Hangers

Ignoring Ceiling Moisture Conditions

Untrained Labour or Lack of Supervision

Solutions: Allied Ispat GI channels are made with colour-coated zinc and moisture-proof treatments to withstand diverse Indian climates.

6. Moisture-Proof & Fire-Resistant Ceiling Materials: What to Know

A high-quality ceiling must stand the test of fire safety and moisture resistance.

Key Insights:

How Moisture Affects GI Channel Longevity

Benefits of Allied Ispat's Colour-Coated GI Frames

Fire-Resistance Ratings and Standards Explained

Coating Options: Galvanized, Powder-Coated, etc.

Maintenance and Inspection for Long-Term Use

7. Why Choose Allied Ispat India for GI Channels?

We’re more than a POP Parts Manufacturer we’re your long-term project partner.

What Sets Us Apart:

ISO 9001:2015 Certification

In-House Quality Control and Durability Testing

Affordable Wholesale Rates with Bulk Support

Trusted by Top Contractors Across India

Quick Delivery Across Mumbai, Delhi, Hyderabad & More

8. POP Ceiling Installation Costing & Bulk Order Support

Understanding pricing helps you bid more confidently for client projects.

Pricing Breakdown:

GI Channel Costs: Based on size, thickness, and coating

Installation Cost: ₹75–₹130 per sq. ft. including materials & labour

Bulk Order Discounts: Up to 25% for large orders

Installation Kits & Customization Options

Allied Ispat’s B2B Order and Support Contact Info

📩 Need a quote? We’ll send you a free estimate within 24 hours!

✅ Call to Action: Buy Premium GI Channels at Wholesale Prices

Ready to build safer, stronger, and sleeker false ceilings? Buy premium GI channels at wholesale prices from Allied Ispat India, your trusted POP Parts Manufacturer in Mumbai.

🔗 Explore Products: https://alliedispatindia.com/pop-frame/ 📦 Factory Rates | 📑 ISO Certification | 🧰 Free Installation Guide Allied Ispat Mumbai Central Office Address: Shop 69, Maulana Shaukat Ali Road, Chhota Sonapur, Siddharth Nagar, Mumbai Central, Mumbai, Maharashtra 400008 📧 Email: [email protected] 📞 Phone: 098211 77009 📍 Get Directions

0 notes

Text

Sanitary plumber: the importance of duties in daily life

Sanitary plumber: the importance of duties in daily life

Before The sanitary set is considered the basic of our daily life, and it is part of ensuring the flow of clean water and the disposal of sewage in a safe manner. The quality of public life depends entirely on the comforts of homes and public buildings, which makes it possible to have a healthy bathroom indispensable.

Health task Sanitary plumbing is not just installing pipes, but it includes the design and maintenance of water and sewage systems, which includes providing clean water and safe sewage, differing from many small and healthy things such as water leakage, sewer blockage, and contamination of drinking water.

Health tasks Do you need health care from the necessary, including:

Organizing water systems: installing pipes, valves, tanks and adjusting the water flow. Repairing faults: dealing with leaks, burst pipes, and blocking sewers in a dance way. Sanitary sewer system: implementing a ventilation system in a way that suppresses water hybridization without harming the body. Periodic maintenance: The system of innovation periodically starts from the future future of effective applications. Plumbing Tools The plumber relies on a variety of tools, including:

The English wrench: to adjust and connect pipes and valves. The screwdriver of its types: to loosen and install different connections. The Vietnamese machine: plastic parts in a comprehensive manner. Sewer inspection cameras: detect internal blockages without the need for drilling. Plumbing installation challenges You face many challenges, including:

Dealing with old electronics: When some old data requires continuous maintenance or complete replacement. Insurance for health risks: Such as dealing with sewage, which requires the use of new equipment such as nails and masks. Large space: You may need to take appropriate and inappropriate positions for work, which requires the skill of dealing with tools in those circumstances. Requirements for success in sanitary installation In order to be a successful plumber, you must be welcomed by skills and qualities, such as:

Technical skill: The ability to accurately understand engineering and theoretical designs. Problem solving ability: Finding quick solutions to surprising answers. Explanations: Ability to work in difficult giraffes and for long hours. Adherence to safety standards: to ensure the protection of the bad structure.

see also

تسليك مجاري الأندلس الكويت تسليك مجاري الظهر الكويت

The impact of good health on society Providing health as an essential part of improving the level of public health, as it includes:

Providing clean water for drinking and daily use. Reducing the growth of plants from water. Improving the quality of modern life by developing sewage systems. Ring Plumbing preparations are one of the essential and indispensable professions, as they include the operation of water and comprehensive sewage. Despite the challenges facing plumbers, they provide an essential service, making them part of everyday life.

0 notes

Text

The Ultimate Guide to Built-In Dishwashers

A built-in dishwasher is a modern convenience that every household should consider. It saves time, conserves water, and ensures dishes are spotless with minimal effort. Whether you're upgrading your kitchen or installing one for the first time, understanding built-in dishwashers can help you make the right choice.

Why Choose a Built-In Dishwasher?

1. Space-Saving Design

Unlike portable dishwashers, built-in dishwashers are designed to fit seamlessly into your kitchen cabinetry. They help maintain a clean and uncluttered space, making your kitchen look sleek and organized.

2. Energy and Water Efficiency

Modern built-in dishwashers use less water and energy compared to handwashing or older models. Many come with eco-friendly settings that reduce power consumption and minimize water wastage.

3. Convenience and Time-Saving

A built-in dishwasher handles the tedious task of washing dishes, allowing you to focus on more important things. Simply load the dishes, set the cycle, and let the machine do the work.

4. Enhanced Cleaning Performance

With powerful spray arms, heated drying, and multiple wash cycles, built-in dishwashers provide a thorough cleaning that is hard to achieve manually.

Challenges of Using a Built-In Dishwasher

While built-in dishwashers offer numerous benefits, they also come with a few challenges.

1. Installation Complexity

Unlike portable dishwashers, a built-in dishwasher requires plumbing and electrical connections, which may involve professional installation.

2. Higher Initial Cost

Built-in dishwashers can be more expensive than countertop or portable models. However, their long-term efficiency and durability often justify the cost.

3. Maintenance Requirements

Regular maintenance is necessary to prevent issues such as clogs, leaks, and buildup of food debris.

4. Space Limitations

For smaller kitchens, finding the right spot for a built-in dishwasher can be a challenge, especially in compact apartments.

Step-by-Step Guide to Installing a Built-In Dishwasher

If you're planning to install a built-in dishwasher, follow this step-by-step guide to ensure a smooth setup.

Step 1: Gather Necessary Tools and Materials

Before starting, make sure you have the following:

Adjustable wrench

Screwdrivers

Level

Drill (if needed)

Water supply line and drain hose

Step 2: Turn Off Water and Electricity

For safety, shut off the water supply and disconnect the power before beginning the installation.

Step 3: Prepare the Space

Ensure the cabinet space is the correct size for the dishwasher. The standard width for built-in dishwashers is 24 inches, but compact models may be around 18 inches.

Step 4: Connect the Water Supply Line

Attach the water supply line to the dishwasher’s inlet valve. Make sure it is securely fastened to prevent leaks.

Step 5: Connect the Drain Hose

Attach the drain hose to the sink drain or garbage disposal unit. Ensure it is properly positioned to prevent backflow.

Step 6: Secure the Dishwasher in Place

Slide the dishwasher into the cabinet space, making sure it is level. Secure it using mounting brackets.

Step 7: Connect Power and Test

Plug in the power cord or connect the electrical wiring if it's a hardwired unit. Turn on the water supply and run a test cycle to check for leaks and proper functionality.

Case Study: How a Built-In Dishwasher Transformed a Family Kitchen

The Challenge: The Johnson family, a busy household of five, struggled with piles of dirty dishes every day. With a hectic schedule, they found it challenging to keep up with cleaning.

The Solution: They decided to install a built-in dishwasher to streamline their kitchen routine.

The Result: After installation, the family saved significant time and effort. Their kitchen remained clean, and they reduced their water bill by 20% due to the dishwasher’s efficient water usage.

Conclusion

A built-in dishwasher is an excellent investment for any modern kitchen. It saves time, improves cleaning efficiency, and enhances convenience. While there are some challenges, the benefits far outweigh the drawbacks. By understanding installation steps, maintenance requirements, and usage tips, you can ensure a smooth experience with your built-in dishwasher.

0 notes

Photo

“I consider lace to be one of the prettiestimitations ever made of the fantasy of nature.”“A WOMAN SHOULD HAVE…a set of screwdrivers, a cordless drill, and– Pamela Redmond Satran –Since its invention, lace has always been in style. It’s pretty and best of all, exclusive to women. It’s the detail that signals femininity and elevates any look – be it romantic or rocker (leather & lace). It is, therefore, kismet that both lace and lingerie are conjoined.While COVID cocooning, most turned to comfort bras. However, with the slow opening back up to normal life again, isn’t there also a tinge of desire to return to wearing something pretty and feminine? It’s my opinion that every woman should have at least one special lacy bra. Should you agree with me, the following is a short primer on the different laces used in lingerie.Lace vs. EmbroideryGenuine lace is a fabric or trim solely created by twisting or knitting many individual threads into an airy pattern. However, saying a garment has “lace” has been a bit hijacked. Now, embroidery on a garment with a similar design to lace is being called lace as well. This blurring of the term is due to most modern-day women not being familiar with the differences between lace and embroidery. I can confirm this through our search data. No one searches for “embroidered bras”. Here’s a quick explanation: Lace is created during the making of the fabric. Embroidery is stitching placed on top of finished fabric.Why Lace is ExpensiveLace and embroidery on lingerie makes it more expensive. Here are a few reasons why:It’s complicated to make. The fibers used in making lace may be basic and inexpensive, but it’s the hours of manual labor going into its manufacture that creates its higher costs. Some lace is handmade. Others are made on machines, but all have complex patterns that must be carefully designed, programmed, and implemented, which is very labor-intensive.Lace creates waste. Something most of us don’t think about is that excess lace can be wasted in order to get the lace pattern to look perfect on the garment. Here are a few lace examples to further explain this point.Notice the perfect symmetry of the lace in the first example. Each side lace panel is a mirror image of the other. The center has been cut out and carefully placed. To accomplish this, parts of the lace panel were not used. In the second example, the lace has simply been cut and sewn without the lace design being considered. The rose pattern on the waistband is not a mirror image and the lace pattern on the front is not centered. This example has much less lace waste because the pieces can be cut very economically. It is, therefore, cheaper to manufacture.Itchy, Scratchy LaceMany avoid purchasing lacy lingerie for fear of it itching. This was a legitimate issue years ago. But far, far less today. I have spoken to many of the leading lingerie designers about this. All are very aware of this concern, so give careful thought to the laces they choose to ensure softness and comfort. To this point, you will rarely see a review on our site where someone is complaining the lace is itchy, and even then, the reviewer will admit to having highly sensitive skin.One thing to know about lace is that many manufacturers will spray it with starch to give it some stiffness for more accurate sewing; it allows the seamstress to sew without the lace slipping. This starch is sometimes left in the lace, making it feel stiff and possibly scratchy. A quick hand wash or soak in cool water with a lingerie detergent will remove this starch and return your lace to its intended softness. Another option is to use fabric softener (3 parts water to 1 part softener). And, for those of you who prefer not to use any chemicals, a white distilled vinegar rinse is a natural fabric softener without adding chemicals.This special type of lace is named after the “Leavers” lace machine invented in 1813 and discontinued by the 1930s. The few machines that remain are primarily maintained in the French region of Calais.Leavers lace is known as the “Queen of Laces” due to its fine and delicate details. The Leavers machine intertwines 5,000 bobbins that must be set in these antique machines manually. The limited number of remaining machines in existence and the intensive human labor required makes Leavers lace scarce and expensive.Kate Middleton’s wedding dress was made with French Chantilly lace – the only fabric in her gown not sourced from a British company. Chantilly lace is named after the city of Chantilly, France where it first was made in the 17th century. This lace has a bit of a disturbing history. It was highly prized by Marie Antoinette and her court. Once she was guillotined, the lace makers – considered protégés of the then royals – were also killed. Chantilly lace no longer existed until Napoleon I sponsored its revival around 1810.The best Chantilly laces are made in silk or linen. Notable to Chantilly lace is its use of a half-and-whole stitch which acts as a slightly raised fill that creates light and shadow in its patterns. Chantilly lace shawls in black or white were an important fashion statement in the 19th century.Technically, Guipure lace is not lace. It’s a type of heavy embroidery applied on top of a tulle base. The tulle is then chemically dissolved leaving a free-standing embroidery design behind. It is common for pieces of Guipure lace to be sewn on as applique.Stretch lace is a recent phenomenon, which is now ubiquitous. It’s basically a machine-knit mesh with programmed-in designs using very fine elastic fibers mixed in with synthetics such as nylon on polyester. It has great stretch and is quite durable due to the synthetic fibers that are used. It’s so versatile it’s also used in other types of clothing beyond lingerie. Stretch lace is more reasonably priced due to it being made by machines and constructed from man-made fibers.So, there you have it. Whether you select the finest or the more affordable, lace lingerie gives a touch of feminine elegance. It has the power to make you feel special by just putting it on –- with or without showing it to others.Final Thought…For those of you who frequently wear lace lingerie, you may have noticed some of your favorite bra styles being discontinued. Lace is quite difficult to source right now. Manufacturers who cannot source the exact lace, will discontinue the style, and create a new style number with a different lace design so you, the customer, will not be disappointed. My buyers also continue to find great new lace options like Natori’s Embolden Wireless with supertextronic lace made from recycled yarns, Andres Sarda’s Mamba with lace and snake-inspired print, Aubade’s Mon Bijou in luxurious Emeraude, and Cleo by Panache Lana now in Blue Moon. HerRoom has lace options in hundreds of styles and colors. I’m sure you will find something pretty, feminine, and worth the indulgence.Final Fit: YIKES! or YEAHS!As you probably know, it is my pet peeve to see ill-fitting bras photographed on models in marketing. It’s tough enough to find your correct bra size, so at the very least, the photography should show you the proper fit for a bra. Below is my YIKES! or YEAHS! challenge for the week. Make your choices and then click to see if you qualify as a bra fit expert. In my answers, I’ll detail where the YIKES! bras went wrong. Source link

0 notes

Text

Top Industrial Hardware Tools You Should Invest In for Your Business

Introduction

Running a successful construction or industrial business requires the right set of tools to ensure efficiency, safety, and high-quality work. Industrial hardware tools play a crucial role in streamlining operations, enhancing productivity, and reducing downtime on job sites. Whether you are managing a small-scale workshop or a large construction project, investing in high-quality industrial tools is essential for achieving precision and durability.

In this guide, we will explore the must-have industrial hardware tools for businesses and why you should prioritize purchasing them from trusted online suppliers like AHM Building Materials.

1. Power Tools: The Backbone of Industrial Work

Power tools are indispensable in industrial settings as they provide efficiency and precision for various tasks such as cutting, drilling, grinding, and fastening. Investing in durable, high-performance power tools ensures long-term reliability and reduced manual labor.

Essential Power Tools for Industrial Use:

Electric Drills: Used for drilling holes and driving screws into wood, metal, and concrete.

Angle Grinders: Ideal for cutting, grinding, and polishing surfaces.

Impact Wrenches: Provide high torque for loosening or tightening bolts efficiently.

Rotary Hammers: Essential for heavy-duty drilling into concrete or masonry.

Circular Saws: Perfect for making precise cuts in wood, plastic, and metal.

When buying power tools, opt for brands known for durability and efficiency to ensure that your investment lasts for years.

2. Hand Tools: The Essentials for Precision Work

Even with advancements in power tools, hand tools remain a necessity for fine-tuning, assembling, and finishing tasks. These tools provide control and accuracy in situations where power tools might not be suitable.

Must-Have Hand Tools for Every Industrial Business:

Wrenches and Pliers: Used for gripping, bending, and turning nuts and bolts.

Hammers and Mallets: Essential for driving nails and breaking materials.

Screwdrivers: Available in different types for handling various fasteners.

Measuring Tape & Levels: Ensure accuracy and precision in construction tasks.

Utility Knives: Used for cutting materials like plastic, cardboard, and insulation.

For builders and technicians, multi-purpose screwdrivers and wrenches are crucial tools that enhance efficiency and ease of work.

3. Fasteners and Fixing Tools: Ensuring Strong and Secure Joints

Fasteners are used to assemble, secure, and connect different components in industrial and construction work. Without high-quality fasteners, the stability of a structure or equipment can be compromised.

Common Types of Industrial Fasteners:

Bolts, Nuts, and Screws: Used in metal and wood constructions.

Anchors and Rivets: Provide additional support in concrete and brick structures.

Washers and Studs: Improve grip and durability in fastened joints.

To maintain efficiency and quality, always buy industrial hardware tools online from reputable suppliers who offer a wide range of fastening solutions.

4. Cutting and Welding Equipment: Precision in Metalwork

If your business involves metalworking, fabrication, or construction, then having cutting and welding tools is essential. These tools help shape and join metals for various industrial applications.

Must-Have Cutting and Welding Equipment:

Welding Machines: Used for joining metal components.

Cutting Torches: Ideal for slicing through thick metal sheets.

Plasma Cutters: Provide precision cutting for complex designs.

Welding Rods: Available in different types for various welding applications.

When buying welding rods and cutting tools, always consider durability and ease of use to ensure seamless operations.

5. Heavy-Duty Lifting Equipment: Handling Large Loads Safely

Industrial and construction projects often require lifting and transporting heavy materials, making heavy-duty lifting equipment a necessity. This equipment helps prevent workplace injuries while improving workflow.

Reliable Lifting Equipment for Businesses:

Electric Hoists: Used for lifting heavy materials effortlessly.

Lifting Slings and Chains: Ensure safe and secure transportation of loads.

Cranes and Winches: Essential for large-scale lifting tasks.

Hydraulic Jacks: Provide lifting power for automotive and industrial applications.

Investing in the right lifting tools not only enhances productivity but also ensures worker safety. If you’re looking to buy electric hoists online, choose models with high load capacity and durable construction.

6. Construction Toolkits: A One-Stop Solution for Professionals

Instead of purchasing tools individually, many professionals opt for comprehensive construction toolkits for professionals that include a variety of essential tools in one package.

Benefits of Using Construction Toolkits:

✔ Cost-Effective: Buying a complete set is often more affordable than purchasing tools separately. ✔ Convenience: Having all necessary tools in one kit saves time and effort. ✔ Portability: Toolkits come with cases that make transportation easy. ✔ Versatility: Includes tools for multiple industrial applications.

For large-scale projects, investing in high-quality toolkits ensures that your workers have everything they need to perform tasks efficiently.

7. Where to Buy the Best Industrial Hardware Tools Online?

Finding premium-quality industrial hardware tools can be challenging, but online shopping has made it easier than ever to access a wide range of products.

✔ Why Buy Industrial Hardware Tools Online?

Wider Selection: Online stores offer more brands and tool varieties.

Convenience: Shop from anywhere and get tools delivered to your location.

Competitive Pricing: Many online suppliers offer discounts and bulk deals.

Detailed Product Information: Access reviews and specifications before purchasing.

For the best selection of industrial hardware tools, construction toolkits, and heavy-duty equipment, visit AHM Building Materials and explore high-quality products at competitive prices.

Conclusion

Investing in industrial hardware tools is a necessity for businesses that prioritize efficiency, safety, and durability. Whether you need power tools, hand tools, fasteners, or lifting equipment, selecting high-quality materials will improve work performance and ensure long-term reliability.

By purchasing from reputable online suppliers like AHM Building Materials, businesses can access premium tools at the best prices, making every investment worthwhile.

Are you ready to upgrade your industrial hardware collection? Explore the best tools online today!

0 notes

Photo

“I consider lace to be one of the prettiestimitations ever made of the fantasy of nature.”“A WOMAN SHOULD HAVE…a set of screwdrivers, a cordless drill, and– Pamela Redmond Satran –Since its invention, lace has always been in style. It’s pretty and best of all, exclusive to women. It’s the detail that signals femininity and elevates any look – be it romantic or rocker (leather & lace). It is, therefore, kismet that both lace and lingerie are conjoined.While COVID cocooning, most turned to comfort bras. However, with the slow opening back up to normal life again, isn’t there also a tinge of desire to return to wearing something pretty and feminine? It’s my opinion that every woman should have at least one special lacy bra. Should you agree with me, the following is a short primer on the different laces used in lingerie.Lace vs. EmbroideryGenuine lace is a fabric or trim solely created by twisting or knitting many individual threads into an airy pattern. However, saying a garment has “lace” has been a bit hijacked. Now, embroidery on a garment with a similar design to lace is being called lace as well. This blurring of the term is due to most modern-day women not being familiar with the differences between lace and embroidery. I can confirm this through our search data. No one searches for “embroidered bras”. Here’s a quick explanation: Lace is created during the making of the fabric. Embroidery is stitching placed on top of finished fabric.Why Lace is ExpensiveLace and embroidery on lingerie makes it more expensive. Here are a few reasons why:It’s complicated to make. The fibers used in making lace may be basic and inexpensive, but it’s the hours of manual labor going into its manufacture that creates its higher costs. Some lace is handmade. Others are made on machines, but all have complex patterns that must be carefully designed, programmed, and implemented, which is very labor-intensive.Lace creates waste. Something most of us don’t think about is that excess lace can be wasted in order to get the lace pattern to look perfect on the garment. Here are a few lace examples to further explain this point.Notice the perfect symmetry of the lace in the first example. Each side lace panel is a mirror image of the other. The center has been cut out and carefully placed. To accomplish this, parts of the lace panel were not used. In the second example, the lace has simply been cut and sewn without the lace design being considered. The rose pattern on the waistband is not a mirror image and the lace pattern on the front is not centered. This example has much less lace waste because the pieces can be cut very economically. It is, therefore, cheaper to manufacture.Itchy, Scratchy LaceMany avoid purchasing lacy lingerie for fear of it itching. This was a legitimate issue years ago. But far, far less today. I have spoken to many of the leading lingerie designers about this. All are very aware of this concern, so give careful thought to the laces they choose to ensure softness and comfort. To this point, you will rarely see a review on our site where someone is complaining the lace is itchy, and even then, the reviewer will admit to having highly sensitive skin.One thing to know about lace is that many manufacturers will spray it with starch to give it some stiffness for more accurate sewing; it allows the seamstress to sew without the lace slipping. This starch is sometimes left in the lace, making it feel stiff and possibly scratchy. A quick hand wash or soak in cool water with a lingerie detergent will remove this starch and return your lace to its intended softness. Another option is to use fabric softener (3 parts water to 1 part softener). And, for those of you who prefer not to use any chemicals, a white distilled vinegar rinse is a natural fabric softener without adding chemicals.This special type of lace is named after the “Leavers” lace machine invented in 1813 and discontinued by the 1930s. The few machines that remain are primarily maintained in the French region of Calais.Leavers lace is known as the “Queen of Laces” due to its fine and delicate details. The Leavers machine intertwines 5,000 bobbins that must be set in these antique machines manually. The limited number of remaining machines in existence and the intensive human labor required makes Leavers lace scarce and expensive.Kate Middleton’s wedding dress was made with French Chantilly lace – the only fabric in her gown not sourced from a British company. Chantilly lace is named after the city of Chantilly, France where it first was made in the 17th century. This lace has a bit of a disturbing history. It was highly prized by Marie Antoinette and her court. Once she was guillotined, the lace makers – considered protégés of the then royals – were also killed. Chantilly lace no longer existed until Napoleon I sponsored its revival around 1810.The best Chantilly laces are made in silk or linen. Notable to Chantilly lace is its use of a half-and-whole stitch which acts as a slightly raised fill that creates light and shadow in its patterns. Chantilly lace shawls in black or white were an important fashion statement in the 19th century.Technically, Guipure lace is not lace. It’s a type of heavy embroidery applied on top of a tulle base. The tulle is then chemically dissolved leaving a free-standing embroidery design behind. It is common for pieces of Guipure lace to be sewn on as applique.Stretch lace is a recent phenomenon, which is now ubiquitous. It’s basically a machine-knit mesh with programmed-in designs using very fine elastic fibers mixed in with synthetics such as nylon on polyester. It has great stretch and is quite durable due to the synthetic fibers that are used. It’s so versatile it’s also used in other types of clothing beyond lingerie. Stretch lace is more reasonably priced due to it being made by machines and constructed from man-made fibers.So, there you have it. Whether you select the finest or the more affordable, lace lingerie gives a touch of feminine elegance. It has the power to make you feel special by just putting it on –- with or without showing it to others.Final Thought…For those of you who frequently wear lace lingerie, you may have noticed some of your favorite bra styles being discontinued. Lace is quite difficult to source right now. Manufacturers who cannot source the exact lace, will discontinue the style, and create a new style number with a different lace design so you, the customer, will not be disappointed. My buyers also continue to find great new lace options like Natori’s Embolden Wireless with supertextronic lace made from recycled yarns, Andres Sarda’s Mamba with lace and snake-inspired print, Aubade’s Mon Bijou in luxurious Emeraude, and Cleo by Panache Lana now in Blue Moon. HerRoom has lace options in hundreds of styles and colors. I’m sure you will find something pretty, feminine, and worth the indulgence.Final Fit: YIKES! or YEAHS!As you probably know, it is my pet peeve to see ill-fitting bras photographed on models in marketing. It’s tough enough to find your correct bra size, so at the very least, the photography should show you the proper fit for a bra. Below is my YIKES! or YEAHS! challenge for the week. Make your choices and then click to see if you qualify as a bra fit expert. In my answers, I’ll detail where the YIKES! bras went wrong. Source link

0 notes

Photo

“I consider lace to be one of the prettiestimitations ever made of the fantasy of nature.”“A WOMAN SHOULD HAVE…a set of screwdrivers, a cordless drill, and– Pamela Redmond Satran –Since its invention, lace has always been in style. It’s pretty and best of all, exclusive to women. It’s the detail that signals femininity and elevates any look – be it romantic or rocker (leather & lace). It is, therefore, kismet that both lace and lingerie are conjoined.While COVID cocooning, most turned to comfort bras. However, with the slow opening back up to normal life again, isn’t there also a tinge of desire to return to wearing something pretty and feminine? It’s my opinion that every woman should have at least one special lacy bra. Should you agree with me, the following is a short primer on the different laces used in lingerie.Lace vs. EmbroideryGenuine lace is a fabric or trim solely created by twisting or knitting many individual threads into an airy pattern. However, saying a garment has “lace” has been a bit hijacked. Now, embroidery on a garment with a similar design to lace is being called lace as well. This blurring of the term is due to most modern-day women not being familiar with the differences between lace and embroidery. I can confirm this through our search data. No one searches for “embroidered bras”. Here’s a quick explanation: Lace is created during the making of the fabric. Embroidery is stitching placed on top of finished fabric.Why Lace is ExpensiveLace and embroidery on lingerie makes it more expensive. Here are a few reasons why:It’s complicated to make. The fibers used in making lace may be basic and inexpensive, but it’s the hours of manual labor going into its manufacture that creates its higher costs. Some lace is handmade. Others are made on machines, but all have complex patterns that must be carefully designed, programmed, and implemented, which is very labor-intensive.Lace creates waste. Something most of us don’t think about is that excess lace can be wasted in order to get the lace pattern to look perfect on the garment. Here are a few lace examples to further explain this point.Notice the perfect symmetry of the lace in the first example. Each side lace panel is a mirror image of the other. The center has been cut out and carefully placed. To accomplish this, parts of the lace panel were not used. In the second example, the lace has simply been cut and sewn without the lace design being considered. The rose pattern on the waistband is not a mirror image and the lace pattern on the front is not centered. This example has much less lace waste because the pieces can be cut very economically. It is, therefore, cheaper to manufacture.Itchy, Scratchy LaceMany avoid purchasing lacy lingerie for fear of it itching. This was a legitimate issue years ago. But far, far less today. I have spoken to many of the leading lingerie designers about this. All are very aware of this concern, so give careful thought to the laces they choose to ensure softness and comfort. To this point, you will rarely see a review on our site where someone is complaining the lace is itchy, and even then, the reviewer will admit to having highly sensitive skin.One thing to know about lace is that many manufacturers will spray it with starch to give it some stiffness for more accurate sewing; it allows the seamstress to sew without the lace slipping. This starch is sometimes left in the lace, making it feel stiff and possibly scratchy. A quick hand wash or soak in cool water with a lingerie detergent will remove this starch and return your lace to its intended softness. Another option is to use fabric softener (3 parts water to 1 part softener). And, for those of you who prefer not to use any chemicals, a white distilled vinegar rinse is a natural fabric softener without adding chemicals.This special type of lace is named after the “Leavers” lace machine invented in 1813 and discontinued by the 1930s. The few machines that remain are primarily maintained in the French region of Calais.Leavers lace is known as the “Queen of Laces” due to its fine and delicate details. The Leavers machine intertwines 5,000 bobbins that must be set in these antique machines manually. The limited number of remaining machines in existence and the intensive human labor required makes Leavers lace scarce and expensive.Kate Middleton’s wedding dress was made with French Chantilly lace – the only fabric in her gown not sourced from a British company. Chantilly lace is named after the city of Chantilly, France where it first was made in the 17th century. This lace has a bit of a disturbing history. It was highly prized by Marie Antoinette and her court. Once she was guillotined, the lace makers – considered protégés of the then royals – were also killed. Chantilly lace no longer existed until Napoleon I sponsored its revival around 1810.The best Chantilly laces are made in silk or linen. Notable to Chantilly lace is its use of a half-and-whole stitch which acts as a slightly raised fill that creates light and shadow in its patterns. Chantilly lace shawls in black or white were an important fashion statement in the 19th century.Technically, Guipure lace is not lace. It’s a type of heavy embroidery applied on top of a tulle base. The tulle is then chemically dissolved leaving a free-standing embroidery design behind. It is common for pieces of Guipure lace to be sewn on as applique.Stretch lace is a recent phenomenon, which is now ubiquitous. It’s basically a machine-knit mesh with programmed-in designs using very fine elastic fibers mixed in with synthetics such as nylon on polyester. It has great stretch and is quite durable due to the synthetic fibers that are used. It’s so versatile it’s also used in other types of clothing beyond lingerie. Stretch lace is more reasonably priced due to it being made by machines and constructed from man-made fibers.So, there you have it. Whether you select the finest or the more affordable, lace lingerie gives a touch of feminine elegance. It has the power to make you feel special by just putting it on –- with or without showing it to others.Final Thought…For those of you who frequently wear lace lingerie, you may have noticed some of your favorite bra styles being discontinued. Lace is quite difficult to source right now. Manufacturers who cannot source the exact lace, will discontinue the style, and create a new style number with a different lace design so you, the customer, will not be disappointed. My buyers also continue to find great new lace options like Natori’s Embolden Wireless with supertextronic lace made from recycled yarns, Andres Sarda’s Mamba with lace and snake-inspired print, Aubade’s Mon Bijou in luxurious Emeraude, and Cleo by Panache Lana now in Blue Moon. HerRoom has lace options in hundreds of styles and colors. I’m sure you will find something pretty, feminine, and worth the indulgence.Final Fit: YIKES! or YEAHS!As you probably know, it is my pet peeve to see ill-fitting bras photographed on models in marketing. It’s tough enough to find your correct bra size, so at the very least, the photography should show you the proper fit for a bra. Below is my YIKES! or YEAHS! challenge for the week. Make your choices and then click to see if you qualify as a bra fit expert. In my answers, I’ll detail where the YIKES! bras went wrong. Source link

0 notes

Text

Best Garage tools suppliers in Jaipur

If you are searching for the best garage tools suppliers in Jaipur, look no further than the reputed shops in Murlipura, a hub for high-quality tools and equipment. Whether you are a professional mechanic, a DIY enthusiast, or a workshop owner, having the right set of tools is essential for efficiency and precision.

Why Choose a Reliable Tool Shop in Murlipura?

Murlipura is known for its well-established tool shops that provide a wide range of hand tools in Murlipura and power tools in Murlipura. A reliable tool shop ensures that you get genuine, high-quality tools from top brands, which can significantly enhance your work efficiency. With the right supplier, you can be assured of durability, reliability, and excellent after-sales service.

Wide Range of Hand Tools and Power Tools

One of the primary reasons professionals and workshop owners prefer tool shops in Murlipura is the extensive range of hand tools and power tools available. From simple wrenches and pliers to advanced electric drills and grinders, you can find every tool you need under one roof. The availability of reputed brands ensures that you get premium quality tools that provide long-lasting performance.

Hand Tools in Murlipura

Hand tools are the backbone of any workshop or garage. Some of the most commonly used hand tools include:

Wrenches

Screwdrivers

Hammers

Pliers

Spanners

Socket sets

Buying hand tools in Murlipura ensures that you have access to top-quality products that enhance precision and efficiency.

Power Tools in Murlipura

For heavy-duty tasks, power tools play a crucial role. Some of the widely used power tools include:

Drilling machines

Angle grinders

Impact wrenches

Electric saws

Cordless screwdrivers

Welding machines

A well-equipped tool shop in Murlipura will offer a diverse range of power tools from top brands, ensuring you get the best performance and safety features.

Trusted Taparia Tools Distributors in Jaipur

For those looking for Taparia tools distributors in Jaipur, Murlipura is home to authorized dealers offering genuine Taparia products. Taparia is a leading brand in the tool industry, known for its high-quality, durable, and precision-engineered tools. Whether you need spanners, pliers, hammers, or cutting tools, choosing an authorized distributor guarantees that you get original products at the best prices.

Finding the Best Garage Tools Suppliers in Jaipur

When searching for the best garage tools suppliers in Jaipur, it is essential to consider factors such as product variety, brand availability, pricing, and after-sales support. One of the most trusted names in Jaipur’s tool industry is Govind Tools - Best Garage Tools Suppliers in Jaipur. They offer a vast selection of high-quality hand tools, power tools, and garage equipment, ensuring that professionals get the best products for their needs.

Conclusion

Whether you need hand tools in Murlipura, power tools in Murlipura, or are looking for reliable Taparia tools distributors in Jaipur, Murlipura has some of the best options available. Investing in high-quality tools from a reputed tool shop in Murlipura ensures that your work is efficient, safe, and precise. Choose wisely and enhance your productivity with the right tools for your garage or workshop!

0 notes