#Digital Manufacturing Inkjet Ink Market Trends

Explore tagged Tumblr posts

Text

Ink Receptive Coatings Market Witnesses Increased Application in Sustainable Paper and Film Alternatives

The ink receptive coatings market has seen substantial growth over the past decade, largely due to advancements in digital printing technologies, the rise of customization in consumer goods, and the increasing demand for sustainable printing solutions. However, like many markets, it has not been immune to volatility. Market volatility refers to the unpredictable and sometimes rapid changes in demand, pricing, supply chain stability, and input costs. In the case of ink receptive coatings, several factors ranging from raw material fluctuations to shifting industry demands contribute to this volatility. Understanding these factors is essential for manufacturers, suppliers, and end-users aiming to navigate and adapt to market uncertainties.

Supply Chain Disruptions and Raw Material Price Fluctuations

One of the key sources of volatility in the ink receptive coatings market is the fluctuation in raw material prices. Most ink receptive coatings are composed of complex chemical formulations that rely on polymers, resins, solvents, and other additives. Many of these inputs are derived from petrochemical sources, making them highly sensitive to changes in global oil prices and geopolitical tensions.

For instance, when oil prices surge due to conflict or regulatory constraints, the cost of production for solvent-based and even some water-based coatings rises. These increased production costs are often passed down the supply chain, affecting pricing and margins at multiple levels. Additionally, supply chain disruptions, such as those experienced during the COVID-19 pandemic or due to geopolitical unrest, can lead to delays in raw material procurement. This not only slows down manufacturing but also causes price spikes, adding to market unpredictability.

Shifting Regulatory Landscape

Environmental regulations are another major driver of market volatility. Around the world, governments are tightening regulations on the use of volatile organic compounds (VOCs) and other environmentally harmful substances found in certain types of coatings. While this has led to a positive shift toward eco-friendly formulations, it has also introduced instability for manufacturers that must rapidly adapt their formulations to stay compliant.

For example, new environmental rules may render a commonly used ingredient non-compliant, requiring reformulation or the search for alternative materials both of which take time and investment. This can temporarily disrupt production and affect market supply. Moreover, compliance costs can rise unpredictably as regions impose differing environmental standards, making it challenging for global manufacturers to maintain a consistent product line across markets.

Technological Shifts and Evolving End-Use Demands

The ink receptive coatings market is closely tied to the printing industry, which is itself undergoing rapid change. The rise of digital printing technologies such as inkjet and UV printing is reshaping the landscape, pushing demand for more specialized coatings that can handle a broader range of substrates and ink types.

However, this evolution also brings volatility. As new technologies emerge, older formulations may become obsolete, and demand can shift rapidly. Coating manufacturers must be agile, investing in R&D to stay relevant. At the same time, end-user industries from packaging to textiles to electronics are constantly updating their preferences and performance expectations. This can lead to fluctuations in demand, with sudden increases for some formulations and declines for others.

The growing trend toward personalization and short-run printing also introduces instability. While digital printing and ink receptive coatings are perfectly suited to meet these demands, they often require smaller batches and rapid formulation adjustments, making production and inventory management more complex.

Global Economic Uncertainty

Macroeconomic factors also play a significant role in market volatility. Economic slowdowns, inflation, currency fluctuations, and interest rate changes can affect both the demand for printed products and the investment capacity of manufacturers. For example, in times of economic uncertainty, businesses may cut back on marketing and packaging expenditures, leading to a temporary reduction in demand for ink receptive coatings.

Likewise, interest rate hikes and inflation can impact borrowing costs and operational expenses, making it harder for smaller coating manufacturers to invest in innovation or expand capacity. These macroeconomic pressures contribute to an uneven market landscape where sudden booms may be followed by equally sudden contractions.

Navigating Volatility: Strategies for Stakeholders

To address and adapt to market volatility, stakeholders in the ink receptive coatings sector are adopting several strategies:

Diversification of raw material sources to minimize the impact of supply chain disruptions.

Investment in research and development to stay ahead of technological changes and evolving customer needs.

Agile manufacturing practices that allow for quick formulation changes and batch flexibility.

Geographical diversification to spread risk across multiple markets and regulatory environments.

By embracing these strategies, companies can not only cushion themselves against volatility but also find new avenues for growth and innovation.

Conclusion

The ink receptive coatings market, while full of promise, is subject to a range of volatile forces. From supply chain instability and raw material price swings to regulatory shifts and technological disruption, stakeholders must remain vigilant and adaptable. Volatility, while challenging, can also drive innovation pushing companies to become more resilient, responsive, and forward-thinking in their approach. For those willing to invest in agility and innovation, the ink receptive coatings market continues to offer significant opportunities despite its inherent unpredictability.

0 notes

Text

Printing Ink and Toner Market: Growth Driven by Packaging, Sustainability, and Technological Advancements

The global printing ink and toner market has undergone significant transformation over the years, shaped by evolving consumer needs, technological advancements, and changing industrial applications. These products—critical to both commercial and consumer printing—are essential across various industries, from publishing and packaging to textiles and electronics. The market is driven by several key factors that continue to shape its growth trajectory and strategic direction.

1. Growth in Packaging and Labeling Industry

One of the most prominent drivers of the printing ink and toner market is the rapid expansion of the packaging and labeling sector. As consumer demand for packaged goods increases, especially in emerging economies, the need for high-quality and visually appealing packaging grows in parallel. Printing inks and toners are essential in achieving attractive, durable, and informative packaging. This trend is particularly strong in the food and beverage, cosmetics, and pharmaceutical sectors, where branding and regulatory information are critical.

Additionally, the rise of e-commerce has amplified the need for packaged goods, resulting in greater usage of labels and printed shipping materials. This surge in online shopping has increased demand for both functional and aesthetic packaging, reinforcing the importance of printing materials in the supply chain.

2. Technological Advancements in Printing

The development and adoption of advanced printing technologies, such as digital printing, inkjet, and laser printing, have fueled the growth of the ink and toner market. Digital printing, in particular, has revolutionized the industry by offering flexibility, reduced turnaround times, and cost-effective short runs. These advantages are especially beneficial for small and medium-sized enterprises (SMEs) that require customized packaging or promotional materials.

In parallel, innovations in ink formulations—such as UV-curable, water-based, and eco-solvent inks—have improved performance, sustainability, and versatility. These new formulations cater to a broader range of substrates and applications, including textiles, ceramics, and electronics. As print technology continues to evolve, so does the demand for high-performance inks and toners that can support these capabilities.

3. Environmental Regulations and Demand for Sustainable Solutions

Environmental concerns and regulatory mandates are compelling manufacturers to develop eco-friendly inks and toners. Traditional solvent-based inks have been criticized for their volatile organic compounds (VOCs), which contribute to air pollution and pose health risks. In response, the industry has seen a significant shift toward sustainable alternatives such as water-based, soy-based, and bio-based inks.

These alternatives not only meet regulatory requirements but also align with growing consumer awareness and demand for sustainable products. In many markets, especially across Europe and North America, sustainability is no longer optional—it is a competitive necessity. Companies that can offer environmentally responsible printing solutions are more likely to secure partnerships with eco-conscious brands and institutions.

4. Expansion of the Textile and Apparel Printing Market

The growth of digital textile printing is another important driver. The fashion and home décor sectors have increasingly embraced digital printing due to its design flexibility, lower waste generation, and rapid prototyping capabilities. Inks designed specifically for fabrics—such as sublimation, reactive, and pigment inks—are seeing increased demand.

This trend is further fueled by the customization boom, where consumers and businesses alike seek personalized apparel, accessories, and interiors. As a result, the printing ink industry is investing heavily in R&D to develop ink systems that deliver vibrant, long-lasting colors on various textile materials.

5. Commercial Printing and Publishing Resilience

Although digital media has affected traditional publishing, commercial printing remains an enduring market segment, particularly in regions where physical media still dominates education, advertising, and documentation. Books, magazines, brochures, and promotional materials continue to be printed in large quantities, especially in developing economies with growing literacy rates.

Moreover, certain niches within publishing, such as art books, coffee table editions, and limited-run publications, have maintained steady demand. These applications often require premium inks that deliver high-definition print quality and color accuracy.

6. Rapid Industrialization and Urbanization in Emerging Economies

Emerging markets in Asia-Pacific, Latin America, and Africa are seeing rapid urbanization and industrial expansion, leading to increased demand for printed materials across sectors. From consumer packaging to administrative documents, these economies rely heavily on printed content for communication, branding, and operational efficiency.

As infrastructure develops, so too does the retail, healthcare, and education sectors—each of which contributes to rising consumption of printing inks and toners. Furthermore, the presence of cost-effective labor and manufacturing capabilities in these regions encourages the establishment of printing and packaging hubs.

Conclusion

The global printing ink and toner market is being propelled by a complex interplay of technological, economic, and environmental factors. The shift toward digital and sustainable printing, coupled with rising demand from industries such as packaging, textiles, and commercial printing, continues to drive innovation and investment. Market players must remain agile, continuously innovating to meet evolving customer needs, comply with environmental standards, and leverage emerging market opportunities. As industries increasingly embrace customization, sustainability, and digital workflows, the printing ink and toner sector is well-positioned for steady, diversified growth.

0 notes

Text

The Best Techniques for Custom T-Shirt Printing in Chennai: Screen Printing vs. Digital Printing

Introduction to Custom T-Shirt Printing

In today’s world, fashion is no longer limited to the ramps and retail stores. Personalized fashion is booming, and custom t-shirt printing has become a major trend in Chennai. Whether you are an individual who wants to express your creativity or a business looking to promote your brand, custom t-shirt printing is an incredible solution. Among the various techniques available, screen printing and digital printing are two of the most popular methods used by almost every top t-shirt manufacturers in Chennai. Understanding these methods can help you make an informed decision for your next project.

Understanding Screen Printing: A Traditional Favorite

Screen printing has been a classic choice for custom t-shirt printing for decades. It involves creating a stencil (or screen) and using it to apply layers of ink on the fabric. Each color requires a separate screen, making the process slightly labor-intensive but incredibly durable and vibrant. Many leading t-shirt manufacturer in Chennai still swear by screen printing because of its quality output and rich color payoff.

Screen printing is particularly ideal for bulk orders, as the initial setup cost is spread over multiple units. It’s also best suited for simple designs with fewer colors. One of the reasons screen printing remains popular among every prominent t-shirt manufacturers in Chennai is its ability to produce bold, bright designs that withstand multiple washes without fading.

Exploring Digital Printing: The Modern Innovation

On the other hand, digital printing is a newer, more innovative method that has revolutionized custom apparel. Instead of creating screens, digital printing works much like an inkjet printer you might have at home—printing the design directly onto the fabric. This method is quick, highly detailed, and perfect for intricate designs that use a wide range of colors.

Today, many t-shirt manufacturer in Chennai have embraced digital printing because it allows them to produce high-quality prints for small orders without a significant setup cost. Digital printing offers the flexibility to customize every single t-shirt differently if needed, making it ideal for personalized gifts, small batch merchandising, or event-specific clothing.

Screen Printing vs. Digital Printing: Which is Better?

Choosing between screen printing and digital printing largely depends on your specific needs. If you are placing a large order with a simple design, screen printing is usually the most economical and durable option. If you require detailed artwork or only a few pieces, digital printing offers better flexibility and a faster turnaround.

While screen printing shines in terms of color vibrancy and long-term durability, digital printing is unbeatable when it comes to producing intricate designs and photo-realistic prints. Every reputable t-shirt manufacturer in Chennai advises considering the size of your order, the complexity of your design, and your budget when choosing between these two methods.

Why Chennai is the Hub for Custom T-Shirt Printing

Chennai has rapidly evolved into one of the primary centers for custom t-shirt printing in India. Thanks to its booming textile industry and skilled workforce, the city offers access to some of the best t-shirt manufacturer in Chennai. Whether you are a business planning a large marketing campaign or an artist wanting to showcase your artwork, Chennai’s t-shirt printing industry has the technology and expertise to meet your needs.

Local manufacturers have adopted the latest innovations in printing while maintaining the traditional craftsmanship that ensures superior quality. This perfect blend of tradition and technology makes Chennai a go-to destination for anyone looking to venture into custom t-shirt printing.

How to Choose the Right Printing Method for Your Project

When you approach a t-shirt manufacturer in Chennai, it's essential to discuss your specific requirements clearly. Share your design details, quantity expectations, and budget considerations upfront. An experienced manufacturer will guide you through the pros and cons of screen printing versus digital printing, ensuring you get the best outcome for your project.

If you want a large batch of simple yet vibrant designs, screen printing could be your best bet. However, if your design is colorful, detailed, or you only need a handful of shirts, digital printing might be the right choice. By partnering with a trusted t-shirt manufacturer in Chennai, you ensure that your vision turns into reality without compromising on quality.

Future Trends in Custom T-Shirt Printing

As technology advances, custom t-shirt printing methods will continue to evolve. Techniques like direct-to-film (DTF) printing and hybrid printing that combine the best of screen and digital methods are gaining popularity. In Chennai, manufacturers are constantly upgrading their facilities to stay ahead of the trends, making the city a hub for cutting-edge custom t-shirt printing.

Choosing a forward-thinking t-shirt manufacturer in Chennai means you are not just getting today’s best quality but also tapping into the future of fashion and customization.

Conclusion

Whether you choose screen printing for its vibrant durability or digital printing for its detailed flexibility, custom t-shirt printing in Chennai offers world-class options that suit every need. The combination of rich tradition, innovative technology, and skilled craftsmanship makes Chennai the ultimate destination for anyone looking to print custom t-shirts that truly stand out.

If you are ready to bring your ideas to life, it’s time to collaborate with the best t-shirt manufacturers in Chennai to achieve personalized fashion that speaks volumes.

0 notes

Text

Digital Textile Printing Market: Emerging Trends, Investment Opportunities & Competitive Benchmarking

The global digital textile printing market, valued at USD 6.77 billion in 2025, is expected to reach approximately USD 19.92 billion by 2034, growing at a CAGR of 12.75% from 2024 to 2034. Key market players are increasingly adopting inorganic growth strategies, such as mergers and acquisitions, to drive technological advancements and expand their market presence.

Digital Textile Printing Market Size (2023 – 2034)

Major Key Insights

Asia Pacific dominated the digital textile printing market in 2024.

North America is expected to grow at a significant rate during the forecast period.

Direct-to-fabric (roll-to-roll) printing held the largest market share in 2024.

The single-pass segment dominated the global market in 2024.

Cotton segment expected to grow at a significant rate during the forecast period.

The sublimation ink segment had the largest market share in 2024.

The clothing/apparel segment dominated the digital textile printing market in 2024.

Digital Textile Printing Market: A Versatile Printing Technique

Digital textile printing enables precise and versatile printing directly onto fabrics, allowing intricate and detailed designs with unlimited color combinations. It offers quick design modifications without extensive setup and is ideal for small production runs and custom designs. The process is faster and cost-effective for short runs, using less water and generating less waste compared to traditional methods. This technology is widely utilized in industries such as home décor, fashion, and promotional products.

Market Trends

Smart and Automated Technologies

Advancements in inkjet technology, automation, and color management enhance printing quality, speed, and efficiency.

Innovations like UV gel technology expand application possibilities and market segments.

Eco-Friendly Practices Driving Industry Growth

Digital textile printing employs gentler chemicals and solvents, reducing environmental impact.

Consumer demand for sustainable textile solutions is prompting manufacturers to adopt digital printing.

On-Demand Production and Customization

The ability to produce high-quality, intricate designs quickly caters to demand for personalized products.

The fashion industry is leveraging digital printing for unique and fast-fashion garments.

AI in the Textile Printing Industry

AI integration enhances digital textile printing through:

Design optimization and personalization

Automated defect detection and real-time quality control

Color matching consistency

Predictive maintenance for machinery efficiency

Virtual try-ons for customers

AI chatbots for 24/7 customer support

E-Commerce Growth and Digital Textile Printing

Rising e-commerce demand fuels the need for quick, customizable digital textile solutions.

Direct-to-consumer models are gaining traction, supported by digital printing technology.

Digital printing allows on-demand production, reducing inventory and waste.

Sustainability in textile production appeals to eco-conscious online consumers.

E-commerce retail transactions are projected to surpass $6.8 trillion by 2025, increasing market demand.

Market Restraints

Fabric Compatibility and Production Limitations

Some fabrics, particularly natural fibers like cotton, require pre-treatment.

Durability and color fastness may be lower than traditional methods.

Slower speeds limit large-scale production.

Technical expertise is required for digital textile printing operations.

High costs of specialized inks affect profitability.

Opportunities in the Digital Textile Printing Market

Technological Advancements

Faster print speeds, better quality, and durable inks enhance market capabilities.

AI and IoT integration improve automation and efficiency.

Growing investments in advanced digital printing machines create opportunities for market expansion.

Example: In November 2024, Ricoh Company, Ltd. launched two ink-based versions of its RICOH Pro VC40000 mono webfed inkjet press, improving turnaround time and productivity.

Leading Market Segments

Direct-to-Fabric (Roll-to-Roll Printing)

Dominated the market in 2024 due to customization, flexibility, and cost-effectiveness.

Eliminates the need for screens or plates, making it suitable for short runs.

Compatible with various fabric types, including cotton, polyester, and silk.

Single-Pass Printing Technology

Registered the highest market dominance in 2024.

Enables fast printing speeds for large-scale production.

Reduces per-unit costs over time, making it ideal for high-volume manufacturers.

Source: https://www.towardspackaging.com/insights/digital-textile-printing-market-sizing

0 notes

Text

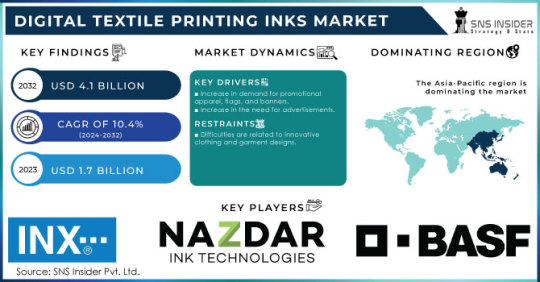

The Future of Digital Textile Printing Inks: Innovations and Market Growth

Rising Demand for Sustainable and High-Quality Printing Solutions Fuels Growth in the Digital Textile Printing Inks Market.

The Digital Textile Printing Inks Market size was USD 1.7 billion in 2023 and is expected to reach USD 4.1 billion by 2032 and grow at a CAGR of 9.6% over the forecast period of 2024-2032.

The Digital Textile Printing Inks Market is experiencing significant growth due to the increasing adoption of digital printing technology across the textile industry. These specialized inks play a vital role in achieving high-quality prints with vibrant colors, durability, and eco-friendly properties. With the rise in customized apparel, home textiles, and promotional products, the demand for efficient, cost-effective, and sustainable printing solutions has surged. Additionally, digital textile printing enables on-demand production, reducing fabric waste and water consumption, making it a preferred choice for textile manufacturers.

Key Players in the Digital Textile Printing Inks Market

INX International Ink (Expedition Inks, NSC Inks)

JK Group (Aqua Inks, J-Teck)

Nazdar Company (Nazdar 700 Series, Nazdar 120 Series)

BASF SE (Texaprint Reactive Inks, Desmodur Ink Systems)

Dover Corporation (Markem-Imaje Inks, DigiDot Inks)

DyStar Group (Remazol Inks, Dystar Pigment Inks)

Zhengzhou Hongsam Digital Science & Technology Co., Ltd. (Hongsam Sublimation Inks, Hongsam Pigment Inks)

Huntsman Corporation (Huntsman Reactive Inks, Huntsman Disperse Inks)

Kornit Digital Ltd. (Kornit Allegro Inks, Kornit Storm Inks)

Sensient Technologies Corporation (Sensient Digital Inks, Sensient Sublimation Inks)

Future Scope of the Market

The future of the Digital Textile Printing Inks Market looks promising with:

Growing demand for sustainable, water-based inks with reduced environmental impact.

Expansion of e-commerce and customized textile products driving digital printing adoption.

Technological advancements leading to improved ink formulations with superior color fastness.

Increasing investments in high-speed digital printing machines for mass production.

Rising preference for pigment inks over dye-based inks due to their versatility and eco-friendliness.

Emerging Trends in the Digital Textile Printing Inks Market

The digital textile printing industry is rapidly shifting towards sustainable and high-performance ink formulations. Eco-friendly water-based inks, including pigment, reactive, and sublimation inks, are gaining traction due to stringent environmental regulations and growing consumer awareness. Moreover, advancements in nanotechnology and inkjet printing techniques are enhancing color vibrancy, print durability, and fabric compatibility. The demand for short-run and on-demand printing solutions is also fueling market growth, particularly in fashion, home décor, and sportswear industries. Additionally, the rise of automation and AI-driven printing processes is optimizing ink consumption and print efficiency.

Key Points:

Rising demand for sustainable, water-based textile printing inks.

Growth in personalized and on-demand textile printing applications.

Technological advancements improving print durability and efficiency.

Shift towards pigment inks for enhanced fabric compatibility.

Expanding adoption of digital printing in fashion, home décor, and industrial textiles.

Conclusion

The Digital Textile Printing Inks Market is set to experience substantial growth as the textile industry embraces��digital transformation and eco-friendly practices. Innovations in ink formulations and printing technologies will further drive market expansion, catering to the evolving needs of fashion brands, home textile manufacturers, and industrial textile producers. Companies focusing on sustainability, high-performance inks, and digital printing advancements will gain a competitive edge in this dynamic market.

Read Full Report: https://www.snsinsider.com/reports/digital-textile-printing-inks-market-1458

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Digital Textile Printing Inks Market#Digital Textile Printing Inks Market Size#Digital Textile Printing Inks Market Share#Digital Textile Printing Inks Market Report#Digital Textile Printing Inks Market Forecast

0 notes

Text

Numerous high-quality textile ink manufacturers gathered on May 19-21 Guangzhou ITCPE!

The textile digital printing technology blends fashion with creativity, so its quality is closely related to the aesthetics and durability of the final product. For this technology, the quality of textile digital printing ink undoubtedly plays a crucial role. It not only affects the definition of the print pattern, and color saturation, but also directly affects the wearing experience of the garment and the overall quality.

In recent years, with the rapid development of technology and the wide application of ink in various fields, the market demand for textile digital printing ink shows a trend of continuous growth. According to statistics, in 2023, the global inkjet ink market size has reached a staggering 15.683 billion yuan, and in China, an important consumer market of inkjet ink, the market size has also reached 3.221 billion yuan. This data not only reflects the huge potential of the market, but also predicts that the field will open up a broader prospect.

Some of the exhibitors (The following are in no particular order)

Shenzhen INKBANK Group Inc. — Booth No. T3009

Shenzhen INKBANK Group Inc. is a leading supplier of inkjet ink and digital application solutions in China, specializing in the research, development and manufacture of inkjet ink for 20 years. The company now has a modern R & D and production base of nearly 30,000 square meters, with an annual production capacity of more than 18,000 tons of products sold well at home and abroad in more than 100 countries and regions.

The products developed by the company mainly include: LED-UV curing ink, coating ink, heat sublimation ink, high temperature dispersion ink, reactive dye ink, acid dye ink, water-based pigment ink and water-based dye ink.

Zhengzhou Hongsam Digital Science & Technology Co., Ltd. — Booth No. T4032

Hongsam digital adheres to the “Hongsam +” business philosophy, is rooted in the industry, and is willing to work with more companies to create a new digital life for mankind through extensive links, and in-depth cooperation. Following the value of “Hongsam Service”, we emphasize on channel construction externally, implement process management internally, and connect many channel partners and end-users with Hongsam technology and process services. Guided by the “user thinking” idea, we strengthen our technology and services, and unite upstream and downstream partners in the industry to form a huge network of customers. The “user thinking” idea makes customers and Hongsam connect closely together to become the “Hongsam+” community.

Foshan Kai Yan New Material Co., Ltd. — Booth No. T4017

Kai Yan New Material, a high-tech enterprise in the field of inkjet printing in China, one of the ink manufacturing supplier, owns a plant with an area of nearly 11,000 square feet so far, with the annual production capacity of more than 3,000 tons of UV ink, and more than 2,000 tons of water-based ink. The products are sold at home and abroad in different countries and regions. In just two years, the domestic sales of UV ink rose to rank amongst the top three, creating a miracle of the industry for a single ink product. The company is now in the forefront of the industry. The company focuses on the development of ink in the field of digital inkjet printing applications. We have always been adhering to the vision of “Doing business for well-being, developing ink with devoted will”, to provide customers with professional inkjet printing solutions and services. Our products cover areas such as the textile industry, labeling industry, building materials industry, advertising industry, special applications, and other daily necessities.

Innovation is the vitality of the development of enterprises. “Kaiyan New Material” pays more attention to R & D innovation, and is committed to the concept of “products lead the industry development, business innovation, win-win with partners in the future,” for the individual needs of different customers, the company gives full play to the spirit of innovation, while ensuring product quality.

Fully in accordance with the relevant national laws and regulations, the production of ink products is in line with RoHS, REACH, which marks our products to obtain the peer recognition from all around the world. Talent is the driving force of the enterprise development, so we keep on to establish talent incentive mechanism, and to provide a high-quality platform for capable, ambitious and aspiring talents, as well as a variety of conditions for the enterprise and the staff to grow together. In the future, Kaiyan New Material will always struggle for the goal of “becoming a company with vitality, innovation and faith”, and strive to make itself a bridge for you and me to grow and win together.

Guangzhou Unity Peak Company Ltd. — Booth No. T4009

Guangzhou Unity Peak Company Ltd. was founded in 2009. It is a national high-tech enterprise, and a specialized and sophisticated enterprise of Guangdong Province, located in Guangzhou Nansha Economic Development Zone. Since its inception, the company has been adhering to the “innovation, quality, integrity” business philosophy, and the route of green sustainable development, and focusing on the research and development and production of textile digital printing coating ink. The product has passed the Zurich (Switzerland)-based Oeko-Tex Standard 100, Class 1 certification for 12 consecutive years. The company’s laboratory has been equipped with Malvern particle size meter, ink drop observer, nano-mill and other professional equipment; in 2023, the company’s laboratory passed the CNAS certification, marking that the independent laboratory of Unity Peak new materials has met the international recognized standards in hardware facilities, testing capabilities and management level.

“Macheng” coating ink is the outstanding research and development achievement of the independent laboratory, which is used to research and develop textile digital printing pigment ink to replace imported ones.

After more than ten years of research, the R & D team in the coating ink application program has accumulated rich experience and improved the performance of the coating ink products to make them more in line with the application in Chinese market. At present, Unity Peak has formed a product matrix integrating thermal transfer machine production, coating ink research and development, white ink hot stamping paper and non-sensitive labels, which is a multi-wheel drive to recreate a new textile future. In the future, the company will increase investment in research and development to ensure the stability of product quality and perspectiveness.

Zhuhai Colour Spring Digital Technology Co., LTD — Booth No. T3038a

Zhuhai Colour Spring Digital Technology Co., LTD is located in the beautiful city, Zhuhai. It is a comprehensive enterprise specializing in the research and development, production and sales of digital inkjet ink. Colour Spring adheres to “rigorous attitude, first-class products, first-class service”. Relying on the company’s strong strength and a group of senior R & D, production and sales team, the company has established a number of series of advanced ink product lines, which are sold both at home and abroad.

The company’s products include: textile direct spray coating ink, white ink hot stamping film transfer ink, direct spray white ink, pretreatment fluid, moisturizing fluid, desktop printer compatible cartridge ink, ink tank printer ink, etc.

Zhuhai Colour Spring Digital is committed to providing environmental friendly, economical and high quality inkjet ink products for the global digital printing users. We are willing to build a win-win cooperation with global merchants and counterparts to create a strategic partnership for the future.

Foshan Createtide Digital Tech Co., Ltd. — Booth No. T4033

Guoci Kanglitai has set up more than twenty offices at home, and formed a business layout in foreign markets with seven major sales regions such as China and Africa, Tulsa, India, Middle East and North Africa, Mumbai, Indo-Malaysia-Taiwan, Southeast Asia and Europe, etc. It not only sets up branch offices in India, Turkey and other countries, but also will establish branch offices in the core countries and regions of the world one after another. In Dongying, Shandong Province, Guoci Kanglitai has built a large ink production base with a production capacity that ranks among the top in the world, with dozens of modernized and intelligent production lines, and an annual production capacity of 30,000 tons of ink. With “digital printing materials” as the core business, the company has expanded from ceramic ink to textile ink and other digital printing fields, and in 2024, its subsidiary, Foshan Createtide, newly launched the “COREMAX” digital textile printing ink brand. At present, COREMAX is mainly committed to the development and application of textile hot stamping ink and reactive ink. In the future, COREMAX will provide customers with a complete set of textile digital printing solutions, including but not limited to textile inkjet ink, digital printing process, pre-processing and post-processing of textile fabrics and raw materials, as well as provide customers with efficient and professional pre-sales and after-sales technical services. COREMAX has established several modern intelligent production lines in Sanshui, Foshan, with an annual production capacity of 10,000 tons of textile ink.

Zhuhai Chungkao New Material Tech Co., Ltd. — Booth No. T4025a

We have a strong professional R&D team, professional production team, professional sales team and after-sales service team, advanced laboratory, testing equipment, instruments and so on. The R&D team has more than 15 years of experience in inkjet printing and digital printing industry, and always keeps leading in the industry in R&D technology.

Our complete equipment and facilities and excellent quality control throughout all stages of production enable us to ensure the overall satisfaction of our customers. We insist on technological innovation, efficient production, strict management process and excellent service to provide our customers with perfect inkjet and textile coating ink products and a series of solutions.

We have ISO9001 quality management system certificate. If you are interested in any of our products, or you would like to negotiate customized orders, please feel free to contact us. Welcome to be our win-win partner.

Dongguan Kingjet Printers Consumables Co., Ltd. — Booth No. T3017

Dongguan Kingjet Printers Consumables Co., Ltd., a high-tech enterprise, was founded in 2007 in the “world factory” city — Dongguan. With 10 years of history, we have been focusing on ink research and development, production and sales as a whole. The company’s main operating brands are “Printing color king (印彩王)” and “KINGJET”.

The company now employs more than 50 people, managers and researchers with bachelor’s degree or above, respectively, from the high polymer materials, fine chemicals and business administration and other professions. The company insists on adopting advanced ink production process and formula, together with a series of advanced production inspection and testing equipment such as the laser particle size distribution meter and QUV weathering tester from abroad, as well as printing test equipment for many types of printheads; adopting imported high-grade raw materials and using advanced large-scale specialized production equipment, which guarantees stable quality, high quality and environmental protection of the products.

Kingjet’s products are suitable for Epson, Canon, HP, Brother, Ricoh, Lexmark, Starfire, Kyocera, Konica, Samba and other printheads of wide-format printers, UV flatbed printers, scanning and Single-Pass industrial machines, desktop inkjet printers and other machines and equipment; they can be widely used in digital textile printing industry, advertising printing industry, digital printing industry, digital imaging industry, digital decoration industry, office printing industry, and food industry.

Products applied in the digital textile industry: textile printing heat sublimation ink, textile printing high-temperature dispersion direct spray ink, textile printing paint direct spray ink, textile printing reactive ink, textile printing acid ink, leather odorless weak solvent ink, offset hot stamping ink, cross stitch dye ink.

Products used in the digital imaging industry, digital decoration industry, advertising spray painting industry, and digital printing industry: oil-based weak solvent ink, solvent ink, water-based weak solvent ink, advertising banner ink, UV ink, wide-format pigment ink, pigment ink for coated paper, wide-format dye ink, water-based latex (LATEX) ink, image printing ink, medical film ink, film ink.

Products used in office printing and graphic digital printing industry: desktop printing dye ink, desktop printing thermal transfer ink, desktop printing pigment ink, HP page width printer pigment ink, EPSON page width printing pigment ink.

Products applied in the food industry: food-grade ink.

Products applied to the digital printing industry: POD newspaper and booklet digital printing pigment ink (newspaper and booklet digital printing machine, corrugated digital printing dye ink and pigment ink (EPSON i3200 printhead, HP 970/980/990 printhead corrugated digital printing machine), label digital printing pigment ink (EPSON i3200 label digital printing machine)

High quality is the root of enterprise survival; new products are the source of enterprise advancement and market development. The company’s products have been exported to Southeast Asia, South America, North America, Central Asia, South Asia, Africa, Europe, the Middle East and domestic provinces and cities. Company tenet: excellent quality, reasonable price, reputation first, customer first, integrity-based, continuous innovation.

Texca New Printing Materials Co., Ltd. — Booth No. T4026b

Texca New Printing Materials Co., Ltd. is a foreign (Canadian) joint venture, now located in High-tech Industrial Park, Daguan District, Anqing, Anhui Province, with a registered capital of 6.4 million U.S. dollars.

After the completion of the company, the printing ink project annual output reached 6,000 tons.The construction is completed in two phases, the first of which has an annual output of 3,000 tons of printing ink and 1,000 tons of digital printing ink.

Our company adheres to the development concept of “safe development, green environmental protection”, and will vigorously develop water-based ink, which is a nationally encouraged project, in the next five years. The company adheres to the enterprise spirit of “honesty, diligence, refinement, progress”, pursues the enterprise business philosophy of “quality is vital, service is essential”, and meets the market demand with first-class products and high-quality service.

Guangzhou SAVEN Technology Co., Ltd. — Booth No. 3001, 3002, 3003, 3004

With years of development experience, SAVEN has formed a good symbiotic relationship with many upstream material suppliers, and works closely with printer manufacturers and printhead manufacturers. 4200D, 4203D, 4203L, 4205 and fluorescent hot stamping inks are very popular, and the latest launches in 2022 are the breathable hot stamping ink 6040-1 and the permanent white anti-sublimation ink YB-12D. SAVEN would like to present the best products and development solutions to the customers.

Dongguan Shinycolor Tech Co., Ltd. — Booth No. T4004b

Eastern Tech Company — Booth No. T043C

Eastern Tech Company, founded in 1995, is a specialty ink & coatings manufacturer, headquartered in Milford, CT.��Our experienced team of chemists and production technicians have researched, developed, and produced the highest quality ink products for various industries in the United States and worldwide.

Eastern Tech works directly with OEM partners, developing solutions for market. We target Ink Innovations in everything that we do.

With a stream-lined production facility, Eastern Tech has a production capacity of over 500 million yuan CNY or more of ink annually.

With the evolving digital print industry, Eastern Tech has innovated piezoelectric-compatible inkjet inks.

Since 2008, Eastern Tech has manufactured water-based pigmented ink for inkjet printing directly onto t-shirts and other textiles. Our chemists have effectively improved color vibrancy, washability, and maintenance of use. Along with specially formulated pretreatment and cleaning solution products, Eastern Tech offers the complete solution for the Direct-To-Garment (DTG) industry.

Eastern Tech has invested millions in R&D, production, and quality control equipment to further ink innovations.

0 notes

Text

Printing Ink and Toner Market Future Trends: How AI, 3D Printing, and Eco-Friendly Solutions Shape Growth

The printing ink and toner market has witnessed significant transformations over the past few years. As businesses and consumers increasingly prioritize efficiency, sustainability, and innovation, the industry is evolving rapidly. From technological advancements to eco-friendly solutions, several trends are shaping the future of this market. In this article, we explore key future trends that will define the printing ink and toner industry in the coming years.

Growing Demand for Sustainable and Eco-Friendly Solutions Environmental concerns have pushed industries to adopt greener practices, and the printing sector is no exception. Governments worldwide are enforcing regulations to reduce carbon footprints, prompting manufacturers to develop sustainable alternatives. Bio-based inks, soy-based toners, and water-based formulations are gaining popularity as they minimize environmental impact without compromising quality. Recycling initiatives are also on the rise, with major players developing ink and toner cartridges that can be reused or refilled. The introduction of biodegradable packaging further strengthens the industry’s commitment to sustainability. These eco-friendly innovations are expected to shape purchasing decisions and market dynamics in the coming years.

Advancements in Digital Printing TechnologiesThe shift from traditional offset printing to digital printing continues to drive market growth. Digital printing offers faster turnaround times, cost efficiency, and superior print quality, making it a preferred choice for businesses. The demand for high-speed, on-demand, and customized printing solutions is fostering advancements in inkjet and laser printing technologies. Nanotechnology-based inks and toners are revolutionizing the industry by offering enhanced color vibrancy, improved adhesion, and longer-lasting prints. These cutting-edge technologies provide superior performance, making them ideal for applications in packaging, textiles, and commercial printing.

Rise of Smart and Functional Printing Smart printing solutions, including conductive inks and toners, are opening new possibilities across various industries. Conductive inks, which contain materials like silver, copper, and carbon, enable the printing of electronic circuits directly onto surfaces. This innovation is particularly beneficial for industries such as flexible electronics, smart packaging, and RFID tags.

Expansion of 3D Printing Applications3D printing is no longer limited to prototyping; it is now a game-changer in various industries, including automotive, aerospace, and healthcare. The development of specialized 3D printing inks and toners, including metal and ceramic-based formulations, is driving innovation in additive manufacturing. As companies invest in research and development, expect to see more sophisticated ink materials that improve print resolution, strength, and flexibility. The demand for 3D printing consumables is projected to rise, fueling the overall growth of the printing ink and toner market.

Shift Towards Cloud-Based and AI-Powered Printing Solutions The integration of cloud computing and artificial intelligence (AI) in printing solutions is enhancing efficiency and automation. Cloud-based printing allows remote access, reducing the need for physical infrastructure and enabling seamless operations. AI-driven printers optimize ink usage, predict maintenance requirements, and improve print quality by adjusting settings in real time. Conclusion The future of the printing ink and toner market is being shaped by sustainability, technological advancements, and evolving consumer preferences. The push for eco-friendly alternatives, digital and functional printing innovations, and the rise of 3D and smart printing solutions are driving significant changes. Businesses that embrace these trends will stay ahead of the curve, ensuring sustainable growth and market competitiveness. As the industry continues to evolve, one thing remains certain: innovation and adaptability will be key to long-term success.

0 notes

Text

Point of Sales (PoS) Printers Market: Drivers, Trends, and Future Growth Forecast

The point of sales (PoS) printers market has witnessed substantial growth over the past decade, driven by the expanding retail sector, the adoption of digital payments, and the increasing need for businesses to streamline their operations. PoS printers are essential devices that enable businesses to issue receipts, invoices, and transaction records to customers. These devices come in a variety of types, including thermal, impact, and inkjet printers, each serving specific business needs. As consumer demands evolve, so too does the technology driving PoS systems, with future growth forecasts suggesting the market will continue its upward trajectory.

Drivers of Market Growth

Several factors contribute to the growth of the PoS printers market, starting with the global expansion of retail and hospitality industries. As businesses increasingly focus on enhancing customer experiences and improving operational efficiency, PoS systems have become an integral part of their operations. PoS printers play a vital role by ensuring smooth transactions and seamless customer interactions, which are crucial in today’s competitive market.

The rise of cashless transactions also significantly influences the demand for PoS printers. With consumers opting for digital payments through credit cards, mobile wallets, and other digital methods, PoS printers must be capable of handling a wide variety of transaction formats. This has led to the adoption of advanced thermal and hybrid printers that can support multiple payment methods while delivering quick and accurate receipts.

Furthermore, the growing preference for cloud-based PoS solutions is driving innovation in the market. Cloud-based systems allow businesses to manage their PoS devices remotely, reducing the need for on-site maintenance and improving the flexibility of operations. This shift toward cloud computing enhances the integration of PoS printers into larger ecosystems, further increasing their utility and driving market demand.

Emerging Trends in the PoS Printers Market

The PoS printers market is undergoing significant transformation, with several key trends shaping its future. One of the most notable trends is the shift toward eco-friendly and sustainable solutions. With increasing environmental concerns, many businesses are adopting printers that use less paper and energy. Thermal PoS printers, for instance, do not require ink or toner cartridges, making them an environmentally friendly option. Additionally, many manufacturers are working toward reducing the carbon footprint of their products by utilizing recyclable materials and energy-efficient technologies.

Another emerging trend is the integration of advanced features such as mobile and wireless connectivity. As mobile payment solutions gain popularity, PoS printers are evolving to accommodate smartphones, tablets, and other mobile devices. This trend is especially prevalent in small businesses and retail environments, where mobility and flexibility are essential. By supporting wireless technologies like Bluetooth and Wi-Fi, PoS printers offer businesses the freedom to print receipts anywhere, enhancing customer convenience and streamlining operations.

The demand for multifunctional PoS printers is also on the rise. Businesses are increasingly seeking printers that can perform multiple tasks, such as printing receipts, coupons, and promotional materials. These all-in-one devices help businesses save space and reduce costs, making them an attractive option for retailers looking to optimize their PoS infrastructure.

Future Growth Forecast

Looking ahead, the PoS printers market is expected to continue its growth trajectory, with projections indicating a steady increase in demand over the next several years. According to market research, the market is poised to expand at a compound annual growth rate (CAGR) of around 6% through 2030. The proliferation of e-commerce, the increasing number of small and medium-sized businesses (SMBs), and advancements in PoS technology are all contributing factors to this optimistic outlook.

As businesses continue to invest in automation and digitalization, PoS printers will remain at the heart of retail and hospitality operations. The evolution of PoS systems will drive further innovation in printer technology, with features such as artificial intelligence (AI) and machine learning likely playing a more prominent role in the future. AI-driven PoS printers could help businesses better manage inventory, predict customer behavior, and personalize the customer experience.

In conclusion, the PoS printers market is experiencing strong growth, driven by the expansion of digital payment solutions, the rise of cloud-based technologies, and consumer demand for efficient, eco-friendly solutions. With technological advancements continuing to shape the industry, PoS printers are set to remain a critical component of modern business operations, ensuring the market’s sustained growth and innovation in the years to come.

Request Sample PDF Report : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NDQ1&RD=Point-of-Sales-(PoS)-Printers-Market-Report

#PointOfSalesPoSPrintersMarket#PointOfSalesPoSPrintersMarketTrends#PointOfSalesPoSPrintersMarketAnalysis#PointOfSalesPoSPrintersMarketGrowth#PointOfSalesPoSPrintersMarketInsights#PointOfSalesPoSPrintersMarketForecast

0 notes

Text

Direct To Garment Printing Market Growth: Key Trends Driving the Future of the Industry

The global direct to garment printing market size was estimated at USD 1.75 billion in 2023 and is expected to grow at a CAGR of 12.5% from 2024 to 2030. DTG has emerged as a transformative technology within the apparel industry. This process involves printing digital designs directly onto fabric using inkjet technology, eliminating the need for traditional methods such as screen printing or embroidery. The DTG market has witnessed substantial growth in recent years, driven by a confluence of factors including technological advancements, changing consumer preferences, and the rise of e-commerce.

The market encompasses a broad spectrum of activities, from the production of printing equipment to the creation and distribution of printed apparel. Key market segments include printer manufacturers, ink suppliers, pre-treatment chemical providers, and apparel brands and retailers. The market is further segmented based on print volume, application (apparel, accessories), and geographic region.

A primary trend driving the market is the increasing demand for personalized and customized apparel. Consumers are seeking unique products that reflect their styles and preferences. DTG printing enables mass customization, allowing for the creation of one-of-a-kind garments with intricate designs and high-resolution images. Moreover, the rise of e-commerce platforms has facilitated the growth of on-demand printing, where orders can be fulfilled quickly and efficiently. Another significant trend is the growing emphasis on sustainability and eco-friendliness. DTG printing offers several environmental benefits compared to traditional methods. It reduces water consumption, waste generation, and chemical usage. Additionally, the ability to print on demand minimizes overproduction and inventory waste.

Gather more insights about the market drivers, restrains and growth of the Direct To Garment Printing Market

Key Direct To Garment Printing Companies Insights

The market is characterized by a competitive landscape with a mix of established equipment manufacturers, ink suppliers, and emerging technology providers. Key players are focused on technological advancements, expanding product portfolios, and strengthening distribution networks. The market is witnessing increased competition due to the entry of new players and the growing popularity of digital printing technology. While established players hold a significant market share, smaller companies are gaining traction by offering specialized solutions and focusing on niche segments. The competitive dynamics are further influenced by factors such as pricing strategies, product differentiation, and after-sales services.

Recent Developments

• In February 2024, Ricoh introduced the RICOH Ri 4000 at the FESPA Global Print Expo 2024, a Direct to garment printer specifically designed for producing high-quality prints on 100% polyester garments. This new printer addresses a market need for cost-efficient, durable, and vibrant printing on polyester, a fabric known for its challenges in retaining print quality. The Ri 4000 features an innovative built-in enhancer that eliminates the need for separate pre-treatment, ensuring consistent print quality and efficiency.

• In May 2023, Seiko Epson Corporation introduced the SureColor F2200 at the FESPA event of 2023, a Direct to garment printer designed for low to medium-volume businesses. This new model enhances productivity by 25% compared to its predecessor, the F2100, while maintaining high print quality. It features Epson’s PrecisionCore MicroTFP printhead technology, enabling faster printing and improved data processing speeds.

Global Direct to Garment Printing Market Report Segmentation

The report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global direct to garment printing market based on operation, substrate, ink type, application, and region.

Operation Outlook (Revenue, USD Million, 2017 - 2030)

• Single Pass

• Multi Pass

Substrate Outlook (Revenue, USD Million, 2017 - 2030)

• Cotton

• Silk

• Polyester

• Others

Ink Type Outlook (Revenue, USD Million, 2017 - 2030)

• Sublimation

• Pigment

• Reactive

• Acid

• Others

Application Outlook (Revenue, USD Million, 2017 - 2030)

• Clothing/Apparel

• Home Decor

• Soft Signage

• Industrial

Regional Outlook (Revenue, USD Million, 2017 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

• Asia Pacific

o China

o India

o Japan

o Australia

o South Korea

• Latin America

o Brazil

• Middle East & Africa (MEA)

o United Arab Emirates (UAE)

o Kingdom of Saudi Arabia (KSA)

o South Africa

Order a free sample PDF of the Direct To Garment Printing Market Intelligence Study, published by Grand View Research.

#Direct To Garment Printing Market#Direct To Garment Printing Market Size#Direct To Garment Printing Market Share#Direct To Garment Printing Market Analysis#Direct To Garment Printing Market Growth

0 notes

Text

The Printing Transfer Paper Market is projected to grow from USD 12940.87 million in 2024 to an estimated USD 17439.83 million by 2032, with a compound annual growth rate (CAGR) of 3.8% from 2024 to 2032. The global printing transfer paper market has grown rapidly in recent years, driven by a surge in demand for personalized and customized printing applications across various industries, from textiles to ceramics. Printing transfer paper is a specialized medium used to transfer images, designs, or patterns onto diverse materials, leveraging techniques such as heat press or inkjet printing. With the market expanding steadily, let’s explore key trends, applications, growth factors, and challenges that define the landscape of printing transfer paper.

Browse the full report https://www.credenceresearch.com/report/printing-transfer-paper-market

Market Overview

The printing transfer paper market is segmented based on type, application, and region. Types of transfer paper typically include **sublimation transfer paper, inkjet transfer paper, laser transfer paper, and electrostatic transfer paper. Each type has unique properties, making it suitable for specific applications and substrates. For instance, sublimation transfer paper is widely used in the textile industry because it allows high-quality, vibrant prints to penetrate polyester fabrics. On the other hand, inkjet transfer paper is common in printing T-shirts, ceramics, and even home décor.

Key Market Drivers

1. Growing Demand for Customization and Personalization With an increased focus on personal branding and individual expression, the demand for customized apparel, accessories, and décor has significantly contributed to the growth of the transfer paper market. Consumers are increasingly seeking personalized products, from t-shirts and mugs to phone cases, driving the need for high-quality transfer paper that can deliver sharp, durable designs.

2. Technological Advancements in Printing Techniques Advancements in printing technologies, such as digital printing and sublimation printing, have made it easier to produce intricate and high-resolution designs. These advancements support efficient and quick production, catering to the demands of both high-volume industrial needs and small-scale businesses. Transfer papers, in turn, have evolved to support different printers, allowing smoother transitions across various media.

3. Sustainability Initiatives As environmental concerns become a priority, manufacturers are introducing **eco-friendly transfer papers** and **non-toxic inks**. Eco-friendly transfer papers, made from biodegradable or recyclable materials, are increasingly sought after, especially in regions where regulations and consumer preferences favor sustainable products. This shift toward greener practices has created opportunities for companies that can innovate in this direction.

Major Applications and End-Use Industries

1. Textile and Apparel The textile industry is the largest consumer of transfer paper, driven by the demand for customized clothing. Sublimation transfer paper, which is highly effective on polyester fabrics, has proven especially popular for athletic wear, corporate uniforms, and fashion apparel. Direct-to-garment (DTG) printing has also expanded the range of fabrics that can be customized.

2. Ceramics and Hard Surfaces Printing on ceramics, such as mugs, tiles, and plates, is another growing application area. Ceramic transfer papers, often using a heat transfer process, allow designs to be transferred permanently, creating a popular option for gift items and promotional products.

3. Home Décor and Interior Design Transfer paper is also finding applications in home décor, where custom-printed curtains, wallpapers, and cushion covers are becoming popular. As consumer tastes evolve, demand for these customized interior solutions is expected to grow, spurring further innovation in transfer paper types and applications.

Regional Market Insights

The Asia-Pacific region is currently the largest market for printing transfer paper, primarily due to the vast textile and apparel industries in countries like China, India, and Vietnam. The region benefits from an expansive manufacturing base, skilled labor, and low production costs, making it a preferred location for transfer paper production and utilization. North America and Europe also hold significant market shares, largely driven by technological advancements, higher adoption of digital printing, and consumer inclination toward personalized products.

Challenges and Market Constraints

Despite its growth, the printing transfer paper market faces certain challenges. **Environmental concerns** about non-biodegradable transfer papers and waste management issues in printing operations are increasingly impacting consumer choices and regulatory policies. Additionally, the **volatility in raw material prices** can influence production costs, thereby affecting profit margins for transfer paper manufacturers. There is also intense competition from direct digital printing, which bypasses the need for transfer paper in some applications, potentially affecting market demand in the long term.

Future Outlook

The printing transfer paper market is expected to continue its upward trajectory, driven by the rapid expansion of the customization trend across consumer goods and industrial sectors. Technological innovations will be critical for future growth, especially in improving print quality, reducing environmental impact, and enhancing compatibility with various printing techniques. Companies focusing on research and development to create versatile, eco-friendly, and high-quality transfer papers are well-positioned to capitalize on the market’s evolving demands.

As sustainability becomes a more prominent consideration, the future of the printing transfer paper market lies in balancing quality with eco-friendliness**. By innovating with sustainable materials and improving transfer technology, manufacturers have the opportunity to cater to an environmentally conscious consumer base while maintaining high standards of performance and print quality.

Segmentation:

By Material Type

Light Transfer Paper

Dark Transfer Paper

Specialty Paper

By Method of Printing

Laser

Inkjet

Lithography

Sublimation

Solvent Based

By Application

Textiles and Apparel

Ceramics and Hard Surfaces

Home Decor and Furniture

Promotional Products

By End-Use

Fashion and Apparel

Home Decor and Interior Design

Printing and Advertising

Consumer Goods

Others:

By Regional

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report https://www.credenceresearch.com/report/printing-transfer-paper-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Printing Inks Industry Dynamics, Growth Prospect and Consumption Analysis till 2028

The global printing inks market was valued at USD 19.2 billion in 2020, with growth projected at a compound annual growth rate (CAGR) of 2.8% from 2021 to 2028. This market is expected to see moderate growth over the forecast period, largely driven by demand from industries such as flexible packaging, commercial printing and publishing, and packaging labels. These sectors utilize printing inks for a wide range of applications, including product labels, advertising, and decorative packaging. The rise in demand for printed materials in packaging and changing consumer preferences are key factors that are sustaining demand for printing inks.

The properties of printing ink constituents including pigments, binders, solubilizers, and various additives allow for the precise creation of text, images, and designs. These characteristics contribute to the inks' widespread use in producing high-quality printed materials, meeting the needs of the packaging industry, commercial printers, and a growing number of consumers seeking enhanced packaging aesthetics. With advancements in ink formulations, printing inks are expected to maintain continuous demand.

Gather more insights about the market drivers, restrains and growth of the Printing Inks Market

As the printing inks market grows, consolidation among companies has become more common, especially in Western markets. Consolidation efforts, including mergers and acquisitions, aim to increase operational efficiency and create stronger relationships with suppliers and customers. This trend is partly due to limited opportunities for organic growth in mature markets, where large companies are looking to optimize resources and expand their market reach.

However, revenue growth in the printing inks market is likely to face challenges from downward pricing pressure. Due to intense competition among industry players, product prices have remained relatively stagnant, limiting revenue increases. Furthermore, strict regulatory frameworks, such as the Federal Food, Drug, and Cosmetic Act and regulations from the U.S. Food and Drug Administration (FDA), control the use of certain inorganic solvents and toxic metals in ink production. Compliance with these regulations can add to production costs, as well as limit the development and use of certain formulations, which may hinder market growth.

Printing ink manufacturers are responding by researching economical and safer alternatives for raw materials. For example, graphene, carbon, and modified celluloid are emerging as potential substitutes for traditional crude oil-based pigments and inorganic materials. Innovations in raw materials are central to reducing toxicity and costs, making it possible to meet regulatory standards while supporting sustainability goals. Additionally, advancements in printing technologies, such as inkjet and digital printing, are driving the market by allowing for faster, more efficient, and more versatile production processes, which align with the needs of modern industries.

Application Segmentation Insights:

The packaging and labels segment stands as the largest and fastest-growing application segment for printing inks, accounting for over 45% of the segment’s total revenue. This segment has experienced rapid growth over the past five years, driven by several factors, including the expanding middle class in emerging economies like India and Thailand. Changing consumer habits, such as a preference for convenient food packaging and a rise in online retailing supported by internet access, have further fueled demand for packaging solutions that rely on high-quality printing inks. Additionally, the push for biodegradable products has increased, with packaging companies seeking inks that align with sustainable practices and regulatory demands for eco-friendly packaging.

Other applications for printing inks include commercial printing and publishing, which has shown a declining trend in various regions. This decline is largely due to the rise of digitalization and the Internet of Things (IoT), which have reduced the demand for printed materials in traditional publishing. Simultaneously, growth has been observed in areas such as textile prints, ceramic printing, printed electronics, and folding cartons and corrugated cardboard within the packaging industry. These applications demonstrate varied trends based on regional markets. For instance, ceramic printing has gained significant traction in China due to the country’s robust production of ceramic tiles, while printed electronics is seeing growth in Thailand as the nation’s electronics industry expands.

In summary, the printing inks market is evolving, with growth fueled by consumer demand in packaging and driven by technological advancements in ink materials and printing processes. However, challenges from price competition and regulatory limitations continue to shape the market, directing companies toward consolidation, innovation, and the adoption of environmentally sustainable practices.

Order a free sample PDF of the Printing Inks Market Intelligence Study, published by Grand View Research.

#Printing Inks Industry#Printing Inks Market Research#Printing Inks Market Forecast#Printing Inks Market Overview

0 notes

Text

Printing Inks Market 2028 Revenue, Top Key Drivers by Manufacturers and Outlook

The global printing inks market was valued at USD 19.2 billion in 2020, with growth projected at a compound annual growth rate (CAGR) of 2.8% from 2021 to 2028. This market is expected to see moderate growth over the forecast period, largely driven by demand from industries such as flexible packaging, commercial printing and publishing, and packaging labels. These sectors utilize printing inks for a wide range of applications, including product labels, advertising, and decorative packaging. The rise in demand for printed materials in packaging and changing consumer preferences are key factors that are sustaining demand for printing inks.

The properties of printing ink constituents including pigments, binders, solubilizers, and various additives allow for the precise creation of text, images, and designs. These characteristics contribute to the inks' widespread use in producing high-quality printed materials, meeting the needs of the packaging industry, commercial printers, and a growing number of consumers seeking enhanced packaging aesthetics. With advancements in ink formulations, printing inks are expected to maintain continuous demand.

Gather more insights about the market drivers, restrains and growth of the Printing Inks Market

As the printing inks market grows, consolidation among companies has become more common, especially in Western markets. Consolidation efforts, including mergers and acquisitions, aim to increase operational efficiency and create stronger relationships with suppliers and customers. This trend is partly due to limited opportunities for organic growth in mature markets, where large companies are looking to optimize resources and expand their market reach.

However, revenue growth in the printing inks market is likely to face challenges from downward pricing pressure. Due to intense competition among industry players, product prices have remained relatively stagnant, limiting revenue increases. Furthermore, strict regulatory frameworks, such as the Federal Food, Drug, and Cosmetic Act and regulations from the U.S. Food and Drug Administration (FDA), control the use of certain inorganic solvents and toxic metals in ink production. Compliance with these regulations can add to production costs, as well as limit the development and use of certain formulations, which may hinder market growth.

Printing ink manufacturers are responding by researching economical and safer alternatives for raw materials. For example, graphene, carbon, and modified celluloid are emerging as potential substitutes for traditional crude oil-based pigments and inorganic materials. Innovations in raw materials are central to reducing toxicity and costs, making it possible to meet regulatory standards while supporting sustainability goals. Additionally, advancements in printing technologies, such as inkjet and digital printing, are driving the market by allowing for faster, more efficient, and more versatile production processes, which align with the needs of modern industries.

Application Segmentation Insights:

The packaging and labels segment stands as the largest and fastest-growing application segment for printing inks, accounting for over 45% of the segment’s total revenue. This segment has experienced rapid growth over the past five years, driven by several factors, including the expanding middle class in emerging economies like India and Thailand. Changing consumer habits, such as a preference for convenient food packaging and a rise in online retailing supported by internet access, have further fueled demand for packaging solutions that rely on high-quality printing inks. Additionally, the push for biodegradable products has increased, with packaging companies seeking inks that align with sustainable practices and regulatory demands for eco-friendly packaging.

Other applications for printing inks include commercial printing and publishing, which has shown a declining trend in various regions. This decline is largely due to the rise of digitalization and the Internet of Things (IoT), which have reduced the demand for printed materials in traditional publishing. Simultaneously, growth has been observed in areas such as textile prints, ceramic printing, printed electronics, and folding cartons and corrugated cardboard within the packaging industry. These applications demonstrate varied trends based on regional markets. For instance, ceramic printing has gained significant traction in China due to the country’s robust production of ceramic tiles, while printed electronics is seeing growth in Thailand as the nation’s electronics industry expands.

In summary, the printing inks market is evolving, with growth fueled by consumer demand in packaging and driven by technological advancements in ink materials and printing processes. However, challenges from price competition and regulatory limitations continue to shape the market, directing companies toward consolidation, innovation, and the adoption of environmentally sustainable practices.

Order a free sample PDF of the Printing Inks Market Intelligence Study, published by Grand View Research.

#Printing Inks Industry#Printing Inks Market Research#Printing Inks Market Forecast#Printing Inks Market Overview

0 notes

Text

The Printer Industry: Trends, Challenges, and Future Outlook

The printer industry has undergone significant transformations in recent years, influenced by technological advancements, changing consumer demands, and the rise of digital alternatives. This blog explores the current state of the printer market, key trends shaping its future, and the challenges it faces.

Current Market Overview