#Diaphragm Gas Meters

Explore tagged Tumblr posts

Text

From Accuracy to Innovation: The AIMS Controls Promise in Pressure Gauge Instrumentation

🧭 Introduction: Why Accuracy Alone Is No Longer Enough

In today’s industrial world, precision isn’t a luxury—it’s a necessity. But with evolving technologies and rising expectations across industries, accuracy alone is no longer enough. What businesses demand now is a balance of reliability, innovation, and smart integration.

This is where AIMS Controls emerges as a game-changer. From legacy industries like petrochemical and steel to modern sectors like pharmaceuticals and HVAC, AIMS Controls has become synonymous with elevated pressure gauge instrumentation—not just measuring pressure, but defining it.

⚙️ AIMS Controls: A Legacy Built on Precision

Founded under the registered trademark of PI Controls Instruments Pvt. Ltd. in 2018, AIMS Controls combines 20+ years of industry expertise to deliver high-performance measuring and control solutions. Their focus? Designing next-gen instruments like the pressure gauge, which consistently outperforms in terms of accuracy, durability, and application versatility.

With a 3,500 sq. ft. state-of-the-art production unit, AIMS Controls crafts pressure gauges that meet the most stringent national and international standards, including IS, ASME, JIS, and EN certifications.

🌡 Pressure Gauge: The Unsung Hero of Industrial Control

A pressure gauge is more than a mechanical meter—it's the pulse monitor of an entire system. Whether it's a chemical plant reactor, a boiler in a food processing facility, or a hydraulic press in a steel mill, the pressure gauge ensures safety, efficiency, and performance.

At AIMS Controls, pressure gauges are not generic tools—they're tailored instruments. Every component, from the bourdon tube to the dial face, is engineered with maximum reliability in mind.

🔍 What Sets AIMS Controls’ Pressure Gauges Apart?

🧪 1. Precision Calibration for Flawless Accuracy

Each pressure gauge undergoes rigorous testing and calibration to ensure it functions at peak precision—often within a 0.5% accuracy margin. These gauges are ideal for critical processes where even the slightest pressure deviation could lead to system failure or safety hazards.

🔩 2. Custom Build Capabilities

No two industries are the same, and neither are their challenges. AIMS Controls offers a wide range of pressure gauge types:

Glycerin-filled gauges for vibration-prone environments

SS316 gauges for corrosive conditions

Low-pressure capsule gauges

Sealed diaphragm-type gauges for sanitary processes

This customization ability allows businesses to meet sector-specific safety standards and operational goals with confidence.

🛡 3. Built to Last: Materials That Matter

Durability isn't an afterthought—it’s a design mandate. AIMS uses high-grade stainless steel, brass, and reinforced glass to ensure their pressure gauges withstand:

High-pressure environments

Extreme temperatures

Aggressive media exposure

Mechanical vibration and fatigue

This means fewer replacements, reduced maintenance costs, and longer operational life cycles.

🔬 Innovation That Redefines Pressure Monitoring

In a landscape where industries are shifting toward automation and smart systems, AIMS Controls stands ahead of the curve by integrating IoT and remote monitoring features into their instrumentation lineup.

From digital pressure gauges with backlit displays to electrical contact gauges that trigger alarms and system responses—innovation is embedded in every product line.

AIMS Controls is not just keeping up with Industry 4.0—it’s enabling it.

💡 Real-World Application: Where Pressure Gauge Meets Performance

Let’s look at a few examples of how AIMS Controls' pressure gauges are transforming industrial workflows:

🏭 Oil & Gas

Installed diaphragm-sealed gauges to manage corrosive crude oil environments

Enabled 24/7 pressure monitoring through signal-integrated gauges

Prevented overpressure events by integrating with SCADA systems

🧴 Pharma

Used tri-clover hygienic connections for sterile cleanrooms

Provided 0.25% accuracy pressure gauges for sensitive batch processes

Calibrated gauges with full traceability documentation for audits

🧊 HVAC & Refrigeration

Delivered dual pressure gauges with color-coded dials

Ensured pressure drop monitoring in chillers for energy optimization

Supplied frost-resistant gauges for sub-zero conditions

In every case, AIMS Controls didn't just deliver a product—they delivered process assurance and operational peace of mind.

🔧 A Value-Driven Approach: From Manufacturing to Maintenance

AIMS Controls provides end-to-end support to its customers:

Free Consultation to select the right pressure gauge

Tailor-made configurations per industrial specs

Calibration and repair services to extend instrument life

Engineering documentation including data sheets, certificates, and compliance documentation

The result? A 360° experience that maximizes uptime and minimizes effort.

📊 Competitive Edge: Why Clients Prefer AIMS Controls Over Global Brands

While global instrumentation brands often dominate the market, AIMS Controls has quickly become a top alternative—and in many cases, the preferred brand in India and abroad.

Why?

🌍 Global-Standard Quality, Local Prices

📦 Shorter Delivery Times due to in-house manufacturing

🛠 Greater Flexibility in custom designs

🤝 More Personalized Support

500+ companies already trust AIMS Controls. That number is growing—not by chance, but by consistent value delivery.

🚀 Future-Ready Vision: Where Is AIMS Controls Headed Next?

The company’s mission is clear—to become the premier supplier of measuring and control instruments, and the pressure gauge is central to this ambition.

Their R&D division is currently exploring:

Smart pressure gauges with wireless connectivity

AI-powered data analytics for predictive maintenance

Cloud dashboards for multi-location monitoring

The goal? To turn every pressure reading into a data-driven decision.

✅ Conclusion: Trust Built on Every Turn of the Needle

From concept to calibration, AIMS Controls redefines what a pressure gauge can do for modern industry. More than a measurement device, it becomes a symbol of trust, precision, and continuous innovation.

So, if your industrial operation depends on reliable pressure measurement—and whose doesn’t?—then it’s time to partner with a company that delivers more than just accuracy.

It’s time to experience the innovation, reliability, and commitment of AIMS Controls—the true pioneers in pressure gauge instrumentation.

0 notes

Text

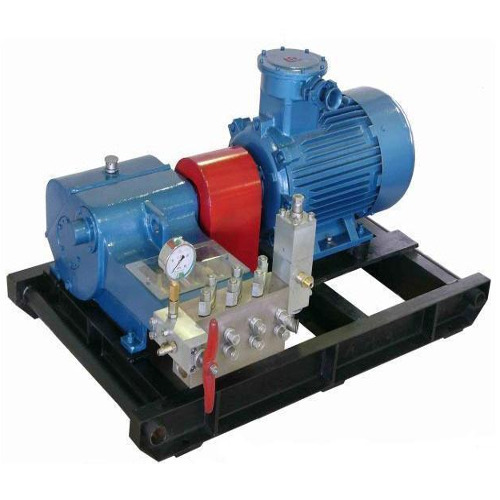

Reciprocating Pump Market Growth Driven by Expanding Industrial Applications and Rising Energy Efficiency Demands

Introduction

The reciprocating pump market has witnessed significant growth over the past decade, driven by increasing demand from industries such as oil and gas, water treatment, chemical processing, and manufacturing. These pumps, known for their ability to handle high-pressure applications with precision, are widely used for fluid transfer and metering purposes. As industries continue to seek efficient and reliable pumping solutions, the reciprocating pump market is poised for steady expansion in the coming years.

What is a Reciprocating Pump?

A reciprocating pump is a type of positive displacement pump that uses a piston, plunger, or diaphragm to create a back-and-forth (reciprocating) motion, resulting in fluid displacement. The pump's working mechanism allows it to deliver a consistent flow rate, making it highly effective for applications requiring precision and control. Reciprocating pumps are commonly used in situations where the fluid viscosity, pressure, or flow rate needs to be maintained with accuracy.

Market Size and Growth Trends

The global reciprocating pump market was valued at approximately $7.5 billion in 2024 and is expected to grow at a compound annual growth rate (CAGR) of around 5-7% over the next five years. This growth is primarily fueled by rising industrialization, increasing energy demand, and the expansion of water treatment and desalination plants worldwide.

The oil and gas sector continues to be a dominant end-user of reciprocating pumps, particularly for applications such as crude oil transportation, enhanced oil recovery (EOR), and hydraulic fracturing. Meanwhile, the pharmaceutical and chemical industries are also contributing to market growth due to the need for precise fluid handling and metering in production processes.

Key Market Drivers

Increasing Demand from Oil and Gas Industry

The oil and gas sector remains a primary driver of the reciprocating pump market. With the resurgence of exploration activities, the need for high-pressure pumps capable of handling crude oil, natural gas, and other hydrocarbons is growing.

The use of reciprocating pumps in hydraulic fracturing (fracking) and well stimulation has surged, particularly in regions such as North America and the Middle East.

Growing Water Treatment and Desalination Projects

The expanding global population and water scarcity issues have led to increased investments in water treatment and desalination plants.

Reciprocating pumps play a critical role in these facilities by ensuring high-pressure fluid transfer, particularly in reverse osmosis systems.

Rising Industrial Automation

The trend toward industrial automation is driving demand for precision pumps with advanced monitoring and control features.

Modern reciprocating pumps equipped with IoT-enabled sensors offer real-time performance data, enabling predictive maintenance and improving operational efficiency.

Technological Advancements

Advancements in pump materials and designs, including the use of corrosion-resistant alloys and enhanced sealing technologies, are boosting the durability and performance of reciprocating pumps.

Smart pump systems with remote monitoring capabilities are becoming increasingly popular, particularly in large-scale industrial applications.

Challenges in the Market

Despite the promising growth, the reciprocating pump market faces several challenges:

High Maintenance Costs: Reciprocating pumps are prone to wear and tear due to their moving parts, resulting in higher maintenance costs. This can deter small and medium-sized enterprises (SMEs) from investing in these pumps.

Energy Consumption: Although efficient, reciprocating pumps consume considerable energy, particularly in high-pressure applications. Energy efficiency regulations could pose challenges for manufacturers.

Competition from Alternative Pump Technologies: Centrifugal pumps and other advanced pumping technologies are becoming more efficient and cost-effective, posing a potential threat to reciprocating pump market share.

Regional Analysis

North America

North America is one of the leading markets for reciprocating pumps, largely driven by the extensive oil and gas operations in the United States and Canada.

The increasing number of shale gas projects and hydraulic fracturing activities is driving the demand for high-pressure pumps.

Europe

The European market is characterized by its focus on industrial automation and sustainability initiatives.

Countries like Germany, the UK, and France are investing heavily in wastewater treatment plants, boosting demand for reciprocating pumps in the region.

Asia-Pacific

The Asia-Pacific region is experiencing rapid industrialization and urbanization, resulting in increased demand for reciprocating pumps in water treatment, chemical processing, and power generation sectors.

China and India are leading markets due to their expanding manufacturing and infrastructure sectors.

Middle East and Africa

The Middle East, with its strong oil and gas sector, continues to be a major market for reciprocating pumps.

Investments in desalination projects, particularly in Saudi Arabia and the UAE, are further driving market growth.

Market Segmentation

The reciprocating pump market can be segmented based on the following criteria:

Type:

Piston pumps

Plunger pumps

Diaphragm pumps

End-User Industry:

Oil and Gas

Water Treatment

Chemical Processing

Pharmaceuticals

Power Generation

Application:

High-pressure cleaning

Fluid metering

Chemical injection

Desalination

Future Outlook

The reciprocating pump market is expected to continue its growth trajectory, driven by ongoing industrialization, infrastructure development, and the increasing need for reliable pumping solutions. Manufacturers are likely to focus on energy-efficient designs and smart pump systems to meet evolving industry demands.

The integration of predictive maintenance features and the use of eco-friendly materials will also become key differentiators. Furthermore, the demand for custom-engineered pumps tailored to specific applications is expected to rise, particularly in specialized sectors such as pharmaceuticals and food processing.

Conclusion

The reciprocating pump market is set for steady growth, fueled by its extensive application across various industries. While challenges such as high maintenance costs and competition from alternative technologies persist, ongoing technological advancements and the rising demand for efficient fluid transfer solutions will continue to drive market expansion. As industries increasingly embrace automation and energy efficiency, the reciprocating pump sector is expected to witness continuous innovation and evolution.

0 notes

Text

Balancing Valve Price, Types & Working Principle – Best Supplier in Delhi

In HVAC systems, hydronic networks, and industrial pipelines, balancing valves are essential for ensuring equal flow distribution and energy efficiency. These valves are designed to maintain hydraulic balance by regulating fluid flow in heating, cooling, and water supply systems.

As a trusted balancing valve manufacturer and supplier in Delhi, Udhhyog offers a complete range of manual, automatic, and advanced balancing valves for industrial, commercial, and residential use.

This guide covers the types of balancing valves, their working principles, flow diagrams, and an updated price list to help you choose the right solution.

What is a Balancing Valve?

A balancing valve is a control valve used to distribute flow evenly across branches of a hydraulic system. By doing so, it maintains consistent temperature, pressure, and energy usage throughout the system.

It is commonly used in:

Chilled water systems

Heating and cooling loops

Hot water recirculation systems

District cooling networks

Balancing Valve Types

🔹 Manual Balancing Valve

Requires manual adjustment using a handwheel.

Ideal for simple or fixed-load systems.

🔹 Automatic Balancing Valve

Self-adjusts based on pressure fluctuations.

Maintains constant flow without manual intervention.

🔹 Pressure Independent Balancing Valve (PIBV)

Combines control and balancing in one unit.

Useful in dynamic systems with load variation.

🔹 Advanced Digital Balancing Valve

Features sensors, actuators, and flow meters.

Provides remote control and diagnostics.

Balancing Valve Diagram & Symbol

A balancing valve diagram illustrates its:

Inlet and outlet ports

Adjustable handle or actuator

Flow measurement points

Symbol:

The balancing valve symbol in engineering drawings includes:

A square box with two diagonal lines

Directional arrows to indicate flow

These symbols and diagrams are essential for system planning, installation, and maintenance.

Automatic Balancing Valve – Working Principle

The automatic balancing valve contains a diaphragm and spring that respond to pressure changes. When differential pressure increases, the diaphragm restricts flow. When pressure drops, it opens to allow more flow.

This ensures:

Constant flow rate regardless of upstream or downstream changes

Improved energy efficiency

Reduced maintenance

Related Valve Types

🔹 Balanced Bellows Safety Relief Valve

Uses bellows to isolate the spring chamber from back pressure.

Ideal for boilers, steam, and gas pipelines.

🔹 Balanced Plug Valve

Plug is pressure-balanced to reduce torque.

Used in chemical plants and high-pressure pipelines.

🔹 Balanced Safety Relief Valve

Maintains accurate opening pressure even with variable backpressure.

Common in compressor discharge lines and steam systems.

Advanced Balancing Valve Flow Chart

An advanced balancing valve flow chart includes:

Design flow rate

Presetting steps

Flow measurement using differential pressure

Adjustments for optimum flow

This is used in digital models and ensures accurate commissioning of HVAC systems.

Balancing Valve Price List – Delhi Market

Valve TypeSize (mm)Price Range (INR)Manual Balancing Valve15–50₹850 – ₹2,200Automatic Balancing Valve20–80₹2,500 – ₹6,500Pressure Independent Valve25–100₹4,500 – ₹10,000Digital Balancing Valve25–150₹15,000 – ₹35,000Balanced Bellows Relief Valve25–100₹6,000 – ₹15,000Balanced Plug Valve25–150₹8,000 – ₹18,000

📌 Note: Prices may vary based on brand, material (bronze, brass, SS), and pressure class.

Applications of Balancing Valves

🏢 HVAC systems in buildings

🏭 Industrial fluid and steam systems

🏥 Hospitals and laboratories

🏬 Shopping malls and multiplexes

🏠 High-rise residential projects

Why Choose Udhhyog – Best Balancing Valve Supplier in Delhi

🛠️ Complete Range of Solutions

From basic manual valves to advanced digital systems, we have everything.

🧪 Tested & Certified Products

All valves are pressure-tested and compliant with IS/ISO standards.

📦 Quick Availability & Bulk Supply

We deliver across Delhi, Haryana, Punjab, Uttar Pradesh, Jammu & Kashmir.

💬 Expert Support

We help you with valve selection, system design, and commissioning.

💰 Affordable Pricing

Get the best prices on high-quality balancing valves, direct from manufacturer.

Conclusion

Balancing valves are vital for maintaining energy efficiency and uniform performance in modern fluid systems. From manual to automatic, Udhhyog manufactures and supplies all types of valves to meet your specific requirements.

With a wide stock range, competitive pricing, and expert assistance, Udhhyog is your go-to balancing valve supplier in Delhi.

Contact Udhhyog Today

📞 Call or Visit Udhhyog for customized quotes, technical catalogs, and delivery information.

#BalancingValve#AutomaticBalancingValve#PressureIndependentValve#ValveSupplierDelhi#Udhhyog#HVACBalancing#IndustrialValves#BellowsReliefValve#BalancedPlugValve#BalancingValveDiagram

0 notes

Text

Balancing Valve Price, Types & Working Principle – Best Supplier in Delhi

In HVAC systems, hydronic networks, and industrial pipelines, balancing valves are essential for ensuring equal flow distribution and energy efficiency. These valves are designed to maintain hydraulic balance by regulating fluid flow in heating, cooling, and water supply systems.

As a trusted balancing valve manufacturer and supplier in Delhi, Udhhyog offers a complete range of manual, automatic, and advanced balancing valves for industrial, commercial, and residential use.

This guide covers the types of balancing valves, their working principles, flow diagrams, and an updated price list to help you choose the right solution.

What is a Balancing Valve?

A balancing valve is a control valve used to distribute flow evenly across branches of a hydraulic system. By doing so, it maintains consistent temperature, pressure, and energy usage throughout the system.

It is commonly used in:

Chilled water systems

Heating and cooling loops

Hot water recirculation systems

District cooling networks

Balancing Valve Types

🔹 Manual Balancing Valve

Requires manual adjustment using a handwheel.

Ideal for simple or fixed-load systems.

🔹 Automatic Balancing Valve

Self-adjusts based on pressure fluctuations.

Maintains constant flow without manual intervention.

🔹 Pressure Independent Balancing Valve (PIBV)

Combines control and balancing in one unit.

Useful in dynamic systems with load variation.

🔹 Advanced Digital Balancing Valve

Features sensors, actuators, and flow meters.

Provides remote control and diagnostics.

Balancing Valve Diagram & Symbol

A balancing valve diagram illustrates its:

Inlet and outlet ports

Adjustable handle or actuator

Flow measurement points

Symbol:

The balancing valve symbol in engineering drawings includes:

A square box with two diagonal lines

Directional arrows to indicate flow

These symbols and diagrams are essential for system planning, installation, and maintenance.

Automatic Balancing Valve – Working Principle

The automatic balancing valve contains a diaphragm and spring that respond to pressure changes. When differential pressure increases, the diaphragm restricts flow. When pressure drops, it opens to allow more flow.

This ensures:

Constant flow rate regardless of upstream or downstream changes

Improved energy efficiency

Reduced maintenance

Related Valve Types

🔹 Balanced Bellows Safety Relief Valve

Uses bellows to isolate the spring chamber from back pressure.

Ideal for boilers, steam, and gas pipelines.

🔹 Balanced Plug Valve

Plug is pressure-balanced to reduce torque.

Used in chemical plants and high-pressure pipelines.

🔹 Balanced Safety Relief Valve

Maintains accurate opening pressure even with variable backpressure.

Common in compressor discharge lines and steam systems.

Advanced Balancing Valve Flow Chart

An advanced balancing valve flow chart includes:

Design flow rate

Presetting steps

Flow measurement using differential pressure

Adjustments for optimum flow

This is used in digital models and ensures accurate commissioning of HVAC systems.

Balancing Valve Price List – Delhi Market

Valve TypeSize (mm)Price Range (INR)Manual Balancing Valve15–50₹850 – ₹2,200Automatic Balancing Valve20–80₹2,500 – ₹6,500Pressure Independent Valve25–100₹4,500 – ₹10,000Digital Balancing Valve25–150₹15,000 – ₹35,000Balanced Bellows Relief Valve25–100₹6,000 – ₹15,000Balanced Plug Valve25–150₹8,000 – ₹18,000

📌 Note: Prices may vary based on brand, material (bronze, brass, SS), and pressure class.

Applications of Balancing Valves

🏢 HVAC systems in buildings

🏭 Industrial fluid and steam systems

🏥 Hospitals and laboratories

🏬 Shopping malls and multiplexes

🏠 High-rise residential projects

Why Choose Udhhyog – Best Balancing Valve Supplier in Delhi

🛠️ Complete Range of Solutions

From basic manual valves to advanced digital systems, we have everything.

🧪 Tested & Certified Products

All valves are pressure-tested and compliant with IS/ISO standards.

📦 Quick Availability & Bulk Supply

We deliver across Delhi, Haryana, Punjab, Uttar Pradesh, Jammu & Kashmir.

💬 Expert Support

We help you with valve selection, system design, and commissioning.

💰 Affordable Pricing

Get the best prices on high-quality balancing valves, direct from manufacturer.

Conclusion

Balancing valves are vital for maintaining energy efficiency and uniform performance in modern fluid systems. From manual to automatic, Udhhyog manufactures and supplies all types of valves to meet your specific requirements.

With a wide stock range, competitive pricing, and expert assistance, Udhhyog is your go-to balancing valve supplier in Delhi.

Contact Udhhyog Today

📞 Call or Visit Udhhyog for customized quotes, technical catalogs, and delivery information.

#BalancingValve#AutomaticBalancingValve#PressureIndependentValve#ValveSupplierDelhi#Udhhyog#HVACBalancing#IndustrialValves#BellowsReliefValve#BalancedPlugValve#BalancingValveDiagram

0 notes

Text

Balancing Valve Price, Types & Working Principle – Best Supplier in Delhi

In HVAC systems, hydronic networks, and industrial pipelines, balancing valves are essential for ensuring equal flow distribution and energy efficiency. These valves are designed to maintain hydraulic balance by regulating fluid flow in heating, cooling, and water supply systems.

As a trusted balancing valve manufacturer and supplier in Delhi, Udhhyog offers a complete range of manual, automatic, and advanced balancing valves for industrial, commercial, and residential use.

This guide covers the types of balancing valves, their working principles, flow diagrams, and an updated price list to help you choose the right solution.

What is a Balancing Valve?

A balancing valve is a control valve used to distribute flow evenly across branches of a hydraulic system. By doing so, it maintains consistent temperature, pressure, and energy usage throughout the system.

It is commonly used in:

Chilled water systems

Heating and cooling loops

Hot water recirculation systems

District cooling networks

Balancing Valve Types

🔹 Manual Balancing Valve

Requires manual adjustment using a handwheel.

Ideal for simple or fixed-load systems.

🔹 Automatic Balancing Valve

Self-adjusts based on pressure fluctuations.

Maintains constant flow without manual intervention.

🔹 Pressure Independent Balancing Valve (PIBV)

Combines control and balancing in one unit.

Useful in dynamic systems with load variation.

🔹 Advanced Digital Balancing Valve

Features sensors, actuators, and flow meters.

Provides remote control and diagnostics.

Balancing Valve Diagram & Symbol

A balancing valve diagram illustrates its:

Inlet and outlet ports

Adjustable handle or actuator

Flow measurement points

Symbol:

The balancing valve symbol in engineering drawings includes:

A square box with two diagonal lines

Directional arrows to indicate flow

These symbols and diagrams are essential for system planning, installation, and maintenance.

Automatic Balancing Valve – Working Principle

The automatic balancing valve contains a diaphragm and spring that respond to pressure changes. When differential pressure increases, the diaphragm restricts flow. When pressure drops, it opens to allow more flow.

This ensures:

Constant flow rate regardless of upstream or downstream changes

Improved energy efficiency

Reduced maintenance

Related Valve Types

🔹 Balanced Bellows Safety Relief Valve

Uses bellows to isolate the spring chamber from back pressure.

Ideal for boilers, steam, and gas pipelines.

🔹 Balanced Plug Valve

Plug is pressure-balanced to reduce torque.

Used in chemical plants and high-pressure pipelines.

🔹 Balanced Safety Relief Valve

Maintains accurate opening pressure even with variable backpressure.

Common in compressor discharge lines and steam systems.

Advanced Balancing Valve Flow Chart

An advanced balancing valve flow chart includes:

Design flow rate

Presetting steps

Flow measurement using differential pressure

Adjustments for optimum flow

This is used in digital models and ensures accurate commissioning of HVAC systems.

Balancing Valve Price List – Delhi Market

Valve TypeSize (mm)Price Range (INR)Manual Balancing Valve15–50₹850 – ₹2,200Automatic Balancing Valve20–80₹2,500 – ₹6,500Pressure Independent Valve25–100₹4,500 – ₹10,000Digital Balancing Valve25–150₹15,000 – ₹35,000Balanced Bellows Relief Valve25–100₹6,000 – ₹15,000Balanced Plug Valve25–150₹8,000 – ₹18,000

📌 Note: Prices may vary based on brand, material (bronze, brass, SS), and pressure class.

Applications of Balancing Valves

🏢 HVAC systems in buildings

🏭 Industrial fluid and steam systems

🏥 Hospitals and laboratories

🏬 Shopping malls and multiplexes

🏠 High-rise residential projects

Why Choose Udhhyog – Best Balancing Valve Supplier in Delhi

🛠️ Complete Range of Solutions

From basic manual valves to advanced digital systems, we have everything.

🧪 Tested & Certified Products

All valves are pressure-tested and compliant with IS/ISO standards.

📦 Quick Availability & Bulk Supply

We deliver across Delhi, Haryana, Punjab, Uttar Pradesh, Jammu & Kashmir.

💬 Expert Support

We help you with valve selection, system design, and commissioning.

💰 Affordable Pricing

Get the best prices on high-quality balancing valves, direct from manufacturer.

Conclusion

Balancing valves are vital for maintaining energy efficiency and uniform performance in modern fluid systems. From manual to automatic, Udhhyog manufactures and supplies all types of valves to meet your specific requirements.

With a wide stock range, competitive pricing, and expert assistance, Udhhyog is your go-to balancing valve supplier in Delhi.

Contact Udhhyog Today

📞 Call or Visit Udhhyog for customized quotes, technical catalogs, and delivery information.

#BalancingValve#AutomaticBalancingValve#PressureIndependentValve#ValveSupplierDelhi#Udhhyog#HVACBalancing#IndustrialValves#BellowsReliefValve#BalancedPlugValve#BalancingValveDiagram

0 notes

Text

0 notes

Text

IVD Liquid Waste Handling Pump in Clinical Diagnostics: Technical Analysis and Systematic Advantages

In the field of in vitro diagnostics (IVD), the reliability of waste liquid treatment systems directly impacts the accuracy of test results and the safety of equipment operation. Facing complex media containing biological residues, corrosive reagents, and gas-liquid mixtures, traditional pumps often encounter challenges such as leakage, clogging, and inadequate lifespan. TOPSFLO mini diaphragm pump, through innovative design and material engineering breakthroughs, provides a highly reliable solution for IVD waste liquid treatment.

Technical Challenges and Demand Analysis of IVD Waste Liquid Treatment Systems

Waste Liquid Characteristics and Treatment Process

The waste liquid generated from IVD testing contains the following high-risk components:

Biological contaminants: Blood cell residues, protein clots, etc. (particle size ≤ 2mm)

Chemical corrosive media: Strong acids (pH 1), strong alkalis (pH 14), and disinfectants such as sodium hypochlorite

Gas-liquid mixed phase: Foam content as high as 30%, prone to cavitation

The treatment process must meet stringent requirements

Safe transfer: Physical isolation throughout the process to prevent cross-contamination

Stable discharge: Capable of withstanding long-duration continuous operation and extreme medium corrosion

Technical Innovations of TOPSFLO Miniatuere Diaphragm Pump

Physical isolation mechanism based on volumetric transfer

The diaphragm’s reciprocating movement changes the volume of the cavity, achieving absolute medium isolation:

Suction phase: The diaphragm moves back, expanding the cavity volume, creating negative pressure to open the intake valve

Discharge phase: The diaphragm moves forward, compressing the cavity, creating positive pressure to close the intake valve and open the outlet valve

Key subsystem collaborative design

Elastic diaphragm: Made of medical-grade polymer materials (such as PTFE, fluororubber), resistant to chemical corrosion and has a long lifespan

One-way valve group: Precisely designed valve plates ensure unidirectional flow and prevent backflow contamination

Drive mechanism: DC brushless or brushed motors provide stable power, supporting precise flow adjustment

Cavity structure: Smooth flow paths without dead spots, reducing residue and making cleaning and disinfection easier

Engineering Optimization and Verification for IVD Applications

Extreme medium tolerance verification

Environmental adaptability enhanced design

High-altitude operation: Using special materials and a torque-enhanced motor, pressure build-up time at 3,000 meters is reduced by 44% (from 5.7s to 3.2s)

Wide temperature stability: Flow deviation < 2% in the temperature range of 10℃ to 50℃

Long pipeline adaptation: Supports 8m lift and dynamic load adjustment

Full lifecycle reliability assurance

Diaphragm lifespan: 20 million fatigue tests (equivalent to 10 years of use)

Maintenance cycle: 10,000 hours of maintenance-free design, downtime for cleaning < 5 minutes

Conclusion

Through multiple technical innovations—material engineering breakthroughs (medical-grade PTFE composite diaphragm), intelligent control algorithms, and system integration design (modular flow channels and buffering structures)—TOPSFLO diaphragm pumps systematically solve the cavitation, corrosion, and biological contamination problems in IVD waste liquid treatment. Clinically validated, its overall performance reaches international leading levels. Coupled with localized rapid response services (48-hour spare parts supply), it is driving the domestic substitution process of core components in medical equipment.

Wanna to get custom pump service? Feel free to contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Visit our Web: https://www.topstec.com/ | http://www.topsflo.com/

0 notes

Text

5 Surprising Benefits of Turbine Gas Meters You Need to Know

In industries where precision and reliability are critical, turbine gas meters have become a cornerstone of efficient gas flow measurement. These devices, which use a rotating turbine to measure the flow of gas, are widely used in sectors like oil and gas, utilities, and manufacturing.

But beyond their basic functionality, turbine gas meters offer a host of surprising benefits that can transform your operations. Here are five advantages you might not have considered.

Discover the perfect turbine gas meter for your needs. Contact us today for a free consultation!

Unmatched Accuracy in Flow Measurement

When it comes to measuring gas flow, accuracy is non negotiable. Turbine gas meters are renowned for their precision, even at low flow rates. This makes them ideal for applications where even a minor error can lead to significant financial losses or operational inefficiencies. For example, in the oil and gas industry, turbine gas meters have reduced measurement errors by up to 99%, saving companies millions annually.

Accurate measurements also ensure fair billing, regulatory compliance, and optimized processes, making these meters a must-have for any industry that relies on precise gas flow data.

Built to Last: Durability in Harsh Environments

Turbine gas meters are designed to withstand extreme conditions, including high pressure, corrosive gases, and fluctuating temperatures. Unlike other meters that may falter in harsh environments, turbine gas meters continue to perform reliably.

This durability translates to lower maintenance costs and fewer replacements, saving businesses both time and money. For instance, while diaphragm meters may require frequent repairs, turbine gas meters offer a longer lifespan with minimal upkeep, making them a cost-effective choice for demanding applications.

Energy Efficiency and Sustainability

In today’s world, sustainability is a top priority, and turbine gas meters are playing a key role in helping businesses reduce their environmental impact. These devices help minimize energy waste by detecting leaks and optimizing gas usage. For example, a utility company reduced its gas leaks by 30% after switching to turbine gas meters, saving both energy and costs.

By lowering gas loss, businesses can also reduce their carbon footprint and contribute to global sustainability goals, making turbine gas meters an eco-friendly choice.

Smart Technology Integration

Modern turbine gas meters are more than just mechanical devices—they’re smart. With IoT integration, these meters can provide real-time data, remote monitoring, and predictive maintenance alerts. This not only improves operational efficiency but also enables data-driven decision making.

For instance, a manufacturing plant used smart turbine gas meters to predict maintenance needs, reducing downtime by 20%. By leveraging smart technology, businesses can stay ahead of the curve and optimize their operations like never before.

Cost Effectiveness Over Time

While the initial cost of turbine gas meters may be higher than other options, their long term benefits far outweigh the investment. With lower maintenance costs, higher accuracy, and extended lifespan, these meters offer a strong return on investment (ROI).

A case study showed that a company recouped its initial investment within two years through reduced operational costs. This makes turbine gas meters a cost effective choice for businesses looking to maximize efficiency and minimize expenses over time.

Common Misconceptions About Turbine Gas Meters

Despite their many benefits, there are some misconceptions about turbine gas meters. For example, some believe they’re only suitable for large scale industries, but in reality, they’re versatile enough for small to medium applications as well. Others think they require frequent maintenance, but turbine gas meters are designed for durability and require minimal upkeep.

Finally, some assume they’re outdated compared to ultrasonic meters, but modern turbine gas meters incorporate advanced features like IoT connectivity, making them a cutting edge choice.

How to Choose the Right Turbine Gas Meter

Selecting the right turbine gas meter depends on several factors, including flow rate, gas type, environmental conditions, and budget. It’s important to choose a meter that can handle your required flow range and withstand your operating environment.

Additionally, evaluating the long term ROI, rather than just the upfront cost, can help you make a more informed decision. By considering these factors, you can find the perfect turbine gas meter for your needs.

Real World Applications

Turbine gas meters are making a difference across a variety of industries. In the oil and gas sector, they’re used to monitor pipeline flow with precision.

Utilities rely on them to ensure accurate billing for consumers, while manufacturers use them to optimize processes and reduce waste. No matter the industry, turbine gas meters are proving to be an invaluable tool for improving efficiency and accuracy.

Want to learn more about how turbine gas meters can save you money? Download our free guide now!

Conclusion

Turbine gas meters are more than just flow measurement devices they’re powerful tools that offer accuracy, durability, sustainability, smart technology, and cost effectiveness. Whether you’re in oil and gas, utilities, or manufacturing, these meters can transform your operations and help you achieve your goals.

Ready to experience the benefits of turbine gas meters for yourself? Explore our range of turbine gas meters today and take the first step toward smarter, more efficient flow measurement.

0 notes

Text

How to Choose the Right Diaphragm Metering Pump for Your Needs

Metering pumps are important to the upstream oil and gas industry as they are responsible for precisely injecting flow assurance chemicals like methanol, monoethylene glycol, and corrosion inhibitors into wells. If the delivery of these vital chemicals falters, well production can grind to a halt. While metering pumps might look like small components on an upstream platform, make no mistake: they are essential. To give you an analogy, their role is as important as that of a rivet on an aeroplane wing—if they fail, the entire operation is at risk. Therefore, choosing the right chemical metering pump is crucial.

#Diaphragm metering pump#Hydraulic diaphragm metering pump#Metering pump#Proportional Dosing Pump#IDEX India

0 notes

Text

Fuel Pump Replacement

Fuel pump replacement is a necessary part of your car's maintenance. A fuel pump transfers fuel from your tank to your engine. It supplies the fuel at a constant pressure to ensure that the engine is running smoothly. Mechanical or electronic fuel pumps are standard in your vehicle.

A mechanical pump has a diaphragm mounted on the outside of the fuel tank that expands and contracts, creating a vacuum system that expels fuel out of the gas tank and into the engine. Electronic pumps use an electromagnetic motor inside the fuel tank that forces fuel into the engine at a high pressure. Cars with carburetors contain mechanical pumps while vehicles with fuel injection systems have electric pumps.

The motion of the engine directly drives a mechanical pump. Since mechanical pumps contain few moving parts, they tend to be reliable and easy to diagnose and fix. The most common problems with mechanical pumps occur when the diaphragm is damaged in some way, which throws the pressure system off kilt.

Electronic pumps contain increased complexity and include multiple moving parts. Electronic pumps are linked to electronic control systems. Because of this, electric pumps are more prone to failure. Any part of the control system can fail and lead to fuel pump issues.

SYMPTOMS OF FAILING FUEL PUMPS

The symptoms of failure are similar in both types of pumps, although mechanical and electronic pumps fail for different reasons.

1.CAR JERKS OR SPUTTERS AT HIGH SPEEDS

2.YOU LOSE POWER WHEN ACCELERATING

3.YOU HAVE BEEN LOSING POWER WHILE DRIVING UPHILL OR TOWING A LOAD

4.YOUR ENGINE SURGES

5.YOUR ENGINE WILL NOT START

IF YOU THINK YOU NEED A FUEL PUMP REPLACEMENT

If you have encountered any of the symptoms of a failing fuel pump, it is best to bring your car to us at Autopartsproducts. Other mechanical problems can cause some of the symptoms of a bad pump. Our shop can perform tests to isolate the exact cause of the problem. If no other sources seem likely, they will confirm the fuel pump replacement diagnosis with a variety of procedures.

We will begin by checking your car’s electrical system. Mainly, the fuses that direct power to your fuel system. Blown fuses are well-known but inexpensive to replace. If the fuses are not damaged and fixing them does not solve the problem, our mechanics will then check the voltage on the pump itself. Using a multi-meter, the mechanics will measure the voltage drop on either end of the fuel pump to determine the problems with the pump itself.

Your fuel pump is an indispensable part of your car, providing your engine with a constant quantity of the fuel it needs to keep you driving. Like any device, however, fuel pumps eventually wear out after thousands of miles of use. If your car struggles with weak or unreliable power, it may be time to replace the fuel pump on your vehicle.

Searching for Power Oem Injector, Auto Sensor, Igintion Coils, Fuel Pump, Turn Signal Switch and Oxygen Sensor System Manufacturer in China? FASTWIN EFI SYSTEM mainly focus on the fuel injection parts for Car, Motorcycle, General Motor & SCR System Parts for Diesel Vehicle for Chinese Car, Japanese Car, Korean Car, French Car, American Car & German Car.

For all of your European car maintenance needs including fuel pump replacement, you can count on the experienced automotive professionals at Autopartsproducts! Check out our Specials page for money saving discounts on our repairs or services. We are located at: Yinzhou. Ningbo City. PR.China.

0 notes

Text

Smart Gas Meter Market: Key Trends and Growth Drivers

The global smart gas meter market size was valued at USD 3.24 billion in 2023 and is expected to grow at a CAGR of 6.9% from 2024 to 2030. Efforts to reduce greenhouse gas emissions have emphasized the importance of using natural gas in various applications. Additionally, emerging technologies that enable users to monitor their energy consumption are fueling the growth of the smart gas market. Although this technology is currently new and available only in a few countries, its operational advantages and economic feasibility are expected to facilitate widespread adoption across many countries during the forecast period. Gas pipelines are being installed in many countries to ensure natural gas is available in every home. Gas meters provide several benefits, including accurate readings, eliminating manual involvement, tracking usage data, preventing unaccounted consumption, and assessing monthly tariffs.

Operational advantages such as continuous pipeline monitoring, the elimination of manual monthly readings, real-time data availability, and operational precision drove the adoption of smart gas metering. Additionally, the cost savings and one-time investment in smart meters fueled market growth. Along with the benefits to gas companies, smart gas meters also offer customers advantages such as better control over monthly bills, detailed feedback on energy use, and reduced system failures.

Gather more insights about the market drivers, restrains and growth of the Smart Gas Meter Market

Key Smart Gas Meter Company Insights

Key companies include ABB, Honeywell International, Inc., Itron, Inc., and Landis+Gyr. Companies active in the smart gas meter market are focusing aggressively on expanding their customer base and gaining a competitive edge over their rivals. Hence, they pursue various strategic initiatives, including partnerships, mergers & acquisitions, collaborations, and new product/ technology development. For instance, in January 2024, Italgas S.p.A announced the fulfillment of the rollout of the initial 20,000 units of its new hydrogen-ready gas smart meters. The installation of these first 20,000 Nimbus units marks a significant step in accelerating the energy transition towards green gas. The widespread adoption of these devices across the Italgas user network will significantly boost the use of renewable gases, paving the way for a new frontier in Italy and globally.

Recent Developments

• In February 2024, IGL Genesis Technologies announced to the exchanges that it had signed an agreement with Hangzhou Beta Meter Co., Ltd. The deal involves purchasing smart meter manufacturing technology for USD 2.4 million. IGTL has already begun setting up a production facility in India to manufacture smart gas meters, utilizing technical expertise from Hangzhou Beta Meter Co., Ltd.

• In December 2023, Honeywell International, Inc. announced the European launch of its diaphragm gas meter, capable of operating with 100% hydrogen. This new meter can measure both natural and hydrogen gas, offering versatility throughout Europe. Once deployed, these meters will not need future alternates, even as networks transition to hydrogen, thereby improving operational sustainability and reducing long-term costs.

• In February 2022, Vikas Lifecare Limited announced that its recent acquisition, GenesisGas, secured orders to supply over 30,000 gas meters to Gujarat Gas Limited, an Indian natural gas distribution company. GenesisGas, a leader in smart water and gas metering in India, holds about 20% of the domestic gas metering market share.

Smart Gas Meter Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global smart gas meter market report based on component, technology, type, end-use, and region.

Component Outlook (Revenue, USD Billion, 2017 - 2030)

• Hardware

• Software

• Services

Type Outlook (Revenue, USD Billion, 2017 - 2030)

• Smart Ultrasonic Gas Meter

• Smart Diaphragm Gas Meter

Technology Outlook (Revenue, USD Billion, 2017 - 2030)

• Advanced Metering Infrastructure (AMI)

• Auto Meter Reading (AMR)

End Use Outlook (Revenue, USD Billion, 2017 - 2030)

• Residential

• Commercial

• Industrial

Regional Outlook (Revenue, USD Billion, 2017 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o UK

o Germany

o France

• Asia Pacific

o China

o India

o Japan

o Australia

o South Korea

• Latin America

o Brazil

• MEA

o UAE

o South Africa

o KSA

Order a free sample PDF of the Smart Gas Meter Market Intelligence Study, published by Grand View Research.

#Smart Gas Meter Market#Smart Gas Meter Market Size#Smart Gas Meter Market Share#Smart Gas Meter Market Analysis#Smart Gas Meter Market Growth

0 notes

Text

The Ultimate Guide to Metering Pumps: Precision, Performance, and Applications

In various industrial and commercial applications, precise fluid measurement is crucial. Whether for chemical dosing, water treatment, or pharmaceutical production, metering pumps have become indispensable tools that ensure accurate and reliable fluid delivery. In this article, we’ll explore what metering pumps are, how they work, and the key benefits of incorporating them into your operations.

What Are Metering Pumps?

Metering pumps are mechanical devices designed to pump fluids at precise, adjustable flow rates. These pumps are particularly essential when a high degree of accuracy in fluid delivery is required. Metering pumps can handle a wide range of substances, from water and oils to chemicals and adhesives. They are commonly used in applications where the precise injection of a specific volume of liquid is necessary, such as water treatment, chemical processing, or pharmaceuticals.

Unlike other types of pumps, which may focus on volume or general fluid movement, metering pump deliver fluid at consistent rates, often down to milliliter or microliter precision. This makes them ideal for applications that demand accuracy and efficiency.

How Metering Pumps Work

Metering pumps operate based on a variety of mechanisms, with the most common types being positive displacement pumps. These pumps move a fixed amount of liquid with each stroke or cycle, ensuring that the same volume is dispensed at regular intervals. The flow rate can be adjusted manually or electronically, depending on the type of pump.

There are two main categories of metering pumps: diaphragm and piston. Both serve the same purpose but differ in their construction and the types of fluids they can handle. Diaphragm pumps use a flexible diaphragm to create the suction and discharge pressure required to move the fluid, while piston pumps use a reciprocating piston to generate the force needed to move the liquid.

Types of Metering Pumps

1. Diaphragm Metering PumpsThese pumps are the most widely used in applications where chemical resistance and accuracy are critical. Diaphragm pumps have a flexible diaphragm that moves back and forth, creating suction that draws fluid into a chamber and then pushes it out through a discharge valve. This type of pump is ideal for aggressive or corrosive liquids.

2. Piston Metering PumpsPiston pumps are commonly used in high-pressure applications. They rely on a piston that moves back and forth inside a cylinder to displace fluid. Piston pumps are highly accurate and durable, making them perfect for applications requiring consistent pressure and flow.

3. Peristaltic Metering PumpsIn this design, a rotor compresses a tube to move the fluid through it, creating a consistent and controlled flow. These pumps are highly effective for dosing delicate or shear-sensitive fluids because they do not contact the fluid directly, minimizing the risk of contamination.

Key Features and Benefits of Metering Pumps

1. Precision and AccuracyMetering pumps are engineered to provide precise control over the flow of liquid, making them a vital component in any process that requires accurate chemical dosing. Whether you are adding a small quantity of a reagent or maintaining a constant flow of an essential fluid, metering pumps deliver unparalleled consistency.

2. Flexibility and VersatilityMetering pumps are adaptable to a wide range of industries and applications. From pharmaceuticals and food processing to water treatment and oil & gas, metering pumps can be customized to suit a variety of needs. Different pump designs can accommodate varying viscosities and chemical compositions, allowing for the accurate dosing of nearly any liquid.

3. Efficiency and Cost-EffectivenessBy providing precise fluid delivery, metering pumps reduce the risk of overuse, which can lead to unnecessary waste and additional costs. Their reliability means fewer operational disruptions and lower maintenance costs over time, making them an investment that can lead to significant savings for businesses in the long run.

4. Easy IntegrationMetering pumps are designed to be easily integrated into existing systems. With adjustable flow rates and simple installation processes, these pumps can be incorporated into new systems or retrofitted into existing ones with minimal effort.

5. Safety and ReliabilityMany metering pumps come equipped with safety features such as pressure relief valves, which prevent overpressure situations and potential damage to your equipment. Additionally, their durable construction ensures that they can withstand harsh conditions, making them reliable even in demanding environments.

Applications of Metering Pumps

1. Water TreatmentIn water treatment, metering pumps are used to inject chemicals like chlorine or pH-adjusting agents into the water supply. Accurate dosing is vital to ensure that water quality standards are met and that the right amount of chemicals is added to ensure effective treatment.

2. Chemical ProcessingMetering pumps are essential in the chemical industry for accurately dosing solvents, acids, and other chemicals into manufacturing processes. These pumps ensure that formulations are consistent and within regulatory guidelines, reducing the risk of errors and improving product quality.

3. Food and Beverage IndustryIn food production, metering pumps are used for tasks such as injecting flavors, preservatives, and sweeteners. The accuracy of dosing ensures that each batch is consistent, safe, and meets both industry standards and customer expectations.

4. PharmaceuticalsIn the pharmaceutical industry, precise dosing of active ingredients is critical to ensure the safety and efficacy of medications. Metering pumps play an essential role in pharmaceutical manufacturing, where accuracy in ingredient delivery can make the difference between effective and ineffective products.

5. Oil & Gas IndustryMetering pumps are used to inject chemicals into pipelines and refineries, such as anti-corrosion agents, scale inhibitors, and surfactants. These pumps ensure that the correct amount of chemical is injected to optimize production and prevent issues such as pipeline corrosion.

Choosing the Right Metering Pump

When selecting a metering pump, it’s important to consider several factors, including the type of fluid being handled, the required flow rate, pressure conditions, and the environment in which the pump will be used. Additionally, ensure that the materials of construction are compatible with the fluid, especially in the case of corrosive or hazardous chemicals.

At Unique Dosing, we offer a variety of metering pumps designed to meet your specific application needs. Our products are known for their reliability, durability, and precision, providing cost-effective solutions for businesses across industries. To learn more about our high-performance metering pumps, visit us today.

Visit: https://www.uniquedosing.com/metering-pump.php

Contact :- +91 9822420535

0 notes

Text

SUPPLIER POMPA TACMINA 0813-3535-3290

Pendahuluan

Dalam dunia industri modern, efisiensi dan keandalan adalah kunci keberhasilan operasional. Salah satu perangkat penting yang sering digunakan untuk memastikan kelancaran proses produksi adalah pompa industri. Dari pengolahan makanan hingga industri kimia, keberadaan pompa berkualitas tinggi memainkan peran penting. Di antara berbagai merek yang tersedia di pasar, Pompa Tacmina telah menjadi pilihan utama berkat kualitas, presisi, dan inovasi teknologinya.

Pompa Tacmina adalah produk unggulan dari Tacmina Corporation, perusahaan Jepang yang telah berdiri sejak tahun 1965. Tacmina dikenal sebagai pelopor dalam pengembangan pompa transfer cairan presisi dengan fokus pada inovasi dan kualitas. Pompa Tacmina dirancang untuk memberikan solusi transfer cairan yang efisien, akurat, dan ramah lingkungan, sehingga sangat cocok untuk berbagai aplikasi industri.

Keunggulan Pompa Tacmina

1. Presisi Tinggi

Pompa Tacmina menggunakan teknologi canggih yang memastikan akurasi tinggi dalam mengalirkan cairan. Hal ini sangat penting untuk industri seperti farmasi dan kimia, di mana kesalahan kecil dalam proporsi dapat berakibat fatal.

2. Tahan Lama dan Andal

Pompa ini dibuat dari material berkualitas tinggi, sehingga tahan terhadap berbagai jenis cairan, termasuk bahan kimia korosif. Ketahanannya terhadap tekanan tinggi juga menjadikannya andal untuk aplikasi berat.

3. Desain Bebas Kebocoran

Pompa Tacmina menggunakan sistem non-seal diaphragm, yang mencegah kebocoran cairan. Fitur ini tidak hanya meningkatkan keamanan operasional tetapi juga mengurangi biaya perawatan.

4. Efisiensi Energi

Tacmina dikenal karena produknya yang hemat energi, sehingga membantu perusahaan mengurangi biaya operasional sekaligus mendukung inisiatif ramah lingkungan.

5. Mudah Dipasang dan Dirawat

Desain yang sederhana namun inovatif membuat pompa ini mudah dioperasikan dan dirawat, sehingga meminimalkan waktu henti produksi.

Jenis-Jenis Pompa Tacmina

Pompa Tacmina tersedia dalam berbagai jenis, yang dirancang untuk memenuhi kebutuhan spesifik industri. Berikut adalah beberapa jenis utamanya:

1. Metering Pump (Pompa Dosis)

Pompa ini dirancang untuk aplikasi yang membutuhkan aliran cairan dengan tingkat presisi tinggi. Metering pump sering digunakan di industri farmasi, makanan, dan kimia.

2. Transfer Pump

Transfer pump Tacmina ideal untuk memindahkan cairan dari satu tempat ke tempat lain tanpa mengurangi kualitas cairan. Pompa ini sering digunakan dalam industri minyak dan gas, serta pengolahan air.

3. Diaphragm Pump

Pompa jenis ini terkenal dengan desain bebas kebocoran dan kemampuan menangani cairan dengan viskositas tinggi. Diaphragm pump cocok untuk industri yang menangani bahan kimia berbahaya.

4. Process Pump

Dirancang untuk aplikasi berat, process pump dapat digunakan dalam kondisi ekstrem, seperti tekanan tinggi dan suhu yang ekstrim.

“Optimalkan efisiensi keran air sesuai yang anda inginkan dengan POMPA TACMINA yang berkuaitas tinggi”

Jika Bapak/Ibu ingin informasi lebih lengkap dan ingin berkonsultasi tentang permasalahan yang dialami terhadap saluran air di rumah, dapat menghubungi pihak dari kami :

Kontak : https://wa.me/6281335353290

Alamat : https://maps.app.goo.gl/XA6LhwHGwh4gudhWA

Merketplace: https://www.tokopedia.com/heframid/pompa-dosing-kimia-selenoid-matering-dosing-tacmina-pz-100-vtcf?extParam=whid%3D13549232

youtube

Aplikasi Pompa Tacmina di Industri

1. Industri Kimia

Pompa Tacmina sering digunakan untuk mengalirkan bahan kimia korosif dengan tingkat presisi tinggi. Kemampuan ini memastikan proses produksi tetap aman dan efisien.

2. Pengolahan Makanan dan Minuman

Dalam industri makanan, presisi dan kebersihan adalah prioritas utama. Pompa Tacmina dirancang untuk memenuhi standar higienis, sehingga aman digunakan untuk bahan pangan.

3. Industri Farmasi

Keakuratan dalam pengaliran cairan farmasi sangat penting untuk menjaga kualitas produk. Dengan presisi tinggi, Tacmina memastikan setiap dosis tepat dan konsisten.

4. Pengolahan Air

Pompa Tacmina membantu dalam proses pengolahan air, seperti desalinasi, pengolahan limbah, dan sistem irigasi, dengan efisiensi energi yang tinggi.

5. Industri Minyak dan Gas

Pompa Tacmina mampu menangani cairan dengan tekanan tinggi dan viskositas yang bervariasi, membuatnya ideal untuk aplikasi di sektor minyak dan gas.

Tips Memilih Pompa Tacmina yang Tepat

Untuk mendapatkan manfaat maksimal dari Pompa Tacmina, penting untuk memilih jenis pompa yang sesuai dengan kebutuhan Anda. Berikut adalah beberapa tips:

Identifikasi Jenis Cairan Pastikan Anda mengetahui viskositas, tingkat korosif, dan karakteristik cairan yang akan dipompa.

Perhatikan Kapasitas dan Tekanan Pilih pompa dengan kapasitas dan tekanan yang sesuai dengan kebutuhan aplikasi Anda.

Konsultasikan dengan Ahli Jika ragu, konsultasikan kebutuhan Anda dengan distributor resmi Tacmina untuk mendapatkan rekomendasi terbaik.

Pertimbangkan Faktor Lingkungan Pastikan pompa yang dipilih mendukung efisiensi energi dan ramah lingkungan.

Kesimpulan

Pompa Tacmina adalah solusi unggulan untuk berbagai kebutuhan industri. Dengan presisi tinggi, keandalan, dan desain inovatif, pompa ini mampu meningkatkan efisiensi operasional sekaligus mengurangi risiko dan biaya. Baik untuk aplikasi di industri kimia, farmasi, makanan, atau pengolahan air, Pompa Tacmina adalah pilihan yang tepat. Dengan memilih Pompa Tacmina, Anda tidak hanya mendapatkan alat berkualitas tinggi tetapi juga investasi jangka panjang untuk keberhasilan bisnis Anda. Untuk memastikan Anda mendapatkan produk asli dan dukungan teknis terbaik, pastikan untuk membeli dari distributor resmi.

#pompatacmina#tacminapump#dosingpumptacmina#tacminadosingpump#tacmina#pompadosingtacmina#alatpenjernihair#filterpenjernihair#alatpengolahair#alatpengolahairbersih#Youtube

0 notes

Text

How to Choose Your Vacuum Pump

What is a Vacuum Pump?

A vacuum pump is a device that removes gas molecules from a sealed volume to create a partial or high vacuum. These pumps are essential in various industries, including manufacturing, medical, scientific research, and electronics, where controlling the atmospheric pressure within a system is crucial. By evacuating air or other gases, vacuum pumps reduce the pressure inside a chamber, which can then be used for processes such as coating, drying, or testing under controlled conditions.

Types of Vacuum Pumps and Their Applications

Vacuum pumps come in several types, each suited to different applications. The three primary categories are positive displacement pumps, momentum transfer pumps, and entrapment pumps.

Positive Displacement Pumps

Positive displacement pumps work by mechanically trapping a volume of gas and moving it through the pump to the exhaust. These pumps are ideal for low to medium vacuum applications. Common types include:

Rotary Vane Pumps: Used in laboratories and industrial processes where a stable vacuum is required. They are reliable and provide a consistent vacuum.

Diaphragm Pumps: Suitable for applications requiring a clean and oil-free vacuum, such as in the medical and food industries.

Piston Pumps: Often used in small-scale laboratory settings for specific, low-volume applications.

Momentum Transfer Pumps

Momentum transfer pumps, also known as molecular pumps, use high-speed rotating blades or magnetic fields to impart momentum to gas molecules, effectively transferring them out of the chamber. These pumps are typically used for high and ultra-high vacuum applications.

Turbomolecular Pumps: Widely used in the semiconductor and coating industries due to their ability to achieve high vacuum levels.

Diffusion Pumps: Employed in processes like metal deposition and electron microscopy, where high vacuum is necessary.

Entrapment Pumps

Entrapment pumps capture gases through chemical or physical means. These pumps are essential in creating ultra-high vacuum environments.

Cryopumps: Used in applications requiring extremely low temperatures, such as in the cooling of superconductors and in some scientific research facilities.

Sorption Pumps: Often utilized in small-scale applications and scientific experiments where ultra-clean environments are essential.

How to Choose the Right Vacuum Pump

Selecting the right vacuum pump depends on several factors, including the desired vacuum level, the nature of the gases being pumped, the required pumping speed, and the operating environment. Here are some key considerations:

Vacuum Level Requirements: Determine the vacuum range required for your application. Low vacuum (up to 1 mbar) can be achieved with rotary vane or diaphragm pumps, while high vacuum (down to 10^-9 mbar) requires turbomolecular or cryopumps.

Gas Composition: Consider the type of gases that will be evacuated. For corrosive or reactive gases, a diaphragm pump with chemical resistance or a specialized coating on a rotary vane pump might be necessary.

Pumping Speed: The pumping speed, measured in liters per second (L/s) or cubic meters per hour (m^3/h), should match the volume of gas to be evacuated within a specific time frame. Larger systems or those requiring faster evacuation rates will need pumps with higher pumping speeds.

Operating Environment: Evaluate the working conditions, such as temperature, humidity, and cleanliness requirements. For example, oil-free diaphragm pumps are ideal for environments where contamination must be avoided.

Maintenance and Cost: Consider the total cost of ownership, including initial purchase price, operating costs, and maintenance requirements. Some pumps, like rotary vane pumps, require regular oil changes, while others, like diaphragm pumps, have minimal maintenance needs.

How to Maintain Your Vacuum Pump

Proper maintenance is crucial to ensure the longevity and efficiency of your vacuum pump. Here are some general maintenance tips:

Regular Inspections: Conduct routine inspections to check for wear and tear, oil levels (for oil-sealed pumps), and overall pump performance. Early detection of issues can prevent costly repairs and downtime.

Oil Changes: For rotary vane pumps, regularly change the oil as per the manufacturer's recommendations. Contaminated oil can reduce pump efficiency and lead to mechanical failures.

Cleaning: Keep the pump and its components clean to prevent the buildup of debris, which can obstruct airflow and reduce performance. Use appropriate cleaning agents that do not damage the pump's materials.

Seal and Gasket Checks: Inspect seals and gaskets for signs of wear or damage. Replacing them timely ensures a proper seal and prevents leaks that can affect vacuum levels.

Filter Replacement: Replace filters as recommended to maintain optimal airflow and prevent contaminants from entering the pump.

Monitor Operating Parameters: Regularly monitor the pump's operating parameters, such as pressure, temperature, and power consumption. Any deviations from the norm can indicate potential problems.

Choosing the right vacuum pump involves understanding your specific application requirements and the various types of pumps available. By considering factors such as vacuum level, gas composition, pumping speed, and operating environment, you can select a pump that meets your needs. Proper maintenance, including regular inspections, oil changes, and cleaning, is essential to keep your pump running efficiently and prolong its lifespan. With the right knowledge and care, your vacuum pump can provide reliable performance for years to come.

(More information available at wsvacuum.com)

0 notes

Text

Metering Pumps Market Size, Trends, Revenue Share Analysis, Forecast, 2024–2030

The Metering Pumps Market was valued at USD 6.5 billion in 2023-e and will surpass USD 8.5 billion by 2030; growing at a CAGR of 3.8% during 2024 - 2030. The report focuses on estimating the current market potential in terms of the total addressable market for all the segments, sub-segments, and regions. In the process, all the high-growth and upcoming technologies were identified and analyzed to measure their impact on the current and future market. The report also identifies the key stakeholders, their business gaps, and their purchasing behavior.

Metering pumps, also known as dosing pumps, are designed to deliver a precise flow rate of fluids. They play a crucial role in applications requiring exact dosing, ensuring that the right amount of liquid is delivered consistently over a specified period. These pumps are integral to processes that demand high levels of accuracy and control, such as the injection of chemicals into water treatment systems or the precise dosing of ingredients in pharmaceutical manufacturing.

Read More about Sample Report: https://intentmarketresearch.com/request-sample/metering-pumps-market-3237.html

Market Trends and Dynamics

1. Technological Advancements

The metering pumps market is witnessing significant technological advancements aimed at enhancing efficiency and accuracy. Innovations such as digital metering pumps and automated control systems have revolutionized the industry, providing users with greater control and real-time monitoring capabilities. These advancements not only improve the precision of dosing but also reduce operational costs by minimizing waste and optimizing resource use.

2. Rising Demand in Water and Wastewater Treatment

One of the primary drivers of the metering pumps market is the increasing demand for efficient water and wastewater treatment solutions. As global populations grow and urbanize, the need for clean water and effective wastewater management becomes more pressing. Metering pumps are essential in treating water by accurately dosing chemicals like chlorine and fluoride, ensuring safe and potable water supplies.

3. Growth in the Chemical Processing Industry

The chemical industry relies heavily on metering pumps for the precise dosing of chemicals in various processes. With the expansion of chemical production and the introduction of more complex formulations, the demand for reliable and accurate metering pumps is on the rise. These pumps ensure that chemical reactions occur under optimal conditions, leading to higher quality products and increased operational efficiency.

4. Environmental Regulations and Standards

Stringent environmental regulations and standards are driving the adoption of metering pumps across various industries. Governments and regulatory bodies are enforcing strict guidelines to minimize environmental impact, necessitating the use of accurate and efficient dosing systems. Metering pumps help industries comply with these regulations by ensuring precise chemical dosing, reducing the risk of overuse and contamination.

Market Segmentation

The metering pumps market can be segmented based on type, application, and region.

1. By Type

Diaphragm Pumps: Known for their accuracy and reliability, these pumps are widely used in applications requiring high precision.

Piston Pumps: These are used in high-pressure applications where consistent flow rates are crucial.

Peristaltic Pumps: Ideal for handling viscous and abrasive fluids, these pumps are commonly used in the food and beverage industry.

2. By Application

Water and Wastewater Treatment

Chemical Processing

Pharmaceuticals

Food and Beverage

Oil and Gas

3. By Region

North America: Leading the market due to advanced industrial infrastructure and stringent environmental regulations.

Europe: Significant growth driven by technological advancements and environmental concerns.

Asia-Pacific: Rapid industrialization and urbanization are fueling market growth in this region.

Latin America and Middle East & Africa: Emerging markets with increasing industrial activities and environmental awareness.

Ask for Customization Report: https://intentmarketresearch.com/ask-for-customization/metering-pumps-market-3237.html

Future Prospects

The future of the metering pumps market looks promising, with continued growth expected across various sectors. Key areas to watch include:

Integration of IoT and Smart Technologies: The adoption of IoT-enabled metering pumps will enable real-time monitoring, predictive maintenance, and enhanced operational efficiency.

Sustainable and Eco-friendly Solutions: Development of metering pumps with eco-friendly materials and energy-efficient designs will cater to the growing demand for sustainable solutions.

Expansion in Emerging Markets: Increasing industrial activities in emerging markets will create new opportunities for market growth.

Conclusion

The metering pumps market is poised for substantial growth, driven by technological advancements, rising demand in water treatment, and stringent environmental regulations. As industries continue to prioritize efficiency, accuracy, and sustainability, metering pumps will remain an indispensable component of modern industrial processes. The ongoing innovations and expanding applications underscore the market's dynamic nature and its crucial role in shaping a sustainable future.

0 notes

Text

0 notes