#DCmotor

Explore tagged Tumblr posts

Text

Open-source lab shaker to agitate parts with PVA supports! 🔧🔄🧪

This DIY shaker uses an Adafruit Crickit, Circuit Playground Express and DC motor. The speed is adjustable with a potentiometer!

#adafruit#electronics#opensource#opensourcehardware#lab#shaker#pva#crikit#dcmotor#labequipment#diyproject#makersgonnamake#innovation#engineering#hardwarehacks#makercommunity#techdiy#learningresource#circuits#adjustablespeed

2 notes

·

View notes

Text

#solarpump #solarpumpcontroller #acsolarpump #bldcsolarpump #dcmotor #dcsolarpump #dcsubmersible #dcwaterpump #design #supply #installation #solarfarmer #solaragriculturepump #mppt #mpptvfd #submersible #monoblock #openwell #solar #sssolarpump #v4 #v6 #suratexim #9227455399

#solarpump#solarpumpcontroller#acsolarpump#bldcsolarpump#dcmotor#dcsolarpump#dcsubmersible#dcwaterpump#design#supply#installation#solarfarmer#solaragriculturepump#mppt#mpptvfd#submersible#monoblock#openwell#solar#sssolarpump#v4#v6#suratexim#9227455399

0 notes

Text

Midea 11002015009325 Brushless DC Motor Hnkparts

The Midea 11002015009325 is a brushless DC motor specifically designed for use in Midea central air conditioning systems, by incorporating brushless DC motor technology, Midea aims to deliver more efficient, quieter, and longer-lasting air conditioning systems for enhanced comfort and reduced environmental impact.

0 notes

Text

LG EAU59551204 Refrigerator DC Motor HnKParts

Manufacturer Name: LGE Product Number: EAU59551204 OEM Part Number: EAU59551204 Product Description: Motor-Dc

Order LG EAU59551204 Refrigerator DC Motor today! Shop home & kitchen appliance parts at HnK Parts with same-day shipping, available at the best prices.

#LGE#EAU59551204#LGEParts#Refrigerator#DCMotor#HnKparts#homeappliances#HnKBuzz#KitchenApplianceParts#appliacepartsonline

0 notes

Text

Calliope Mini 3 Tutorial: Technik-Upgrade - Zwei Motoren separat steuern

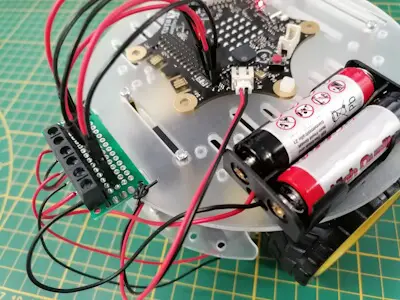

Der Calliope Mini 3 verfügt über eine echte H-Brücke, mit welcher man zwei Motoren separat steuern kann. Dieses ist ein deutlicher Vorteil zur Vorgängerversion, denn dort konnte man die Motoren immer nur gleich laufen lassen. https://youtu.be/Gy6feiBBRls Im Beitrag DIY-Freude: 2WD Auto von Grund auf aufbauen habe ich dir erläutert, wie man ein 2WD aufbaut. Hier soll es nun darum gehen, wie du dieses mit dem Calliope Mini 3 steuern kannst.

Vorbereiten des 2WD Chassis für den Calliope Mini 3

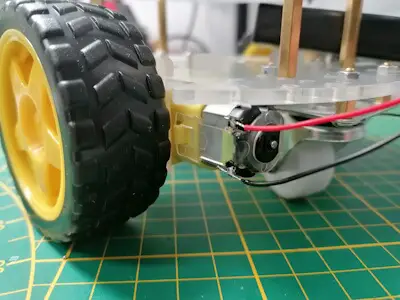

Am 2WD Chassis findest du zwei DC-Motoren, an welche wir noch zwei Drähte anlöten müssen. Hier sind die Farben rot für Plus und schwarz für Minus im Vorteil. Da jedoch die Motoren je nach Polung der Spannung sich in unterschiedliche Richtungen drehen ist es zunächst eigentlich egal wo du welchen Draht anschließt.

angelötete Litzen am DC-Motor

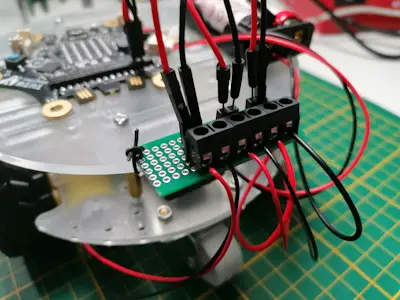

Anschlusspaneele für die Litzen

Anschlusspaneele für die Motoren und die Stromversorgung Von den beiden DC-Motoren und vom Batteriehalter kommen 6 Litzen insgesamt, diese müssen mit dem Calliope Mini verbunden werden. Dafür habe ich mir auf einer Lochrasterplatine 6 Schraubklemmen und ebenso drei 2er-Buchsenleisten aufgelötet und verbunden. Damit kann ich jetzt von diesen mit Breadboardkabel die Kontakte abgreifen und in die Buchsenleiste des Calliope Mini 3 stecken.

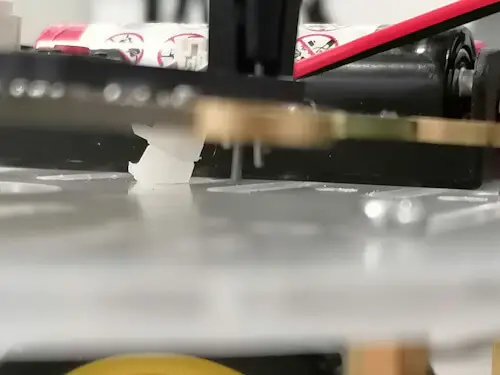

Montage des Calliope Mini auf der Acrylplatte

Mein 2WD Chassis hat zwei Acrylplatten, auf diese kann ich ganz einfach mit Kabelbinder diesen befestigen. Dazu stecke ich einen Kabelbinder durch einen Schlitz und schiebe auf diesen zwei weitere so das ich einen Abstand zwischen der Platte und dem Mikrocontroller erhalte.

Diesen gewonnenen Abstand benötigen wir, damit die Breadboardkabel / Jumperkabel in die Buchsenleiste eingesteckt werden können.

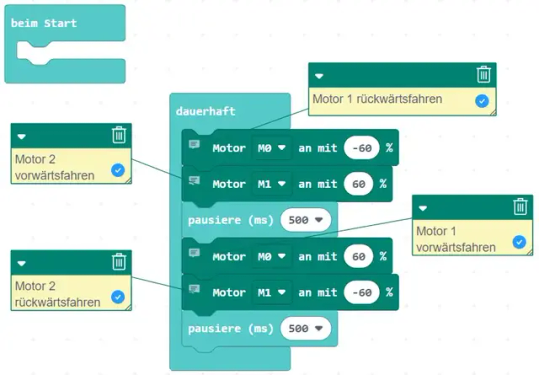

Programmieren der DC-Motoren in MakeCode am Calliope Mini 3

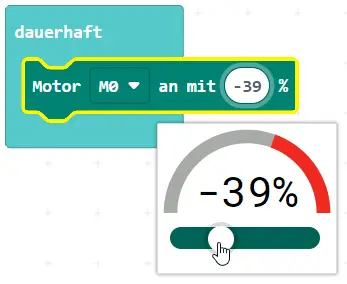

Nachdem wir die Motoren an den Mikrocontroller angeschlossen haben, können wir diese in MakeCode programmieren und damit unser 2WD Chassis steuern. Dazu haben wir unter dem Menüpunkt "Motoren" einen Block über welchen wir den Motor 1 "M0" und Motor 2 "M1" vorwärts (positiver Zahlenwert) und rückwärts (negativer Zahlenwert) fahren lassen können.

Calliope Mini - MakeCode - Motor rückwärtsfahren

Calliope Mini - MakeCode - Motor vorwärtsfahren Wie erwähnt können wir am neuen Calliope Mini 3 die Motoren separat in eine Richtung steuern und können somit engere Kreise ziehen, da wir einen Motor vorwärts und den anderen parallel dazu rückwärts laufen lassen können. Calliope Mini 3 auf 2WD Chassis In dem Video läuft ein kleines einfaches Programm, welches immer abwechselnd den linken & rechten Motor auf positiv 61 % laufen lässt und den anderen dann auf negativen 61 %.

Programm zum steuern von DC-Motoren am Calliope Mini 3 Programm - Calliope Mini 3 - DC-Motoren steuernHerunterladen

Fazit & Ausblick

Um nun das kleine 2WD Auto autonom fahren zu lassen, bedarf es noch an einigen Sensoren wie Ultraschallsensor oder für die Linienverfolgung eines Helligkeitssensors. Wie du diese programmierst, zeige ich dir jedoch in separaten Beiträgen auf diesem Blog. Read the full article

0 notes

Text

From Macro to Micro: Harnessing the Potential of Miniature Gear Motors

Miniature gear motors are a technological marvel that is transforming industries across the globe. In our blog, "From Macro to Micro: Harnessing the Potential of Miniature Gear Motors," we explore the incredible capabilities of these small powerhouses and their impact on various applications.

Size is no longer a limitation when it comes to power and efficiency. Miniature gear motors offer a perfect balance between compact size and impressive performance. These motors are engineered to deliver exceptional torque, precision, and reliability, making them suitable for a wide range of applications.

From robotics and automation to medical devices and consumer electronics, miniature gear motors are revolutionizing industries. Their compact design allows for seamless integration into space-constrained environments without compromising on performance. Whether it's a robotic arm performing intricate tasks or a wearable device providing precise motion control, miniature gear motors offer unprecedented possibilities.

One of the key advantages of these motors is their exceptional precision. With finely tuned gear ratios and high torque capabilities, they enable accurate motion control and smooth operation. This level of precision is crucial in industries where even the slightest movement can make a significant difference.

At SGMADA, we are at the forefront of miniature gear motor technology. Our range of miniature gear motors is designed to meet the diverse needs of different industries. We prioritize quality and performance, ensuring that our motors deliver reliable and efficient operation in any application.

Moreover, miniature gear motors also contribute to energy efficiency. Their optimized design and reduced weight minimize energy consumption, resulting in cost savings and reduced environmental impact. This makes them an ideal choice for sustainable and eco-friendly solutions.

0 notes

Text

https://electronicsbuzz.in/electric-dc-motors-driving-efficiency-in-industrial-and-automotive-applications/

#DCMotors#ElectricMotors#IndustrialAutomation#EVs#SmartManufacturing#Electrification#EnergyEfficiency#GreenTechnology#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

How to Optimize Performance with Linear Motors in Your Machinery

Linear motors are transforming the way modern machinery operates by providing high precision, speed, and efficiency. These motors convert electrical energy directly into linear motion without needing intermediate mechanical components, making them ideal for applications that require smooth, fast, and accurate positioning. Whether you're in manufacturing, automation, or robotics, optimizing the performance of linear motors in your machinery can significantly enhance productivity and reduce operational costs. This blog will explore practical strategies to help you make the most of linear motors in your machinery.

Understanding Linear Motors

What Are Linear Motors?

Linear motors are electromagnetic devices that produce linear force and motion instead of rotational motion, as seen with traditional motors. They consist of a stator, which generates a magnetic field, and a moving part called a forcer or slider. The stator's magnetic field interacts with the magnets on the slider to create a direct linear thrust, allowing precise and smooth movements without mechanical contact or friction.

Benefits of Using Linear Motors

Linear motors offer several advantages that make them ideal for various applications, including:

High Precision and Accuracy: Linear motors provide precise control over movement, making them suitable for tasks requiring high accuracy, such as CNC machines and semiconductor manufacturing.

Fast Response and High Speed: The direct motion provided by linear motors allows for rapid acceleration and deceleration, reducing cycle times and increasing productivity.

Smooth Motion: The absence of mechanical components like belts or gears reduces friction and vibration, resulting in smoother motion and less wear and tear.

Low Maintenance: Fewer moving parts mean less maintenance and lower downtime, saving time and money over the machinery's lifespan.

Tips to Optimize Performance with Linear Motors

To maximize the benefits of linear motors in your machinery, it’s essential to implement strategies that enhance their performance. Here are some key tips to consider:

1. Choose the Right Linear Motor for Your Application

Selecting the right type of linear motor is critical to achieving optimal performance. Linear motors come in various forms, such as iron-core, ironless-core, and tubular designs. Each type has unique characteristics suited to specific applications:

Iron-Core Linear Motors: Provide high force and are ideal for heavy-duty applications where high thrust is required. However, they can generate cogging (uneven motion) due to magnetic attraction.

Ironless-Core Linear Motors: Offer smooth motion with minimal cogging, making them suitable for precision applications like semiconductor manufacturing or laser cutting.

Tubular Linear Motors: Provide a balance between force and precision, with a compact design that works well in applications where space is limited.

Understanding your application requirements, such as force, speed, precision, and environmental conditions, will help you choose the right linear motor for optimal performance.

2. Optimize the Motor Drive and Control System

The performance of a linear motor is heavily influenced by its drive and control system. A well-matched motor drive ensures that the linear motor receives the correct amount of current and voltage to achieve the desired motion profile. To optimize performance:

Use Advanced Controllers: Invest in controllers that offer high-resolution feedback and advanced algorithms for precise control of speed, position, and acceleration. Modern controllers can compensate for non-linearities and disturbances, improving accuracy and stability.

Implement Real-Time Monitoring: Use real-time monitoring tools to track motor performance, detect anomalies, and make adjustments as needed. This helps prevent potential issues and ensures consistent operation.

Adjust Tuning Parameters: Fine-tune the control parameters, such as gain settings, to match the motor's characteristics and application requirements. Proper tuning minimizes overshoot, oscillations, and vibrations, enhancing performance and longevity.

3. Maintain Optimal Operating Conditions

Linear motors perform best under specific operating conditions. To ensure optimal performance:

Temperature Control: Linear motors can generate heat during operation, affecting performance and lifespan. Ensure proper cooling and ventilation to maintain the motor's temperature within its recommended range.

Clean Environment: Dust, debris, and contaminants can impact linear motors' performance and cause premature wear. Keep the operating environment clean and free from pollutants to avoid damage to the motor components.

Minimize Friction and Load: Excessive friction and load can reduce the efficiency of linear motors. Use lubricants, if necessary, and ensure that moving parts are aligned correctly to minimize resistance and maximize performance.

4. Integrate Feedback Devices

Integrating feedback devices, such as encoders or linear scales, can significantly improve the performance of linear motors by providing real-time position and velocity data. Feedback devices help:

Improve Accuracy: By providing precise position data, feedback devices enable the control system to make minute adjustments, ensuring accurate and consistent movement.

Enhance Stability: Feedback devices help detect and correct deviations in real-time, minimizing vibrations and oscillations and ensuring smooth operation.

Facilitate Diagnostics: Real-time feedback helps diagnose performance issues, allowing for quick corrective action and reducing downtime.

5. Regularly Inspect and Maintain the Motor

Regular inspection and maintenance are crucial to optimizing the performance of linear motors. Maintenance tasks should include:

Inspecting Cables and Connectors: Check for wear, fraying, or damage to cables and connectors, and replace them as needed to prevent electrical issues.

Checking Alignment: Ensure that the motor and load are properly aligned to avoid excessive wear and maintain smooth motion.

Monitoring for Wear and Tear: Regularly inspect the motor components, such as bearings and rails, for signs of wear. Promptly address any issues to prevent further damage.

6. Use Simulation and Modeling Tools

Utilize simulation and modeling tools to analyze the performance of linear motors in your specific application. These tools can help you:

Predict Motor Behavior: Understand how the motor will perform under various conditions, such as different loads, speeds, and temperatures.

Optimize Design: Make informed design decisions that enhance motor performance and efficiency.

Reduce Development Time: Identify potential issues early in the design phase, reducing the need for costly modifications during production.

Conclusion

Linear motors offer exceptional precision, speed, and reliability for various industrial applications. By choosing the right motor, optimizing the control system, maintaining optimal conditions, integrating feedback devices, and performing regular maintenance, you can maximize the performance of linear motors in your machinery. Leveraging these strategies will help you enhance productivity, reduce downtime, and achieve better overall efficiency in your operations.

With a solid understanding of linear motors and how to optimize their use, you can fully unlock their potential and ensure that your machinery operates at its best.

0 notes

Text

Quality DC Motors | Manufacturer, Wholesale, Factory

Explore a wide range of high-quality DC motors at DH Motor, a trusted DC motors manufacturer, offering wholesale and factory-direct options. Our DC motors are engineered for efficiency and reliability, meeting diverse industrial needs. Whether you require single or multiple units, our extensive catalog has you covered. With DH Motor, you get superior performance and competitive pricing. Discover the perfect DC motor solution for your applications today.

0 notes

Text

#ElectricalMachines#DCMotors#DrivesAndControl#EngineeringFundamentals#IndustrialApplications#ElectricalSystems#ProductivityOptimization#CostSavings#InnovationInEngineering#TechnicalExpertise

0 notes

Video

youtube

Master 370 Welding Technique A Comprehensive Guide #factory#dcmotor #dcm...

0 notes

Video

youtube

🔥 Fire Hole Dc Motor Project – Amazing DIY Experiment #dcmotor #tech #yo...

0 notes

Text

LG EAU63503709 Refrigerators DC Motor Assembly | HnKParts

Manufacturer Name:LGE

Product Number:EAU63503709

OEM Part Number:EAU63503709

The LG EAU63503709 DC Motor Assembly for Refrigerators, available at HnKParts, is an essential component that helps regulate the cooling system in LG refrigerators. This motor assembly is designed to circulate air efficiently, ensuring even cooling throughout the refrigerator compartments.

0 notes

Text

LG EAU61524007 Refrigerator DC Motor HnKParts

Manufacturer Name: LGE Product Number: EAU61524007 OEM Part Number: EAU61524007 Product Description: Motor-Dc

Order LG EAU61524007 Refrigerator DC Motor today! Shop home & kitchen appliance parts at HnK Parts with same-day shipping, available at the best prices.

#LGE#LGEParts#EAU61524007#Refrigerator#DCMotor#HnKParts#homeappliances#HnKBuzz#KitchenApplianceParts#appliacepartsonline

0 notes

Text

#solarpump #solarpumpcontroller #acsolarpump #bldcsolarpump #dcmotor #dcsolarpump #dcsubmersible #dcwaterpump #design #supply #installation #solarfarmer #solaragriculturepump #mppt #mpptvfd #submersible #monoblock #openwell #solar #sssolarpump #v4 #v6 #suratexim #9227455399

0 notes

Text

Things to know about brushless dc gear motor

Here are some important things to know about brushless DC (BLDC) gear motors:

Brushless DC Motor: A brushless DC motor is a type of electric motor that operates using electronic commutation instead of brushes and a commutator found in traditional brushed DC motors. This design offers several advantages, including improved efficiency, higher reliability, and longer lifespan.

Gear Motor Combination: A brushless DC gear motor combines the brushless DC motor with a gear reduction mechanism. The gear train reduces the motor's high-speed, low-torque output and provides higher torque at lower speeds, making it suitable for applications requiring increased torque or precise control.

High Efficiency: Brushless DC motors are known for their high efficiency. The absence of brushes eliminates friction and reduces energy losses, resulting in improved overall efficiency compared to brushed DC motors. When combined with a gear reduction mechanism, the efficiency can be further optimized.

Speed Control: Brushless DC gear motors offer excellent speed control capabilities. By adjusting the electrical signals provided to the motor's control circuitry, the speed and direction of the motor can be precisely controlled. This makes them suitable for applications that require variable speeds or reversible motion.

Compact Size: Brushless DC gear motors are designed to be compact and lightweight. They often have a high power-to-weight ratio, making them suitable for applications where space is limited or weight is a concern.

Reduced Maintenance: The absence of brushes in brushless DC motors eliminates brush wear and the need for regular maintenance associated with brushed DC motors. This reduces maintenance requirements and extends the motor's lifespan.

Lower Noise and EMI: Brushless DC motors generally produce less noise and electromagnetic interference (EMI) compared to brushed motors. The electronic commutation system eliminates the arcing and sparking associated with brushes, resulting in quieter operation and reduced interference with sensitive electronic equipment.

Wide Operating Range: Brushless DC gear motors can operate over a wide voltage range, typically ranging from low-voltage DC to higher-voltage configurations. This flexibility allows them to be used in various applications and environments.

Applications: BLDC gear motors are widely used in numerous applications that require high torque, precise control, and compact size. They are commonly found in robotics, industrial automation, electric vehicles, medical devices, aerospace equipment, and many other systems where efficient and reliable motor operation is crucial.

Cost: Brushless DC gear motors are typically more expensive than brushed DC motors due to the advanced technology and control electronics involved. However, their improved efficiency, reliability, and performance often justify the higher cost in applications where these benefits are essential.

As always, it's important to refer to the specific product documentation and manufacturer guidelines for detailed information about a particular brushless DC gear motor, as different models may have unique specifications and considerations. SGMADA Manufacturers premium quality Brushless DC gear motors .Shop Now.

0 notes